Page 1

Industrial

Switches

and

Product solutions on the Interactive Catalogue

Sensors

Global switches

Heavy duty switches

Compact switches

Precision switches

Hazardous location switches

Safety switches

Relays

Position products

Ultrasonic distance sensors

Pressure sensors

July 2003

Page 2

Inside front

cover

WARNING

!

PERSONAL INJURY

DO NOT USE these products* as safety or emergency stop

devices, or in any other application where failure of the

product could result in personal injury.

*

Does not apply to 24CE/924CE Series (page 23), GSS Series

(page 80), GK Series (pages 78, 83, 85) or CPS Series (page 89)

Failure to comply with these instructions could result in

death or serious injury.

WARNING

!

MISUSE OF DOCUMENTATION

• The information presented in this product sheet (or

catalogue) is for reference only. DO NOT USE this

document as product installation information.

• Complete installation, operation and maintenance

information is provided in the instructions supplied with

each product.

Failure to comply with these instructions could result in

death or serious injury.

2

www.honeywell.com/sensing

Page 3

CONTENTS

Introduction - How to use this catalogue

EVN2000 Series

Fast Install Limit Switches

A recent addition to our range. Saves over 50 % in installation

time with a design that eliminates the need to gain access to the

inside of the housing in order to connect the switch.

SZL-VL Series

Limit Switches

New, economic, compact, rugged, dependable limit switches.

GL Series EN50041/47

Global Limit Switches

A complete range of CENELEC approved products,

suitable for most industrial applications.

SL1 Series

Space saving size for machine miniaturization,

different contact and actuators available.

14/914CE Series

Miniature Enclosed Switches

Miniature, rugged, pre-wired switches, meeting the requirements

of the Low Voltage directive. They come with a range of head

styles and sealing options.

Page 2

Page

Page

Page

Page

Page

HDLS Series

Heavy Duty Limit Switches

Suitable for special applications in corrosive environments. Housed

in a rugged die-cast zinc body and epoxy coated for protection,

they are available with a range of switching and head options.

Explosion Proof Switches

A range of switches designed for use in hazardous applications

in potentially explosive atmospheres. Most are UL-CSA listed and

some meet the requirement of the new European Directive 94/9/EC

(commonly referred to as the ATEX Directive).

Levers for Limit Switches

A range of levers for use with Honeywell’s Limit Switches.

Select the best one for your application.

Safety Switches for machine guarding

Safety interlock switches, limit switches and cable-pull limit

switches for industrial machine safety.

Relays

Designed for a wide range of applications including power as

well as logic control for factory machines and control panels.

Linear and Rotary Position

A wide selection of Hall-effect, magnetoresistive, and

potentiometric devices for detecting the presence of a magnetic

field or linear and rotary position.

Page

Page

Page

Page

Page

Page

24/924CE Series

Miniature Enclosed Switches

Miniature, rugged, direct opening action contacts. This switch

is available with a variety of actuators and is pre-wired.

LS Series

Compact Limit Switches

A range of compact limit switches designed for accurate

repeatability under the most stringent conditions. Special oil

resistant and high temperature versions are available.

BF Series

Medium Duty Limit Switches

Rugged plastic enclosure, with large internal cavity for ease of wiring.

BZE/DTE Series

Medium Duty Limit Switches

Side or flange mount, momentary or maintained contact, sealed

or unsealed actuators, removal of bottom enclosure for ease of wiring.

BAF/DTF Series

High Capacity Enclosed Switches

Rugged cast aluminium housed switches, sealed for

wash-down applications. Momentary or maintained contacts,

right or left hand actuators, 3 hole mounting.

Page

Page

Page

Page

Page

Opto Sensors

Ultrasonic Distance Sensors

Ultrasonic position sensors for presence/absence sensing,

precision distance sensing or tracking for areas where other

sensing technologies have difficulty, such as clear or

shiny objects, foggy or particle laden air, or splashing liquids.

Pressure sensors

We offer stainless steel and silicon pressure sensors depending

on the application, as well as a variety of high purity pressure sensors.

Honeywell Sensing and Control products

Index

Page

Page

Page

Page

Page

www.honeywell.com/sensing

1

Page 4

INTRODUCTION

HONEYWELL INDUSTRIAL SWITCHES AND SENSORS

Honeywell Industrial Switches and Sensors provide a wide selection of products and technologies for applications in most industrial applications. This catalogue

contains our most popular listings. To view our complete range of products, visit our website at http://www.honeywell.com/sensing.

Honeywell is a worldwide leader in advanced switching and sensing technology. Our reputation for technology, quality and reliability is second to none. We have

more than 60 years of experience; and extensive knowledge of Industrial applications, an extensive customer service and support network. Honeywell

manufactures the original MICROSWITCH brand switch and we offer one of the most complete lines of global electro-mechanical heavy duty limit switches.

Sealed versions keep out moisture and other contaminates. Explosion proof types are designed for use in hazardous locations. Safety versions provide direct

opening action contacts for machine guarding and emergency stops.

We are a recognized technology leader in the development and manufacture of pressure and position-sensing transducers and controls. We use the latest in

manufacturing technology to produce hundreds of thousands of transducers a year. Millions of units are currently performing in a multitude of continuous-duty

applications around the world, where they typically outlast the systems they support. We have ISO 9001 certified facilities and Class 10 cleanroom capability, and

we manufacture a full line of high purity pressure sensing and control products; each individually tested, inspected and certified to be in full compliance with the

product specification.

A comprehensive and diverse line of speed and position sensors for the Industrial market place is also available. With the combined capabilities of three wellknown product brands - Data Instruments, Clarostat, Electro and New England Instruments - Honeywell continuously strives to solve customers’ application

problems. Whether you need custom designed sensors for proprietary OEM applications or off-the-shelf sensor solutions, our extensive in-house design,

manufacturing and environmental testing capabilities offer solutions and alternatives to meet your needs.

2

www.honeywell.com/sensing

Page 5

INTRODUCTION

How to use this catalogue

For each referenced listing, key specification parameters, descriptions and

mounting drawing information are presented. These illustrate our capabilities

while the specifications include allow easy differentiation between similar

products.

There are, of course, many more product options available. Full product

specification may be accessed on our website (www.honeywell.com/sensing).

At the Home page enter the catalogue listing reference in the SEARCH box and

click GO! This will take you directly to the interactive catalogue/specification

search tables for this listing. Alternatively select and click the interactive

catalogue icon on the Home page and then choose a product category against

which to do a specification search.

Also on the website you can access installation instructions, application notes,

Frequently Asked Questions (FAQs), selection guides and additional technical

information.

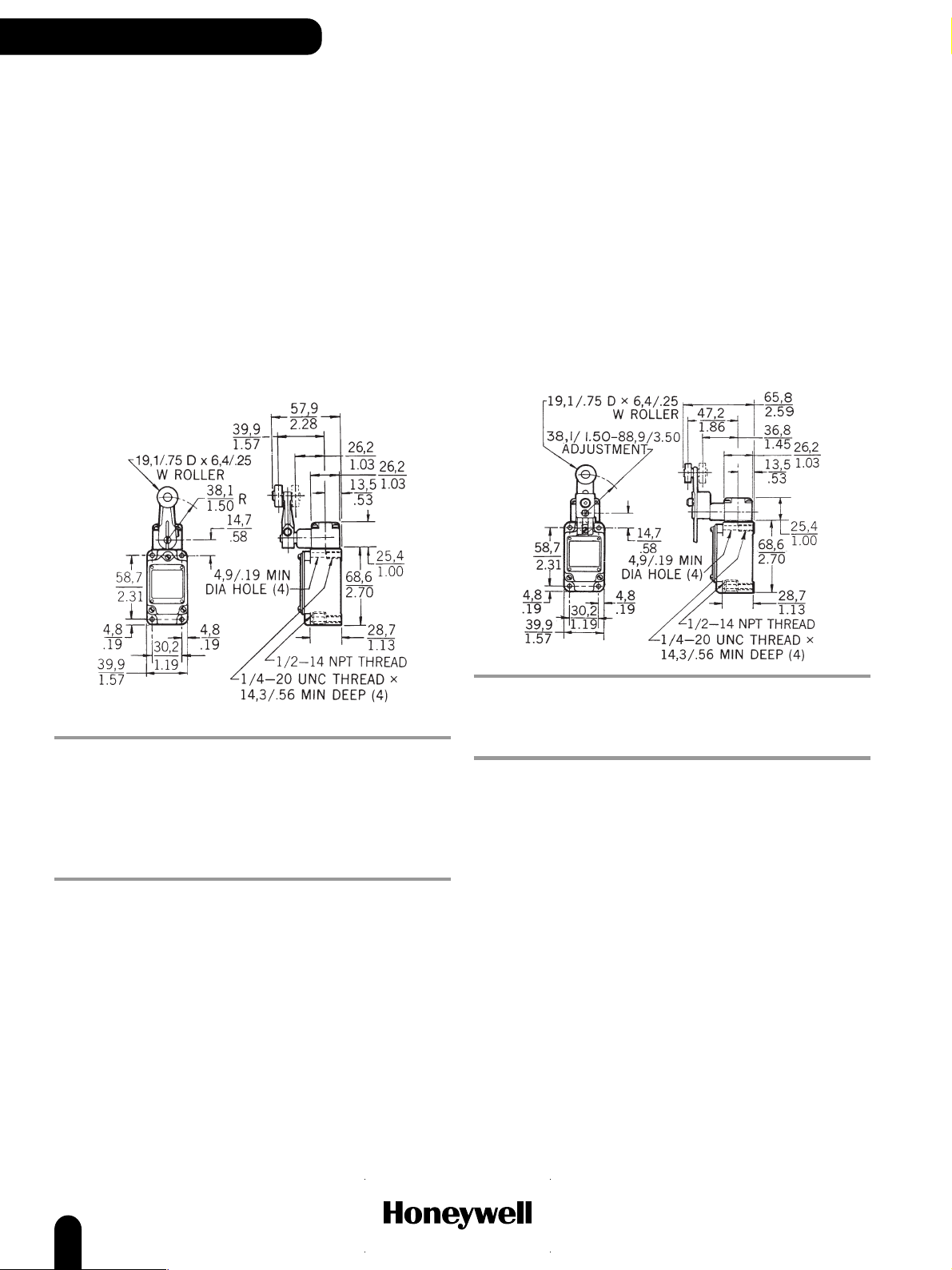

Mounting dimensions

Mounting dimensions shown in each product section are for reference only.

For exact information, request an engineering drawing from you nearest

Honeywell sales office or visit our website and access it through the interactive

catalogue. Where dual dimensions are shown on mounting drawings, the first

or upper one is millimetres (mm) and the second or lower is inches (in).

Where single dimensions are shown, they are millimetres (mm), unless

otherwise stated.

To order these products

Simply contact your local Honeywell Sales Representative, your Honeywell

Distributor or your local Honeywell office.

If you need a product not listed in this catalogue

One of Honeywell’s strengths is in application-specific packaging of sensing

technology. Honeywell provides many variations of our basic switches and

sensors. For more information, either browse the full interactive catalogue

available on our website, or telephone the following numbers:

USA 1-800-537-6945/1-815-537-6945

UK +44 (0)1698 481 481 Germany +49 69 8064 444

France +33 1 60 19 80 40 Italy +39 02 92146 450/456

More information on Honeywell Sensing & Control products and how to

contact us can be found on our website.

Select the right product – select the right supplier

Delivering excellence in system critical sensing

solutions

A system is critical if the quality, reliability, delivery and customer service

associated with a component part is essential to the performance of the

operation or end product. If a sensor or a switch is critical to the

performance, cost effectiveness, delivery or safety of a product or operation

then it’s systems critical. It is therefore a defining element in the performance

of the system under whatever conditions apply. Failure of the component - or

failure of delivery of the component - results in lost productivity, increased

costs or a catastrophic event such as a shutdown. Therefore selecting the

right product is essential. It can make the difference between success and

failure.

Honeywell Sensing and Control – delivering

excellence

To select the right product, first select the right supplier. To deliver the right

products for our customers’ applications we listen to them to understand their

needs. Using techniques such as “Voice of the Customer and “Concept

Engineering” we make sure that the products and solutions we deliver are the

right ones. As part of Honeywell we can use local knowledge and

understanding combined with global expertise and resources to achieve this.

We can deploy many key technologies to bring innovative solutions to

customers’ problems.

Our products are manufactured to work well and to last. We use Six Sigma

Plus productivity to ensure this is the case. We have award winning

manufacturing facilities around the world and recognised world class

business excellence in manufacturing and supply chain management to

deliver on time, anywhere in the world.

Our e-business approach offers instant access to product information,

technical support and application knowledge through out Internet site. Check

out our powerful new interactive catalogue that can search and find the right

products for customers’ needs and deliver a drawing ready for incorporation

in a CAD system direct to your desk.

And of course, we manage our whole business for the benefit of our

customers, using an acknowledged world-class business excellence approach

that incorporates Six Sigma principles.

Expanded Product Lines

As well as many new and innovative switches, this catalogue includes an

expanded range of Pressure and Position Sensors, previously known under

the Clarostat, NEI and Electrocorporation brand names.

www.honeywell.com/sensing

3

Page 6

Blank page

4

www.honeywell.com/sensing

Page 7

Industrial Electromechanical

Limit Switches

Honeywell offers an advanced line of heavy duty limit switches and a wide

selection of application-proven enclosed switches (precision snap-acting

switches sealed in rugged metal housing). Sealed versions keep out moisture

and other contaminants. Our products meet or exceed critical standards

allowing for global use. Our rugged switches are suitable for use in harshduty, wash-down environments. We offer a variety of circuitry, terminations

and actuators to ensure that can match your choice of switch to your

application.

Limit and enclosed switches are the cost effective switches of choice for

detecting objects which can be touched. When an object comes in contact

with an actuator, the switch operates. Rugged and dependable, these

switches are offered in a variety of sizes, with different seals, enclosures,

actuation, circuitries and electrical ratings. Enclosed switches are known for

high precision and low cost. Limit Switches are especially rugged and well

sealed. Explosion proof switches are designed for use in hazardous locations.

The Honeywell switches featured here are all proven in a broad range of

Industrial applications - machine tools, packaging machinery, lifting gear,

presses and construction machinery.

More information about our complete product range - and the depth of

product available within each product line - can be found on our interactive

catalogue at www.honeywell.com/sensing.

LIMIT SWITCHES

MICRO SWITCH Brand products

Honeywell has been at the forefront of switching technology since we were the

first to develop the precision snap-action switch more than 60 years ago.

Ever since we introduced the MICRO SWITCH Brand Products in 1937, we

have been recognized as the performance standard that all other switches are

measured against. We continue in that tradition by constantly improving the

technology, cost-effectiveness, and delivery of these hardworking, versatile

electromechanical switches.

www.honeywell.com/sensing

5

Page 8

LIMIT SWITCHES

Proper application of limit switches

The following are guidelines for the correct application of Limit Switches.

Never use the Limit Switch as a physical end stop. Mechanical damage or

incorrect operation may occur if this is done. Always ensure that the

mechanical actuator is protected from excessive mechanical shock. Never

release the actuator suddenly - gradual actuation and release will ensure that

stress on the mechanics of the switch is kept to a minimum. This has the

added benefit that the switch life will be improved. The diagrams illustrate how

to actuate your limit switch for optimum performance.

WRONG WRONG

RIGHT FIXED STOP

RIGHT

Standards and Electrical rating

IEC/EN 60947-1 explains the general rules relating to Low Voltage switchgear

and controlgear. The purpose of this standard is to harmonize as much as

possible the product performance and test requirements for equipment where

the rated voltage does not exceed 1,000 Vac or 1,500 Vdc.

IEC 60947-5-1 is part 5 of the general rules which relates to Control-circuit

devices and switching elements, where rated voltage does not exceed 1,000

Vac or 600 Vdc. There are special requirements for control switches with

positive opening operation. These switches are marked on the outside with

this symbol:

The Contact Element form defines the configuration and number of contacts

within the switch.

Form Za – both contact elements have the same polarity

Form Zb – the two contact elements are electrically separated.

The Utilization Category defines the type of current carried – ac or dc – and

the typical application where the switch is used.

The contact rating Designation relates to the Utilization Categories and defines

the conventional thermal current Ith (a) rated operational current Ie (A) at

rated operational voltages Ue and the VA rating.

Actuators

A range of actuators is available for limit switches. Illustrations of actuator

types available from this catalogue are shown at the beginning of each

product family. Other actuators may be available - for more information

please contact your local Honeywell office.

Roller lever

Top roller

lever

Adjustable

roller lever

Top pin

plunger

Top pin

plunger,

boot seal

For limit switches with pushrod actuators, the actuating force should be applied as

nearly as possible in line with the pushrod axis.

WRONG WRONG

over-riding

cam

RIGHT RIGHT

over-riding

cam

Cam or dog arrangements should be such that the actuator is not suddently released

to snap back freely.

free position

interference

WRONG WRONG

free position

end of

overtravel

operated

position

end of

overtravel

RIGHT RIGHT

Operating mechanisms for limit switches shoud be so designed that, under any

operating or emergency conditions, the limit switch is not operated beyond its

overtravel limit position. A limit switch should not be used as a mechanical stop.

Top roller

plunger

Side

pin plunger

6

Top roller

plunger,

boot seal

Side

roller plunger

Top roller

plunger,

perpendicular

Roller lever

Top roller

plunger,

perpendicular,

boot seal

Yoke lever

WRONG

Ball bearing

plunger

RIGHT

Rod lever

Wobble head

For limit switches with lever actuators, the actuating force should be applied as

nearly perpendicular to the lever as practical and perpendicular to the shaft axis

about which the lever rotates.

www.honeywell.com/sensing

non-over-riding

over-riding

Page 9

A Note on Degrees of Protection

IP Classification

The IEC 529 standard describes a system for classifying the degree of

protection provided by the enclosures of electrical equipment. The level of

protection given by the enclosure is indicated by the IP code. This code

system uses the letters ‘‘IP’’ (International Protection) followed by up to four

digits. Normally only the first two digits are used.

IP 1st Digit 2nd Digit 3rd Digit 4th Digit

The first digit is numerical and indicates the level of protection within the

enclosure against the ingress of solid foreign objects and access to hazardous

parts by persons.

The second digit is also numerical and indicates the level of protection

against the ingress of WATER into the enclosure.

The third digit is a letter and indicates a higher level of protection for persons

against access to hazardous parts.

The fourth digit is also a letter and is used in exceptional cases for

supplementary information.

If the first or second digit is not required to be specified, then it is replaced by

the letter ‘‘X’’ (‘‘XX’’ if both digits are not required). While the tables below

serve as a guide to the level of protection, Honeywell recommends that

customers refer to the full official IEC specification for the exact definitions. If

in doubt about the degree of protection required for a particular application,

please consult your local Honeywell office.

Note:

The IEC 529 standard does not relate to protection against rust, corrosion,

icing or corrosive solvents (e.g. cutting fluids) and that product coded IP 67

may not necessarily meet IP 66 requirements.

First Digit Protection against ingress of solid objects

IP TEST

0 no protection

1 protected against solid objects with a diameter greater than 50 mm

2 protected against solid objects with a diameter greater than 12 mm

3 protected against solid objects with a diameter greater than 2.5 mm

4 protected against solid objects with a diameter greater than 1 mm

5 protected against dust-limited ingress (no harmful deposit)

6 totally protected against dust

Second Digit Protection against ingress of water

IP TEST

0 no protection

1 protected against vertically falling drops of water

2 protected against vertically falling drops of water when the enclosure is tilted

at an angle up to 15 degrees

3 protected against water sprayed at an angle of 60 degrees from the vertical

4 protected against splashing water from all directions – limited ingress (no

harmful effects)

5 protected against low pressure jets of water from all directions – limited

ingress permitted

6 protected against powerful jets of water from all directions – limited ingress

permitted

7 protected against the effects of temporary immersion in water

8 protected against the effects of continuous immersion in water

LIMIT SWITCHES

NEMA Classification (USA)

NEMA (National Electrical Manufacturer’s Association) prepares standards

which define a product, process or procedure with reference to one or more of

the following: nomenclature, composition, construction, dimensions,

tolerances, safety, operating characteristics, performance, quality, electrical

rating, testing and the service for which designed. This standard provides

degrees of protection for Enclosures for Electrical Equipment (1000 Volts

Maximum) similar to that of the IEC 529 standard. The reference standard

herein reflects the latest data in the NEMA Standards Publication when this

information went to print. Please check for the latest information.

Non-hazardous locations

Type 1 enclosures are intended for indoor use primarily to provide a degree of

protection against contact with the enclosed equipment.

Type 3 enclosures are intended for outdoor use primarily to provide a degree

of protection against windblown dust, rain, sleet, and external ice formation.

Type 4 enclosures are intended for indoor or outdoor use primarily to provide

a degree of protection against windblown dust and rain, splashing water, and

hose-directed water.

Type 4X enclosures are intended for indoor or outdoor use primarily to

provide a degree of protection against corrosion, windblown dust and rain,

splashing water, and hose-directed water.

Type 6 enclosures are intended for indoor or outdoor use primarily to provide

a degree of protection against the entry of water during occasional temporary

submersion at a limited depth.

Type 6P enclosures are intended for indoor or outdoor use primarily to

provide a degree of protection against the entry of water during prolonged

submersion at a limited depth.

Type 12 enclosures are intended for indoor use primarily to provide a degree

of protection against dust, falling dirt, and dripping noncorrosive liquids.

Type 13 enclosures are intended for indoor use primarily to provide a degree

of protection against dust, spraying water, oil and noncorrosive coolant.

Note:

Enclosures are based, in general, on the broad definitions outlined in NEMA

Standards. Therefore, it will be necessary to ascertain that a particular

enclosure will be adequate when exposed to the specific conditions that might

exist in intended applications.

Except as might otherwise be noted, all references to products relative to

NEMA enclosure type are based on Honeywell evaluation and Underwriter’s

Laboratory (UL) tested. This NEMA Standards Publication does test for

environmental conditions such as corrosion, rust, icing, oil, and coolants. The

IEC 529 does not, and does not specify degree of protection against

mechanical damage of equipment. For this reason, and because the tests and

evaluations for other characteristics are not identical, the IEC Enclosure

Classification Designations cannot be exactly equated with NEMA Enclosure

Type Numbers.

www.honeywell.com/sensing

7

Page 10

GLOBAL LIMIT SWITCHES

Zb

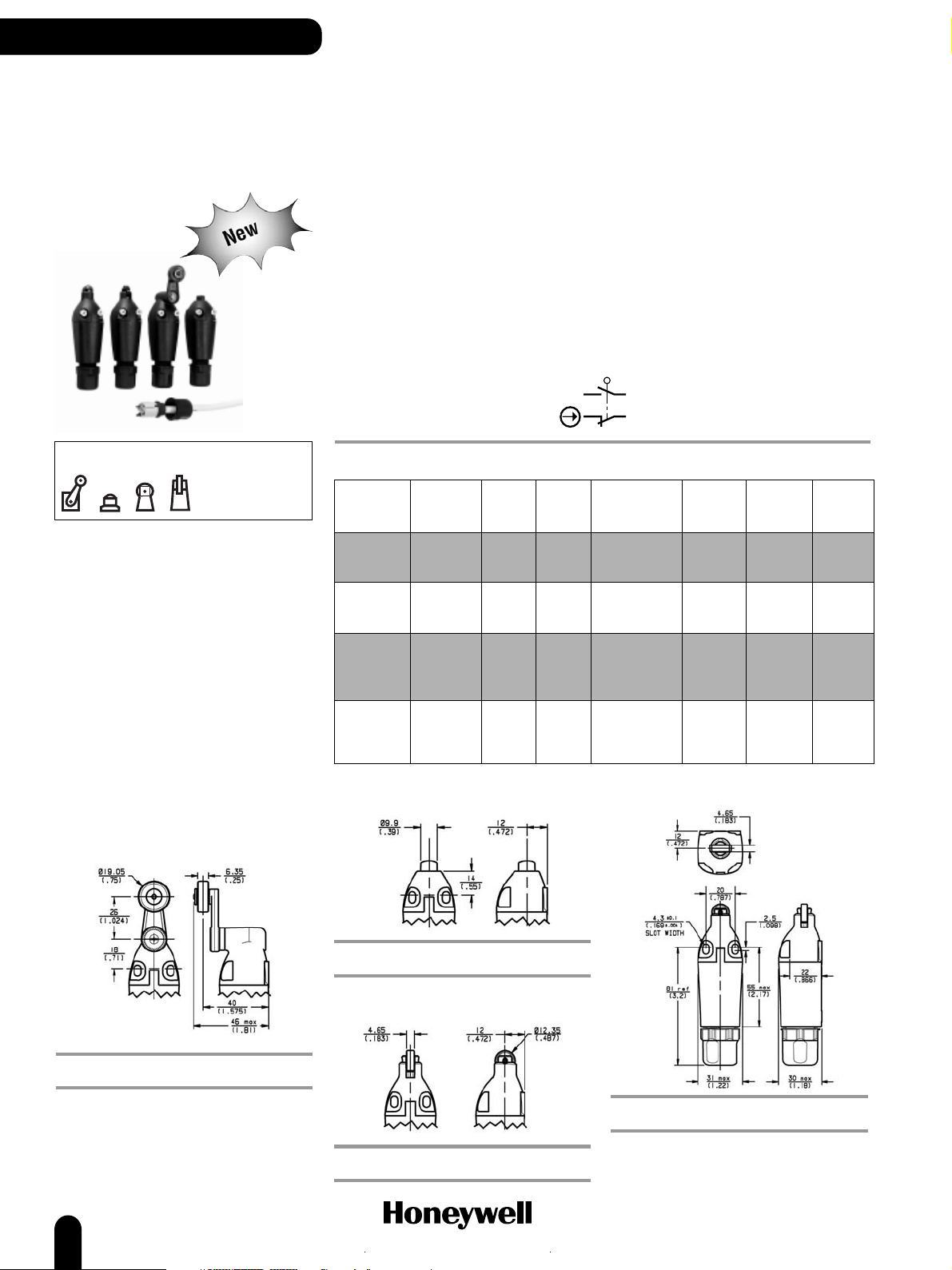

EVN2000 Series

EN 50047

Global Limit

Switches

The EVN2000 series limit switch is an innovative product which has been developed to address a need

highlighted by Original Equipment Manufacturers (OEM), where “Ease of Wiring” is required. With the

new design there is no need for access to the inside of the housing and therefore the housing cover,

cover screws and gasket become obsolete. Furthermore, the integrated cable gland eliminates the need

for additional conduit or cable gland hardware. All Normally Closed (NC) contacts are Direct Opening.

Mechanical life: 10 million

Sealing: IP 66/67, NEMA 1, 12, 13

Operating temperature: -25 °C to 85 °C (-13 °F to 185 °F)

Approvals: IEC/EN 60947-5-1

EN 60529

EN81-1

AC15 A300

DC13 Q300

UL, CE

Housing material: Plastic

Termination: Insulation Displacement Terminals (IDT)

Switching options: SPDT Single Pole, Double Throw,

Snap action contacts (1NC/1NO)

Actuators

OPTIONS

Side rotary plastic roller

Operating characteristics

Actuator Operating Free Pretravel Travel to Overtravel Differential Operating

type torque/force position positive opening travel point

Side

rotary 0,120 N m 0° 25° 45° 45° 12° 25°

A (1.10 lb in)

Top pin

plunger 16,0 N 20,0 mm 2,0 mm 3,5 mm 4,0 mm 1,0 mm 18,0 mm

B (3.60 lb) (0.79 in) (0.08 in) (0.14 in) (0.16 in) (0.04 in) (0.71 in)

Top roller

plunger, 16,0 N 30,0 mm 2,0 mm 3,5 mm 4,0 mm 1,0 mm 28,0 mm

parallel (3.60 lb) (1.18 in) (0.08 in) (0.14 in) (0.16 in) (0.04 in) (1.10 in)

C

Top roller

plunger, 16,0 N 30,0 mm 2,0 mm 3,5 mm 4,0 mm 1,0 mm 28,0 mm

perpendicular (3.60 lb) (1.18 in) (0.08 in) (0.14 in) (0.16 in) (0.04 in) (1.10 in)

D

Top pin plunger

(OF) (FP) (PT) (PO) (OT) (DT) (OP)

Top roller plunger, parallel

REFERENCE

EVN2000B

Top roller plunger, perpendicular

REFERENCE

EVN2000A

REFERENCE

EVN2000C

REFERENCE

EVN2000D

8

www.honeywell.com/sensing

Page 11

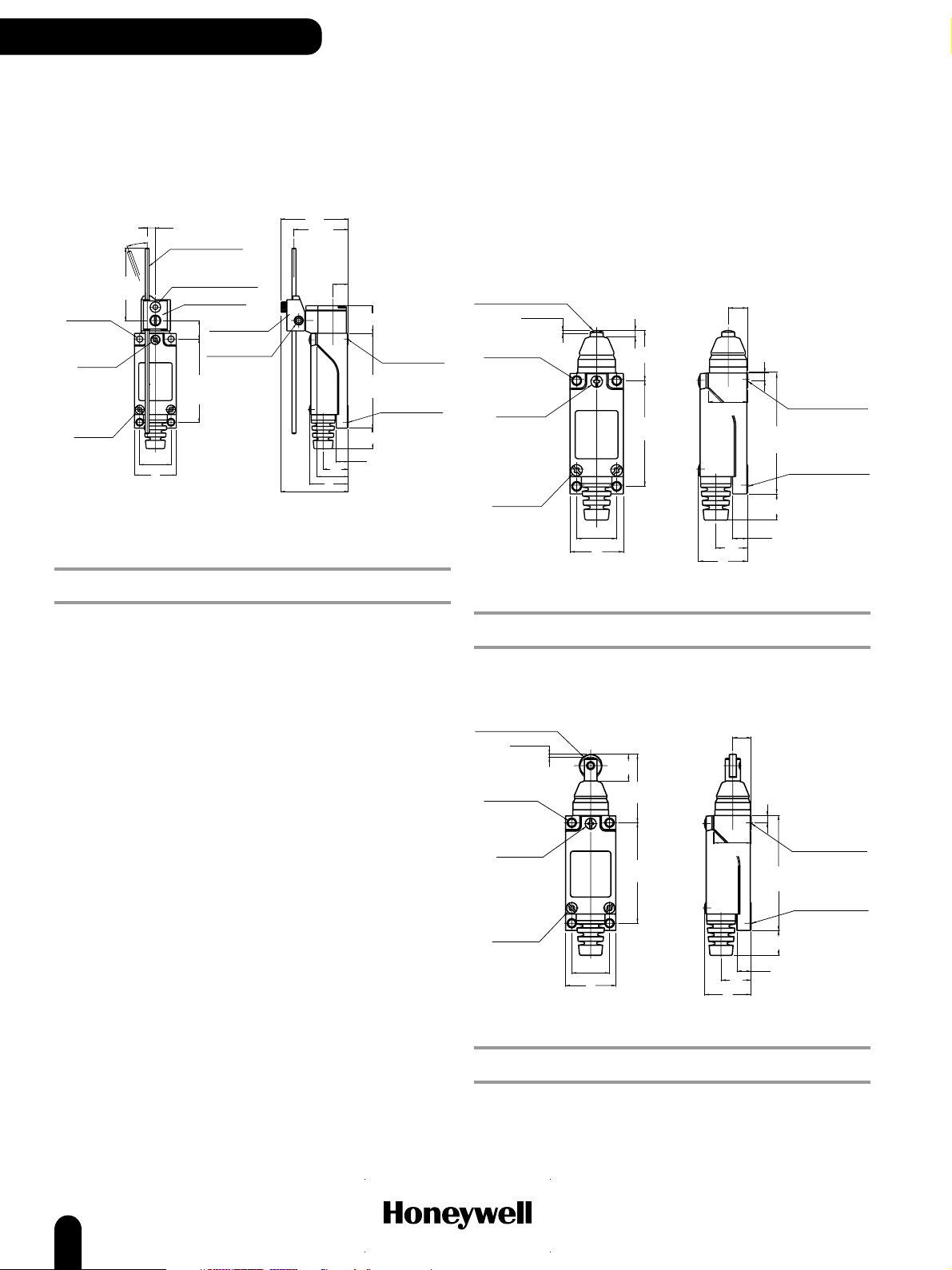

VL Series

General Purpose Compact

Limit Switches

GLOBAL LIMIT SWITCHES

The new economical SZL-VL Series miniature type limit switches are specially

designed for applications of small mounting space. These miniature switches

are ideal for OEM machinery which requires a rugged and reliable limit switch

that is capable of being mounted in space restricted applications. A wide range

of actuators and optional neon lamp indicators add additional flexibility. A

special pre-molded flexible cable gland allows for fast and simple wiring

termination.

Mechanical life: up to 10 million operations

Sealing: IP 64

Operating temperature: -20 °C to 60 °C (-4 °F to 140 °F)

Approvals: UL, C-UL, CE

Termination: Cable gland

Contacts: Gold plated silver

Electrical ratings: 250 Vac 125 Vdc max.

Ampere rating: 5 A @ 250 Vac max./0.4 A @ 125 Vdc max.

Switching options:

SPDT Single Pole, Double Throw, Double break

(1NC/1NO)

Actuators

Side rotary actuated switches

Pretravel max. (PT): 20°

Overtravel min. (OT): 75°

Differential travel max. (DT): 10°

OPTIONS

Roller lever

41.2±.08

holes)

1.622±.031

36.2±0.8

1.425±.031

20.4±0.3

.803±.012

38.1

1.5

15.1

.594

10.2

.402

18.5

.728

64

2.520

14

.551

7.5±0.2

.295±.008

25

.984

(Standard type)

2-M5 (P=0.8)

tapped

7 .276 in depth

mounting holes

2-M5 (P=0.8)

tapped

mounting holes

M4 arm fixing nut

+0.2

2-4.1

dia.

-0

mounting holes

+0.008

.161

-0

mounting holes

cover screw

M3x6

2-M3x23

cover screw

dia.

P

T

m

˚

0

2

21±0.2

.827±.008

a

1.102

x

28

18 dia.x7

nylon roller

(Roller can be

rotated and locked

in any position

through 360˚)

0

3

M4 arm

R

fixing screw

(with hexagonal

12.5

.492

56±0.3

2.205±.012

34

NO

NC

Roller lever, adjustable

Adjustable length

of arm

(30-70)

+0.2

2-4.1

dia.

0

mounting holes

+0.008

.161

dia.

-0

mounting holes

M3x6

cover screw

2-M3x23

cover screw

T

P

.827±.008

0

2

21±0.2

1.102

m

˚

28

18 dia.x7 nylon rooler

(Roller can be rotated

x

a

and locked in any

position through 360˚)

M4 arm fastening

plate screw with

hexagonal holes

Arm fasteni ng plate

56±0.3

2.205±.012

12.5

.492

Mounting metal

M6 arm fastening

plate screw with

hexagonal holes

VL

47.7±0.8

1.878±.031

1.319±.031

2.0

.079

(46.4)

33.5±0.8

28.5±0.8

1.122±.031

25

.984

(1.827)

21

10.2

.402

15.1

.594

NO

NC

42.7±0.8

1.681±.031

64

2.520

7.5±0.2

.295±.008

20.4±0.3

.803±.012

(Standard type)

18.5

.728

2-M5 (P=0.8) tapp ed

7 .276 in depth

mounting holes

2-M5 (P=0.8) tapp ed

mounting holes

14

.551

Operating torque max.: 5,88 N (1.32 lb)

REFERENCE

SZL-VL-A

www.honeywell.com/sensing

Operating torque max.: 3,35 N to 7,84 N (0.75 lb to 1.76 lb)

REFERENCE

SZL-VL-B

9

Page 12

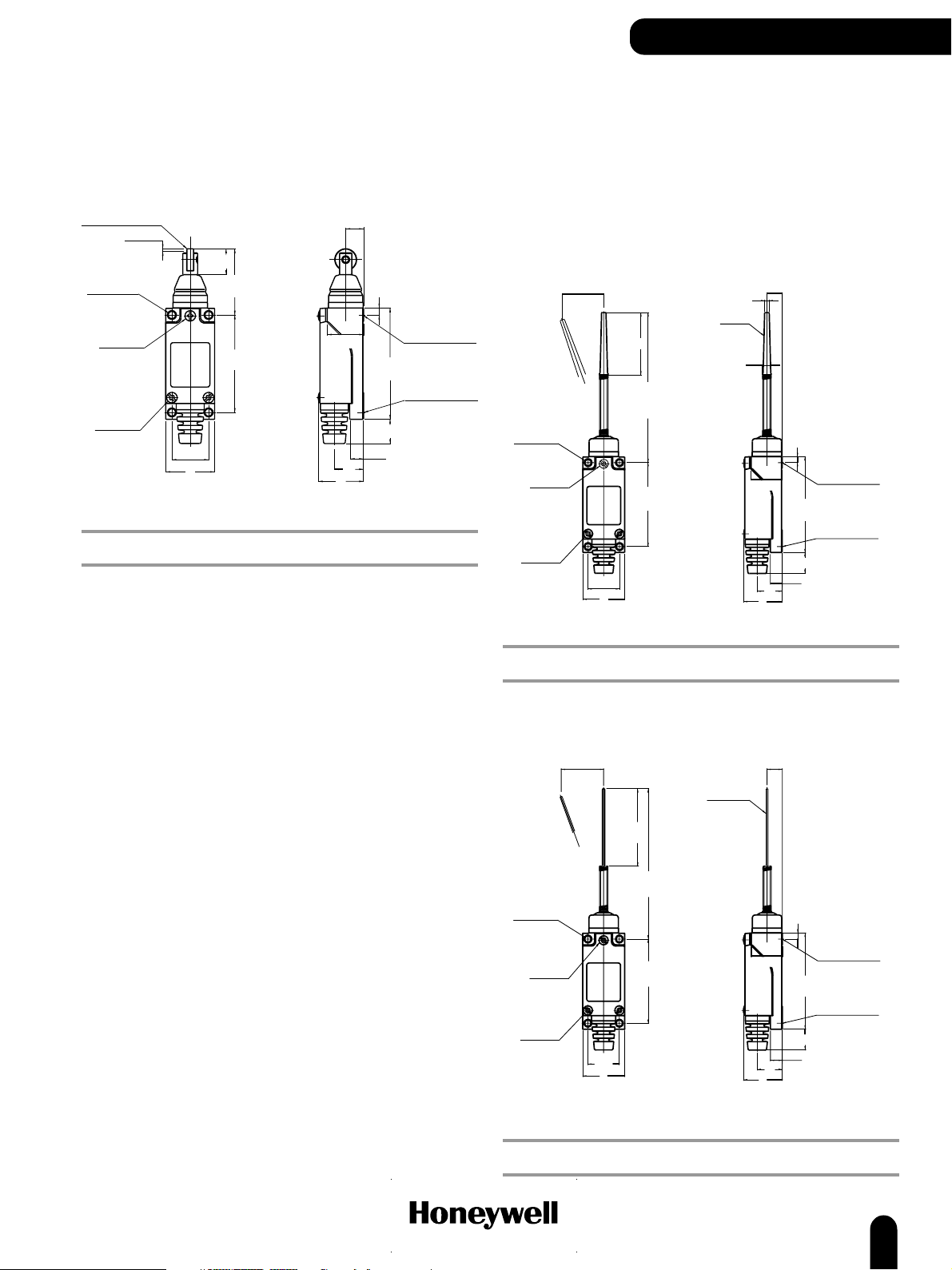

GLOBAL LIMIT SWITCHES

VL Series

Side rotary actuated switches (continued)

Plunger actuated switches

Adjustable rod

5.5

.217

2.6 .102 dia. rod

x

a

m

˚

0

2

T

P

Adjustable lenght of rod

+0.2

dia.

2-4.1

0

mounting holes

+0.008

.161

-0

mounting holes

M3x6

cover screw

2-M3x23

cover screw

(30-118)

dia.

and locked in any

(Roller can be rotated

position through 360˚)

M4 rod fastening plate

screw with hexagonal holes

21±0.2

.827±.008

28

1.102

Rod fastening plate

Rod mounting metal

12.5

.492

M6 mounting rod

fastening screw with

hexagonal holes

56±0.3

2.205±.012

Operating torque max.: 2 N to 7,84 N

44.9

1.768

36.3±0.8

1.429±.031

(44.9)

(1.768)

REFERENCE

SZL-VL-C

10.2

.402

2.520

7.5±0.2

15.1

.295±.008

20.4±0.3

.594

.803±.012

25

.984

(0.45 lb to 1.76 lb)

18.5

.728

2-M5 (P=0.8) tapped

7 .276 in dept h

mounting holes

64

2-M5 (P=0.8) tapped

mounting holes

14

.551

(Standard type)

Pretravel max. (PT): 1,5 mm (0.060 in)

Overtravel min. (OT): 4,0 mm (0.158 in)

Differential travel max. (DT): 0,7 mm (0.028 in)

Operating force max. (OF): 8,83 N (2 lb)

Top pin plunger

7. 276 dia.

stainless steel plunger

+0.2

dia.

2-4.1

0

mounting holes

+0.008

.161

-0

mounting holes

M3x6

cover screw

2-M3x23

cover screw

PT 1.5 max

dia.

21±0.2

.827±.008

28

1.102

3

.118

26.5

1.043

56±0.3

2.205±.012

10.2

402

.

20.4±0.3

.803±.012

15.1

.594

25

.984

4

.157

64

2.520

14

.551

7.5±0.2

.295±.008

(Standard type)

2-M5 (P=0.8) tapped

7 .276 in depth

mounting holes

2-M5 (P=0.8) tapped

mounting holes

Top roller plunger

12.5 dia.x3.8

stainless steel roller

PT 1.5 max

+0.2

2-4.1

dia.

0

mounting holes

+0.008

.161

dia.

-0

mounting hole s

M3x6

cover screw

2-M3x23

cover screw

21±0.2

.827±.008

28

1.102

14.8

.583

38

1.496

56±0.3

2.205±.012

REFERENCE

SZL-VL-D

10.2

.402

20.4±0.3

.803±.012

15.1

.594

25

.984

REFERENCE

SZL-VL-H

4

.157

64

2.520

14

.551

7.5±0.2

.295±.008

(Standard type)

2-M5 (P=0.8) tapped

7 .276 in depth

mounting hole s

2-M5 (P=0.8) tapped

mounting holes

10

www.honeywell.com/sensing

Page 13

GLOBAL LIMIT SWITCHES

Plunger actuated switches (continued)

Cross roller plunger

12.5 dia.x3.8

stainless steel roller

PT 1.5 max

+0.2

2-4.1

dia.

0

mounting holes

+0.008

.161

dia.

-0

mounting holes

M3x6

cover screw

2-M3x23

cover screw

21±0.2

.827±.008

28

1.102

14.8

.583

56±0.3

2.205±.012

38

1.496

20.4±0.3

.803±.012

15.1

.594

25

.984

REFERENCE

SZL-VL-E

10.2

.402

4

.157

64

2.520

14

.551

7.5±0.2

.295±.008

(Standard type)

2-M5 (P=0.8) tapped

7 .276 in depth

mounting holes

2-M5 (P=0.8) tapped

mounting holes

Wobble actuated switches

Pretravel max. (PT): 30 mm (1.18 in)

Overtravel min. (OT): 20 mm (0.788 in)

Operating force max. (OF): 0,88 N (0.2 lb)

Plastic rod, coil spring

10.2

3 dia.

.118

5.8 dia.

.228

.402

20.4±0.3

.803±.012

15.1

.594

25

.984

4

.157

2-M5 (P=0.8) tapped

7 .276 in depth

mounting holes

64

2.520

2-M5 (P=0.8) tapped

mounting holes

14

.551

7.5±0.2

.295±.008

(Standard type)

+0.2

dia.

2-4.1

0

mounting holes

+0.008

.161

dia.

-0

mounting holes

M3x6

cover screw

2-M3x23

cover screw

PT 50 max

21±0.2

.827±.008

28

1.102

41.5

1.634

100±1.5

3.937±.059

56±0.3

2.205±.012

Nylon rod

Coil spring

SZL-VL-G

2-4.1

mounting holes

.161

mounting holes

2-M3x23

cover screw

+0.2

dia.

0

+0.008

dia.

-0

M3x6

cover screw

PT 30 max

21±0.2

.827±.008

28

1.102

51.5

2.028

100±1.5

3.937±.059

56±0.3

2.205±.012

REFERENCE

SZL-VL-F

1.2 dia.

.047 stainless

steel wire

10.2

.402

20.4±0.3

.803±.012

15.1

.594

25

.984

4

.157

2-M5 (P=0

7 .276 in depth

mounting holes

64

2.520

2-M5 (P=0.8)

mounting holes

14

.551

7.5±0.2

.295±.008

(Standard type)

.8) tapped

tapped

www.honeywell.com/sensing

REFERENCE

SZL-VL-G

11

Page 14

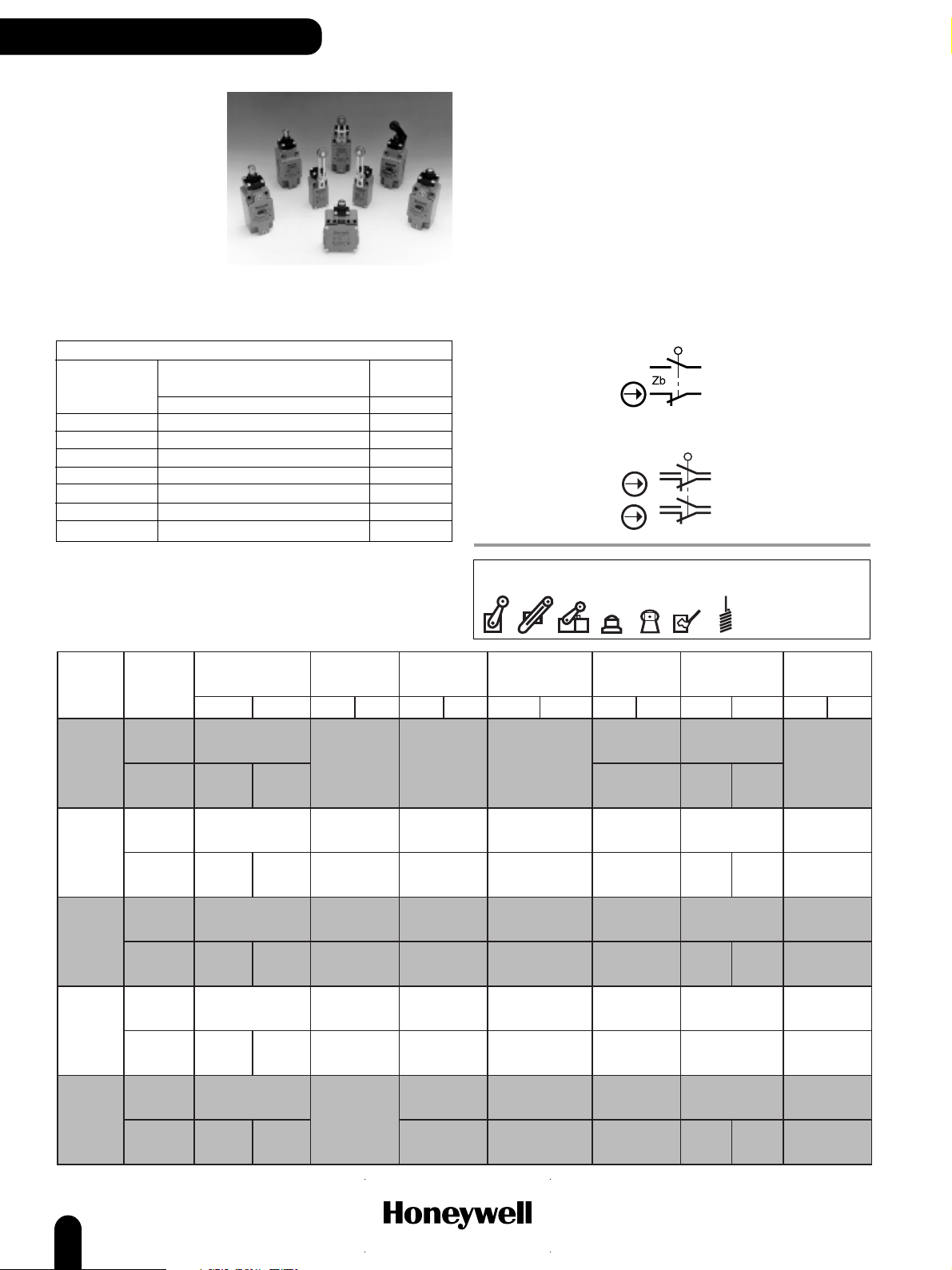

GLOBAL LIMIT SWITCHES

GLS Series

Global Limit

Switches

Electrical ratings

IEC947-5-1/EN60947-5-1

Designation & Rated operational current Ie (A) VA

Utilization Category at rated operational voltage Ue rating

120V 240V 380V 480V 500V 600V Make Break

AC15 A600 6 3 1.9 1.5 1.4 1.2 7200 720

AC15 A300 6 3 - - - - 7200 720

AC15 B300 3 1.5 - - - - 3600 360

AC14 D300 0.6 0.3 - - - - 432 72

125V 250V

DC13 Q300 0.55 0.27 69 69

DC13 R300 0.22 0.1 28 28

GLS Series switches offer a complete range of CENELEC approved products,

and are suitable for most industrial applications.

The standard product EN 50041 norm defines the switch mounting centres as

30 mm x 60 mm and also defines the switching characteristics of the side

rotary head with fixed lever, top pin plunger and top roller plunger. This means

that the switch can be interchanged in the application with other EN 50041

switches with mounting and switching characteristics maintained. Honeywell

offers many more head styles and switching options.

The miniature EN 50047 product range offers the user a choice of plastic,

metal and three conduit versions which are all mounting (20 mm x 22 mm)

compatible with each other. The EN 50047 standard defines how the switches

are mounted and the switching characteristics for fixed side rotary lever, top

pin plunger and top roller plunger.

Switching options:

SPDT Single Pole, Double Throw, Snap action contacts (1NC/1NO)

13

14

22

21

DPDT Double Pole, Double Throw Snap action contacts (2NC/2NO)

13

11

23

21

14

12

24

22

Operating characteristics

Actuator

type

Lever types

A,

A*A, A*B,

A4J

Top pin

plunger

B

Top roller

plunger

C

Top roller

lever

D

Wobble head

E7B, E7D,

K8B, K8C

Body

size

EN50041

(GLA)

EN50047

(GLC, GLD,

GLE)

EN50041

(GLA)

EN50047

(GLC, GLD,

GLE)

EN50041

(GLA)

EN50047

(GLC, GLD,

GLE)

EN50041

(GLA)

EN50047

(GLC, GLD,

GLE)

EN50041

(GLA)

EN50047

(GLC, GLD,

GLE)

Operating torque/force

SPDT DPDT SPDT DPDT SPDT DPDT SPDT DPDT SPDT DPDT SPDT DPDT SPDT DPDT

0,120 N m

(1.10 lb in)

16,0 N

(3.60 lb)

16,0 N

(3.60 lb)

11,0 N

(2.4 lb)

1,3 N

(0.29 lb)

(OF)

0,330 N m

(2.90 lb in)

0,165 N m

(1.50 lb in)

GLE only

16,0 N

(3.60 lb)

(2.90 lb)

GLE only

16,0 N

3.60 lb

(2.90 lb)

GLE only

9,5 N

(2.10 lb)

GLE only

0,1 N

(0.90 in lb)

(0.25 lb)

GLE only

13,0 N

13,0 N

9,0 N

(1.9 lb)

1,1 N

Free position

(FP)

0˚ 55˚26˚

37,5 mm

(1.48 in)

21,0 mm

(0.83 in)

50,5 mm

(2.00 in)

31,0 mm

(1.22 in)

65,2 mm

(2.57 in)

39,25 mm

(1.55 in)

0˚

Pretravel

(PT)

2,5 mm

(0.10 in)

3,0 mm

(0.12 in)

2,5 mm

(0.10 in)

3,0 mm

(0.12 in)

4,2 mm

(0.165 in)

3,45 mm

(0.14 in)

18˚

16˚

Actuators

Travel to

positive opening

(PO)

4,5 mm

(0.18 in)

5,0 mm

(0.20 in)

4,5 mm

(0.18 in)

5,0 mm

(0.20 in)

8,3 mm

(0.33 in)

6,9 mm

(0.27 in)

__

__

Overtravel

(OT)

59˚

49˚

4,5 mm

(0.18 in)

3,0 mm

(0.12 in)

4,5 mm

(0.18 in)

3,0 mm

(0.12 in)

9,0 mm

(0.35 in)

5,2 mm

(0.205 in)

__

__

Differential travel

(DT)

12˚

11.5˚ 8˚

0,9 mm

(0.035 in)

0,9 mm

(0.035 in)

0,9 mm

(0.035 in)

0,6 mm

(0.024 in)

0,9 mm

(0.035 in)

0,6 mm

(0.024 in)

1,7 mm

(0.067 in

1,3 mm

(0.19 in)

8˚

10˚ 7˚

Operating point

(OP)

26˚

35,0 mm

(1.38 in)

18,0 mm

(0.71 in)

48,0 mm

(1.89 in)

28,0 mm

(1.10 in)

61,0 mm

(2.40 in)

35,8 mm

(1.41 in)

__

__

12

www.honeywell.com/sensing

Page 15

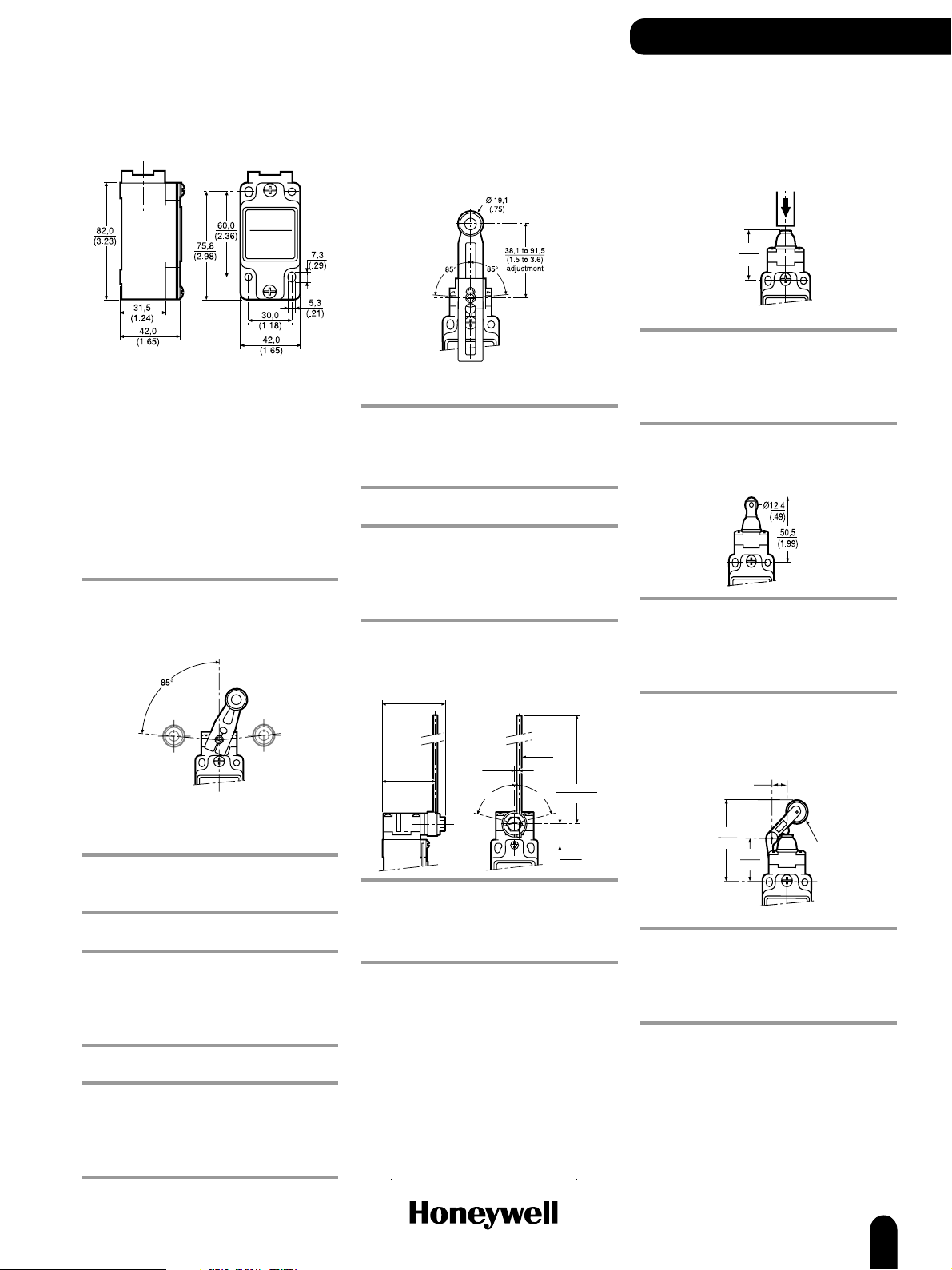

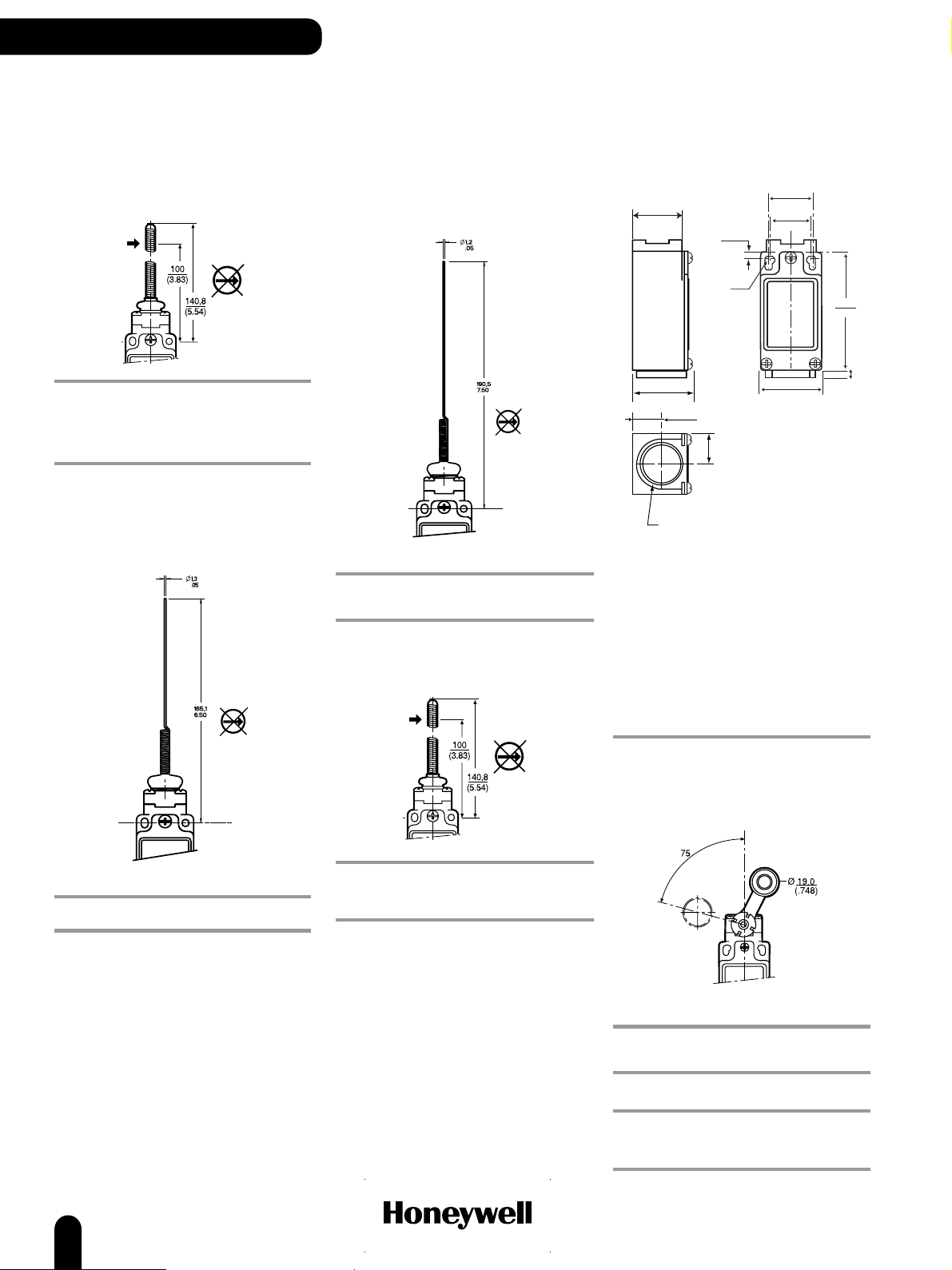

GLA EN 50041

Standard metal body

GLOBAL LIMIT SWITCHES

Mechanical life: up to 15 million

Sealing: IP 67, NEMA 1, 4, 12, 13

Operating temperature: -25 °C to 85 °C

(-13 °F to 185 °F)

Approvals: IEC/EN 60947-5-1

AC15 A300/A600

DC13 Q300

UL, CSA, CE

Switching options:

SPDT Single Pole, Double Throw

Snap action contacts (1NC/1NO)

DPDT Double Pole, Double Throw

Snap action contacts (2NC/2NO)

HEAD OPTIONS

Side rotary

Side rotary adjustable roller

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01A2A

DPDT ½ in NPT GLAA20A2A

SPDT PG 13,5 GLAB01A2A

DPDT PG 13,5 GLAB20A2A

SPDT 20 mm GLAC01A2A

Metal roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01A2B

DPDT ½ in NPT GLAA20A2B

SPDT PG 13,5 GLAB01A2B

DPDT PG 13,5 GLAB20A2B

SPDT 20 mm GLAC01A2B

DPDT 20 mm GLAC20A2B

Side rotary adjustable metal rod

41

(1.61)

Top pin plunger

37,5

FP

(1.48)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01B

DPDT ½ in NPT GLAA20B

SPDT PG 13,5 GLAB01B

DPDT PG 13,5 GLAB20B

SPDT 20 mm GLAC01B

DPDT 20 mm GLAC20B

Top roller plunger

FP

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01C

DPDT ½ in NPT GLAA20C

SPDT PG 13,5 GLAB01C

DPDT PG 13,5 GLAB20C

SPDT 20 mm GLAC01C

DPDT 20 mm GLAC20C

No lever

Levers: Levers for side rotary types are ordered

separately (see pages 69-71 for details)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01A

DPDT ½ in NPT GLAA20A

SPDT PG 13,5 GLAB01A

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01A1A

DPDT ½ in NPT GLAA20A1A

SPDT PG 13,5 GLAB01A1A

DPDT PG 13,5 GLAB20A1A

SPDT 20 mm GLAC01A1A

DPDT 20 mm GLAC20A1A

Metal roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01A1B

DPDT ½ in NPT GLAA20A1B

SPDT PG 13,5 GLAB01A1B

DPDT PG 13,5 GLAB20A1B

SPDT 20 mm GLAC01A1B

DPDT 20 mm GLAC20A1B

¯ 3,2

4,5

34

(1.34)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01A4J

DPDT ½ in NPT GLAA20A4J

SPDT PG 13,5 GLAB01A4J

DPDT PG 13,5 GLAB20A4J

SPDT 20 mm GLAC01A4J

(.17)

(.13)

75˚75˚

32 - 134

(1.26 - 5,28)

15

(.6)

Top roller lever

13,0

(.51)

65,2

FP

(2.51)

35

(1.38)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01D

DPDT ½ in NPT GLAA20D

SPDT PG 13,5 GLAB01D

DPDT PG 13,5 GLAB20D

SPDT 20 mm GLAC01D

DPDT 20 mm GLAC20D

Ø 18,7

(.74)

www.honeywell.com/sensing

13

Page 16

GLOBAL LIMIT SWITCHES

GLA EN 50041

Standard metal body

(continued)

Wobble, coil actuator

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01E7B

SPDT PG 13,5 GLAB01E7B

DPDT PG 13,5 GLAB20E7B

SPDT 20 mm GLAC01E7B

DPDT 20 mm GLAC20E7B

Coil wobble head, stainless steel

spring actuator

Wobble, cat whisker

GLC EN 50047

Standard metal body

24,75

(0.97)

30

(1.18)

14,5

(.57)

conduit thread

PG 13,5

(.12)

R

15,25

(.600)

3

(.08)

2,15

(.87)

(.78)

30,5

(1.20)

22

20

55

(2.16)

3,5

(0.138)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01E7D

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01K8B

SPDT PG 13,5 GLAB01K8B

Wobble, cat whisker, coil actuator

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLAA01K8C

DPDT ½ in NPT GLAA20K8C

SPDT PG 13,5 GLAB01K8C

Mechanical life: up to 10 million

Sealing: IP 66, NEMA 1, 4, 12, 13

Operating temperature: -25 °C to 85 °C

-13 °F to 185 °F

Approvals: IEC/EN 60947-5-1

AC15 A300

DC13 Q300

UL, CSA, CE

Switching options:

SPDT Single Pole, Double Throw

Snap action contacts (1NC/1NO)

HEAD OPTIONS

Side rotary

°

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01A1A

SPDT PG 13,5 GLCB01A1A

14

www.honeywell.com/sensing

Metal roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01A1B

SPDT PG 13,5 GLCB01A1B

SPDT 20 mm GLCC01A1B

Page 17

GLC EN 50047

Standard metal body

(continued)

GLOBAL LIMIT SWITCHES

Side rotary adjustable

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01A2A

SPDT PG 13,5 GLCB01A2A

Metal roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01A2B

SPDT PG 13,5 GLCB01A2B

SPDT 20 mm GLCC01A2B

Side rotary adjustable, metal rod

41

(1.61)

Top pin plunger

Ø 9.9

(.390)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01B

SPDT PG 13,5 GLCB01B

SPDT 20 mm GLCC01B

DT

OP

±0,5

18

(.709)

Top roller plunger

31,0

FP

1.22

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01C

SPDT PG 13,5 GLCB01C

SPDT 20 mm GLCC01C

Top roller lever

Wobble, coil actuator

➞

Mechanical life: up to 5 million

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01E7B

SPDT PG 13.5 GLCB01E7B

SPDT 20 mm GLCC01E7B

Wobble, cat whisker

¯ 3,2

4,5

34

(1.34)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01A4J

SPDT PG 13,5 GLCB01A4J

(.17)

(.13)

75˚75˚

32 - 134

(1.26 - 5,28)

15

(.6)

Ø

39,2

FP

(1.54)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01D

SPDT PG 13,5 GLCB01D

SPDT 20 mm GLCC01D

Mechanical life: 5 million

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLCA01K8A

SPDT PG 13,5 GLCB01K8A

www.honeywell.com/sensing

15

Page 18

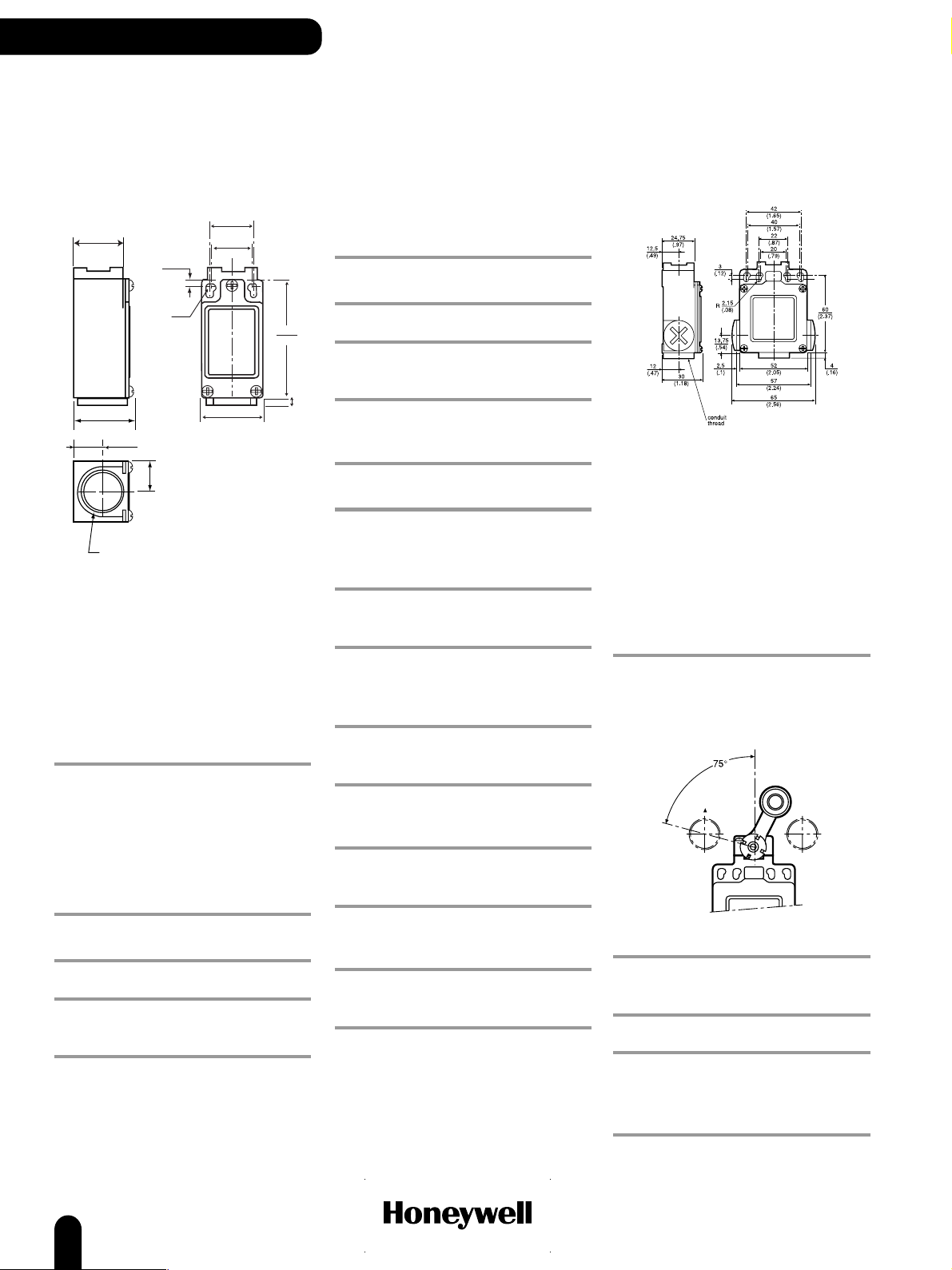

GLOBAL LIMIT SWITCHES

GLD EN 50047

Double insulated

standard body

22

24,75

(0.97)

3

(.12)

2,15

R

(.08)

30

(1.18)

14,5

(.57)

15,25

(.600)

conduit thread

PG 13,5

Mechanical life: See GLC section

Sealing: IP 66, NEMA 1, 2, 13

Operating temperature: -25 °C to 85 °C

Approvals: IEC/EN 60947-5-1

Switching options:

SPDT Single Pole, Double Throw

Snap action contacts (1NC/1NO)

HEAD OPTIONS

(.87)

20

(.78)

55

(2.16)

30,5

(1.20)

3,5

(0.138)

-13 °F to 185 °F

AC15 A600

DC13 Q300

UL, CSA, CE

Side rotary adjustable

Plastic roller/metal lever

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01A2A

SPDT PG 13.5 GLDB01A2A

Metal roller/metal lever

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01A2B

SPDT PG 13,5 GLDB01A2B

SPDT 20 mm GLDC01A2B

Side rotary adjustable metal rod

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01A4J

SPDT PG 13,5 GLDB01A4J

Top pin plunger

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01B

SPDT PG 13,5 GLDB01B

SPDT 20 mm GLDC01B

Top roller plunger

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01C

SPDT PG 13,5 GLDB01C

SPDT 20 mm GLDC01C

GLE EN 50047 Compatible

3 conduit

metal standard body

Mechanical life: up to 10 million

Sealing: IP 66, NEMA 1, 4, 12, 13

Operating temperature: -25 °C to 85 °C

-13 °F to 185 °F

Approvals: IEC/EN 60947-5-1

AC15 A300

DC13 Q300

UL, CSA, CE

Switching options:

SPDT Single Pole, Double Throw

Snap action contacts (1NC/1NO)

DPDT Double Pole, Double Throw

Snap action contacts (2NC/2NO)

HEAD OPTIONS

Side rotary

See GLC section for dimension

illustrations

Side rotary

Plastic roller/lever

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01A1A

SPDT PG 13,5 GLDB01A1A

Metal roller/lever

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01A1B

SPDT PG 13,5 GLDB01A1B

SPDT 20 mm GLDC01A1B

16

Top roller lever

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01D

SPDT PG 13,5 GLDB01D

SPDT 20 mm GLDC01D

Wobble, coil actuator

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLDA01E7B

SPDT PG 13,5 GLDB01E7B

SPDT 20 mm GLDC01E7B

www.honeywell.com/sensing

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01A1A

SPDT PG 13,5 GLEB01A1A

DPDT PG 13,5 GLEB24A1A

Metal roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01A1B

DPDT ½ in NPT GLEA24A1B

SPDT PG 13,5 GLEB01A1B

DPDT PG 13,5 GLEB24A1B

SPDT 20 mm GLEC01A1B

Page 19

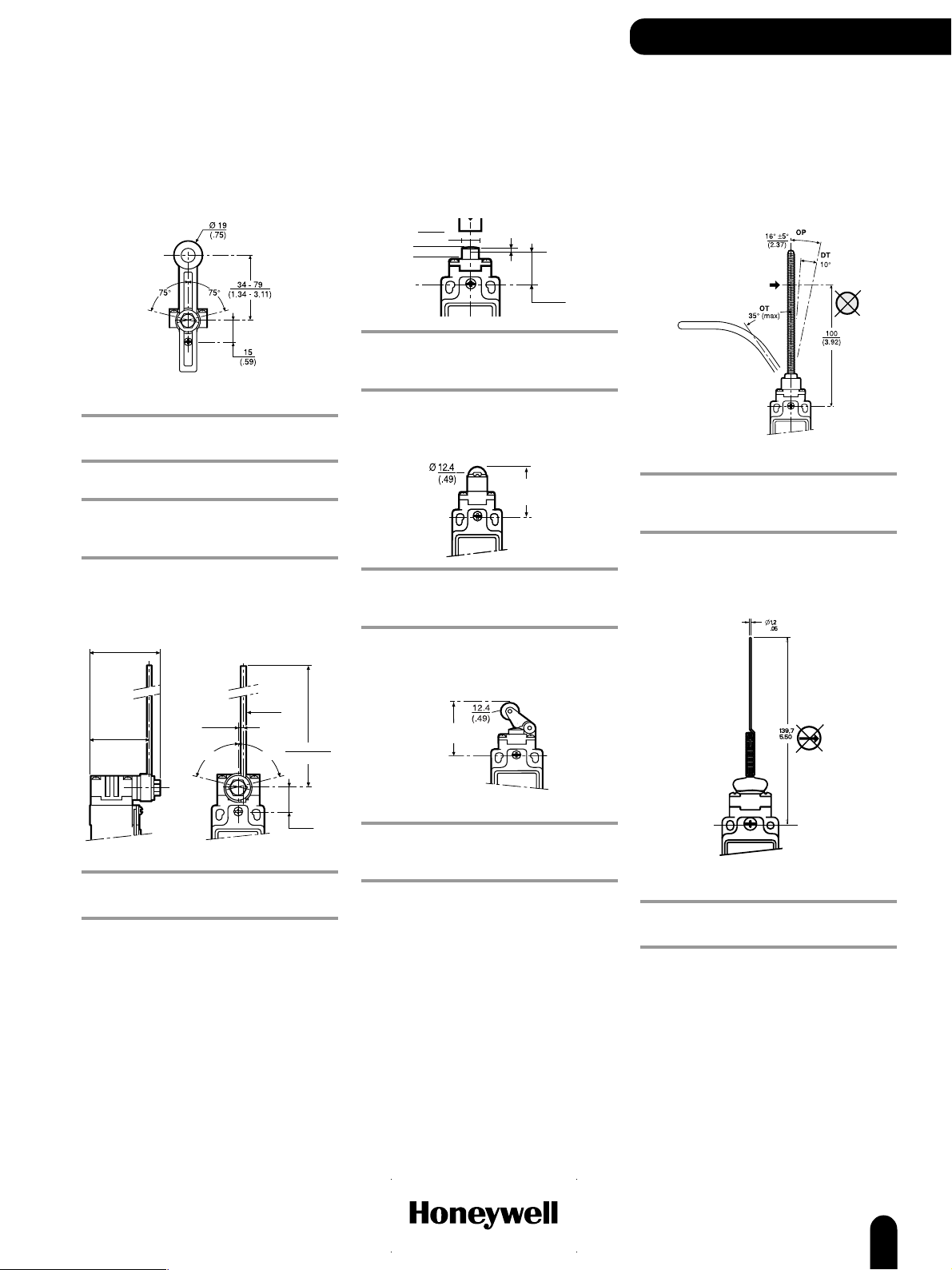

GLE EN 50047 Compatible

Þ

OT

35˚ (max)

DT

10˚

16˚ ±5˚

(2.37)

OP

100

(3.92)

3 conduit

metal standard body

(continued)

GLOBAL LIMIT SWITCHES

Offset side rotary roller

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01A5A

SPDT PG 13,5 GLEB01A5A

Side rotary adjustable

Side rotary adjustable metal rod

41

(1.61)

¯ 3,2

4,5

34

(1.34)

CONTACT CONDUIT REFERENCE

SPDT PG 13,5 GLEB01A4J

DPDT PG 13,5 GLEB24A4J

(.17)

(.13)

75˚75˚

32 - 134

(1.26 - 5,28)

15

(.6)

Top pin plunger

18

(0.709)

Top roller lever

39,2

FP

(1.54)

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01D

DPDT ½ in NPT GLEA24D

SPDT PG 13,5 GLEB01D

DPDT 13,5 GLEB24D

SPDT 20 mm GLEC01D

DPDT 20 mm GLEC24D

Wobble, coil actuator

Plastic roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01A2A

DPDT ½ in NPT GLEA24A2A

SPDT PG 13,5 GLEB01A2A

Metal roller

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01A2B

SPDT PG 13,5 GLEB01A2B

DPDT PG 13,5 GLEB24A2B

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01B

DPDT ½ in NPT GLEA24B

SPDT PG 13,5 GLEB01B

DPDT PG 13,5 GLEB24B

Top roller plunger

Ø 12,4

31,0

FP

1.23

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01C

DPDT ½ in NPT GLEA24C

SPDT PG 13,5 GLEB01C

DPDT PG 13,5 GLEB24C

DPDT 20 mm GLEC24C

(0.49)

Mechanical life: up to 5 million

CONTACT CONDUIT REFERENCE

SPDT ½ in NPT GLEA01E7B

DPDT ½ in NPT GLEA24E7B

SPDT PG 13,5 GLEB01E7B

DPDT PG 13,5 GLEB24E7B

www.honeywell.com/sensing

17

Page 20

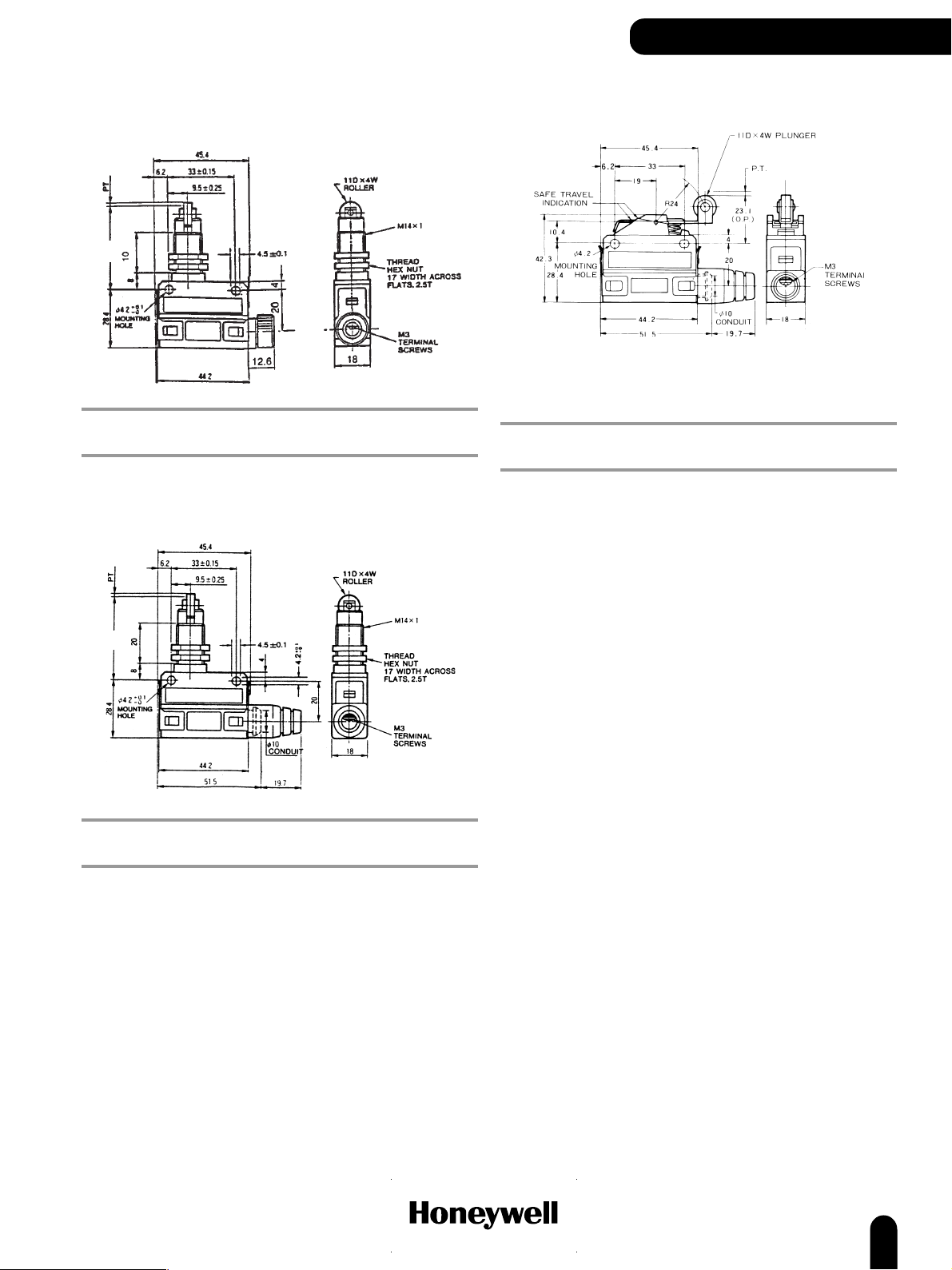

COMPACT LIMIT SWITCHES

SL1 Series

Compact Limit

Switches

Actuators

OPTIONS

The SL1 Series compact limit switches are sealed, sensitive and have a long life. The compact size makes them suitable

for the total miniaturization of machinery or equipment.

Mechanical life: 10 million

Sealing: IP 67, NEMA 3, 4, 13

Operating temperature: -10 °C to 70 °C (14 °F to 160 °F)

Approvals: UL, CSA, CE

Termination: Cable gland

Operating force max. (OF): 11,76 N (2.64 lb)

Pretravel max. (PT): 1,5 mm (0.060 in)

Overtravel min. (OT): 3,0 mm (0.118 in)

Differential travel max. (DT): 0,10 mm (0.004 in)

Electrical rating/contact: SL1-* 5A - 125, 250 Vac Silver

SL1-* K 0.1 A - 125 Vac; 0.1 A - 30 Vdc Gold clad cross point

Switching options:

SPDT Single Pole, Double Throw,

Snap action contacts (1NC/1NO)

Top pin plunger

25,4

(OP)

CONTACT REFERENCE

Silver SL1-H

Gold clad cross point SL1-HK

Top roller plunger, parallel

31,4

(OP)

Top roller plunger, parallel, boot seal

PT

CONTACT REFERENCE

Silver SL1-B

Gold clad cross point SL1-BK

Top roller plunger, long, parallel

41,4

(OP)

11 D X 4W ROLLER

CONTACT REFERENCE

Silver SL1-A

Gold clad cross point SL1-AK

18

CONTACT REFERENCE

Silver SL1-E

Gold clad cross point SL1-EK

www.honeywell.com/sensing

Page 21

COMPACT LIMIT SWITCHES

Top roller plunger, perpendicular

31,4

(OP)

CONTACT REFERENCE

Silver SL1-D

Gold clad cross point SL1-DK

Top roller plunger, long, perpendicular

Top roller lever

Operating force max. (OF): 3,92 N (0.88 lb)

Pretravel max. (PT): 2,0 mm (0.079 in)

Overtravel min. (OT): 4,0 mm (0.158 in)

Differential travel max. (DT): 0,3 mm (0.012 in)

CONTACT REFERENCE

Silver SL1-P

Gold clad cross point SL1-PK

41,4

(OP)

CONTACT REFERENCE

Silver SL1-K

Gold clad cross point SL1-KK

www.honeywell.com/sensing

19

Page 22

COMPACT LIMIT SWITCHES

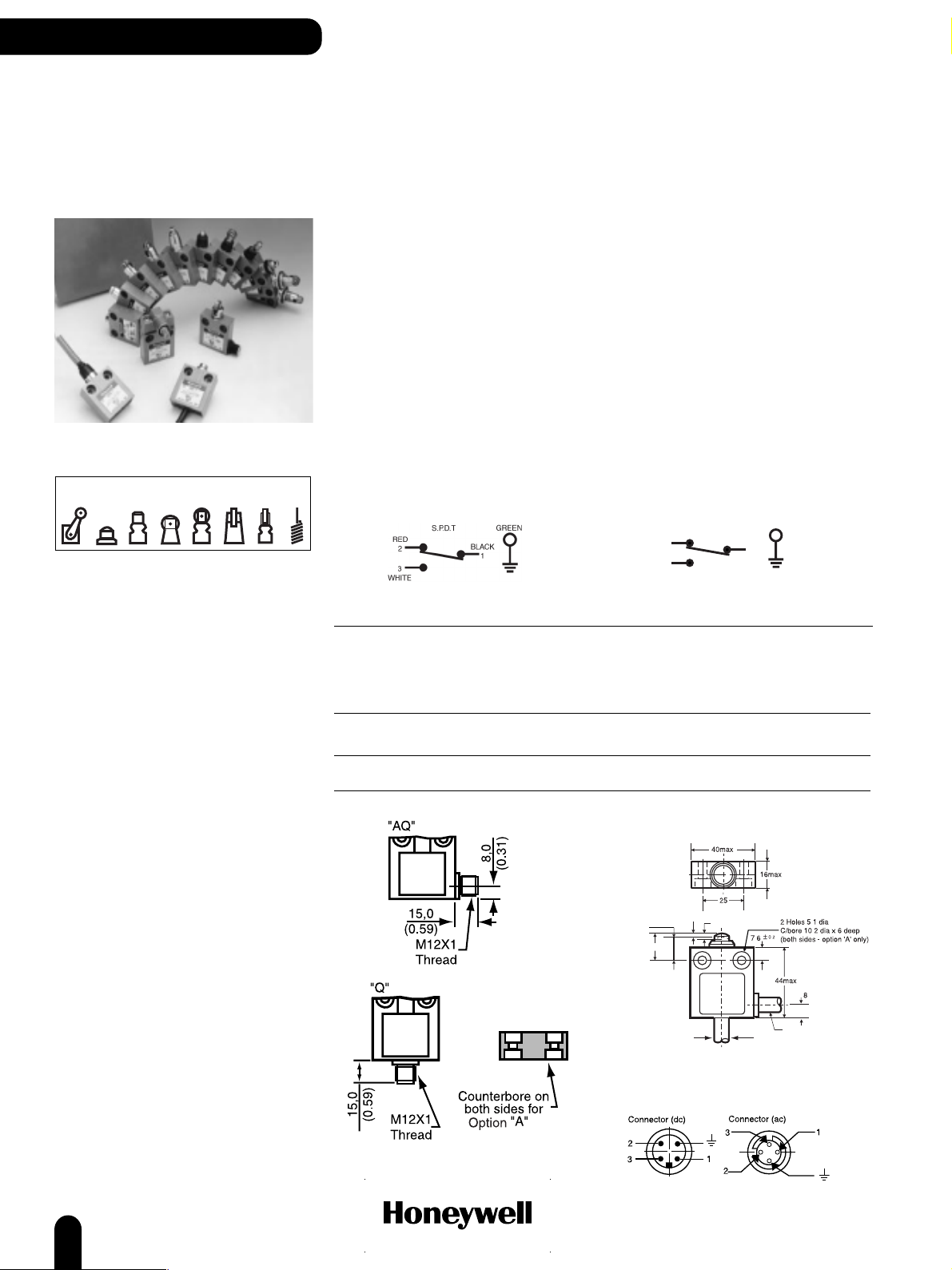

14CE/914CE Series

Miniature Enclosed

Switches

Actuators

The 14CE/914CE Series offers a miniature, rugged, compact, pre-wired switch which has proved itself

successful and gained wide market acceptance. The entire range of 14CE and 914CE switches has been

approved to meet the requirements of the Low Voltage directive and is therefore CE marked.

CE switches have different degrees of protection from IP66 to IP68 for the fully booted head styles. The

cable entry is fully potted using a special compound to ensure that ingress is virtually impossible.

Mechanical life: 10 million

Sealing: IP66, IP67, IP68

NEMA 1, 2, 3, 3R, 4, 6, 6P, 12 (boot seal), 13

Operating temperature: 14CE 0 °C to 70 °C (32 °F to 158 °F)

914CE 0 °C to 105 °C (32 °F to 221 °F)

Approvals: 14CE CE

914CE CSA, UL, CE

AC14 D300

DC13 R300

Operating force (OF): 11,8 N (2,65 lb) max.

Pretravel (PT): 1,8 mm (0.71 in) max.

Overtravel (OT): 3,0 mm (0.118 in) min.

Differential travel (DT): 0,1mm (0.004 in) max.

Contact/Rating: (9)14CE* -* Silver A

(9)14CE* -*G Gold B

(9)14CE* -Q, -AQ, -AQ1 Silver C

Connection: Harmonised CENELEC 4 x 0,75 mm2 cable (14CE)

SJTO 4 x 0,75 mm2 (18 AWG) cable (914CE)

Connector (dc), 4 pin male, M12 thread (-Q)

Connector (ac), 4 pin male, ½ in x 20 thread (-Q1)

Switching options: SPDT Single Pole, Double Throw

Snap action contacts (1NC/1NO)

GREEN/YELLOW

S.P.D.T

914CE 14CE

BROWN

2

3

BLACK

BLUE

1

Electrical ratings: Amps

Make Break

A 240 Vac, ind. 1.2 0.2

240 Vac, res. 5 5

28 Vdc, res. 3 3

28 Vdc, ind. 3 3

UL/CSA: 5 A, 1/10 Hp, 125 or 250 Vac

B 1 A res., 0.5 A ind., 30 Vdc

UL: 1 A, 125 Vac

C UL/CSA: 3 A, 125 or 250 Vac

Operating

point

Free position

914CE 8,65 (0.34)

1,8 max PT

(OP)

(FP)

Ø

14CE 7,4 (0.29)

3 min OT

,

,

,

Side exit cable

(Option 'A')

20

www.honeywell.com/sensing

Page 23

Plunger actuated switches

OPTIONS

COMPACT LIMIT SWITCHES

Top pin plunger

Ø 10,0

(0.39)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE1-3

3 ft cable, side exit 914CE1-3A

3 ft cable, bottom exit, gold contacts 914CE1-3G

6 ft cable, bottom exit 914CE1-6

6 ft cable, bottom exit, gold contacts 914CE1-6G

9 ft cable, bottom exit 914CE1-9

Connector (dc), bottom exit 914CE1-Q

Connector (ac), bottom exit 914CE1-Q1

EUROPE REFERENCE

1 metre cable, bottom exit 14CE1-1

1 metre cable, side exit 14CE1-1A

1 metre cable, bottom exit, gold contacts 14CE1-1G

2 metre cable, bottom exit 14CE1-2

3 metre cable, bottom exit 14CE1-3

3 metre cable, side exit 14CE1-3A

3 metre cable, bottom exit, gold contacts 14CE1-3G

Connector (dc), side exit 14CE1-AQ

Connector (dc), bottom exit 14CE1-Q

OP

15,7

(0.62)

Top pin plunger, boot seal

Ø 7,0

(0.28)

OP

24,6

(0.98)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE18-3

3 ft cable, side exit 914CE18-3A

6 ft cable, bottom exit 914CE18-6

9 ft cable, bottom exit 914CE18-9

9 ft cable, side exit 914CE18-9A

Connector (ac), side exit 914CE18-AQ1

Connector (dc), bottom exit 914CE18-Q

Connector (ac), bottom exit 914CE18-Q1

EUROPE REFERENCE

1 metre cable, bottom exit 14CE18-1

3 metre cable, bottom exit 14CE18-3

Connector (dc), bottom exit 14CE18-Q

Top pin plunger, panel mounted

OP

29,2

(1.15)

M10x1 Thread

Ball bearing plunger

OP

24,4

(0.96)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE66-3

6 ft cable, bottom exit 914CE66-6

EUROPE/ REFERENCE

1 metre cable, bottom exit 14CE66-1

2 metre cable, bottom exit 14CE66-2

Adjustable plunger

OP

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE19-3

9 ft cable, bottom exit 914CE19-9

Manually operated

OP

27,4

(1.08)

Operating force (OF): 9,0 N (2.02 lb)

NORTH AMERICA/GLOBAL REFERENCE

6 ft cable, bottom exit 914CE22-6

Top roller plunger, parallel

Ø 12,4

(0.49)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE2-3

3 ft cable, side exit 914CE2-3A

3 ft cable, bottom exit, gold contacts 914CE2-3G

6 ft cable, bottom exit 914CE2-6

6 ft cable, side exit 914CE2-6A

9 ft cable, bottom exit 914CE2-9

Connector (dc), side exit 914CE2-AQ

Connector (dc), bottom exit 914CE2-Q

Connector (ac), bottom exit 914CE2-Q1

EUROPE REFERENCE

1 metre cable, bottom exit 14CE2-1

1 metre cable, side exit 14CE2-1A

1 metre cable, bottom exit, gold contacts 14CE2-1G

2 metre cable, bottom exit 14CE2-2

2 metre cable, side exit 14CE2-2A

3 metre cable, bottom exit 14CE2-3

3 metre cable, side exit 14CE2-3A

3 metre cable, bottom exit, gold contacts 14CE2-3G

Connector (dc), side exit 14CE2-AQ

Connector (dc), bottom exit 14CE2-Q

OP

28,4

(1.12)

Top roller plunger, parallel, boot

seal

Ø 12,4

(0.49)

OP

34,4

(1.35)

Operating force (OF): 17,5 N (3.82 lb)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE31-3

6 ft cable, bottom exit 914CE31-6

EUROPE REFERENCE

1 metre cable, bottom exit 14CE31-1

3 metre cable, bottom exit 14CE31-3

Top roller plunger, parallel, panel

mounted

OP

42,5

(1.67)

NORTH AMERICA/GLOBAL REFERENCE

Connector (dc), bottom exit 914CE27-Q

www.honeywell.com/sensing

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE28-3

6 ft cable, bottom exit 914CE28-6

Connector (dc), bottom exit 914CE28-Q

21

Page 24

COMPACT LIMIT SWITCHES

Ø 12,4

(0.49)

OP

28,5

(1.12)

5,1

(0.20)

14CE/914CE Series

Plunger actuated switches

(continued)

Top roller plunger, perpendicular

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE3-3

6 ft cable, bottom exit 914CE3-6

6 ft cable, side exit 914CE3-6A

9 ft cable, bottom exit 914CE3-9

Connector (dc), bottom exit 914CE3-Q

Connector (ac), bottom exit 914CE3-Q1

EUROPE REFERENCE

1 metre cable, bottom exit 14CE3-1

2 metre cable, bottom exit 14CE3-2

3 metre cable, bottom exit 14CE3-3

Top roller plunger, perpendicular,

boot seal

OP

34,4

(1.35)

Side rotary and wobble

actuated switches

OPTIONS

Rotary motion

(actuating lever not included - use any

LSZ51*, LSZ52*, LSZ54*, LSZ55* or LSZ61*

Series shown on page ??

Operating torque: 0,3 Nm (2.66 in lb)

Pretravel (PT): 30° max.

Overtravel (OT) mm: 40° min.

Differential travel: 3°

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE16-3

3 ft cable, side exit 914CE16-3A

6 ft cable, bottom exit 914CE16-6

9 ft cable, bottom exit 914CE16-9

Connector (dc), bottom exit 914CE16-Q

EUROPE REFERENCE

1 metre cable, bottom exit 14CE16-1

2 metre cable, bottom exit 14CE16-2

3 metre cable, bottom exit 14CE16-3

Wobble Spring wire

Operating force (OF): 17,5 N (3.82 lb)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE55-3

3 ft cable, side exit 914CE55-3A

Top roller plunger, perpendicular,

panel mounted

OP

42,5

(1.67)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE29-3

6 ft cable, bottom exit 914CE29-6

22

Operating Force (OF): 0,55 N (0.12 lb)

NORTH AMERICA/GLOBAL REFERENCE

3 ft cable, bottom exit 914CE20-3

6 ft cable, bottom exit 914CE20-6

9 ft cable, bottom exit 914CE20-9

Connector (dc), bottom exit 914CE20-Q

EUROPE REFERENCE

1 metre cable, bottom exit 14CE20-1

3 metre cable, bottom exit 14CE20-3

www.honeywell.com/sensing

Page 25

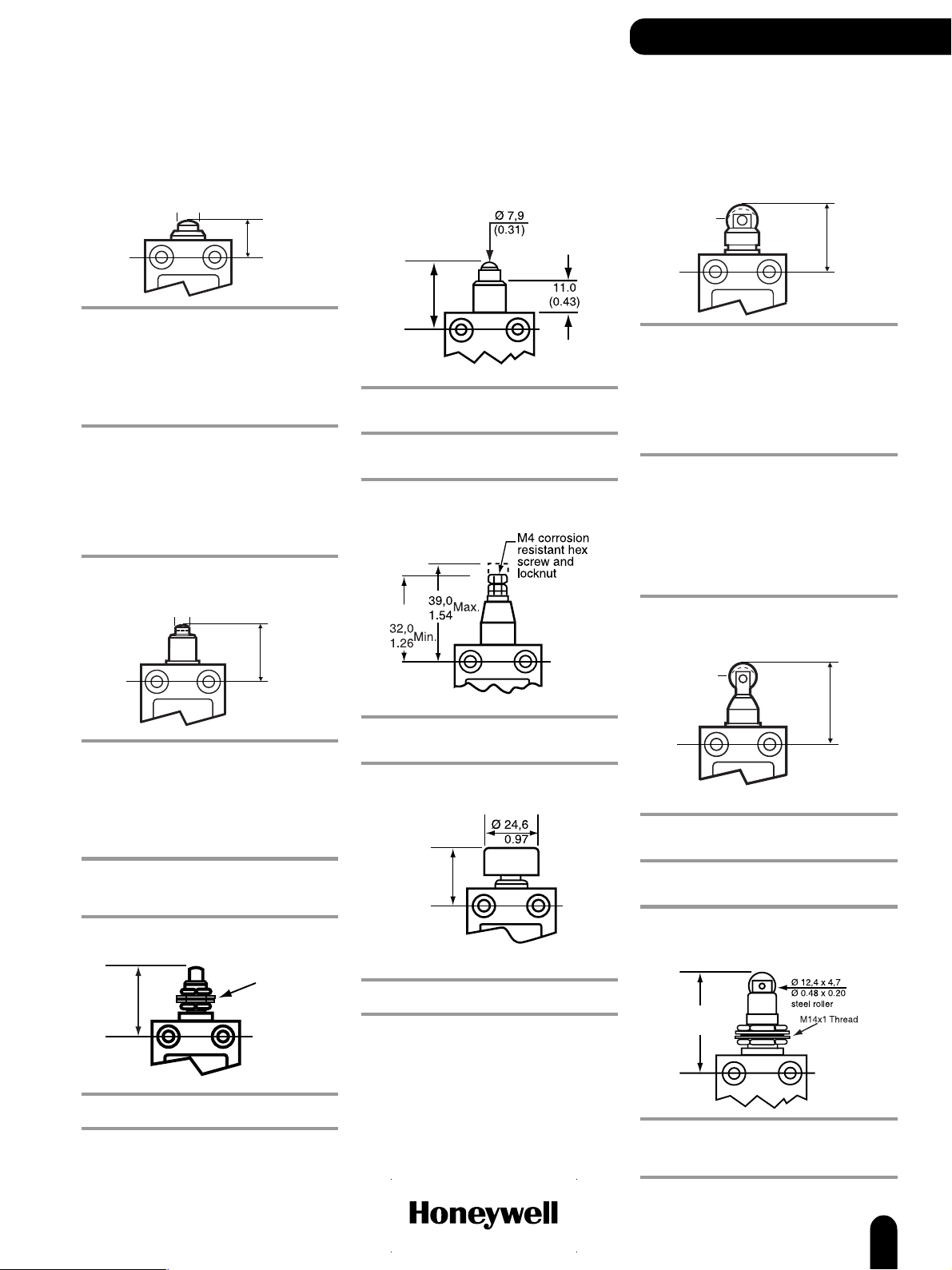

COMPACT LIMIT SWITCHES

24CE/924CE Series

Miniature Safety

Electromechanical

Switches

Actuators

For position sensing and switching applications requiring direct acting, positive opening contacts the

24CE and 924CE ranges are ideal. They have been tested and approved to meet the requirements of the Low

Voltage directive and positive opening safety contacts per IEC/EN 60947-5-1-3. The devices are CE marked.

The red colour clearly differentiates this safety component in the application. The 924CE range also has UL

and CSA approval.

It is possible for the end user to enhance the safety level of these switches from Category 1 on their own to

Categories 2, 3 or 4 when the switches are used in conjunction with our wide range of FF-SR safety relays to

form a safety system.

Typical applications for these switches would use the roller plunger 24CE2- or 24CE3- style in conjunction

with cams on doors with hinges; or our fixed side rotary 24CE16- style for detection of sliding doors. Also

available are a range of panel mounting or top mounting versions to ensure that small space or difficult

mounting can be simply achieved.

Several contact arrangements are available.

Mechanical life: 10 million

Sealing: standard type: IP66; with boot seal type: IP67

Operating temperature: 24CE 0 °C to 70 °C (32 °F to 158 °F)

Low temperature: -40 °C (-40 °F)

924CE 0 °C to 105 °C (32 °F to 221 °F)

Approvals: 24CE CE

AC15 B300

DC13 R300

924CE CSA, CE

per UL file #E41859, 10 A 250 Vac; 1/3 Hp 125-250 Vac

AC15 B300

DC13 R300

Connection: Harmonised CENELEC 3 or 5 x 0,75 mm

2

cable (24CE)

SJTO 3 or 5 x 18 AWG cable (924CE)

Contacts: Silver

Switching options:

924CE 24CE

Slow action contacts (1NC)

black red

Zb

white

black

Zb

white

Electrical ratings:

green

Slow action contacts (1NC/1NO), Break Before Make (BBM)

redblack

green

white

Zb

black

Slow action contacts (1NC/1NO), Make Before Break (MBB)

red

green

white

Free position

Designation & Utilization

Category

AC15 B300 3 1.5 ---- 3600 360

DC13 R300 0,22 0,1 28 28

120 V 240 V 380 V 480 V 500 V 600 V Make Break

125 V 250 V

40 /

max.

1.58

25 /

0.98

blue

Zb

black

IEC 60947-5-1/EN 60947-5-1

Rated operational current le (A) VA

at rated operational voltage Ue rating

16 /

max.

0.63

2 Holes 5,1 dia

Counter Bored 10,2 dia x 6 deep

(both sides - option 'A' only)

brownblue

green/yellow

brownblue

green/yellow

black

brown

green/yellow

black

1NC: 8,4 /

.33

1NC/1NO: 9,5 /

.374

www.honeywell.com/sensing

49 /

max.

1.93

8 /

0.32

Side exit cable

(Option 'A')

Note: connector versions also available

23

Page 26

COMPACT LIMIT SWITCHES

24CE/924CE Series

OPTIONS

Side rotary

PTPT

DT

DT

OTOT

North America/Global

CABLE LENGTH CONTACT REFERENCE

3 ft 1NC, BBM 924CE16-S3

9 ft 1NC, BBM 924CE16-S9

3 ft 1NC, MBB 924CE16-T3

3 ft 1NC 924CE16-Y3

9 ft 1NC 924CE16-Y9

Europe

CABLE LENGTH CONTACT REFERENCE

1 m 1NC/1NO, BBM 24CE16-S1

1 m 1NC 24CE16-Y1

6 m 1NC 24CE16-Y6

Top pin plunger

ø10

17,5

max.

Top pin plunger, boot sealed

ø7,1

24,3 max.

North America/Global

CABLE LENGTH CONTACT REFERENCE

6 ft 1NC/1NO, BBM 924CE18-S6

Adjustable plunger

26,8

(1.05)

North America/Global

CABLE LENGTH CONTACT OPTION REFERENCE

3 ft 1NC/1NO, BBM low temperature 924CE19-S3L1

Top roller plunger, parallel

ø12,4

30,3

max.

North America/Global

CABLE LENGTH CONTACT OPTION REFERENCE

15 ft 1NC, BBM 924CE2-S15

21 ft 1NC, BBM 924CE2-S21

3 ft 1NC, BBM 924CE2-S3

6 ft 1NC, BBM 924CE2-S6

6 ft 1NC, BBM side exit 924CE2-S6A

9 ft 1NC, BBM 924CE2-S9

25 ft 1NC, MBB 924CE2-T25

25 ft 1NC, MBB side exit 924CE2-T25A

3 ft 1NC, MBB 924CE2-T3

6 ft 1NC, MBB 924CE2-T6

9 ft 1NC, MBB 924CE2-T9

3 ft 1NC 924CE2-Y3

9 ft 1NC 924CE2-Y9

Europe

CABLE LENGTH CONTACT OPTION REFERENCE

1 m 1NC/1NO, BBM 24CE2-S1

2 m 1NC/1NO, BBM 24CE2-S2

2 m 1NC/1NO, BBM side exit 24CE2-S2A

2 m 1NC/1NO, BBM low temperature 24CE2-S2B

3 m 1NC/1NO, BBM 24CE2-S3

6 m 1NC/1NO, BBM 24CE2-S6

2 m 1NC/1NO, MBB 24CE2-T2

1 m 1NC 24CE2-Y1

2 m 1NC 24CE2-Y2

2 m 1NC side exit 24CE2-Y2A

4 m 1NC 24CE2-Y4

6 m 1NC side exit 24CE2-Y6A

North America/Global

CABLE LENGTH CONTACT OPTION REFERENCE

3 ft 1NC, BBM 924CE1-S3

6 ft 1NC, BBM 924CE1-S6

9 ft 1NC, BBM 924CE1-S9

25 ft 1NC, MBB side exit 924CE1-T25A

3 ft 1NC, MBB 924CE1-T3

3 ft 1NC, MBB side exit 924CE1-T3A

6 ft 1NC, MBB side exit 924CE1-T6A

9 ft 1NC, MBB 924CE1-T9

9 ft 1NC, MBB side exit 924CE1-T9A

3 ft 1NC 924CE1-Y3

9 ft 1NC 924CE1-Y9

Europe

CABLE LENGTH CONTACT OPTION REFERENCE

12 m 1NC/1NO, BBM low temperature 24CE1-S12B

2 m 1NC/1NO, BBM 24CE1-S2

2 m 1NC/1NO, BBM side exit 24CE1-S2A

2 m 1NC/1NO, BBM low temperature 24CE1-S2B

3 m 1NC/1NO, BBM 24CE1-S3

6 m 1NC/1NO, BBM 24CE1-S6

1 m 1NC side exit 24CE1-Y1A

2 m 1NC 24CE1-Y2

3 m 1NC 24CE1-Y3

24

www.honeywell.com/sensing

Page 27

Top roller plunger, parallel,

boot sealed

ø12,4

36,1

max.

North America/Global

CABLE LENGTH CONTACT OPTION REFERENCE

3 ft 1NC, BBM 924CE31-S6

20 ft 1NC 924CE31Y20

3 ft 1NC low temperature 924CE31Y3L1

Europe

CABLE LENGTH CONTACT OPTION REFERENCE

1 m 1NC/1NO, BBM 24CE31-S1

2 m 1NC/1NO, BBM 24CE31-S2

2 m 1NC/1NO, BBM low temperature 24CE31-S2B

5 m 1NC/1NO, BBM 24CE31-S5

1 m 1NC 24CE31-Y1

2 m 1NC 24CE31-Y2

3 m 1NC 24CE31-Y3

Top roller plunger, perpendicular

ø12,4

30,3

max.

North America/Global

CABLE LENGTH CONTACT REFERENCE

3 ft 1NC, BBM 924CE3-S3

6 ft 1NC, BBM 924CE3-S6

9 ft 1NC, BBM 924CE3-S9

9 ft 1NC, MBB 924CE3-T9

Europe

CABLE LENGTH CONTACT REFERENCE

2 m 1NC/1NO, BBM 24CE3-S2

1 m 1NC 24CE3-Y1

2 m 1NC 24CE3-Y2

Top roller plunger, perpendicular,

boot sealed

ø12,4

COMPACT LIMIT SWITCHES

Top roller plunger, parallel, panel

mounted

27,7

(1.75)

North America/Global

CABLE LENGTH CONTACT REFERENCE

15 ft 1NC, BBM 924CE28S15

Europe

CABLE LENGTH CONTACT REFERENCE

2 m 1NC/1NO, BBM 24CE28-S2

36,1

max.

Europe

CABLE LENGTH CONTACT REFERENCE

1 m 1NC/1NO, BBM 24CE55-S1

2 m 1NC/1NO, BBM 24CE55-S2

1 m 1NC 24CE55-Y1

www.honeywell.com/sensing

25

Page 28

COMPACT LIMIT SWITCHES

Blank page

26

www.honeywell.com/sensing

Page 29

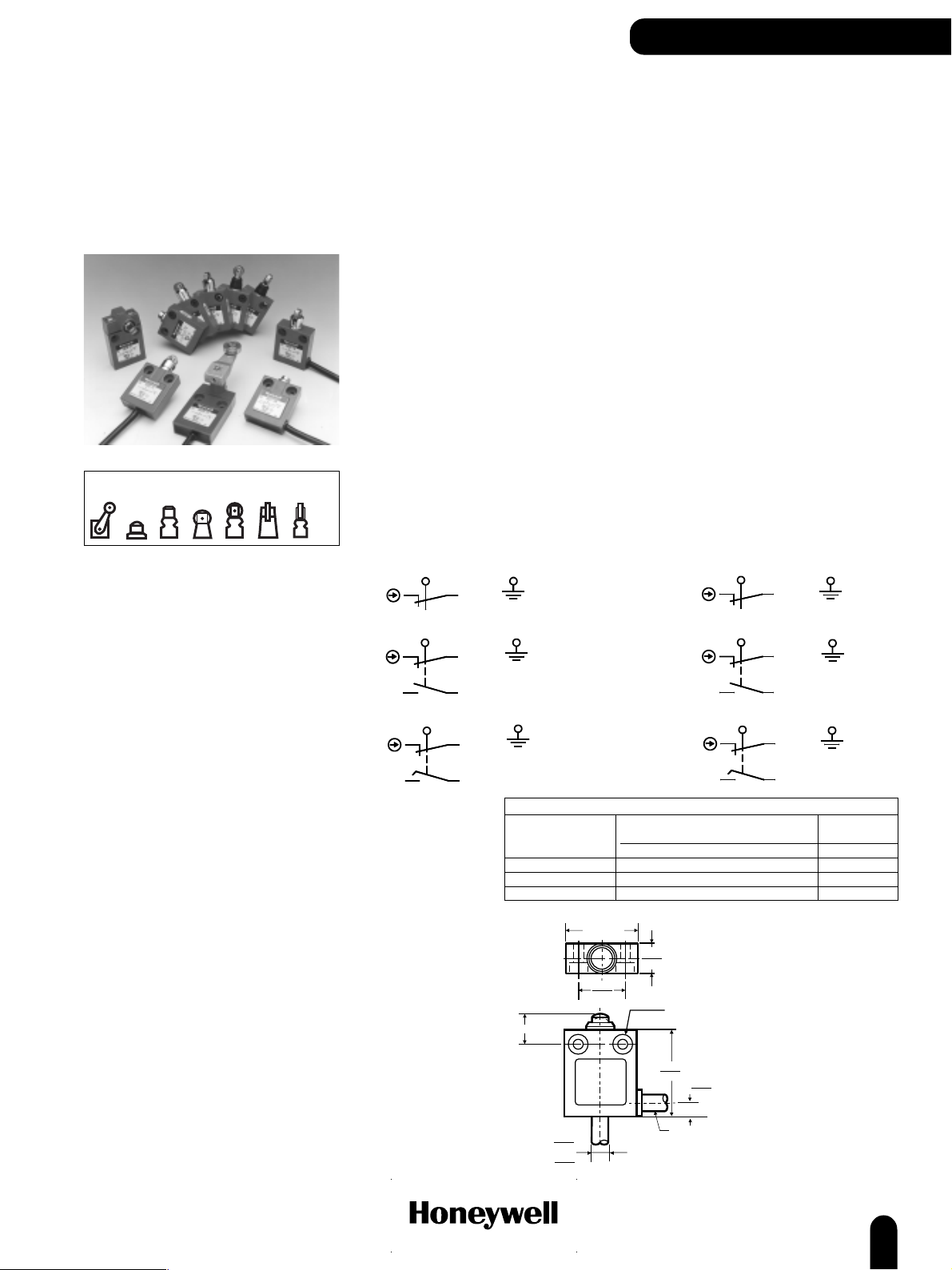

LS Series

Compact Limit

Switches

Actuators

COMPACT LIMIT SWITCHES

LS Series compact limit switches are carefully designed for accurate repeatability under the most stringent conditions.

Compact size and field adjustable features greatly extend the flexibility of these switches. Heads may be positioned at

90° increments. Side rotary models can be adjusted for clockwise and/or counter-clockwise operation. Actuators can be

set and locked in any position through 360°.

The rugged housings and actuator heads are constructed from cast aluminium, capable of withstanding physical abuse.

Protection against oil, water and dust is achieved by O-ring seals on the actuator shaft; a ring seal between head and

body; and a seated compression seal between cover and case.

The LS fits in many places too small for any other fully adjustable limit switch.

Conduit: ½ in - 14 NPT

Sealing: ½ in - 14 NPT conduit NEMA 1, 3, 4, 6, 13

Operating temperature: Standard -29 °C to 71 °C (-20 °F to 160 °F)

Approvals: LS-L UL, CSA

Contacts: Electrical ratings A, B, C, D, E Silver Cadmium Oxide

Switching options: SPDT Single Pole, Double Throw

20 mm conduit IP67

High -29 °C to 121 °C (-20 °F to 250 °F)

Electrical ratings F, G Fine Silver

Snap action contacts (1NC/1NO)

4

3

20 mm

(1)

1

Electrical ratings: A 10 A, 120, 240 or 480 Vac; 1/3 hp, 120 Vac; ¾ hp, 240

B 10 A, 120, 240 or 480 Vac; ¼ hp, 120 Vac; ½ hp, 240

C 10 A, 120 Vac; 1/3 hp, 120 Vac.

D 10 A, 120, 240, 480 Vac; ¼ hp, 120 Vac; ½ hp, 240 Vac;

E 10 A, 120, 240 or 480 Vac; 1/3 hp, 120 Vac; ¾ hp, 240

F UL Rating:

10 A, 125, 250, or 480 Vac; 1/3 hp, 125 Vac; ¾ hp, 250 Vac;

G UL Rating:

10 A, 125, 250 or 480 Vac; ¼ hp, 125 Vac; ½ hp, 250 Vac;

** Resistive rating

(1)

Designed for use with inductive loads such as relays, contactors, motors and solenoids. Honeywell does

recommend the use of silver cadmium oxide switch contacts in non-arcing loads. Non-arcing loads are

generally loads less than 12 volts and/or 0.5 amp.

2

Vac;

0.8 A, 115 Vdc**; 0.4 A, 230 Vdc;** 0.1 A, 550 Vdc;**

Pilot Duty, 600 Vac max.

Vac.

Pilot Duty, 600 Vac max.

0.8 A, 115 Vdc**; 0.4 A, 230 Vdc**; 0.1 A, 550 Vdc**;

Pilot Duty, 600 Vac max.

Vac.

Pilot Duty, 600 Vac max.

0.8 A, 125 Vdc**; 0.4 A, 250 Vdc**

0.8 A, 125 Vdc**; 0.4 A, 250 Vdc**

not

www.honeywell.com/sensing

27

Page 30

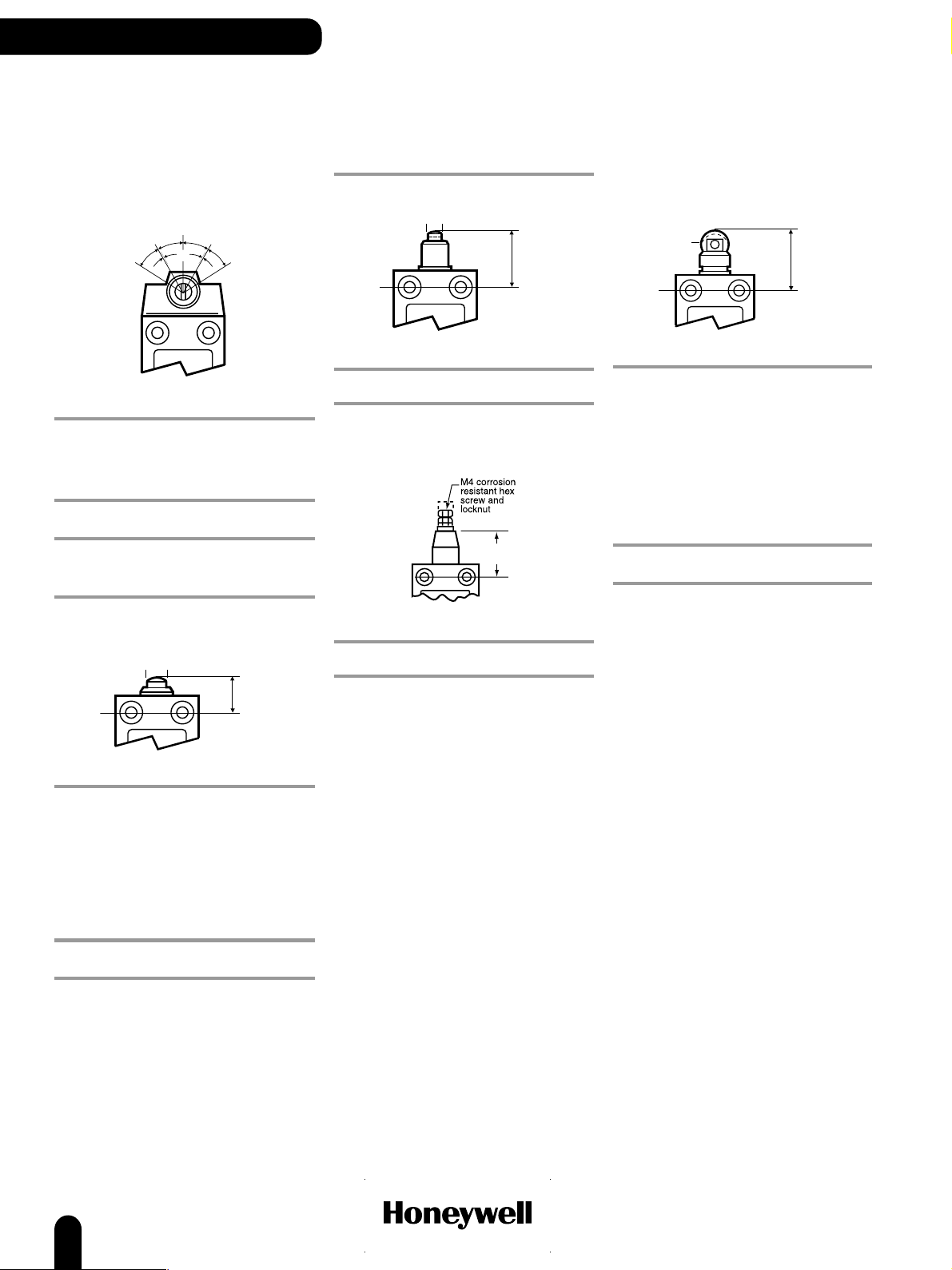

COMPACT LIMIT SWITCHES

LS Series

Side rotary actuated switches

OPTIONS

Fixed length lever

Operating force max. (OF): Standard 13,3 N (3.0 lb)

Low 5,0 N (18 oz)

Pretravel max. (PT): Standard 20°

Low 5°

Overtravel min. (OT) 30°

Differential travel max. (DT): Standard 12°

Low 4°

Switching options: SPDT

Lever: Aluminium, steel roller

Adjustable roller lever

Operating force max. (OF): Standard 13,3 N (3.0 lb)

Low 5,0 N (18 oz)

Pretravel max. (PT): Standard 20°

Low 5°

Overtravel min. (OT) 30°

Differential travel max. (DT): Standard 12°

Low 4°

Switching options: SPDT

Lever: Aluminium, nylon roller

CONDUIT ELECTRICAL RATING REFERENCE

Low PT/OF B 1LS131

Low PT B 1LS19

Low PT 20 mm B 1LS19-4C

High temperature A 1LS243

High temperature 20 mm A 1LS243-4C

Indicator light C 1LS501

Low OF A 1LS6

20 mm A 1LS1-4C

A 1LS1

F 1LS1-L

CONDUIT ELECTRICAL RATING REFERENCE

Low PT B 1LS58

Low OF/PT/DT B 1LS59

20 mm A 1LS3-4C

A1LS3

F 1LS3-L

28

www.honeywell.com/sensing

Page 31

COMPACT LIMIT SWITCHES

No lever

Note: Levers are ordered separately (see pages 69-71

for details)

Operating force max. (OF): Standard 0,51 N m (4.5 in lb)

Pretravel max. (PT): Standard 20°

Overtravel min. (OT) Standard 30°

Differential travel max. (DT): Standard 12°

Switching options: SPDT

Low with standard PT 0,21 N m (30 in oz)

Low with low PT 0,11 N m (1 in lb)

Low 5°

Maintained contact 55°

Maintained contact 35°

Low PT 4°

Maintained contact 20°

Maintained contact

SPDT contact

CONDUIT ELECTRICAL RATING REFERENCE

Low OF A 1LS23

Low OF/PT B 1LS56

Low PT B 1LS9

20 mm A 1LS2-4C

A 1LS2

F 1LS2-L

Maintained contact

CONDUIT ELECTRICAL RATING REFERENCE

A 6LS2

F 6LS2-L

Adjustable rod

Operating force max. (OF): Standard 1,39 N (5 oz)

Pretravel max. (PT): Standard 20°

Overtravel min. (OT) 30°

Differential travel max. (DT): Standard 12°

Switching options: SPDT

Lever: Aluminium rod

CONDUIT ELECTRICAL RATING REFERENCE

Low PT B 1LS47

Low PT/OF/DT B 1LS53

20 mm A 1LS10-4C

A 1LS10

F 1LS10-L

Low 0,83 Nm (3 oz)

Low 5°

Low 4°

Side rotary, yoke lever, maintained contact

Operating force max. (OF): 8,9 N (2.0 lb)

Pretravel max. (PT): 55°

Switching options: Maintained

Lever: 6LS1 Steel rollers on opposite sides of arm

6LS3 Nylon rollers on same side of arm

CONDUIT ELECTRICAL RATING REFERENCE

20 mm A 6LS1-4C

www.honeywell.com/sensing

A 6LS1

A 6LS3

29

Page 32

COMPACT LIMIT SWITCHES

LS Series

Plunger actuated switches

OPTIONS

Top pin plunger

Operating force max. (OF): Standard 31,14 N (7 lb)

Pretravel max. (PT): 1,65 mm (0.065 in)

Overtravel min. (OT) Standard 6,35 mm (0.25 in)

Differential travel max. (DT): Standard 0,51 mm (0.020 in)

Switching options: SPDT

CONDUIT ELECTRICAL RATING REFERENCE

Low OF/OT/DT E 2LS111

20 mm A 2LS1-4C

A 2LS1

F 2LS1-L

Low 10 N (36 oz)

Low 5,56 mm (0.219 in)

Low 0,23 mm (0.009 in)

Side pin plunger

Operating force max. (OF): 40,03 N (9 lb)

Pretravel max. (PT): 2,8 mm (0.110 in)

Overtravel min. (OT) 6,35 mm (0.25 in)

Differential travel max. (DT): 1,02 mm (0.040 in)

Switching options: SPDT

CONDUIT ELECTRICAL RATING REFERENCE

20 mm A 4LS1-4C

A4LS1

Side roller plunger

Top roller plunger

Operating force max. (OF): 31,14 N (7 lb)

Pretravel max. (PT): 1,65 mm (0.065 in)

Overtravel min. (OT) 5,56 mm (0.219 in)

Differential travel max. (DT): 0,51 mm (0.020 in)

Switching options: SPDT

CONDUIT ELECTRICAL RATING REFERENCE

20 mm A 5LS1-4C

A 5LS1

F 5LS1-L

Operating force max. (OF): 40,03 N (9 lb)

Pretravel max. (PT): 2,8 mm (0.110 in)

Overtravel min. (OT) 5,56 mm (0.219 in)

Differential travel max. (DT): 1,02 mm (0.040 in)

Switching options: SPDT

CONDUIT ELECTRICAL RATING REFERENCE

20 mm A 3LS1-4C

A3LS1

30

www.honeywell.com/sensing

Page 33

Wobble actuated switches

191,3

(7.53)