SV9501/SV9502/SV9601/SV9602

TM

SmartValve

APPLICATION

The Honeywell TRADELINE® SmartValveTM System

Controls provide easy field replacement of a wide range

of SV9500, SV9501, SV9502 and SV9602 SmartValve

System models. Gas appliance manufacturers use these

models in many types of gas fired heating appliances

including central furnaces, residential boilers, rooftop

furnaces, commercial cooking appliances, and unit

heaters. These TRADELINE® controls provide

intermittent pilot gas ignition sequencing, pilot flame

sensing, and both pilot and main gas control functions in

a single control. They are directly compatible with the

Q3450 or Q3480 Intermittent Pilot burners used with the

original controls on the appliance.

The TRADELINE® SV9501 and SV9502 SmartValve

models are replacement controls only for the SV9500,

SV9501, and SV9502 models noted in Table 5. Do not

use these controls to replace other types of intermittent

pilot or direct ignition controls. Do not use these controls

to replace SmartValve

Replacement table. The controls might fit, but the gas

flow control functions might not be compatible with the

appliance.

The TRADELINE® SV9602 SmartValve

replacement controls only for the SV9500P, SV9501P,

SV9502P, SV9600P and SV9601P models noted in Table

5. The SV9602 is a prepurge, step-opening model.

IMPORTANT

Do not use these controls to replace

SmartValve

replacement table.

Prepurge is nominally 30 seconds.

The step opening function provides a timed step outlet

pressure at the start of each heating cycle to allow main

burner ignition at reduced outlet pressure.

Reducer bushings are provided with the SV9602 and

SV9601 models for adapting to smaller pipe sizes.

TM

models not listed in the

TM

models not listed in the

System Control

INSTALLATION INSTRUCTIONS

IMPORTANT

Carefully determine the full Honeywell model

number of the existing control. Use Table 4 or

Table 5 to make sure the replacement control

model is suitable for replacing the original

control. If the control is not suitable, obtain the

correct TRADELINE® replacement control as

shown in Table 4 or Table 5, or contact the

appliance manufacturer for the proper

replacement control.

INSTALLATION

When Installing this Product…

1. Read this instructions carefully. Failure to follow

the instructions as written can damage the product

or cause a hazardous situation.

2. Check the relevant chart and the ratings given in

these instructions and on the specific model to

make sure the product is suitable for the

application.

3. Installer must be a trained, experienced, licensed

(if required by local ordinance) technician.

4. Use these instructions to check product operation

after completing installation.

IMPORTANT

Make sure the control being replaced is

defective. See Fig. 13 through 16 for SV9500,

SV9501, and SV9502 Sequence of Operation

and Troubleshooting procedures.

Planning the Installation

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly as written.

1. Plan the installation as outlined in this section.

2. Plan for frequent maintenance as described in

the Maintenance section of this manual.

Intermittent pilot systems used on heating equipment in

barns, greenhouses, and commercial properties, and on

heating appliances such as commercial cookers,

agricultural equipment, and pool heaters make heavy

TM

models are

TM

TM

69-1270-3

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

demands on the controls. Special steps are

recommended to prevent nuisance shutdowns and control

failures due to frequent cycling, or severe environmental

conditions such as exposure to moisture, corrosive

chemicals, dust, or excessive heat. Following are the

possible causes of shutdown and the preventative

solutions.

Frequent Cycling

These controls are designed to cycle three to four times

each hour during the heating season. Year around

applications and applications with more frequent cycling

rates can wear out controls more quickly than normal

operation. Perform monthly system checks to make sure

the system operates properly.

Water or Steam Cleaning

Replace any electronic control that gets wet. If the

appliance is likely to be cleaned with water or steam,

cover the control and wiring to protect them from water or

steam flow. Mount the control high enough above the

cabinet bottom to avoid getting it wet during cleaning

procedures.

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never install

an appliance where water can drip on the control. High

humidity around the control can cause the control to

corrode and fail. If the appliance is located in a humid

atmosphere, make sure the air circulation around the

control is adequate to prevent water condensing on the

control. Check the system regularly for signs of

condensation and corrosion.

Corrosive Chemicals

Corrosive chemicals can erode the control, eventually

causing a failure. If chemicals are used for routine

cleaning, make sure they do not touch the control. Where

chemicals are suspended in air, for example, in some

industrial or agricultural applications, protect the control

with an enclosure.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease are

problems, cover the control to limit contamination.

Installation

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly as written.

1. Disconnect the power supply before wiring to

prevent electrical shock and equipment

damage.

2. Turn of the gas supply at the appliance service

valve before starting installation to avoid

dangerous accumulation of fuel gas.

3. Perform gas leak test after completing

installation.

4. Do not bend pilot tubing at ignition system

control or pilot burner after tightening the

compression fitting. Bending can cause gas

leakage at the connection.

5. Always install a sediment trap in the gas supply

line to prevent contamination of the ignition

system.

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow this warning exactly as written.

• Always change the main and pilot burner

orifices when converting between LP and

natural gas. Follow appliance manufacturer

specifications and instructions.

CAUTION

Equipment Damage Hazard.

Improper device replacement will damage the

equipment.

The SV9501, SV9502, SV9602, and SV9601

provide direct replacement only as shown in Table

4 or Table 5 of this manual. Use the Y8610 to

convert standing pilot systems to electronic

ignition systems.

Heat

Excessively high (above 175°F [79°C]) temperatures can

damage the control. Make sure the ambient temperature

at the control does not exceed the control rating. If the

appliance operates at very high temperatures, use

insulation, shielding and proper air circulation as

necessary to protect the control. The appliance

manufacturer should provide proper insulation or

shielding. Make sure there is proper air circulation when

installing the appliance.

69-1270—3 2

CAUTION

Equipment Damage Hazard.

Can Burn Out Heat Anticipator in Thermostat.

1. Never apply a jumper across or short the

terminals in the SV9501, SV9502, SV9602, or

SV9601 connectors or appliance wiring

harnesses.

2. Never short the electric fan timer (EFT) output.

Shorting the output can damage the EFT drive

circuitry.

IMPORTANT

These ignition system controls are shipped with

protective seals over inlet and outlet tappings.

Do not remove seals until ready to connect

piping.

Follow the appliance manufacturer’s instructions if

available. Otherwise, use these instructions as a guide.

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

Ignition system controls are set at the factory for natural

or LP gas. Do not attempt to use an ignition control made

for LP gas on a natural gas system. Do not attempt to use

an ignition control made for natural gas on an LP gas

system.

Ignition system controls with standard opening regulators

(SV9501M, SV9502M, and SV9601M) or slow opening

regulators (SV9501H and SV9502H) can be converted

between natural gas and LP gas.

Ignition system controls with step opening regulators (P

suffix) cannot be converted between gases.

Selecting the Valve

Make sure when replacing any SmartValveTM that you

know what valve is going in and what valve is coming out.

The SV9501 and SV9502 look slightly different from the

SV9500. The SV9500 features an ON/OFF control knob,

as shown in Fig. 1. The SV9501, SV9502, SV9602, and

SV9601 have an ON/OFF switch, as shown in Fig. 2. The

SV9501, SV9502, SV9601, and SV9602 have a

connector located at the top of the valve instead of on the

front.

The SV9501, SV9502, SV9602, and SV9601 have

identical valve body features and use the same

connectors.

NOTE: The SV9601 and the SV9602 do not have flange

mounting capability.

Use of Pipe Adapters

In some field service applications, space limitations make

it difficult or impossible to thread the gas control onto the

gas supply line. This problem can be resolved for many

installations by using a pipe adapter. Install the pipe

adapter on the end of the supply line in place of the gas

control by following the same precautions and instructions

that are used for installing the gas control. After the pipe

adapter is installed, attach the gas control to the adapter.

NOTE: Using a pipe adapter increases the overall length

of the gas control.

Install Pipe Adapter to Gas Control

Install adapter to gas control as follows:

Bushings

1. Remove seal over gas control inlet or outlet.

2. Apply moderate amount of good quality pipe com-

pound to bushing, leaving two end threads bare.

3. Insert bushing into gas control and carefully thread

pipe into the bushing until tight.

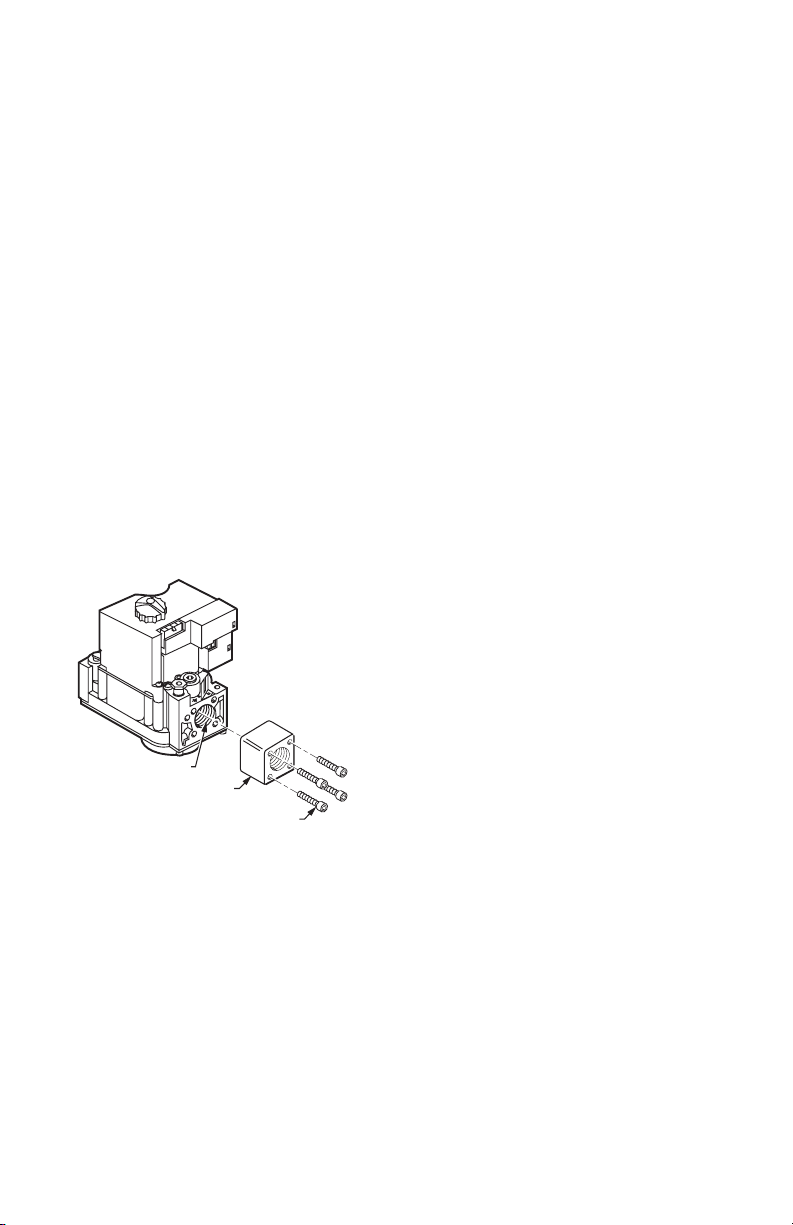

Installing Flange Adapters to Control

(If Required)

Mount any necessary adapters as follows:

Flanges

1. Choose the correct flange for the application.

2. Remove the seal over the ignition system control or

outlet.

3. Make sure the O-ring is fitted in the flange groove. If

the O-ring is not attached or is missing, do not use

the flange.

4. With the O-ring facing the ignition system control,

align the screw holes on the ignition system control

with the holes in the flange.

5. Insert the screws provided with the flange.

6. Tighten the screws firmly but do not over tighten

VALVE OUTLET

FLANGE

9/64 INCH HEX SCREWS (4)

Fig. 1. Front view of SV9500. Notice the ON/OFF

control knob.

M3342A

Location

Mount the SV9501, SV9502, SV9602, or SV9601 on the

gas manifold in the appliance.

Installing Piping to Control

IMPORTANT

Do not use Teflon® tape.

All piping must comply with local codes or ordinances or

with the National Fuel Gas Code (ANSI Z223.1 NFPA No.

54), whichever applies. Tubing installation must comply

with approved standards and practices.

1. Use new, properly reamed pipe that has no chips.

2. Make sure the ends are square, deburred, and

clean.

3. Make sure all tubing bends are smooth and without

deformation.

4. Get a tube-to-pipe coupling if necessary.

5. Run pipe or tubing to the ignition system control.

6. Install a sediment trap in the supply line to the

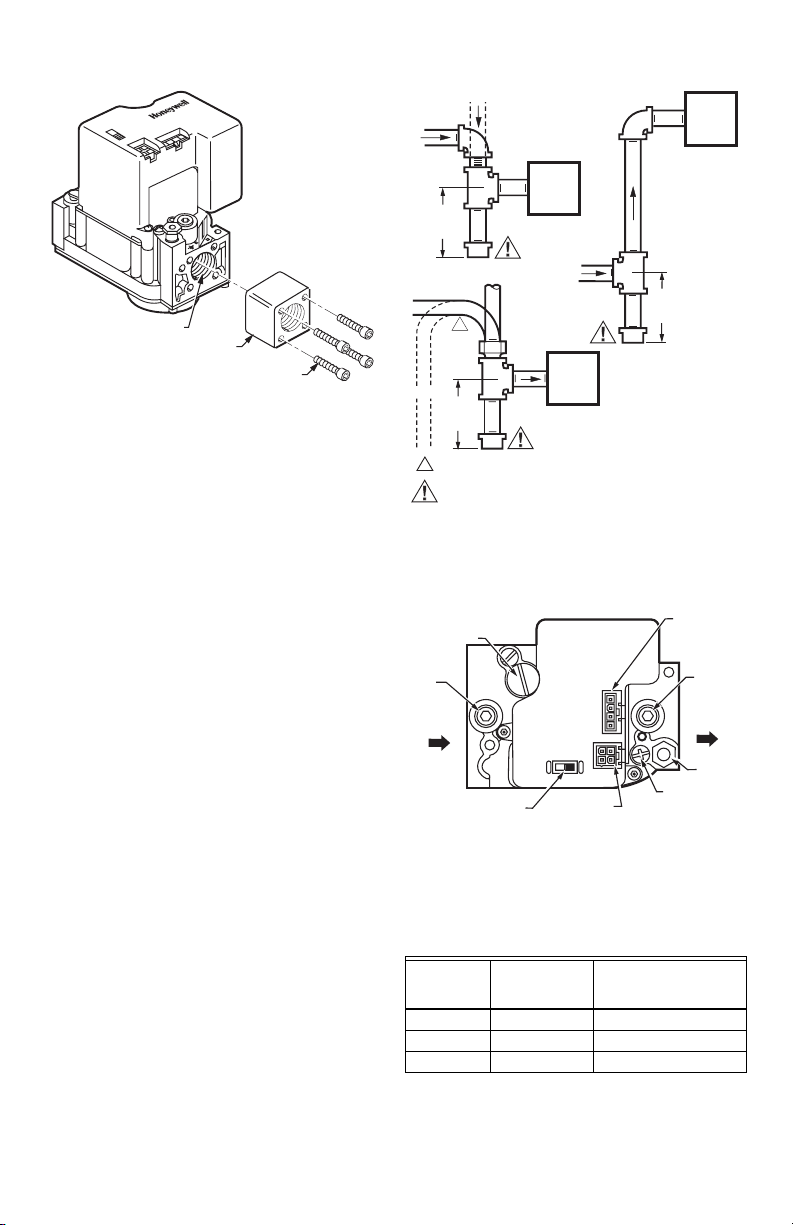

ignition system control as shown in Fig. 3.

3 69-1270—3

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

VALVE OUTLET

M17142

Fig. 2. Front view of SV9501 or SV9502. Notice the

connectors and the ON/OFF control switch.

FLANGE

9/64 INCH HEX SCREWS (4)

Installing the Control

This ignition system can be mounted from 0 to 90 degrees

in any direction including vertically from the upright

position of the ignition system control switch.

IMPORTANT

Make sure to mount the replacement control

in the same location and orientation as the

original control.

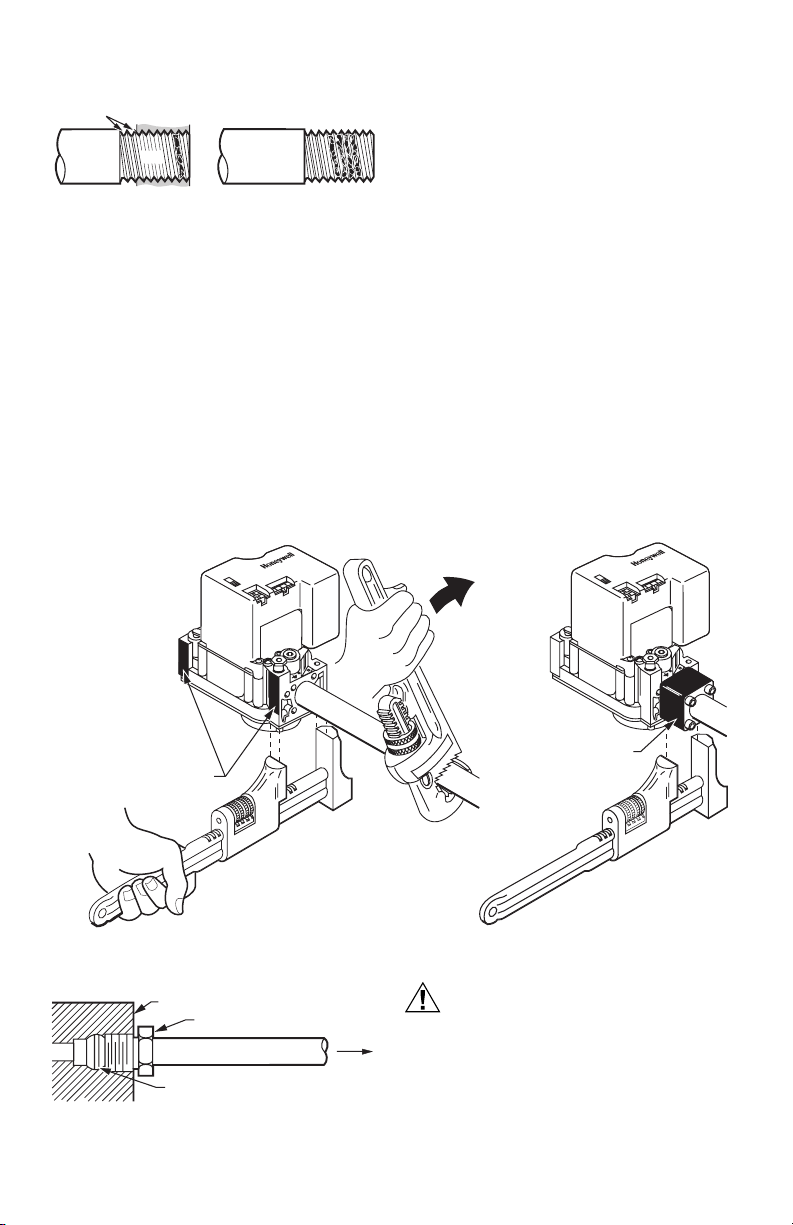

1. Mount the control so the gas flow is in the direction

of the arrow on the bottom of the ignition system

control, as shown in Fig. 4.

2. Apply a moderate amount of good quality pipe compound to the pipe, leaving the two end threads bare,

as shown in Fig. 5. For LP controls make sure to

use an LP resistant pipe compound.

3. Remove the seals over the ignition system control

inlet and outlet if necessary.

4. Thread the pipe the amount shown in Table 1. Do

not thread the pipe too far, because this could

cause valve distortion or malfunction.

5. Using a wrench on the square ends of the ignition

system control, connect the pipe to the ignition

system control inlet and outlet.

DROP

HORIZONTAL

3 IN.

(76 MM)

MINIMUM

HORIZONTAL

RISER

3 IN.

(76 MM)

MINIMUM

1

ALL BENDS IN METALLIC TUBING MUST BE SMOOTH.

CAUTION

Gas Leakage Hazard.

Failure to follow precautions can result in a gas-filled work area.

Shut off the main gas supply before removing end cap. Test for gas

leakage when installation is complete.

PIPED

GAS

SUPPLY

IGNITION

SYSTEM

CONTROL

DROP

TUBING

1

GAS

SUPPLY

IGNITION

SYSTEM

CONTROL

RISER

PIPED

GAS

SUPPLY

3 IN.

(76 MM)

MINIMUM

IGNITION

SYSTEM

CONTROL

M3343C

Fig. 3. Sediment trap installation.

PRESSURE REGULATOR

ADJUSTMENT (UNDER

CAP SCREW)

INLET

PRESSURE

TAP

ON

OFF

CONTROL

CONTROLS

CONNECTOR

IGNITER

INLET

IGNITION SYSTEM

CONTROL SWITCH

M7934

Fig. 4. Mount so gas flows in the

direction of the arrows.

NOTE: If the control has a flange, place the wrench on

the flange instead of on the ignition system control, as shown in Fig. 6.

IGNITER

CONNECTOR

OUTLET

PRESSURE

TAP

OUTLET

PILOT

OUTLET

PILOT ADJUSTMENT

(UNDER CAP SCREW)

Table 1. Threading the Pipe.

Maximum Depth Pipe

can be Inserted into

Control

Pipe Size

Thread Pipe

this Amount

3/8 in. 9/16 in. 3/8 in.

1/2 in. 3/4 in. 1/2 in.

3/4 in. 13/16 in. 3/4 in.

69-1270—3 4

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TWO

IMPERFECT

THREADS

THREAD PIPE THE AMOUNT

SHOWN IN TABLE FOR INSERTION

INTO IGNITION SYSTEM CONTROL

IGNITION

SYSTEM

CONTROL

PIPE

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND ONLY TO PIPE

(LEAVE TWO END THREADS BARE).

Fig. 5. Use a moderate amount of pipe compound.

Connecting the Pilot Gas Tubing

NOTE:

1. The pilot tubing provides the SmartValve

system’s flame sense current path. Make

sure the connections are clean and tight.

2. Do not make sharp bends or deform the

tubing. Do not bend tubing at the ignition

system control after the compression nut is

tightened, because this can cause gas

leakage.

1. Cut the tubing to the desired length.

2. Bend the tubing as necessary for routing to the pilot

burner.

3. Square off and debur the end of the tubing.

TM

4. Unscrew the brass compression fitting from the pilot

outlet.

5. Slip the fitting over the tubing and out of the way.

6. Push the tubing into the pilot gas outlet.

7. Tap the outlet end of the control.

8. Remove and discard the old fitting.

While holding tubing all the way in, slide the new fit-

9.

ting (included with the new SmartValve

and begin thread until finger tight as shown in Fig. 7.

10. Tighten fitting one more full turn with the wrench.

M3344

Do not overtighten.

11. Connect the other end of the tubing to the pilot

burner as described in the instructions supplied with

Q3450 or Q3480 pilot hardware.

Wiring

Follow the wiring instructions supplied by the appliance

TM

manufacturer if available. Otherwise, use the following

general instructions.

NOTE:

1. In most cases, connect the wiring by plugging

the appliance wiring harness connector into

the SmartValve

sion harness if necessary.

2. Where the general instructions are different

from the appliance manufacturer ’s instructions, use the appliance manufacturer’s

instructions.

TM

. Use the supplied exten-

SYSTEM CONTROL

TM

) into place

WHEN FLANGE IS NOT USED

APPLY WRENCH FROM TOP OR

BOTTOM OF IGNITION SYSTEM

CONTROL TO EITHER SHADED AREA

Fig. 6. Proper use of wrench on ignition system control with and without flanges.

IGNITION SYSTEM CONTROL

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

FITTING BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

Fig. 7. Tighten new fitting and nut.

Always use a new compression fitting.

TO PILOT

BURNER

M3346

WHEN FLANGE IS USED

APPLY WRENCH

TO FLANGE ONLY

CAUTION

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Disconnect the power supply before making wiring

connections.

IMPORTANT

All wiring must comply with applicable electrical

codes and ordinances.

M7928

5 69-1270—3

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

NOTE: If the wiring harness is damaged, contact the

equipment manufacturer for a replacement

harness.

1. Make sure the power rating on the ignition system

matches the available supply. The system transformer should be NEMA rated at 40 VA or larger.

2. Install a transformer, thermostat, and other controls

as required.

3. Connect the control circuit to the ignition system

control, as shown in Fig. 8 through 11.

TM

SYSTEM CONTROL

L2

PILOT BURNER GROUND

(THROUGH PILOT TUBING)

24 VOLT

COMMON

24 VOLT

HOT

EFT

OUTPUT

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

POWER SUPPLY. PROVIDE

1

DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

Fig. 8. SV9501/SV9502/SV9602/SV9601 basic wiring

PILOT BURNER

GROUND

(THROUGH

PILOT TUBING)

diagram.

120/240 VAC

L1

1

POWER

SUPPLY

NEMA 40 VA

TRANSFORMER

24 VAC

THERMOSTAT

TO

ELECTRONIC FAN

TIMER (IF USED)

LIMIT

M7935C

FUSE

HUMIDIFIER

AIR CLEANER

INDUCER

MOTOR

STARTING

CAP

LO

ML

MH

CIRCULATING

FAN

W

CONNECT ONLY IF CONTINUOUS SPEED IS AVAILABLE AND USED.

1

CONNECT ONLY IF CONTINUOUS SPEED IS NOT USED.

2

CONNECT IF EAC AND HUM TERMINALS ARE AVAILABLE AND USED.

3

SOME MODELS USE MALE 1/4-INCH QUICK-CONNECTS INSTEAD

4

OF SCREW TERMINALS FOR THERMOSTAT CONNECTIONS.

2

HI

THERMOSTAT

GR

Y

3

UNUSED

3 DI

EAC N

HUM N

1 2

Z1

Z2

DELAY

SPEED

1

2

UP

OFF

Fig. 9. SV9501/SV9502/SV9602/SV9601 typical wiring connections in fan assisted warm air furnace

L1(H)

TO 115/230 VAC

POWER SUPPLY

L2(N)

115/230 VAC

TRANSFORMER

24 VAC

2

3

1

4

CX

MOTOR

C Y

N

LEADS

ST9120

NEUTRAL

CIR

C

COOL

CONT

1

G

BLWR

HEAT

X

SEC

XFMR

4

Y

W

COOLING

CONTACTOR

R

= DENOTES STANDARD TERMINAL.

NOTE:

= DENOTES OPTIONAL TERMINAL.

DENOTES LOW VOLTAGE WIRING.

DENOTES LINE VOLTAGE WIRING.

with ST9120 Electric Fan Timer.

ROLL-OUT

SWITCH

LIMIT

CONTROL

PRESSURE

SWITCH

PILOT BURNER

GROUND

(THROUGH

PILOT TUBING)

24 VOLT

COMMON

24 VOLT

HOT

EFT

OUTPUT

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

M7937D

69-1270—3 6

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

D892

VENT DAMPER

4 3 2 1

BLACK

M7936C

Fig. 10. SV9501/SV9502/SV9602/SV9601 typical wiring

CABLE AND

CONNECTOR

TO SUIT

AQUASTAT

CONTROL

ROLLOUT

RED

BLACK

COIL

SWITCH

SPILL

SWITCH

THERMOSTAT

RED

W

G

Y

CIRCULATOR PUMP

PILOT BURNER GROUND

(THROUGH PILOT TUBING)

R8285D

R

C

diagram in atmospheric boiler.

COMBUSTION

AIR BLOWER

BLACK

L1

L2

POWER SUPPLY. PROVIDE

1

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

24V THERMOSTAT

1

120 VAC

POWER SUPPLY

STARTUP AND CHECKOUT

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not force the ignition switch on the appliance.

Do not use tools to move the ignition switch. If the

switch does not move by hand, a qualified service

technician must replace the control.

Ignition System Control Switch Settings

NOTE: The control switch only controls gas flow. It does

not control the igniter circuit.

Ignition system control switch settings are:

OFF

Prevents pilot and main gas flow through the ignition

system control. The rest of the ignition sequence occurs

normally.

ON

Allows gas to flow through the control valve. The

thermostat controls the gas flow to the pilot and main

burners.

PRESSURE

SWITCH

NC

R8222U RELAY

1

4

3

6

NO

C

C

R

Y

W

G

1

L2

L1

(HOT)

CIRCULATOR

POWER SUPPLY. PROVIDE DISCOUNNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

1

3

4

6

R8285D CONTROL CENTER

LIMIT

ROLL-OUT

SWITCH

PILOT BURNER

GROUND (THROUGH

PILOT TUBING)

24 VOLT

COMMON

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

24 VOLT

HOT

EFT

OUTPUT

Fig. 11. SV9501/SV9502/SV9602/SV9601 typical wiring diagram in induced draft boiler application.

7 69-1270—3

M13036B

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

Turning on the System

Push the switch to the ON position.

Turning on the Main Burner

Follow the instructions provided by the appliance

manufacturer or turn up the thermostat to call for heat. If

the main burner does not light, refer to the troubleshooting

table.

PROPER FLAME

ADJUSTMENT

3/8 TO 1/2 IN.

(10 TO 13 MM)

GROUND

ELECTRODE

Perform Gas Leak Test

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. Check for gas leaks with soap and water

solution every time work is done on a gas

system.

2. Stand clear of the main burner when lighting it

to prevent injury from hidden leaks that could

cause flashback.

Gas Leak Test

1. Paint the pipe connections located upstream from

the ignition system control with a rich soap and

water solution.

Bubbles indicate a gas leak.

2. If a leak is detected, tighten the pipe connections.

3. Repeat steps 1 and 2 until no leaks are detected in

that area.

4. Light the main burner.

5. With the main burner in operation, paint the pipe

joints, adapters, and control inlet and outlet with a

rich soap and water solution.

6. If a leak is detected, tighten the adapter screws,

joints, and pipe connections.

7. Repeat steps 5 and 6 until no leaks are detected.

8. Replace the part with the same model number if

any leak cannot be stopped.

Adjust the Pilot Flame

The pilot flame should envelop 3/8 in. to 1/2 in. (10 mm to

13 mm) of the tip of the flame rod, as shown in Fig. 12.

1. Remove the pilot adjustment cover screw.

2. Turn the inner adjustment screw clockwise to

decrease or counterclockwise to increase the pilot

flame.

3. After adjusting the flame, replace and tighten firmly

the cover screw to prevent gas leakage.

NOTE: Controls are provided with adjustment screws

set at the maximum pilot flow position.

FLAME ROD

HOT SURFACE

NOTE: GROUND ELECTRODE MUST NOT TOUCH FLAME

ROD (.050 IN. MINIMUM CLEARANCE). BEND GROUND

ELECTRODE IF NECESSARY. DO NOT BEND FLAME ROD.

Fig. 12. Proper flame adjustment.

IGNITER

M3350A

Check and Adjust Gas Input

and Burner Ignition

IMPORTANT

— Many replacement valves require outlet pressure

adjustment.

— Do not exceed the input rating stamped on the

appliance nameplate.

— Do not exceed the manufacturer’s

recommended burner orifice pressure for size of

orifice used.

— Make sure the primary air supply to the main

burner is properly adjusted for complete

combustion.

— Follow the appliance manufacturer’s

instructions.

If Checking Gas Input by Clocking Gas Meter

1. Make sure there is no gas flow through the meter

other than the flow to be checked.

2. Other appliances supplied by this meter must

remain off with their pilots extinguished or their gas

consumption must be deducted from the meter

reading.

3. Convert flow rate to Btuh as described in Gas

Controls Handbook, form 70-2602, and compare

the result to the Btuh input rating on the appliance

nameplate.

If Checking Gas Input with Manometer

1. Make sure gas supply is shut off at the manual

valve in the natural gas piping to an appliance or at

the tank for LP gas before removing the inlet

pressure plug.

2. Make sure the ignition system control is in OFF

position when removing the gauge and replacing

the plug.

3. Make sure the ignition system control is in OFF

position before removing the outlet pressure tap

plug and connecting the manometer (pressure

gauge).

4. Shut off the gas supply before disconnecting the

manometer and replacing the plug.

5. Repeat the gas leak test at the plug with the main

burner operating.

69-1270—3 8

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

Standard Pressure Regulator (M Models),

Slow Open (H models), Step Open (P

Models)

1. Check the full rate manifold pressure listed on the

appliance nameplate. The ignition system control

outlet pressure must match the full rate pressure

listed on the nameplate. Adjust the pressure if they

do not match.

NOTE: Slow opening (H models) and step opening

(P models) may take several seconds to reach

full flow rate. M models will take 2 to 3 seconds

to reach full flow rate.

2. With the main burner ON, check the ignition system

control flow rate using the meter clocking method,

or check the pressure using a manometer

connected to the outlet pressure tap on the ignition

system control.

3. Adjust the pressure regulator to match the

appliance rating if necessary. See Table 2 and 3 for

factory set nominal outlet pressure and adjustment

range.

a. Remove the pressure regulator adjustment cap

screw.

b. Using a screwdriver, turn the inner adjustment

screw clockwise to increase or counter

clockwise to decrease gas pressure to the

burner.

c. Replace the cap screw and tighten it firmly to

prevent gas leakage.

4. If the desired outlet pressure or flow rate cannot be

achieved by adjusting the ignition system control,

check the ignition system control inlet pressure

using a manometer at the ignition system control

inlet pressure tap.

Table 2. SV9501/SV9502/SV9602/SV9601 Pressure Regulator Specification Pressures.

Factory Set Nominal Outlet

Nominal Inlet

Model

Typ e o f

Typ e

Standard,

Slow

Step NAT 5.0-7.0 1.2-1.7 0.9 0.2 3.5 0.9 None None 3-5 0.7-1.2

SV9501/SV9502 1/2 x 1/2

SV9602/SV9601 3/4 x 3/4

The maintenance program should include regular

checkout of the control as described in the Startup and

Checkout section, and the control system as described in

the application manufacturer’s literature.

Maintenance frequency must be determined individually

for each application. Some considerations follow:

• Cycling frequency. Appliances that cycle 20,000 times

NAT 5.0-7.0 1.2-1.7 — — 3.5 0.9 — — 3-5 0.7-1.2

LP 12.0-14.0 2.9-3.9 — — 10.0 2.5 — — 8-12 2-3

LP 12.0-14.0 2.9-3.9 2.2 0.2 10.0 2.5 None None 8-12 2.0-3.0

Model

annually should be checked each month.

Pressure Range

Gas

in. wc kPa in. wc kPa in. wc kPa in. wc kPa in. wc kPa

Table 3. Capacity of SV9501/SV9502/SV9602/SV9601.

Size

(Inlet x Outlet) (in.)

Step Full Rate Step Full Rate

Capacity (at 1 inch

wc pressure drop)

150 ft

300 ft

5. If the inlet pressure is in the factory specified

nominal range, as shown in Table 2 and 3, replace

the ignition system control. Otherwise, take the

necessary steps to provide proper gas pressure to

the control.

NOTE: If the burner firing rate is above the maximum

capacity as shown in Table 3, it might not be possible to deliver the desired outlet pressure. This

is an application issue, not a control failure. Take

whatever steps are necessary to correct the situation.

MAINTENANCE

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to take the control apart or clean it.

Improper cleaning or reassembly may cause gas

leakage.

Regular preventive maintenance is important in

applications that place a heavy load on system controls.

This include applications in commercial cooking,

agricultural, and industrial industries where these

conditions often exist:

• Heavy cycling. In commercial cooking, the operation,

the equipment operates 100,000 to 200,000 cycles per

year. This can wear out a gas control in one to two

years.

• Exposure to water, dirt, chemicals, and heat can

damage the gas control and shut down the control

system.

Pressure Setting Range

Minimum Regulated

3

/hr (3.7m3/hr) 20 ft3/hr (0.6m3/hr) 200 ft3/hr 95.7m3/hr)

3

/hr (8.5m3/hr) 30 ft3/hr (0.8 m3/hr) 415 ft3/hr (11.8m3/hr)

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and before each

use.

• Consequence of unexpected shutdown. Where the

cost of an unexpected shutdown would be high, check

the system frequently.

• Dusty, wet, or corrosive environment. Since these

environments can cause the gas control to deteriorate

more rapidly, check the system frequently.

Capacity

Maximum Regulated

Capacity

9 69-1270—3

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

Replace the system if any of the following conditions

occur:

• The system does not perform properly at checkout or

troubleshooting.

• The gas control switch is difficult to move.

• The gas control has operated for more than 200,000

cycles.

• The control is wet or shows signs of moisture.

SERVICE

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not disassemble the ignition system control. It

contains no replaceable parts. Attempted

disassembly or repair can damage the ignition

system control.

CAUTION

Equipment Damage Hazard.

Can burn out heat anticipator in thermostat.

1. Do not apply a jumper across or short the

control terminals. Doing so may burn out the

heat anticipator in the thermostat or damage

the system transformer.

2. Make sure to check operation after service.

Sequence of Operation

1. Make sure the ignition system control switch is in

the ON position.

2. Follow the sequence of operation shown in Fig. 14.

If the Main Burner Does Not Come On with

Call for Heat

1. Make sure the ignition system control switch is in

the ON position.

2. Adjust the thermostat several degrees above room

temperature.

3. Make sure the appliance is receiving power. See

Fig. 15 or 16, as applicable.

INSTRUCTIONS TO THE

HOMEOWNER

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow these warnings exactly as written.

1. Do not light the pilot flame manually. Pilot flame

lights automatically.

2. Smell around the appliance for gas. Be sure to

smell next to the floor, because LP gas is

heavier than air.

3. If you smell gas:

• Turn off the gas supply at the appliance

service valve. For LP gas systems, turn off

the gas supply at the gas tank.

• Do not light any appliances in the house.

• Do not touch any electrical switches.

• Do not use the phone.

• Leave the building, and go to a neighbor’s

phone to call your gas supplier.

• If you cannot reach your gas supplier, call the

fire department.

4. Do not force or use tools to move the ignition

system control switch. If the switch does not

operate by hand, the ignition system control

must be replaced by a qualified, licensed (if

required) service technician. Force or

attempted repair can result in fire or explosion.

5. Replace the ignition system control if it shows

any evidence of physical damage, tampering,

bent terminals, missing or broken parts,

stripped threads, or exposure to excessive

heat.

IMPORTANT

Follow the warnings in the Instructions to the

Homeowner section.

Follow the operating instructions provided by the

manufacturer of your heating appliance. The

following information assists in a typical ignition

system control application, but the specific

controls used and the procedures outlined by the

manufacturer of your appliance can be different.

Such appliances require special instructions.

Turning the Appliance ON

The pilot flame is lit automatically. If the appliance does

not turn on when the thermostat is set several degrees

above room temperature, follow these instructions:

69-1270—3 10

1. Set the thermostat to its lowest setting to reset the

safety control.

2. Disconnect all electric power to the appliance.

3. Remove the ignition system control access panel.

4. Move the ignition system control switch to OFF.

5. Wait a minimum of five minutes to clear out any

unburned gas. If you smell gas, follow step 3 in the

warning. Otherwise continue to the next step.

6. Move the ignition system control switch to ON.

7. Replace the ignition system control access panel.

8. Reconnect the power to the appliance.

9. Set the thermostat to the desired setting.

10. If the appliance still does not turn on, set the ignition

system control switch to OFF and contact a

qualified, licensed (if required) service technician.

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

NOTE: The SV9502 and SV9602 have an

approximately 30-second prepurge delay before

start of Ignition Trial. Be sure to wait for prepurge

to be completed.

Turning the Appliance OFF

Vacation Shutdown

Set the thermostat to the desired temperature while you

are away.

START

SELF-CHECK

IGNITION

MAIN BURNER

OPERATION

SV9500/SV9600 SmartValve® FAMILY SEQUENCE OF OPERATION

APPLY 24V POWER TO SYSTEM

THERMOSTAT CALLS FOR HEAT

FLAME SIGNAL DETECTED

A POWERED PILOT VALVE OPENS AND IGNITER

ENERGIZES

PILOT LIGHTS, FLAME ROD SENSES FLAME

• IGNITER OFF

• MAIN VALVE OPENS

• MAIN BURNER LIGHTS

• ELECTRONIC FAN TIMER OUTPUT ENERGIZES

THERMOSTAT CALL FOR HEAT ENDS

NO

YES

YES

Complete Shutdown

1. Turn off the power to the appliance.

2. Move the ignition system control switch to OFF

without forcing it.

The appliance shuts off completely.

Follow the instructions in Instructions to the Homeowner

to resume normal operation.

OPERATING SEQUENCE

The following flowcharts describes the basic operating

sequence for the SV9500 and SV9501/SV9502/SV9602/

SV9601 controls. This information is designed to assist

field technicians to analyze normal appliance operation.

YES

NO

NO

FLAME

OUTAGE

OCCURS

DURING

RUN CYCLE

• WAIT FOR FLAME SIGNAL TO DISAPPEAR

• ELECTRONIC FAN TIMER OUTPUT ENERGIZES

• PILOT VALVE AND IGNITER REMAIN OFF

IGNITER

MISSING

OR

BROKEN

IGNITER

OPENS

NO SYSTEM RESPONSE—PILOT VALVE OFF

IGNITER STAYS ON, PILOT VALVE REMAINS OPEN

MAIN VALVE CLOSES

SV9500 POWERS IGNITER CIRCUIT

PILOT AND MAIN VALVES CLOSE, SYSTEM SHUTS DOWN

• MAIN AND PILOT VALVES CLOSE

END

• ELECTRONIC FAN TIMER OUTPUT DE-ENERGIZES

Fig. 13. SV9500/SV9600 SmartValve

M17145B

TM

System Sequence of Operation.

11 69-1270—3

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

START

PREPURGE/

SYSTEM

CHECK

TRIAL

FOR

IGNITION

MAIN

BURNER

OPERATION

END

APPLY 24 VAC TO APPLIANCE

THERMOSTAT CALLS FOR HEAT

PREPURGE (SV9502/SV9602 ONLY)

YES

FLAME SIGNAL DETECTED?

INTERNAL CHECK OKAY?

• PILOT VALVE OPENS

• IGNITER POWERED

PILOT LIGHTS AND FLAME IS SENSED

DURING TRIAL FOR IGNITION?

• IGNITER OFF

• MAIN VALVE OPENS

ELECTRONIC FAN TIMER (EFT) OUTPUT ENERGIZES

FLAME SIGNAL LOST?

THERMOSTAT CALL FOR HEAT ENDS

• MAIN AND PILOT VALVES CLOSE

• EFT OUTPUT DE-ENERGIZES

IGNITER WILL TURN OFF ABOUT 30 SECONDS INTO THE TRIAL FOR IGNITION IF THE PILOT FLAME HAS NOT LIT. IT WILL TURN BACK

1

ON FOR THE FINAL 30 SECONDS OF THE 90 SECOND TRIAL FOR IGNITION. THE PILOT VALVE WILL BE ENERGIZED DURING THE

ENTIRE TRIAL FOR IGNITION. THIS IS NORMAL OPERATION FOR THIS GAS IGNITION SYSTEM.

NO

YES

1

YES

NO

• WAIT FOR FLAME SIGNAL TO DISAPPEAR.

• PILOT VALVE/IGNITER REMAIN OFF

NO

NO

• PILOT VALVE CLOSES

• IGNITER OFF

YES

• MAIN AND PILOT VALVES CLOSE

• EFT OUTPUT DE-ENERGIZES

FLAME LOST MORE THAN FIVE TIMES

IN ONE CALL FOR HEAT?

YES

THREE-SECOND FLAME

FAILURE RECYCLE DELAY

Fig. 14. SV9501/SV9502/SV9602/SV9601 SmartValveTM Sequence of Operation.

SV9501/SV9502/SV9601/SV9602 SmartValve® FAMILY SEQUENCE OF OPERATION

NO

FIVE-MINUTE

RETRY DELAY

M17144A

TROUBLESHOOTING

The attached flowcharts provide specific troubleshooting

information for the SV9500, SV9501 and SV9502/

SV9600, SV9601, SV9602 products. These charts assist

the field technician to analyze appliance operation

difficulties.

CAUTION

Equipment Damage.

Can damage connectors on wiring harness.

1. Proper troubleshooting requires measurement

of voltage and resistance with a volt/ohm meter.

2. Use proper size probes and appropriate testing

techniques to assure good test information

without damaging the control terminals,

Use the following basic troubleshooting procedure.

connectors or wiring harness.

1. Review this information carefully prior to going to

the job site.

2. Identify the specific SmartValve

SV9501, SV9502, SV9600, SV9601, SV9602).

3. Make sure the Q3450/Q3480 HSI element is good.

Disconnect the HSI element from the SmartValveTM.

4.

5. Using a multimeter, measure the HSI element room

temperature resistance. It should be less than 10

ohms.

TM

(SV9500,

69-1270—3 12

NOTE: The HSI element action for SV9501/SV9502/

TM

6. Make sure the SmartValve

SV9500/SV9600) is in the ON position (unless

directed otherwise in the Troubleshooting

flowchart).

7. Make sure the appliance call for heat function

provides proper inputs to the SmartValve

the 2X2 power connector. (Measure with voltmeter

on the ac scale.)

8. Follow the Operating Sequence and

Troubleshooting flow charts as shown in Fig. 13 and

15 for the installed SmartValve

to make sure replacement is necessary.

9. Follow the Operating Sequence and

Troubleshooting flow chart in Fig. 14 and 16 for the

replacement SV9501/SV9502/SV9601/SV9602

SmartValve

TM

.

SV9601/SV9602 is different from the HSI

element action for SV9500/SV9600. For

SV9500/SV9600, the element is on continuously

during a call for heat until shortly after the pilot

flame is detected, the main valve energizes and

the element turns off. For SV9501/SV9502/

SV9601/SV9602, the call for heat generates a

90-second “trial for pilot ignition.” If no pilot flame

is sensed, it retries after a five minute delay. The

element cycles off and back on once during the

trial for pilot ignition.

switch (knob if

TM

TM

SV9500/SV9600

through

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

SV9500SV9600 SmartValve™ TROUBLESHOOTING SEQUENCE

NOTE: BEFORE TROUBLESHOOTING,

BECOME FAMILIAR WITH THE STARTUP

START

• TURN OFF GAS SUPPLY

• ASSURE SmartValve SWITCH IS IN ON POSITION

• DISCONNECT SYSTEM CONTROL HARNESS

• SET THERMOSTAT TO CALL FOR HEAT

CHECK FOR PROPER VOLTAGE AT CONTROL

HARNESS (SEE INSET A). VOLTAGE SHOULD BE

24V BETWEEN THERMOSTAT OR PRESSURE

SWITCH AND 24V COMMON, AND 24V

BETWEEN 24V COMMON AND 24V HOT.

PLUG HARNESS INTO SmartValve CONTROL.

WAIT FOR INTERNAL CHECK DELAY.

WAIT FOR PREPURGE.

IGNITER WARMS UP AND GLOWS RED

• TURN ON GAS SUPPLY

• PILOT BURNER LIGHTS

MAIN VALVE OPENS AND MAIN BURNER LIGHTS

YES

YES

YES

YES

1

AND CHECKOUT PROCEDURE. ALSO

CHECK PILOT BURNER ELEMENT FOR

RESISTANCE LESS THAN 10 OHMS WITH

ELEMENT AT ROOM TEMPERATURE.

CHECK:

• LINE VOLTAGE POWER

• LOW VOLTAGE TRANSFORMER

NO

• LIMIT CONTROLLER

• THERMOSTAT

2

• WIRING

• AIR PROVING SWITCH ON COMBUSTION AIR

BLOWER SYSTEM

• VENT DAMPER (IF USED) IS OPEN AND END

SWITCH MAKES

WITH PILOT BURNER CABLE CONNECTED, MEASURE

NO

VOLTAGE AT SmartValve HSI ELEMENT

OUTPUT (SEE INSET B) 24V NOMINAL.

REPLACE IGNITER/FLAME ROD ASSEMBLY

NO

CHECK THAT PILOT GAS IS FLOWING. WAIT TO

ASSURE PILOT GAS TUBING IS PURGED.

MEASURE VOLTAGE BETWEEN 24V HOT AND 24V

COMMON LEADS TO SmartValve CONTROL. MUST

MEASURE AT LEAST 19.5 VAC WITH IGNITER

POWERED. SEE INSET A TO IDENTIFY PROPER LEAD.

THIS CHECK MUST BE DONE WITH THE SmartValve

CONTROL CONNECTED AND IGNITER POWERED.

REPLACE IGNITER/FLAME ROD ASSEMBLY

NO

• CHECK THAT PILOT FLAME MAKES GOOD

CONTACT WITH PILOT BURNER FLAME ROD.

• CHECK FOR GOOD ELECTRICAL CONNECTION

THROUGH THE PILOT TUBING.

• IF BOTH OF THE ABOVE ARE GOOD, REPLACE

IGNITER/FLAME ROD ASSEMBLY

YES

YES

YES

INSET A

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

24 VOLT

COMMON

CHECK FOR DAMAGED OR MISSING

TERMINALS IN CONNECTOR

INSET B

HSI

TERMINALS

NO

2

1

REPLACE SmartValve CONTROL

NO

REPLACE SmartValve CONTROL

NO

CHECK TRANSFORMER AND LINE

VOLT SUPPLY

2

END VIEW

OF CONTROL

HARNESS

CONNECTOR

EFT

OUTPUT

24 VOLT

HOT

SYSTEM IS OKAY

1

IGNITER WILL STAY ENERGIZED AS LONG

AS APPLIANCE CALL FOR HEAT IS IN PLACE.

CYCLE THERMOSTAT OFF AND BACK ON

MAIN BURNER LIGHTS

WHEN MEASURING VOLTAGE AT CONNECTIONS, USE

2

CARE TO ASSURE TERMINALS ARE NOT DAMAGED.

Fig. 15. SV9500/SV9600 troubleshooting guide.

13 69-1270—3

NO

REPLACE SmartValve CONTROL

M17146A

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

SV9501/SV9502/SV9601/SV9602 SmartValve™ TROUBLESHOOTING SEQUENCE

NOTE: BEFORE TROUBLESHOOTING,

START

• TURN OFF GAS SUPPLY

• ASSURE SmartValve SWITCH IS IN ON POSITION

• DISCONNECT SYSTEM CONTROL HARNESS

• SET THERMOSTAT TO CALL FOR HEAT

CHECK FOR PROPER VOLTAGE AT CONTROL

HARNESS (SEE INSET A). VOLTAGE SHOULD BE

24V BETWEEN THERMOSTAT OR PRESSURE

SWITCH AND 24V COMMON, AND 24V

BETWEEN 24V COMMON AND 24V HOT.

PLUG HARNESS INTO SmartValve CONTROL.

WAIT FOR INTERNAL CHECK DELAY (SV9501/SV9601)

OR PREPURGE (SV9502/SV9602)

IGNITER WARMS UP AND GLOWS RED

• TURN ON GAS SUPPLY

• PILOT BURNER LIGHTS

MAIN VALVE OPENS AND MAIN BURNER LIGHTS

STEP MODELS (P

NOTE:

DESIGNATOR) WILL

TAKE SEVERAL

SECONDS TO REACH

FULL FIRING RATE.

SYSTEM IS OKAY

1

IGNITER WILL CYCLE OFF AND BACK ON ONCE DURING THE

90 SECOND IGNITION TRIAL. ALL VOLTAGE MEASUREMENTS

MUST BE TAKEN WHILE THE IGNITER IS POWERED.

YES

YES

YES

1

YES

BECOME FAMILIAR WITH THE STARTUP

AND CHECKOUT PROCEDURE. ALSO

CHECK PILOT BURNER ELEMENT FOR

RESISTANCE LESS THAN 10 OHMS WITH

ELEMENT AT ROOM TEMPERATURE.

CHECK:

• LINE VOLTAGE POWER

• LOW VOLTAGE TRANSFORMER

NO

• LIMIT CONTROLLER

2

• THERMOSTAT

• WIRING

• AIR PROVING SWITCH ON COMBUSTION AIR

BLOWER SYSTEM

• VENT DAMPER (IF USED) IS OPEN AND END

SWITCH MAKES

WITH PILOT BURNER CABLE CONNECTED, MEASURE

NO

VOLTAGE AT SmartValve HSI ELEMENT

OUTPUT (SEE INSET B) 24V NOMINAL.

REPLACE IGNITER/FLAME ROD ASSEMBLY

NO

CHECK THAT PILOT GAS IS FLOWING. WAIT TO

ASSURE PILOT GAS TUBING IS PURGED. RECYCLE

CALL FOR HEAT IF NECESSARY.

MEASURE VOLTAGE BETWEEN 24V HOT AND 24V

COMMON LEADS TO SmartValve CONTROL. MUST

MEASURE AT LEAST 19.5 VAC WITH IGNITER

POWERED. SEE INSET A TO IDENTIFY PROPER LEAD.

THIS CHECK MUST BE DONE WITH THE SmartValve

CONTROL CONNECTED AND IGNITER POWERED.

REPLACE IGNITER/FLAME ROD ASSEMBLY

NO

• CHECK THAT PILOT FLAME MAKES GOOD

CONTACT WITH PILOT BURNER FLAME ROD.

• CHECK FOR GOOD ELECTRICAL CONNECTION

THROUGH THE PILOT TUBING.

• IF BOTH OF THE ABOVE ARE GOOD, REPLACE

IGNITER/FLAME ROD ASSEMBLY

CYCLE THERMOSTAT OFF AND BACK ON

MAIN BURNER LIGHTS

YES

YES

YES

WHEN MEASURING VOLTAGE AT CONNECTIONS, USE

2

CARE TO ASSURE TERMINALS ARE NOT DAMAGED.

METER ELEMENT MUST BE CONNECTED.

3

NO

2

1

NO

NO

2

NO

INSET A

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

24 VOLT

COMMON

CHECK FOR DAMAGED OR MISSING

TERMINALS IN CONNECTOR

INSET B

HSI

TERMINALS

REPLACE SmartValve CONTROL

REPLACE SmartValve CONTROL

CHECK TRANSFORMER AND LINE

VOLT SUPPLY

REPLACE SmartValve CONTROL

END VIEW

OF CONTROL

HARNESS

CONNECTOR

EFT

OUTPUT

24 VOLT

HOT

M17143B

3

Fig. 16. SV9501/SV9502/SV9601/SV9602 SmartValveTM Troubleshooting Sequence.

69-1270—3 14

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

Table 4. Replacement chart for SV9500, SV9501, and SV9502.

Pressure Regulator

Order Number

Inlet/Outlet

Size

SV9502H2522 1/2 in. x 1/2 in. 3.5 0.87 Slow 15 sec. Natural

SV9501M2528 Standard None SV9500M2603

SV9501M8129 3.4 Fast SV9500M8600

SV9601M4571 3/4 in. x 3/4 in. 3.5 Standard

a

Regulator setting in replacement control differs from original. Adjust to rated pressure as necessary for optimum

performance.

b

Shipped by Honeywell as LP gas only; may have been converted to natural gas. Use Natural to LP gas conversion kit

(included) if necessary. Follow instructions in conversion kit.

c

Requires vent fitting (part no. 392877, order separately).

d

Requires 3/4 in. straight flange (part no. 393690-14, order separately).

e

Replacement control includes prepurge time not included with original control.

Setting

Type of

Opening

Prepurge

Time

Typ e o f

Gas Replacesin. wc kPa

SV9500H2609

SV9500H2617

SV9500H2724

SV9500H3607

SV9500H3615

SV9501H2409

SV9501H2417

SV9501H2425

SV9501H3415

SV9501H3423

SV9502H1706

SV9502H2522

SV9502H2704

SV9500M2629

SV9500M2637

SV9500M2645

SV9500M2652

SV9500M2674

SV9500M2682

SV9500M2686

SV9500M2690b

SV9500M2736

SV9500M2835

SV9500M3601

SV9500M3619

SV9500M3635

SV9500M6604

SV9501M2031

SV9501M2049

SV9501M2056

SV9501M2064

SV9501M2239

SV9501M2528

SV9501M2700

SV9501M2718

SV9501M2726

SV9501M2734

SV9501M2742

SV9500M8618

SV9500M8659

SV9500M8667

SV9500M8808

SV9501M8103

SV9501M8111

SV9501M8129

SV9501M2080

SV9601M4167

SV9601M3003

SV9601M4225

a,e

a,e

e

a,d,e

b,d,e

a,e

e

b,e

a,d,e

b,d,e

a,d

d

b

a,c

a

a

b,d

b

b,d

a

a

a,c

b

b

b

b

b

15 69-1270—3

SV9501/SV9502/SV9601/SV9602 SMARTVALVE

TM

SYSTEM CONTROL

Table 5. SV9602 Replacement Chart.

Pressure Regulator

Order Number

Inlet/Outlet

Size

SV9602P4816 3/4 in. x 3/4 in. 3.5 0.7 Step 30 Sec.

SV9602P4824 2.5

SV9602P4832 10 2.5 LP

SV9602P4840 1.4

a

Regulator setting in replacement control differs from original. Adjust to rated pressure as necessary for optimum per-

formance.

b

Requires reducer accessory (included).

c

Replacement control includes prepurge time not included with original control.

d

These models were field convertible to LP gas. If the appliance has been converted to LP gas, use SV9602P4832 as

the replacement.

e

These models were field convertible to natural gas. If the appliance has been converted to natural gas, use

SV9602P4824 as the replacement.

Setting

Type of

Opening

Prepurge

Time

30 sec.

Typ e o f

Gas Replacesin. wc kPa

Natural

SV9500P2600

SV9500P2634

SV9500P2642

SV9501P2004

SV9501P2053

SV9502P2101

SV9600P4612

SV9600P4620

SV9600P4646

SV9601P4107

SV9602P4105

SV9602P4816

SV9501P2087

SV9502P2127

SV9601P4172

SV9602P4121

SV9602P4824

SV9500P2618

SV9500P2659

SV9501P2020

SV9501P2046

SV9502P2119

SV9502P2135

SV9601P4149

SV9601P4164

SV9602P4113

SV9602P4139,e

SV9602P4832

SV9600P4604

SV9600P4638

SV9600P4840

SV9601P4115

b,c

b,c

a,b,c

b,c

a,b,c

b

c

a,c

c

c

b,c,d

b,d

c,d

d

b,c

b,c

b,c,e

b,c

b

b,e

c

d,e

c

c

c

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

69-1270—3 M.S. Rev. 08-06

Loading...

Loading...