Honeywell SV9540, SV9640 Installation Manual

SV9540; SV9640

SmartV alve™ System Controls

INSTALLATION INSTRUCTIONS

APPLICATION

The SV9540; SV9640 SmartValve™ System Controls

combine gas flow control and electronic intermittent pilot

sequencing functions into a single unit. The low voltage

igniter, flame sensor and pilot burner are supplied by the

Q3450 or Q3480 Pilot Hardware. Provides all gas ignition

safety functions by controlling gas flow, ignition source,

and a 120 Vac or 240 Vac combustion air blower. The

control also monitors the appliance airflow proving switch

and limit string to assure proper appliance operation.

Provides prepurge, postpurge, timed trial for pilot igniton,

with 100 percent shutoff and continuous retry. Diagnostic

LED indicates system status.

This control communicates directly with the ST9160

Electronic Fan Timer (EFT) in typical forced warm air

furnace applications. It also interfaces with the 208907

Terminal Board, providing compatibility with power stealing

thermostats. Or, it directly interfaces with the appropriate

power supplies and a system thermostat for additional

appliance applications. When controlled directly by a

thermostat, the control does not provide a postpurge

function, as power to the control is removed when the

thermostat call for heat ends.

The SV9540; SV9640 system is suitable for a wide range

of fan assisted combustion gas-fired appliances including

furnaces, rooftop furnaces, boilers, unit heaters, infrared

heaters, water heaters and commercial cooking appliances. The specific application of the SmartValve System

is the responsibility of the appliance manufacturer. See

Table 1 for temperature ranges and regulator types.

SPECIFICA TIONS

CA UTION

The SV9540; SV9640 provide direct replacement

only. Use the Y8610 to convert standing pilot

systems to electronic ignition systems.

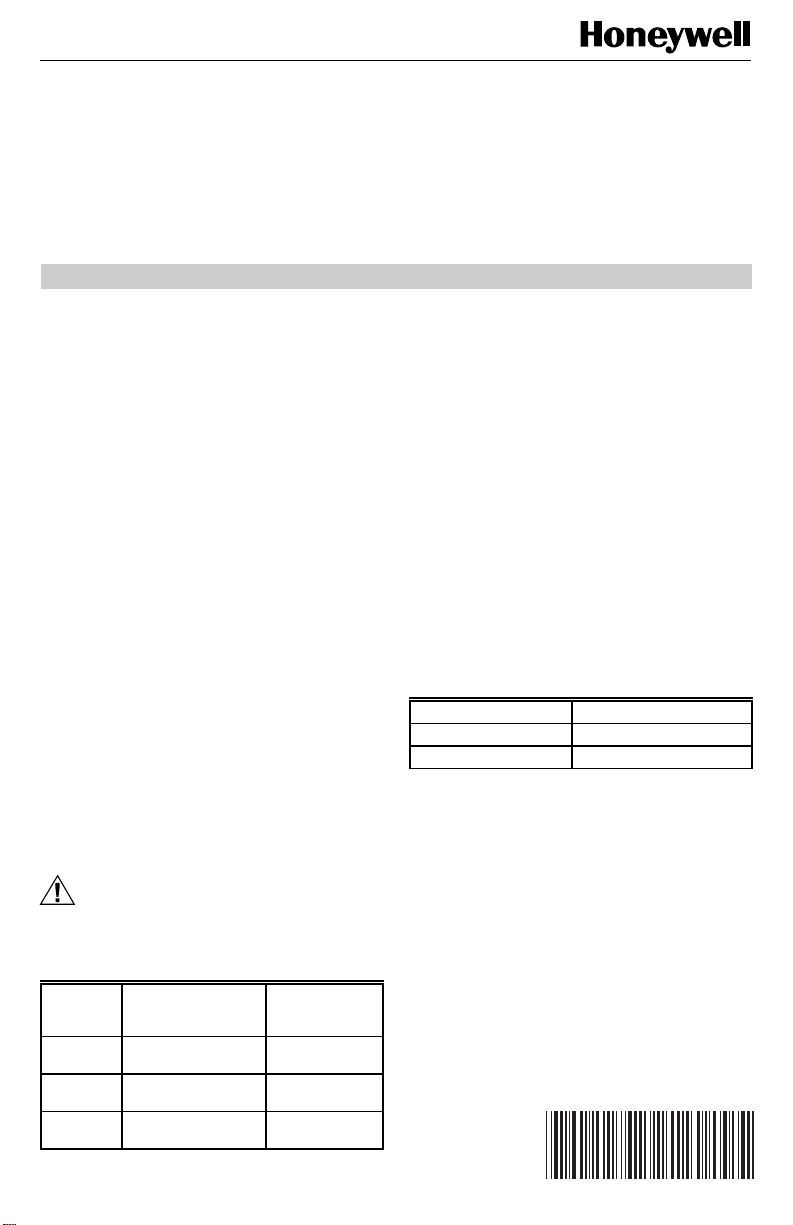

Table 1. Model Number Suffix Letter Designation.

Model No.

Suffix

Letter

H0°F to 175°F

M-40°F to +175°F

P-40°F to +175°F

Ambient

Temperature Range

(-18°C to +79°C)

(-40°C to +79°C)

(-40°C to +79°C)

Pressure

Regulator Type

Slow-opening

Standard

Step-opening

Body Pattern:

SV9540: Straight through with 1/2 in. inlet and 1/2 in.

outlet; or 1/2 in. NPT inlet and 1/2 in. inverted flare

outlet.

SV9640: Straight through with 1/2 in. inlet and 1/2 in.

outlet, 1/2 in. inlet and 3/4 in. outlet, or 3/4 in. inlet

and 3/4 in. outlet.

Electrical Ratings:

System Transformer:

SV9540: 40 VA minimum NEMA rated.

SV9640: 40 VA minimum NEMA rated.

NOTE: Larger system transformer may be

Voltage and Frequency:

Output Ratings:

Current at 24 Vac:

Table 2. Thermostat Current (Run Mode); with

Prepurge Time (Factory-set):

3, 15, 30 or 45 seconds, depending on model.

Trial for Ignition:

90 seconds.

Postpurge Time (Factory-set):

5 seconds; this is not available when the SmartValve

System Control is connected directly to the thermostat.

Retry Delay:

5 minutes.

Flame Failure Response Time:

1.6 seconds maximum at 2 µA.

Capacity:

See Table 3.

Conversion:

Use conversion factors in Table 4 to convert capacities for

other gases.

required for specific applications.

24 Vac, 60 Hz; 50 Hz models available.

Igniter Load: 1.5A maximum.

Induced Draft Motor Load: 2.5A Full Load, 10A

Locked Rotor at 120 Vac; 1.75A Full Load, 5A

Locked Rotor at 240 Vac.

24V Thermostat: See Table 2.

control connected directly to thermostat.

Model 24 Vac, 60 Hz

SV9540 0.25A

SV9640 0.25A

®U.S. Registered Trademark

Copyright © 1997 Honeywell Inc. • All Rights Reserved

X-XX UL

69-1059

SV9540; SV9640 SmartValve™ SYSTEM CONTROLS

Regulation Range (Btuh);

SV9540 with 1/2 in. NPT Outlet:

Natural Gas:

Minimum: 20,000.

Maximum: 200,000.

LP Gas:

Minimum: 40,000.

Maximum: 200,000.

SV9540 with 1/2 in. Inverted Flare Outlet:

Natural Gas:

Minimum: 20,000.

Maximum: 180,000.

LP Gas:

Minimum: 40,000.

Maximum: 180,000.

SV9640 (3/4 in. x 3/4 in.):

Natural Gas:

Minimum: 30,000.

Maximum: 415,000.

LP Gas:

Minimum: 30,000.

Maximum: 415,000

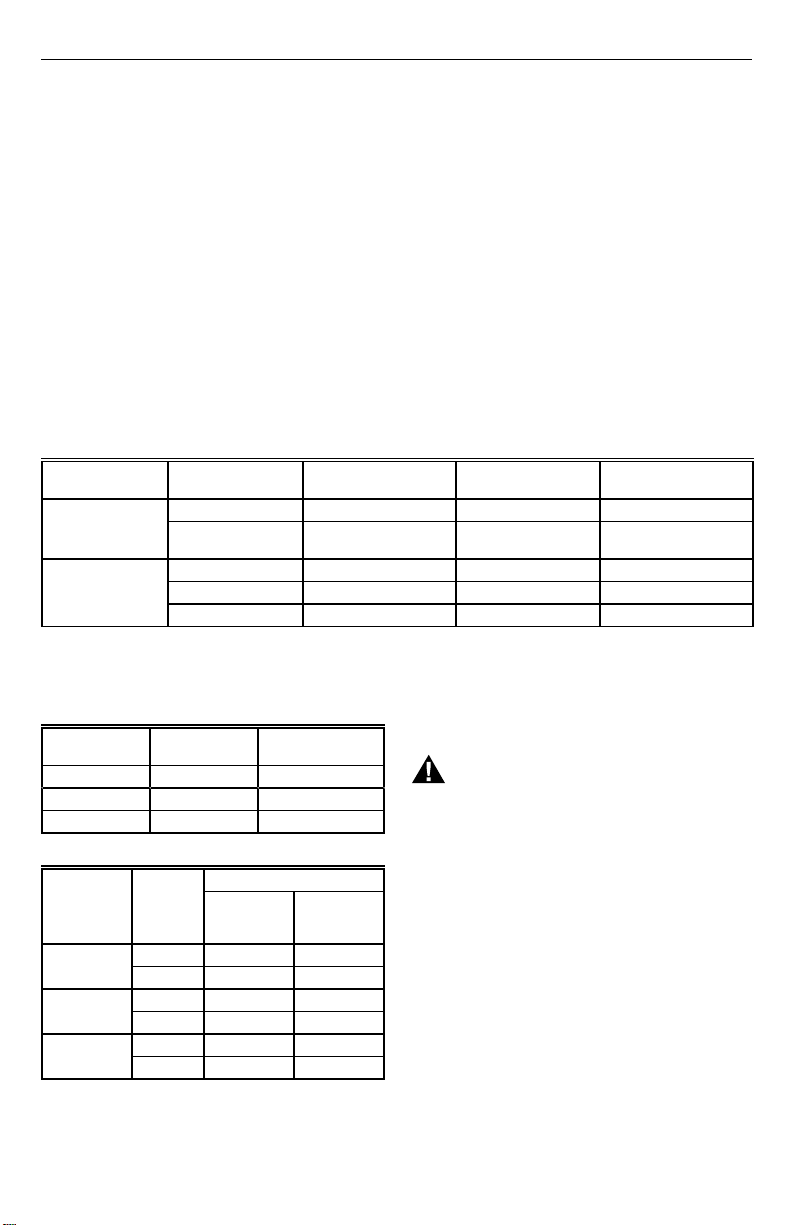

Table 3. Capacity

Model

SV9540 1/2 x 1/2 NPT 150 ft3/hr (4.2 m3/hr) 20 ft3/hr (0.6 m3/hr) 200 ft3/hr (5.7 m3/hr)

SV9640 1/2 x 1/2 240 ft3/hr (6.8 m3/hr) 30 ft3/hr (0.8 m3/hr) 340 ft3/hr (9.6 m3/hr)

a

Capacity based on 1000 Btu/feet3, 0.64 specific gravity natural gas at 1 in. wc pressure drop (37.3 MJ/meter3, 0.64

specific gravity natural gas at 0.25 kPa pressure drop).

b

Capacity is reduced by 5 percent with the use of outlet screen.

c

Valves are guaranteed at only 77 percent of the rating.

Table 4. Gas Capacity Conversion Factor.

Gas

Manufactured 0.60 0.516

Mix e d 0.70 0.765

Propane 1.53 1.62

Table 5. Adapter (Flange) Part Numbers.

Inlet/Outlet

Pipe Size

3/8 in. NPT Straight 393690-1 393690-11

1/2 in. NPT Straight 393690-6 393690-16

3/4 in. NPT Straight 393690-4 393690-14

a

Flange kits include one flange, one O-ring and four

mounting screws.

b

Do not use flanges on control models with 3/4 in. inlet

and 3/4 in. outlet. On models with 1/2 in. inlet and

3/4 in. outlet, use flanges only on the 1/2 in. inlet side.

Flange

Type

Elbow 393690-2 393690-12

Elbow 393690-3 393690-13

Elbow 393690-5 393690-15

Size

(Inlet x Outlet) (in.)

1/2 NPT x 1/2

inverted flare

1/2 x 3/4 270 ft3/hr (7.6 m3/hr) 30 ft3/hr (0.8 m3/hr) 370 ft3/hr (10.5 m3/hr)

3/4 x 3/4 300 ft3/hr (8.5 m3/hr) 30 ft3/hr (0.8 m3/hr) 415 ft3/hr (11.8 m3/hr)

Specific

Gravity

Part No.

Without

Hex

Wrench

Capacity (at 1 in.

wc pressure drop

130 ft3/hr (3.7 m3/hr) 20 ft3/hr (0.6 m3/hr) 180 ft3/hr (5.1 m3/hr)

Multiply Listed

Capacity By

a,b

With Hex

Wrench

Natural-LP Gas Conversion Kits:

Natural Gas to LP:

393691 Conversion Kit.

LP to Natural Gas:

394588 Conversion Kit.

IMPORTANT

SV9540P; SV9640P CANNOT be field-converted

to LP or natural gas.

Pipe Adapters:

Angle and straight adapters available for 3/8-, 1/2- and 3/

4-in. pipe. See Table 5. Flange kits include one flange with

attached O-ring, four mounting screws, a 9/64 in. hex

wrench and instructions.

Approvals:

International Approval Services (IAS):

Design Certified C2030025.

b

of SV9540; SV9640.

a,c

Minimum

)

Regulated Capacity

Maximum

Regulated Capacity

PLANNING THE INSTALLATION

W ARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Follow these warnings exactly:

1. Plan the installation as outlined below.

2. Plan for frequent maintenance as described in

the Maintenance section.

When intermittent pilot systems are used on central

heating equipment in barns, greenhouses, and commercial

properties and on heating appliances such as commercial

cookers, agricultural equipment, industrial heating

equipment and pool heaters, heavy demands are made on

the controls. Special steps may be required to prevent

nuisance shutdowns and control failure due to frequent

cycling, severe environmental conditions related to

moisture, corrosive chemicals, dust or excessive heat.

These applications require Honeywell Home and Building

Control Engineering review; contact your Honeywell Sales

Representative for assistance.

Review the following conditions that can apply to your

specific installation and take the precautionary steps

suggested.

69-1059

2

SV9540; SV9640 SmartValve™ SYSTEM CONTROLS

Frequent Cycling

This control is designed for use on appliances that typically

cycle three to four times an hour only during the heating

season. In year-around applications with greater cycling

rates, the control can wear out more quickly. Perform a

monthly checkout.

Water or Steam Cleaning

If a control gets wet, replace it. If the appliance is likely to

be cleaned with water or steam, protect (cover) the control

and wiring from water or steam flow. Mount the control

high enough above the bottom of the cabinet so it does not

get wet during normal cleaning procedures.

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never install

an appliance where water can drip on the control.

In addition, high ambient humidity can cause the control to

corrode and fail. If the appliance is in a humid atmosphere,

make sure air circulation around the control is adequate to

prevent condensation. Also, regularly check out the

system.

Corrosive Chemicals

Corrosive chemicals can attack the control, eventually

causing a failure. If chemicals are used for routine

cleaning, avoid contact with the control. Where chemicals

are suspended in air, as in some industrial or agricultural

applications, protect the control with an enclosure.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease can be

a problem, provide covers for the control to limit

contamination.

Heat

Excessively high temperatures can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control. If the

appliance operates at very high temperatures, use

insulation, shielding, and air circulation, as necessary, to

protect the control. Proper insulation or shielding should be

provided by the appliance manufacturer; verify proper air

circulation is maintained when the appliance is installed.

INST ALLA TION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH

Follow these warnings exactly:

1. Disconnect power supply before wiring to

prevent electrical shock or equipment

damage.

2. To avoid dangerous accumulation of fuel gas,

turn off gas supply at the appliance service

valve before starting installation, and perform

Gas Leak Test after completion of installation.

3. Do not bend pilot tubing at ignition system

control or pilot burner after compression fitting

is tightened, or gas leakage at the connection

can result.

4. Always install a sediment trap in gas supply

line to prevent contamination of ignition

system control.

WARNING

LINE VOLTAGE

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH.

Never apply a jumper across or short any of the

terminals in the SV9540; SV9640 wiring harness.

This can damage the system transformer or the

control.

Follow the appliance manufacturer instructions if available;

otherwise, use these instructions as a guide.

Converting Ignition System Control

from Natural Gas to LP Gas Application

(or LP Gas to Natural Gas Application)

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH

Do NOT attempt to convert step-opening models

(SV9540P/SV9542P; SV9640P/SV9642P). Always

change the main and pilot burner orifices when

converting from natural to LP gas or from LP to

natural gas. Follow appliance manufacturer

specifications and instructions carefully to assure

proper appliance conversion.

Ignition system controls are factory-set for natural (and

manufactured) or LP gas. Do not attempt to use an ignition

system control set for natural (manufactured) gas on LP

gas, or an ignition system control set for LP gas on natural

(manufactured) gas.

Ignition system controls with standard or slow opening

regulators (SV9540M,H; SV9640M,H) can be converted

from one gas to the other with a conversion kit (ordered

separately). Order part no. 393691 to convert from natural

(manufactured) to LP gas; order part no. 394588 to

convert from LP to natural (manufactured) gas.

IMPORTANT

Ignition system controls with step-opening

regulators (SV9540P; SV9640P) CANNOT be

field-converted to LP or natural gas.

69-10593

SV9540; SV9640 SmartValve™ SYSTEM CONTROLS

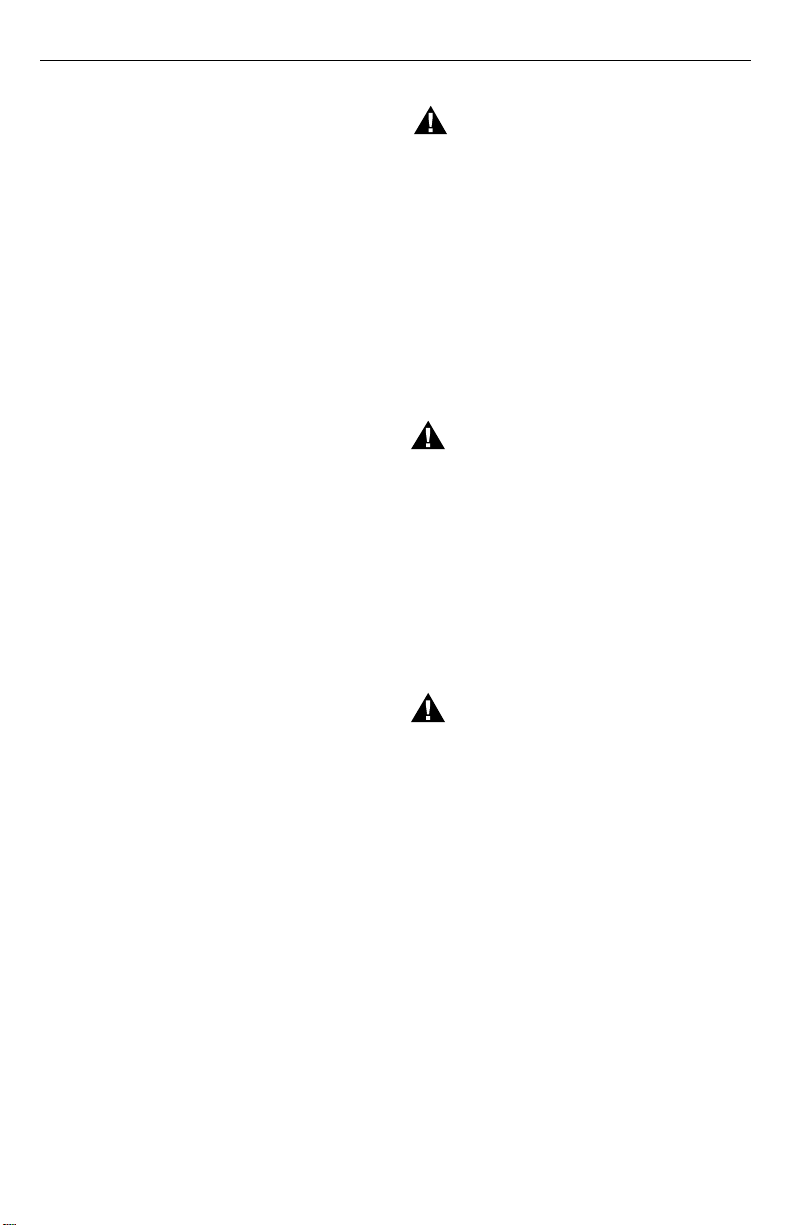

Install Adapters To Control

If adapters are being installed on the control, mount them

as follows:

Flanges

1. Choose the appropriate flange for your application.

2. Remove the seal over the ignition system control

inlet or outlet.

3. Make sure that the O-ring is fitted in the groove of

the flange. If the O-ring is not attached or missing,

do not use the flange.

4. With the O-ring facing the ignition system control,

align the screw holes on the ignition system control

with the holes in the flange. Insert and tighten the

screws provided with the flange. See Fig. 1. Tighten

the screws to 25 inch-pounds of torque to provide a

gas-tight seal.

VALVE OUTLET

1

FLANGE

9/64 INCH

HEX

SCREWS

(4)

1 DO NOT USE FLANGES ON 3/4 IN. INLET

AND 3/4 IN. OUTLET MODELS, AND ON

THE 3/4 IN. OUTLET SIDE OF 1/2 IN.

INLET AND 3/4 IN. OUTLET MODELS.

Fig. 1. Firmly fasten flange to valve,

but do not overtighten screws.

Bushings

1. Remove the seal over the ignition system control

inlet or outlet.

2. Apply a moderate amount of good quality pipe

compound to the bushing, leaving two end threads

bare. On an LP installation, use compound resistant

to LP gas. Do not use Teflon tape.

3. Insert the bushing in the ignition system control and

carefully thread the pipe into the bushing until tight.

Complete the instructions below for installing the piping,

installing the control, connecting the pilot tubing and wiring.

Make sure the leak test you perform on the control after

completing the installation includes leak testing the

adapters and screws. If you use a wrench on the valve

after the flanges are installed, use the wrench only on the

flange, not on the control. See Fig. 5.

Location

The SV9540; SV9640 are mounted in the appliance

vestibule on the gas manifold.

IMPORTANT

These ignition system controls are shipped with

protective seals over the inlet and outlet tappings.

Do not remove the seals until ready to connect

the piping.

M12168

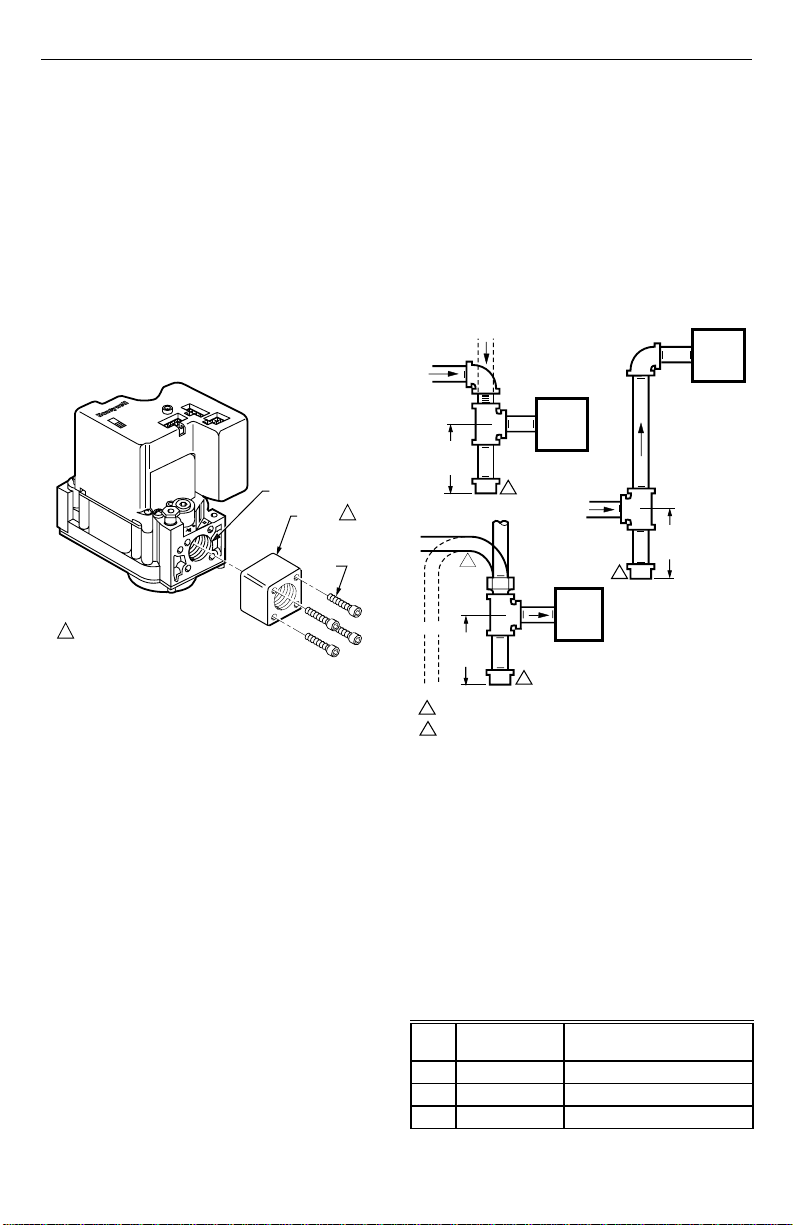

Install Piping to Control

All piping must comply with local codes and ordinances or

with the National Fuel Gas Code (ANSI Z223.1 NFPA No.

54), whichever applies. Tubing installation must comply

with approved standards and practices.

1. Use new, properly reamed pipe free from chips. If

tubing is used, make sure the ends are square,

deburred and clean. All tubing bends must be

smooth and without deformation.

2. Run pipe or tubing to the ignition system control. If

tubing is used, obtain a tube-to-pipe coupling to

connect the tubing to the ignition system control.

3. Install a sediment trap in the supply line to the

ignition system control. See Fig. 2.

DROP

HORIZONTAL

3 IN.

(76 MM)

MINIMUM

HORIZONTAL

RISER

3 IN.

(76 MM)

MINIMUM

ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.

1

CAUTION: SHUT OFF THE MAIN GAS SUPPLY BEFORE REMOVING

2

THE END CAP TO PREVENT GAS FROM FILLING THE WORK AREA.

TEST FOR GAS LEAKAGE WHEN INSTALLATION IS COMPLETE.

PIPED

GAS

SUPPLY

IGNITION

SYSTEM

CONTROL

2

DROP

TUBING

1

GAS

SUPPLY

2

IGNITION

SYSTEM

CONTROL

2

Fig. 2. Sediment trap installation.

Install Control

1. This ignition system control can be mounted 0 to

90 degrees in any direction, including vertically,

from the upright position of the ignition system

control switch.

2. Mount the control so the gas flow is in the direction

of the arrow on the bottom of the ignition system

control.

3. Thread the pipe the amount shown in Table 6 for

insertion into ignition system control or adapters. Do

not thread pipe too far. Valve distortion or malfunction can result if the pipe is inserted too deeply.

RISER

PIPED

GAS

SUPPLY

3 IN.

(76 MM)

MINIMUM

IGNITION

SYSTEM

CONTROL

M3343A

Table 6. NPT Pipe Thread Length (in.).

Pipe

Size

Thread Pipe

this Amount

Maximum Depth Pipe can

be Inserted into Control

3/8 9/16 3/8

1/2 3/4 1/2

3/4 13/16 3/4

69-1059

4

SV9540; SV9640 SmartValve™ SYSTEM CONTROLS

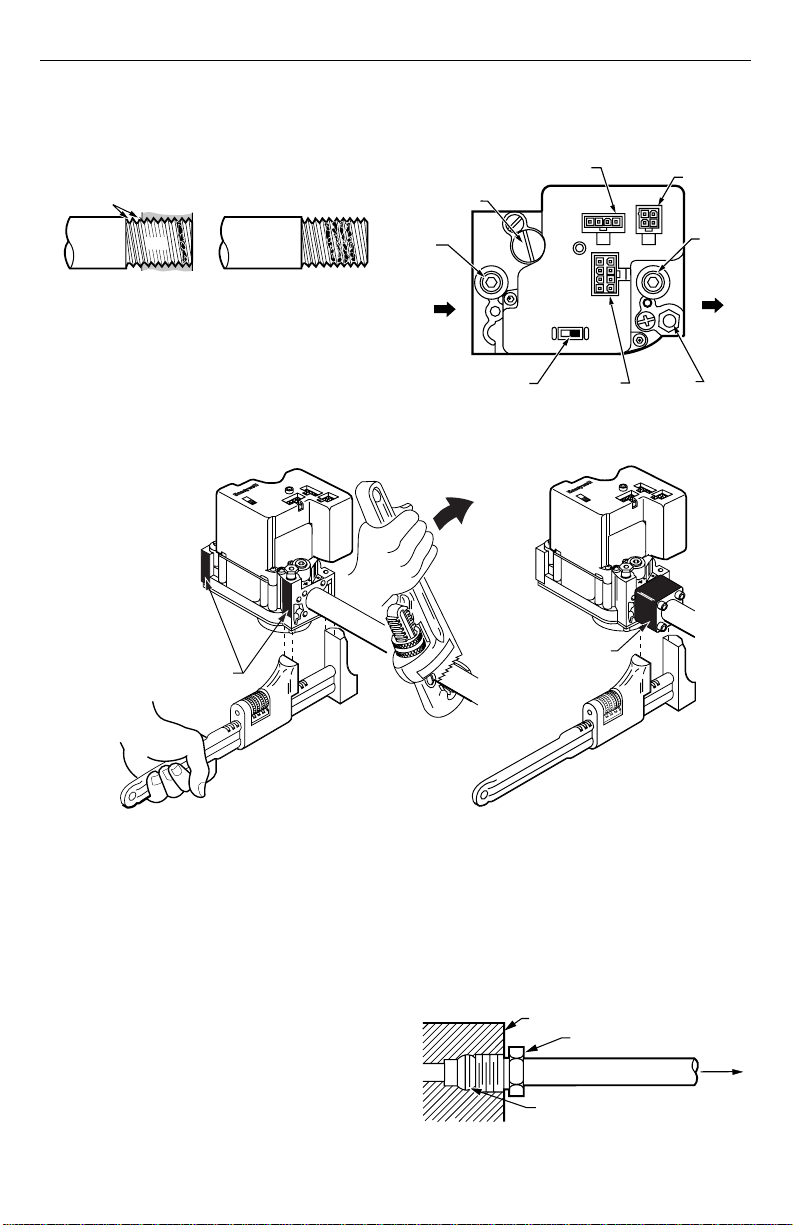

4. Apply a moderate amount of good quality pipe

compound (do not use Teflon tape) only to the pipe,

leaving two end threads bare. On LP installations,

use a compound resistant to LP gas. See Fig. 3.

TWO

IMPERFECT

THREADS

THREAD PIPE THE AMOUNT

SHOWN IN TABLE FOR INSERTION

INTO IGNITION SYSTEM CONTROL

IGNITION

SYSTEM

CONTROL

PIPE

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND ONLY TO PIPE

(LEAVE TWO END THREADS BARE).

M3344

Fig. 3. Use moderate amount of pipe compound.

5. Remove the seals over the ignition system control

inlet and outlet, if necessary.

6. Connect the pipe to the ignition system control inlet

and outlet. Use a wrench on the square ends of the

ignition system control. If a flange is used, place the

WHEN FLANGE IS NOT USED

APPLY WRENCH FROM TOP OR

BOTTOM OF IGNITION SYSTEM

CONTROL TO EITHER SHADED AREA

wrench on the flange rather than on the ignition

system control. Refer to Fig. 4 and 5.

IGNITER

PRESSURE REGULATOR

ADJUSTMENT (UNDER

CAP SCREW)

INLET

PRESSURE

TAP

INLET

IGNITION SYSTEM

CONTROL SWITCH

CONNECTOR

OFF

CONTROLS

CONNECTOR

C2

C1

ON

Fig. 4. Top view of ignition system control.

WHEN FLANGE IS USED

APPLY WRENCH

TO FLANGE ONLY

C3

PILOT

OUTLET

LINE VOL TAGE

CONNECTOR

OUTLET

PRESSURE

TAP

OUTLET

M15045

Fig. 5. Proper use of wrench on ignition system control with and without flanges.

Connect Pilot Gas Tubing

1. Cut tubing to the desired length and bend as

necessary for routing to the pilot burner. Do not

make sharp bends or deform the tubing. Do not

bend the tubing at the ignition system control after

the compression nut is tightened, because this can

result in gas leakage at the connection.

2. Square off and remove burrs from the end of

the tubing.

3. Unscrew the brass compression fitting from the pilot

outlet (Fig. 4). Slip the fitting over the tubing and

slide out of the way. See Fig. 6

4. Push the tubing into the pilot gas tapping on the

outlet end of the control until it bottoms. While

holding the tubing all the way in, slide the fitting into

place and engage the threads—turn until finger tight.

Then tighten one more turn with a wrench. Do not

overtighten.

M12169

5. Connect the other end of the tubing to the pilot

burner according to the instructions supplied with

Q3450/Q3480.

NOTE: The pilot tubing provides the SmartValve System

flame sense current path. Make sure the

connections are clean and tight for proper

operation.

IGNITION SYSTEM CONTROL

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

FITTING BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

TO PILOT

BURNER

M3346

Fig. 6. Always use new compression fitting.

69-10595

Loading...

Loading...