Honeywell STT850, STT750 Quick Start Guide

STT850/750 SmartLine Temperature Transmitter

Quick Start Guide

This document provides descriptions

Figure 17: Fieldbus Write Protect ............................................................. 5

adjustments to the transmitter.

Figure 3 - Pipe Mount, Vertical

34-TT-25-04, Revision 9, November 2020

and procedures for the Quick

Installation of Honeywell’s family of

SmartLine Temperature Transmitters.

The SmartLine Temperature

Transmitter is available in a variety of

models for measuring Ohms, mV and

temperature from RTD’s and

thermocouples.

For full details refer to the man uals

listed below for Protocols, User

Interface (HMI) Operation, Install atio n,

Configuration, Calib ration,

Maintenance, Parts, Safety and

Approvals etc. including options.

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

Copyrights, Notices and

Trademarks

Copyright 2020 by Honeywell

Revision 9, November 2020

Trademarks

SFC, SmartLine, STT850 are

U.S. registered trademarks of

Honeywell Inc.

HART® and FOUNDATION

Trademarks of FieldComm

Group™

™

URL ........................................................................................................... 1

Note ........................................................................................................... 1

Installation ................................................................................................. 1

Features and options ................................................................................ 1

Mounting the Transmitter .......................................................................... 1

Bracket Mounting ................................................................................ 2

Optional Mounting Bracket ................................................................. 2

Conduit Entry Plugs and Adapters ............................................................ 2

Wiring Connections and Power Up ........................................................... 2

Wiring Variations ................................................................................. 3

Input Sensor Wiring ............................................................................ 3

Digital Output Wiring ........................................................................... 4

Setting Failsafe Direction and Write Protect Jumpers ........................ 4

Write Protect Jumper on Fo un dati on Fieldbus (FF) ................................. 5

Figure 1 – Electronics Housing Components ........................................... 1

Figure 2 –STT with adapter housing - Horizontal Wall Mounting ............. 1

Figure 3 - Pipe Mount, Vertical ................................................................. 1

Figure 4 - Pipe Mount wit h adapter housing - Horizontal & Vertical ......... 2

Figure 5: Flat and Angle Mounting Brackets secured to Horizontal or

Vertical Pipe .............................................................................................. 2

Figure 6: Electronic Housing Conduit Entries ........................................... 2

Figure 7: HART and DE Transmitter Operating Ranges .......................... 2

Figure 8: Transmitter 9-Screw Terminal Board and Grounding Screw .... 3

Figure 9: HART/DE/FF Single Input Wiring Diagram ............................... 3

Figure 10: DE Dual Input Wiring Diagram ................................................ 3

Figure 11: HART/FF – Dual Input Wiring Diagram ................................... 3

Figure 12: HART/FF Dual Input Wiring Diagram, mixed sensors ............ 3

Figure 13: Digital Output Connections for mA Load (HART only) ............ 4

Figure 14: Digital Output Connections for PLC Counting Input (HART

only) ........................................................................................................... 4

Figure 15: Jumper Location HART/DE ..................................................... 4

Figure 16: Jumper Settings ....................................................................... 4

Table of Contents

Figures

Note

This Quick Start Guide is for both STT850 and STT750 transmitters.

Please note the fol l o wing do not apply to th e STT750: Foundation

Fieldbus, DE, Dual Inputs, Advanced Display, Advanced Diagnostic,

MID and Marine approvals.

I

nstallation

Evaluate the site selected for the Transmitter installation with respect to the process

system design specifications and Honeywell’s published performance characteristics

for your particular model.

Temperature extremes can affect display quality. The display can become unreadable

at temperature extremes; however, this is only a temporary condition. The display will

again be readable when temperatures return to within operable limits.

The display will show power up message as "SmartLine Temperature Transmitter”. If

there are any critical fault messages on the display, then refer to the STT850

Temperature transmitter user's manual (34-TT-25-03) document for recommended

corrective actions and different screen formats

Features and options

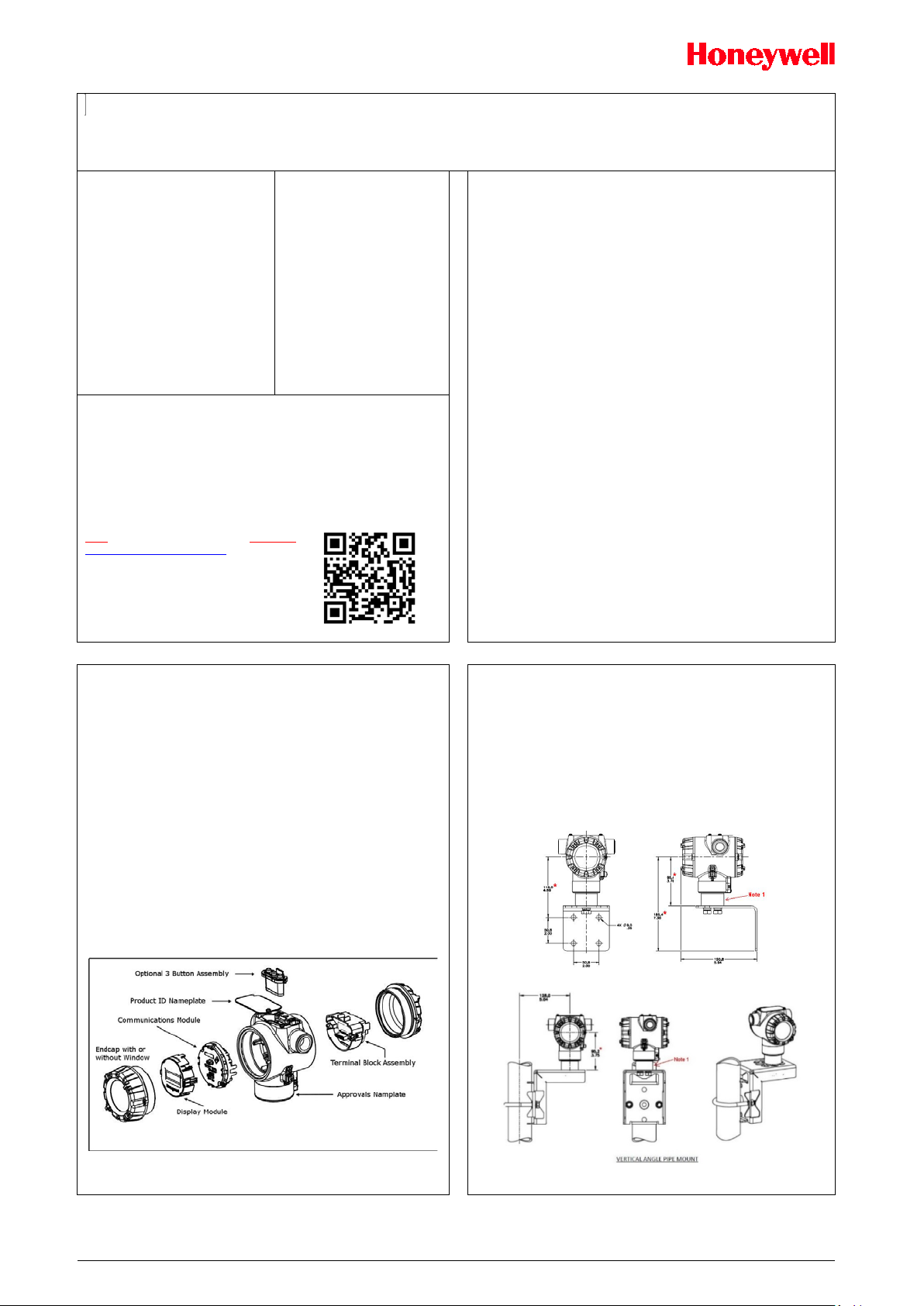

The STT850 and STT750 are packaged in one major assembly: the Electronics

Housing.

The elements in the Electronic Housing are connected to the process sensors,

measure the process variables, respond to setup commands and execute the

software and protocol for the different temperature measurement types. Figure 1

shows the assemblies in the Electronics Housing with available options.

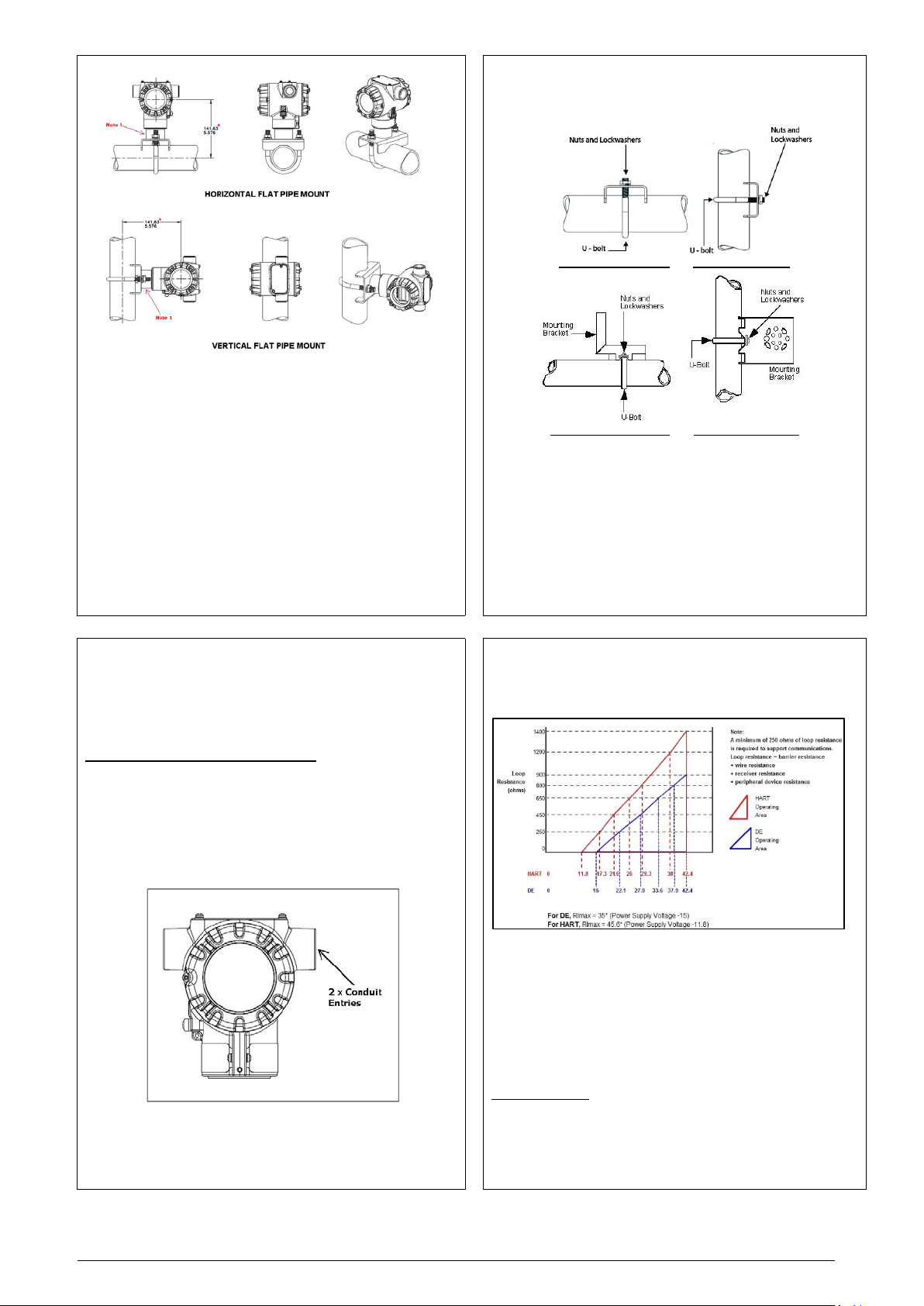

Mounting the Transmitter

Transmitter models can be attached to a two-inch (50 millimeter) vertical or

horizontal pipe using Honeywell’s optional angle; alternately you can use your own

bracket.

Honeywell’s optional wall mounting bracket is also shown below:

For Housing with Adaptor refer to Honeywell drawings 50095917 (Pipe mount) and

50095918 (Wall mount) for detailed mounting specifications.

For Housing without adaptor refer to Honeywell drawings 32306827 (No-Adaptor,

Pipe mount) and 32306828 (No-adaptor, Wall mount).

TRANSMITTER ENCLOSURE CAN BE ROTATED A TOTAL OF 90O

FROM THE STANDARD MOUNTING POSITION

Figure 2 –STT with adapter housing - Horizontal Wall Mounting

An optional 3-button assembly is located under the nameplate and provides a user

interface and operation capability without opening the transmitter to set up and make

Figure 1 – Electronics Housing Components

STT850/750 Quick Start Guide 1

Optional Mounting Bracket

Position bracket on 2-inch (50.8 mm) and install “U” bolt around pipe and through holes

in bracket. Secure with nuts and lock washers provided. Optional mounting bracket, see

Figure 5

HORIZONTAL FLAT PIPE VERTICAL FLAT PIPE

Figure 4 - Pipe Mount with adapter housing - Horizontal & Vertical

Bracket Mounting

If you are using an optional brack et, s ta rt wit h Ste p 1.

1. Align the two mounting holes in the transmitter with the two slots

in the mounting bracket and assemble the (2) M8 hex cap

screws, (2) lockwashers and (2) flat washers provided. Rotate

transmitter assembl y to the desi re d pos it ion an d torq ue the M8

hex cap screws to 27,0 Nm/20,0 Lb-ft maximum.

2. Pipe Mount Option: Refer to Figure 5. Position the bracket on a 2-

inch (50.8 mm) horizontal or ve rt ical pip e, and i nst al l a “U” bol t

around the pipe and through the holes in the bracket. Secure the

bracket with the nuts, flat was he rs and l ock wash ers pr ov id ed.

3. Wall Mount Option: Position the bracket on the mounting surface

at the desired location and secure the bracket to the mounting

surface using the appropriate hardware (Wall mounting hardware

requirements to be determined and supplied by the end user).

Existing mounting bracket, see Fi gu re 5

Conduit Entry Plugs and Adapters

Procedures

It is the User/Installer’s responsibility to install the Transmitters in accordance

with national and local code requirements. Conduit entry plugs and adapters

shall be suitable for the environment, shall be certified for the hazardous

location when required and acceptable to the authority having jurisdiction for

the plant.

CONDUIT ENTRY PRECAUTIONARY NOTICE

THE CONDUIT/CABLE GLAND ENTRIES OF THIS PRODUCT ARE

SUPPLIED WITH PLASTIC DUST CAPS WHICH ARE NOT TO BE USED IN

SERVICE.

IT IS THE USER’S RESPONSIBILITY TO REPLACE THE DUST CAPS

WITH CABLE GLANDS, ADAPTORS AND/OR BLANKING PLUGS WHICH

ARE SUITABLE FOR THE ENVIRONMENT INTO WHICH THIS PRODUCT

WILL BE INSTALLED. THIS INCLUDES ENSURING COMPLIANCE WITH

HAZARDOUS LOCATION REQUIREMENTS AND REQUIREMENTS OF

OTHER GOVERNING AUTHORITIES AS APPLICABLE

.

Figure 5: Flat and Angle Mounting Brackets secured to Horizontal or Vertical Pipe

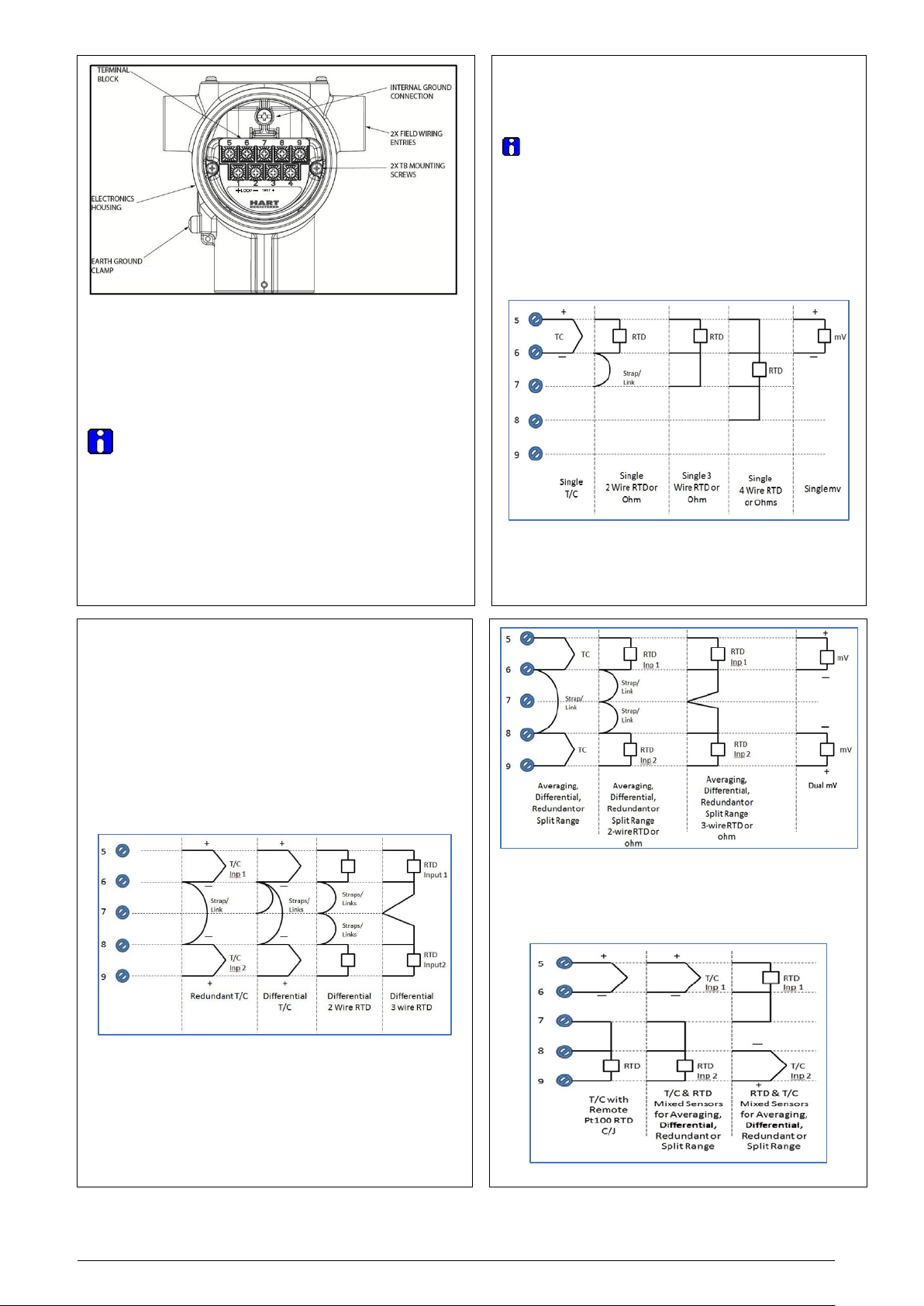

Wiring Connections and Power Up

Summary

The transmitter is designed to operate in a two-wire power/current loop with

loop resistance and power supply voltage within the HART and DE

operating ranges shown in Figure 7.

HORIZONTAL ANGLE PIPE VERTICAL ANGLE PIPE

Note. No plugs come installed in the housings. All housings come with

temporary plastic dust protectors (red) installed and are not certified for use

in any installation.

Figure 6: Electronic Hous ing Conduit Entries

*Only HART available for STT750 transmitter

For DE operation, add 3.0V to these values.

Loop wiring is connected to the Transmitter by simply attaching the positive

(+) and negative (–) loop wires to the positive (+) and negative (–) terminals

on the transmitter terminal block in the Electronics Housing, shown in

Figure 8.

Grounding Details:

Connect the Loop Power wiring shield to earth ground only at the power

supply end.

Note: The transm i tte r is not pol arity-sensitive.

Figure 7: HART* and DE Transmitter Operating Ranges

STT850/750 Quick Start Guide 2

250 ohms of resistance (typically within the barriers) needed for digital communications.

Wiring Variations

Remote C/J and Mixed Sensors Connections

The above procedures are used to connect power to a Transmitter. For loop wiring and

external wiring, detailed drawings are provided for Transmitter installation in

non-intrinsically safe areas and for intrinsically safe loops in hazardous area locations.

This procedure shows the steps for connecting power to the transmitter.

Wiring must comply with local codes, regulations and ordinances. Grounding

may be required to meet various approval body certification, for example CE

conformity. Refer to the SmartLine Transmitter User’s Manual 34-TT-25-03

(STT850) or 34-TT-25-13 (STT750) for details.

NOTE: After wiring, torque the screws to around 4 to 5(lb-in). Maximum should not exceed 1.1 Nm (10 lb-in). Don’t pull the wires after connecting to the screw terminals.

Input Sensor Wiring

Connect the input sensors as shown in Figures below:

Figure 9: HART/DE/FF Single Input Wiring Diagram.

*Only HART available for STT750 transmitter

Figure 8: Transmitter 9-Screw Terminal Board and Grounding Screw

As shown in Figure 8, each Transmitter has an internal terminal to connect it to earth

ground. Connect sensor shield to the internal ground screw. The ground terminal can be

added to the outside of the Electronics Housing. Grounding the Transmitter for proper

operation is required, as doing so tends to minimize the possible effects of noise on the

output signal and affords protection against lightning and static discharge. An optional

lightning terminal block can be installed in place of the non-lightning terminal block for

Transmitters that will be installed in areas that are highly susceptible to lightning strikes. As

noted above, the Loop Power wiring shield should only be connected to earth ground at the

power supply end.

Wiring must comply with local codes, regulations and ordinances. Grounding may

be required to meet various approval body certification,

for example CE conformity. Refer to Appendix A of this document for details.

Note: Terminal #3 is for loop test and is not applicable for Fieldbus option.

Terminal #4 is for Digital Output and is not applicable for Fieldbus option.

Foundation Fieldbus not applicable to STT750

For HART and DE the Transmitter is designed to operate in a two-wire power/current loop

with loop resistance and power supply voltage within the operating range; see Figure 7

With an optional remote meter, the voltage drop for this must be added to the basic power

supply voltage requirements to determine the required Transmitter voltage and maximum

loop resistance. Additional consideration is required when selecting intrinsic safety barriers

to ensure that they will supply at least minimum Transmitter voltage, including the required

Figure 9: HART*/DE/FF Single Input Wiring Diagram

RTD Thermocouple, mV and Ohm Connections

Figure 10: DE Dual Input Wiring Diagram

• Resistance temperature detector (RTD) measurements use the 3 or 4 wire

approach.

• Dual-input units wired for a 4-wire RTD will automatically disable Input 2.

• DE dual input device needs to be power cycled whenever sensor input wiring

changed

• Supports dual thermocouple or RTD inputs for differential temperature

measurement

• Supports dual thermocouple sensor inputs for redundant sensor operation.

• To operate DE dual input device, it is required to connect both sensor inputs

• To minimize common noise problems in the application, a strap/jumper

For differential T/C operation on DE Models, a second strap/jumper should be wired

between terminals 6 and 7. Do not install this strap for Non-DE models. The output for

differential operation is calculated as T/C 1 - T/C 2.

should be wired between terminals 6 and 8.

Thermocouple and RTD Connections (not applicable to single input sensor)

Figure 10: DE Dual Input Wiring Diagram

DE not applicable to STT750 transmitter

STT850/750 Quick Start Guide 3

Figure 11: HART/FF – Dual Input Wiring Diagram

RTD Thermocouple, mV and Ohm Connections

Figure 12: HART/FF Dual Input Wiring Diagram

• For External C/J compensation, the first input is a thermocouple

type and the second input is a 3-wire PT100 ohm RTD

• The STT850 can have different sensor types on its inputs for split

range or averaging applications

Figure 12: HART/FF Dual Input Wiring Diagram, mixed sensors

Loading...

Loading...