Page 1

STT750 Series HART Option

User’s Manual

34-TT-25-15

Revision 3.0

November 2020

Honeywell Process Solutions

Page 2

Copyrights, No tices and Trademarks

© Copyright 2020 by Honeywell, Inc.

Revision 3, November 2020

While the information in this document is presented in good faith and believed to be

accurate, Honeywell disclaims any implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in the written

agreement with and for its customers. In no event is Honeywell liable to anyone for any

indirect, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Honeywell, TDC 3000, SFC, SmartLine, PlantScape, Experion PKS, and TotalPlant are

registered trademarks of Honeywell International Inc. Other brand or product names and

service marks are the property of their respective owners.

Honeywell Process Solutions

2101 City West Blvd

Houston, TX 77042

Page ii STT750 Series HART/DE Option User’s Manual Revision 3.0

Page 3

About This Manual

This manual provides the details of programming Honeywell STT750 SmartLine Temperature

Transmitters for applications involving HART versions 5, 6, and 7 communication protocols. For

installation, wiring, and maintenance information

refer to the STT750 SmartLine Temperature Transmitter User Manual, document number

#34-TT-25-13.

The configuration of your transmitter depends on the mode of operation and the options selected

for it with respect to operating controls, displays and mechanical installation. Details for

operations involving the Honeyw ell Multi-Communication MC Toolkit (MCT404) are provided

only to the extent necessary to accomplish the tasks-at-hand. Refer to the associated MC Toolkit

User Manual, document # 34-ST-25-50 (MCT404) for complete details. The “Reference” section

in the front matter of this manual lists document titles and numbers.

The STT750 SmartLine Temperature Transmitter can be digitally integrated with one of two

systems:

• Experion PKS: you will need to supplement the information in this document with the data and

procedures in the Experion Knowledge Builder.

• Honeywell’s Tot alPlant Solutions (TPS): you will need to supplement the information in this

document with the data in the PM/APM SmartLine Tra nsmitte r Integration Manual, which is

supplied with the TDC 3000 book set. (TPS is the evolution of the TDC 3000).

Release Information

STT750 Series HART Option User Manual, Document # 34-TT-25-15 (this document)

Rev. 1.0, August 2015, 1

Rev. 2.0, March 2016 CVD, Soft DO, NE89 and RTD Cu10,

RTD Ni120 input details added

Rev. 3.0 November 2020 Series 2 updates

st

Release

References

The following list identifies publications that may contain information relevant to the information

in this document.

STT750 SmartLine Temperature Transmitter Quick Start Installation Guide, # 34-TT-25-14

SmartLine Temperature Transmitter w/ HART Comms Safety Manual, 34-TT-25-05

STT750 SmartLine Temperature Transmitter User Manual, # 34-TT-25-13

MC Toolkit User Manual, Document # 34-ST-25-20

PM/APM SmartLine Transmitter Integration Manual, # PM 12-410

STT750 Series Temperature, Transmitter, Agency IS Control Drawing, 50091227

MC Toolkit Modem Code Download Instruction Manual, Document # 34-ST-25-33

Revision 3.0 STT750 Series HART Option User’s Manual Page iii

Page 4

United States and

Canada

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

Global Email

Support

Honeywell Process

Solutions

Patent Notice

The Honeywell STT750 SmartLine Tempera tu re Tran smitter family is covered by one or more of the

following U. S. Patents: 5,485,753; 5,811,690; 6,041,659; 6,055,633; 7,786,878; 8,073,098 ; and other

patents pending.

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, see back page or refer to the

appropriate Honeywell Solution Support web site:

Honeywell Corporate www.honeywellprocess.com

Honeywell Process Solutions https://www.honeywellprocess.com/smartline-temperature/

Training Classes http://www.automationccollege.com

Telephone and Email Contacts

Area Organization Phone Number

Honeywell Inc.

ask-ssc@honeywell.com

Page iv STT750 Series HART Option User’s Manual Revision 3.0

Page 5

Contents

1 STT750 Physical and Functional Characteristics ........................................................................... 1

1.1 Overview ................................................................................................................................ 1

1.2 Features and Options .............................................................................................................. 1

1.2.1 Physical Characteristics .................................................................................................. 2

1.2.2 Functional Characteristics .............................................................................................. 3

1.3 STT750 SmartLine Transmitter NamePlate ........................................................................... 3

1.4 Safety Certification Information ............................................................................................. 3

1.5 Transmitter Adjustments ........................................................................................................ 3

1.6 Local Display Options ............................................................................................................ 4

1.7 Optional 3-Button Assembly .................................................................................................. 5

2 Communication Modes .................................................................................................................. 7

2.1 Overview ................................................................................................................................ 7

2.2 HART Mode Communication ................................................................................................ 7

3 Configuration Tools and Interfaces ................................................................................................ 9

3.1 Overview ................................................................................................................................ 9

3.2 Pre-requisites .......................................................................................................................... 9

3.3 Application Design, Installation, Startup, and Operation ....................................................... 9

3.3.1 Organization ................................................................................................................... 9

3.4 MC Toolkit Participation ...................................................................................................... 10

3.4.1 MC Toolkit Software Applications .............................................................................. 10

3.4.2 Configuration Databases .............................................................................................. 10

3.4.3 Configuration ................................................................................................................ 10

3.4.4 MC Toolkit–Transmitter Electrical/Signal Connections .............................................. 11

4 HART Transm itte r Co n figuration ................................................................................................ 13

4.1 Overview .............................................................................................................................. 13

4.1.1 Personnel Requirements ............................................................................................... 13

4.2 Overview of FDC Homepage ............................................................................................... 14

4.2.1 Settings ......................................................................................................................... 15

4.2.2 Manage DDs ................................................................................................................. 15

4.2.3 Online configuration ..................................................................................................... 18

4.2.4 Offline configuration .................................................................................................... 18

4.2.5 Online Configuration Overview ................................................................................... 18

4.2.6 Overview of Device Homepage ................................................................................... 19

4.2.7 Tabs on the Device Home page .................................................................................... 20

4.2.8 Using FDC for various device operations .................................................................... 22

4.2.9 Device Configurat ion and P aram eter Descrip ti ons ...................................................... 24

4.2.10 Procedure to Enter the Transm itter Tag ....................................................................... 39

4.2.11 Selecting the Process Variable (PV) Unit of Temperature Measurement .................... 39

4.2.12 Setting PV URV, and LRV Range Values ................................................................... 40

4.2.13 Setting Range Values for Applied Temperature ........................................................... 41

4.2.14 Saving device history ................................................................................................... 41

4.2.15 Exporting device history records to FDM .................................................................... 43

4.2.16 Exporting device history records to Documint ............................................................. 44

4.2.17 Custom Views .............................................................................................................. 44

4.2.18 Offline Configuration ................................................................................................... 46

Revision 3.0 STT750 Series HART Option User’s Manual Page v

Page 6

5 HART Calibration ........................................................................................................................ 50

5.1 About This Section .............................................................................................................. 50

5.1.1 About Calibration ......................................................................................................... 50

5.1.2 Input Calibration Procedure ......................................................................................... 50

5.1.3 Correct Input at URV ................................................................................................... 53

5.1.4 Equipment Required .................................................................................................... 55

5.2 Analog Output Signal Calibration ........................................................................................ 56

5.3 Calibrating Analog Inputs .................................................................................................... 57

5.3.1 Calibrate (Correct) Sensor Input at Lower Calibration Point (LRV Corrects) ............ 58

5.3.2 Calibrate (Correct) Sensor Input at Upper Calibration Point (URV Corrects) ............ 59

5.3.3 Resetting Calibration.................................................................................................... 59

5.3.4 STT750 Calibration Records ....................................................................................... 60

6 HART Advanced Diagnostics ...................................................................................................... 61

6.1 About This Section .............................................................................................................. 61

6.2 Advanced Diagnostics.......................................................................................................... 61

6.2.1 Installation and Device Life ......................................................................................... 62

6.2.2 PV Tracking Diagnost ics ............................................................................................. 64

6.2.3 SV Tracking ................................................................................................................. 66

6.2.4 Comm Board ET Tracking Diagnostics ....................................................................... 67

6.2.5 Sensor Board ET Tracking Diagnostics ....................................................................... 69

6.2.6 Operating Voltage Diagnostics .................................................................................... 69

6.2.7 Sensor Supply Voltage (AVDD) Tracking Diagnostics .............................................. 70

6.2.8 Sensor CPU Temperature Tracking Diagnostics ......................................................... 70

6.2.9 Power Cycles ............................................................................................................... 72

7 Troubleshooting and Maintenance ............................................................................................... 73

7.1 HART Diagnostic Message s ................................................................................................ 73

7.2 HART Diagnostic Details .................................................................................................... 74

8 Using DTMs ................................................................................................................................. 75

8.1 Introduction .......................................................................................................................... 75

8.2 Components ......................................................................................................................... 75

8.3 Downloads ........................................................................................................................... 75

8.4 Procedure to Install and Run the DTM ................................................................................ 75

8.5 STT750 Online Parameterization ......................................................................................... 76

8.5.1 Key Parameters ............................................................................................................ 76

8.6 Basic Setup Page .................................................................................................................. 77

8.6.1 Device Information: ..................................................................................................... 77

8.7 STT750 Offline Parameterization ........................................................................................ 78

9 HART DD Binary File Format Compatibility Matrix ................................................................. 79

Glossary ............................................................................................................................................... 80

Page vi STT750 Series HART Option User’s Manual Revision 3.0

Page 7

List of Figures

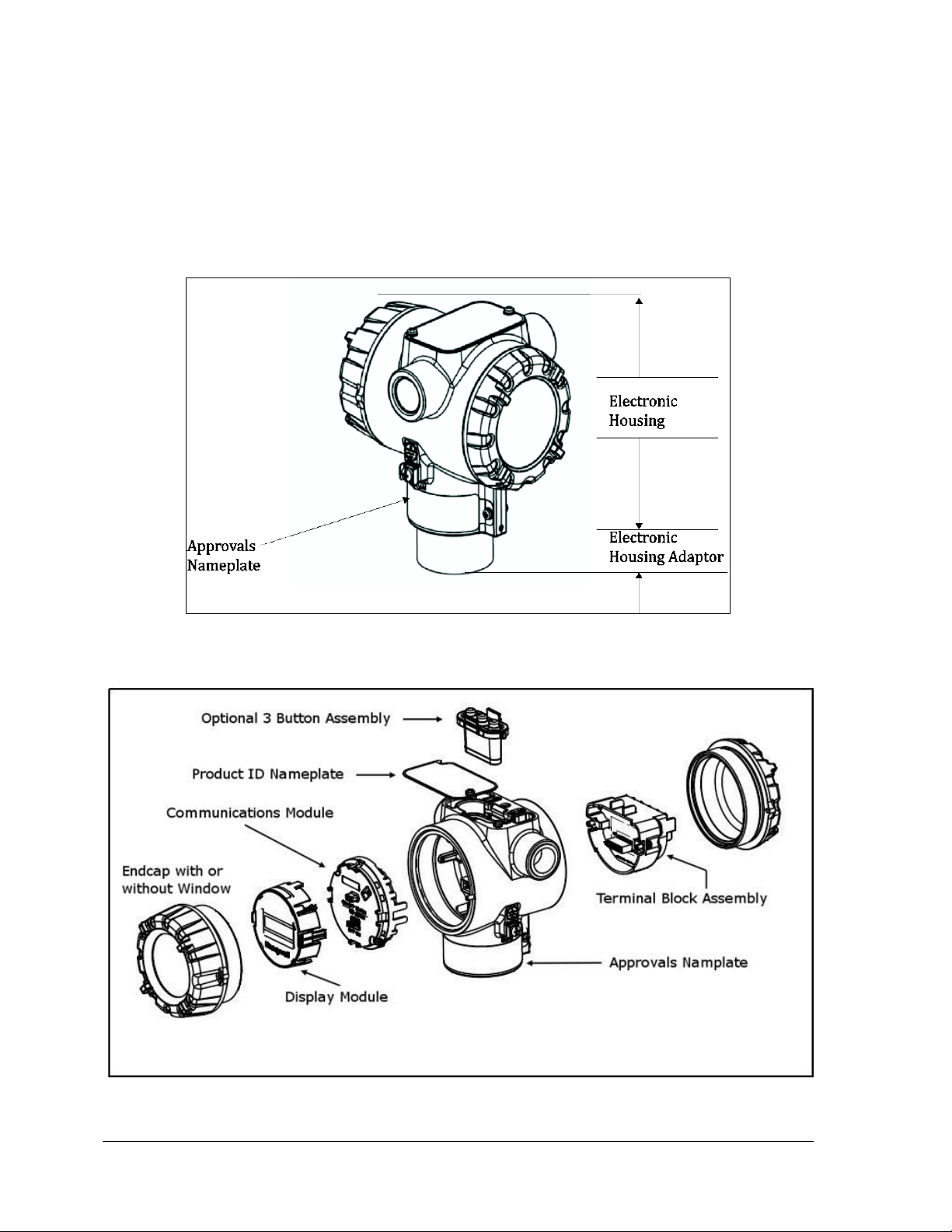

Figure 1 – STT750 Major Assem blies ................................................................................................... 2

Figure 2 – Electronics Housing Components ......................................................................................... 2

Figure 3 –Typical STT750 Nameplate ................................................................................................... 3

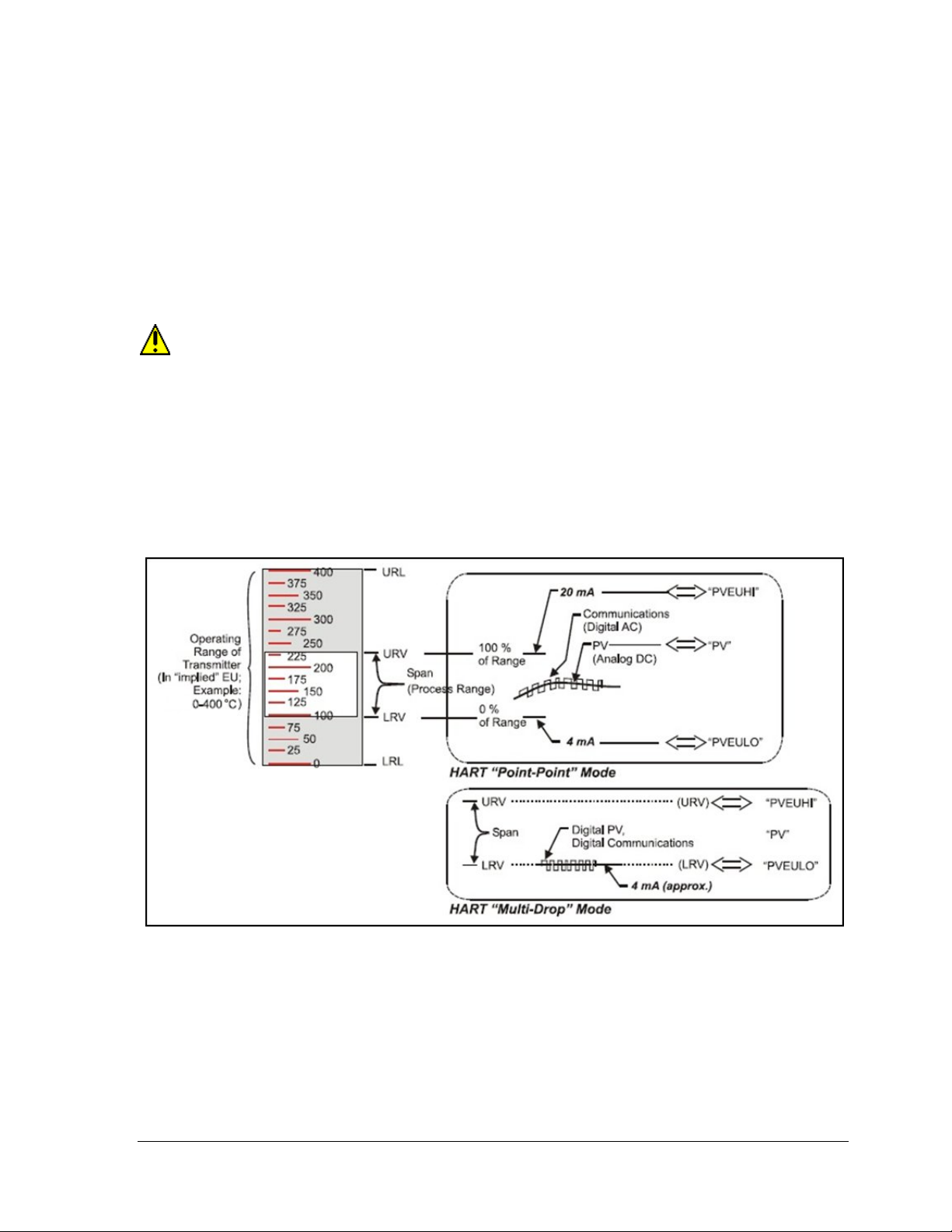

Figure 4 – HART Point-to-Point and Multi-drop Value Scaling ........................................................... 7

Figure 5 – MC Toolkit-Transmitter Electrical/Signal Connections ..................................................... 11

Figure 6 – FDC Homepage................................................................................................................... 14

Figure 7 – Device Homepage ............................................................................................................... 19

List of Tables

Table 1 – Features and Options .............................................................................................................. 1

Table 2 – Available Display Characteristics .......................................................................................... 4

Table 3 – User Manual Related Topics .................................................................................................. 9

Table 4 – FDC homepage elements ...................................................................................................... 14

Table 5 – Device health status .............................................................................................................. 19

Table 6 – HART Transmitter Param eters ............................................................................................. 24

Table 7 – Tamper Reporting Logic Implementation with Write Protect .............................................. 38

Table 8 – Calibration Records .............................................................................................................. 60

Table 9 – Viewing Advanced Diagnostics ........................................................................................... 61

Table 10 – Maximum PV Tracking ...................................................................................................... 64

Table 11 – Minimum PV Tracking ...................................................................................................... 65

Table 12 – Maximum SV Tracking ...................................................................................................... 66

Table 13 – Minimum SV Tracking ...................................................................................................... 66

Table 14 – Maximum ET Diagnostics .................................................................................................. 67

Table 15 – Minimum ET Diagnostics .................................................................................................. 68

Table 19 – Sensor Board ET Diagnostics ............................................................................................. 69

Table 16 – Operating Voltage Diagnostics........................................................................................... 69

Table 17 – Maximum and Minimum AVDD Tracking ........................................................................ 70

Table 18 – Maximum Sensor CPU Temperature Tracking .................................................................. 70

Table 19 – Minimum Sensor CPU Temperature Tracking ................................................................... 72

Table 20 – Power Cycles ...................................................................................................................... 72

Table 21 – HART Diagnostic Messages .............................................................................................. 73

Table 22 – HART Critical and Non-Critical Diagnostic Details .......................................................... 74

Revision 3.0 STT750 Series HART Option User’s Manual Page vii

Page 8

This page has been intentionally left blank

Page viii STT750 Series HART Option User’s Manual Revision 3.0

Page 9

Communication Protoco ls

HART

Human-Machine Interface (HMI) Options

Basic Digital Display

Three-button programming (optional)

Basic display language: English only

Calibration

Single

Approvals (See Appendix C for details.)

ATEX, CSA, FM, IECx, NEPSI

Mounting Brackets

Angle/flat carbon steel/304 stainless steel, Marine

304 stainless steel

Integration Tools

Experion, FDM and DTM

1 STT750 Physical an d Functional Characteristics

1.1 Overview

This section is an introduction to the physical and functional characteristics of Honeywell’s family of

STT750 SmartLine Temperature Tr ansm itt er s.

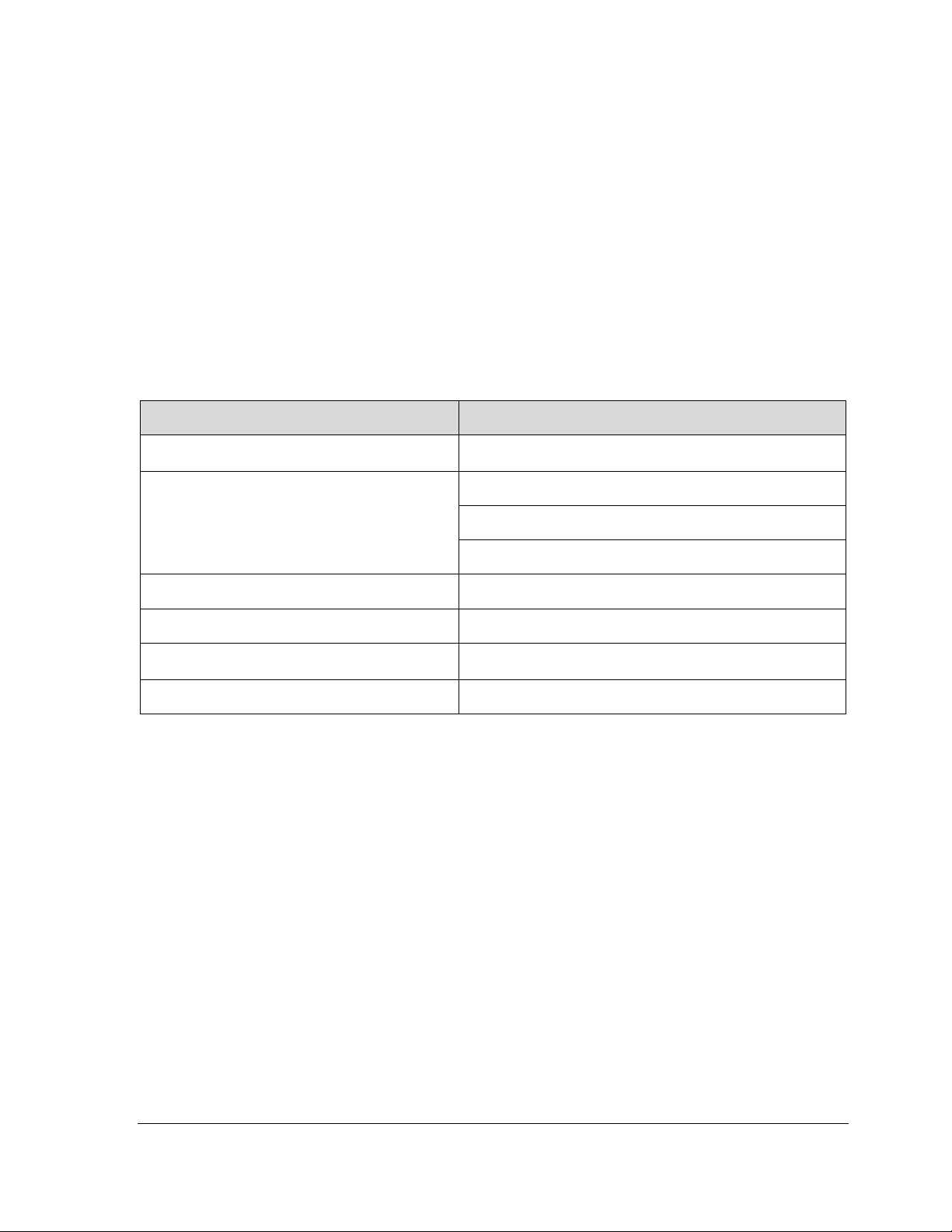

1.2 Features and Options

The STT750 SmartLine Temperature Transmitter is available in a variety of models for measuring

Thermocouples, RTD, Millivolts, and Volt or ohm sensor types. Table 1 lists the protocols, human

machine interface (HMI), materials, approvals, and mounting bracket options for the STT750.

Table 1 – Features and Options

Feature/Option Standard/Available Options

(Basic Display)

Revision 3.0 STT750 Series HART Option User’s Manual Page 1

Page 10

1.2.1 Physical Characteristics

As shown in Figure 1, the STT750 is packaged in one major assembly: The Electronics Housing. The

elements in the Electronic Housing are connected to the process sensors, measure the process

variables, respond to setup commands and execute the software and protocol for the different

temperature measurement types. Figure 2 shows the assemblies in the Electronics Housing with

available options.

Figure 1 – STT750 Major Assemblies

Figure 2 – Electronics Housing Components

Page 2 STT750 Series HART Option User’s Manual Revision 3.0

Page 11

• T = Temperature

1.2.2 Functional Characteristics

The transmitter measures process temperature and outputs a signal proportional to the measured

process variable (PV). Available output communication protocols include analog 4 to 20 mA and

HART protocol.

An optional 3-button assembly is available to set up and m ak e adjustm ents to the transm itter. In addition,

a Honeywell Multi-Communication MC Toolkit (MCT404) (not supplied with the transmitter) can

facilitate setup and adjustment procedures in the case of HART.

1.3 STT750 SmartLine Transmitter NamePlate

The Transmitter nameplate mounted on the top of the Electronics Housing (see Figure 2) lists the

model number, physical configuration, electronics options, accessories, certifications, and

manufacturing specialties. Figure 3 is an example of a typical STT750 temperature Name plate. The

model number format consists of a Key Number with several table selections.

Figure 3 –Typical STT750 Nameplate

You can readily identify the series and basic transmitter type from the key number. The letter in the

third digit represents one of these basic transmitter types:

For a complete selection breakdown, refer to the appropriate Specification and Model Selection Guide

provided as a separate docum ent.

1.4 Safety Certification Information

An “approvals” name plate is located on the bottom of the Electronics Assembly; see Figure 1 for

exact location. The approvals name plate contains information and service marks that disclose the

transmitter compliance information. Refer to Appendix A in the STT750 SmartLine Transmitters

User’s Manual, document number 34-ST-25-13 for details.

1.5 Transmitter Adjustments

Span adjustments are possible in new generation STT750 SmartLine Temperature Transmitters by

using the optional 3-button assembly located at the top of the Electronic Housing, see Optional 3-

Button Assembly on page 5. However, certain c ap ab il i ties are limited in th e fo l lo w ing configurat ion s :

• Without a display –Span setting only for a HART device.

• With a display – Complete transm itter configuration is possible for a HART device.

Revision 3.0 STT750 Series HART Option User’s Manual Page 3

Page 12

For HART you can also use the Honeywell MC Toolkit or other third-party hand-held to make any

adjustments to an STT750 SmartLine Temperature Transmitter. Alternately, certain adjustments can

be made through the Experion or Universal Station, if the transmitter is digitally integrated with a

Honeywell Experion or TPS system.

.

1.6 Local Display Options

The STT750 Temperature Transmitter has a Basic Digital Display; see Table 2

.

Table 2 – Available Display Characteristics

• Suitable for basic process needs

o

rotation in 90o Increments

Basic Display

• 360

• 8 configurable screens

• 2 lines, 16 characters

• Standard engineering units

• Diagnostic messaging

• Supports optional 3-Butt on c onf igurat ion and calibr at io n

Page 4 STT750 Series HART Option User’s Manual Revision 3.0

Page 13

1.7 Optional 3-Button Assembly

The optional 3-button assembly is located under the nameplate and p rovides the following features:

• Opportunity for immediate reaction with minimal disruptions

• Improved maintenance time

• Potential savings on hand-held units

• Suitable for all environments: hermetically sealed for long life in harsh environments

• Suitable for use in all electrical classifications (flameproof, dustproof, and intrinsically safe)

The 3-button assembly is externally accessible and provides the following capabilities:

• Menu-driven configuration with optional display:

o Using increment, decrement & enter keys

o A comprehensive on screen menu guides the way

o Configure the transmitter

o Configure the display

o Set span

• Zero and span settings without optional display

Revision 3.0 STT750 Series HART Option User’s Manual Page 5

Page 14

This page is left blank intentionally.

Page 6 STT750 Series HART Option User’s Manual Revision 3.0

Page 15

2 Communication Modes

2.1 Overview

The STT750 SmartLine Temperature Transmitter can be configured for operation with HART version

7 communication. This manual addresses the processes to configure and calibrate a transmitter for

HART communication.

2.2 HART Mode Communication

When using MCToolkit (MCT404), but before connecting to a HART transmitter, verify that

the FDC application is used and not the MC Toolkit application.

• Transmitters with HART capability have features that vary among manufacturers and with the

characteristics of specific devices. The FDC software application executing on the MCT404

supports the HART Universal, Common Practice and Device Specific Commands which are

implemented in the Honeywell transmitters.

As indicated in Figure 4, the output of a transmitter co nfig ured for HART protocol includes two

primary modes:

Figure 4 – HART Point-to-Point and Multi-drop Value Scaling

• Point-to-Point Mode, in which one transmitter is connected via a two-conductor, 4-20 mA

current loop to one receiver.

• Multi-Drop Mode, in which several transmitte rs are co nnec ted through a two-conductor

network to a multiplexed receiver device.

Revision 3.0 STT750 Series HART Option User’s Manual Page 7

Page 16

In point-to-point mode, the value of the primary Process Variable (PV) is represented by a 4-20 mA

current loop, almost identical to that of a tr ansm itter operating in analog m ode. You can also have one

device in analog output mode when you are configured as multi-drop. In this case, however, the analog

signal is modulated by Frequency Shift Keying (FSK), using frequencies and current amplitude that do

not affect analog sensing at the receiver. The accuracy of the analog level must be precisely controlled

for accurate sensing. HART communication will not bump process variables.

In multi-drop mode, up to 16 transmitters in HART 5 (addresses 0-15) and up to 64 transmitters in

HART6/7 (addresses 0-63) can exist on the two-conductor network.

Page 8 STT750 Series HART Option User’s Manual Revision 3.0

Page 17

Site evaluation

Startup tasks and procedures

3 Configuration Tools and Interfaces

3.1 Overview

This section describes the tools and interfaces involved in configuring a new STT750 SmartLine

Temperature Transmitter for HART communication operation. The information in this section also

applies to adjusting the configuration of a transmitter that has been in operation and updating one that

is currently in operation.

3.2 Pre-requisites

The information and procedures in this manual are based on the assumption that personnel performing

configuration and calibration tasks are fully qualified and knowledgeable in the use of the Honeywell

MCT404. The name MC Toolkit (MCT404) are used interchangeably as MCT404 is the model name

for the Honeywell MC Toolkit product. Furthermore, we assume that the reader is intimately familiar

with the STT750 family of SmartLine Temperature Transmitters and thoroughly experienced in the

type of process application targeted for transmitter deployment. Therefore, detailed procedures are

supplied only in so far as necessary to ensure satisfactory completion of configuration tasks.

3.3 Application Design, Installation, Startup, and Oper a ti on

The STT750 SmartLine Temperature Transmitters User’s Manual, document number 34-ST-25-13,

provides the details for application design, installation, and startup; see Table 3 for topics.

Table 3 – User Manual Related Topics

STT750 SmartLine Temperature Transmitters Users Manual

Section 2. Application Design Section 3. Installation and Startup Section 4. Operation

Safety and accuracy

Diagnostics messages

Design consideration

Toolkit issues

Display installation concerns

Transmitter mounting & zerocorrection

Wiring

Three-button option

Failsafe (burnout)

direction setup

Monitoring displays

3.3.1 Organization

This information in this section is arranged in the following sequence:

• MC Toolkit participation in STT750 transmitter setup and configuration:

o Physical circuit connection s

o Application components

o Configuration for Analog and HART operation

• STT750 Transmitter

o Basic display

o Health indications

o Ability to be configured and operate in a process system

Revision 3.0 STT750 Series HART Option User’s Manual Page 9

Page 18

3.4 MC Toolkit Participation

Before using the MC Toolkit, be sure that you are aware of the potential consequences of

each procedure, and that you use appropriate safeguards to avoid possible problems. For

example, if the transmitter is an element in a control loop, the loop needs to be put in manual

mode, and alarms and interlocks (i.e., trips) need to be disabled, as appropriate, before starting

a procedure.

3.4.1 MC Toolkit Software Applications

The MC Toolkit has two software applications to work with STT750 SmartLine Temperature

Transmitters:

• Field Device Configurator (FDC). This application is used for configuring, calibrating,

monitoring, and diagnosing HART devices. FDC conforms to the IEC 61804-3 EDDL

(Electronic Data Desc riptio n Lang uage) stan dard specific ation. The FDC application is an open

solution that supports devices with a registered device description (DD) file compatible with

HART Communication Foundation (HCF) requirements.

Details for work in g with the MC Toolkit are provided in the MC Toolkit User Manual, document,

#34-ST-25-50 (MCT404). In subsequent sections of this manual, explicit operating instructions are

provided only in so far as necessary to complete required tasks and procedures.

3.4.2 Configuration Databases

The MC Toolkit is used to establish and/or change selected operating pa ram eters in a transmitter

database.

3.4.3 Configuration

Configuration can be accomplished both online and offline with the transmitter powered up and

connected to the MC Toolkit. Online configuration immediately changes the transmitter operating

parameters. For offline configuration, transmitter operating characteristics are entered into Toolkit

memory for subsequent downloading to a transmitter.

When you set up or configure a transmitter, it can take up to 30 seconds for the value to

be stored in it. If you change a value and transmitter power is interrupted before the change

is copied to nonvolatile memory, the changed value will not be moved to nonvolatile memory.

Page 10 STT750 Series HART Option User’s Manual Revision 3.0

Page 19

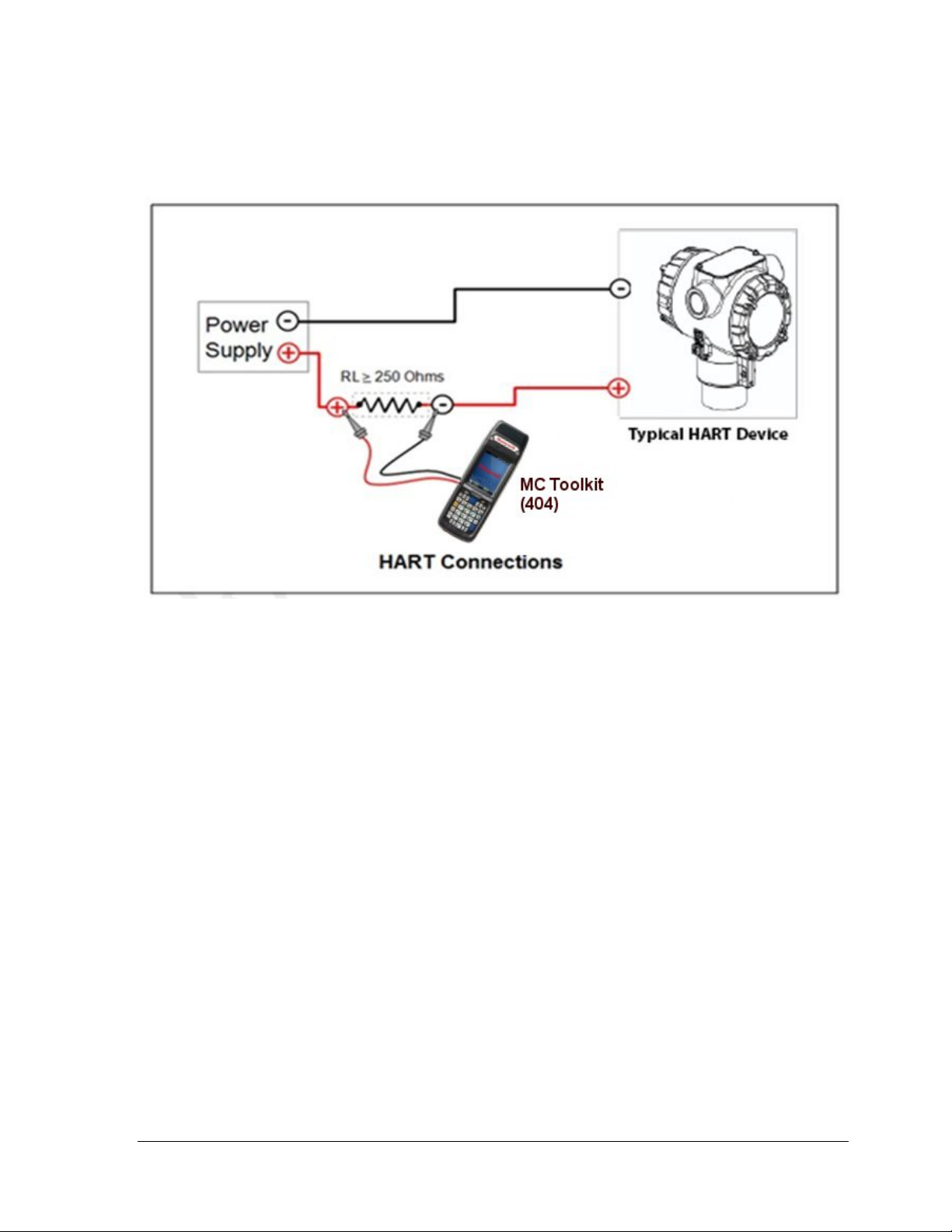

3.4.4 MC Toolkit–Transmitter Electrical/Signal Connections

Figure 5 displays how to connect the MC Toolkit directly to the terminals of a HART-only transmitter

(bottom).

Figure 5 – MC Toolkit-Transmitter Electrical/Signal Connections

Revision 3.0 STT750 Series HART Option User’s Manual Page 11

Page 20

This page is left blank intentionally.

Page 12 STT750 Series HART Option User’s Manual Revision 3.0

Page 21

4 HART Transmitter Configuration

4.1 Overview

Each new STT750 Temperature Transmitter configured for HART protocol is shipped from the factory

with a basic configuration database installed. This basic configuration database must be edited or

revised to meet the requirements of your process system. The process in this section assumes that you

will use the Field Device Communicator (FDC) application for HART configura tion tasks. The FDC

application provides the facilities for the online and offline configuration of trans mitters operating with

HART protocol

Online configuration requires that the transmitter and MC Toolkit are connected and communication

between the two has been established. Online co nfiguration provides a set of functions with which to

perform various operations on a HART communication network through an active communication

link. These operations primarily include configuration, calibration, monitoring, and diagnostics.

Typically, these operations could be realized through various constructs exposed by the Device

Description (DD) file. In addition, the FDC application provides some functions for convenient

execution of these functions.

Offline Configuration refers to configuring a device when the device is not physically present or

communicating with the application. This process enables you to create and save a configuration for a

device, even when the device is not there physically. Later when the device becomes available with

live communication, the same configuration can be downloaded to the device. This feature enables you

to save on device commissioning time and even helps you to replicate the configuration in multiplicity

of devices with lesser efforts. Currently, FDC does not support creating offline configuration.

However, it supports importing of offline configuration from FDM R310 or later versions. The

configurations thus imported can be downloaded to the device from FDC.

The following are the tasks that you need to perform for importing offline configuration in FDC

application software and then downloading it to the device.

• Create offline configuration template in FDM

• Save the configuration in FDM in FDM format.

• Import the offline configuration in FDC

• Download the offline configuration to the device

Note: For details on creating and using offline configuration, refer to section Offline configuration in

FDM User’s Guide.

4.1.1 Personnel Requirements

The information and procedures in this section are based on the assumption that the person

accomplishing configuration tasks is fully qualified and knowledgeable on the use of the MC Toolkit

and is intimately familiar with the STT750 family of SmartLine Temperature Transmitters. Therefore,

detailed procedures are supplied only in so far as necessary to ensure satisfactory configuration. The

other HART configuration tools are Honeywell Experion in conjunction with FDM, iDTMs running

on FDM or Pactware, and Emerson 375/475. The organization of Device Configuration and Parameter

Descriptions on page 24 is given in

Revision 3.0 STT750 Series HART Option User’s Manual Page 13

Table 6.

Page 22

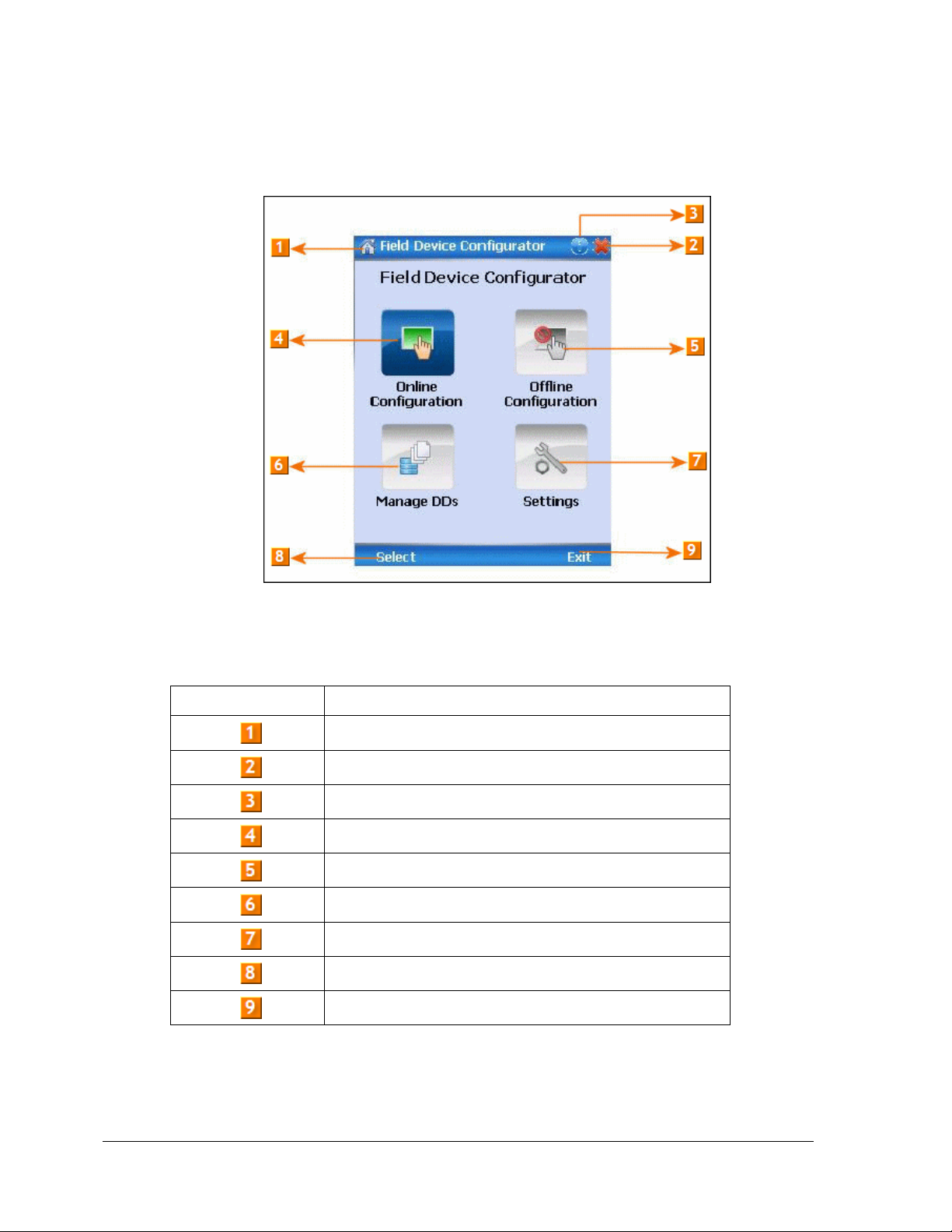

4.2 Overview of FDC Homepage

The FDC homepage consists of links for Online Configuration, Offline Configuration, Manage DDs,

and Settings. See below.

Figure 6 – FDC Homepage

Table 4 lists the items that appear on the FDC homepage and its descriptions.

Table 4 – FDC homepage elements

Items Description

Screen title.

Tap to quit FDC.

Tap to view the application information.

Tap to navigate to Online Configuration screen.

Tap to navigate to Offline configuration screen.

Tap to navigate to Manage DDs screen.

Tap to navigate to Settings screen.

Tap to select the highlighted menu option.

Tap to quit FDC.

Note: To select a particular option in FDC you can either select the option and then tap Select or you

can directly double-tap the option.

Page 14 STT750 Series HART Option User’s Manual Revision 3.0

Page 23

4.2.1 Settings

Use this feature to customize FDC. You can customize FDC for device detection, DD selection, and

other application settings.

4.2.1.1 Device Identification

Use the following options to configure FDC to identify a device.

• Using Poll Address

− Use poll address 0 only: Use this to detect a device with the poll address as zero.

− Find first poll address and use: Use this to detect a device with the first available

poll address in the range of poll addresses that are avai lab le.

− Use selected poll address: Use this to detect a device with a specific poll address in

the range of zero to 63.

− Use From: Use this to detect a device based on a range of poll addresses.

Using Device TAG: Use this to detect a device with a known HART tag.

•

Using Device LONG TAG: Use this to detect a device with a known HART long tag

•

(applicable for devices with HART 6 or later Universal revisions).

Note: If you choose the option Using Device TAG or Using Device LONG TAG, FDC prompts you to

enter a device tag/long tag name during device detection.

4.2.1.2 DD selection

Use the following options to configure FDC to select DD files when a DD with matching device

revision is not available.

- Use DD file of previous device revision: Use this option to automatically communicate using

a DD file having device revision lower than that of the device.

- Use generic DD file: Use this option to automatically communicate to the device using an

appropriate generic DD file.

- Always ask user: Use this option to always prompt you with a choice for communicating to

the device either using the previous device revision or using a generic DD file.

- Always Use Generic: Use this option to always communicate to the device using generic DD

files even if a DD file with matching device revision as the device is present.

Note: A generic DD file is a DD file that provides access and interface to the universal data and

features of a HART device.

4.2.1.3 Other settings

Low storage notification: Use this option to set a percentage value and to notify you with a warning

message when the available storage card space is less than the percentage set.

Application diagnostics: Use this option to enable or disable the logging infrastructure for application

diagnostics. With this option enabled, FDC creates necessary log files for troubleshooting and

diagnostics. These files are stored in SD Card\FDC folder.

Note: You must not enable this option unless suggested by Honeywell TAC because this may impact

the application performance.

4.2.2 Manage DDs

Using this feature, you can manage the DD files installed with FDC. A DD file contains descriptive

information about the functionality of a device. By default, a set of DD files are installed with FDC.

Revision 3.0 STT750 Series HART Option User’s Manual Page 15

Page 24

However, if you do not have a DD for a given device, you can install it using the “Add DD” feature.

Similarly, you can uninstall a DD file or a set of DD files using “Delete DD” feature. You can also

directly copy the DD files in appropriate hierarchy using a card reader or “Active Sync/Mobile Device

Center” mechanisms. In such a case, you should validate the library view using the “Refresh” feature.

4.2.2.1 Overview

Using Manage DDs, you can view, add, or delete DD files for devices. A list of already available DD

files is maintained in the DD Library. FDC lists the installed DD files in a hierarchy as below:

Manufacturer

Device Type

DevRev xx, DDRev yy

DevRev pp, DDRev qq

4.2.2.2 Add a DD file

To add a DD file for a device, perform the following steps.

1. From the FDC homepage, tap Manage DDs > Select.

The Manage DDs dialog box appears.

2. Tap Options > Add DD.

Or

Tap .

The ADD DD files dialog box appears.

3. Browse to the location in which the DD file (.fm8) is located and tap OK.

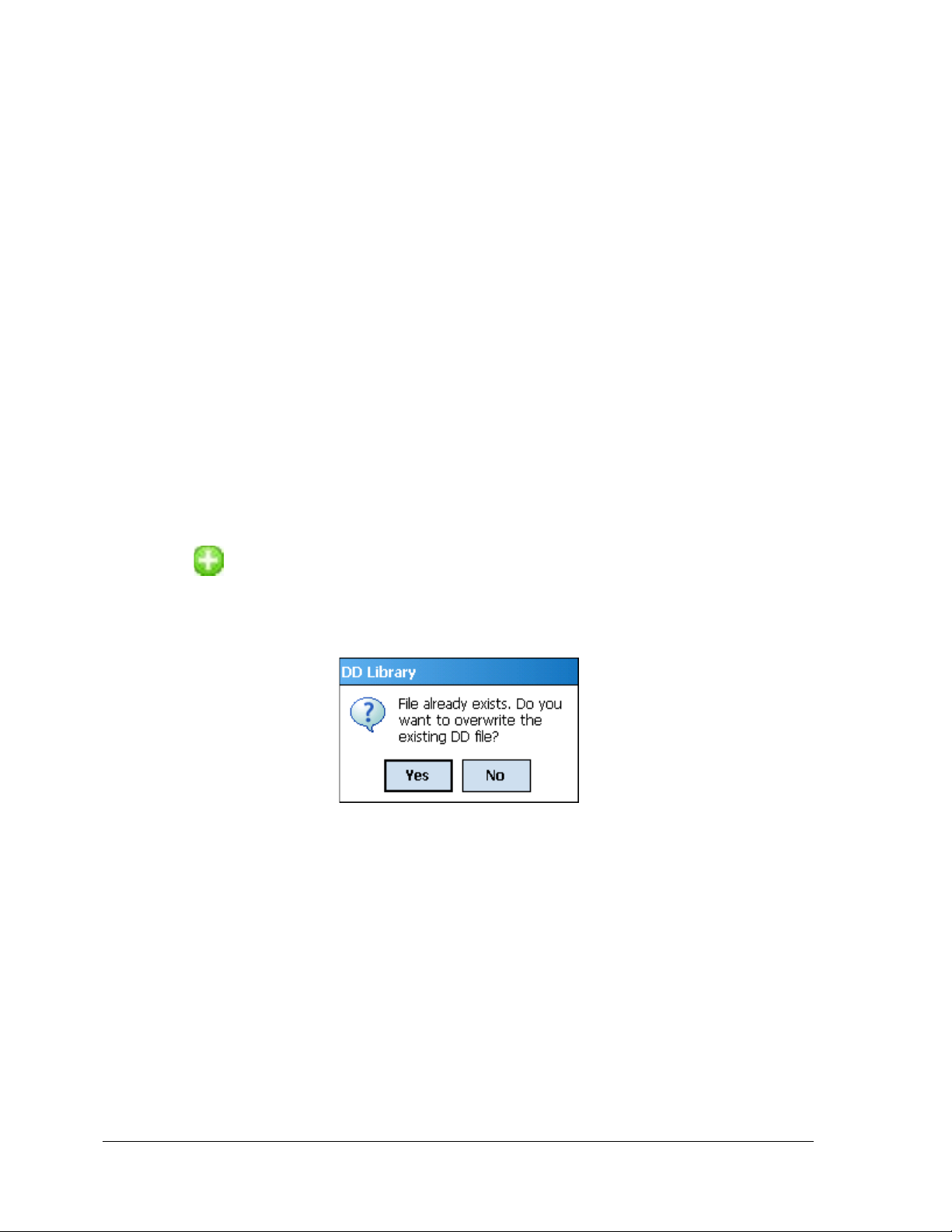

4. If the DD file already exists, then the following message appears.

5. Tap Yes to overwrite the existing DD files.

6. If the DD file is added successfully, a success message appears.

Page 16 STT750 Series HART Option User’s Manual Revision 3.0

Page 25

4.2.2.3 Delete a DD file

Using this option, you can delete a particular version of a DD file. To delete a DD file for a device,

perform the following steps.

1. From the FDC homepage, tap Manage DDs > Select.

The Manage DDs dialog box appears.

2. You can choose to delete DD(s) in one of the following ways:

a) By device manufacturer – Select a device manufacturer to delete all device types and

DDs associated with the manufacturer’s devices.

b) By device type – Select a device type to delete all DDs associated with the device.

c) By device revision and DD revision – Select the specific entry of device revision, DD

revision to delete the specific DD

3. Tap Options > Delete DD.

Or

Tap .

A confirmation message appears.

4. Tap Yes.

If the DD file is deleted successfully, a success message appears.

5. Tap OK to return to DD Library page.

4.2.2.4 Validating a manually edited library

Besides using the Add/Delete DD features, advanced users may also manipulate a DD library by

directly editing the contents of the FDC\Library folder. DD files can also be transferred directly to this

location by accessing the SD Card on MCT101 through a card reader and/or by connecting the

MCT404 to a PC. In such cases, you must perform the following steps to validate a DD Library, thus

edited manually:

1. From the FDC ho mepage , tap Manage DDs > Select

The Manage DDs dialog box appears

2. Tap Options.

3. Tap Refresh Library.

Or

Tap .

A confirmation message appears.

4. Tap Yes. The DD library is now validated and refreshed.

Revision 3.0 STT750 Series HART Option User’s Manual Page 17

Page 26

4.2.3 Online configuration

Using online configuration, you can configure, calibrate, monitor and diagnose a HART device which

is connected to MC Toolkit. FDC provides the features to perform these functions through the various

constructs offered through the DD file of the device. Besides there are certain other features available

under this link for you to conveniently work with a HART device with live communication. After

making changes to the device you can also save a snapshot of the device data as history to later

transfer it to FDM for record and audit purposes.

4.2.4 Offline configuration

Offline configuration refers to configuring a device offline (without physically connecting to

the device) using a template and then downloading the configuration to the device. Presently,

FDC application software does not support creating offline configuration. However, it

supports importing of offline configuration from FDM (R310 and above).

4.2.5 Online Configuration Overview

Online Configuration option provides you a set of functions with which you can perform various

operations on a device with an active communication link. These operations primarily include

configuration, calibration, monitoring, and diagnostics of a HART device. Typically, these operations

could be realized through various constructs exposed by the DD file of the device. In addition, FDC

also provides some additional application functions for you to perform these functions more

conveniently.

Online configuration includes a set of functions to perform various operations on a transmitter with

active communication link. These operations primarily include:

• Identifying a transmitter

• Reading and reviewing transmitter variable values

• Editing transmitter variable values

• Downloading the selected/edited variable set to the transmitter

4.2.5.1 Detecting and loading a device

Tap the Online Configuration button on the Application Home page.

The device detection and loading process automatically gets started. Depending upon the Device

Detection and DD Selection settings you may have chosen, you may be prompted for certain inputs as

described in the Settings section.

Page 18 STT750 Series HART Option User’s Manual Revision 3.0

Page 27

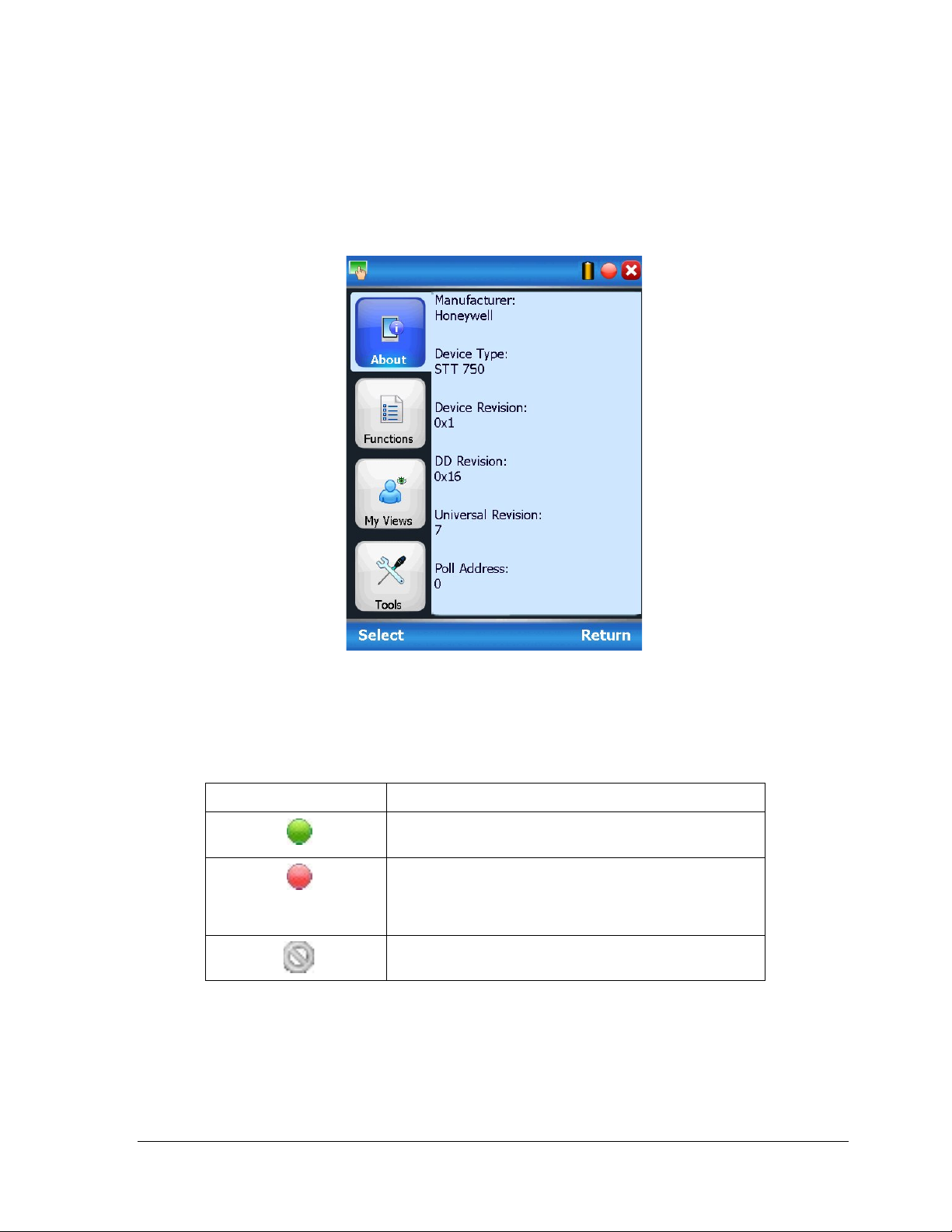

4.2.6 Overview of Device Homepage

Once the device is detected and loaded successfully, you can view the device homepage for the

identified device.

The workspace area on the device homepage consists of 4 tabs on the left hand side. Selecting a tab

displays functions/information associated with that tab on the right hand side.

Figure 7 – Device Homepage

Table 5 lists the device health status and their indications.

Table 5 – Device health status

Device health icons Indications

Indicates there’s no health or status indicators reported

by the device

Indicates that the device is potentially reporting a status

which needs attention and further investigation. It is

advised that you use Device Status under Functi ons tab

to further investigate the details.

Indicates that the device has lost communic atio n w ith M C

Toolkit

Revision 3.0 STT750 Series HART Option User’s Manual Page 19

Page 28

4.2.7 Tabs on the Device Home page

The following are the options that are available on the device homepage

• Information tab: Use this option to view the device identity related information. You can

view the manufacturer name, device type, device revision, DD revision, and universal

revision of the HART device.

• Functions tab: This tab provides various options which you may use for navigating

through the device specific user interface and some standard features offered by FDC

across all devices. For the sake of explanations, the right side options under this tab shall be

referred as “Entry points” throughout the rest of the document.

Page 20 STT750 Series HART Option User’s Manual Revision 3.0

Page 29

• My Views tab: Quite often, you may be interested only in a set of variables of a device.

But navigating through the menu tree of a device may not be helpful because of time and

further all variables that you want may not be in the same location. Using this unique

feature of FDC, you can now choose what you want to view in a device in your own views.

FDC allows you to create two such views per device revision of a specific device type. You

can always modify them as per your needs.

• Tools tab: This tab is a placeholder for FDC specific tools for providing certain functionality.

Currently t he only option it provides is called as Save History. Using thi s option you can save the

snapshot of the device variables. This snapshot is saved in a format which can be later imported as a

history record in FDM.

Revision 3.0 STT750 Series HART Option User’s Manual Page 21

Page 30

4.2.8 Using FDC for various device operations

Typical operations with a smart field device involve configuration, calibration, monitoring, and

diagnostics. FDC enables you to achieve these operations with a HART device via the various

interfaces/constructs exposed through the DD file of the device.

The “Functions” tab under the device home page provides the entry points for navigating through the

device specific user interface to perform the above mentioned operations. A device may define up to

four entry points in the DD file. All devices shall have at least one entry point, generally referred to as

“Online”. Besides the device specific entry points, FDC provides custom entry points for navigational

aids to specific ty pe s of information/features. One such entry point is called Device Status, which is

used for reviewing device health. Another is called Methods List, which is used to navigate to all the

methods available in a device.

All of the device specific entry points represent the device interface, as explained using the Online

entry point as an example. All the other device specific entry points have a similar interface except for

the fact that the variables and other DD constructs provided under each may vary as indicated by the

title of each entry point.

For the sake of explanation, the pages that appear on navigating through the device

specific entry points are referred to as “Device Configuration” pages in this document. However

it must be noted that this does not prohibit you from performing other device operations as

explained above.

Page 22 STT750 Series HART Option User’s Manual Revision 3.0

Page 31

Online Device Entry Point: When you tap on to open the Online tab, the device configuration screen

appears as shown below.

Typical Online Menu is shown below. Based on the connected Device type, Menu items will be shown

Alternately you can access the full EDDL features by selecting the “My Device” Tab. Typical My

Device Tab is shown. Based on the connected device type Menu items will be show n

Navigate through the Menus to access various functions. See Table 6 for lists all the parameters in the

STT750.

Revision 3.0 STT750 Series HART Option User’s Manual Page 23

Page 32

Online Menu Flow

Parameter menu/

name

Description/Valid values

Tag

Enter tag identification up to eight

alphanumeric characters.

PV(Loop)

Displays the current value of the

engineering units

AO Alrm Typ

Displays the current position of the

Loop Test

This function enables the user to

Current mode) is Enabled.

Online/Device Settings/ Ke y

PV UTL

Displays Process Variab le Upper

Transducer Limit

PV URV

Display/Configure the current value

UTL1, LTL2 and UTL2.

PV LRV

Display/Configure the current value

UTL1, LTL2 and UTL2.

PV LTL

Displays Process Variable Lo wer

Transducer Limit

4.2.9 Device Configuration and Parameter Descriptions

Table 6 lists descriptions of all parameters for a HART transmitter with the Online tab menu path. The

same parameters may be accessed via the Shortcuts menu under the My Device tab.

Table 6 – HART Transmitter Parameters

Online/Device Settings/ Ke y Parameters

Primary Variable (loop PV

according to the loop control mode

selected) in user selected

failsafe jumper on the electronics

board (upscale/ lowscale burnout)

test the Analog Output

measurement at any value over the

full operational range. Select a

current value to apply to the output

and verify the measured current on

the loop with a calibrated meter.

Note that this function is only

available when “Loop mA” (Loop

Parameters/PV Ranges/Limits

of the Upper Range Value (input

which represents 100% output) in

user selected engineering units.

This value may be configured to

any value within the range as per

selected loop control mode (It will

be computed depending on LTL1,

of the Lower Range Value (input

which represents 0% output) in

user selected engineering units.

This value may be configured to

any value within the range as per

selected loop control mode (It will

be computed depending on LTL1,

Page 24 STT750 Series HART Option User’s Manual Revision 3.0

Page 33

Online/Device Settings/ De vice

Tag

Enter tag identification up to eight

alphanumeric characters.

Long Tag

Enter a long tag name up to 32

alphanumeric characters.

Descriptor

Enter a descriptor for user information

characters)

Transmitter Install

Date

Enter the date of site installation. This

is a one-time configuration.

Sensor 1 Install

A one-time writable date used for

Polling Address

configure the current polling address of

the device.

Message

Enter a message (up to 32

menu.

Maintenance

Displays the Maintenance mode set by

Experion Knowledge Builder

Info/General

Date

only (up to 16 alphanumeric

Advanced Diagnostics on the Sensor 1

health.

alphanumeric characters) that will be

sent to the Display. The message will

be shown on the Display interspersed

with the configured screens. To stop

displaying the message, select “Clear

Display” in the Device Information

Mode

Experion PKS.

When a HART device requires

maintenance, the engineer or the

operator changes the PV Source value

of the corresponding AI channel to

MAN. As soon as the PV Source value

is changed for the channels connected

to the STT850 transmitters, Experion

communicates the channel mode

status to the corresponding STT850

transmitters. Upon receiving this

status, if the value is MAN, the

transmitter displays an M and

Available for Maintenance on the

local display of the transmitter. The

status display on the transmitter

ensures that the field technician can

locate and perform the maintenance

work on the correct transmitter without

impacting the integrated devices in the

process loop. The transmitter

continues to display the Available for

Maintenance status on its local display

until the PV Source status of the

corresponding AI channel is changed

to AUTO / SUB or the transmitter is

power cycled.

For more information, refer to the

Revision 3.0 STT750 Series HART Option User’s Manual Page 25

Page 34

Online/Device Settings/ De vice

Universal Rev

Displays the HART Universal Revision

Transmitter

Fld dev rev

Displays Field Device Revision of the

STT850 Temperature Transmitter

Software rev

Displays the Electronics Board

Temperature Transmitter

DD Rev

Displays the Device Description

Revision

Comm Module

Rev

Displays the communication Board

Firmware Revision

Display Module

Rev

Displays the Displa y Board F irmware

Revision

Sensor Module

Rev

Displays the Sensor Board Firmware

Revision

Online/Device Settings/ Pro c es s

PV Unit

Configure the engineering unit for

process variable.

PV(Loop)

Display the process variable Value in

user selected engineering unit.

Online/Device Settings/ Pro c es s

UTL 1

Displays Upper Transducer Limit of

Sensor 1

URL 1

Displays Upper Range Limit of Sensor

1

LRL 1

Displays Lower Range Limit of Sensor

1

LTL 1

Displays Lower Transducer Limit of

Sensor 1

SV(Cold Jn.

Unit

Configure the Secondary Variable (CJ

SV

Displays the current value of the

in user selected engineering units

CJ Selection

Displays the CJ Compensation

CJ Compensation

Select Internal or Fixed Cold Junction

Value must be configured.

Fixed

Value

If Fixed CJ Compensation has been

of Cold Junction temperature here.

Info/Software Details

Variables/Sensor Units

Variables/Sensor 1 Ranges/Limits

of the STT850 Temperature

Software Revision of the STT850

Online/Device Settings/ Pro c es s

Variables/SV (Cold Jn. Temperature)

Temperature)

compensation

Temperature) engineering units

Secondary Variable (CJ Temperature)

method. It can be Internal or Fixed.

Compensation for the temperature

measurement. If Internal

Compensation is selected, the Cold

Junction temperature measured

internally by the sensor is used. If

Fixed Compensation is selected, the

Fixed Cold Junction Temperature

selected, enter the desired fixed value

Page 26 STT750 Series HART Option User’s Manual Revision 3.0

Page 35

Online/Device Settings/ Pro c es s

Sensor 1 Type

Displays the Sensor 1 type, can be TC,

RTD, Ohms or mv

Sensor 1 Id

Displays Sensor 1 Id

Sensor 1 Lead

Enter any desired lead wire resistanc e

measurement

Sensor 1 Bias

Enter any desired bias value to be

Sensor Scratch

Enter any notes desired pertaining to

Changes Sensor

Change Sensor Type: select the

Online/Device Settings/ Pro c es s

Loop Controlled

Displays the Sensor(s) that are

Loop Control

Displays the Loop control mode can be

Online/Device Settings/ Pro c es s

Latching Alarm

Configure Latching Alarm as Enable or

Disable

Break Detect

Select to Enable or Disable Sensor

Variables/Sensor Configuration/

Sensor Type

Wire Resistance

value to be used for Sensor 1

used for Sensor 1 measurement. Bias

is generally applied to compensate for

input drift due to sensor

deterioration. Final Sensor 1 value =

Sensor 1 input + Sensor 1 Bias.

Variables/Sensor Configuration/ Loop

Control

Variables/Sensor Configuration/

Alarm

Pad

Type/ID

By

Mode

Sensor

specific type of thermocouple, RTD,

ohms or millivolt sensor for both

Sensor 1 inputs.

currently controlling the loop, based on

the selection of the Loop Control

mode.

one from below list:

Sensor 1

Break Detection. It is highly

recommended to keep this option

Enabled. If there is a break or open in

either Sensor input, and Break Detect

is Enabled, a Critical Status will be

generated. If Break Detection is

Disabled, no Critical Status is set and

the input value will be unreliable.

Revision 3.0 STT750 Series HART Option User’s Manual Page 27

Page 36

Online/Device Settings/ Pro c es s

Sensor1 CVD

Sensor1 CVD Activate: Can be

b) CVD OFF

Sensor 1 CVD

Sensor1 CVD High and Low Limit will

f) Beta: A Floating Point Value

Online/Device Settings/ Pro c es s

PV Unit

Configured unit of process variable.

PV (Loop)

Displays the current value of the

selected engineering units

PV UTL

Displays Process Variables Upper

Transducer Limit

PV URV

Configure the current value of the

on LTL, UTL.

PV LRV

Configure the current value of the

on LTL and UTL.

PV LTL

Displays Process Variables Lower

Transducer Limit

SET LRV and

performs a Set LRV and/or Set URV to

Variables/Sensor

Configuration/Sensor 1 CVD

Coefficient

(CVD:

CVD menu will be seen only when

sensor type is configured as RTD PT

type Sensors)

Variables/Sensor Configuration/ 4-20

ma Output/ PV Ranges/ Limits

Activate

(RTD only)

Coefficients

configured with any of the below

a) CVD ON

be seen when Sennsor1 CVD Activate

is ON

a) Sensor1 CVD Low Limit: A read only

floating point value

b) Sensor1 CVD High Limit: A read

only floating point value

c) R0: A Floating Point Value

d) Alpha: A Floating Point Value

e) Delta: A Floating Point Value

Primary Variable (loop PV according to

the control mode selected) in user

Upper Range Value (input which

represents 100% output) in user

selected engineering units. This value

may be configured to any value within

the range as per selected loop control

mode (It will be computed depending

URV

Lower Range Value (input which

represents 0% output) in user selected

engineering units. This value may be

configured to any value within the

range as per selected loop control

mode (It will be computed depending

configure the LRV/URV to applied

inputs.

Enter Values: enter desired LRV and

URV value to configure the desired

operating range. Valid entries are from

LTL UTL (lower/upper transducer

limits).

Page 28 STT750 Series HART Option User’s Manual Revision 3.0

Page 37

Online/Device Settings/ Pro c es s

Namur Level

Displays a diagram of the operating

Online/Device Settings/ Pro c es s

Saturation

Select from the following:

AO Alrm typ

Displays the current position of the

PV Alrm typ

Type: displays the current position of

PV Damp

Enter a value for damping of the device

Loop Current

Select the Loop Current Mode

Online/Device Settings/ Pro c es s

PV Levels

Displays a graphic representation of all

Online/Device Settings/ Display

Display

Display as Yes, when Display

connected.

Type of Display

Connected

Indicates the type of display installed

on the transmitter (Basic).

Variables/Sensor Configuration/ 4-20

ma Output/ Output Condition/Namur

Option

Variables/Sensor Configuration/ 4-20

ma Output/Output Condition

Selection

range and failsafe range of the Analog

output for Normal and Namur

configurations.

Namur Selection: select to enable or

disable the Namur option for the

output. (Refer to the PV

Ranges/Limits chart) for effect on

output signal.

Namur Level: Displays a diagram of

the operating range and failsafe range

of the Analog output for Honeywelll

and Namur configurations.

failsafe jumper on the electronics

board (upscale/downscale failsafe)

the failsafe jumper on the electronics

board (upscale/ downscale failsafe)

output. Entries may be any floatingpoint value from 0.00 to 102.00

seconds.

Variables/Sensor Configuration/ 4-20

ma Output/Ranges/Limits Graphical

View

Setup/ Display Installation Det a ils

Mode

Connected

configuration:

“Enable”: enables loop current mode

(analog output will operate as a 4 to 20

mA signal consistent with the

transmitter output)

“Disable”: disables loop current mode

(analog output will be fixed at 4 mA)

PV ranges and limits for the STT850

Temperature Transmitter.

connected as advanced or Basic.

Display as No, when Display not

Revision 3.0 STT750 Series HART Option User’s Manual Page 29

Page 38

Online/Device Settings/ Display

Displays configured information for

“Screen Configuration” menu.

The display screen may be customized

characters.

Common Setup

The following screen options are

choose the “default” (5).

Online/Device Settings/ Ser vices /

Transmitter Install

Date

Enter the date of site installation. This

is a one-time configuration.

Sensor Install

Sensor install date is used for

health

Master Reset

Selecting this option will cause a

device.

Lock/Unlock

Select the Lock state for access by

device, the lock state will be cleared.

Setup

(for Basic Display, Only)

Read Screen Info

Screen

Configuration

each of the eight display screens.

Select a screen number to view details

of the configurations selected in the

with the following settings:

PV Selection: select the displayed

process variable as:

Loop Output, Percent

Output,

Loop PV, CJ Temperature,

Sensor1,

Sensor1Resistance

Temperature Units: select desired

standard Temperature unit.

Number of Decimals: select the

number of decimal places for

the PV display from none to

3.

Custom Tag: enter a custom tag

name for the screen title up

to 14 alphanumeric

available:

Rotation Time: Set the length of time

the PV display is visible before rotating

to another screen (such as a

diagnostic display). Select from 3 to

30 seconds.

Contrast Level: Select a display

contrast level from 1(low) to 9 (high) or

Global Access

Page 30 STT750 Series HART Option User’s Manual Revision 3.0

Date

Device

Advanced Diagnostics on the Sensor1

Master Reset of the transmitter, which

is the equivalent to power cycling the

HART configuration tools.

If “Yes” is selected to lock the device,

also select “Yes” or “No” to choose

whether or not the lock is “permanent.”

If the lock is not permanent, it will be

cleared on power cycle or Master

Reset of the device.

If “Yes” is selected to unlock the

Page 39

Online/Device Settings/

Write Protect

Displays a picture of the Electronics

the hardware write protect jumper.

Write Protect

Displays the current configuration of

enabled.

Write Protect

Configure the firmware write protect

configured by the user.

Changes

Password

Change the write protect password to a

new 4-digit code.

Reset/Forgot

password

Reset existing password using master

password.

Online/Device Settings/

Tamper Mode

Displays the current configuration of

Logic” in Table 12

Attempt Counter

Displays the number of times a

Attempt.

Services/Write Protect Settings

Graphical View

ON/OFF

module to demonstrate how to connect

the write protect function. Write

Protect is “Yes”(enabled) if either the

write protect jumper on the electronics

board is in the “ON” position or the

firmware write protect has been

option.

Write Protect selections are:

“Enable”: enables the firmware write

protect option (changes in

configuration parameters will not be

permitted).

“Disable”: disables the firmware write

protect option (requires a password).

A 4-digit password is required to

change the Write Protect option from

“Enabled” to “Disabled” to allow

configuration changes. The default

password is “0000”, and can be re-

Services/Tamper Mode Settings

the Tamper detection feature (outside

attempts to change device

configuration when Write Protect is

enabled and Tamper Mode is Enabled

or Tamper Mode alo ne is

Enabled). Refer to the “Tamper

Reporting Logic and Write Protect

tamper attempt (configuration write)

has occurred. This parameter works

as below:

1) The attempt counter will get reset

on following instances:

- When tamper is reset using the

“Reset Tamper Counter”

Method.

- When Tamper Mode is

configured. During the

configuration, if the Tamper

Mode is Enabled and the other

Tamper parameters are

configured, then that is also

considered as a Tamper

Revision 3.0 STT750 Series HART Option User’s Manual Page 31

Page 40

Online/Device Settings/

2) When tamper attempts are already

reconfigured attempts.

Tamper Latency

Displays the current setting of the

Max allowable

Displays the current setting for the

status.

Configure

Configure all of the settings controlling

device sets the Tamper Alarm status

Reset Tamper

Counter

Reset the Attempt Counter to zero.

Services/Tamper Mode Settings

attempt

incremented, if tamper is

reconfigured then following

happens,

- If the reconfigured value is

greater than tamper attempts,

then the tamper attempts value

is retained.

If the reconfigured value is smaller

than tamper attempts, then the tamper

attempts value is clamped to the

Tamper Latency (0-60

seconds). Tamper latency is the

time period for which the tamper

alarm remains set in response of

command 48 and reflected as

“Tamper Alarm” Device Status

condition.

Tamper Maximum Attempts

configuration. This is the maximum

number of tamper attempts to be

permitted during one Latency period

before setting the Tamper Alarm

Tamper Alarm

the Tamper Detection

option. Selections include:

Select Tamper Mode: enable or

disable tampering detection.

When enabled, the “Tamper

Counter” will keep track of the

number of times an attempt is

made. After the configured “Max

Attempts”, an alarm status is

generated.

Tamper Latency:

Configure the desired latency (in

seconds) for the Tamper

detection.

Maximum Attempts:

Configure the maximum number of

tamper attempts allowed before the

Page 32 STT750 Series HART Option User’s Manual Revision 3.0

Page 41

Online/Device Settings/ Cal ibrat ion

D/A Trim

Perform an analog output calibration at

output).

Loop Test

This function enables the user to test

Online/Device Settings/ Cal ibrat ion

Sensor Lower

Calib point

Configure the lower calibration point

value for sensor

Sensor Upper

Calib point

Configure the upper calibration point

value for sensor

Sensor LRV

perform an input calibration correction

configured Low Calibration Poi nt

Sensor URV

perform an input calibration correction

Sensor Reset

Corrects

clear all user calibration adjustments.

Online/Device Settings/ Cal ibrat ion

Prev. Sensor

Records

Displays the time and date history

Correct calibrations.

Last Sensor LRV

Displays the time and date history

Correct calibrations.

Curr. Sensor

Records

Displays the time and date history

Correct calibrations.

Online/Device Settings/ Cal ibration

Prev. Sensor

Records

Displays the time and date history

Correct calibrations.

Last Sensor URV

Displays the time and date history

Correct calibrations.

Curr. Sensor

Records

Displays the time and date history

Correct calibrations.

Online/Device Settings/ Cal ibration

Prev. Sensor

Displays the time and date history

Reset Corrects

Last Sensor 1

Displays the time and date history

Corrects

Curr. Sensor 1

Displays the time and date history

Corrects

and Correction Records/Analog

Output Calibration

and Correction Record/Sensor 1

Calibration

Corrects

Corrects

4.00 and 20.00 mA (0% and 100%

the Analog Output measurement at

any value over the full operational

range. Select a current value to apply

and verify the current output on the

loop with a calibrated meter.

Note that this function is only available

when “Loop mA” (Loop Current mode)

is Enabled.

by applying process input at the

by applying process input at the

configured High Calibration Point.

and Correction Record/Sensor 1

Calibration / Correct Sensor 1 LRV

Records

and Correction Record/Sensor 1

Calibration / Correct Sensor 1 URV

Records

and Correction Record/Sensor 1

Calibration / Reset Sensor 1 Correct

Records

LRV Correct

Correct Records

LRV Correct

URV Correct

Correct Records

URV Correct

Reset Records

Reset Records

Reset Records

records for the Previous Sensor 1 LRV

records for the Last Sensor 1 LRV

records for the current Sensor 1 LRV

records for the Previous Sensor 1 URV

records for the Last Sensor 1 URV

records for the current Sensor 1 URV

records for the Previous Sensor 1

records for the Last Sensor 1 Reset

records for the Current Sensor 1 Reset

Revision 3.0 STT750 Series HART Option User’s Manual Page 33

Page 42

Online/Device Monitoring/Process

Loop Control

Mode

Displays the selected loop control

mode

Loop Controlled

Displays the Sensor(s) that are

mode.

PV Unit

Select one of the pre-programmed

C, oF, oKelvin, oR, mV, Ohms

PV(Loop)

Displays the current value of Process

Variable

SV(Cold Jn.

Unit

Configure the Secondary Variable (CJ

SV

Displays the current value of the

in user selected engineering units

TV[Sensor ]

Displays the first sensor input value

PV % rnge

Displays the current value of

transmitter Output in %

PV Loop Current

Displays the current value of Analog

Output in mA

ET

Displays the current value of

Electronics Temperature in degrees C

Online/Device Monitoring/Process

PV Trend

Displays a trending chart of the current

(temperature input)

SV Trend

Displays a trending chart of the current

temperature)

TV Trend

Displays a trending chart of the current

temperature)

ET Trend

Displays a trending chart of the current

value of the Electronics Temperature

AO Trend

Displays a trending chart of the current

value of the Analog Output

Online/Device Monitoring/Device

Critical Faults

Displays all possible Critical Status

faults or ON for active faults.

Non-Critical

Displays the first set of possible Non-

faults.

Additional Status

Displays an advanced diagnostic

Non-Critical faults

Variables/Process Values

By

currently controlling the loop, based on

the selection of the Loop Control

engineering units. STT750

Temperature readings can be

displayed in the following engineering

units:

o

Variables/Process Values/Trend

Charts

Temperature)

Temperature) engineering units

Secondary Variable (CJ Temperature)

value of the Primary Variable

value of the Secondary Variable (CJ

value of

the Tertiary Variable (Sensor 1

Status

Page 34 STT750 Series HART Option User’s Manual Revision 3.0

Faults

faults and indicates OFF for inactive

Critical Status faults and indicates OFF

for inactive faults or ON for active

detailed breakdown of all Critical and

Page 43

Online/Diagnostics

Displays Advanced Diagnostics details

Online/Diagnostics/C onfig History

Config History

Displays a history of the last five

Online/Diagnostics/Fault History

Log Fault History

Available to enable and disable error

Online/Maintenance/Services/Global

Transmitter Install

Enter the date of site installation. This

Sensor 1 Install

Sensor1 install date is used for

Master Reset

Selecting this option will cause a

Lock/Unlock

Select the Lock state for access by

Online/Maintenance/Services/Write

Write Protect

Displays the current configuration of

for tracking basic device operation.

For more detailed information on

Advanced Diagnostics, refer to HART

Advanced Diagnostics section in this

Manual. Diagnostic information

includes:

Installation and Device Life details

PV Tracking details

SV Tracking details

ET Tracking details

Operating Voltage details

AVDD Tracking details

Sensor CPU Temp. Tracking details

Power Up Diagnostics details

configuration parameters that have

been changed.

logging.