Honeywell STG800 User Manual

SmartLine

Technical Information

STG800 SmartLine Gauge Pressure

Specification 34-ST-03-83, Jan 2021

Introduction

Part of the SmartLine® family of products, the STG800 and

STG80L are high performance gauge pressure transmitter

featuring piezoresistive sensor technology combining

pressure sensing with on chip temperature compensation

capabilities providing high accuracy, stability and

performance over a wide range of application pressures and

temperatures. The SmartLine family is also fully tested and

compliant with Experion® PKS providing the highest level of

compatibility assurance and integration capabilities.

SmartLine easily meets the most demanding application

needs for pressure measurement applications.

Best in Class Features:

Accuracies up to 0.0375 % of span standard & 0.025%

of span optional.

Stability up to 0.015% of URL per year for 15 years

Automatic temperature compensation

Rangeability up to 100:1

Response times as fast as 80ms

Multiple local display capabilities

External zero, span, & configuration capability

Polarity insensitive electrical connections

Comprehensive on-board diagnostic capabilities

Integral Dual Seal design for highest safety based

on ANSI/NFPA 70-202 and ANSI/ISA 12.27.1

Full compliance to SIL 2/3 requirements.

Modular design characteristics

Available with additional 15-year warranty

Plugged Impulse Line Detection Option

Dual/Triple Calibration Option (HART & Fieldbus

Only)

Figure 1 – STG800 Gauge Pressure Transmitters feature

field-proven piezoresistive sensor technology

Communications/Output Options:

4-20mA dc

Honeywell Digitally Enhanced (DE)

HART ® (version 7.0)

FOUNDATION™ Fieldbus

All transmitters are available with the above listed

communications protocols.

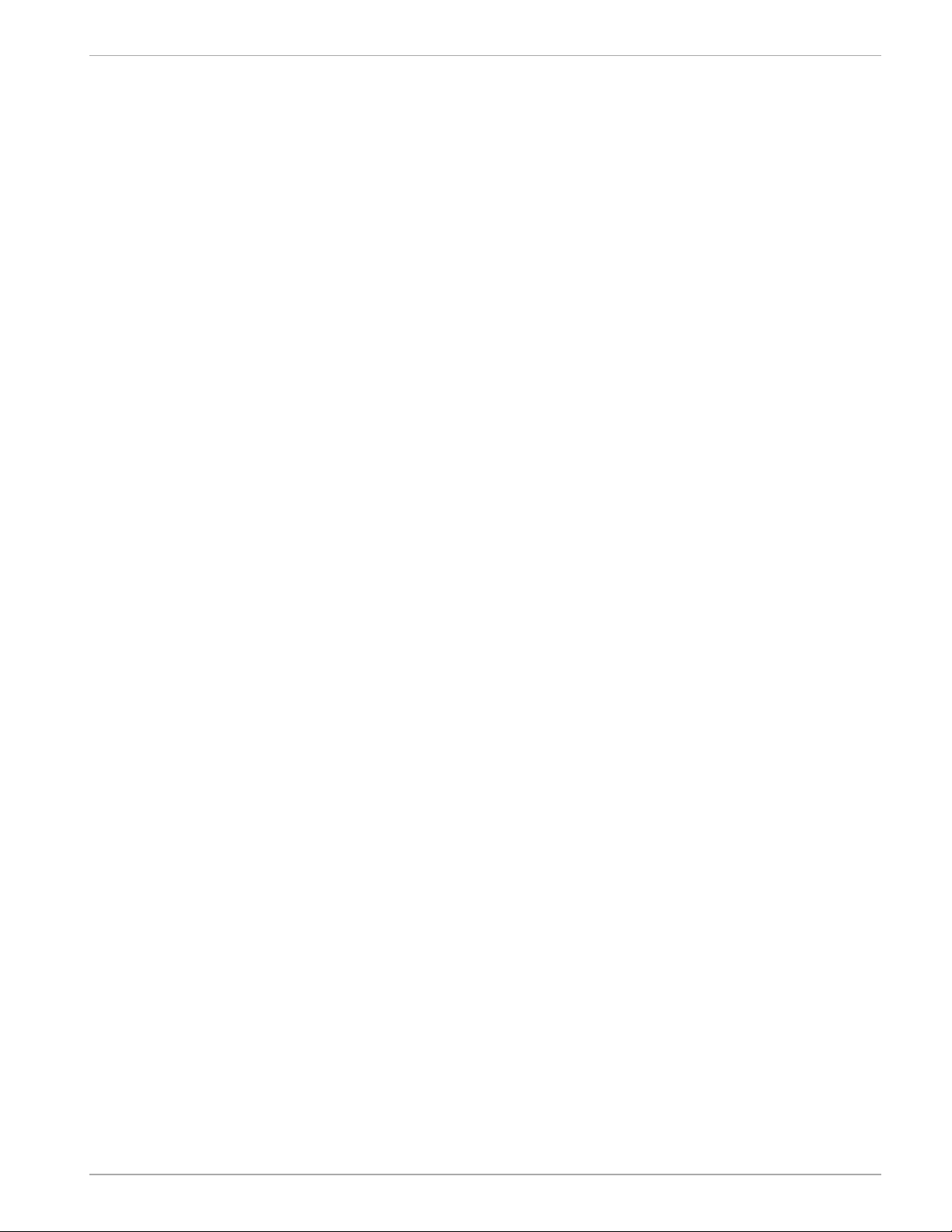

Span & Range Limits:

Model

URL psi

(bar)

LRL

psi (bar)

Min

Span

STG830/STG83L

50 (3.5)

-14.7 (-1.0)

0.5 (.35)

STG840/STG84L

500 (35)

-14.7 (-1.0)

5 (.35)

STG870/STG87L

3000 (210)

-14.7 (-1.0)

30 (2.1)

STG88L

6000 (420)

-14.7 (-1.0)

60 (4.2)

STG89L

10000 (690)

-14.7 (-1.0)

100 (6.9)

2 STG800 Smart Pressure Transmitter

Description

The SmartLine family of gauge pressure, differential

pressure, and absolute pressure transmitters is designed

around a high performance piezo-resistive sensor. This one

sensor actually integrates multiple sensors linking process

pressure measurement with on-board static pressure (DP

Models) and temperature compensation measurements

resulting in the best total performance available. This level of

performance allows the ST 800 to replace virtually any

competitive transmitter available today.

Unique Indication/Display Options

The ST 800 modular design accommodates a basic

alphanumeric LCD display or a unique advanced graphics

LCD display with many unparalleled features.

Basic Alphanumeric LCD Display Features

Modular (may be added or removed in the field)

0, 90,180, & 270 degree position adjustments

Configurable (HART only) and standard (Pa, KPa,

MPa, KGcm2, Torr, ATM, inH2O, mH2O, bar, mbar,

inH2O, inHG, FTH2O, mmH2O, mm HG, & psi)

measurement units

2 Lines 16 Characters (4.13H x 1.83W mm)

Square root output indication (√)

Advanced Graphics LCD Display Features

Modular (may be added or removed in the field)

0, 90, 180, & 270 degree position adjustments

Standard and custom measurement units available.

Up to eight display screens with 3 formats are

possible

(Large PV with Bar Graph or PV with Trend Graph)

Configurable screen rotation timing (1 to 30 sec)

Display Square Root capabilities may be set

separately from the 4-20mA dc output signal

Unique “Health Watch” indication provides instant

visibility of diagnostics

Multiple language capability. (EN, DE, FR, IT, ES,

RU, TR, CN, JP)

Diagnostics

SmartLine transmitters all offer digitally accessible

diagnostics which aid in providing advanced warning of

possible failure events minimizing unplanned shutdowns,

providing lower overall operational costs

Configuration Tools

Integral Three Button Configuration Option

Suitable for all electrical and environmental requirements,

SmartLine offer the ability to configure the transmitter and

display via three externally accessible buttons when either

display option is selected. Zero/span capabilities are also

optionally available via these buttons with or without selection

of a display option.

Hand Held Configuration

SmartLine transmitters feature two-way communication and

configuration capability between the operator and the

transmitter. All Honeywell transmitters are designed and tested

for compliance with the offered communication protocols and

are designed to operate with any Standards compliant

handheld configuration device.

Personal Computer Configuration

Honeywell’s SCT 3000 Configuration Toolkit provides an easy

way to configure Digitally Enhanced (DE) instruments using a

personal computer as the configuration interface. Field Device

Manager (FDM) Software and FDM Express are also available

for managing HART & Fieldbus device configurations.

System Integration

SmartLine communications protocols all meet the

most current published standards for

HART/DE/Fieldbus.

Integration with Honeywell’s Experion PKS offers the

following unique advantages.

o Transmitter messaging

o Maintenance mode indication

o Tamper reporting

o FDM Plant Area Views with Health

summaries

o All ST 800 units are Experion tested to

provide the highest level of compatibility

assurance

3 STG800 Smart Pressure Transmitter

Modular Design

To help contain maintenance & inventory costs, all ST 800

transmitters are modular in design supporting the user’s ability

to replace meter bodies, add indicators or change electronic

modules without affecting overall performance or approval body

certifications. Each meter body is uniquely characterized to

provide in-tolerance performance over a wide range of

application variations in temperature and pressure and due to

the Honeywell advanced interface, electronic modules may be

swapped with any electronics module without losing intolerance performance characteristics.

Modular Features

o Meter body replacement

o Exchange/replace electronics/comms modules*

o Add or remove integral indicators*

o Add or remove lightning protection (terminal connection)*

* Field replaceable in all electrical environments (including IS)

except flameproof without violating agency approvals.

With no performance effects, Honeywell’s unique modularity

results in lower inventory needs and lower overall operating

costs.

Plugged Impulse Line Detection:

STG800 models are offered with a PILD option which

provides indication of a plugged impulse line or process

connection. When used in conjunction with a basic or

advanced display, a non-critical diagnostic indication appears

on the integral display. For units without an integral display,

an indication can be seen via the host or hand held device

when HART Protocol is utilized.

Dual/Triple Calibration:

STG800 models are optionally offered with multiple

calibrations. In lieu of a standard factory calibration, units

can be supplied with 1, 2, or 3 customer specified

calibrations. These calibrations are stored in the meter body

and provide users with factory calibrated performance at up

to three different calibrated ranges. This increases

application flexibility without requiring any costly recalibration

or additional inventory.

4 STG800 Smart Pressure Transmitter

Performance Specifications

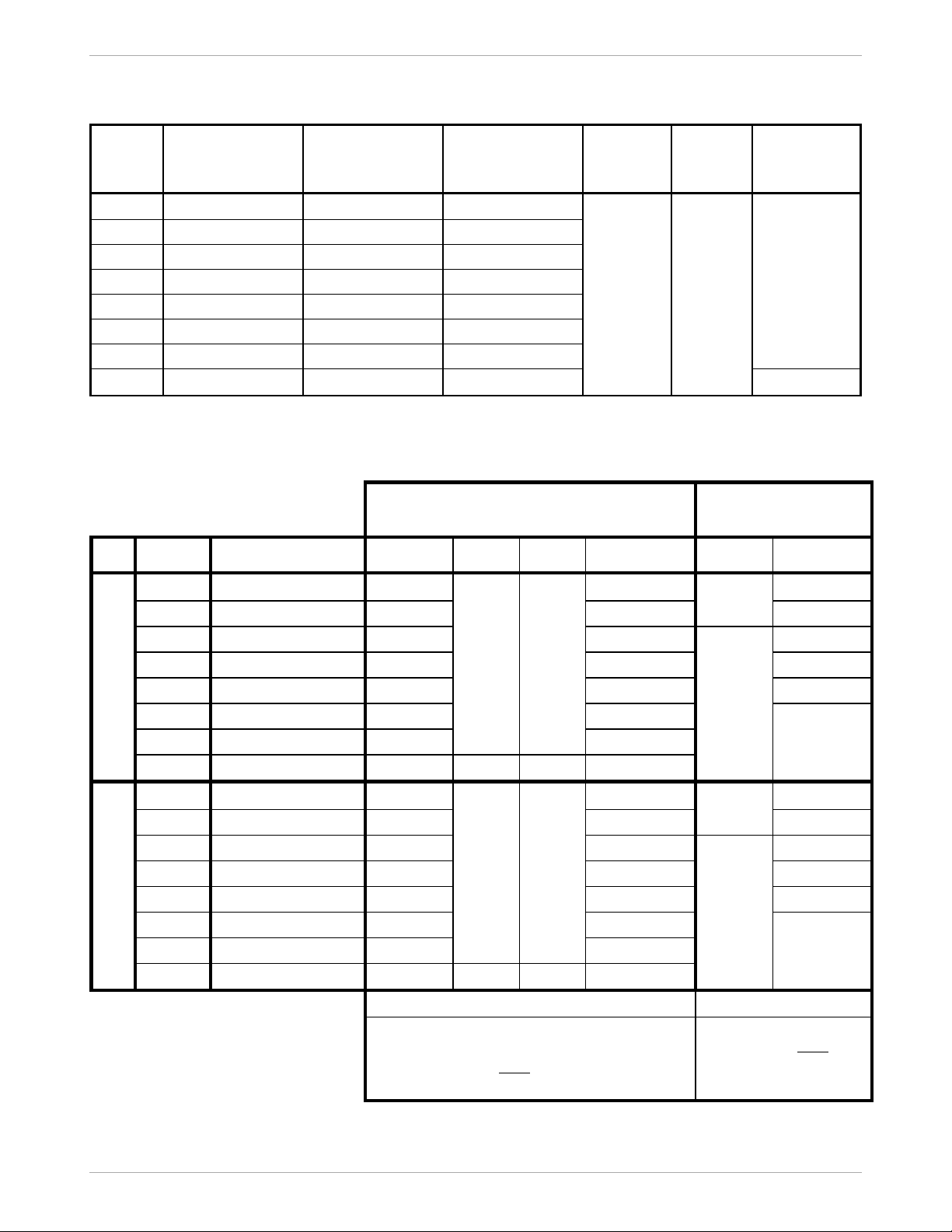

Reference Accuracy: (conformance to +/-3 Sigma)

Table 1

Model

URL

LRL

Min Span

Maximum

Turndown

Ratio

Stability

(% URL/

Yr for 15

years)

Reference

Accuracy

1,2

(% Span)

Std / Opt.

STG830

50 psi (3.5 bar)

-14.7 psi (-1.0 bar)

0.5 psi (.035 bar)

100:1

0.010

0.0375 / 0.025

STG83L

50 psi (3.5 bar)

-14.7 psi (-1.0 bar)

0.5 psi (.035 bar)

STG840

500 psi (35 bar)

-14.7 psi (-1.0 bar)

5 psi (.35 bar)

STG84L

500 psi (35 bar)

-14.7 psi (-1.0 bar)

5 psi (.35 bar)

STG870

3000 psi (210 bar)

-14.7 psi (-1.0 bar)

30 psi (2.1 bar)

STG87L

3000 psi (210 bar)

-14.7 psi (-1.0 bar)

30 psi (2.1 bar)

STG88L

6000 psi (420 bar)

-14.7 psi (-1.0 bar)

60 psi (4.2 bar)

STG89L

10000 psi (690 bar)

-14.7 psi (-1.0 bar)

100 psi (6.9 bar)

0.055 / 0.04

Zero and span may be set anywhere within the listed (URL/LRL) range limits

Accuracy at Specified Span and Temperature: (Conformance to +/-3 Sigma)

Table 2

Accuracy

1,2

(% of Span)

Combined Zero & Span

Temperature Effect

(% Span/ 28

o

C (50

o

F))

Model

URL

Reference

Turndown

A

B

C

(see URL units)

D

E

Standard

Accuracy

STG830

50 psi (3.5 bar)

33.3:1

0.005

0.0325

1.5 (0.105)

0.030

0.003

STG83L

50 psi (3.5 bar)

16:1

3 (0.21)

0.006

STG840

500 psi (35 bar)

35:1

14.5 (1.0)

0.025

0.004

STG84L

500 psi (35 bar)

35:1

14.5 (1.0)

0.007

STG870

3000 psi (210 bar)

10:1

300 (21)

0.005

STG87L

3000 psi (210 bar)

10:1

300 (21)

0.010

STG88L

6000 psi (420 bar)

12:1

600 (35)

STG89L

10000 psi (690 bar)

10:1

0.015

0.0400

1000 (69)

High Accuracy Option

STG830

50 psi (3.5 bar)

0.005

0.0200

1.5 (0.105)

0.030

0.003

STG83L

50 psi (3.5 bar)

16:1

3 (0.21)

0.006

STG840

500 psi (35 bar)

24:1

14.5 (1.0)

0.025

0.004

STG84L

500 psi (35 bar)

14.5 (1.0)

0.007

STG870

3000 psi (210 bar)

6.7:1

300 (21)

0.005

STG87L

3000 psi (210 bar)

300 (21)

0.010

STG88L

6000 psi (420 bar)

600 (35)

STG89L

10000 psi (690 bar)

15:1

0.015

0.0250

1000 (69)

Turn Down Effect

Temp Effect

5 STG800 Smart Pressure Transmitter

Total Performance (% of Span):

Total Performance Calculation: = +/- √ (Accuracy)2 + (Temperature Effect)2

Total Performance Examples (for comparison): Standard accuracy 5:1 Turndown, +/-50 oF (28oC) shift

STG830 @ 10 psi

0.059% of span

STG840 @ 100 psi

0.059% of span

STG870 @ 600 psi

0.063% of span

STG83L @ 10 psi

0.071% of span

STG84L @ 100 psi

0.071% of span

STG87L @ 600 psi

0.084% of span

STG88L @ 1200 psi

0.084% of span

STG89L @ 2000 psi

0.093% of span

Typical Calibration Frequency:

Calibration verification is recommended every four (4) years

Notes:

1. Terminal Based Accuracy - Includes combined effects of linearity, hysteresis, and repeatability. Analog output adds 0 .005% of span.

2. For zero based spans and reference conditions of: 25 oC (77oF) for LRV>= 0 psia, 10 to 55% RH, and 316 Stainless Steel barrier diaphragm.

3. STG830 and STG83L, for LRV<0 and / or URV<0, B = 1.25 and E = 0.25.

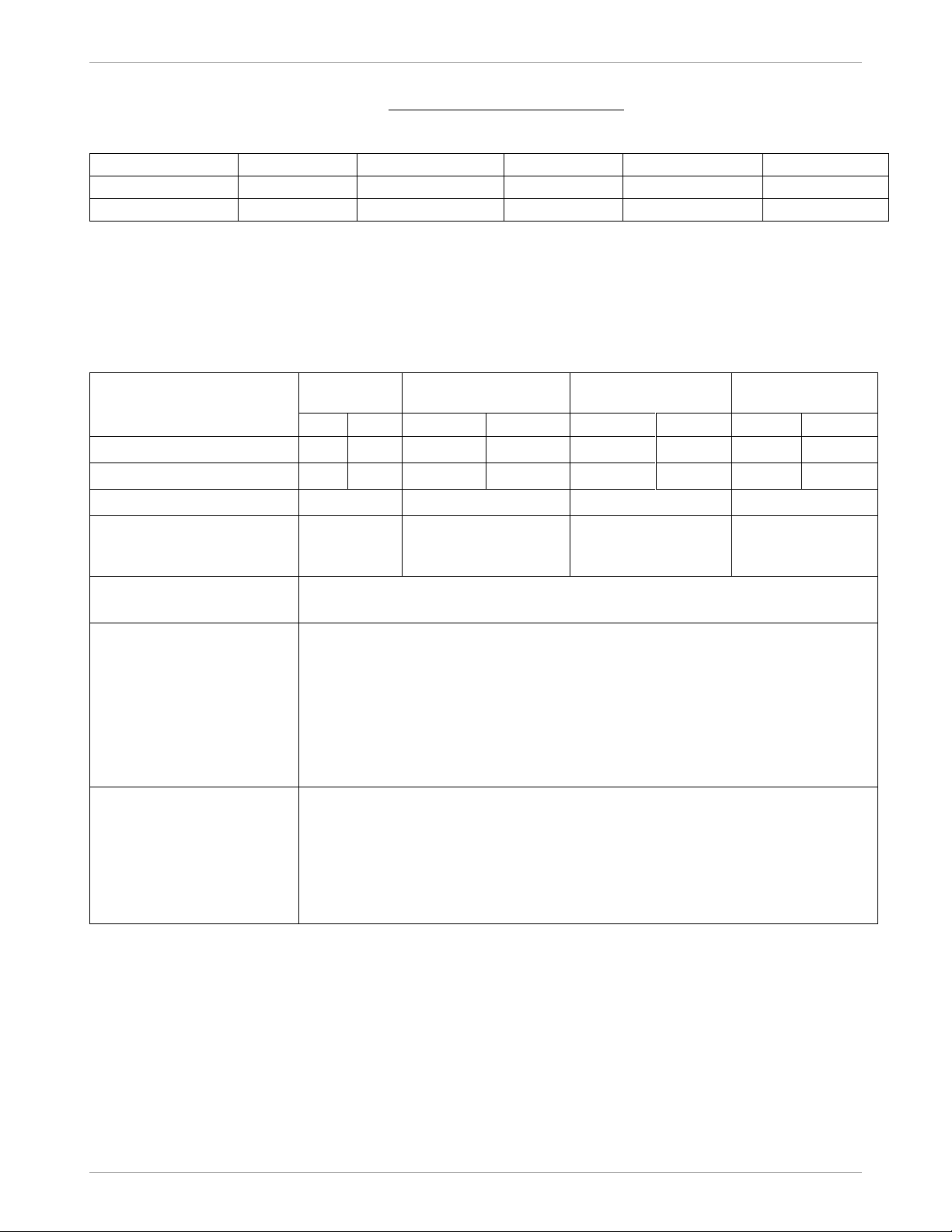

Operating Conditions – All Models

Parameter

Reference

Condition

Rated Condition

Operative Limits

Transportation and

Storage

C

F

C

F

C

F

C

F

Ambient Temperature1

25±1

77±2

-40 to 85

-40 to 185

-40 to 85

-40 to 185

-55 to 120

-67 to 248

Meter Body Temperature2

25±1

77±2

-40 to 1101

-40 to 2301

-40 to 125

-40 to 257

-55 to 120

-67 to 248

Humidity %RH

10 to 55

0 to 100

0 to 100

0 to 100

Vac. Region – Min. Pressure

mmHg absolute

inH2O absolute

Atmospheric

Atmospheric

25

13

2 (short term)3

1 (short term)3

Supply Voltage

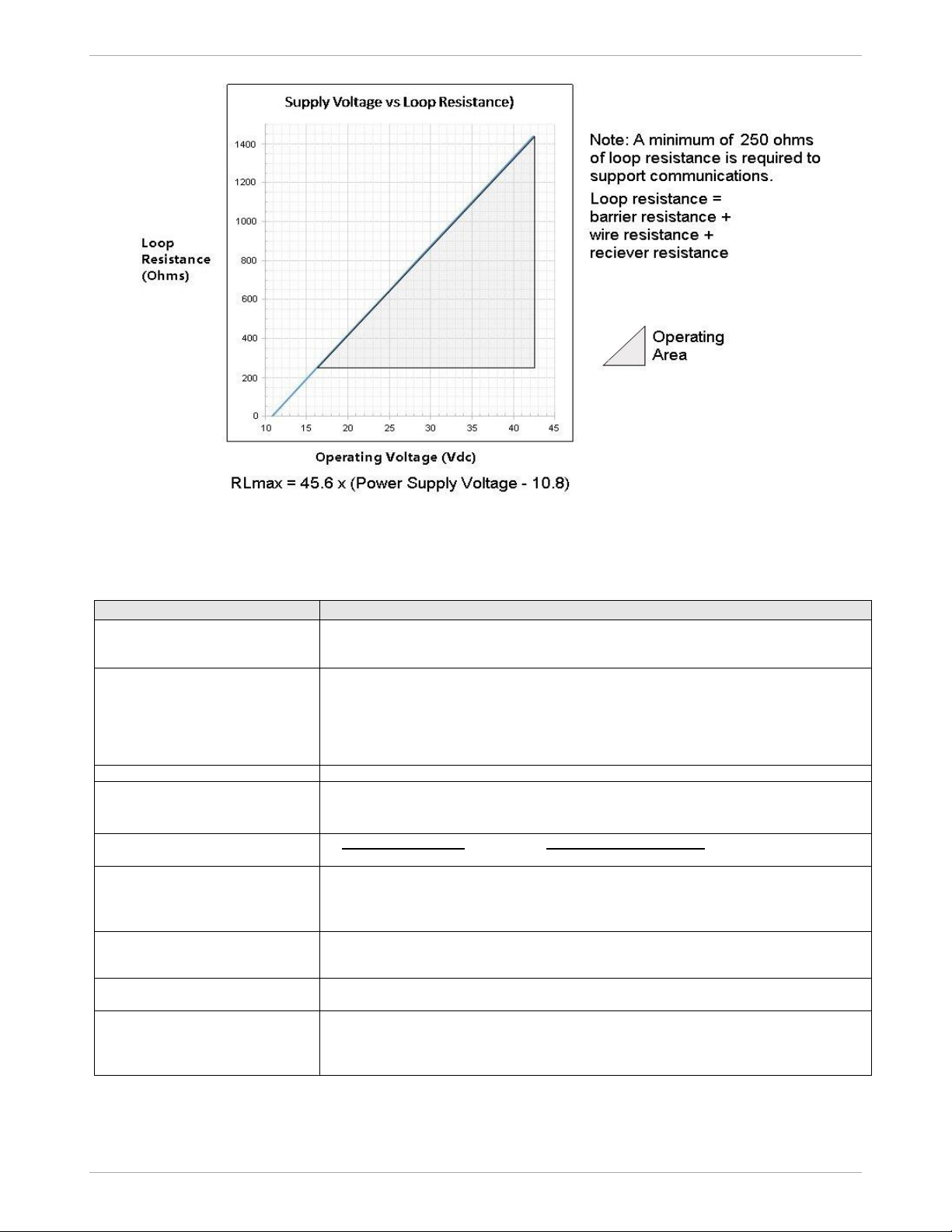

Load Resistance

10.8 to 42.4 Vdc at terminals

0 to 1,440 ohms (as shown in Figure 2)

Maximum Allowable

Working Pressure (MAWP)4

(Maximum allowable working

pressure is the maximum pressure

allowed for the normal transmitter

operation. MAWP depends on

Approval agencies and transmitter

material of construction. MAWP are

same as URL for gauge and

absolute pressure transmitters)

STG830: 50 psi (3.5 bar) STG83L: 50 psi (3.5 bar)

STG840: 500 psi (35 bar) STG84L: 500 psi (35 bar)

STG870: 3000 psi (210 bar ) STG87L: 3000 psi (210 bar)

STG88L: 6000 psi (420 bar)

STG89L: 10000 psi (690 bar)

Over pressure

These are the pressure limits

the transmitters can

withstand without damage

STG830: 75 psi (5.25 bar) STG83L: 75 psi (5.25 bar)

STG840: 1500 psi (103 bar) STG84L: 1500 psi (103 bar)

STG870: 4500 psi (310 bar) STG87L: 4500 psi (310 bar)

STG88L: 9000 psi (620 bar)

STG89L: 15000 psi (1035 bar)

1

LCD Display operating temperature -20C to +70C . Storage temperature -30C to 80C.

2

Silicone 704 minimum temperature rating is 0oC (32oF). CTFE minimum temperature rating is -30C (-22F).

NEOBEE M-20 minimum temperature rating is -15oC (5oF). NEOBEE

is a registered trademark of Stepan Company.

3

Short term equals 2 hours at 70C (158F).

4

Consult factory for MAWP of ST 800 transmitters with CRN approval.

6 STG800 Smart Pressure Transmitter

Figure 2 - Supply voltage and loop resistance chart & calculations

Performance Under Rated Conditions – All Models

Parameter

Description

Analog Output

Digital Communications:

Two-wire, 4 to 20 mA (HART & DE Transmitters only)

Honeywell DE, HART 7 protocol or FOUNDATION Fieldbus ITK 6.0.1 compliant

All transmitters, irrespective of protocol have polarity insensitive connection.

HART & DE Output Failure

Modes

(NAMUR for DE Units requires

selecting display and

configuration buttons or factory

configuration)

Honeywell Standard: NAMUR NE 43

Compliance:

Normal Limits: 3.8 – 20.8 mA 3.8 – 20.5

mA

Failure Mode: ≤ 3.6 mA and ≥ 21.0 mA ≤ 3.6 mA and ≥

21.0 mA

Supply Voltage Effect

0.005% span per volt.

Transmitter Turn on Time

(includes power up & test

algorithms)

HART or DE: 2.5 sec

Foundation Fieldbus: Host dependent

Response Time

(delay + time constant)

DE/HART Protocol FOUNDATION Fieldbus

80ms 150ms (Host Dependent)

Damping Time Constant

HART: Adjustable from 0 to 32 seconds in 0.1 increments. Default Value: 0.5

seconds

DE: Discrete values 0, 0.16, 0.32, 0.48, 1, 2, 4, 8, 16, 32 seconds. Default Value:

0.48 seconds

Vibration Effect

Less than +/- 0.1% of URL w/o damping

Per IEC60770-1 field or pipeline, high vibration level (10-2000Hz: 0.21

displacement/3g max acceleration)

Electromagnetic Compatibility

Complies with EMC directive 2004/108/EC per IEC 61326-3-1 (HART/ DE Units) IEC

61326-1 (FF Units)

Lightning Protection Option

Leakage Current: 10uA max @ 42.4VDC 93C

Impulse rating:

8/20uS 5000A (>10 strikes) 10000A (1 strike min.)

10/1000uS 200A (> 300 strikes)

7 STG800 Smart Pressure Transmitter

Materials Specifications (see model selection guide for availability/restrictions with various models)

Parameter

Description

Barrier Diaphragms Material

STG800: 316L SS, Hastelloy® C-2762, Monel® 4003, Tantalum, Gold-plated 316L SS,

Gold-plated Hastelloy® C-276, Gold-plated Monel® 400

STG80L: 316L SS, Hastelloy C-276

Process Head Material

STG800: Carbon Steel (Zinc Plated), 316 SS4, Hastelloy® C-2766, Monel® 400

7

STG80L: 316L SS, Hastelloy C-2766

Vent/Drain Valves & Plugs

1

STG800:316 SS4, Hastelloy C-2762, Monel 400

7

STG80L: N/A

Head Gaskets

STG800: Glass-filled PTFE standard. Viton® and graphite are optional. STG80L: N/A

Meter Body Bolting

STG800: Carbon Steel (Zinc plated) standard. Options include 316 SS, NACE A286

SS bolts and nuts or NACE A286 SS bolts and 304 SS nuts STG80L: N/A

Mounting Bracket

Carbon Steel (Zinc-plated) or 304 SS or 316SS angle bracket or Carbon Steel or

304SS or 316SS flat bracket available with 2” pipe bracket. See Figure 3.

Fill Fluid

Silicone 200, CTFE, NEOBEE M-20 or Silicone 704

Electronic Housing

Pure Polyester Powder Coated Low Copper (<0.4%)-Aluminum. Meets NEMA 4X,

IP66, IP67 and NEMA 7 (explosion proof). All stainless steel housing is optional.

Process Connections

STG800: ½ -inch NPT female, DIN 19213 (standard)

STG80L: ½ -inch NPT female, ½ -inch NPT male, 9/16 Aminco, DIN19213 (except

STG89L),

G ½ -B Male threaded

Wiring

Accepts up to 16 AWG (1.5 mm diameter).

Dimensions

See Figure 4 and 5

Net Weight

STG800: 8.3 pounds (3.8 Kg). STG80L: 3.6 pounds (1.6 Kg) with Aluminum Housing

1

Vent/Drains are sealed with Teflon®

2

Hastelloy

®

C-276 or UNS N10276

3

Monel® 400 or UNS N04400 4 Supplied as 316 SS or as Grade CF8M, the casting equivalent of 316 SS.

5

Carbon Steel heads are zinc-plated and not recommended for water service due to hydrogen migration. For that service, use 316 stainless steel wetted

Process Heads.

6

Hastelloy

®

C-276 or UNS N10276. Supplied as indicated or as Grade CW12MW, the casting equivalent of Hastelloy® C-276

7

Monel® 400 or UNS N04400. Supplied as indicated or as Grade M30C, the casting equivalent of Monel® 400

Loading...

Loading...