Page 1

Airport Systems

Installation and Operation Guide

Manual Number EPM-00000019-001

for

High Intensity Obstruction

Lighting System

Model SG-60

Honeywell Airport Systems

2162 Union Place

Simi Valley, CA 93065

Phone (805) 581-5591

Fax (805) 581-5032

www.oblighting.com

Copyright 2002 Honeywell Inc.

All Rights Reserved

Page 2

Airport Systems

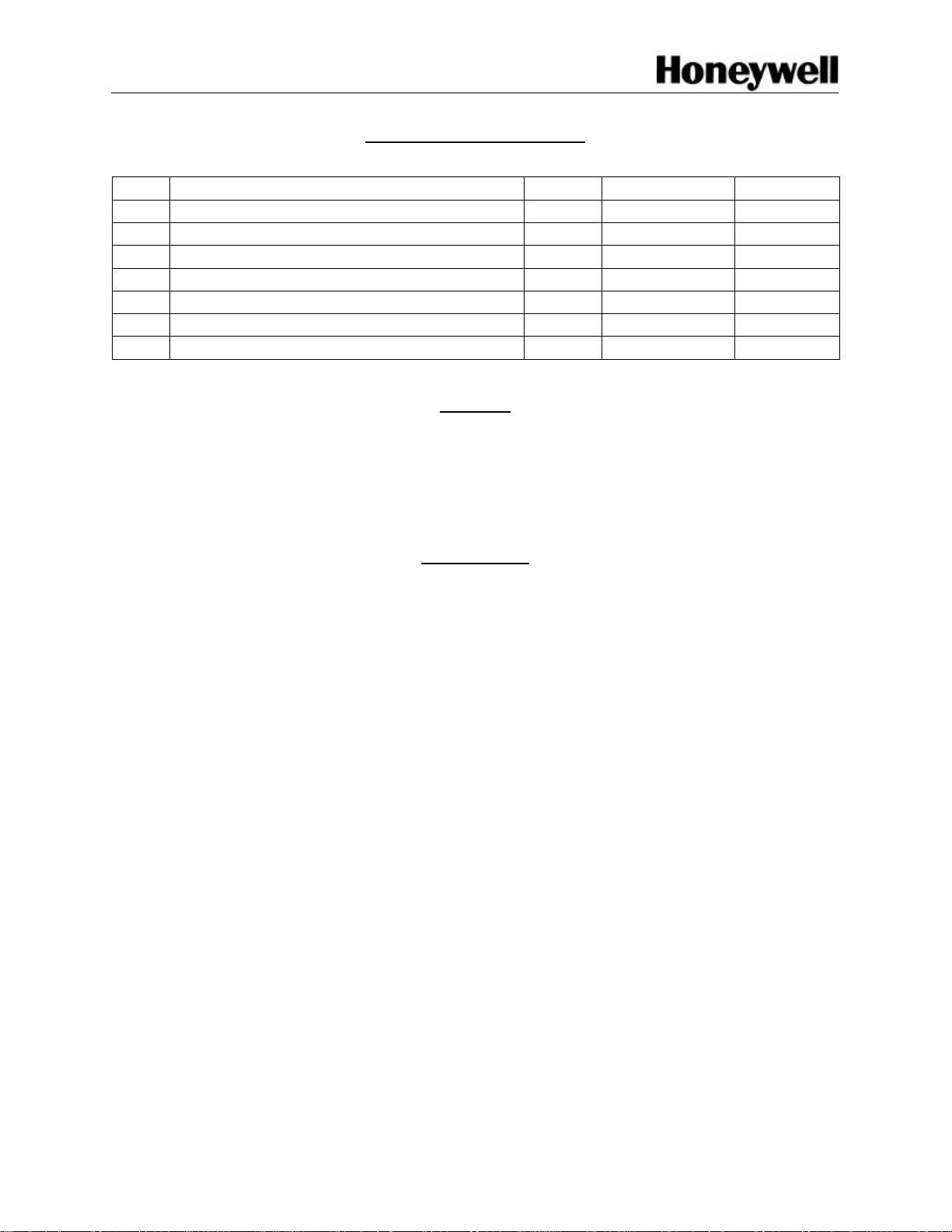

HISTORY OF REVISIONS

Rev. Comment ECO# Approved Date

A First Release (New Boards) 3637 S. Hammond 8/30/2002

NOTICE

The integrity and reliability of Honeywell airport lighting systems are dependent on the use

of Honeywell parts and components. To ensure the optimum performance and reliability of

your Honeywell system, it is strongly advised that only components and modules provided

by Honeywell be used.

WARRANTY

Honeywell warrants the equipment described in this instruction manual and sold to

the purchaser to be free from defects in material and workmanship at the time of shipment.

Honeywell’s liability under this warranty being limited to repairing or replacing, at

Honeywell’s option, items which are returned to it prepaid within one year from date of

installation or a maximum of two years from date of shipment (whichever is less) to the

original Purchaser and found, to Honeywell’s satisfaction, to have been defective. In no

event shall Honeywell be liable for consequential damages. NO PRODUCT IS

WARRANTED AS BEING FIT FOR A PARTICULAR PURPOSE AND THERE IS NO

WARRANTY OF MERCHANTABILITY. This warranty applies only if: (I) the items are

used solely under the operating conditions and in the manner recommended in Honeywell’s

instruction manual, specifications, or other literature; (II) the items have not been misused

or abused in any manner or repairs attempted thereon; (III) written notice of the failure

within the warranty period is forwarded to Honeywell and the directions received for

properly identifying items returned under warranty are followed; and (IV) such return notice

authorizes Honeywell to examine and disassemble returned products to the extent

Honeywell deems necessary to ascertain the cause of failure. The warranties stated herein

are exclusive. THERE ARE NO OTHER WARRANTIES, EITHER EXPRESSED OR

IMPLIED, BEYOND THOSE SET FORTH HEREIN, and Honeywell does not assume, nor

does Honeywell authorize anyone else to assume for it, any other obligation or liability in

connection with the sale or use of said products. Honeywell’s liability on any claim of any

kind, including negligence, for loss or damages arising out of or connected with the

manufacture, sale, delivery, repair or use of any equipment or services provided by

Honeywell shall in no case exceed the price allocable to the item or service or part thereof

which gives rise to the claim.

EPM-00000019-001 i Rev A

Page 3

Airport Systems

DISCLAIMERS

This manual could contain technical inaccuracies or typographical errors. Honeywell

reserves the right to revise this manual from time to time of the contents thereof without

obligation of Honeywell to notify any person of such revision or change. Details and

values given in this manual are average values and have been compiled with care.

They are not binding, however, and Honeywell disclaims any liability for damages or

detriments suffered as a result of reliance on the information given herein or the use of

product, processes or equipment to which this manual refers. No warranty is made that

the use of the information or of the products processes or equipment to which this

manual refers will not infringe any third party’s patents or rights. The information given

does not release the buyers from making their own experiments and tests.

EPM-00000019-001 ii Rev A

Page 4

Airport Systems

TABLE OF CONTENTS

SAFETY INFORMATION ............................................................................................... V

SECTION 1. GENERAL INFORMATION.....................................................................1-1

1.1 SCOPE ......................................................................................................................................1-1

1.2 GENERAL DESCRIPTION ..............................................................................................................1-1

1.2.1 Model SGC-60 Master Controller.....................................................................................1-1

1.2.2 Model SGF-60 Flashhead................................................................................................1-1

1.2.3 Ambient Light Sensor (P/N 12H00107-001).......................................................................1-1

1.3 SAFETY PRECAUTIONS................................................................................................................1-4

1.4 SPECIFICATIONS.........................................................................................................................1-6

SECTION 2. INSTALLATION & POWER UP...............................................................2-1

2.1 UNPACKING ...............................................................................................................................2-1

2.2 SYSTEM CONFIGURATION.............................................................................................................. 2-1

2.2.1 Master Controller Configuration .......................................................................................2-1

2.2.2 Flashhead Configuration..................................................................................................2-3

2.3 INSTALLATION ............................................................................................................................2-6

2.3.1 SGC-60 Master Controller...............................................................................................2-6

2.3.2 SGF-60 Flashhead...........................................................................................................2-6

2.3.3 Ambient Light Sensor (Photocell) .....................................................................................2-7

2.3.4 Cables and Junction Boxes ..............................................................................................2-8

2.4 INSTALLATION WIRING ..............................................................................................................2-11

2.4.1 Master Controller to Photocell Wiring.............................................................................2-12

2.4.2 Master Controller Data/Communications Wiring............................................................. 2-12

2.4.3 Master Controller Power Wiring .....................................................................................2-12

2.4.4 Master Controller Wiring For Dual Systems ...................................................................2-13

2.4.5 Flashhead Wiring........................................................................................................... 2-14

2.4.6 Conduit and Tower Wiring Detail ...................................................................................2-14

2.4.7 Junction Box Details...................................................................................................... 2-18

2.5 FINAL INSTALLATION CHECK ......................................................................................................2-27

2.5.1 Preliminary ....................................................................................................................2-27

2.5.2 Verify Correct Wiring in Master Controller ......................................................................2-27

2.5.3 Verifying Photocell Wiring.............................................................................................. 2-27

2.5.4 Verify Proper Tower Wiring for Data/Control Cable........................................................2-27

2.6 POWER UP AND SYSTEM TESTS.................................................................................................2-28

2.6.1 Master Controller Status Indicators ................................................................................2-28

2.6.2 Flashhead Status Indicators...........................................................................................2-29

2.6.3 System Power Up..........................................................................................................2-29

2.6.4 Verify Local Mode Operation..........................................................................................2-30

2.6.5 Verify Photocell Operation Connected to Controller .......................................................2-33

2.6.6 Verify Photocell Operation Not Connected to Controller.................................................2-33

SECTION 3. PRINCIPLES OF OPERATION ...............................................................3-1

3.1 OVERALL DESCRIPTION...............................................................................................................3-1

3.2 SGF-60 FLASHHEAD.................................................................................................................. 3-1

3.2.1 SGF-60 Motherboard....................................................................................................... 3-3

3.2.2 SGF-60 Digital Board.......................................................................................................3-3

3.2.3 SGF-60 Trigger/High-Voltage Board................................................................................3-6

3.3 SGC-60 MASTER CONTROLLER ..................................................................................................3-8

3.3.1 Power Supply...................................................................................................................3-8

3.3.2 Flash Requests and Flashhead Status.............................................................................3-8

3.3.3 System Mode Selection...................................................................................................3-9

EPM-00000019-001 iii Rev A

Page 5

Airport Systems

3.3.4 Communications Circuitry.............................................................................................. 3-10

SECTION 4. TROUBLESHOOTING............................................................................4-1

SECTION 5. MAINTENANCE ......................................................................................5-1

5.1 SGC-60 MASTER CONTROLLER ..................................................................................................5-1

Transformer Replacement ............................................................................................................5-1

5.2 SGF-60 FLASHHEAD.................................................................................................................. 5-2

5.2.1 Flashtube Replacement...................................................................................................5-2

5.3 AMBIENT LIGHT SENSOR (PHOTOCELL).........................................................................................5-3

SECTION 6. REPLACEMENT PARTS ........................................................................6-1

SECTION 7. ANTENNA OBSTRUCTION LIGHT (AOL) .............................................7-1

TABLE OF FIGURES

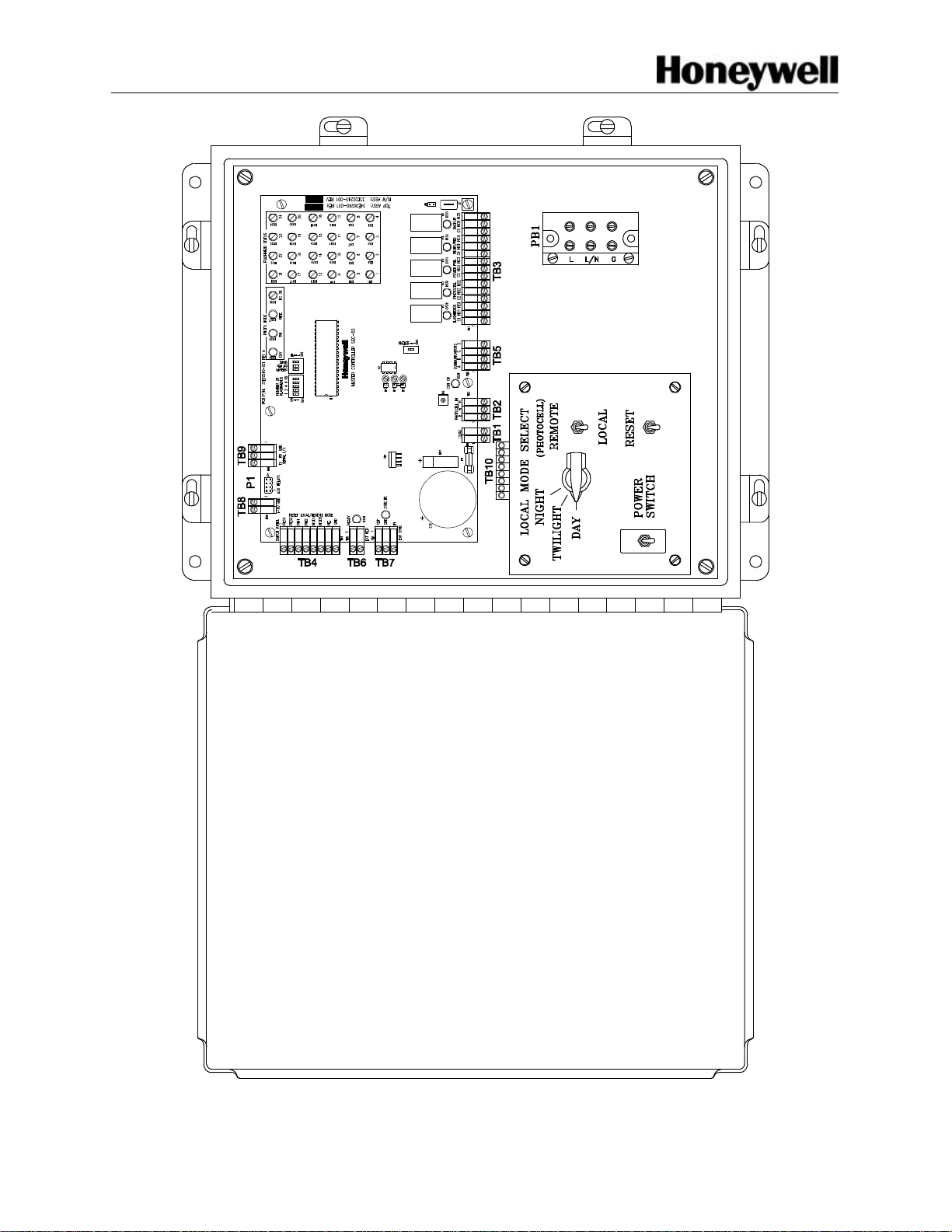

Figure 1-1: Model SGC-60 Master Controller...............................................................1-2

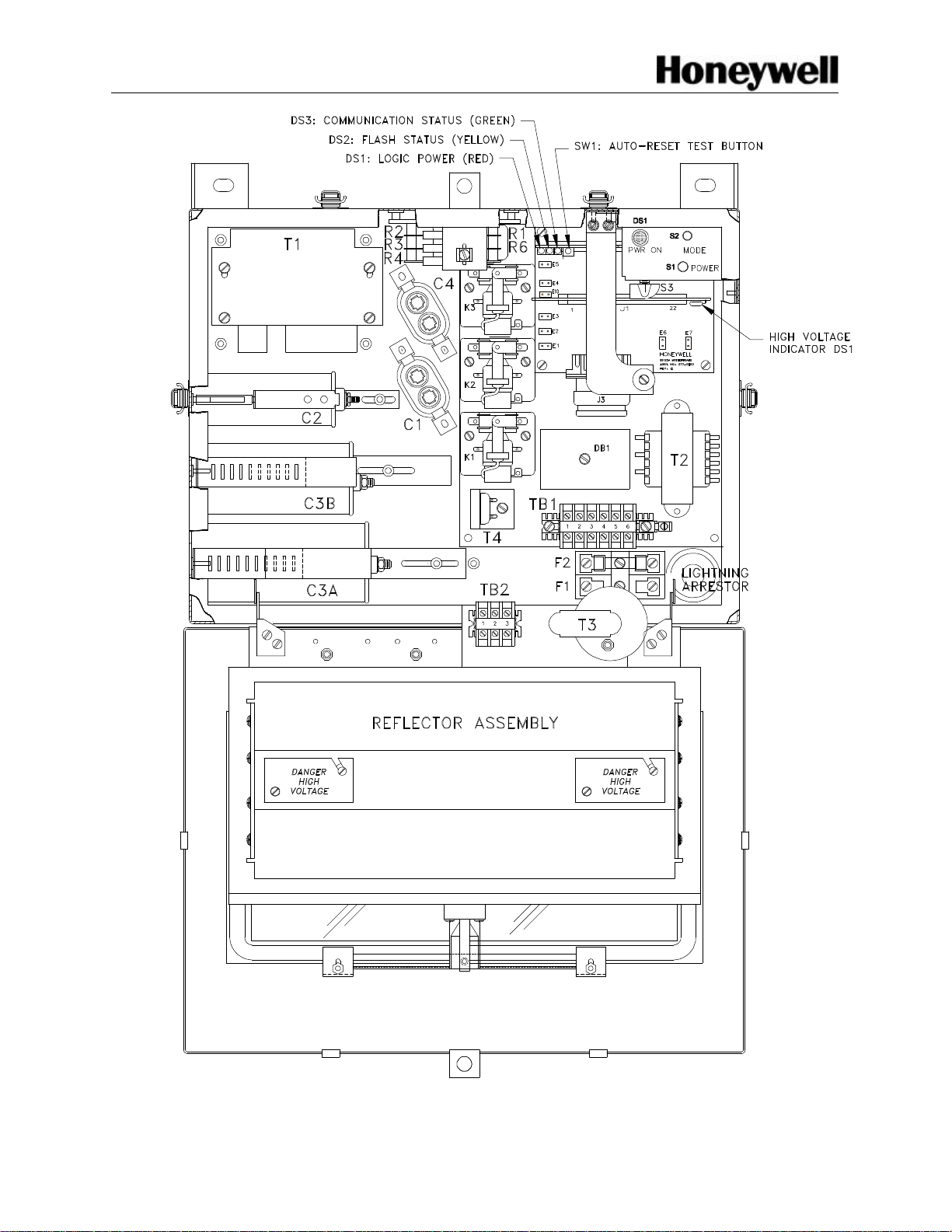

Figure 1-2: Model SGF-60 Flashhead..........................................................................1-3

Figure 2-1: Flashtube Installation.................................................................................2-6

Figure 2-2: Master Controller Mounting Dimensions....................................................2-9

Figure 2-3: Flashhead Outline and Mounting Dimensions............................................2-10

Figure 2-4: Typical Wiring Installation..........................................................................2-11

Figure 2-5: Flex Conduit Typical Installation Layout..................................................2-15

Figure 2-6: Junction Box Wiring Details.....................................................................2-19

Figure 2-7: Flex Conduit Installation Detail................................................................2-20

Figure 2-8: WC000001 Cable Overview ....................................................................2-21

Figure 2-9: Flashhead Cable.......................................................................................2-24

Figure 2-10: Master Controller Circuit Board .............................................................2-25

Figure 2-11: Flashhead Digital Control Board............................................................2-26

Figure 3-1: Master Controller Board Schematic.........................................................3-11

Figure 3-2: SGF-60 Flashhead System Schematic....................................................3-12

Figure 3-3: SGF-60 Digital Board Schematic.............................................................3-13

Figure 3-4: SGF-60 Trigger/High-Voltage Board Schematic......................................3-14

Figure 4-1: General Troubleshooting – All Flashheads Stuck in Day Mode ................4-3

Figure 4-2: General Troubleshooting – Flashhead Does Not Flash.............................4-4

Figure 4-3: General Troubleshooting – Flashhead Stuck in Day Mode.......................4-5

Figure 4-4: Dual System-Specific Troubleshooting......................................................4-6

Figure 4-5: Catenary System-Specific Troubleshooting Chart.....................................4-7

Figure 5-1: SGC-60 Replacement Transformer ...........................................................5-1

Figure 5-2: Flashtube Installation.................................................................................5-3

Figure 7-1: SG-60 AOL Flashhead Mounting Dimensions...........................................7-2

Figure 7-2: SG-60 AOL Power Supply Mounting Dimensions......................................7-3

Figure 7-3: SG-60 AOL Wiring Installation...................................................................7-4

Figure 7-4: SG-60 AOL Flashhead Component Locations...........................................7-5

Figure 7-5: SG-60 AOL Power Supply Component Locations......................................7-6

Figure 7-6: SG-60 AOL Schematic...............................................................................7-7

EPM-00000019-001 iv Rev A

Page 6

Airport Systems

SAFETY INFORMATION

This section contains general safety instructions for using your Honeywell equipment. Task

and equipment-specific Warnings are included in other sections of this manual where

appropriate. Read all Warnings and follow all instructions carefully. Failure to do so may

result in personal injury, death, or property damage. To use this equipment safely, refer to

the following:

1. Refer to the FAA Advisory Circular AC 150/5340-26, Maintenance of Airport Visual

Aids Facilities, for instructions on safety precautions.

2. Observe all safety regulations. To avoid injuries, always remove power prior to making

any wire connections and/or touching any parts. Refer to FAA Advisory Circular AC

150/5340-26.

3. Read and become familiar with the general safety instructions provided in this section

of the manual before installing, operating, maintaining, or repairing this equipment.

4. Read and carefully follow the instructions given throughout this manual before

performing specific tasks and working with specific equipment.

5. Store this manual within easy reach of personnel installing, operating, maintaining, or

repairing this equipment.

6. Follow all applicable safety procedures required by your company, industry standards,

and government or other regulatory agencies.

7. Obtain and read Material Safety Data Sheets (MSDS) for all materials used.

SAFETY AND WORKMANSHIP ALERTS

This manual uses two types of markings when giving instructions requiring special

attention. The markings will be followed by indented text:

WARNING!

The WARNING sign in this manual denotes a hazard. The WARNING

calls attention to a procedure or practice which, if not correctly

performed or adhered to, could result in property damage, injury or

death. Do not proceed beyond a WARNING sign until the indicated

conditions are fully understood and met.

.

CAUTION

Failure to obey the instructions following a CAUTION marking may

result in equipment damage.

EPM-00000019-001 v Rev A

Page 7

Airport Systems

QUALIFIED PERSONNEL

The term “qualified personnel” is defined here as individuals who thoroughly

understand the equipment and its safe operation, maintenance, and repair. Qualified

personnel are physically capable of performing the required tasks, familiar with all

relevant safety rules and regulations and have been trained to safely install, operate,

maintain, and repair the equipment. It is the responsibility of the company operating

this equipment to see that its personnel meet these requirements.

INTERLOCKS

This equipment contains interlocks for your protection. To ensure safety, always

remove power from the equipment prior to opening access panels or doors if possible.

Do not depend on the interlocks or door switches when working with the equipment.

Do not short-circuit or tamper with any access gate, door or other safety interlock

switch. Discharge capacitors with an approved insulated grounding rod prior to

touching any part. When it is absolutely mandatory that an interlock be bypassed for

the purpose of tracing or correcting a malfunction, authorized maintenance personnel

may perform the bypass for the specific test to be made. Immediately after completing

the test, restore the interlock to working condition.

WARNING!

INTENDED USE

HONEYWELL IS NOT RESPONSIBLE FOR INJURIES OR DAMAGES

RESULTING FROM NONSTANDARD, UNINTENDED APPLICATIONS OF

ITS EQUIPMENT. THIS EQUIPMENT IS DESIGNED AND INTENDED

ONLY FOR THE PURPOSE DESCRIBED IN THIS MANUAL. USES NOT

DESCRIBED IN THIS MANUAL ARE CONSIDERED UNINTENDED USES

AND MAY RESULT IN SERIOUS PERSONAL INJURY, DEATH OR

PROPERTY DAMAGE. UNINTENDED USES MAY RESULT FROM

TAKING ANY OF THE ACTIONS LISTED BELOW.

1. Making changes to the equipment that have not been recommended

or described in this manual, or using parts that are not genuine

Honeywell replacement parts.

2. Failing to make sure that auxiliary equipment complies with approval

agency requirements, local codes, and all applicable safety

standards.

3. Using materials or auxiliary equipment that are inappropriate or

incompatible with your Honeywell equipment.

4. Allowing unqualified personnel to perform any task.

EPM-00000019-001 vi Rev A

Page 8

Airport Systems

KEEP AWAY FROM LIVE CIRCUITS. OPERATION AND MAINTENANCE

PERSONNEL MUST OBSERVE ALL SAFETY REGULATIONS AT ALL

TIMES. DO NOT CHANGE PLUG-IN COMPONENTS OR MAKE

ADJUSTMENTS INSIDE EQUIPMENT WITH THE HIGH VOLTAGE

SUPPLY ON. UNDER CERTAIN CONDITIONS, THERE IS A POTENTIAL

FOR SERIOUS INJURY FROM CIRCUITS WITH POWER CONTROLS IN

THE OFF POSITION. THIS IS DUE TO CHARGES RETAINED BY THE

CAPACITORS. TO AVOID SERIOUS INJURY, ALWAYS DISCONNECT

POWER, THEN DISCHARGE CAPACITORS BY USING AN APPROVED

GROUNDING ROD PRIOR TO TOUCHING ANY PART.

RESUSCITATION. MAINTENANCE PERSONNEL SHOULD BE TRAINED

IN CARDIOPULMONARY RESUSCITATION (CPR).

WARNING!

CAUTION

This equipment contains static sensitive semiconductor devices and

integrated circuits that may be damaged by Electro-Static Discharge

(ESD). Take the necessary precautions before attempting service.

Any replacement circuit boards should be kept in metallized anti-static

bags until immediately before installation. Ground yourself (touch the

outside of a grounded metal enclosure) before removing circuit boards

from their protective bags. Avoid touching components when handling

the boards.

EPM-00000019-001 vii Rev A

Page 9

Airport Systems

SECTION 1. GENERAL INFORMATION

1.1 Scope

This manual provides information about the installation, operation, and maintenance of

the StrobeGuard, Model SG-60, High Intensity Obstruction Lighting System

manufactured by Honeywell.

1.2 General Description

The StrobeGuard system is a high intensity flashing white obstruction lighting system

with a xenon flashtube as the light source. It designed for use as a high intensity

aviation obstruction warning system. The system is designed and manufactured to

comply with Federal Aviation Administration Advisory Circular 150/5345-43E. The

StrobeGuard system can support up to 24 Flashheads controlled by a single

controller at distances up to 2500 feet. The Flashheads are FAA light type L-856 or

L-857.

System components are shown in Figure 1-1 on Page 1-2, and Figure 1-2 on Page 1-3.

The system consists of the following units:

• Model SGC-60 Master Controller

• Model SGF-60 Flashhead

• Ambient Light Sensor

1.2.1 Model SGC-60 Master Controller

The Master Controller is a microprocessor-based system that controls the flash interval

and timing, flash intensity, and monitors the complete StrobeGuard system. The

controller is designed with LED status indicators and relays for remote alarming.

1.2.2 Model SGF-60 Flashhead

The Flashhead is designed as a capacitor discharge xenon flashtube unit. The

Flashhead consists of the following major components:

• Xenon flashtube

• Reflector

• High voltage trigger transformer

• Power supply (including high voltage)

• Control circuits

1.2.3 Ambient Light Sensor (P/N 12H00107-001)

The Ambient Light Sensor (photocell) is used to provide input to the controller. With

this input, the controller adjusts the operation of the system between day, twilight, and

night.

SG-60 High Intensity Strobe System 1-1 Manual EPM-00000019 Rev A

Page 10

Airport Systems

Figure 1-1: Model SGC-60 Master Controller

SG-60 High Intensity Strobe System 1-2 Manual EPM-00000019 Rev A

Page 11

Airport Systems

Figure 1-2: Model SGF-60 Flashhead

SG-60 High Intensity Strobe System 1-3 Manual EPM-00000019 Rev A

Page 12

Airport Systems

1.3 Safety Precautions

The following general safety precautions must be observed during all phases of operation,

service, and repair of this equipment. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of this equipment. Honeywell assumes no liability for the

customer’s failure to comply with these requirements, as listed below.

1. Any interruption of the protective grounding conductor (inside or

outside the instrument) or disconnecting the protective earth ground

terminal is likely to make this equipment dangerous. Intentional

interruption is prohibited.

2. Whenever it is likely that the ground protection has been impaired, the

equipment must be made inoperative by removing AC line power, and

then shall be secured against any unintended operation.

3. Ensure that only fuses with the required rated current and of the

specified type (normal blow, time delay, etc.) are used for replacement.

The use of repaired fuses and the short-circuiting of fuseholders must

be avoided.

4. Electrical energy available at many points may result in personal injury

or death if touched. Any adjustment, maintenance, and repair of the

opened equipment while power is applied shall be avoided as much as

possible, however some maintenance described in this manual is

performed with power supplied to the equipment while protective

covers are removed. When repair with power applied is unavoidable,

maintenance shall be carried out only by a skilled person who is aware

of the hazard involved. Do not attempt internal service or adjustment

unless another person, capable of rendering first aid and resuscitation,

is present.

5. Do not install substitute parts or perform any unauthorized modification

to the equipment.

6. Capacitors inside the equipment may still be charged after the

equipment has been disconnected from its power source, even though

the equipment was designed to drain charge from the capacitors when

power is removed. Do not put hands or tools in the Flashhead until

the High Voltage Indicator neon lamp DS1 on the High Voltage &

Trigger board is extinguished. (Refer to Figure 1-2, Page 1-3, for

the location of High Voltage Indicator DS1 - do not confuse the High

Voltage Indicator DS1, with the PWR ON lamp DS1.) Note that it is

possible for the High Voltage Indicator DS1 to be lit even when the

PWR ON lamp DS1 is off. If this happens, the energy storage

capacitors C1 - C3 must be discharged before performing

maintenance.

SG-60 High Intensity Strobe System 1-4 Manual EPM-00000019 Rev A

Page 13

Airport Systems

This system uses lethal voltages in the Flashhead. Unless absolutely

necessary, do not attempt to service or adjust the equipment with AC

line power applied.

Safety interlock switches are provided in the Flashhead enclosure to

interrupt main AC power to the power supply. These interlock switches

are activated when the Flashhead door is opened in a conventional

manner. No interlock is provided when other means of access are used.

Never tamper with (remove, short circuit) the interlocks in any way.

AC LINE VOLTAGE IS STILL PRESENT WHEN INTERLOCKS ARE

ACTIVATED. DISCONNECT POWER AT THE MAIN AC CIRCUIT

BREAKERS BEFORE INSPECTING OR SERVICING, UNLESS

ABSOLUTELY NECESSARY TO PERFORM MAINTENANCE WITH

POWER ON.

WARNING!

WARNING!

Flashtubes in this lighting system produce brilliant flashes of light

containing some ultraviolet radiation that can cause temporary or

permanent eye damage.

DO NOT LOOK DIRECTLY AT THE FLASHHEAD WHILE IT IS IN

OPERATION.

SG-60 High Intensity Strobe System 1-5 Manual EPM-00000019 Rev A

Page 14

Airport Systems

1.4 Specifications

Light Output:

Day Intensity..............................................270,000 ±25% effective candelas, single flash

Twilight Intensity..........................................20,000 ±25% effective candelas, single flash

Night Intensity.........................................2,000 ±25% effective candelas, burst of flashes

Beam Pattern...............................................................120º horizontally, 3º min. vertically

max. intensity of 3% of peak at -10º

Flash Rate: Day.........................................................................40 fpm - single white flash

Twilight..................................................................40 fpm - single white flash

Night................................................................40 fpm - white burst of flashes

Master/Slave Operation........Up to 24 slave SGF-60 Flashheads may share a common

sync and photocell circuit from one SGC-60 Master Controller.

Electrical Input:

Master Controller......................50 Watts. 120, 208, 240, 277, 380, 480 VAC. 50, 60Hz

Flashhead...............................500 Watts. 120, 208, 240, 277, 380, 480 VAC. 50, 60Hz

Requires specific voltage selector block and manual

change to transformer wiring for different AC voltages.

Mechanical Properties:

Flashhead

Weight...........................................................................................82 pounds (37.2 kg)

Dimensions............. 18.88"w (479.4mm) x 15.25"h (387.4mm) x 10.75"d (273.1mm)

Surface Area.......................................................................................1.89 square feet

Wind Load..............................................................100 pounds at 150 mph (240kph)

Master Controller

Weight ……………………………………………………… ........24 pounds (10.89 kg)

Dimensions .......................................14"w (356mm) x 12"h (305mm) x 6"d (152mm)

Operating Environment:

Operating Temperature..............................................................................-55ºC to +55ºC

Humidity.............................................................................................95% relative humidity

System Operating Status Indicators:

Flashhead, AC line power present ...............................................PWR ON Indicator DS1

Flashhead, high voltage present on capacitors ....................High Voltage Indicator DS1

(located on Trigger / High Voltage board)

Master Controller Indicators

Flashhead Status ..........................................................LEDs DS1 - DS24, red/green

Day Mode ..............................................................................................LED DS25 red

Twilight Mode ........................................................................................LED DS26 red

Night Mode ............................................................................................LED DS27 red

SG-60 High Intensity Strobe System 1-6 Manual EPM-00000019 Rev A

Page 15

Airport Systems

Flashhead Fail.........................................Relay K1 de-energized and LED DS29 Off

Photocell Fail.......................................... Relay K2 de-energized and LED DS30 Off

Power Fail................................................Relay K3 de-energized and LED DS31 Off

Night Mode Operation............................. Relay K4 de-energized and LED DS32 Off

White Night Backup (Dual Systems)........... Relay K5 energized and LED DS33 On

SG-60 High Intensity Strobe System 1-7 Manual EPM-00000019 Rev A

Page 16

Airport Systems

SECTION 2. INSTALLATION & POWER UP

WARNING!

Modifications to the Power Supply are required for certain applications.

Remove input power at circuit breakers and discharge capacitors with

an approved grounding rod before attempting any necessary

modifications.

2.1 Unpacking

Carefully unpack each item and remove any internal packing material from the master

controller, and the flashhead/power supply. Carefully check the supplied materials with

the High Intensity Lighting System bill of materials. There are many small items that

should be supplied inside clear plastic bags, verify each of these bags contain the

proper amount of parts per the bill of materials. Report any shortages of materials

immediately to the Honeywell Technical Support.

Examine each item for obvious physical damage. Report any claims to the carrier

immediately. Pertinent data such as installation drawings, schematics, interconnection

drawings, and operation manuals are included in the Master Controller carton. The

flashtubes are packaged separately inside each Flashhead carton. Do not remove

flashtubes from their boxes until you are ready to install them.

2.2 System Configuration

Honeywell pre-configures the system to match the installation. However, there are

cases where complete installation information is not available prior to the system

leaving the factory or the installation has changed. Setting the configuration may also

be necessary when replacing individual units in the system. The following is a guide

for configuring the Master Controller and the Flashheads.

2.2.1 Master Controller Configuration

There are a number of system control switches and configuration switch blocks (DIP

switches) on the Master Controller. The configuration switch blocks may have multiple

switches. Reference to the individual switches will be made by referring to the switch

block number followed by the number of the individual switch as labeled on the switch

block. For example, SW1 (Figure 2-10, Item 1, Page 2-25) has 5 individual switches.

The third switch from the left is labeled as #3 on the switch block and will be referred to

as SW1-3.

SG-60 High Intensity Strobe System 2-1 Manual EPM-00000019 Rev A

Page 17

Airport Systems

2.2.1.1 System Controls

Set Master Controller switches (Figure 1-1, Page 1-2) as follows:

POWER SWITCH -------------------------------------------------------------------------- OFF

LOCAL / REMOTE Switch ------------------------------------------------------------ LOCAL

MODE Switch ------------------------------------------------------------------------------- DAY

The Master Controller has the following control switches (Figure 1-1, Page 1-2):

• POWER SWITCH: Toggle switch that turns input AC line power on/off in the Master

Controller. Does not affect AC power to the Flashheads. Input voltage is present at

terminal block PB1, even with the power switch turned off.

• RESET Switch: Momentary pushbutton that resets the Master Controller. Switch

must be held for about one second to activate.

• REMOTE / LOCAL Mode Switch: Two-position toggle switch that permits manual

(local) selection of the flash intensity level using the DAY / TWILIGHT / NIGHT

rotary switch. In normal (remote) operation, permits automatic operation controlled

by the Ambient Light Sensor photocell.

• DAY / TWILIGHT / NIGHT Switch: Three-position rotary switch that allows manual

selection of three light intensities of the system (DAY = high, TWILIGHT =

intermediate, and NIGHT = low). The REMOTE / LOCAL Mode Switch must be in

the LOCAL position to use this switch.

2.2.1.2 Power Configuration

The input voltage selection is set at the factory prior to shipping. The user shall verify

the correct voltage as indicated by the label by Power In terminal block PB1 (Figure

1-1, Page1-2). If the voltage listed on the label does not match the voltage at the site,

contact Tech Support at (805) 581-5591.

2.2.1.3 Configuration Switches

• SW1 – (Figure 2-10, Item 1, Page 2-25). This switch is used to set the

number of Flashheads (including antenna obstruction light (AOL)) in the

system up to 24. If the switches are set for more than 24 the system will still

monitor only 24 Flashheads. The number of lights configured equals the sum

of all the switches set to ON (positive binary). For example, to configure for

10 Flashheads, set SW1-4 (8 lights) to ON and SW1-2 (2 lights) to ON for a

total of 10 (8+2) lights.

§ SW1-1 – Set to ON (up) for 1 light

§ SW1-2 – Set to ON (up) for 2 lights

§ SW1-3 – Set to ON (up) for 4 lights

§ SW1-4 – Set to ON (up) for 8 lights

§ SW1-5 – Set to ON (up) for 16 lights

SG-60 High Intensity Strobe System 2-2 Manual EPM-00000019 Rev A

Page 18

Airport Systems

• SW2 – (Figure 2-10, Item 2, Page 2-25) This switch is used to set for

Catenary operation (suspended cable warning lights) and for Dual systems

(Red lights at night, and white strobes during the day).

§ SW2-1 – Set to ON (up) for Catenary system.

§ SW2-2 – Set to ON (up) for Dual system.

§ SW2-3 – Set to OFF (down). Reserved for future use.

• SW3 – (Figure 2-10, Item 8, Page 2-25) This switch is used to set the

termination resistor for the communications line.

§ SW3-1 – Set to ON if the Master Controller is at the end of the

communications line. In a typical installation, the communications lines

are terminated at the Master Controller and at the top level of

Flashheads. In this case, this switch should be set ON.

2.2.2 Flashhead Configuration

All of the configuration for the Flashhead in done on the digital controller board.

Because of the high voltage present in the Flashhead, there are interlock switches and

fuses as follows (Figure 1-2, Page 1-3):

• S1 POWER Interlock Switch: Three-position push/pull switch. When the

Flashhead door is opened, S1 interrupts AC line power to transformers T1 and

T2 when using 120VAC single-phase power. (When using 2-phase AC power,

S1 does not interrupt AC power to transformers T1 and T2.) When the

Flashhead door is opened, the PWR ON lamp DS1 to turn off. Also interrupts

power to relay K1, causing the high voltage to be shut off and the energy storage

capacitors to discharge. When door is open and S1 is pulled out manually, the

interlock is defeated, which allows the Flashhead to operate under power.

• S2 MODE Interlock Switch: Three-position push/pull switch. When the

Flashhead door is opened, transfers flash intensity mode select from remote

control (by SGC-60 Master Controller) to local control using switch S3. When

door is open and S2 is pulled out manually, the interlock is defeated, which

allows the Flashhead to operate under remote mode control.

• S3 MODE TEST Switch: Three-position rotary switch allows local flash intensity

mode selection (Day, Twilight or Night) for the individual Flashhead, while not

affecting the operation of any other Flashhead in the system.

• F1 Main Power Line Fuse: Provides protection for AC power to transformer T1.

Value varies with input AC line voltage. Refer to Section 7.0 for the correct fuse

values. Honeywell provides the correct fuse for the supplied power configuration.

• F2 Logic Power Line Fuse: Provides protection for the AC power to the logic

transformer T2. Value varies with input line voltage. Refer to Section 7.0 for the

correct fuse values. Honeywell provides the correct fuse for the supplied power

configuration.

SG-60 High Intensity Strobe System 2-3 Manual EPM-00000019 Rev A

Page 19

Airport Systems

2.2.2.1 Power Configuration

The Flashhead(s) are factory set for the correct AC input line voltage. However, the

user shall verify that the AC line voltage selector block (located on the transformer

board on top of transformer T1, Figure 1-2, Page 1-3) is labeled with the correct AC

line voltage used at the site. For example, voltage selector block part number 77-3319

is labeled for 120VAC. If the voltage selector block is not labeled for the correct AC

line voltage used at the site, the correct voltage selector block must be obtained from

Honeywell, and the AC input wiring to transformer T2 must also be verified and

corrected if necessary according to Figure 3-2, Page 3-12.

2.2.2.2 Configuration Switches

• SW1 – (Figure 2-11, Item 2, Page 2-26) This switch is used to reset the

processor

§ Press and hold – resets the processor and tests the automatic power

reset circuit. Press and hold SW1 until the 5v power indicator (DS1,

Figure 2-11, Item 1, Page 2-26) turns OFF momentarily then release.

• SW2 – (Figure 2-11, Item 4, Page 2-26) This switch is used to set special

operation options. Set all four switches to OFF unless your system meets

one of the two conditions below:

CONDITION 1: You have a Catenary System

§ SW2-1 – Set ON for all Flashheads on top level of a Catenary installation.

§ SW2-2 – Set ON for all Flashheads on bottom level of Catenary

installation.

§ SW2 -1 & -2 – Set both to ON for all Flashheads on middle level of a

Catenary installation.

CONDITION 2: You have Dual (Red/White) system with an older-model

Master Controller.

§ SW2-3 – Set to ON. This is provided for backward compatibility with

older installations only. For new installations this switch is always

OFF. For older white-only installations this switch is also OFF.

To determine if an existing installation has an older Master Controller,

refer to the new Master Controller in Figure 2-10, Page 2-25. Older

Master Controllers do not have terminals TB5-TB9, or an EXT RED switch

SW2-2 (Item 2 in the figure).

Note: Switch SW2-4 is a spare reserved for future use.

SG-60 High Intensity Strobe System 2-4 Manual EPM-00000019 Rev A

Page 20

Airport Systems

• SW3 – (Figure 2-11, Item 3, Page 2-26) Used to specify the ID number for

the Flashhead. Each Flashhead must be set with a unique ID number as

indicated on the installation drawings. There is a diagram next to the switch

showing the values for the switch. The ID number is the total of the values of

the switches set to OFF (negative binary). For example, to set ID #10, set

SW3-2 (value 2) OFF (down) and SW3-4 (value 8) OFF (down) for a total of

10 (2+8).

§ SW3-1 – Set to OFF (down) for value 1

§ SW3-2 – Set to OFF (down) for value 2

§ SW3-3 – Set to OFF (down) for value 4

§ SW3-4 – Set to OFF (down) for value 8

§ SW3-5 – Set to OFF (down) for value 16

• SW4 – (Figure 2-11, Item 5, Page 2-26) This is used for the terminating

resistor on the communications line.

§ SW4-1 – Set to ON (up) for terminating resistor. This should be set ON

only for the Flashhead where the communication lines are terminated. In

a typical installation, the communications lines are terminated at the

Master Controller and the upper most Flashhead. In systems with an

AOL, the AOL is typically the upper most Flashhead. In systems without

an AOL, any one but only one of the Flashheads at the top level can be

set to ON. For all others, set to OFF. If the system is being installed in

stages as the tower is erected, SW4-1 should be set ON for one of the

flashheads at the highest installed level. As additional flashheads are

added at higher levels, adjust the configuration by setting SW4-1 to OFF

in the previous flashhead and set SW4-1 to ON for one of the flashheads

at the highest installed level.

2.2.2.3 Flashtube Installation

The Flashheads are shipped from the factory without the flashtubes installed to prevent

damage during shipping. Install the flashtubes per the following procedure:

1. If Flashhead is already wired to AC power: Shut off the power to the system

by opening the main AC power circuit breakers.

2. Release the Flashhead cover latches.

3. Swing the cover open, exercising caution not to damage the glass face or the

gasket.

4. Unpack the flashtube. Do not touch the glass envelope - contamination from

a fingerprint will degrade the reliability of the flashtube.

5. Holding the flashtube by its metal ends, center it in the reflector assembly

and snap it into place. Make sure the red mark on the flashtube matches the

red mark on the socket assembly.

6. Attach the fast-on connector at each end of the flashtube to each socket

assembly. Make sure wires are not twisted - the metal to glass bond is fragile.

SG-60 High Intensity Strobe System 2-5 Manual EPM-00000019 Rev A

Page 21

Airport Systems

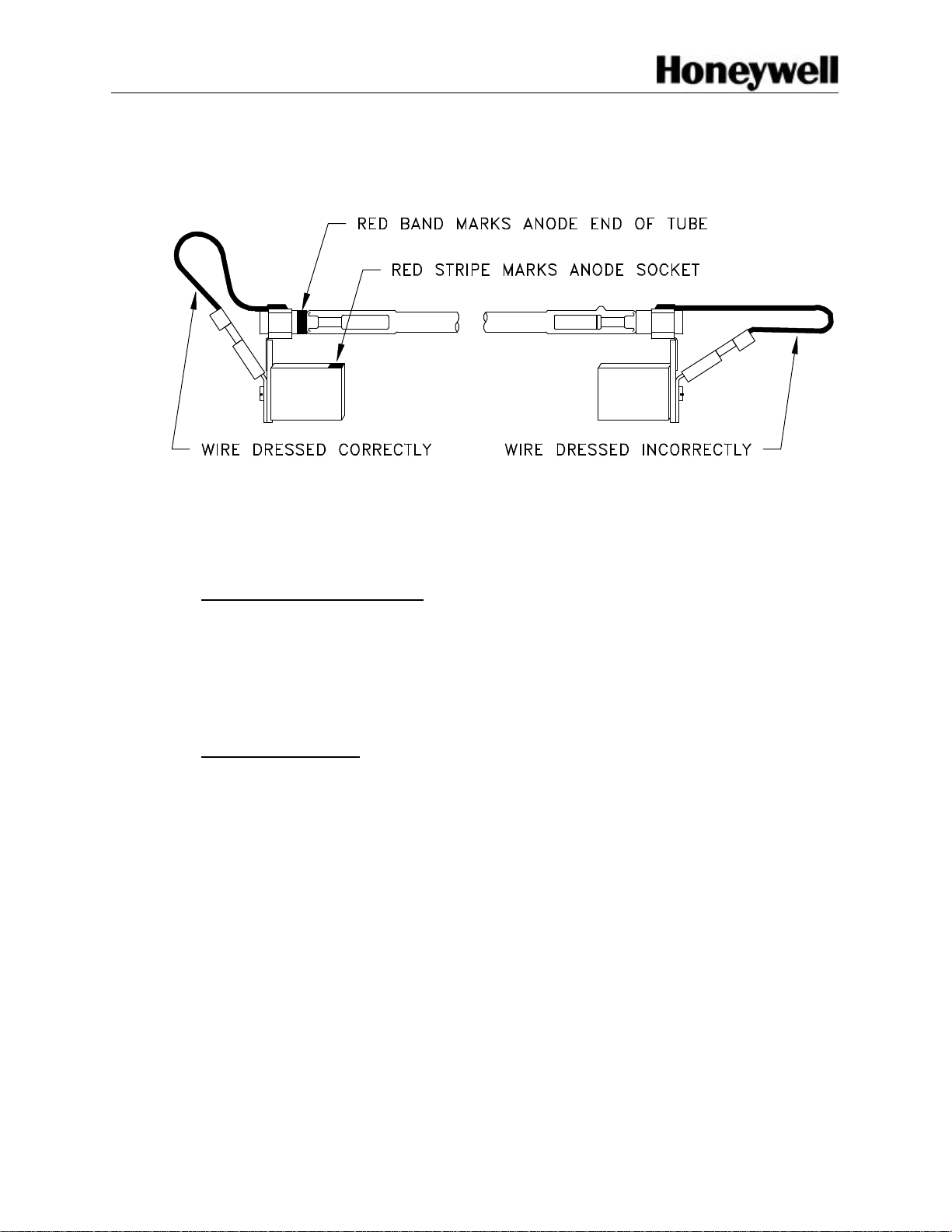

7. Refer to Figure 2-1 below. Dress the electrode wires away from the sides of

the reflector.

8. Close and fasten the Flashhead cover.

Figure 2-1: Flashtube Installation

2.3 Installation

2.3.1 SGC-60 Master Controller

The Master Controller is connected to Flashheads via the data communications cable

provided by Honeywell. The length of this cable (up to 2500 feet) determines how far

the Master Controller can be mounted from the Flashheads.

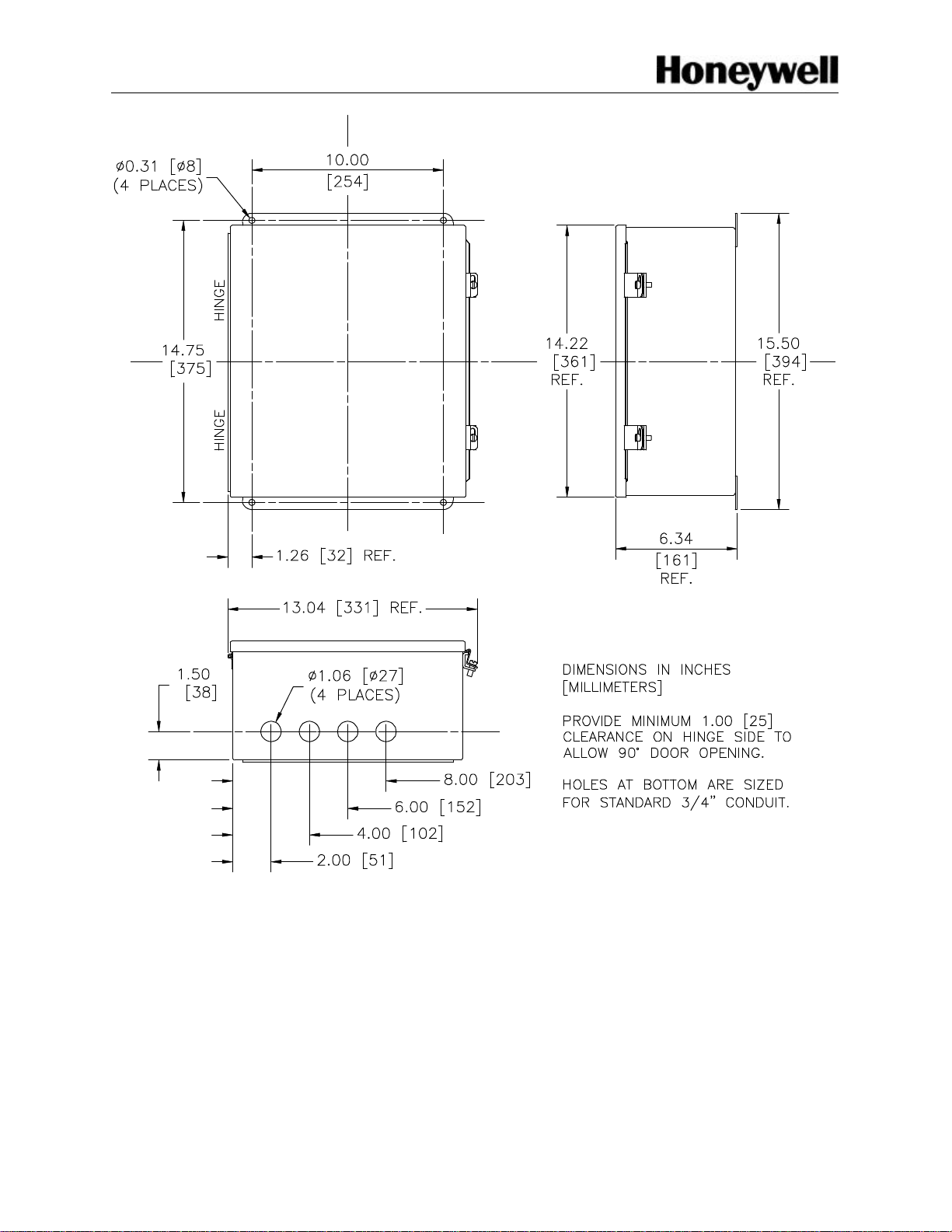

A detailed drawing for mounting the Master Controller is shown in Figure 2-2, Page 2-9

2.3.2 SGF-60 Flashhead

Normally the Flashheads are mounted at the uppermost point and additional

referenced elevations on the structure. The Flashhead is connected to its Master

Controller via the data communications cable provided by Honeywell. The length of

this cable (up to 2500 feet) determines how far any Flashhead can be mounted from

the Master Controller.

Honeywell labels all the Flashheads with numbers ranging from 1 to 24 depending on

the number of required lights for the structure. Typically, the upper most level of lights

will contain the lights with numbers 1 through 3 or 4. If the structure has an

appurtenance of greater that 40 feet, an AOL (Antenna Obstruction Light) is required

and it will have a Flashhead Number of 1. The High Intensity Flashheads will start with

Flashhead Number 2. The flashheads should continue down the tower from the top

sequentially ending with the highest number at the bottom level.

The vent hole on the bottom surface of the power supply is covered with a solid plug

prior to shipping. Optional screened plugs are furnished separately.

SG-60 High Intensity Strobe System 2-6 Manual EPM-00000019 Rev A

Page 22

Airport Systems

Typically, the Flashhead is mounted to a bracket, which is then attached to the

structure. Honeywell can supply brackets for most types of installations.

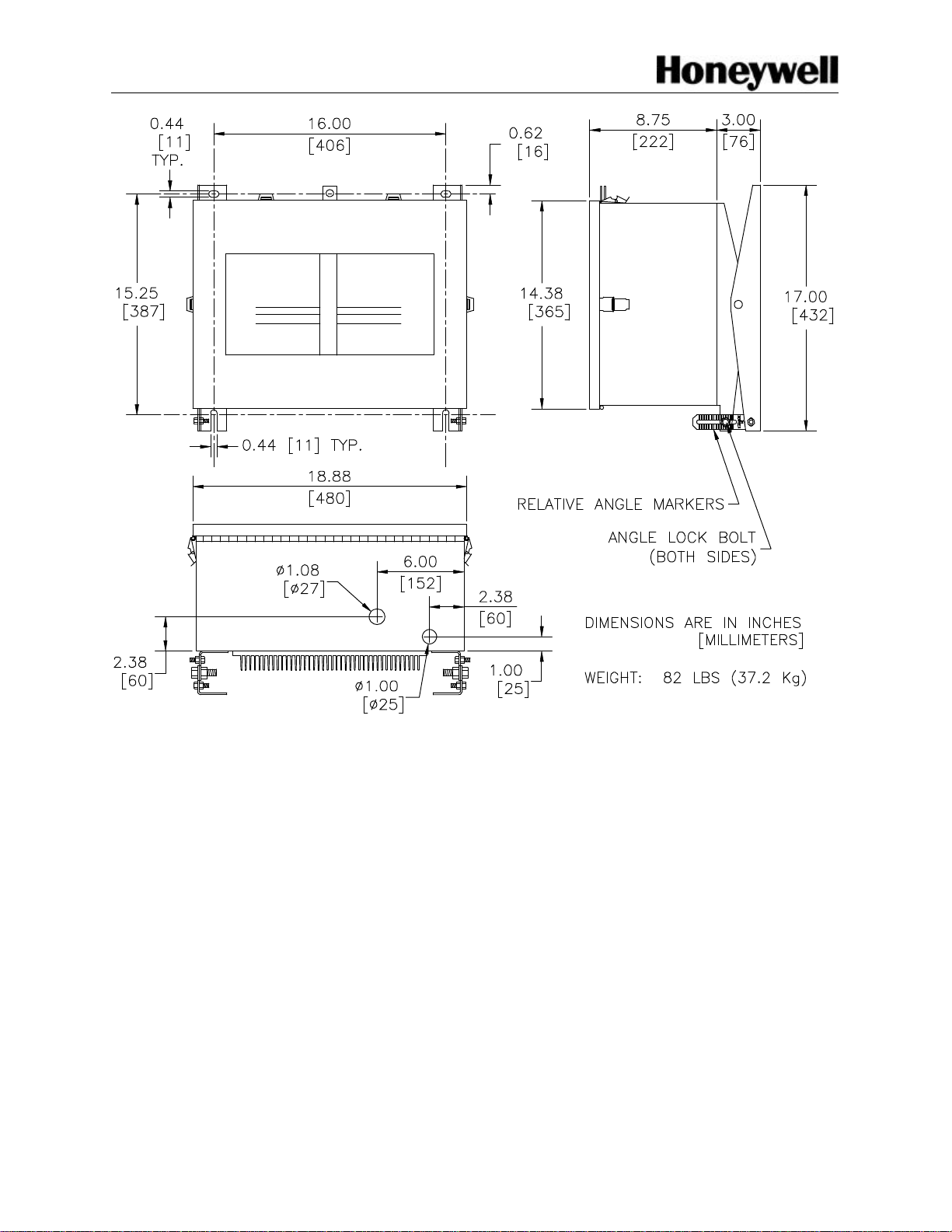

A detailed drawing for mounting the Flashhead is shown in Figure 2-3, Page 2-10.

2.3.2.1 Setting the Flashhead Elevation

Flashheads must be mounted at the proper vertical angle to assure proper light output.

Depending on the elevation of the light level, the Flashhead may need to be adjusted to

reduce the amount of ground scatter. Please refer to the table below for proper

elevation for the lights.

1. Slightly loosen the angle lock bolts, which are at the bottom of the mounting

arms (see Figure 2-3, Page 2-10). The bolt heads and nuts fit 7/16" wrenches or

nut drivers (tightening will require a pair of tools).

2. Adjust the Flashhead enclosure until the bubble indicator on top of the enclosure

reads level.

3. Take note of the position of the bolt with respect to the silk-screened markings

on the angle indicator. This position is the zero degree position. The markings

are screened at intervals of one degree.

4. Adjust the Flashhead enclosure to aim the beam upward until the bolt head has

shifted by the number of degrees indicated in the table below.

5. Securely tighten both angle lock bolts.

Light Unit Elevation Above the Horizontal

Height of Light Unit Above

Ground Level

More than 500 feet

401 feet to 500 feet

301 feet to 400 feet

Less than 300 feet

2.3.3 Ambient Light Sensor (Photocell)

The Ambient Light Sensor, when supplied with the system, shall be mounted upright,

away from artificial light (e.g. floodlights), and in a location that will enable the sensor

window to have an unobstructed view of the polar sky (pointed north in the northern

hemisphere, not pointed toward the sun). The photocell housing wire entry is tapped to

allow mounting to 1/2" threaded pipe. Conduit and related hardware will be

supplied by the customer. A 21-foot 3-conductor cable is attached to the photocell

for remote installation.

Degrees of Elevation above

Horizontal

0°

1°

2°

3°

SG-60 High Intensity Strobe System 2-7 Manual EPM-00000019 Rev A

Page 23

Airport Systems

2.3.4 Cables and Junction Boxes

The cables shall be properly supported and terminated in the junction boxes per the

detailed description provided in section 2.4, page 2-11 of this document. Additional

information regarding cables and junction box installation can be found on the drawing set

for the lighting system. Particular attention should be paid to assure that the data cable

shields are isolated from the junction box housings.

SG-60 High Intensity Strobe System 2-8 Manual EPM-00000019 Rev A

Page 24

Airport Systems

Figure 2-2: Master Controller Mounting Dimensions

SG-60 High Intensity Strobe System 2-9 Manual EPM-00000019 Rev A

Page 25

Airport Systems

Figure 2-3: Flashhead Outline and Mounting Dimensions

SG-60 High Intensity Strobe System 2-10 Manual EPM-00000019 Rev A

Page 26

Airport Systems

2.4 Installation Wiring

Follow the procedure below to perform the installation wiring. Note that the wiring of the

Alarm Relay outputs is customer and site specific and is therefore not specified in this

manual.

Figure 2-5: Typical Wiring Installation

SG-60 High Intensity Strobe System 2-11 Manual EPM-00000019 Rev A

Page 27

Airport Systems

2.4.1 Master Controller to Photocell Wiring

The photocell is supplied with a length of wire attached. If a longer wire is needed, this

should be accomplished using a junction box. Make the interconnect between the

external Photocell and the Master Controller TB2 per Figure 2-5, Page 2-11, as

follows.

Black wire Photocell ------------------------to -----------Master Controller TB2-B

White wire Photocell ------------------------to ---------- Master Controller TB2-W

Red wire Photocell ------------------------to -----------Master Controller TB2-R

2.4.2 Master Controller Data/Communications Wiring

Typically, the data/communications wiring is done with Honeywell P/N WC000002, a

shielded, twisted-pair cable. It has one pair of conductors, and a drain wire for making

shield connections. This cable is routed up the structure in the same conduit as the

Flashhead power wiring. Connect the data cable wires to Master Controller TB5

according to Figure 2-5, Page 2-11, and as follows:

White or Clear wire (Data signal "A")------- to ----------------Master Controller TB5-A

Blue wire (Data signal "B")--------------------- to ----------------Master Controller TB5-B

Shield drain wire (Data shield) ----------- to -------------- Master Controller TB5-S

(TB5-S is position 4)

The Data Shield (TB5-S) is grounded by the factory-installed wire that connects

the E1 ground lug on the Master Controller circuit board to PB1-G.

If you need to connect a Flashhead directly to the Master Controller using the data

cable integrated into Flashhead Cable WC000002, use the following connections.

White or Clear wire-----Master Controller TB5-A -----------to---- Flashhead TB1-4

Blue wire-------------------Master Controller TB5-B -----------to---- Flashhead TB1-5

Inner Shield---------------Master Controller TB5-S (4) -------to---- Flashhead TB1-6

Outer Shield ---------------------------------------------------------not connected at either end

2.4.3 Master Controller Power Wiring

Make the connections for incoming AC line power to Master Controller PB1 per Figure

2-5, Page 2-11 as follows. These wires (or cable) are not supplied by Honeywell. A

separate circuit breaker is recommended for the Master Controller. The Master

Controller may, if desired, use a different AC line voltage than the Flashheads.

The wire colors below are typical for single-phase power. Be sure to check your own

installation colors.

Black wire (Phase or hi)-----------------------------to -----------Master Controller PB1-L

White wire (Phase or neutral)----------------------to --------Master Controller PB1-L/N

Green wire (Equipment ground) ----------------to--------- Master Controller PB1-G

SG-60 High Intensity Strobe System 2-12 Manual EPM-00000019 Rev A

Page 28

Airport Systems

2.4.4 Master Controller Wiring For Dual Systems

If your installation is a Dual (Red/White) system, you must make additional connections

to coordinate between the High Intensity Strobe System and the Red Light System.

See the sections below for wiring details. For configuration switch settings for a Dual

system, see 2.2.1.3 on Page 2-2.

2.4.4.1 Controlling the Red Light System

The Master Controller uses Relay K4 to control the Red Light System. The Relay K4

contacts should be wired to the Red Light System in such a way that when K4 is

energized, the Red Lights turn off, and when K4 is de-energized, the Red Lights turn

on.

Typically this is done by disconnecting the Red Light System photocell, and wiring

those photocell inputs to the Relay K4 contact. The contacts are rated for up to 5A,

and up to either 30VDC or 250VAC.

If your red light system has a Honeywell 9LCA-Series Red Light Controller, the 9LCA

photocell is not used. Instead of connecting the 9LCA photocell to 9LCA terminal TB3,

make the following connections:

Master Controller TB3-C4--------------- to-------- 9LCA Red Light Controller TB3-B

Master Controller TB5-NO4 ------------ to----------9LCA Red Light ControllerTB3-R

Configure the 9LCA Red Light Controller to use Automatic mode control. Other Red

Light Systems may require different connections. Refer to the Tower Kit drawing (if

Honeywell provided both systems as a kit), refer to the Red Light System's manual, or

contact Honeywell for assistance.

2.4.4.2 Responding to Top Red Beacon Failures

When a top-level red beacon fails at night, a Dual system must switch from red to white

lights. The Master Controller will switch to the white strobes at night if it detects an

open circuit between TB6-1 and TB6-2 ("EXT RED").

Install external wiring must in a single electrical loop from TB6-1 to TB6-2 in such a way

that the loop is closed when all the top-level red beacons are operating correctly, and

the loop is opened (broken) when any top-level red beacon fails.

The External Red Ready indicator (LED DS36 -- Item 10 in Figure 2-10, Page 1-2)

turns on to indicate a closed loop (Red Lights OK), and turn off to indicate an open loop

(Red Light Failure).

SG-60 High Intensity Strobe System 2-13 Manual EPM-00000019 Rev A

Page 29

Airport Systems

If your red light system has a Honeywell 9LCA Series Red Light Controller, locate the

Alarm terminals and Flasher Bypass terminals corresponding to the top beacon, and

make the following connections:

Master Controller TB6-1-----------------to----------------------9LCA Flasher Bypass C1

9LCA Flasher Bypass NC1 -------------to----------------------------9LCA Alarm Card C1

Master Controller TB6-2-----------------to--------------------------9LCA Alarm Card NC1

Note: Usually the top beacon terminals are found on the top/left Flasher Bypass Card

(TB4), and the left channel of the top Alarm Card (TB3).

Other Red Light Systems may require different connections. Refer the to Tower Kit

drawing (if both systems were provided as a kit by Honeywell), the Red Light System's

manual, or contact Honeywell for assistance.

2.4.5 Flashhead Wiring

Incoming AC power and data communications enter the Flashhead in a single cable,

Honeywell P/N WC000001, that combines three wires for AC power with a

twisted-pair/double-shielded data cable (See Figure 2-9, Page 2-21). Typically,

Flashheads are supplied with a 10-20 foot length of this cable already installed.

Should you need to install or replace this cable, make the connections for incoming AC

power and data to Flashhead TB1 per Figure 2-5, Page 2-11, and Figure 2-10, Page 224, as follows.

Green wire (Equipment ground)------------------------to-----------------Flashhead TB1-1

White wire (Phase or neutral)---------------------------to-----------------Flashhead TB1-2

Black wire (Phase or hi)----------------------------------to-----------------Flashhead TB1-3

Data Cable

White or Clear wire (Data signal "A") ------------to-----------------Flashhead TB1-4

Blue wire (Data signal "B") --------------------------to----------------- Flashhead TB1-5

Inner shield (Data shield)----------------------------to----------------- Flashhead TB1-6

Outer shield-------------------------------------------------------- trim short; not connected

2.4.6 Conduit and Tower Wiring Detail

This section details a standard practice of installing conduit and the related tower

lighting wires for the system. Please use this guide to help install the wires into the

conduit system. The wires and cables for the SG-60 High Intensity system need to be

run properly to insure that the system will work properly. Wire insulation that is

damaged will lead to a system that will not function properly and may void the warranty.

Insure that the following procedure is followed. Pay close attention to all bold text.

SG-60 High Intensity Strobe System 2-14 Manual EPM-00000019 Rev A

Page 30

Airport Systems

Figure 2-5: Flex Conduit Typical Installation Layout

2.4.6.1 Procedures for installation of conduit and tower wiring

1. All conduit, junction boxes, mounting hardware, fixtures, etc. provided for

installation of the electrical system (i.e. lighting or equipment power distribution)

should be inventoried and checked against the appropriate bills of materials.

(a) Conduit and junction box components provided for electrical

systems should be checked against appropriate bills of materials to

ensure all are present and of proper size.

(b) Numbers of wires to be carried by each conduit run should be

checked against National Electrical Code. Honeywell sizes the

conduit run for a 40% fill of the conduit by the NEC.

2. Use pipe compound or equivalent for all threaded connections in the conduit

run. This will prevent water from entering the conduit system and make an

electrical connection between the conduit and ground.

3. All custom cut pieces of conduit must be de-burred after they are threaded to

remove sharp edges that may cut wiring insulation. Honeywell supplies conduit

in 10-foot lengths, therefore cutting and threading of the conduit may be

necessary.

4. Insure that “chase nipples” or bushings are properly installed in all junction box

ports to protect the wiring insulation from pipe threads and other sharp edges in

SG-60 High Intensity Strobe System 2-15 Manual EPM-00000019 Rev A

Page 31

Airport Systems

the junction box ports. Do not begin to run wire through a junction box port

before a chase nipple or grommet is in place.

5. Before running the wire into a box insure the wire insulation will be

protected from any sharp edges on the junction boxes. Pieces of carpet,

wide copper braid, etc. can be fastened in place over sharp edges to protect

wire insulation.

6. Precut and bundle method of wire installation:

(a) Cut all conductors to length for their respective run with adequate

excess to allow for strain relief and additional slack for

connections.

(b) Ensure that there is plenty of wire pulling lubricant on site before

beginning to pull wiring. Use plenty of lubricant as the wire is

being run through the conduit.

(c) The wiring bundle should be hoisted above the junction box at the

top of the run into which it is to be inserted then lowered down into

the conduit. There should be someone at the top junction box

of the run to insure the wiring does not get scuffed or cut on

junction box edges and to apply lubricant to the wiring as it

enters the conduit.

(d) If the conduit and wire will be installed on the ground, use the

same methods described here. Insure proper amount of

lubricant is available and that the wire is shielded from any rough

edges on the conduit or ground that might damage the wire/cable

insulation.

(e) Adequate slack should be pulled back up into the uppermost

junction box to effect strain relief and to make proper wiring

connections. Once wiring bundle is supported by the strain relief

mechanism, make all wiring connections in the junction box.

i. To make proper connections the wiring entering the box from

above and the wiring above, the strain relief mechanism at the

bottom of the box must be long enough. The wires at the top of

the box should be formed into a “J” shape and the last 1/2-inch

of insulation should be stripped off the conductor. The wires

from the bottom of the box supported by the strain relief

mechanism should be run up to a point just short of the top of

the junction box and cut off. The last 1/2-inch of insulation

should then be stripped from those. Wire connections should

be made with proper sized Scotch® Twist wire nuts or split bolt

connectors.

ii. Once a wire nut is installed, hold the wire nut and tug on all

wires firmly to ensure the connection of all conductors is tight.

iii. Finish each connection with at least 6 wraps of Scotch 33+ tape

or equivalent for proper moisture protection.

iv. When a proper connection is complete, the wire nut should be

positioned upside-down (wire nut opening pointing downward)

SG-60 High Intensity Strobe System 2-16 Manual EPM-00000019 Rev A

Page 32

Airport Systems

(f) Move down to the next intermediate (strain relief) junction box and

(g) Move down to the next intermediate junction box and repeat the

and the connection should be at the top end of the junction box.

Wiring from ports in the sides of junction boxes should also be

made such that the wire nuts are at the top of the junction box

with the wire nut openings pointing downward, (see Figure 2-6,

Page 2-19) for proper moisture protection.

pull enough of the wiring into the box to provide for the proper

installation of the strain relief mechanism.

above procedure until the entire tower is wired.

SG-60 High Intensity Strobe System 2-17 Manual EPM-00000019 Rev A

Page 33

Airport Systems

2.4.7 Junction Box Details

This section will detail the proper wire interconnection details for the input voltage and

data cable to the flashhead pigtail cable. These connections are very important to the

proper operation of the lighting system. The flashhead pigtail contains all the wires

required for proper interconnection between the conduit wiring and flashhead.

Additional reference materials can be found on the High Intensity Lighting system

drawing set. Please reference the below information and drawings for a proper

installation. Mis-wiring of these wires will not allow the flashheads to operate properly.

Please call the Honeywell Technical Support if you have any questions regarding the

installation of these connections. Systems that are improperly wired may void the

warranty.

2.4.7.1 Flex Conduit Installation

On each of the high intensity flashheads, a pigtail is attached at the factory for

installation to the junction box. This pigtail may not be long enough for proper routing

along the horizontal and vertical struts on the tower. The high intensity lighting system

will have a 100-foot spool of pigtail cable, Honeywell P/N WC000001, for installer to

use for those flashheads that do not have a long enough pigtail. If this spool of cable

will not accommodate all the flashheads, extra cable can be ordered from Honeywell.

The ¾” flex conduit will be used for shielding of possible RF Interference generated by

some broadcast and radio towers. The conduit will be positioned over the flashhead

pigtail and connected at the junction box and flashhead enclosure by watertight

connector designed for the ¾” flex conduit. The installation will consist of the following

materials:

¾” Flex Conduit – Honeywell part number CL000002

¾” Sealing Ring – P/N *77-1085

¾” Bushing Insulator – P/N *77-1087

¾” Flex Conduit Fitting – P/N CD000003

Consists of: Gland nut, body, edge cone, nylon seal ring, and ¾” locknut

Please reference Figure 2-7, Page 2-20 for proper installation of this conduit.

SG-60 High Intensity Strobe System 2-18 Manual EPM-00000019 Rev A

Page 34

Airport Systems

Figure 2-6: Junction Box Wiring Details

SG-60 High Intensity Strobe System 2-19 Manual EPM-00000019 Rev A

Page 35

Airport Systems

Figure 2-7: Flex Conduit Installation Detail

SG-60 High Intensity Strobe System 2-20 Manual EPM-00000019 Rev A

Page 36

Airport Systems

The flex conduit will need to be properly mounted to the horizontal and vertical struts by

way of the supplied 20-inch cable ties. These cable ties should be placed at a

minimum of 3 feet apart for proper bonding to the tower structure. The distance

between the cable ties may need to be reduced if the installer sees that the 3-foot

distance will not allow for proper bonding and securing to the tower.

Figure 2-5, Page 2-15 depicts a standard installation layout for the Flashhead pigtails

and flex conduit.

2.4.7.2 Splicing Details for WC000001 Cable

The installation of the data/communication cable is the most important part of the High

Intensity Lighting system installation. Without a sound connection for the data cable,

the entire system will not work properly. Insure that the following steps are followed to

insure a proper installation and connection.

NOTE: Splicing of the cables at any other location besides the light level is not

recommended. The intermediate junction boxes between the light levels should be

used as pull boxes and for strain relief only, with no splices.

The WC000001 cable is a multi-conductor cable that is used for the interconnection of

the flashhead to the junction box. The WC000001 cable consists of the following

wires/cable:

Figure 2-9: WC000001 Cable Overview

Item 1 (A, B, S) is the data/communication cable that is used to transmit all the data

from the master controller, SGC-60, to the flashhead, SGF-60. Without a proper

connection, the lighting system will flash erratically, or default to Day mode.

Items 2, 3, and 4 are used for the power input from the junction box to the flashhead.

Item 5 is the Drain Wire for the outer cable shield.

SG-60 High Intensity Strobe System 2-21 Manual EPM-00000019 Rev A

Page 37

Airport Systems

Item 6 is a shield drain wire that will not be used for interconnection. This wire should

be cut off flush from the cable when the outer jacket is stripped back for interconnection

of the system.

The following section is a guideline to a proper installation of the WC000001 cable.

Please follow this guideline to ensure a proper installation and interconnection in the

junction box.

1. Strip back at least 16” of the outer jacket of the WC000001 cable. Make

sure that during this removal, the other wires are not damaged. If the

insulation is damaged on one of the other wires, a potential of lighting

problems can occur shortly after the system is connected.

2. Remove all the aluminum foils and braids from the exposed conductors.

These will not be used for interconnection.

3. Cut off Item #6, bare shield wire, that protrudes from the cable. This wire

will not be used for interconnection.

4. Connect Item #5, bare shield wire, and Item #4, #12-AWG Green wire,

from all the cables to the ground lug inside the junction box. This ground

lug can be found on the back plane of the junction box or at an internal

locknut that has a ground screw attached. No other wires will be

connected to ground.

5. Connect Item #1S, data/communication inner shield drain wire, to the

other data shield drain wires from the additional data cables. Trim back

the associated shield neatly. Make sure that this drain wire and the shield

cannot contact the walls of the junction box or other wires. Do not

connect inner shield to outer shield. Extra taping may be required for

proper isolation. The inner shield should only have a connection to

ground inside the SGC-60 controller.

On a typical installation, there will be a total of 5 wires that will be

connected together. One from the lower junction box level, three from the

flashhead cables on that level, and one for the cable going to the next

level.

6. Connect Item #1A to corresponding wires in other four cables as stated

above in step 5.

7. Connect Item #1B to corresponding wires in other four cables as stated

above in step 5.

8. Connect the #12-AWG Black and #12-AWG White wires as required by

the installation drawing set supplied with the lighting system. If the

system has a 3-phase input, ensure proper connection between the

3-phase wires (typically brown, orange, and yellow) and the black and

white wires from the flashhead. Proper load balancing is required on the

three-phase input to operate efficiently (distribute the flashheads as

evenly as possible across the phases).

SG-60 High Intensity Strobe System 2-22 Manual EPM-00000019 Rev A

Page 38

Airport Systems

9. The power wires should be spliced together using split bolt connectors.

The data wires should be spliced together using Scotch® Twist Lock

connectors. After splicing, ensure all wires are secure by pulling on each

wire. Wrap each connection with at least 6 wraps of Scotch 33+ tape or

equivalent for moisture protection. All connection ends should be located

in the upper corners of the junction box with all closed end of the

connector pointing up. See Figure 2-6, Page 2-19 for reference.

Note: The Master Controller can operate from a different AC voltage than the

Flashheads if desired.

SG-60 High Intensity Strobe System 2-23 Manual EPM-00000019 Rev A

Page 39

Airport Systems

** It is extremely important to connect all

Data cable inner shields together, but isolate

them from all other shields and grounds **

Figure 2-10: Flashhead Cable

SG-60 High Intensity Strobe System 2-24 Manual EPM-00000019 Rev A

Page 40

Airport Systems

Figure 2-10: Master Controller Circuit Board

SG-60 High Intensity Strobe System 2-25 Manual EPM-00000019 Rev A

Page 41

Airport Systems

Figure 2-11: Flashhead Digital Control Board

SG-60 High Intensity Strobe System 2-26 Manual EPM-00000019 Rev A

Page 42

Airport Systems

2.5 Final Installation Check

Before applying power to the equipment, perform the procedures in Sections 2.5.1 -

2.5.4. If any test does not pass, please consult SECTION 4. TROUBLESHOOTING in

this manual or call Honeywell Technical Support at (805) 581-5591.

2.5.1 Preliminary

1. Verify that all AC input power circuit breakers are turned off.

2. Check that all printed circuit boards are properly seated in their sockets, and

retaining brackets are securely fastened..

3. Check that any user-installed wiring does not interfere with relay operation

when covers are closed.

4. Check that all Flashheads are mounted are mounted at the correct

elevation per Section 2.3.2.1, Page 2-7. Check that all Flashhead covers

are shut properly for a weather-tight seal with all latches closed.

5. Set Master Controller switches as follows:

POWER SWITCH ----------------------------------------------------------------- OFF

LOCAL / REMOTE Switch --------------------------------------------------- LOCAL

MODE Switch ----------------------------------------------------------------------- DAY

2.5.2 Verify Correct Wiring in Master Controller

Verify correct wiring of the Master Controller as specified in section 2.4 page 2-11.

2.5.3 Verifying Photocell Wiring

Verify correct wiring of the photocell as specified in section 2.4.3 page 2-12.

2.5.4 Verify Proper Tower Wiring for Data/Control Cable

This test assumes a typical tower configuration with the data cable terminating at the

Master Controller.

1. Unplug Data Cable connector TB5 from PCB1 in Master Controller.

2. Verify 120-140 ohms resistance between TB5-A and TB5-B on the Data

Cable. (This checks that a single 100-ohm data line termination resistor is

in the circuit. Resistance of 70 ohms or less indicates that more than one

Flashhead has the terminating resistor switch set to on. See SW4 page

2-5.

3. Verify open circuit by measuring resistance between TB5-S on the Data

Cable and panel ground.

4. Verify open circuit between TB5-A on the Data Cable and panel ground.

5. Verify open circuit between TB5-B on the Data Cable and panel ground.

SG-60 High Intensity Strobe System 2-27 Manual EPM-00000019 Rev A

Page 43

Airport Systems

6. Verify open circuit between TB5-S and TB5-A (both on Data Cable)

7. Verify open circuit between TB5-S and TB5-B (both on Data Cable).

8. In one of the top-most Flashheads, install a jumper (or alligator clip)

between TB1-5 and TB1-6.

9. Verify short circuit between (<20 ohms) TB5-S and TB5-B (both on Data

Cable).

10. Remove the jumper between TB1-5 and TB1-6.

11. Verify open circuit between TB5-S and TB5-B (both on Data Cable)

12. On the Master Controller card, measure between TB5-A and TB5-B and

verify 120 ohms +/- 10% resistance. If not, check for proper configuration.

See SW4 on page 2-5.

13. Plug Data Cable Connector TB5 back into PCB1.

14. Verify short circuit between TB5-S screw terminal and panel ground.

2.6 Power Up and System Tests

During the power up of the system, there are indicator lights which will be checked to

verify correct operation and installation. The following is a description of all the

indicators in the Master Controller and the Flashheads. The indicators in the

Flashhead need not be checked unless problems are encountered during the normal

power up tests.

2.6.1 Master Controller Status Indicators

• Photo Mode Indicators (Figure 2-10, Item 3, Page 2-25)

§ DS25 – Red indicates active mode is Day

§ DS26 – Red indicates active mode is Twilight

§ DS27 – Red indicates active mode is Night

§ DS28 – Green indicates photocell is OK, Red indicates photocell is bad

• Individual Flashhead Status (Figure 2-10, Item 4, Page 2-25)

§ DS1-24 – Green indicates Flashhead is good, OFF indicates Flashhead

has not been selected for monitoring, Red indicates Flashhead is bad.

• Miscellaneous Indicators

§ DS34 – (Figure 2-10, Item 7, Page 2-25) ON indicates transmit OK

§ DS35 – (Figure 2-10, Item 9, Page 2-25) Flashing indicates sync input

read OK.

§ DS36 – (Figure 2-10, Item 10, Page 2-25) ON indicates red lights are

available, OFF indicates red lights are reporting alarm or not installed

SG-60 High Intensity Strobe System 2-28 Manual EPM-00000019 Rev A

Page 44

Airport Systems

§ DS32 - 33 – (Figure 2-10, Item 5, Page 2-25) The indications on these

lights are dependent on the setting for external red light system on SW2.

If SW2-2 is set for an EXTERNAL RED system (ON), then

• DS32 – ON indicates there has been a red light system alarm

sometime during the night and the red light system is off, but will reset

the next day. OFF when in night mode and the red light system is not

in alarm

• DS33 – ON indicates in night mode, red lights are turned off and white

strobes are operating, OFF indicates NORMAL operation.

If SW2-2 is set for no EXTERNAL RED system (OFF) then

• DS32 – ON during DAY and TWILIGHT, OFF during NIGHT mode

• DS33 - Not used (lower right of board)

§ DS31 – (Figure 2-10, Item 5, Page 2-25) ON indicates power OK, OFF

indicates power failure

§ DS30 – (Figure 2-10, Item 5, Page 2-25) ON indicates photocell is

GOOD, OFF indicates photocell is BAD or not connected

§ DS29 – (Figure 2-10, Item 5, Page 2-25) ON indicates all Flashheads are

good, OFF indicates one or more Flashheads are bad

2.6.2 Flashhead Status Indicators

• Miscellaneous Indicators (Figure 2-11, Item 1, Page 2-26)

§ DS1 Red ON for 5-Volt logic power OK

§ DS2 Yellow ON for Flash Current Feedback OK

§ DS3 Green ON Steady for communications OK (receive & transmit)

OFF for no communications reception

Slow Blink (1/sec) for receiving but not being addressed to

transmit

Fast Blink (4/sec) for receiving, being addressed to transmit

but failing to transmit

2.6.3 System Power Up

All switches and indicators listed in this section are in the Master Controller, except for

the external system circuit breakers.

1. Verify POWER SWITCH is turned OFF.

2. Verify LOCAL / REMOTE switch is set to LOCAL.

3. Verify MODE switch is set to DAY.

4. Turn on circuit breaker to apply power to Master Controller.

5. Turn on circuit breaker to apply power to Flashheads.

6. Turn POWER SWITCH to ON.