Page 1

SG150

Safety group

with interchangeable safety valve insert

Product specification sheet

Application

Safety groups of this type are used to protect pressurised water

heaters according to the requirements of DIN 4753, Part 1,

DIN 1988 and DIN EN1488.

They are compact appliances which incorporate all the necessary

safety devices such as check valve, shutoff valve, test point and

diaphragm type safety valve in one unit.

The safety valve protects the downstream cylinder, pressure

vessel etc. by automatically opening when excess pressure

occurs. The check valve prevents back pressure, backflow and

back syphonage of water from the hot water unit.

Special Features

• DVGW-approval requested

• Fully approved for noise level protection to class 1

• Replacement insert tested to TRD 721

• Easy venting

• Meets KTW recommendations for potable water

Construction

The safety group comprises:

• Housing with test socket G

• Connections (versions AA, AB and AC)

• Shutoff valve

• Check valve cartridge

• Approved safety valve exchange insert

• Drain connector

• Insulation shells

• Pressure gauge optional

Materials

• Dezincification resistant brass housing

• Brass threaded connections

• Cut-off valve, test socket, plug-in backflow stopper, safety

valve replacement set and flow-guide made of high-quality

plastic

• Fibre-reinforced NBR diaphragm

• NBR seals

EN0H-1355GE23 R1007 • Subject to change

• EPP insulation shells

1

/4"

Range of Application

For closed hot water storage units up to 200 litres according to

DIN 4753 Part 1 and DIN 1988. Tested to TRD 721 for 1.0 to 10.0

bar pressure range.

Medium Water

Operating pressure Maximum at least below 20 % opening

pressure of safety

Technical Data

Installation position Horizontal and vertical

Opening pressure Set by manufacturer at 6.0, 8.0 or 10.0 bar

Subsequent alteration of the setting is not

permitted and is impossible without

destroying the security cap

Operating temperature

Connection size

Max. 40 °C

1

/2" + 3/4"

www.honeywell.com 1

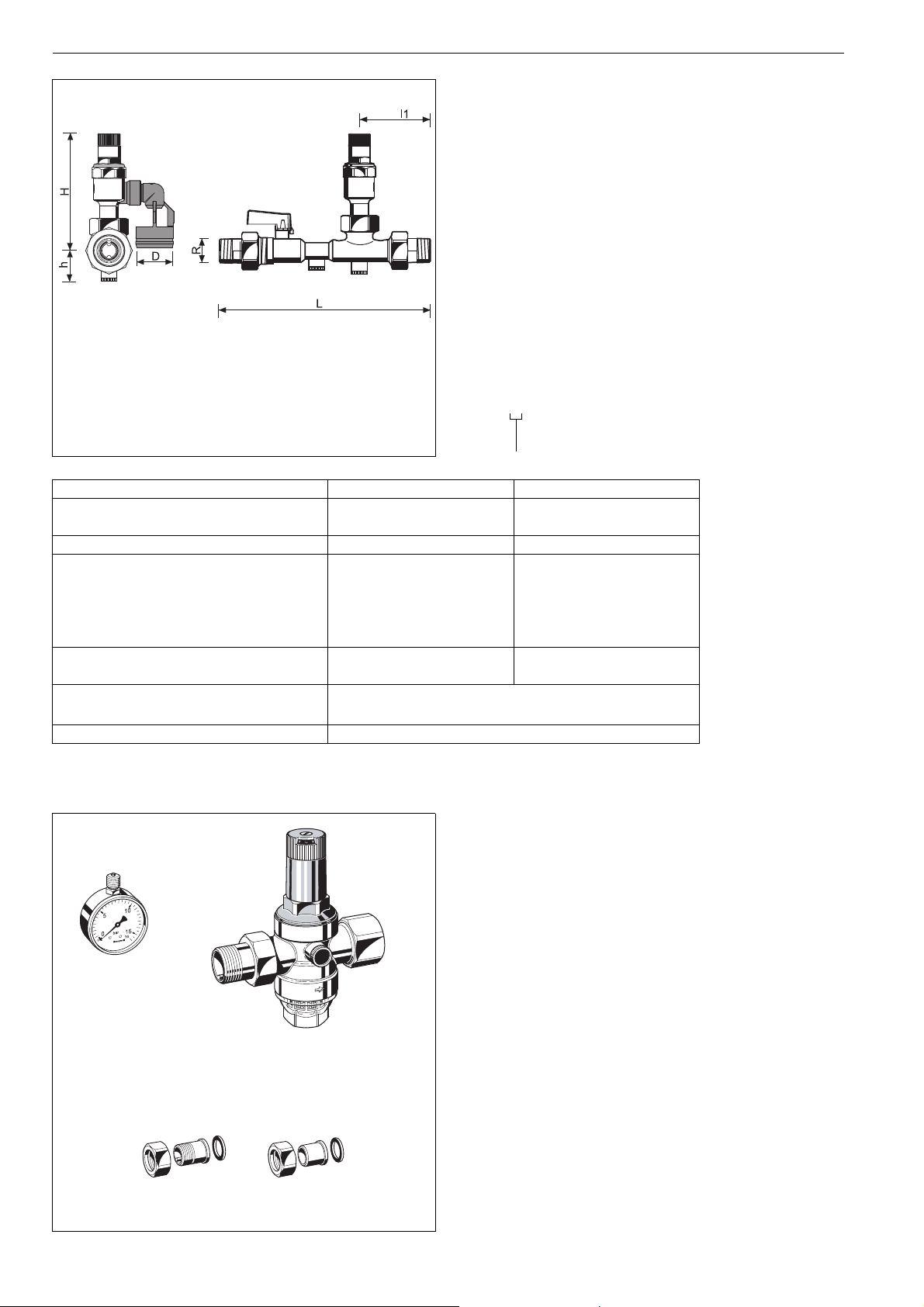

Page 2

SG150 Safety group

Method of Operation

Safety groups of this type combine check valve, shutoff valve,

test point and diaphragm type safety valves in one appliance.

Flow first passes through the check valve and this flow holds the

valve disc in the open position against the force of a spring.

The downstream safety valve is a direct operating safety valve.

That is, the opening force operates against the force of a spring.

The shutoff valve enable the check valve to be checked and

serviced.

Options

SG150- ... AA = With threaded male connections, 6.0 bar

SG150- ... AB = With threaded male connections, 8.0 bar

SG150- ... AC = With threaded male connections, 10.0 bar

SG150- ... EA = Without fittings, set pressure 6.0 bar

SG150- ... EB = Without fittings, set pressure 8.0 bar

SG150- ... EC = Without fittings, set pressure 10.0 bar

Connection size

Connection size R

Weight Version A

approx. kg 0.7

Version E

1

/2"

0.55

3

/4"

0.9

0.67

Funnel outside-ø (mm) D 40 40

Dimensions (mm)

L

l

1

H

h

165

55

124

28

186

67

132

30

For water heaters with capacity (litres)

200 200

Safety valve

Approval numbers

TÜV · SV · ..*2 - 700 · (

TÜV · SV · ..* - 617 · (1/2", 3/4") · W · p (8, 10 bar)

1

/2", 3/4") · W · p (6 bar)

DIN/DVGW Approval No. requested

..* valid Approval No.

Accessories

M08M Pressure gauge

Housing ∅ 50 mm, connecting pin above G

Partition: 0-16 bar

D150 Pressure reducing valve

Pressure reducer D150-1/2 for completion of the

M08M

safety group SG 150 with connection size 1/2”

D160S Pressure reducing valve

Pressure reducer D160S-3/4 for completion of the

safety group SG 150 with connection size 3/4“

D150/D160S

VST06-A Connection set

Threaded connections

1

/4"

VST06-A

2 www.honeywell.com

VST06-B

VST06-B Connection set

Solder connections

EN0H-1355GE23 R1007 • Subject to change

Page 3

Installation Example

SG150 Safety group

Arrangement of the safety group as channel design

Arrangement of the safety group as corner design

Installation Guidelines

• Safety group must be fitted in the cold water supply to the hot

water storage unit

• Installation in horizontal or vertical pipeline possible

• The installation must be carried out so that:

o There are no shutoff valves or fittings, narrowing of the

pipework or strainers between the water heater and the

safety valve

o Good access is provided for service and maintenance

o The safety valve is fitted above the top of the water heater

to avoid the need for draining down when exchanging the

safety valve insert

• If there is no drainage facility in the room where the heater is

installed, then the safety valve may be fitted in an adjacent

area. DIN 1988, part 2 is to be observed

Typical Applications

Safety groups of this type are installed in accordance with their

specification upstream of water heaters.

The following are some typical applications:

• Central hot water supply systems

• Hot water storage units

Maintenance

In accordance with DIN 1988, Part 8, the following operations should be carried out regularly. A planned maintenance scheme is

recommended.

Operation Interval Carried out by

Inspection Backflow stopper: functional check by opening the test plug and closing

Annually User

the cut-off valve.

Safety valve: Check operation as follows: With the system operating,

Every six months User or specialist

open the venting device. The resulting water flow must fully drain away.

When the ventil is released,the valve must fully close.

Maintenance Safety valve: If a malfunction occurs,this may be cured by repeated

Annually Specialist

manual opening and closing of the valve. If this method does not

EN0H-1355GE23 R1007 • Subject to change

succeed, then an overhaul of the valve will be necessary.

www.honeywell.com 3

Page 4

SG150 Safety group

Spare Parts

Safety group SG150, from 2007 onwards

1

No. Description Dimension Part No.

1 Safety valve

1

3

5

4

5

2

exchange insert

Approval No. - TÜV · SV · ..* - 617 Approval No. - TÜV · SV · ..* - 700 6 bar

8 bar

10 bar

1

/2" A152-1/2AA

3

/4" A152-3/4AA

1

/2" A152-1/2AB

3

/4" A152-3/4AB

1

/2" A152-1/2AC

3

/4" A152-3/4AC

1

/2"+3/4"·W·p

1

/2"+3/4"·W·p

..* valid approval No.

2 Blanking plug

with O-ring R

1

/4"

S06K-1/4

(5 pcs.)

3 Discharge tundish TA160S

4 Check valve insert

5 Sealing ring

(10 pcs.)

1

/2" 2166200

3

/4" 2110200

1

/2" 0901443

3

/4" 0901444

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1355GE23 R1007

Subject to change without notice

© 2007 Honeywell GmbH

Loading...

Loading...