Honeywell Series 8 I/O User Manual

Honeywell Process Solutions

Series 8 I/O User's Guide

EXDOC-X110-en-500A

R500

April 2017

Release 500

Honeywell

Notices and Trademarks

Copyright 2017 by Honeywell International Sárl.

Release 500 April 2017

While this information is presented in good faith and believed to be accurate, Honeywell disclaims

the implied warranties of merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The

information and specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion LX, and TotalPlant are registered trademark of Honeywell

International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell Process Solutions

1860 W. Rose Garden Lane

Phoenix, AZ 85027 USA

1-800 822-7673

ii Series 8 I/O User's Guide R500

Honeywell April 2017

Document Name

Document ID

Release

Number

Publication

Date

Series 8 I/O User's Guide

EXDOCX110-en500A

500

April 2017

About This Document

The procedures in this document are intended to give you the ability to perform basic

tasks with the Series 8 I/O such as configuring hardware devices, continuous control

strategies. Respective forms are shown to illustrate a procedure/concept only.

Release Information-

Intended audience

This guide is intended for the following users:

Persons responsible for system planning, initial hardware installation, and control

strategy configuration.

Operators who help to maintain control system operations on a day-by-day basis.

Service persons responsible for routine maintenance of control hardware, and who

also diagnose and repair faults.

Prerequisite Skills

It is assumed that you should have some knowledge of Experion control systems and

experience of working in a Microsoft Windows environment.

R500 Series 8 I/O User's Guide iii

April 2017 Honeywell

Document Title

Information

Control Hardware Planning Guide

Provides general information to assist you in planning

and design of control hardware in Experion LX

system. Control hardware includes all I/O families,

(except Series 8 I/O). It includes some supervisory

network considerations for general reference.

C300 Controller Guide

This guide provides information that will assist you in

planning and designing activities, as well as the

installation, operation, and troubleshooting of Series 8

and C300 Controllers in an Experion LX system.

Fault Tolerant Ethernet Overview and

Implementation Guide

Provides basic installation instructions and

configuration requirements for a Fault Tolerant

Ethernet (FTE) network and its components.

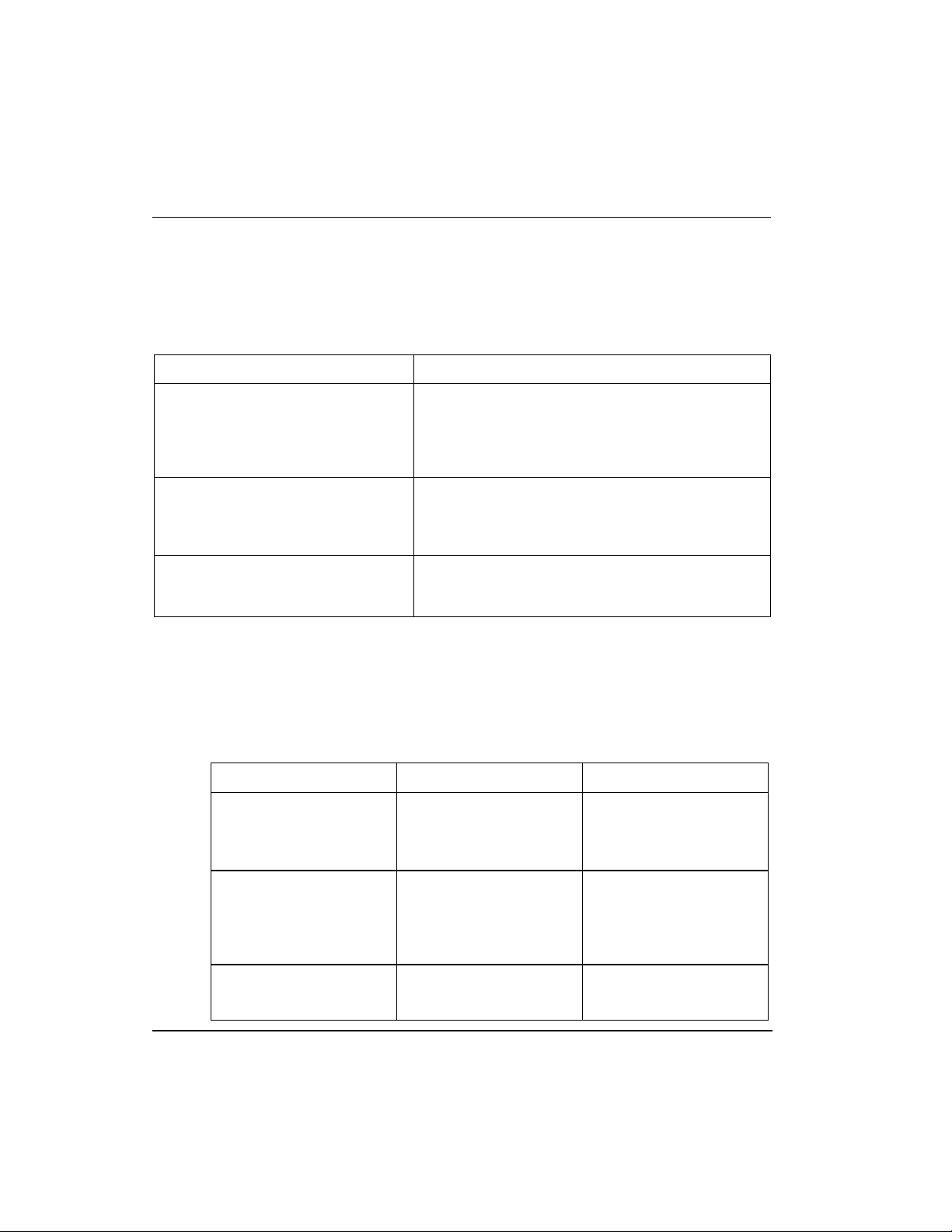

Term/conventions

Meaning

Example

Click

Click left mouse button

once. (Assumes cursor is

positioned on object or

selection.)

Click the Browse button.

Double-click

Click left mouse button

twice in quick succession.

(Assumes cursor is

positioned on object or

selection.)

Double click the Station

icon.

Drag

Press and hold left mouse

button while dragging

cursor to new screen

Drag the PID function

block onto the Control

Support and Other Contacts

References

The following list identifies all the documents that may be sources of reference for

material discussed in this publication.

Terms and acronyms

The following table summarizes the terms and type representation conventions used in

this guide.

Table 1 Terms and conventions

iv Series 8 I/O User's Guide R500

Honeywell April 2017

Support and Other Contacts

Term/conventions

Meaning

Example

location and then release

the button. (Assumes

cursor is positioned on

object or selection to be

moved.)

Drawing.

Right-click

Click right mouse button

once. (Assumes cursor is

positioned on object or

selection.)

Right-click the AND

function block.

<F1>

Keys to be pressed are

shown in angle brackets.

Press <F1> to view the

online Help.

<Alt>+<F4>

Keys to be pressed

together are shown with a

plus sign.

Press <Alt>+<F4> to

close the window.

File->New

Shows menu selection as

menu name followed by

menu selection

Click File->New to start

new drawing.

>D:\setup.exe<

Data to be keyed in at

prompt or in an entry field.

Key in this path location

>D:\setup.exe<.

R500 Series 8 I/O User's Guide v

April 2017 Honeywell

Support and Other Contacts

Support and Other Contacts

For support, contact your local Honeywell Process Solutions Customer Contact Center (CCC). To

find your local CCC visit the website, https://www.honeywellprocess.com/en-US/contact-

us/customer-support-contacts/Pages/default.aspx.

vi Series 8 I/O User's Guide R500

Honeywell April 2017

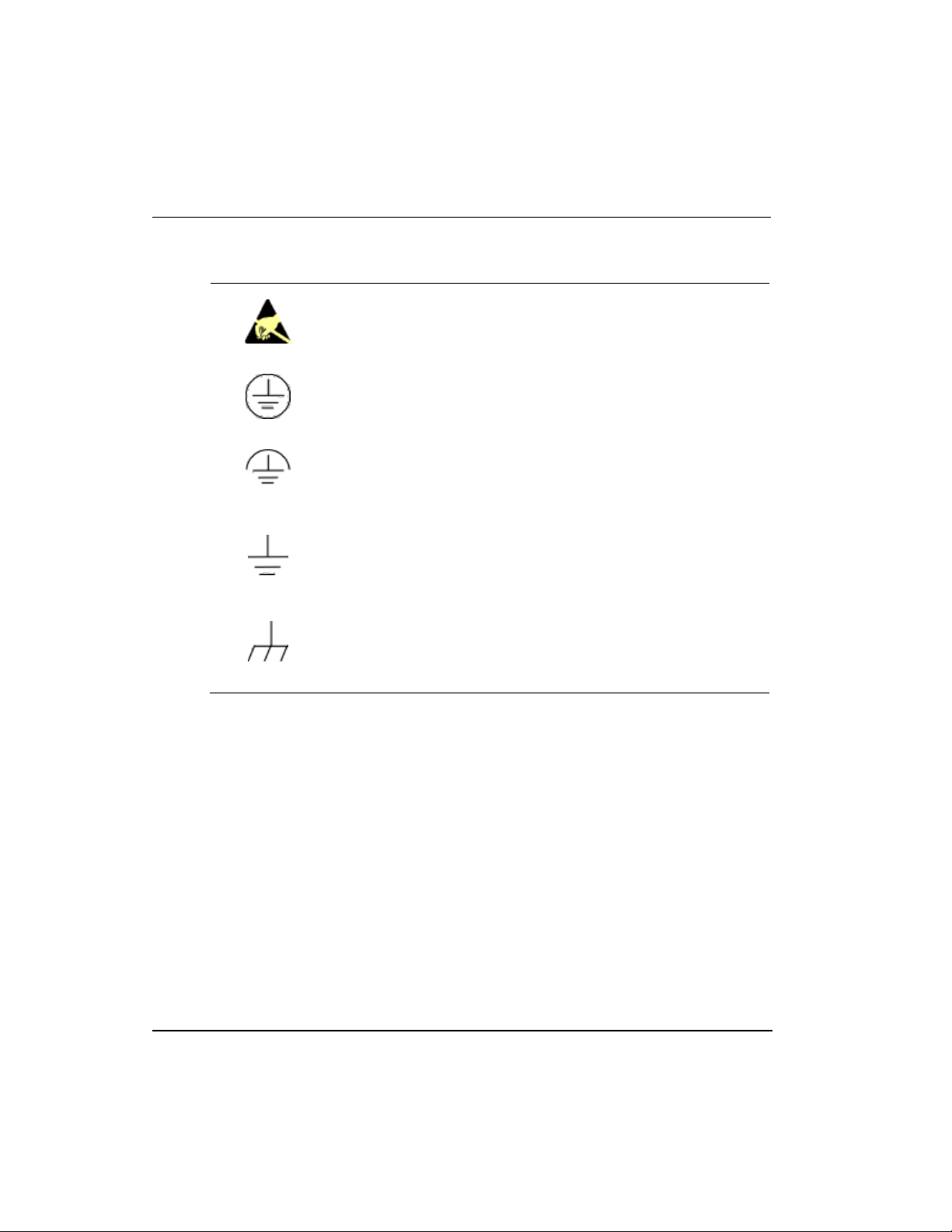

Symbol Definitions

Symbol

Definition

ATTENTION: Identifies information that requires special

consideration.

TIP: Identifies advice or hints for the user, often in terms of

performing a task.

REFERENCE -EXTERNAL: Identifies an additional source of

information outside of the bookset.

REFERENCE - INTERNAL: Identifies an additional source of

information within the bookset.

CAUTION

Indicates a situation which, if not avoided, may result in equipment

or work (data) on the system being damaged or lost, or may result in

the inability to properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices.

CAUTION symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or

60 VDC may be accessible.

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

R500 Series 8 I/O User's Guide vii

April 2017 Honeywell

Symbol

Definition

ESD HAZARD: Danger of an electro-static discharge to which

equipment may be sensitive. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the

protective earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as

noise immunity improvement. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance

with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This

connection shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

Chassis Ground: Identifies a connection to the chassis or frame of

the equipment shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

Symbol Definitions

viii Series 8 I/O User's Guide R500

Honeywell April 2017

Contents

1. SERIES 8 I/O PURPOSE ............................................................. 23

1.1 Overview ........................................................................................................ 23

1.2 What is I/O? .................................................................................................... 23

Series 8 I/O .......................................................................................................................... 23

2. SERIES 8 I/O PLANNING AND DESIGN ..................................... 25

2.1 Overview ........................................................................................................ 25

2.2 Series 8 I/O appearance and features ......................................................... 25

Look and feel ........................................................................................................................ 25

2.3 Series 8 I/O and C300 topology ................................................................... 27

Examining the topology rules ............................................................................................... 28

2.4 Supported Series 8 I/O modules .................................................................. 30

Available Series 8 I/O modules ............................................................................................ 30

Identifying supported Series 8 I/O modules.......................................................................... 31

2.5 Pulse Accumulation module ........................................................................ 32

What is Pulse Accumulation (Digital Input Pulse Accumulation) module ............................. 32

Features of Digital Input Pulse Accumulation ....................................................................... 32

Limitations of Digital Input Pulse Accumulation .................................................................... 32

2.6 Supported Series 8 I/O options .................................................................... 32

Available Series 8 I/O options .............................................................................................. 32

Inspecting the Series 8 I/O library ........................................................................................ 33

Inspecting IOM function blocks ............................................................................................ 33

Inspecting channel function blocks ....................................................................................... 34

Defining module containment ............................................................................................... 34

2.7 I/O Link performance specifications ........................................................... 36

Reviewing Link Unit utilization .............................................................................................. 36

Reducing I/O Link traffic ....................................................................................................... 37

Event collection .................................................................................................................... 37

PV and Back calculation scanning ....................................................................................... 37

3. SERIES 8 I/O INSTALLATION AND UPGRADES ....................... 39

3.1 Overview ........................................................................................................ 39

3.2 Installation Declarations ............................................................................... 39

Introduction .......................................................................................................................... 40

R500 Series 8 I/O User's Guide ix

April 2017 Honeywell

Contents

I/O Link Number and IOM Number DIP switch .................................................................... 40

Cabling ................................................................................................................................ 41

3.3 Installing the Series 8 IOTA on the Panel .................................................... 43

Prerequisites ....................................................................................................................... 43

Considerations .................................................................................................................... 43

Mounting the IOTA .............................................................................................................. 43

3.4 Mounting the I/O module on the IOTA ......................................................... 45

Prerequisites ....................................................................................................................... 45

Mounting the module ........................................................................................................... 45

3.5 Grounding and power considerations - IOTA boards ................................ 46

Attaching the IOTA board .................................................................................................... 46

Testing for power ................................................................................................................. 46

3.6 Connecting IOMs and field devices through I/O Termination Assemblies47

IOTAs wiring diagrams ........................................................................................................ 47

3.7 Powering the Series 8 system ...................................................................... 49

Supplying power to I/O modules.......................................................................................... 49

3.8 Fusing - Series 8 IOTA boards ..................................................................... 49

Protecting the Series 8 I/O components .............................................................................. 49

4. SERIES 8 IOTA PINOUTS ........................................................... 51

4.1 HART/Non-HART Analog Input IOTA (Models 8X-TAIXA1, 8X-TAIXB1) ... 51

Analog Input wiring .............................................................................................................. 54

4.2 Differential Analog input IOTA (Models 8X-TAIDA1 and 8X-TAIDB1) ...... 59

Compatible IOTA models for differential analog input and output channels ........................ 59

Analog Input wiring .............................................................................................................. 59

4.3 Analog Output IOTA Models 8X-TAOXA1, 8X-TAOXB1 ............................. 74

HART/Non-HART Analog Output IOTA (Models 8X-TAOXA1, 8X-TAOXB1) ...................... 79

4.4 TC/RTD IOTA Models 8X-TAIMA1 ............................................................... 80

Field wiring and module protection ...................................................................................... 81

IOTA board and connections ............................................................................................... 81

4.5 Digital Input 24V IOTA Models 8X- TDILA1, 8X- TDILB1 ............................ 85

Field wiring and module protection ...................................................................................... 85

4.6 Digital Output 24V IOTA Models 8X-TDODA1, 8X-TDODB1 ...................... 93

Field wiring and module protection ...................................................................................... 93

IOTA board and connections ............................................................................................... 93

4.7 AC Digital Output (Source) Relay Extension Board Models 8U-SDOX01,

8C-SDOX01 .............................................................................................................. 100

4.8 Upgrading firmware in Series 8 I/O components ..................................... 104

x Series 8 I/O User's Guide R500

Honeywell April 2017

Contents

5. SERIES 8 I/O CONFIGURATION FORM REFERENCE ............ 105

5.1 Overview ...................................................................................................... 105

Rules for Configuring/Reconfiguring redundant IOMs ........................................................ 105

5.2 Determining Series 8 I/O block redundancy ............................................. 107

Main tab checkbox invokes redundancy ............................................................................ 107

5.3 Switchover and Secondary readiness ...................................................... 108

5.4 Failure conditions and switchover ............................................................ 109

5.5 Configuration tools ..................................................................................... 109

Using Control Builder to create control strategies .............................................................. 109

5.6 Configuring the Main tab - IOM block ....................................................... 110

Configuring modules - Main tab ......................................................................................... 110

5.7 Status Data tab - IOM block ........................................................................ 114

Modules - Status Data tab .................................................................................................. 114

5.8 Configuring the Maintenance tab - IOM block .......................................... 116

Configuring modules - Maintenance tab ............................................................................. 116

5.9 Configuring Box Soft Failures tab - IOM block ........................................ 118

Configuring modules - Box Soft Failures tab ...................................................................... 118

5.10 Configuring Channel Soft Failures tab - IOM block ............................. 120

Configuring modules - Channel Soft Failures tab ............................................................... 120

5.11 Configuring Server History tab - IOM block .......................................... 122

Configuring modules - Server History tab........................................................................... 122

5.12 Configuring Server Displays tab - IOM block ....................................... 125

Configuring modules - Server Displays tab ................................ ........................................ 125

5.13 Configuring Control Confirmation tab - IOM block .............................. 129

Configuring modules - Control Confirmation tab ................................................................ 129

5.14 Configuring Identification tab - IOM block ............................................ 131

Configuring modules - Identification tab ............................................................................. 131

5.15 Configuring the Calibration tab - IOM block ......................................... 134

Configuring modules - Calibration tab ................................................................................ 134

5.16 Configuring HART Status tab - IOM block ............................................ 137

Configuring modules HART - Status tab ............................................................................ 137

5.17 Configuring the Configuration tab - Channel block ............................. 139

Configuring modules - Identification tab ............................................................................. 139

5.18 Configuring HART Configuration tab - Channel block ........................ 141

Configuring modules - HART Configuration tab ................................................................. 141

R500 Series 8 I/O User's Guide xi

April 2017 Honeywell

Contents

5.19 Configuring HART Device Status tab - Channel block ......................... 144

Configuring modules - Identification tab ............................................................................ 144

5.20 Configuring HART Identification tab - Channel block .......................... 146

Configuring modules - Identification tab ............................................................................ 146

5.21 Configuring HART Variables tab - Channel block ................................ 148

Configuring modules - Identification tab ............................................................................ 148

5.22 Configuring HART Notifications tab - Channel block .......................... 151

Configuring modules - Identification tab ............................................................................ 151

5.23 Configuring Dependencies tab - Channel block ................................... 153

Configuring modules - Dependencies tab ......................................................................... 153

5.24 Configuring Template Defining tab - Channel block ............................ 155

Configuring modules - Identification tab ............................................................................ 155

6. SERIES 8 I/O CONFIGURATION .............................................. 157

6.1 Adding an IOM to Project ............................................................................ 157

Using the File menu method ............................................................................................. 157

Using the drag and drop method ....................................................................................... 159

6.2 Assigning an IOM to an IOLINK in the Project tab ................................... 159

Using the Assignment dialog box ...................................................................................... 159

6.3 Adding an IOC block to a Control Module ................................................ 161

Using the Project tab drag and drop .................................................................................. 161

Using the Library tab - drag and drop ................................................................................ 163

6.4 Assigning an IOC block to an IOM ............................................................. 166

IOC block assignment ....................................................................................................... 166

6.5 Unassigning an IOC block from an IOM .................................................... 168

IOC block unassignment ................................................................................................... 168

6.6 Defining Channel blocks ............................................................................. 169

Overview ........................................................................................................................... 169

Common features of I/O channel blocks ........................................................................... 170

Defining Mode and Attribute settings ................................................................................. 170

Enabling HART.................................................................................................................. 178

Using Block Copy .............................................................................................................. 182

6.7 Defining Analog Input Channel Blocks ..................................................... 182

Overview ........................................................................................................................... 182

Determining PV Characterization ...................................................................................... 184

Determining Linear Conversion ......................................................................................... 185

Determining Square Root Conversion ............................................................................... 185

Determining Thermal Conversion ...................................................................................... 186

Checking and Filtering PV Range ..................................................................................... 187

xii Series 8 I/O User's Guide R500

Honeywell April 2017

Contents

6.8 Defining Analog Output Channel Blocks .................................................. 188

Overview ............................................................................................................................ 188

Determining Direct/Reverse Output ................................................................................... 189

Determining Output Characterization ................................................................................. 190

Determining Calibration Compensation .............................................................................. 191

Determining Modes ............................................................................................................ 191

6.9 Defining Digital Input Channel Blocks ...................................................... 191

Overview ............................................................................................................................ 191

Determining Status Digital Input channel ........................................................................... 192

Determining Latched Digital Input channel ......................................................................... 193

6.10 Defining Digital Output Channel Blocks ............................................... 193

Overview ............................................................................................................................ 193

Determining Status Output type ......................................................................................... 195

Determining Pulse Width Modulated (PWM) Output type .................................................. 195

Determining On-Pulse and Off-Pulse Output type .............................................................. 196

Determining Initialization Request Flag .............................................................................. 198

Determining Modes ............................................................................................................ 198

Determining Output Verification ......................................................................................... 198

Determining Over-current protection .................................................................................. 199

6.11 Defining DIGITAL INPUT PULSE ACCUMULATION Channel Blocks . 199

Overview ............................................................................................................................ 199

Determining the Digital Input channel properties or DIGITAL INPUT PULSE ACCUMULATION

channel properties .............................................................................................................. 200

PV Source Selection .......................................................................................................... 201

6.12 Electronic Short-Circuit Protection (Digital Output 24VDConly) ........ 201

Non-redundant Configuration ............................................................................................. 201

Redundant Configuration ................................................................................................... 202

Electronic Short-Circuit Fault Recovery ............................................................................. 203

7. SERIES 8 I/O OPERATIONS ..................................................... 205

7.1 Overview ...................................................................................................... 205

7.2 Reviewing the Control Builder icons ........................................................ 205

Series 8 I/O block icons ..................................................................................................... 205

IOLINK icons ...................................................................................................................... 207

Block icons ......................................................................................................................... 208

Channel icons .................................................................................................................... 208

7.3 Series 8 I/O LED Descriptions .................................................................... 209

7.4 Powering up the IOM .................................................................................. 212

7.5 Activating a control strategy from the Monitoring tab ............................ 214

Starting an IOM .................................................................................................................. 214

Issuing Shutdown command .............................................................................................. 215

R500 Series 8 I/O User's Guide xiii

April 2017 Honeywell

Contents

7.6 Activating HART .......................................................................................... 215

Assigning a channel to HART - Series 8 ........................................................................... 215

Enabling HART Alarm and Events - Series 8 .................................................................... 216

7.7 IOM configuration values not copied during Block Copy operation ...... 218

7.8 Sequence of Events Scenarios .................................................................. 218

Input chatter scenario ........................................................................................................ 218

PVCHGDLY scenarios ...................................................................................................... 219

PV State Change event Regeneration .............................................................................. 220

7.9 Sequence of Events Events and Configuration........................................ 221

Sequence of Events Event Configuration .......................................................................... 221

Sequence of Events Events .............................................................................................. 222

7.10 DIMODE related scenarios ...................................................................... 223

DIMODE Parameter Changes ........................................................................................... 223

Low Latency Mode ............................................................................................................ 224

7.11 Enabling point type selection in Digital Input Pulse Accumulation

channel 224

7.12 Enabling the configuration in Digital Input Pulse Accumulation channel

225

8. SERIES 8 I/O LOADING ............................................................ 227

8.1 Loading Series 8 I/O components .............................................................. 227

Load order guidelines ........................................................................................................ 227

8.2 Loading an IOLINK ...................................................................................... 228

IOLINK Load with Contents ............................................................................................... 228

8.3 Loading the IOM block the first time ......................................................... 228

Loading the IOM block present on the IOLINK .................................................................. 228

Loading with the IOM block missing on the IOLINK .......................................................... 231

Reloading the IOM block from Project or Monitoring ......................................................... 232

Reviewing IOM reconfiguration rules ................................................................................. 232

8.4 Common I/O block load activities .............................................................. 233

Uploading the I/O block ..................................................................................................... 233

Update to Project............................................................................................................... 234

Using IOM Checkpoint ...................................................................................................... 234

8.5 Loading a CM ............................................................................................... 234

Loading the CM the first time ............................................................................................ 234

Reloading the CM from Project or Monitoring ................................................................... 235

8.6 Setting Priority IOMs ................................................................................... 236

xiv Series 8 I/O User's Guide R500

Honeywell April 2017

Contents

9. SERIES 8 I/O LINK FIBER OPTIC EXTENDERS (FOE) ........... 241

9.1 Overview

Fiber Optic Extender assembly .......................................................................................... 241

FOE features ...................................................................................................................... 243

Fiber Optic redundancy ...................................................................................................... 244

....................................................................................................... 241

9.2 FOE Installation ........................................................................................... 244

Handling components - ESD .............................................................................................. 244

Work practices ................................................................................................................... 244

9.3 Component mounting sequence ............................................................... 245

Mounting the FOE module onto the IOTA .......................................................................... 246

Mounting the FOE module/back panel assembly to the carrier .......................................... 246

To mount the FOE module/back panel assembly to the carrier.......................................... 246

Connecting the IOLINK interface cable to the FOE module ............................................... 246

Connecting the fiber optic cables to the FOE module ........................................................ 247

FOE connection rules ......................................................................................................... 248

LED indicators .................................................................................................................... 249

9.4 Defining the Fiber Optic topology ............................................................. 249

FOE capacity ...................................................................................................................... 250

FOE capacity...................................................................................................................... 250

Required hardware ............................................................................................................. 250

FOE topologies .................................................................................................................. 251

Fiber optic budget considerations ...................................................................................... 252

I/O link extender cable selection ........................................................................................ 253

Allowable standard I/O Link extender cable signal loss ...................................................... 254

10. SERIES 8 I/O TROUBLESHOOTING......................................... 255

10.1 Initial checks ............................................................................................ 255

Checking Control Builder error code reference .................................................................. 255

Checking front panel display and LEDs ............................................................................. 255

Upgrading Firmware in Series 8 I/O components ............................................................... 255

10.2 Self-test diagnostics at power-up .......................................................... 256

Power-up diagnostics ......................................................................................................... 256

10.3 Communication problems ...................................................................... 257

IOLINK - loss of communications ....................................................................................... 257

IOLINK - re-establishing communications .......................................................................... 257

11. SERIES 8 I/O MAINTENANCE .................................................. 258

11.1 Series 8 recommended spares............................................................... 258

IOM removal and installation under power ......................................................................... 258

R500 Series 8 I/O User's Guide xv

April 2017 Honeywell

Contents

11.2 Replacing a Series 8 IOTA ...................................................................... 264

11.3 Replacing an I/O module ......................................................................... 264

Prerequisites ..................................................................................................................... 265

12. SERIES 8 POWER SUB-SYSTEM CONNECTIONS AND ALARM

INDICATIONS ..................................................................................... 267

12.1 Series 8 DC Power Connections and Indicators ................................... 267

12.2 Series 8 Power Sub-System Alarm Contacts and LED Activation Levels

268

13. SERIES 8 I/O ALARMS AND FAILURES ................................. 269

13.1 Reviewing IOM alarms generated by the C300 ..................................... 269

IOM alarms ........................................................................................................................ 269

HART alarms/events ......................................................................................................... 269

13.2 Reviewing IOM soft failures .................................................................... 270

IOM soft failures ................................................................................................................ 270

01 STCOVRUN .......................................................................................................... 270

06 FTAMISSG ............................................................................................................ 271

07 EECKSMER .......................................................................................................... 271

08 EECNTERR ........................................................................................................... 271

09 EEFLAGER ........................................................................................................... 271

21 INPTFAIL ............................................................................................................... 272

23 OUTPUTFL ........................................................................................................... 272

24 STCKLIM ............................................................................................................... 272

26 DIAGCTFL ............................................................................................................. 272

31 FTAMSMCH .......................................................................................................... 273

32 VZERO-FL ............................................................................................................. 273

33 BADRJVAL ............................................................................................................ 273

36 FTA1FAIL .............................................................................................................. 274

37 FTA2FAIL .............................................................................................................. 274

38 CALBABRT ........................................................................................................... 274

39 BADCALRF ........................................................................................................... 274

41 VREFFAIL ............................................................................................................. 275

42 ADOUTUDF .......................................................................................................... 275

43 ADOUTCAL ........................................................................................................... 275

44 BADFLREG ........................................................................................................... 275

45 BDSNDLTC ........................................................................................................... 275

46 BDOUTBFR ........................................................................................................... 276

47 VCALFAIL ............................................................................................................. 276

48 F1NOTCAL ............................................................................................................ 276

49 F2NOTCAL ............................................................................................................ 277

50 F1COM_FL ............................................................................................................ 277

xvi Series 8 I/O User's Guide R500

Honeywell April 2017

Contents

51 F2COM_FL ............................................................................................................ 277

52 F1_IDERR ................................................................ .............................................. 277

53 F2_IDERR ................................................................ .............................................. 277

54 F1VREFFL ............................................................................................................. 278

55 F2VREFFL ............................................................................................................. 278

56 F1CAL_FL ................................................................ .............................................. 278

57 F2CAL_FL ................................................................ .............................................. 279

58 WRITENBL ............................................................................................................. 279

60 MLTINPFL ................................................................ .............................................. 279

61 REDNDIAG ............................................................................................................ 279

63 WRONG_HW ......................................................................................................... 280

69 DTPATHFL ............................................................................................................. 280

70 DTPATHTO ............................................................................................................ 280

72 PIFAULTY .............................................................................................................. 280

161 HMODEM1 ............................................................................................................. 281

162 HMODEM2 ............................................................................................................. 281

163 HMODEM3 ............................................................................................................. 281

164 HMODEM4 ............................................................................................................. 281

165 HDIAGTO ............................................................................................................... 282

166 HSTACKHI ............................................................................................................. 282

167 FTA3FAIL ............................................................................................................... 282

168 FTA4FAIL ............................................................................................................... 282

169 F3NOTCAL ............................................................................................................ 283

170 F4NOTCAL ............................................................................................................ 283

171 F3COMFL .............................................................................................................. 283

172 F4COMFL .............................................................................................................. 283

173 F3IDERR ................................................................................................................ 283

174 F4IDERR ................................................................................................................ 284

175 F3VREFFL ............................................................................................................. 284

176 F4VREFFL ............................................................................................................. 284

177 F3CALFL ................................................................................................................ 285

178 F4CALFL ................................................................................................................ 285

179 OPENWIRE ............................................................................................................ 285

180 DOVRCRNT ........................................................................................................... 285

181 FTAPOWFL ............................................................................................................ 286

182 DPADIAFAIL .......................................................................................................... 286

183 RDBKRGDIAGFL ................................................................................................... 286

184 WDTDIAGFAIL ....................................................................................................... 286

185 RLYEXTBDMSSNG ............................................................................................... 287

186 REDHWFAIL .......................................................................................................... 287

187 HARTCHANFAIL ................................ .................................................................... 287

13.3 Reviewing IOM hard failures .................................................................. 288

IOM hard failures ................................................................................................................ 288

IOM Behavior during Hard Failures .................................................................................... 289

13.4 Getting further assistance ...................................................................... 291

Other troubleshooting sources ........................................................................................... 291

Guidelines for requesting support ...................................................................................... 291

R500 Series 8 I/O User's Guide xvii

April 2017 Honeywell

Contents

Tables

Tables

Table 1 Terms and conventions ...................................................................................... iv

Table 2 Series 8 features ............................................................................................... 25

Table 3 Topology rules ................................................................................................... 29

Table 4 Available I/O modules ....................................................................................... 30

Table 5 Series 8 I/O channel function blocks ................................................................. 34

Table 6 Link Unit utilization rates ................................................................................... 36

Table 7 I/O parameters scanned when the IOM is loaded ............................................ 37

Table 8 Series 8 I/O cable types .................................................................................... 41

Table 9 IOMs, IOTAs, and ancillary cards ..................................................................... 48

Table 10 Analog Input 6 inch, non-HART Analog Input, non-redundant - terminal block 1

................................................................................................................................ 53

Table 11 Analog Input 6 inch, HART/non-HART Analog Input, non-redundant terminal

block 2 ..................................................................................................................... 54

Table 12 Summary - Analog Input wiring connections................................................... 56

Table 13 Custom wiring to support differential Analog Input ......................................... 61

Table 14 Series 8 differential Analog Input 9 and 12 inch – terminal block 1 ................ 68

Table 15 Series 8 differential Analog Input 9 inch and 12 inch IOTAs – terminal block 268

Table 16 Jumpers to support Analog Input connections ................................................ 70

Table 17 Analog Output 6 inch, non-redundant - terminal block 1 ................................ 76

Table 18 Analog Output 6 inch, HART/non-HART Analog Output, non-redundant -

terminal block 1 ....................................................................................................... 79

Table 19 Digital Input 9 inch, non-redundant - terminal block 1 .................................... 87

Table 20 Digital Input 9 inch, non-redundant - terminal block 2 .................................... 88

Table 21 Digital Input 9 inch, non-redundant - terminal block 3 .................................... 89

Table 22 24V Digital Output 9 inch, non-redundant - terminal block 1 .......................... 95

Table 23 24V Digital Output 9 inch, non-redundant - terminal block 2 .......................... 96

Table 24 24V Digital Output 9 inch, non-redundant - terminal block 3 .......................... 97

Table 25 AC Digital Output (Source) Relay Extension Board - terminal block 1 ......... 100

Table 26 AC Digital Output (Source) Relay Extension Board - terminal block 2 ......... 101

Table 27 Redundancy state and module readiness ..................................................... 108

Table 28 Failure conditions and switchover ................................................................. 109

Table 29 Main tab parameters ..................................................................................... 112

Table 30 Server History tab parameters ...................................................................... 124

Table 31 Server Display tab parameters ..................................................................... 127

Table 32 Identification tab parameters ......................................................................... 132

Table 33 HART Configuration tab parameters ............................................................. 142

Table 34 HART Device Status tab parameters ............................................................ 145

Table 35 HART Identification tab ................................................................................. 147

Table 36 HART Variables tab parameters ................................................................... 150

Table 37 HART Notifications tab parameters .............................................................. 152

R500 Series 8 I/O User's Guide xviii

April 2017 Honeywell

Contents

Tables

Table 38 I/O Channel block type ................................................................................. 170

Table 39 Mode parameter - channel block .................................................................. 171

Table 40 Mode Attribute parameter - channel block ................................................... 171

Table 41 Channel block fault conditions and results ................................................... 172

Table 42 Analog Output fault handling ........................................................................ 173

Table 43 Digital Output fault handling ......................................................................... 174

Table 44 FAULTOPT parameter settings .................................................................... 175

Table 45 IOM hard failure and output state ................................................................. 176

Table 46 PV Source settings ....................................................................................... 177

Table 47 PVSRCOPT settings .................................................................................... 177

Table 48 REDTAG settings ......................................................................................... 177

Table 49 HART parameters ......................................................................................... 182

Table 50 Analog Input engineering unit conversions .................................................. 184

Table 51 RTD lead wire characteristics ....................................................................... 186

Table 52 Status Output settings .................................................................................. 197

Table 53 Setting DOTYPE to ONPULSE or OFFPULSE ............................................ 197

Table 54 Digital Output channel initialization .............................................................. 198

Table 55 Channel block icons ..................................................................................... 205

Table 56 IOLINK icons ................................................................................................. 207

Table 57 Block icons .................................................................................................... 208

Table 58 Channel icons ............................................................................................... 208

Table 59 I/O LED descriptions ..................................................................................... 211

Table 60 Sequence of activating components - Monitoring tab .................................. 214

Table 61 Sequence of activating components - Project tab ........................................ 227

Table 62 IOM reconfiguration rules ............................................................................. 233

Table 63 FOE module and back panel summary ........................................................ 242

Table 64 FOE LED descriptions .................................................................................. 249

Table 65 Recommended spare parts .......................................................................... 258

Table 66 IOM alarms displayed by the C300 controller .............................................. 269

Table 67 IOM hard failures .......................................................................................... 290

R500 Series 8 I/O User's Guide xix

April 2017 Honeywell

Contents

Figures

Figures

Figure 1 Series 8 I/O and C300 topology ....................................................................... 28

Figure 2 Series 8 I/O library ........................................................................................... 33

Figure 3 Execution State ................................................................................................ 35

Figure 4 Point Execution State ....................................................................................... 35

Figure 5 Series 8 board connections ............................................................................. 40

Figure 6 Series 8 cabling ............................................................................................... 42

Figure 7 IOLINK’s terminal on the header board for power testing ............................... 47

Figure 8 Series 8 HART/non-HART Analog Input 6 inch, non-redundant IOTA ............ 52

Figure 9 Non-redundant Analog Input 9 inch, standard 2-wire transmitter wiring ......... 55

Figure 10 Series 8 HART/non-HART Analog Input 12 inch, redundant IOTA ............... 58

Figure 11 Non-redundant Analog Input 9 inch, standard 2-wire transmitter wiring ....... 60

Figure 12 Non-redundant Analog Input 9 inch, self-powered 2-wire transmitter wiring . 60

Figure 13 Series 8 differential non-redundant Analog Input 9 inch, jumper configuration65

Figure 14 Series 8 differential redundant Analog Input 12 inch, jumper configuration .. 66

Figure 15 Series 8 differential Analog Input 9 inch, non-redundant IOTA ..................... 67

Figure 16 Series 8 differential Analog Input 12 inch, redundant IOTA .......................... 74

Figure 17 Series 8 Analog Output 6 inch, non-redundant IOTA .................................... 75

Figure 18 Series 8 Analog Output 6 inch, non-redundant IOTA and field wiring connection

................................................................................................................................ 77

Figure 19 Series 8 Analog Output 12 inch, redundant IOTA ......................................... 78

Figure 20 Series 8 TC/RTD 6 inch, non-redundant IOTA .............................................. 82

Figure 21 Series 8 TC/RTD IOTA and field wiring connections ..................................... 83

Figure 22 Series 8 24V Digital Input 9 inch, non-redundant IOTA ................................. 86

Figure 23 Series 8 24V Digital Input 9 inch, non-redundant IOTA and field wiring

connection ............................................................................................................... 90

Figure 24 Series 8 24V Digital Input 12 inch, redundant IOTA ...................................... 91

Figure 25 Series 8 24V Digital Output 9 inch, non-redundant IOTA .............................. 94

Figure 26 Series 8 24V Digital Output 9 inch, non-redundant IOTA and field wiring

connections ............................................................................................................. 98

Figure 27 Series 8 24V Digital Output 12 inch, redundant IOTA ................................... 99

Figure 28 Series 8 AC Digital Output (Source) Relay Extension Board ...................... 100

Figure 29 Series 8 AC Digital Output (Source) Relay Extension Board and field wiring

connections ........................................................................................................... 103

Figure 30 Defining redundancy from the Main tab ....................................................... 108

Figure 31 Main tab ....................................................................................................... 111

Figure 32 Status Data tab ............................................................................................ 115

Figure 33 Maintenance tab .......................................................................................... 117

Figure 34 Box Soft Failures tab .................................................................................... 119

Figure 35 Channel Soft Failures tab ............................................................................ 121

Figure 36 Server History tab ........................................................................................ 123

xx Series 8 I/O User's Guide R500

Honeywell April 2017

Contents

Figures

Figure 37 Server Display tab ....................................................................................... 126

Figure 38 Control Confirmation tab ............................................................................. 130

Figure 39 Identification tab .......................................................................................... 132

Figure 40 Calibration tab ............................................................................................. 135

Figure 41 HART Status tab ......................................................................................... 138

Figure 42 Configuration tab ......................................................................................... 140

Figure 43 HART Configuration tab .............................................................................. 142

Figure 44 HART Device Status tab ............................................................................. 145

Figure 45 HART Identification tab ............................................................................... 147

Figure 46 HART Variables tab ..................................................................................... 149

Figure 47 HART Notifications tab ................................................................................ 152

Figure 48 Dependencies tab ....................................................................................... 154

Figure 49 Template Defining tab ................................................................................. 156

Figure 50 Analog Output and Digital Output fault state (FAULTST) transitions .......... 173

Figure 51 Series 8 I/O Analog Input or Analog Output withHART tabs ....................... 181

Figure 52 Analog Input conversion .............................................................................. 183

Figure 53 Analog Output conversion ........................................................................... 189

Figure 54 Determining fixed endpoint .......................................................................... 190

Figure 55 Digital input conversion ............................................................................... 192

Figure 56 Digital output conversion ............................................................................. 194

Figure 57 Pulse Width Modulated Output .................................................................... 196

Figure 58 On-Pulse and Off-Pulse Output types ......................................................... 196

Figure 59 DIGITAL INPUT PULSE ACCUMULATION conversion ............................. 200

Figure 60 Series 8 I/O LED indicators ......................................................................... 210

Figure 61 : Sequence of Events PV Change Delay Scenario ..................................... 220

Figure 62 Loading the IOM block the first time ............................................................ 229

Figure 63 Reloading the IOM block ............................................................................. 232

Figure 64 Loading the CM ........................................................................................... 235

Figure 65 Setting Priority IOM ..................................................................................... 237

Figure 66 FOE assembly ............................................................................................. 242

Figure 67 Example of possible FOE usage ................................................................. 250

Figure 68 Typical dc power and power control module connections in Series 8 cabinet

with RAM Charger 51454475-100 ........................................................................ 267

Figure 69 Location of hard failure message ................................................................ 288

R500 Series 8 I/O User's Guide xxi

April 2017 Honeywell

1. Series 8 I/O Purpose

1.1 Overview

Series 8 I/O modules, along with I/O Termination Assemblies (IOTAs), perform module

diagnostics input and output scanning and processing on all field I/O data and events. To

allow a more efficient use of Controller resources, I/O processing is performed separately

from control processing functions so that:

I/O sample rates are completely independent of I/O quantity, controller loading,

processing, and alarming

Allows more efficient use of advanced Control Processor capability, and

Provides for future I/O expansion

1.2 What is I/O?

Series 8 I/O

The Experion Series 8 I/O modules are an expanding family of traditional and special

function input/output signal interface devices. They support local software configuration.

These I/O modules share the same form factor as the C300 Controller and reside on the

same type of common mounting system as other Series 8 components.

R500 Series 8 I/O User's Guide 23

April 2017 Honeywell

I/O module/IOTA

Feature/function

Analog Input w/HART

Extensive self-diagnostics

Optional redundancy

HART capable, multivariable instruments

Fast (50 ms) loop scan

Analog Input

Extensive self-diagnostics

Optional redundancy

Fast (50 ms) loop scan

2. Series 8 I/O Planning and Design

2.1 Overview

This guide is intended to provide general information to assist you in planning and

designing the installation of your Experion Series 8 I/O.

2.2 Series 8 I/O appearance and features

Look and feel

The layout of Series 8 components supports enhanced heat management.

The features of Series 8 I/O include:

1. IOL – Each C300 I/O Link can be configured to provide 750 kbps link speeds.

2. Series 8 I/O fully supports HART I/O. This includes the use of Secondary

HART Variables as control parameters.

3. Series 8 Permits Division 2/Zone 2 mounting of the Controller and I/O.

IO Module design - tilted 18 degrees off center:

allows for efficient field wiring

Combination of I/O Module and Field terminations in the same area. The I/O

Module is mounted on the IOTA which reduces cabinet space and eliminates items.

Redundancy is performed directly on the IOTA by simply adding a second IOM to

the IOTA (with the exception of the C300 controller).

For complete feature/functions for the following modules/IOTAs, refer to the Experion

Series 8 I/O Specification and Technical Data document.

R500 Series 8 I/O User's Guide 25

April 2017 Honeywell

Table 2 Series 8 features

2. Series 8 I/O Planning and Design

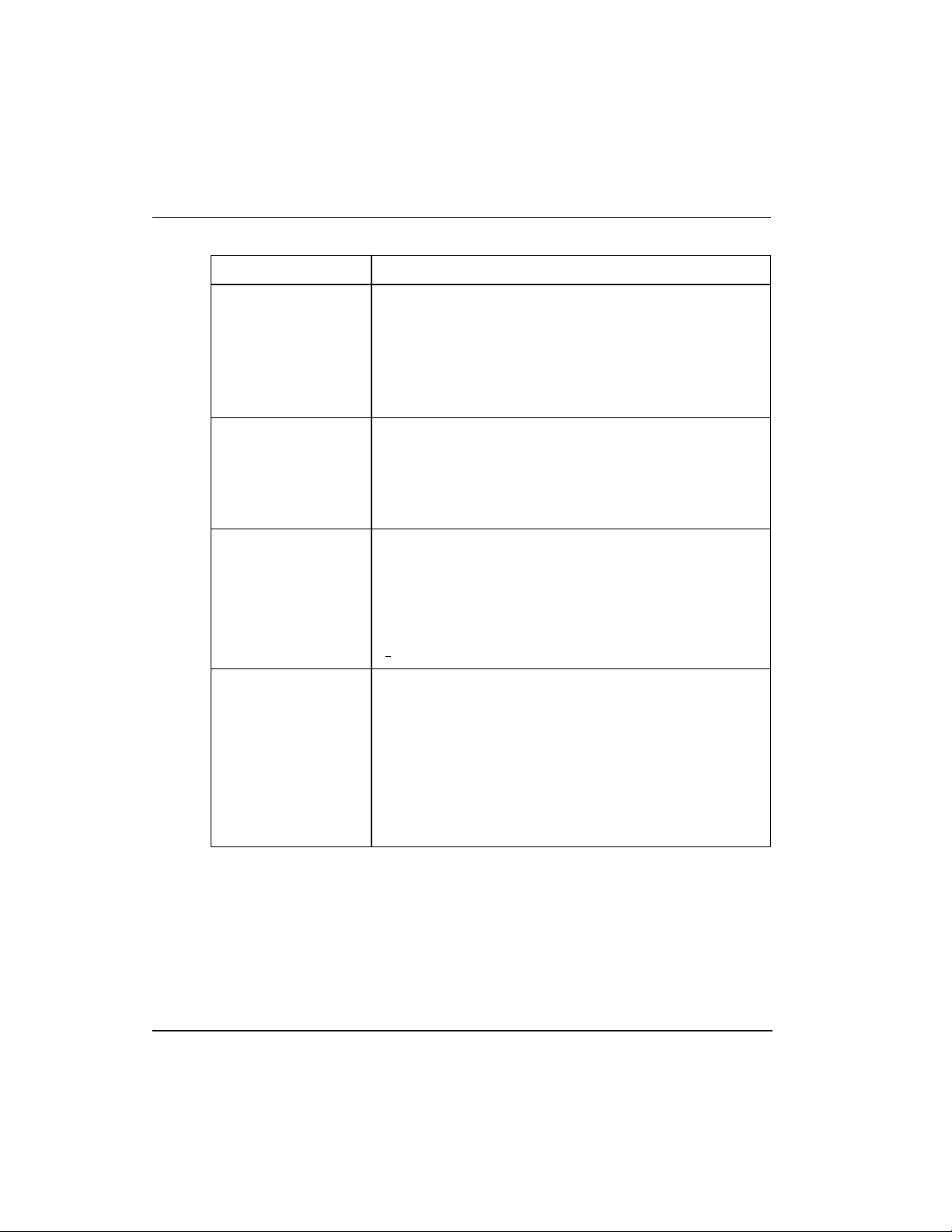

I/O module/IOTA

Feature/function

Analog Output

withHART

Extensive self-diagnostics

Optional redundancy

HART capable, multivariable instruments

Safe-state (FAILOPT) behaviors

Each channel can be configured to HOLD LAST

VALUE, or SHED to a SAFE VALUE.

Analog Output

Extensive self-diagnostics

Optional redundancy

Safe-state (FAILOPT) behaviors

Each channel can be configured to HOLD LAST

VALUE, or SHED to a SAFE VALUE.

Digital Input 24VDC

Extensive self-diagnostics

IOM redundancy

Input direct/reverse

Internal or external field power selections

Galvanic isolation

Low Latency / High Speed Scanning mode

Digital Input

Sequence of Events

DIGITAL INPUT

SEQUENCE OF

EVENTS

Extensive self-diagnostics

Optional redundancy

1ms Sequence of Events for Discrete Inputs

Low Latency / High Speed Scanning mode

On board excitation power (no need for marshalling

power)

Direct / Reverse Input Indication

Galvanic isolation

2.2. Series 8 I/O appearance and features

26 Series 8 I/O User's Guide R500

Honeywell April 2017

2. Series 8 I/O Planning and Design

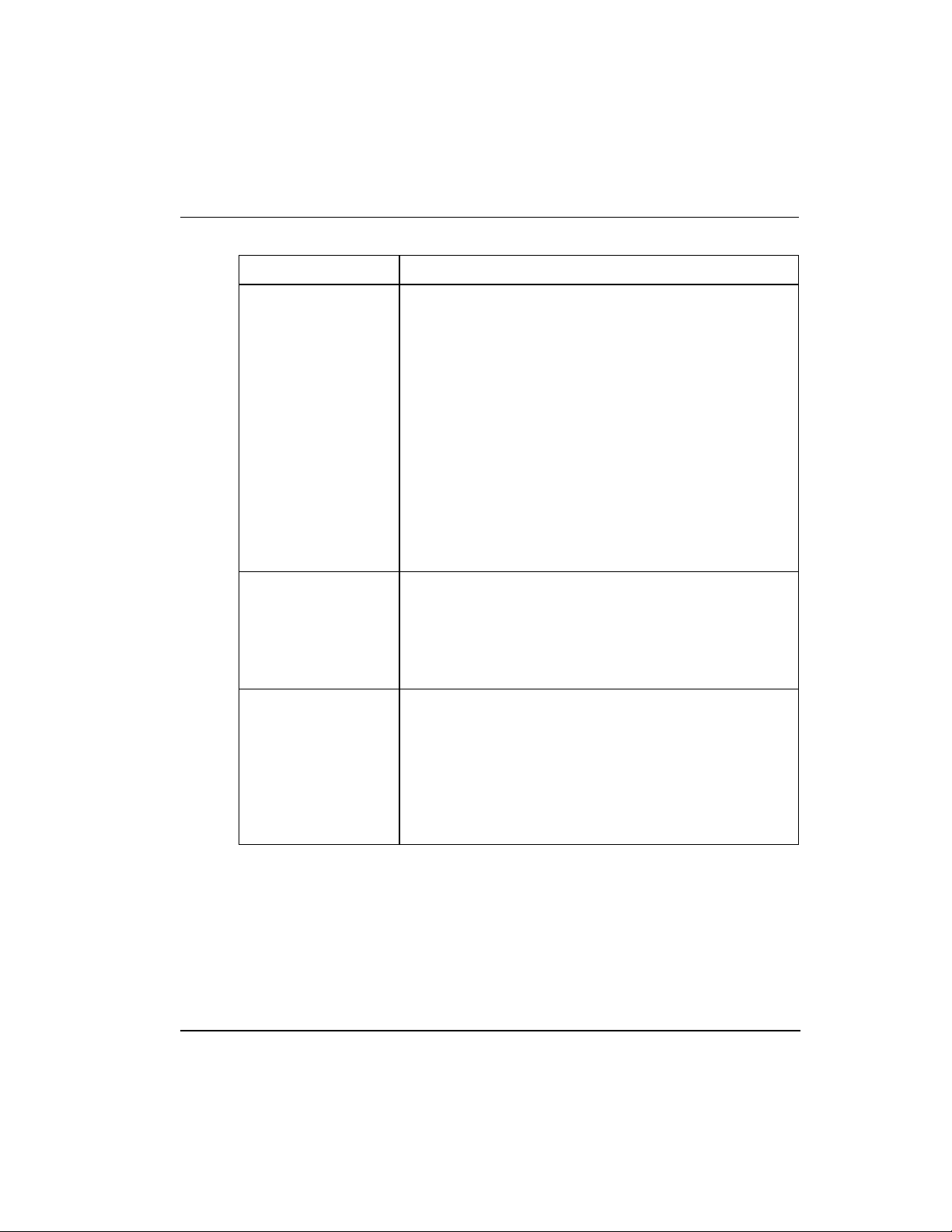

I/O module/IOTA

Feature/function

Digital Output 24Vdc

Extensive self-diagnostics

Functional redundancy

Output direct/reverse

Safe-state (FAILOPT) behaviors

Each channel can be configured to HOLD LAST

VALUE, or SHED to a SAFE VALUE.

Fuse-less short circuit protection allows a short circuit to

exist without blowing any fuses. When a particular

channel is shorted, internal circuits detect this and remove

power to the field connection. The channel remains deenergized until the short circuit is repaired.

Latched, pulsed or pulse-width modulated output

Galvanic isolation

Output read back checking to screw terminal

TC/RTD

TC and RTD operation

Remote cold junction capability

1 sec PV scanning with OTD protection

Configurable OTD protection (See below)

Temperature points can be added in 16 point increments

Digital Input Pulse

Accumulation module

Extensive self-diagnostics

IOM redundancy

Input direct/reverse for Digital Input channels

Internal or external field power selections

Galvanic isolation

PV processing or Pulse Accumulation functionality based

on the user configuration.

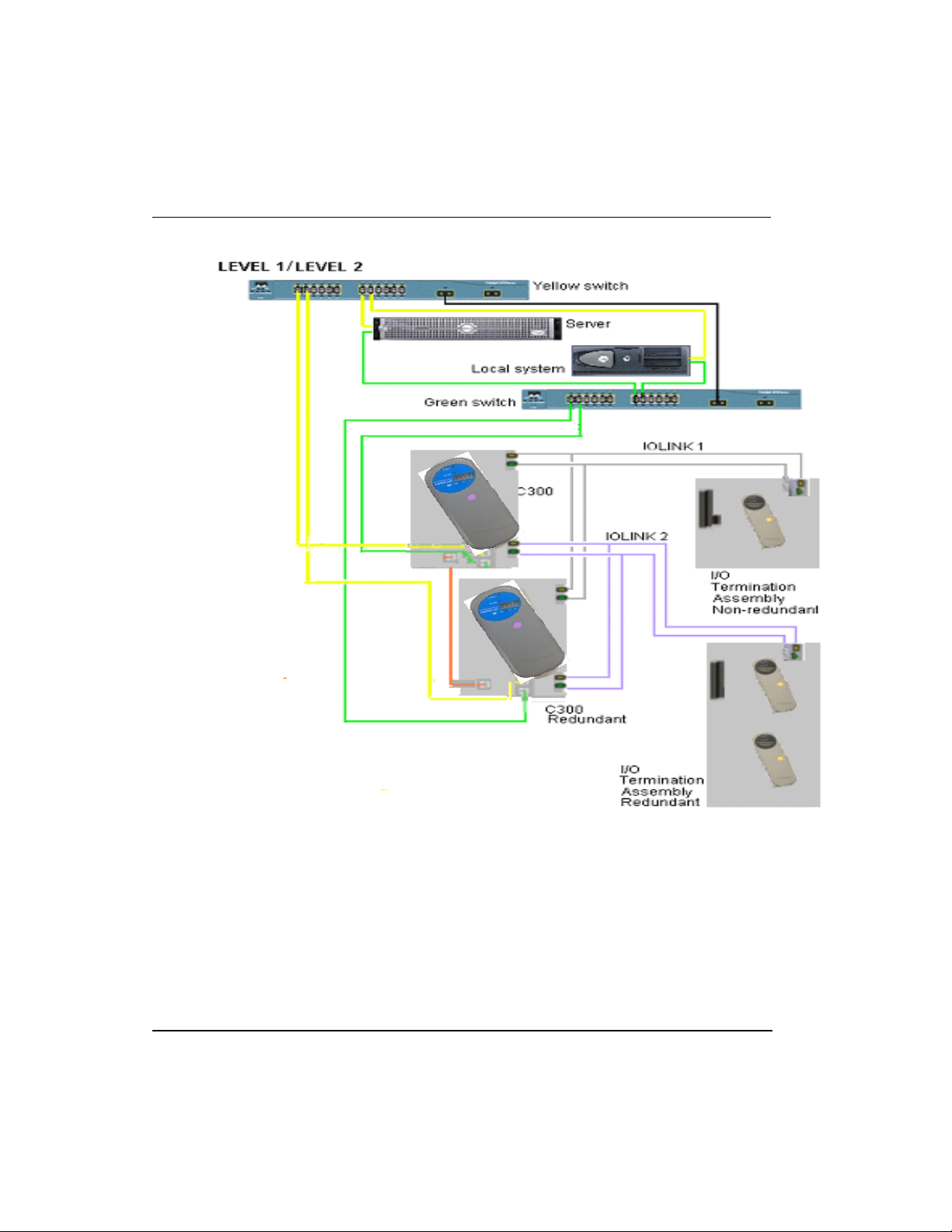

2.3. Series 8 I/O and C300 topology

2.3 Series 8 I/O and C300 topology

Series 8 I/O is attached to an IOLINK that is being mastered by a C300 controller. It is

important to note that the IOLINK serves as data repository for IOM function blocks in

R500 Series 8 I/O User's Guide 27

April 2017 Honeywell

Control Builder to provide communications interface with Series 8 I/O.

2. Series 8 I/O Planning and Design

2.3. Series 8 I/O and C300 topology

Figure 1 Series 8 I/O and C300 topology

Examining the topology rules

The following table provides the topology rules relating to the Series 8 I/O environment.

28 Series 8 I/O User's Guide R500

Honeywell April 2017

2. Series 8 I/O Planning and Design

Item

Impact

Description

Redundancy

None

Redundancy capacity and performance is

displayed while redundancy is present.

Switchover

None

Series 8 I/O hardware and/or software can

switchover, recover, and resume full view.

Initialization

All Series 8 I/O

per C300

Can be initialized in 60 seconds (+/- 25%) after

cabinet-level loss power loss.

1 I/O module

Can be initialized in 10 seconds (+/- 25%) after

IOM level loss power loss.

Multiple I/O Links

2

Design allows the use of multiple Series 8 I/O

Links in the same cabinet.

I/O Link performance

None

I/O Link networks perform at the current

distance.

I/O Link capacity

40 max

Maximum of 40 redundant IOMs per link.

IOMs / C300

80 max

Maximum of 80 redundant IOMs per C300,

using both links.

2.3. Series 8 I/O and C300 topology

Table 3 Topology rules

R500 Series 8 I/O User's Guide 29

April 2017 Honeywell

2. Series 8 I/O Planning and Design

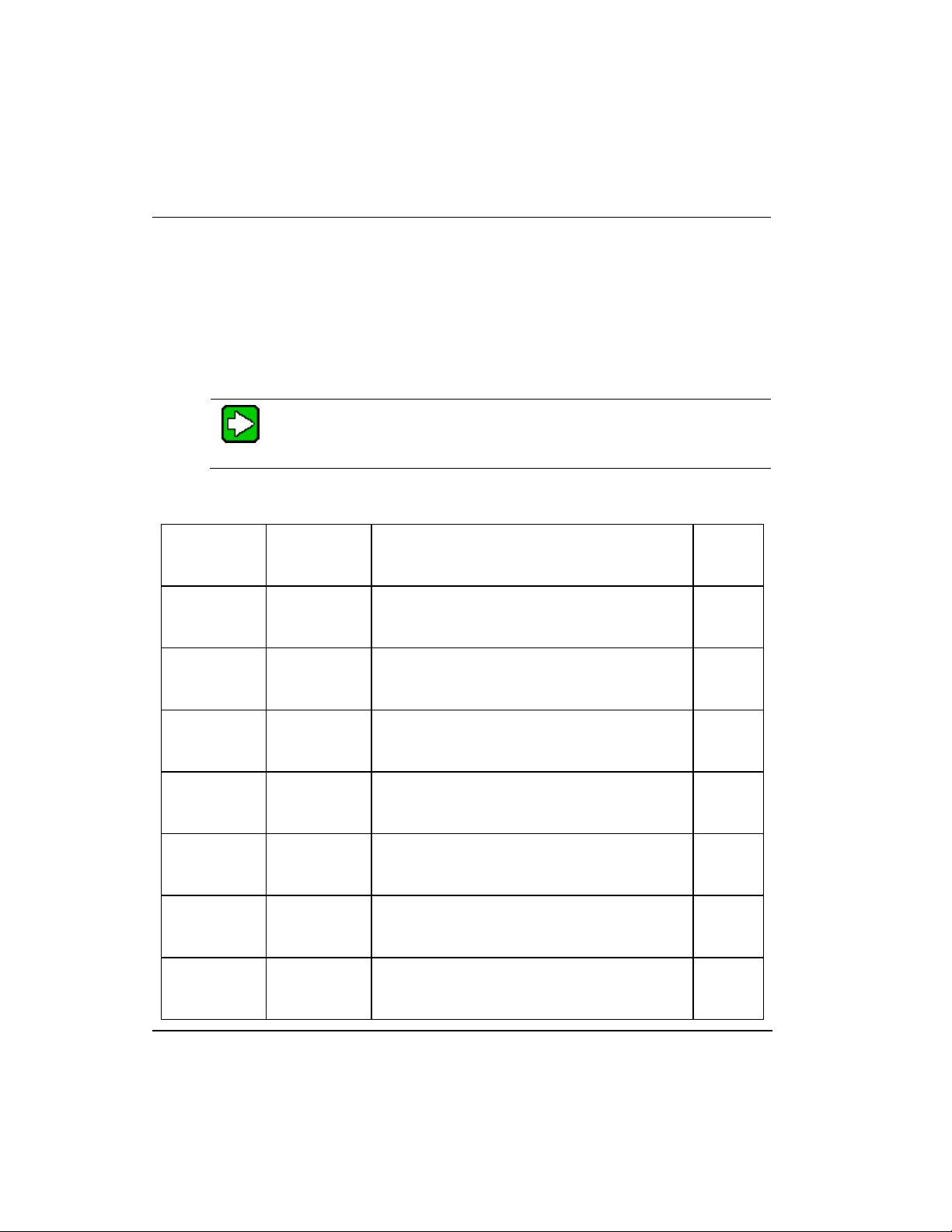

TIP

C300 IOLINK block parameter IOLINKTYPE is used to determine if the

IOLINK supports Series 8 I/O.

IOM model

names

IOM block

name

Description

# of

channels

8C-PAIHA1

8U-PAIHA1

ANALOG

INPUT WITH

HART

Analog Input with HART- Single Ended

16

8C-PAIH54

8U-PAIH54

ANALOG

INPUT WITH

HART

Analog Input with HART - Differential

16

8C-PAINA1

8U-PAINA1

ANALOG

INPUT

Analog Input – Single Ended

16

8C-PAONA1

8U-PAONA1

Analog Output

Analog Output

16

8C-PAOHA1

8U-PAOHA1

Analog Output

Analog Output with HART

16

8U-PAIMA1

8C-PAIMA1

TC/RTD

TC/RTD input

16

8U-PDILA1

8C-PDILA1

DIGITAL

INPUT 24VDC

Digital Input (24 volts DC)

32

2.4. Supported Series 8 I/O modules

2.4 Supported Series 8 I/O modules

Available Series 8 I/O modules

The list of I/O modules below can be used on a Series 8 IOLINK. The IOLINK contains

a function that enables programming and reprogramming the executable image (rather

than substitution of a removable hardware component). The preferred method of delivery

of the image is over the IOLINK.

Table 4 Available I/O modules

30 Series 8 I/O User's Guide R500

Honeywell April 2017

Loading...

Loading...