Page 1

Sensepoint XCD RTD

Remotely monitor toxic gases in

Class 1, Div 2 areas while reducing

the maintenance, training and

overall cost of gas monitoring

Page 2

Sensepoint XCD RTD

Reduce Cost of Ownership

Over Life of the Product

• Cut stocking and procurement costs

with a common transmitter platform

• Reduce maintenance time

and expense with non-intrusive,

one-man operation

• Simplify maintenance with plug-in,

removable sensor

• Reduce inspection and training time

with tri-color ‘traffic light’ display

conveying safety status at a glance

• Simplify set-up and configuration

with non-intrusive magnetic switches

Gain Added Flexibility,

Reliability and Performance

• Extend gas sensing element up to

100 feet (30 meters) from transmitter;

mount in the most difficult to

access areas

• Reduce likelihood of human error

via on-board diagnostics and

easy-to-read display

• Protect against dust/water ingress

with IP66/67 rated stainless steel

or aluminum enclosure

• Prevent false alarms with auto-inhibit

during maintenance

• Select sink or source 4-20mA output;

integral or remote configuration

• Full range of accessories and

purchase options let you choose the

remote monitoring system that’s right

for your application

Sensepoint XCD RTD from Honeywell Analytics

makes it easy on your maintenance team, time

and budget when faced with the challenge of

monitoring toxic gases in Class I, Div 2 areas.

You can mount the unit up to 100 feet from the transmitter to obtain maximum

gas detection coverage in areas not easily accessible or where the sensor

would not be visible, as in high-or low-level concealed areas, or detection

outside the room being monitored. XCD RTD offers unrivaled flexibility and

performance via its easily recognizable display (traffic light pattern) to convey

safety status, communication and mounting options, and onboard diagnostics.

Applications

• Waste water facilities

• Utilities

• Coal processing plants

• Industrial manufacturing facilities

• Power plants

• Food and beverage production

• Oil and gas process areas

FPO

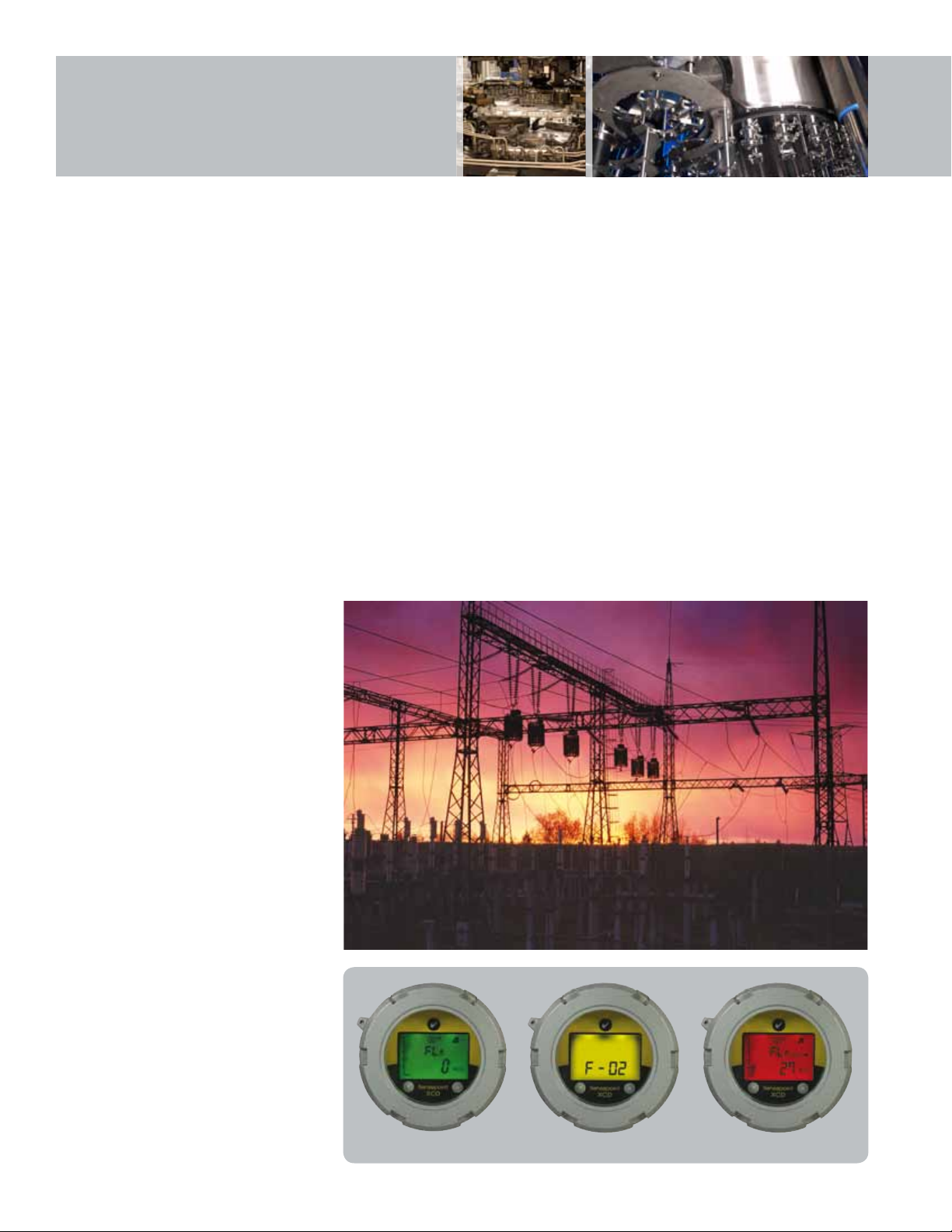

Safety at a Glance!

Sensepoint XCD uses three instantly

recognizable ‘traffic light’ colors to indicate

its status. The large tri-color backlit LCD

is steady green to indicate normal operation,

flashes yellow to indicate a fault/warning

and flashes red to indicate an alarm. This

allows anyone in the area to clearly see

glance

the status of any detector. This can be

particularly useful to identify detector status if

the detector is located in a difficult to access

area or if a number of detectors are located in

the same area.

at a

Normal Fault/Warning Alarm

Page 3

Sensepoint XCD RTD

Sensepoint XCD RTD Gases and Ranges

Gas

Toxic Sensors

Hydrogen Sulfide 50ppm N/A

Carbon Monoxide

Hydrogen 1,000ppm N/A

Nitrogen Dioxide 10ppm N/A

Ammonia 50ppm N/A

Chlorine 5ppm N/A

Sulphur Dioxide 15ppm N/A

Nitric Oxide 100ppm N/A

Oxygen Sensors

Oxygen 25%V/ V N/A

User Selectable

Full Scale Range

200ppm N/A

Range

Increments

Class I,

Division 2

P

P

P

P

P

P

P

P

P

Get More Return on Investment from

the Practical Advantages of XCD RTD

Sensepoint toxic and oxygen sensors detect a wide variety

of industrial gases at common measuring ranges, adding

flexibility to your gas monitoring program, reducing your parts

procurement costs and expanding your safety net.

Remote gas monitoring has never been this easy and

cost-effective. Mount the sensor as shown in the illustration

and view gas safety status via the large tri-color display on

the transmitter, up to 100 feet away from the sensor. The

advantages of this remote monitoring system are added

safety, and reduced time spent on maintenance. There’s no

need for your team to climb ladders or bring in specialized

equipment to view gas concentration readings or to conduct

a safety audit. What’s more, the removable sensor design of

Sensepoint XCD RTD cuts downtime and eliminates the need

for specialized training.

Sensepoint XCD RTD Class I, Division 2

(with Integral Sensor)

Order Sensepoint XCD RTD as a complete kit or a la carte.

Sensepoint XCD RTD Class I, Division 2

(with Remote Sensor)

Page 4

XCD RTD is the right choice for a variety of demanding industrial applications

Industry

SpecicArea

Chemical

Plants

Power

Stations

Waste Water

Treatment

Plants

Steel Industry

General

Industry

Oil & Gas

Find out more

www.honeywellanalytics.com

Contact Honeywell Analytics:

Americas

Honeywell Analytics, Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: 847.955.8200

Toll-free: 800.538.0363

Fax: 847.955.8210

detectgas@honeywell.com

Technical Services

ha.service@honeywell.com

www.honeywell.com

by XCD RTD)

• Raw material storage

• Process Areas

• Laboratories

• Pump rows

• Compressor stations

• Loading/unloading areas

• Turbines

• Coal silos and conveyor

belt areas in older

coal/oil red stations

• Digesters

• Plants sumps

• H2S scrubbers

• Pumps

• Loading and

unloading docks

• Pre-treatment

• Battery rooms

• Loading and

unloading docks

• Process areas

• Machinery rooms

• Exploration drilling rigs

• Production platforms

• Onshore oil and

gas terminals

• Renieries

Europe, Middle East, Africa

Life Safety Distribution AG

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44.943.4300

Fax: +41 (0)44.943.4398

gasdetection@honeywell.com

(Gases Detected

• Oxygen

• Carbon Monoxide

• Ammonia

• Sulfur Dioxide

• Nitric Oxide

• Carbon Monoxide

• Oxygen

• Ammonia

• Hydrogen

• Hydrogen Sulde

• Chlorine

• Carbon Monoxide

• Oxygen

• Nitrogen Dioxide

• Sulfur Dioxide

• Carbon Monoxide

• Oxygen

• Nitric Oxide

• Hydrogen Sulde

• Nitrogen Dioxide

• Ammonia

• Sulfur Dioxide

• Hydrogen Sulde

• Carbon Monoxide

• Oxygen

• Nitric Oxide

• Nitrogen Dioxide

• Carbon Monoxide

• Hydrogen Sulde

• Oxygen

Honeywell Analytics

Serves Every Business

We offer the industry’s most complete

range of gas detection products and

services to meet all customer needs.

Industrial

Honeywell Analytics and renowned legacy

Sieger, Fire Sentry and Manning gas detection

systems with advanced electrochemical,

infrared and open path sensing technologies

» Applications: oil and gas, cold storage,

water/wastewater treatment, chemicals,

engine rooms, plastics and fibers,

agriculture, printing and light industrial

Commercial

Honeywell Analytics and legacy Vulcain

gas detection from standalone units to fully

engineered, multi-point systems, all offering

cost-effective regulatory compliance

» Applications: parking structures, chillers,

mechanical rooms, office towers,

commercial buildings, shopping centers,

swimming pools, golf courses, schools

and universities, laboratories

Portables

Single or multi-gas BW Technologies, Sperian

(Biosystems), Lumidor and other premium

detectors with compact, lightweight designs

ranging from simple alarm only units to

advanced, fully configurable and serviceable

instruments

» Applications: underground utility and

electricity ducts, boiler rooms, post-fire

sites, sewers, industrial plants, industrial

hygiene, first esponder teams,

remote fleets

High Tech/Government

A complete portfolio of gas and chemical

detection instrumentation including infrared

spectroscopy with no cross interference

(MST Technologies), to Chemcassette paperbased solutions (MDA Scientific) offering

detection down to parts per billion

» Applications: semiconductor manufacturing

and nanotechnology, aerospace propulsion

and safety, specialty chemicals industry,

research laboratories, emergency response

Technical Services

24/7 global network includes post-sales

service and Systems Integration teams

» Emergency call out, service contracts, on/

off-site repair, training and commissioning

» Complete range of spares, consumables

and accessories

Asia Pacific

Honeywell Analytics, Asia Pacific

#508, Kolon Science Valley (1)

187-10 Guro-Dong, Guro-Gu

Seoul, 152-050

Korea

Tel: +82 (0)2.2025.0307

Fax: +82 (0)2.2025.0329

analytics.ap@honeywell.com

Please Note:

While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or omissions.

Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations,

standards, and guidelines. This publication is not intended to form the basis of a contract.

DS01154_v1 9/12

© 2012 Honeywell Analytics

Loading...

Loading...