Page 1

Description

Part Number

Quantity

Sensor Duct Adapter

1283-1048

1

Flow Restrictor

1283-1091

1

Washer, #8 Nylon

0950-0079

2

Gasket, #8 Sealing

105637

2

Screw, 8 x ¾, self-tapping

0950-0080

2

O-ring, 7/8 I.D. x 1-1/8 O.D.

0235-1135

2*

O-ring, Sensor

0235-1130

2*

O-ring, Sensor

0235-1131

2*

Duct Mount Adapters

1998-0880 Rev 1

2014

Technical Note

September

For Duct Mounting XCD-RTD, XCD-RFD, Sensepoint Toxic,

Sensepoint Combustible, 705 and XNX w/705

Duct Mounting Kit 1283-1047

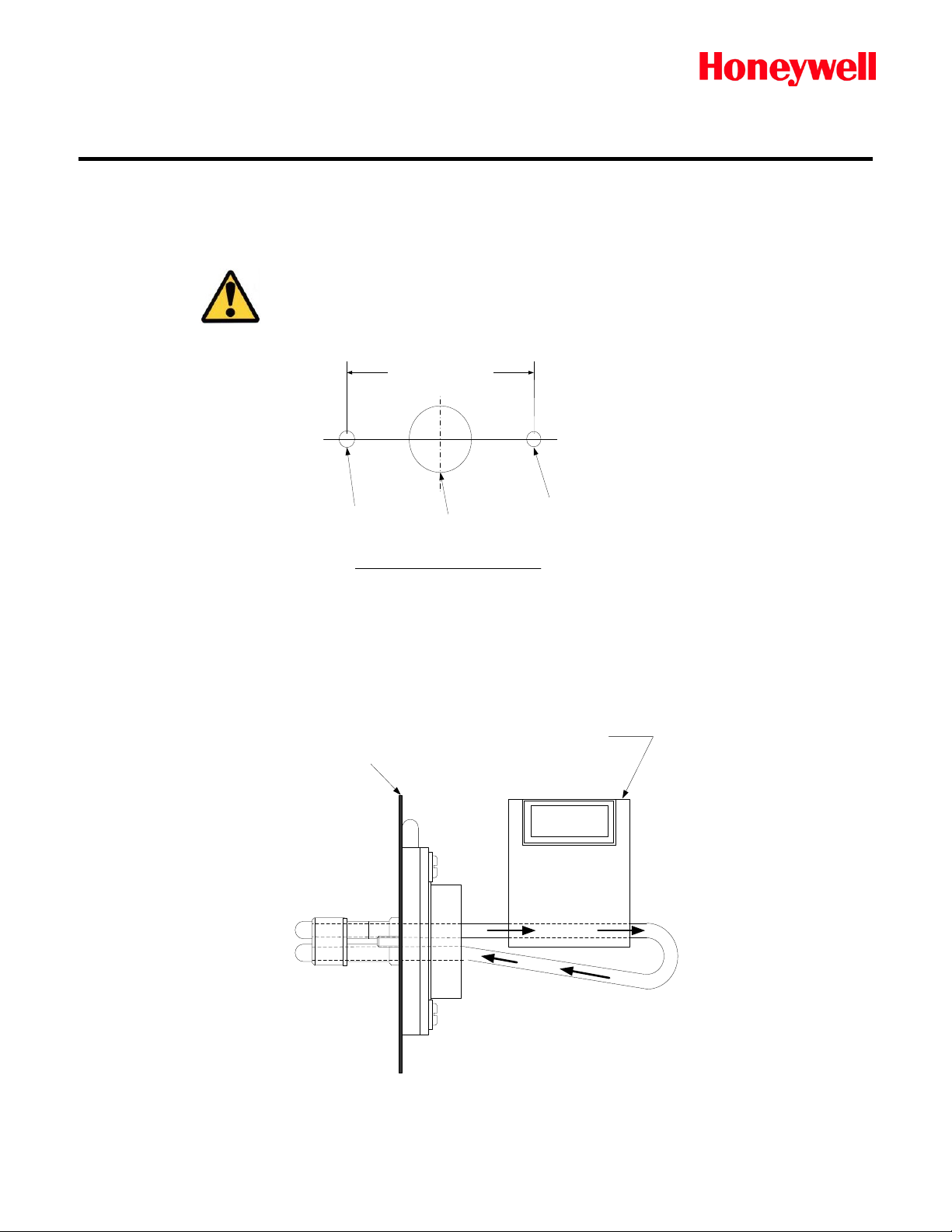

The duct mounting assembly allows installation of sensors directly into ducts with diameters from 3 to 16

inches (8 to 40 cm). The installation uses a minimum number of holes drilled into the ductwork, and

allows quick changeover for exchanging sensors. (Refer to Figure 1)

This technical note provides installation instructions for mounting the sensor duct adapter. A hole

diagram is shown in Figure 3 .

The duct mounting adapter assembly is designed to divert 700cc of sample flow to a sensor over a wide

variety of duct diameters and flow rates. For installations with high flow rates, an adjustable flow

restrictor (included) is attached to the duct adapter. Use the charts (Table 1) to determine the restrictor

settings. The restrictor adjustment settings are shown in Figure 2.

The duct mounting kit (P/N 1283-1047) includes the following:

*Only one item is required; kit contains a spare of this part.

Technical Note 1998-0880

Page 1 of 7

Page 2

Technical Note

Figure 1 – Duct Mounting Adapter

Installation

Use the chart shown in Table 1 to determine if you need to add the flow restrictor to the duct adapter.

If you need the restrictor, install it onto the pitot tubes (the portion of the duct adapter that goes into

the duct). Refer to Figure 2. The pitot tubes have scribed lines which represent Restrictor Lines A

through C. Restrictor Line C offers the most restriction, and is the line closest to the end of the pitot

tubes. Align the chamfered edge of the restrictor with the proper line before tightening the set screw.

Also, make certain the set screw is downstream of the air flow.

Figure 2 – Setting the Flow Restrictor

Technical Note 1998-0880

Page 2 of 7

Page 3

Caution:

insulators provided in this kit.

2.50 Inches (63.5 mm)

Screw mounting holes

must be parallel with

airflow +/- 5°.

7/8 - inch

(22 mm)

9/64 - inch

(3.6 mm)

NOTE: This drawing is NOT TO SCALE

1/4-inch tubing is required, and the total length should be less than 2 feet.

Adjust the position of the restrictor until the flow is 700 cc/min, +/- 100 cc/min.

Pressure drop differential:

0.3 inches H20

Duct Wall

Mass Flowmeter

(Sierra Instruments, Inc Model

822-13-OV1-PV1-V1 or equiv)

Technical Note

Duct mounting is simple. Figure 3 shows the hole pattern. One 7/8-inch (22 mm) hole and two smaller

9/64-inch (3.6 mm) holes for #8 sheet metal screws are the only installation intrusion to the ductwork.

The sheet metal screw holes must be parallel within +/- 5° of the direction of air flow in the duct.

To prevent an earth loop, ensure the duct adapter center does

not come in contact with metal ductwork. Use the O-rings and

Figure 3 – Hole Diagram for Duct Mounting Adapter

If the flow in the duct is not known, you must connect a mass flowmeter to the duct adapter as shown in

Figure 4. Do not use a rotometer or ballmeter.

Important:

Figure 4 – Connecting a Mass Flowmeter to Duct Adapter

Technical Note 1998-0880

Page 3 of 7

Page 4

Sample transport time:

30 seconds or less

Sample flow rate:

0.6 – 1.2 Liters per minute

Minimum:

735 ft/min (224 m/min)

Maximum:

1024 ft/min (312 m/min)

Pipe flow:

Refer to Tables 1and 2

Accuracy:

+/- 10%

Technical Note

Connecting/Changing Sensors

When changing a duct-mounted sensor, twist the sensor counterclockwise 1/4-turn to release. Reinstall per manual instructions.

Flow Performance

Velocity

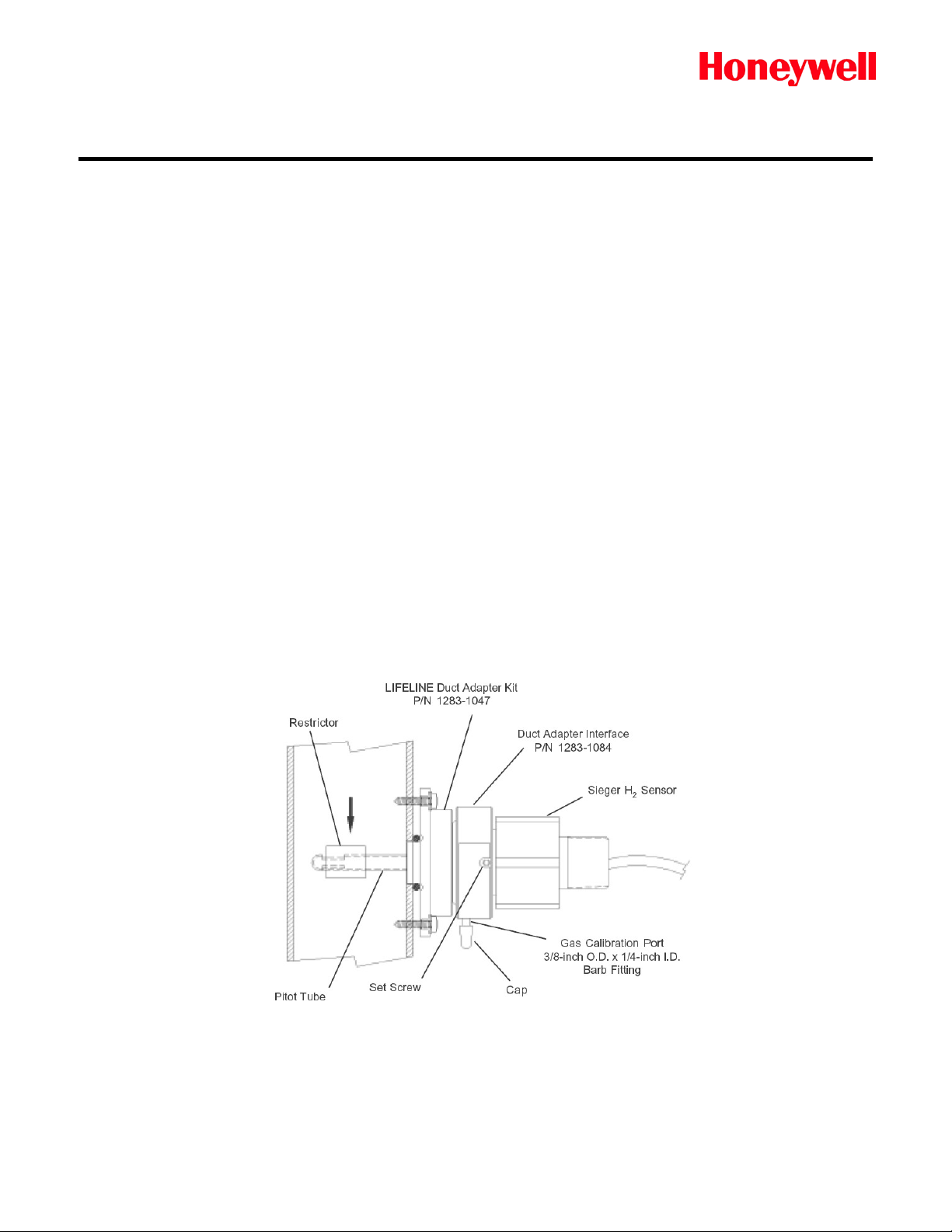

Duct Mount Adapter 1283-1084

Overview

This adapter is an interface between duct adapter kit (P/N 1283-1047 described above) and the XCDRFD, Sensepoint Combustible, 705 and XNX w/705 Detectors. The adapter includes a calibration port

to allow gas testing. The adapter is shown in Figure 5.

How it Works

The adapter is a mechanical interface with the Sensor-style bayonet fitting on one end. This attaches

directly to the sensor duct adapter. The other end of the adapter interface is threaded to mate with the

XCD-RFD, Sensepoint Combustible, 705 and XNX w/705 sensors. A port on the side of the adapter

allows direct attachment to tubing for calibration or live-gas challenges.

Figure 5 – Adapter Interface

Duct Flow Rate

The duct mounting adapter kit (1283-1047) is designed to divert sample flow to a sensor over a wide

variety of duct diameters and flow rates. For installations with high flow rates, an adjustable flow

restrictor (included) is attached to the duct adapter. Use the charts (Table 2) to determine the restrictor

settings for use with the interface adapter and the hydrogen sensor.

Technical Note 1998-0880

Page 4 of 7

Page 5

Technical Note

Catalytic sensors are passive and they require no airflow for accurate and rapid gas response. Sensor

airflow of 5 to 500 cc/min is required to ensure sufficient gas changeover inside the duct adapter. The

orifice restrictor is used to limit the sensor airflow, in order to minimize the dilution of calibration gas t hat

is introduced from the side port.

Refer to the duct adapter for XCD-RTD and Sensepoint Toxic Sensors shown above for more

information about the restrictor settings. The restrictor adjustment settings are shown in Figure 2 of the

duct adapter technical note.

Installation

The duct adapter should be preinstalled in the ductwork. If it is not, refer to the instructions provided with

the duct adapter for XCD-RTD and Sensepoint Toxic Sensors shown above.

Follow the preparation and installation instructions provided with the hydrogen sensor. Make certain the

protective cap over the sensor inlet is removed before installation.

Ensure that the O-ring is in place on the threaded side of the adapter interface. Attach the threaded end

of the adapter interface to the hydrogen sensor. Tighten the set screw on the adapter interface to

secure the sensor.

Make certain that all the duct adapter O-rings are in place around the base of the center pitot tube.

Insert the interface/sensor combination into the duct adapter. A clockwise one-quarter turn secures the

components.

Figure 6 shows the completed assembly installed in a duct.

Figure 6 – Installed Assembly

Technical Note 1998-0880

Page 5 of 7

Page 6

Duct Adapter Restrictor Settings for Sensepoint and XCD-RTD Electrochemical Senso rs

Duct Flow Rate (CFM)

Not

Recommended*

3 Inches

<15

15-50

50-75

75-100

100-130

4 inches

< 65

65-90

90-130

130-180

180-220

6 inches

< 145

145-200

200-300

300-400

400-500

8 inches

< 260

260-360

360-500

500-725

725-875

10 inches

< 400

400-560

560-800

800-1125

1125-1400

12 inches

< 575

575-800

800-1200

1200-1600

1600-2000

14 inches

< 790

790-1100

1100-1550

1550-2200

2200-2700

16 inches

<1025

1025-1430

1430-2000

2000-2900

2900-3500

Duct Adapter Restrictor Settings for XCD-RFD, 705, Sensepoint Combustible, and XNX w/705 Sensors

Duct Flow Rate (CFM)

Not

Recommended

3 Inches

<10

10-50

50-75

75-100

100-130

4 Inches

<25

25-90

90-130

130-180

180-220

6 Inches

<50

50-200

200-300

300-400

400-500

8 Inches

<90

90-360

360-500

500-725

725-875

10 Inches

<140

140-560

560-800

800-1125

1125-1400

12 Inches

<200

200-800

800-1200

1200-1600

1600-2000

14 Inches

<275

275-2000

2000-1550

1550-2200

2200-2700

16 Inches

<360

360-1430

1430-2000

2000-2900

2900-3500

Technical Note

Gas Calibration and Challenges

• Remove the cap on the interface adapter gas port.

• Connect and secure tubing from calibration gas bottle’s regulator. The regulator should deliver 1

L/min.

• Open the gas valve on the calibration gas bottle to apply gas. Leave the gas on for 30 seconds

to allow the sensor to stabilize.

• Calibrate the transmitter and/or controller.

• Shut off the calibration gas.

• Remove tubing and replace the cap on the adapter’s gas calibration port.

Duct Adapter Restriction Setting Tables

Duct Diameter

* Consult Honeywell Analytics for recommendation.

Table 1 – Determining Restrictor Settings

Duct

Diameter

No Restrictor Set to Line A Set to Line B Set to Line C

No Restrictor Set to Line A Set to Line B Set to Line C

* Low flow rates cause a delay in gas response. Consult Honeywell Analytics for flows under the recommended minimums.

Table 2 – Determining Restrictor Settings

Technical Note 1998-0880

Page 6 of 7

Page 7

Technical Note

www.honeywellanalytics.com

Contact Honeywell Analytics:

Toll free: +1 800 538 0363

detectgas@honeywell.com

Europe, Middle East, Africa

Life Safety Distribution AG

Fax: +41 (0)44 943 4398

gasdetection@honeywell.com

Honeywell Analytics Asia Pacific

#508, Kolon Science Valley (I)

187-10 Guro-Dong, Guro-Gu

Fax: +82 (0)2 2025 0329

analytics.ap@honeywell.com

ha.us.service@honeywell.com

Data may change, as well as legislatio n, and you are strongly advised to obta in copies of the most recently issued regulations, standards and guideline s.

This publication is not intended to for m the basis of a contract and t he company reserves the right to am end the design and specification wit hout notice.

While every effort has been made to en sure accuracy in this publication, n o responsibility can be accepted for errors or omi ssions.

Find out more

Americas

Honeywell Analytics Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Fax: +1 847 955 8210

Javastrasse 2

8640 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Asia Pacific

Seoul, 152-050

Korea

Tel: +82 (0)2 2025 0307

Technical Services

www.honeywell.com

Technical Note 1998-0880

Page 7 of 7

Loading...

Loading...