Page 1

Sensepoint XCD RTD

Remote toxic and oxygen gas detector

for industrial applications

Use 3 wire, 4-20mA and RS485 MODBUS output fixed point detector with in-built alarm and fault relays for the protection of personnel and plant from toxic and oxygen hazards.

Electrical

Input Voltage Range 16 to 32VDC (24VDC nominal)

Max Power Consumption Maximum power consumption is dependent on the type of gas sensor being used. Electrochemical cells = 3.7W

Current Output Sink or source

Relays 3 x 5A@250VAC. Selectable normally open or normally closed (switch) and energized/de-energised (programmable)

Communication RS485

Construction

Material Housing: Epoxy painted aluminium alloy LM25 or 316 stainless steel

Sensor: Polyphenylene sulfide (PPS) (see Sensepoint specifications)

Weight (approx) Aluminium Alloy LM25: 4.4lbs

316 Stainless Steel: 11lbs

Mounting Integral mounting plate with 4 x mounting holes suitable for M8 bolts. Optional pipe mounting kit for horizontal or vertical pipe Ø1.5 to 3" (2" nominal)

Cable Entries 2 x ¾”NPT conduit entries. Suitable blanking plug supplied for use if only 1 entry used. Seal to maintain IP rating

Environmental

IP Rating IP67 in accordance with EN60529:1992

Certified Temperature Range 40ºF to +149ºF (-40ºC to +65ºC)

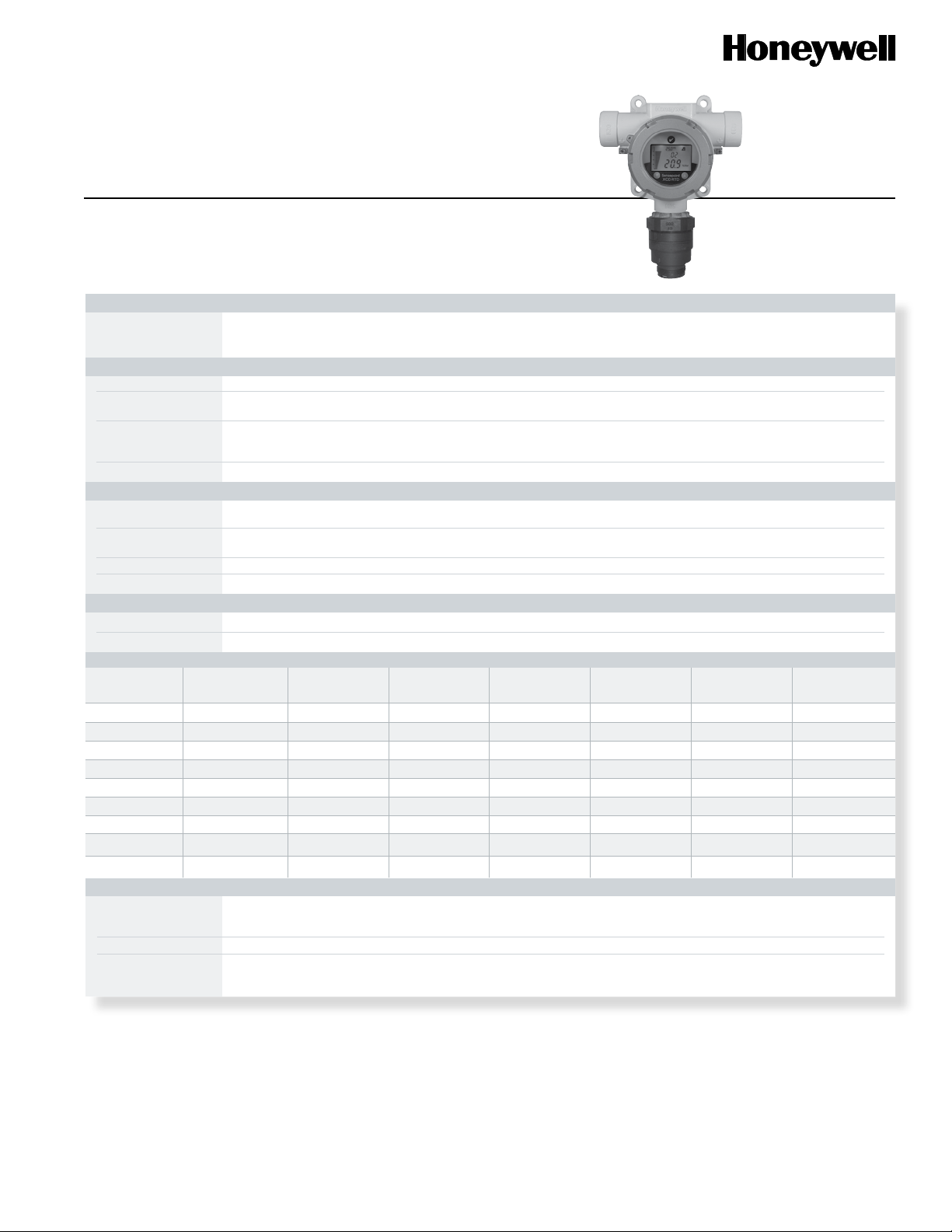

Detectable Gases and XCD RTD Sensor Performance

Gas Displayed Name Range Lower Alarm Lower Alarm Type Higher Alarm Higher Alarm Type Lowest Alarm Level

Incorporating a transmitter with local display and optional remote mounted sensor, fully configurable via non-intrusive magnetic switch interface with a wide range integral and

remote sensors available.

Maximum inrush current = 800mA at 24VDC

Alarm relays default normally open/de-energized. Fault relay default normally open/energized

Hydrogen Sulphide H

Carbon Monoxide CO

Chlorine Cl

Ammonia NH

Hydrogen H

Nitrogen Monoxide NO 100 ppm 20ppm

Sulphur Dioxide SO

Nitrogen Dioxide NO

Oxygen O

Certification

US, Latin America, Canada cCSAus Ex d IIB+H2; Class I, Zone 1, AEx d IIB+H2; Class I, Division 2, Groups B, C & D

Class I, Zone 1, AEx d ia IIC Gb; Class I, Div. 2, Groups B, C and D

Inmetro Ex d IIC T6 Gb, Ex tb IIIC T85ºC Db, IP66, -40ºC < ta < +65ºC

EMC CE: EN50270:2006 EN6100-6-4:2007, Ex d IIC T6 Gb, Ex tb IIIC T85ºC Db, IP66, -40ºC < ta < +65º C

Standards CAN/CSA-C22.2 No. 0-M91, CAN/CSA-C22.2 No. 60079-0:07, CAN/CSA-E60079-11:02, CAN/CSA-C22.2 No. 60079-1:07, ANSI/UL 60079-11:09, ANSI/UL 60079-1:09,

S

2

2

3

2

2

2

2

C22.2 No. 142-M1987, C22.2 No. 213-M1987, UL 508 17th Ed., ANSI/ISA -12.12.01-2010 ABNT NBR IEC 60079-0:2008, ABNT NBR IEC 60079-1:2009, IEC 6007931:2008 e ABNTNBR IEC 60529:2009.

50.0 ppm 10.0ppm

200 ppm 40ppm

5.0 ppm 0.5 ppm

50.0ppm 20.0ppm

1000ppm 200ppm

15.0ppm 2.0ppm

10.0ppm 2.0ppm

25.0% V/V 19.5%Vol

Rising

Rising

Rising

Rising

Rising

Rising

Rising

Rising

Falling

20.0ppm Rising 5.0ppm

80ppm Rising 20ppm

2.0ppm Rising 5.0ppm

30.0ppm Rising 5.0ppm

400ppm Rising 100ppm

40ppm Rising 10ppm

6.0ppm Rising 1.5ppm

4.0ppm Rising 1.0ppm

23.5%Vol Rising 10.0%Vol

Find out more

www.honeywellanalytics.com

Toll-free: 800.538.0363

Please Note:

While every effort has been made to ensure accuracy in this publication, no responsibility can be accepted for errors or omissions.

Data may change, as well as legislation, and you are strongly advised to obtain copies of the most recently issued regulations,

standards, and guidelines. This publication is not intended to form the basis of a contract.

SS01154_v2 10/12

© 2012 Honeywell Analytics

Loading...

Loading...