Honeywell RS-485 Installation Manual

Honeywell Process Solutions

RS-485 Adapter Board

Installation Guide

November 2010

Revision B

Honeywell

Installation Guide

Metretek

RS-485 Adaptor Board

2

www.honeywell.com

Introduction:

Most persons that work with computers and/or communications equipment are at least

somewhat familiar with the terms RS-232, USB, Fire-wire, and LAN to name a few.

RS-485 is less commonly known however, but serves well in applications where high

data rates, excellent noise immunity, and long cable runs are necessary. As is often the

case, there are both advantages and downsides to RS-485 when compared against other

systems. It is the purpose of this manual to help develop a basic understanding of the

RS-485 data transfer system, as well as providing specific details related to installation of

the RS-485 adaptor board.

Overview of RS-232:

RS-232 (also known as V.24) is a relatively aged serial data transfer topology (1969), but

still finds wide acceptance due to the large installed base, simplicity, and proven

performance. Initially introduced with a 25-pin D-Sub style connector, the 9-pin variety

is far more common at the present. Serial data is transferred over TXD and RXD lines

with respect to a signal common. Transition levels are specified at a maximum of +15

volts to a minimum of -15 volts, although in practice it is more common to find swings in

the range of approximately +8 to -8 volt levels. Data is transferred as a series of high and

low signal levels, using a serial data transfer protocol with start bits, data bits, stop bits,

and parity. A typical setting might be 1 start bit, 8 data bits, 1 stop bit, and no parity to

transfer a single byte (8-bits) of useful information.

Maximum practical data transfer rate is 19.2k bits per second (bps), with cable lengths at

50 feet, and several times faster with shorter cable runs. It is only possible to have a

single pair of devices connected; multi-drop capability does not exist. Immunity to

electrical noise is rather poor when operating in harsh environments such as factory floor

sites, traffic light controllers, refineries, etc.

Overview of RS-485:

As previously alluded to, RS-232 has some definite limitations for applications requiring

longer cable runs and higher data transfer rates. RS-485 (EIA-485 standard) uses

balanced transmission lines (differential signaling) to transfer serial data bytes. This

method has inherently higher noise immunity, thereby permitting high data rates and long

cable runs. Theoretical data transfer rates are on the order of 10M bps and 1200m

(approx. 4000 ft) cable length, although it is often necessary to scale back the speed at

such extreme lengths.

In the case of the RS-485 adaptor board coupled with the CNI, the limiting factor is the

CNI board itself, which only supports data transfers up to 38,400 bps. Taking into

consideration the intended applications for the CNI product, higher data transfer rates are

not relevant, and it is the potential long cable runs that are beneficial.

RS-485 specifications state that ‘multi-drops’ are supported for additional transmitters and

receivers sharing the same cable. Receiver impedance is specified to be 12k ohms for a

single unit load. Given this impedance, up to 32 unit loads can be supported on the bus.

3

Receivers with a higher input impedance will have a fractional unit load value assigned,

since the circuit loading effect is correspondingly less.

To obtain optimal performance with long cable runs and high data rates, it is necessary to

carefully select the cable type that is to be used. A typical cable will have twisted pairs of

24awg. wires, be fully shielded, and have a nominal impedance of 120 ohms. Alpha Wire

Company type 5473C, or equivalent is suitable for most applications. Additional

recommendations for wiring practices are detailed in a later section of this document.

While it is beyond the scope of this document to elaborate on transmission line theory, it

is not beyond the scope of the field installed device to demand proper termination of the

signal line. Long cable runs and high data rates will require that a 120 ohm termination

resistor is at the end of the cable, near the last receiver. This prevents reflections from

occurring at the end of the cable, resulting in signal distortion. Referring again to the

CNI product, leisurely data transfer rates of 38.4k bps (or slower) do not require

as much concern about termination resistors. As a matter of practice, it is still a good idea

however, and the RS-485 board can have the 120 ohm termination added by

simply placing a jumper on JP1.

RS-485 differential signaling levels are specified to not exceed a ±6 volt swing for an

unloaded transmitter, and the receiver sensitivity must be at least ±0.200 volts. Since it is

possible to have multiple transmitters on a bus, the data transmission protocol must

ensure that ‘line contention’ events do not take place. Specifics of signaling protocols and

data transmission are not defined within the framework of the EIA-485 standard

however; only the physical interface is detailed.

If the preceding description appears to suggest that the installer must possess an

Engineering degree to understand and setup a system, then it must be admitted that this

feeling is at least partially justified. If the goal was to operate at maximum transfer rates

with lengthy cable runs, and numerous nodes, then it is true that the installation is likely

to be a bit of a challenge. Fortunately enough, most applications for the CNI /

RS-485 combination are relatively straightforward, and the following guidelines are

intended to make the process as simple as possible.

RS-485 Board Installation:

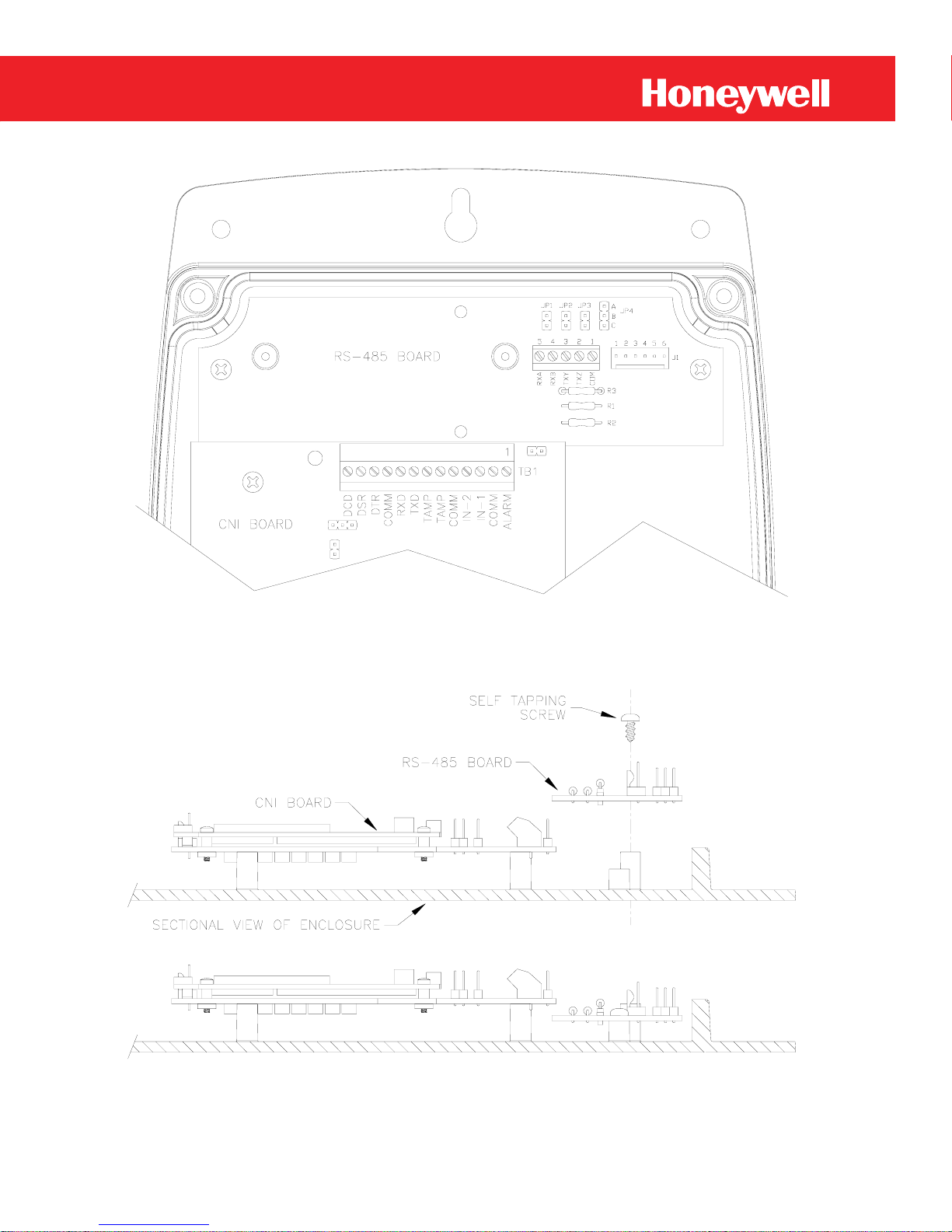

If the RS-485 adaptor board is not already installed into the enclosure, then Figures 1 & 2

should be referenced for assembly. Two small #4 size self-threading type screws and a

cable assembly will have been included with each kit.

4

www.honeywell.com

Figure-1

RS-485 Board Mounting Position

Figure-2

Securing the RS-485 Board

5

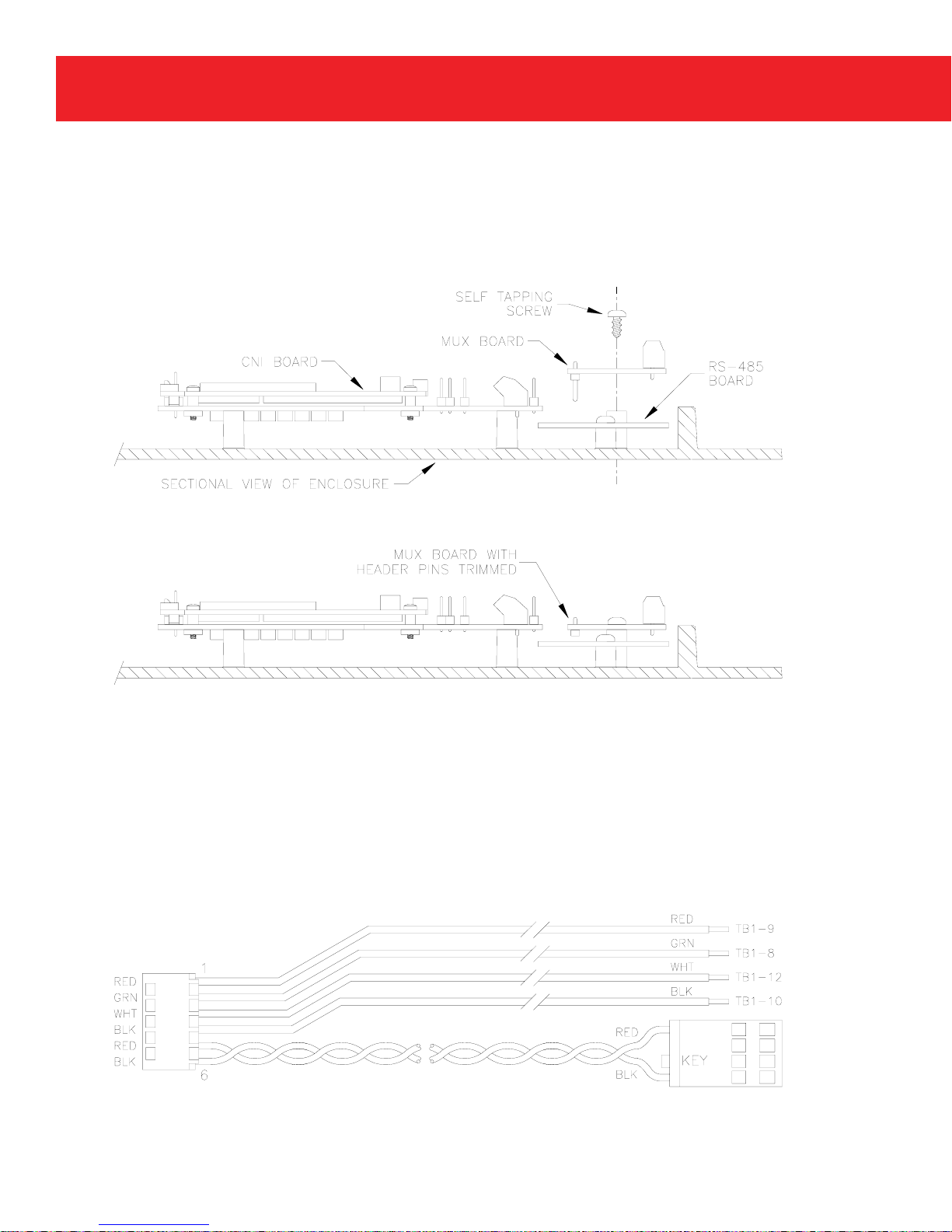

In some cases it may be desirable to install a serial port multiplexer board (Mux) into the

system as well. Detailed information regarding the CNI and Mux board can be found in

the relevant owners manual for these items. It should be mentioned however that it may

be necessary to trim-off the header pins from the Mux board, if this was not previously

done. Access to the header pins is not required, and in fact would pose a mechanical

assembly conflict if left intact as seen in Figure-3.

Figure-3

Optional RS-232 Multiplexer Board

Electrical connections to the CNI board are of course required, and a cable has been

provided for this purpose as illustrated in Figure-4. The six position connector shown at

the left of Figure-4 attaches to J1 of the RS-485 board. The rectangular power connector

(R.H. side of drawing) connects to J3 on the CNI board. Remaining are the four

individual wires that must be attached to the CNI terminal block. Terminal block

positions are indicated for reference.

Figure-4

Cable Assembly, RS-485 Board to CNI Board

6

www.honeywell.com

Loading...

Loading...