Honeywell R7795A, R7795D, R7795B, R7795C Users Manual

Primary Controls

The R7795 Flame Safeguard Primary Control

provides flameout protection plus automatic

control of commercial and industrial gas and

oil burners. Models provide intermittent pilot

or interrupted pilot with delayed main valve.

R7795A,B,C,D

Flame Safeguard

■ Integral solid state color-coded flame amplifiers:

R7795A,C for ultraviolet detection systems (purple).

R795B,D for rectification detection systems (green).

See Table 1.

■ Solid state plug-in ST95A Purge Timers provide

prepurge timings of 1.5, 7, 10, 30, 60, or 90 seconds.

■ Includes terminals for connection of a line voltage

airflow switch to prove airflow from the start of

prepurge through the run period.

■ Mounts on a Q795A Subbase with two captive

screws. All electrical connections are automatically

provided between the device and subbase. Wiring

terminals are accessible for testing.

■ Meter jack on amplifier board for measuring flame

signal with system in operation.

■ Internal light-emitting diode (LED) indicates pres-

ence of flame signal.

■ Field selectable ten or four second trial for pilot

flame ignition.

■ Powered alarm terminal to operate an external line

voltage alarm on safety lockout.

■ R7795 models are available with either intermittent

pilot (interrupted ignition) or interrupted pilot and

delayed main valve. See Table 2.

■ Run-Test switch on interrupted pilot/delayed main

valve models.

■ Safe-start feature prevents start-up with lockout if

flame or a flame simulating failure exists.

■ Recycle or lockout on flame failure is field selectable.

■ Safety switch must be manually reset after lockout.

■ Meets Underwriters Laboratories, Canadian Stan-

dards Association, and Factory Mutual Approved

standards.

CONTENTS

Specifications ................................................. 2

Ordering Information.....................................2

Detailed Operating Sequence ........................4

Installation ..................................................... 8

Checkout....................................................... 11

Troubleshooting ........................................... 17

Service ..........................................................19

1 66-2001—2 B. M. • Rev. 9-93 • ©Honeywell Inc. 1993 • Form Number 66-2001—2

R7795A,B,C,D

SPECIFICATIONS • ORDERING INFORMATION

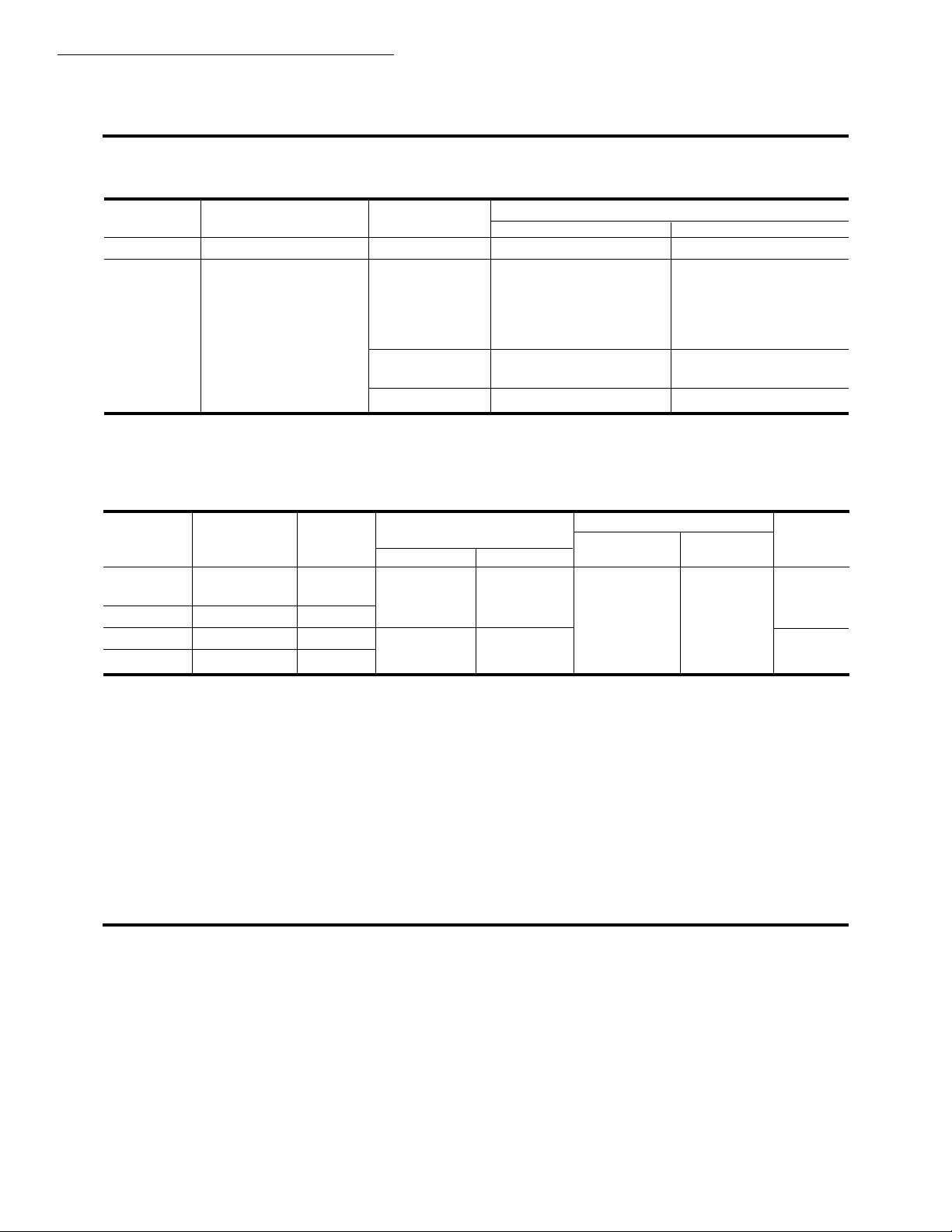

TABLE 1—FLAME DETECTION SYSTEMS.

Flame Detection Applicable Flame Detectors

Model Amplifier Type Fuel Type Models

R7795A,C Ultraviolet (purple) Gas, oil UV (Minipeeper) C7027, C7035, C7044

R7795B,D Rectification (Green) Gas Rectifying flame rods Holders:a C7004,

a

Order flame rod separately.

b

Use Honeywell part no. 38316 Photocell only.

Specifications

C7007, C7011

Complete Assy:

C7005, C7008,

C7009, Q179

Oil Rectifying photo cellsbC7003, C7010,

C7013, C7014

Gas, oil, coal UV (Purple Peeper) C7012A,C

TABLE 2—R7795 MODELS AVAILABLE.

Flame Flame Establishing Flame Failure

Detection Amplifier Period (sec) Nominal Device Run/Test

R7795 Type Color Pilot

R7795A UV Purple Intermittent Intermittent 3 Recycle No

R7795B Rectification Green

R7795C UV Purple 10/4 10 Yes

R7795D Rectification Green Interrupted Seconds

a

Field selectable:

10 sec with the orange jumper wire unclipped.

4 sec with the orange jumper wire clipped.

b

Field selectable:

Recycle with the yellow jumper wire unclipped.

Lockout with the yellow jumper wire clipped.

a

Main Response (sec) Reaction

Pilot or Lockout

b

Switch

Ordering Information

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the

TRADELINE Catalog or price sheets for complete ordering number, or specify—

1. Order number, TRADELINE, if desired.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of phone directory).

2. Home and Building Control Customer Satisfaction

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9. International

Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany,

Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

2

R7795A,B,C,D

SPECIFICATIONS

ELECTRICAL RATINGS:

Voltage and Frequency: 120 Vac, (+10, -15%), 50/60 Hz.

Power Consumption:

R7795A,C: 17 VA (maximum).

R7795B,D: 15 VA (maximum).

TERMINAL RATINGS:

Maximum Rating

Terminal Load at 120 Vac

5Pilot Valve 125 VA pilot duty.

18 Ignition 360 VA.

6, 7 Main Fuel 125 VA pilot duty or

Valve(s) 25 VA pilot duty plus

one or more motorized

valves with a total rating

of 500 VA opening,

250 VA holding.

8 Fan or 9.8A full load; 58.8A

burner motor locked rotor.

9Alarm 1.0A.

NOTE: Allowable inrush can be up to ten times the pilot

duty rating.

Example:

Pilot duty rating = 125 VA. At 120V, running current is

125/120 = 1.05A.

Maximum allowable inrush is 10 times 1.05 = 10.5A.

AMBIENT TEMPERATURE RANGES:

Operating: -40° F [-40° C] to +135° F [+57° C].

FLAME FAILURE RESPONSE: 3 seconds nominal.

DIMENSIONS: Approximately 5 x 5 x 5-1/4 in. [127 x 127

x 133.5 mm].

WEIGHT: 2.0 lb [0.9 kg].

MOUNTING: Two captive screws in device for mounting

onto Q795A Subbase (ordered separately).

APPROVALS:

Underwriters Laboratories Inc. listed: File No. MP268,

Guide No. MCCZ.

Canadian Standards Association certification: pending.

Factory Mutual approved: Report No. J.I. OR4A2.AF

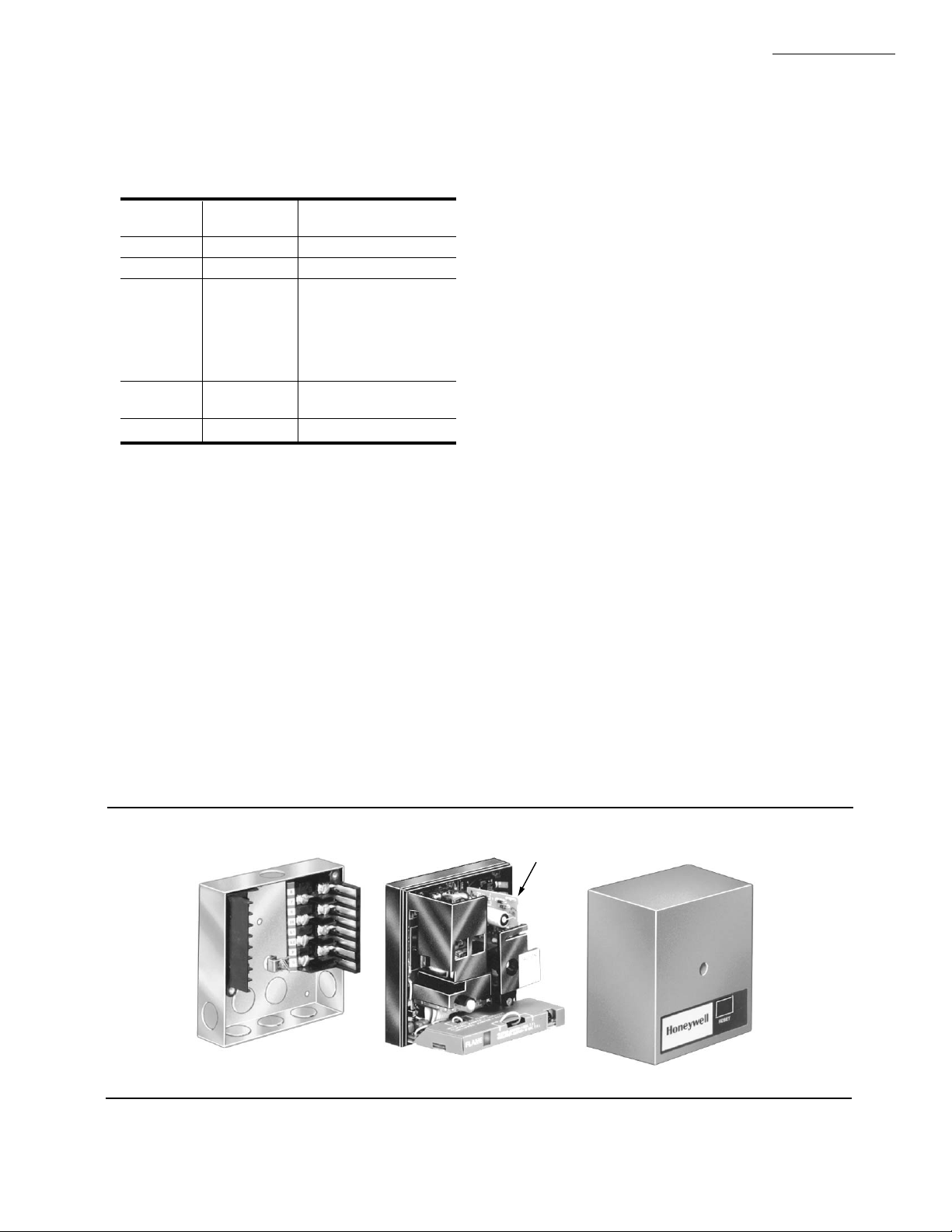

ACCESSORIES (See Fig. 1):

W136A Test Meter (includes 196146 Meter Connector

Plug).

196146 Meter Connector Plug for older W136A Test

Meters.

123514A Flame Simulator for rectification systems.

123514B Flame Simulator for ultraviolet systems.

Q624A Solid State Spark Generator.

Q795A Wiring Subbase.

ST795A Plug-in Purge Timer (models available with

1.5, 7, 10, 30, 60, and 90 second timings).

FSP5004A with adapter for operational check of the

R7795.

R1061012 Ignition Cable for ignition installations in

high temperature environments; rated at 350° F

[177° C] for continuous duty, and up to 500° F

[260° C] for intermittent use; tested to 20,000 Vrms.

R1239001 High Tension Ignition Cable for ignition

installations in a contaminating environment; very

resistant to severe conditions of oil, heat, and corona.

Tested to withstand high voltages up to 25,000 Vrms

in a salt bath for one minute without breakdown.

Rated at 200° F [93° C] for continuous duty, and up

to 250° F [177° C] for intermittent use.

R1298020 Cable for flame detector (F leadwire) instal-

lations in a high temperature environment; rated up

to 400° F [204° C] for continuous duty; tested for

operation up to 600V and breakdown up to 7500V.

198365A Remote Reset Cover. Heavy duty cover with

remote reset assembly; 120 Vac, 50/60 Hz solenoid

will only fit R7795 with a series number of 1.

198365B Remote Reset Cover. Heavy duty cover with

remote reset assembly; 120 Vac, 50/60 Hz solenoid

will only fit R7795 with a series number of 2.

Fig. 1—R7795 System components.

Q795A WIRING SUBBASE COVER

ST795A

PREPURGE

TIMER

M12389

3 66-2001—2

R7795A,B,C,D

DETAILED OPERATING SEQUENCE

Detailed Operating Sequence

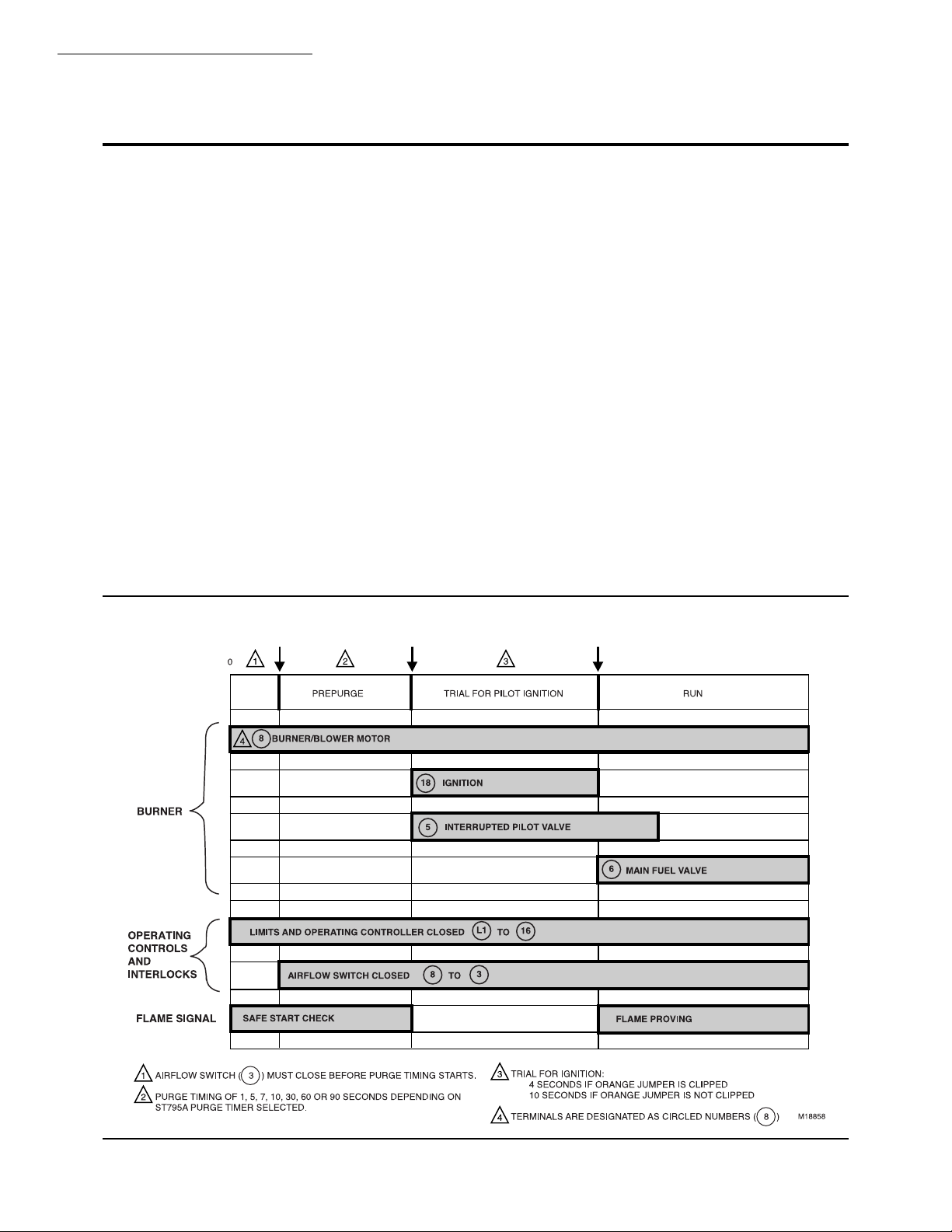

The R7795A,B provides the following operational sequence when used with the appropriate flame detector. (See

Figs. 2 and 3.)

STANDBY

The R7795 Primary Control is ready to start up when

the burner controller closes (limits are closed).

NORMAL START-UP

1. With power applied (limits and controller closed,

terminal L1 to 16, and no flame signal present) the 3K relay pulls in and the burner motor (terminal 8) is energized.

2. As soon as the airflow switch closes (terminal 3 to

8), the ST795A Prepurge Timer starts to time out (prepurge begins).

NOTE: The ST795A Prepurge Timer returns to zero any

time the airflow switch opens. The prepurge restarts

when the airflow switch recloses.

Fig. 2—Operating sequence for the R7795A,B, with intermittent pilot.

3. PILOT FLAME ESTABLISHING PERIOD.

At the end of prepurge (ST795A timed out), the 1K

relay pulls in, energizing the ignition transformer (terminal 18) and the intermittent pilot valve (terminal 5). This

starts the ten or four second pilot flame establishing

period. Safety shutdown and lockout will occur if presence of flame is not proven within:

•Ten seconds if the ORANGE jumper is not clipped.

• Four seconds if the ORANGE jumper is clipped.

4. MAIN FLAME IGNITION TRIAL

At the end of the pilot flame establishing period (ten or

four seconds), and with pilot flame present, the main valve

(terminal 6) is energized.

The R7795 is now in the normal burner run mode of

operation and will remain so until an external command

directs it to do otherwise.

5. NORMAL SHUTDOWN

When the burner controller opens, the pilot valve (terminal 5), the main valve (terminal 6) and the burner/

blower motor (terminal 8) are immediately de-energized.

The R7795 goes into the standby mode, terminating the

operating cycle.

4

Fig. 3—Internal schematic of the R7795A,B with intermittent pilot.

R7795A,B,C,D

DETAILED OPERATING SEQUENCE

BASIC DIAGRAM OF

THE R7795A

BURNER

MOTOR

LINE VOLTAGE

ALARM

LINE VOLTAGE

AIRFLOW SWITCH

CONTROLLER

LIMIT(S)

BASIC DIAGRAM OF

THE R7795B

5

7

2K1

3K3

8

16

S.SW

9

3

OPTO

ISOLATOR

ST795A

3K1

1K2

S.SW

F1

3K

FLAME AMPLIFIER

SOLID STATE

LOGIC CKT.

1K

2K

2K1

6

18

L1

L2

F

G

3

5

INTERRUPTED

PILOT VALVE

MAIN

FUEL VALVE

IGNITION

TRANSFORMER

2

FLAME

DETECTOR

L1

(HOT)

L2

INTERRUPTED

PILOT VALVE

1

120 Vac

60 HZ

BURNER

MOTOR

LINE VOLTAGE

ALARM

LINE VOLTAGE

AIRFLOW SWITCH

CONTROLLER

LIMIT(S)

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

SELECT APPROPRIATE FLAME DETECTOR.

2

8

16

9

3

3K3

S.SW

ST795A

3K1

1K2

F1

S.SW

3K

FLAME AMPLIFIER

SOLID STATE

1K

LOGIC CKT.

2K

CONNECT TERMINAL TO EARTH GROUND.

3

G

2K1

2K1

7

6

18

L1

L2

F

G

3

MAIN

FUEL VALVE

IGNITION

TRANSFORMER

2

FLAME

DETECTOR

L1

(HOT)

L2

M11915

1

120 Vac

60 HZ

5 66-2001—2

R7795A,B,C,D

DETAILED OPERATING SEQUENCE

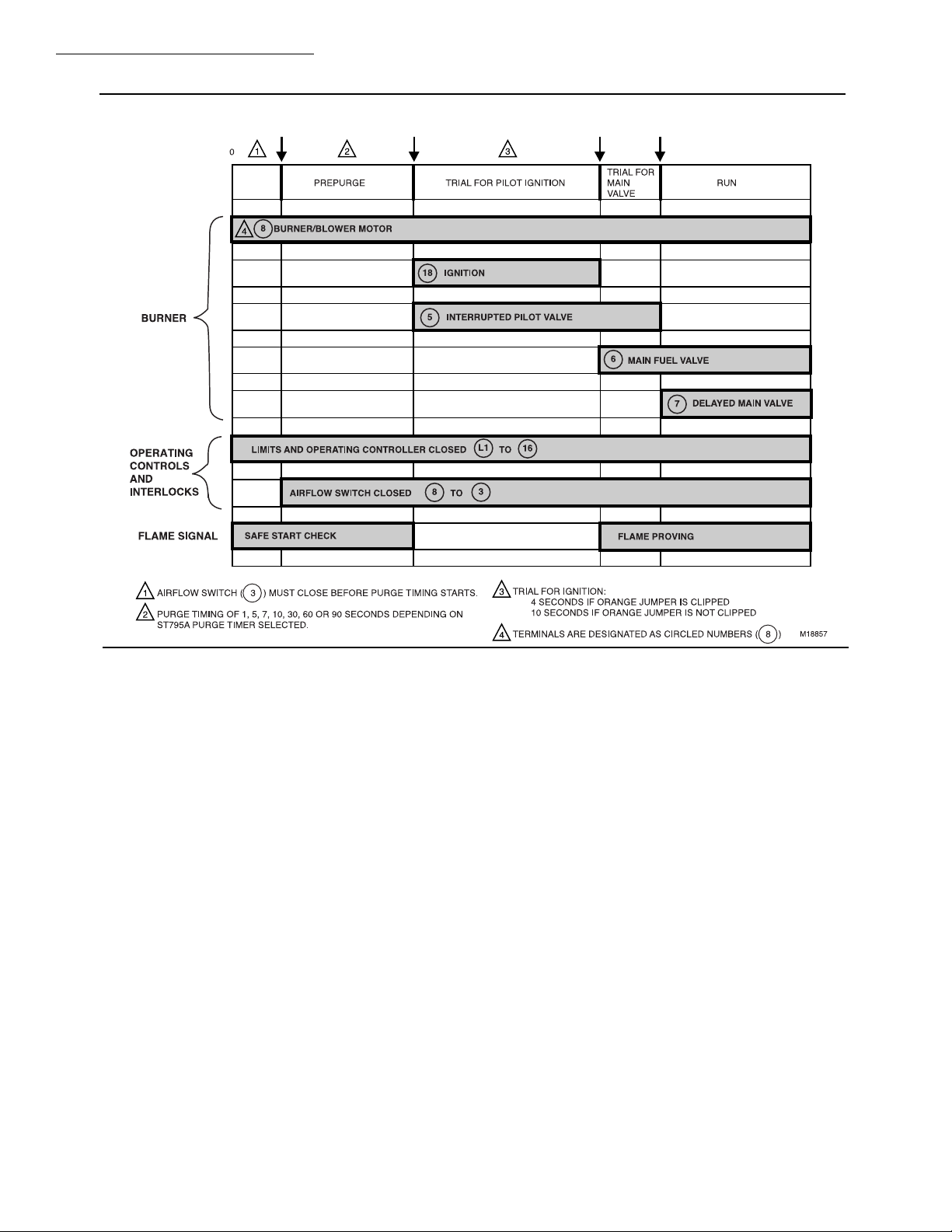

Fig. 4—Operating sequence for the R7795C,D with interrupted pilot.

The R7795C,D provides the following operational sequence when used with the appropriate flame detector. (See

Figs. 4 and 5.)

STANDBY

The R7795 Primary Control is ready to start up when the

burner controller closes (limits are closed).

NORMAL START-UP

1. With power applied (limits and controller closed, terminal L1 to 16, and no flame signal present), the 3K

relay pulls in and the burner motor (terminal 8) is energized.

2. As soon as the airflow switch closes (terminal 3 to

8), and with the RUN/TEST switch in the RUN position, the ST795A Prepurge Timer starts to time out (prepurge begins).

NOTE: The ST795A Prepurge Timer returns to zero any

time the airflow switch opens or the RUN/TEST switch

is moved to the TEST position. The prepurge restarts

when the airflow switch recloses or the RUN/TEST

switch is returned to the RUN position.

3. At the end of prepurge (ST795A timed out), the 1K

and 4K relays pull in, simultaneously energizing the ignition transformer (terminal 18) and the interrupted pilot

valve (terminal 5). This starts the ten or four second pilot

flame establishing period. Safety shutdown and lockout

will occur if presence of flame is not proven within:

•Ten seconds if the ORANGE jumper is not clipped.

• Four seconds if the ORANGE jumper is clipped.

If the RUN/TEST switch is moved to the TEST position during the pilot flame establishing period, the sequence is stopped in trial for pilot flame. The safety switch

heater is energized during this pilot flame establishing

period whenever flame is not present. Safety shutdown

and lockout will occur if the absence of flame exceeds

15 seconds (nominal).

4. MAIN FLAME IGNITION TRIAL

At the end of the pilot flame establishing period (ten or

four seconds), with pilot flame present, and the RUN/TEST

switch in the RUN position, the ignition transformer (terminal 18) is de-energized and the main valve (terminal 6) is

energized, starting the main flame ignition trial.

Ten seconds into the main flame ignition trial, the pilot

valve (terminal 5) is de-energized and the delayed main

valve (terminal 7) is energized. This completes the ten

second main flame ignition trial period.

The R7795 is now in the normal burner run mode of

operation and will remain so until an external command

directs it to do otherwise.

5. NORMAL SHUTDOWN

When the burner controller opens, the main valves

(terminals 6 and 7) and the burner/blower motor (terminal 8) are immediately de-energized. The R7795 goes into

the standby mode, terminating the operating cycle.

6

Loading...

Loading...