Page 1

R7515C MacroCel

Controller

INSTALLATION INSTRUCTIONS

Warning: This equipment generates , uses, and can radiate radio frequency energy , and if not installed and used in accordance

with the Instructions Manual, may cause interference with r adio communication. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference when operated in a commercial en vironment. Operation of this equipment in

a residential area is likely to cause interference, in which case, user at their own expense will be required to take whatever

measures may be required to correct the interference. Any unauthorized modification of this equipment may result in the

revocation of the owner's authority to continue its operation.

™

BEFORE INSTALLATION

1. Unpack Door assembly and Subpanel from carton.

Check equipment and report any damage to a

Honeywell representative.

2. Unpack DeltaNet R7515C MacroCel Controller

(“MacroCel”) Card Cage Assembly (“Assembly”) from

carton. Check Assembly and report any damage to a

Honeywell representative.

3. Before installing, verify that Ring Cabinet is installed per

job drawings. (Refer to General Purpose Cabinet

Installation Instructions 95-7438 for details.)

4. Installation requires No. 10 x 1/2-in. sheet metal screws

(not supplied). Six screws are required for full-sized

subpanel; four for half-sized subpanel.

5. If application requires a tamper switch, use 14505159

Tamper Switch. The Tamper Switch includes a

4-40 x 5/8-in. machine screw.

6. Screw terminals are rated for 12 to 24 AWG solid or

stranded conductors.

7. Install in a controlled environment relatively free of

contaminants.

INSTALLATION

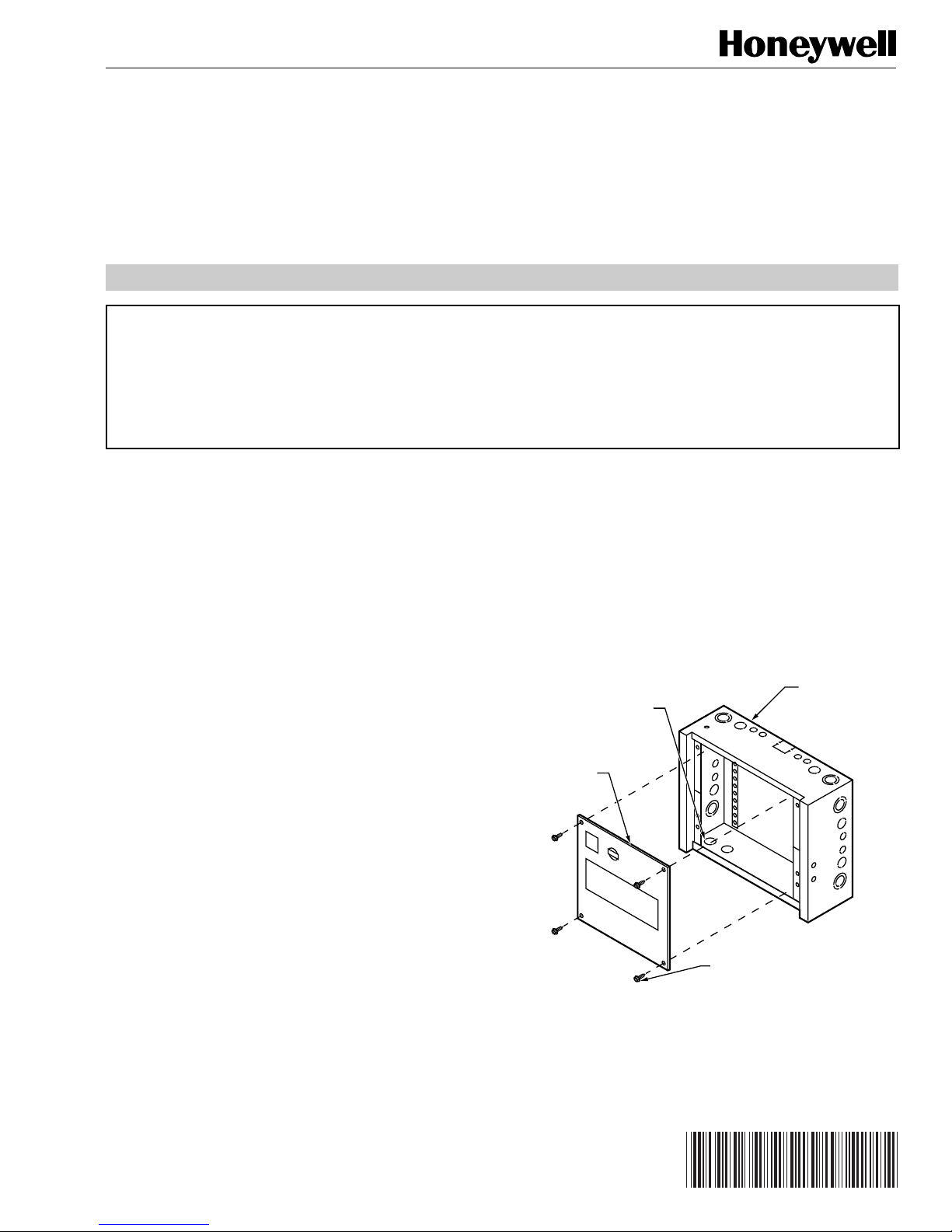

Install Subpanel

1. Position MacroCel subpanel in cabinet so all labeling

is visible.

2. Secure MacroCel subpanel in place with No. 10 x

1/2-in. sheet metal screws (Fig. 1 and 2).

NOTE: Subpanel must mount flat and should not

MacroCel

SUBPANEL

buckle anywhere.

LOWER OUTER

KNOCKOUTS

(4) RECOMMENDED

FOR EASE OF

INSTALLATION

HALF-SIZE

CABINET

® U.S. Registered Trademark

Copyright © 1998 Honeywell Inc. • All Rights Reserved

SIX NO. 10 X 1/2-IN.

MOUNTING SCREWS

Fig. 1. Mounting MacroCel subpanel in half-sized

ring cabinet.

C5691

95-7456-1

Page 2

R7515C MacroCel™ CONTROLLER

SIX NO. 10 X 1/2-INCH

MOUNTING SCREWS

MacroCel

SUBPANEL

LOWER OUTER KNOCKOUTS (4)

RECOMMENDED FOR EASE

OF INSTALLATION

FULL-SIZE

CABINET

C5690

Fig. 2. Mounting MacroCel subpanel in full-sized

ring cabinet.

Wire Subpanel to Interface Board

NOTES:

1. All wiring must conform to local codes,

ordinances, and regulations. Refer to job

drawings for details.

2. Use copper conductors only.

3. For 220/240V ac 50/60 Hz installations, verify

that voltage difference between any conductor

and earth ground does not exceed 150V ac.

4. An End-of-Line Resistor (EOLR) for use with the

C-NAP bus wiring is integral to the MacroCel

Subpanel Interface Board.

CAUTION

Verify that ac power is

power wiring terminal block (H-N-G) until system is

checked by a Honeywell Representative.

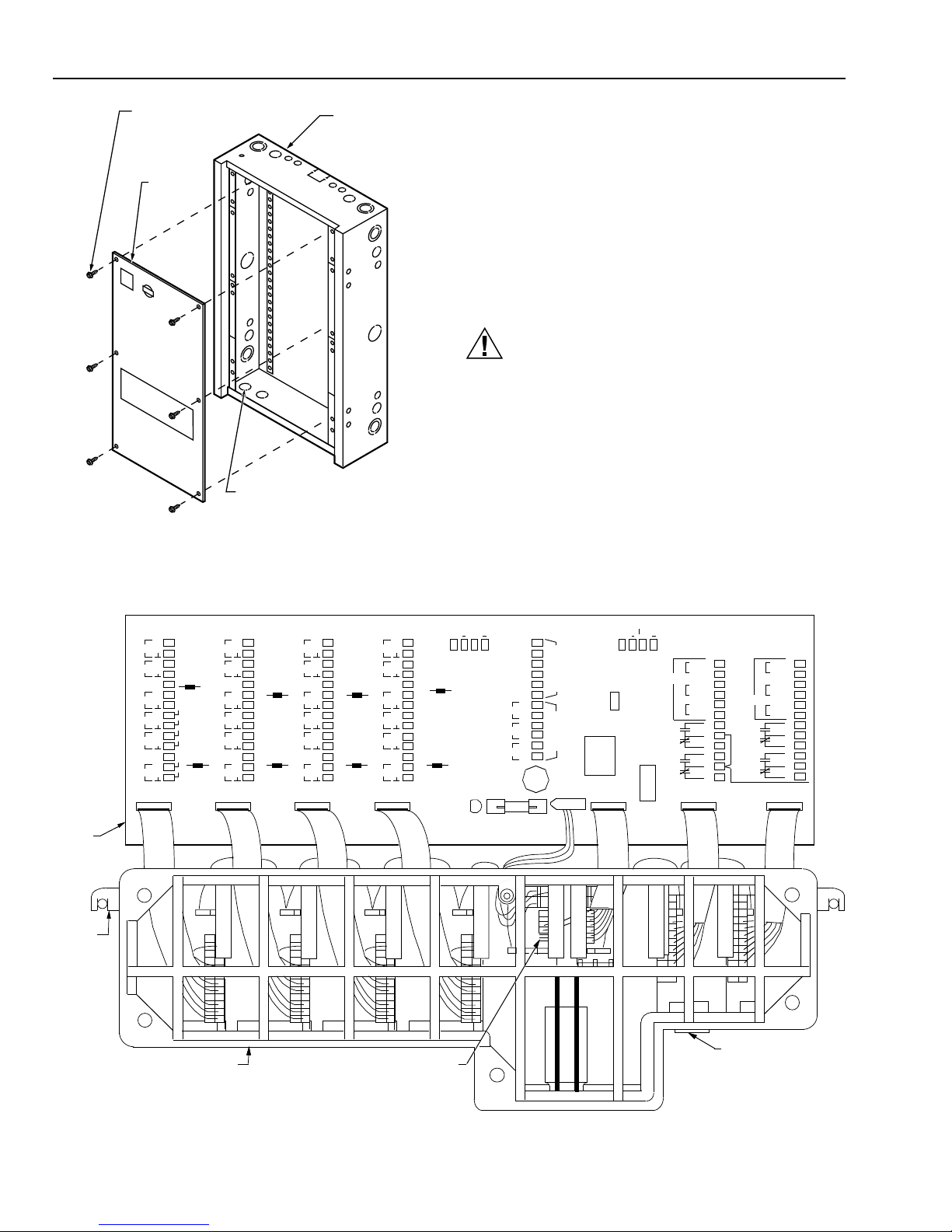

Wire the Subpanel as follows:

1. Connect field wiring to MacroCel subpanel Interface

Board or accessory devices per job drawings. Figure 3

shows MacroCel interface board terminal arrangement.

Figure 4 shows typical wiring.

not

connected to MacroCel

MacroCel

INTERFACE

BOARD

MOUNTING

TAB (2)

RTD

DIG

VOLT

RTD

DIG

VOLT

+10

+10

TB1

R1

D1

V1

R2

D2

V2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TERM V1

R1

TERM V2

R2

RTD

DIG

VOLT

RTD

DIG

VOLT

+10

+10

TB2

R3

D3

V3

R4

D4

V4

15

16

17

18

19

TERM V3

20

R3

21

22

23

24

25

26

TERM V4

27

R4

28

RTD

DIG

VOLT

RTD

DIG

VOLT

+10

+10

TB3

R5

D5

V5

R6

D6

V6

29

30

31

32

33

34

35

36

37

38

39

40

41

42

INPUTS

J1 J2 J3 J4

MacroCel

CARD CAGE

TERM V5

R5

TERM V6

R6

TB4

R7

RTD

D7

DIG

+10

V7

VOLT

R8

RTD

D8

DIG

+10

V8

VOLT

CONNECTOR J8

43

TB10

44

45

46

TERM V7

47

48

49

R7

50

51

52

53

54

TERM V8

55

R8

56

WALL MOD

24 VDC

+ +

5 7 5 8 5 9 6

0. 16A MAX

POWER

LED

CR2

CNAP

OUT IN

TB5

61

TO-1

0

COM1-2

COM3-4

TO-2

TO-3

TO-4

+

C1

F1

2A

O

62

T

U

R

T

63

I

P

64

A

U

C

T

65

66

67

T1

68

T2

2

4

69

T1

V

70

A

T2

C

71

T1

72

T2

TB8

POWER

24VAC T1

24VAC T2

+ +

7

7 7

TB9

3 7 4 5

6

0.16A MAX

A

JB1

1

1&2

IN

2

2&3

OUT

3

EOL

CNAP

BUS

ON

JACK

J8

J5

OFF

ANALOG

K1

K2

CNAP

BUS

S1

TB6

77

AO—1

78RET

79

AO—2

80

RET

ANALOG

81

AO—5

82

RET

83

A

84

C

85

B

86

A

87

C

B

88

OUTPUTS

J6 J7

SUBPANEL

SUPPORT (2)

TB7

89

AO—3

90RET

91

AO—4

92

RET

93

AO—4

94

RET

95

A

K3

K4

96

C

97

B

98

A

99

C

B

100

Fig. 3. MacroCel interface board terminal arrangement.

95-7456—1

C5611

2

Page 3

MacroCel

INTERFACE

BOARD

MOUNTING

TAB (2)

R7515C MacroCel™ CONTROLLER

C5611

123

4

5

678

9

10

111213

14

R1

RTD

D1

DIG

+10

+10

V1

VOLT

R2

RTD

D2

DIG

V2

VOLT

TB1

R1

R2

TERM V1

TERM V2

15161718192021222324252627

28

R3

RTD

D3

DIG

+10

+10

V3

VOLT

R4

RTD

D4

DIG

V4

VOLT

TB2

R3

R4

TERM V3

TERM V4

29303132333435363738394041

42

R5

RTD

D5

DIG

+10

+10

V5

VOLT

R6

RTD

D6

DIG

V6

VOLT

TB3

R5

R6

TERM V5

TERM V6

R7

RTD

D7

DIG

+10

+10

V7

VOLT

R8

RTD

D8

DIG

V8

VOLT

TB4

4748495051

52

53

545556

434546

44

J1

J2

J3

J4

R7

R8

TERM V7

TERM V8

57 58 59 6

0

+

+

24 VDC

TB10

C1

TO-1

TB5

65

66

67

686970717261636462

COM1-2

TO-2

TO-3

COM3-4

TO-4

T1

T2T1T2

T1

T2

O

U

TPU

T

T

R

I

A

C

2

4VA

C

POWER

LED

F1

2A+ CR2

TB8

POWER

24VAC T1

24VAC T2

J5

CNAP

BUS

JACK

ON

OFF

S1 AEOL

J6

J7 123 1&2

2&3

J8

3 74

5

+

+

CNAP

OUT IN

7

6

TB9

IN

OUT

AO—1

TB6

77

78

RET

ANALOG

79

80

AO—2

RET

AO—3

TB7

89

90

RET

ANALOG

91

92

AO—4

RET

MacroCel

CARD CAGE

JB1

INPUTS

WALL MOD

CONNECTOR J8

0. 16A MAX

CNAP

BUS

0.16A MAX

83

84

858687

88

ACB

ACB K1K2

OUTPUTS

959697

9899100

ACB

A

C

B

K3

K4

7

7

SUBPANEL

SUPPORT (2)

81

82

AO—5

RET

93

94

AO—4

RET

Fig. 4. MacroCel typical wiring.

3

95-7456—1

Page 4

R7515C MacroCel™ CONTROLLER

2. Connect C-NAP bus wiring to C-NAP terminal block on

MacroCel per job drawings (Fig. 5).

MacroCel

INTERFACE

BOARD

C5693

C-NAP

TERMINAL

BLOCK

CNAP

OUT IN

+ +

7

7

7

4 5

3

0.16 MAX

YEL

RED

RED

+

+

7

6

YEL

TB9

Fig. 5. Connecting C-NAP bus wiring to C-NAP terminal

block on MacroCel.

3. When required, activate the EOLR on the MacroCel

Subpanel Interface Board by placing the shorting bar in

Position 1-2 (Fig. 6A). Deactivate the EOLR by placing

the shorting bar in Position 2-3 (Fig. 6B).

A A

EOL EOL

A. EOLR "IN"

SHORTING BAR

1

1 & 2 IN

2

3

SHORTING BAR

2 & 3 OUT 2 & 3 OUT

B. EOLR "OUT"

1

1 & 2

2

3

IN

C5687

Fig. 6. MacroCel subpanel interface board EOLR

positions for activation (IN) and deactivation (OUT).

4. Connect line voltage to AC Input Block. Leave power to

MacroCel subpanel OFF until system is checked by a

Honeywell Representative.

5. Mount optional Tamper Switch on cabinet and wire per

job drawings (Fig. 7).

TAMPER

SWITCH

PLUNGER

LOCKNUT

PLUNGER

SCREW

RING

LOCK

WASHERS

FROM

TAMPER

SWITCH

SCREWS

FROM

DOOR

LATCH

Mount MacroCel Card Cage Assembly

NOTES:

1. Lower edge of Assembly is supported by two supports

on the Subpanel (Fig. 8). Do not force Assembly into

supports. If supports interfere with mounting Assembly,

gain proper clearance by using pliers to bend supports

outward slightly.

2. Two mounting tab screws are factory installed (started)

to aid in mounting the Assembly.

PREINSTALLED

MOUNTING TAB

SCREW (2)

INTEGRAL

SUPPORT

MacroCel

SUBPANEL

C5689

Fig. 8. Subpanel supports and preinstalled mounting

tab screws.

Mount the Assembly as follows:

1. Position mounting surface of Assembly flat against

Subpanel, aligning sides of Assembly with sides of

mounting silhouette and top of Assembly approximately

1 in. (25 mm) above top of mounting silhouette.

2. Slide Assembly down, simultaneously engaging lower

supports and preinstalled mounting tab screws.

3. Tighten screws to secure Assembly to Subpanel.

4. Connect input/output board ribbon cables and power

cable to Interface Board in sequential order as they

protrude from the Assembly. Connect farthest-left

ribbon cable connector to J1 on the Interface Board,

farthest right ribbon cable connector to J7 (Fig. 3).

AFTER INSTALLATION

1. Mount cabinet Door.

2. If applicable, adjust Tamper Switch screw (at end of

door switch plunger) so Tamper Switch activates when

door opens.

3. Close and lock Door.

DOOR

LATCH

Fig. 7. Mounting optional tamper switch.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your

use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and

against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the

literature by you.

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

95-7456—1 T.M. 2-98

C6039

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

www.honeywell.com

Loading...

Loading...