Page 1

R7426B,C

MicroniK 200

Fig. 1. Temperature controller

TEMPERATURE CONTROLLER

WITH REAL-TIME CLOCK

SPECIFICATION DATA

GENERAL

The R7426B,C temperature controllers cover all space and/or

discharge air temperature applications within the specified

control range of 0...50°C (LOw range) requiring sequence

operation of heating, mixed air damper or energy recovery

system and cooling with optional outside air temperature

compensation reset of the main setpoint. The controllers can

be configured to perform space or discharge air or spacedischarge air temperature cascade control with limit control.

For special higher temperature control applications, the

control range 0...130C (HI range) can be selected.

FEATURES

Weekly time schedule with up to six switching points

per day

Automatic daylight saving time change

Four different operating modes: Comfort, Standby,

Night, and OFF

Yearly holiday programming in advance

Three types of holiday schedules

Self-adaptive optimum start program for room control

system

Night cycle program

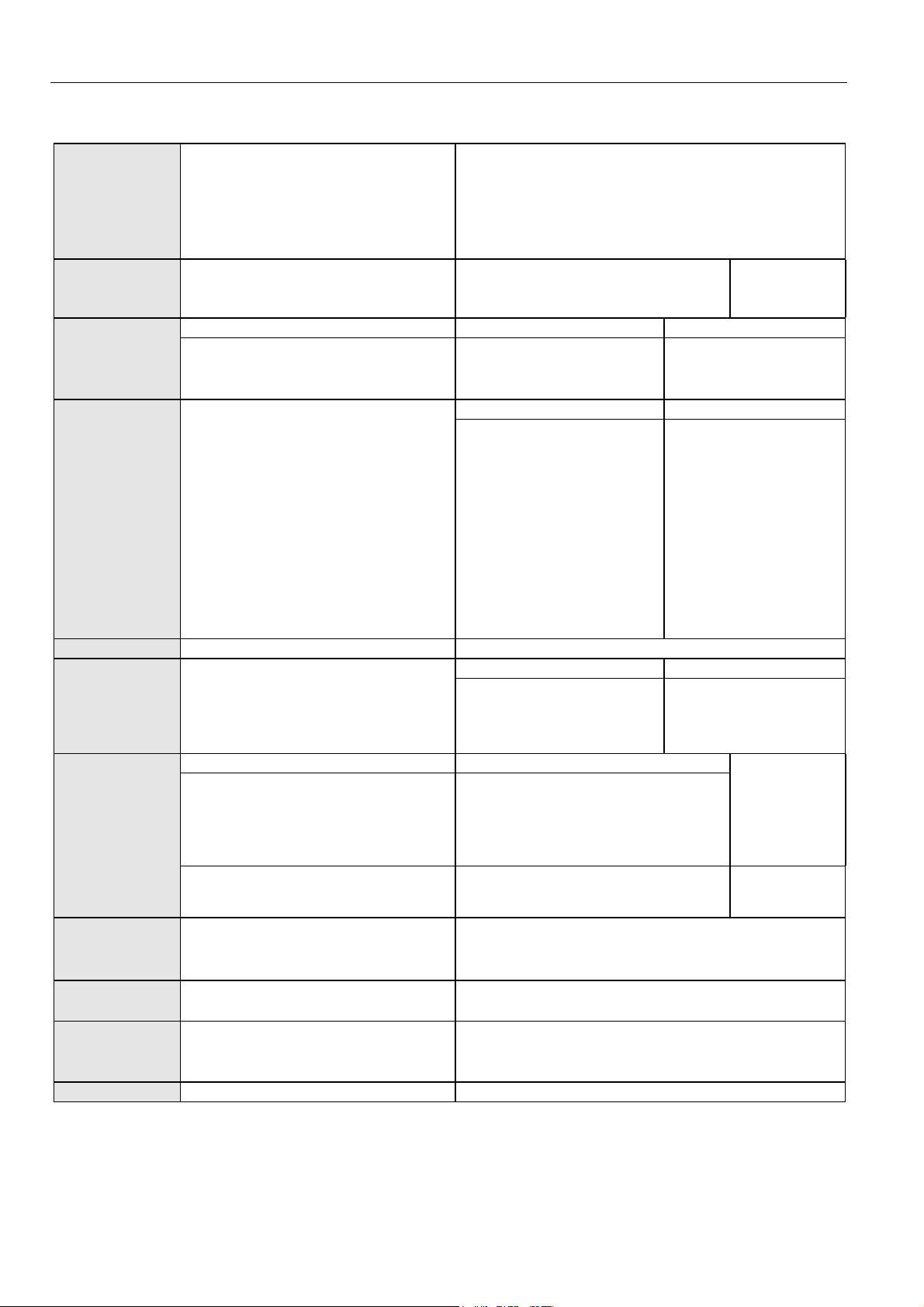

Fig. 2. LC Display

Order Numbers

Order-No. Controller Description

R7426B2012 Temperature controller with integrated

real time clock (RTC), Plant/System

ON/OFF output, and three 3-position

floating outputs. The controller offers the

choice of selectable different output

sequence operations and output signals

suitable to drive solid-state relays or step

relays.

R7426C2010 Temperature controller with integrated

real time clock (RTC), Plant/System

ON/OFF output, and three analog

outputs. The controller offers selection of

different output sequence operations.

EN0B-0301GE51 R0104

Page 2

R7426B,C TEMPERATURE CONTROLLER

TECHNICAL DATA

General

Electronic 8-bit microcontroller, 10-bit A/D converter, EEPROM, and LC

display

Power supply 24 Vac +10...-15%, 50/60 Hz

Power consumption 3 VA + Actuator power requirements

Control range 0...50°C

Temperature

Inputs

Sensor type

1)

CPA/SPA-Input

Battery

T1 Main temperature sensor

T2 Cascade temperature sensor

T3 Compensation temperature sensor

Automatic identification of sensor type Temperature range Characteristics

Pt 1000

BALCO 500

NTC 20kτ -30....+85C / -30....+130C

1)

CPATYP 0

CPATYP 1 (953...1053 τ) CPA: 5 K

CPATYP 2 (0...100 kτ) CPA: 5 K

Type CR2032 (life time 8 years)

accuracy 0.5 K

excluding

sensor

2)

-30....+130C 1000 τ at 0C

-30....+130C 500 τ at 23.3C

1)

20 kτ at 25C

CPA/SPA range Sensor & CPA/SPA types

CPA: 5 K

internal

T7412B1016 (Pt 1000)

T7412B1057 (Pt 1000)

T7412C1030 (Pt 1000)

T7412B1008 (NTC 20kτ)

T7412C1006 (NTC 20kτ)

CPATYP 3 (10...20 kτ) SPA: 15...30C

T7412B1024 (BALCO 500)

T7412B1040 (Pt 1000)

CPATYP 4 (0...10 kτ) CPA: 5 K

HCW 23 (setpoint wheel

printed with +/- 5 K)

CPATYP 5 (0...100 kτ) SPA: 15...30C

CPATYP 6 (0...100 kτ) SPA: 0...50C or 0...130C

Analog input Humidity deviation (X

) -5...+5 Vdc, 200 mV / %rh

wrh

43193982-001

43193982-001

Digital inputs Mode Potential free contact

Occupancy unoccupied

occupied

Freeze protection input freeze protection operation

normal operation

open > 40 kτ

closed < 100 τ

open > 40 kτ

closed < 100 τ

Outputs ON/OFF output OFF / ON

TRIAC outputs

Floating

2, 3, 4, 6 or 15-stage

ON (24 Vac) / OFF (0 Vac)

Pulse-width modulation

1)

1)

max. load

450 mA at

24 Vac per

1)

0...100%

output

based on run time

Analog outputs on controller R7426C Control range

full range 0...12 Vdc

1)

0/2...10 Vdc (0...100%)

max. load

1.2 mA at

12 Vdc

Ambient limits

Operating temperature

Transport and storage temperature

0...50°C (0...122F

)

-35...+70°C (-31...+158F

)

Relative humidity 5...95%rh non-condensing

Safety

Protection class II as per EN60730-1

Protection standard IP30 or IP40 (front panel mounting) as per EN60529

Housing

Dimensions (H x W x D) 105 x 152 x 37 mm

Weight 250 g

Mounting Front door, back panel, wall, or rail

Connections Connection terminal terminals max. 1 x 1.5 mm

1)

Selectable

2)

same sensor type must be used for T1, T2, and T3

2

EN0B-0301GE51 R0104 2

Page 3

CONTROL AND CONFIGURATION PARAMETER

R7426B,C TEMPERATURE CONTROLLER

Control Parameter Setting

Parameter Description

No. Name

Low High Default

Resolution

Unit

P.01 W1 Main setpoint for input T1 0 50 21 0.5 C

P.02 Wlim Limit setpoint (low or high) for input T2 5 50 16 1 C

P.03 Wcomp Compensation changeover point for input T3 -5 40 20 1 C

P.04 Wi Winter compensation authority -350 +350 0 2 %

P.05 Su Summer compensation authority -100 +100 0 1 %

P.06 Wcas Submaster or cascade setpoint OFF, 0 50 20 0.5 C

P.07 Rcas Cascade reset span adjustment 0 40 10 0.5 K

P.08 Xp1 Throttling range (main control loop) T1 0.5 40 2 0.5 K

P.09 Xp2 Throttling range (cascade control loop) T2 0.5 40 10 0.5 K

P.10 Xpc Cooling throttling range for sequence control OFF, 1 40 3 0.5 K

P.11 Xph Heating throttling range for sequence control 1 40 6 0.5 K

P.12 tr1

P.13 tr2

1)

Reset time (main control loop) T1 OFF, 20 s 20min OFF 10/0.5 sec/min

1)

Reset time (cascade control loop) T2 OFF, 20 s 20min OFF 10/0.5 sec/min

P.14 MINPOS Minimal pos. for air damper actuators 0 50 20 1 %

P.15 Ystart Start point for mid range shift of output Y1 -20 +20 0 0.5 K

P.16 SOFFS Offset of main setpoint in Standby mode 0 10 2 0.1 K

P.17 T1Cal Calibration of temperature sensor T1 -20 +20 0 0.1 K

P.18 T2Cal Calibration of temperature sensor T2 -20 +20 0 0.1 K

P.19 T3Cal Calibration of temperature sensor T3 -20 +20 0 0.1 K

P.20 RetOffs Return air offset to simulate exhaust air cond. OFF, 0 5 OFF 0.1 K

P.21 RuntimeY1 Actuator run time for output Y1 6 180 60 1 sec

P.22 RuntimeY3 Actuator run time for output Y3 6 180 60 1 sec

P.23 RuntimeY2 Actuator run time for output Y2 6 180 60 1 sec

P.24 NightLow Night low limit against temperature extremes OFF, 8 19 OFF 1 C

P.25 NightHigh Night high limit against temperature extremes OFF, 21 40 OFF 1 C

P.26 NOFFS Offset of main setpoint in Night mode 0 30 5 0.1 K

Config. Parameter

Values Default Unit

No. Name

C.01 DIR/REVY1 Dir

C.02 DIR/REVY3 Dir, Rev (R7426C, only) Dir

C.03 DIR/REVY2 Dir

C.04 Ctrltyp

2)

Lo = 0...50°C (factory preset), Hi1 = 0...130°C, Hi2 = 0...130°C

0 = internal (default), 1 = 5 K (953...1053 τ), 2 = 5 K (0 τ...100kτ),

C.05 CPATYP

3 = 15 … 30C (10...20 kτ), 4 = 5 K (0...10 kτ),

0

5 = 15 … 30C (0...100 kτ), 6 = 0...50C or 0...130C (0...100 kτ)

C.06 YRange 0 = 2 … 10 Vdc , 1 = 0 … 10 Vdc (R7426C, only) 1

C.08 Y1Mode 4

C.09 Y3Mode 4

C.10 Y2Mode

0= floating, 1= 2 stage ON/OFF, 2= 3 stage ON/OFF, 3 = pwm, 4 = unconfig.

(safe state is configured prior to controller's start-up) (R7426B, only)

4

0: Y1 = D, Y2 = C, Y3 = H 1: Y3/2/1 = H or C

C.11 YMode

2: Y3/1 = H, Y2 = C 3: Y3/1 = C, Y2 = H

0

4: Y1 = 2Pos D, Y2 = C, Y3 = H 5: Y3/1 = 15H, Y2 = C

C.12 T2ext 0 = T2 installed 1 = T1 signal used for T2 0

C.13 LimTyp 0 = Low limit 1 = High limit 0

C.14 Senstyp 0 = Auto detection 1 = NTC sensor type 0

C.15 Y1CTRF

Output Y1 used for: 0 = mixed air damper

1= energy recovery

0

C.16 AddHour Adjusts the month for winter/summer time change: 0 (disabled) = Min. 12 = Max. 3 month

C.17 SubHour Adjusts the month for summer/winter time change: 0 (disabled) = Min. 12 = Max. 10 month

3 EN0B-0301GE51 R0104

Page 4

R7426B,C TEMPERATURE CONTROLLER

Config. Parameter

Values Default Unit

No. Name

C.18 PSTG_H3)Prestart gradient for heating: 0 (disabled) = Min. 2 = Max. 0 K/min

C.19 PSTG_C3)Prestart gradient for cooling: 0 (disabled) = Min. 2 = Max 0 K/min

C.20 tvd Use damper before comfort time: 0 (normal control) = Min. 90 = Max. 15 min

C.21

C.22

C.23

1)

for tr > 2 min resolution = 0.5 min, for tr < 2 min resolution = 10 sec

2)

actual value will not be changed during reset to default parameter

3)

can be overwritten by controller for self-adaption purposes, resolution = 0.01 K/min

FUNCTIONS

Real-Time Clock

The time clock performs automatic change of the controller

mode to OFF, Night, Standby, or Comfort in accordance with

the programmed time schedule. In Standby or Night mode,

the SOFFS or NOFFS is added (cooling) to and subtracted

(heating) from the calculated control point. Schedules for one

Adapt

2)

Adr

DefProg

Optimum Start Self Adaption speed: 0 = Min. 100 = Max. 50 %

Serial communication address: 0 = Min. 255 = Max. 254

0 = No Default programming 1 = Initiates Default programming 0

APPLICATION

The R7426B,C controllers can be used for sequence control

applications of heating, mixed air damper or energy recovery

system, and cooling.

NOTE: All diagrams show proportional control action, only.

If P+I control is in operation, the slopes for heating

and cooling are not defined.

week and up to six switching points per day can be programmed in advance and repeated week after week. In

addition, three different holiday schedule types H1, H2 and

H3 can be programmed. One of these holiday types can be

assigned to each holiday date of the year (01.01. ... 31.12.).

Holiday type H1 and H2 is valid only for this specific day and

is reset to normal time schedule at midnight of that day. H3 is

valid for every year and repeated year after year for fixed

holiday dates. H1 can be programmed to be in OFF mode

the whole day and H2 to be ON for a short period of time on

the last day of a longer holiday period to preheat or precool

the space in advance before the first occupied day.

Temperature Sequence Control with Heating,

Mixed Air Dampers, and Cooling

This application will be active with the R7426B,C controllers

when T2 is not connected. It can be used for sequence

control of a heating valve, a mixed air damper, and a cooling

valve.

The characteristic of each output on the R7426C controller

can be selected via the control parameters DIR/REVx

(x = Y1, Y2, or Y3). The diagram shows Dir characteristic for

all outputs.

Optimum Start Program

The optimum start program’s objective is to minimize total

energy consumption by calculating in room control applications the start time for heating and cooling mode which will

bring its respective space temperature to the boundary of the

comfort zone at the time of occupancy start. The program will

start the ventilation system at the calculated start time with

forced return air recirculation mixed air damper position or full

energy recovery valve position to minimize energy consumption during the start-up period. At a programmable time

before occupancy start, the controller will switch the output

signal Y1 to normal and will supply fresh air to the space in

mixed air applications. The optimum start program uses

historical data for self-adaptive adjustment.

Night Cycle Program

The night cycle program offers not only energy conservation,

but also the ability to assign OFF mode night low or high

limits with 1K hysteresis for the protection of a space and its

Within the range Xp1, the damper signal is controlled as

shown in the diagram below. If no cooling actuator is available, the control parameter Xpc can be set to OFF and the

damper output is maintained at 100% above control point

(CTRP1).

If the damper output should be decreased to MINPOS level

above control point (CTRP1) as shown in the diagram, the

control parameter Xpc has to be adjusted to any value

between 1 and 40 K, also if no cooling actuator is available.

Y[%]

100

MINPOS

0

Y3

Heating

Xph

Damper

Y1

CTRPH

1/4 Xp1 if Xpc = Off

Cooling

Xp1

CTRPC

Xpc

CTRP1

Y2

if Xpc = Off

Xwh / Xwc

contents against temperature extremes. It automatically

cycles between the user selected upper and lower limits and

turns on full heating or cooling whenever the limits are

reached.

NOTE: If the R7426B controller with floating output is used

for mixed air damper control, you must ensure that

the output load of maximum 450 mA is not

exceeded.

Xwd

/

T2

EN0B-0301GE51 R0104 4

Page 5

R7426B,C TEMPERATURE CONTROLLER

Temperature Sequence Control with Heating,

Energy Recovery System, and Cooling

For applications with energy recovery system (ERS), the configuration parameter Y1CTRF has to be set to 1 to perform a

reverse acting Y1 output. The adjustment MINPOS is inactive

in this configuration and the control parameter Xpc has to be

set to OFF if the output should be maintained at 0% above

the control point (CTRP1) for summer operation.

Within the range Xp1, the energy recovery system is controlled as shown in the diagram below. With the R7426C

controller, a rotary energy recovery wheel can also be

controlled instead of a valve if the output signal of 0...10 Vdc

or 2...10 Vdc is suitable to control the rotation speed of this

device.

Y[%]

100

0

Heating

Y3

Xph Xp1

ERS

Y1

CTRP1CTRPH

1/4 Xp1

000

Cooling

Y2

Xpc=off

Xwh/Xwc/Xwd

CTRPC

Xpc

Temperature Cascade Control with Heating,

Mixed Air Dampers, and Cooling

This application will be active with the R7426B,C controllers if

temperature sensor T2 is connected and the control parameter W

for sequence control of a heating valve, a mixed air damper,

and a cooling valve.

The controllers provide cascade control as shown below:

Xp1/2

Offs

Offs

Xp1/2

is set to any value other than OFF. It can be used

cas

T1

C

MASTER

CTRP1

T1

Low limit of CTRP2 is performed if control parameter

LimTyp = 0 and high limit of CTRP2 is performed if control

parameter LimTyp = 1.

Within the range Xp2, the damper signal is controlled as

shown in the diagram below. If no cooling actuator is available, the control parameter Xpc can be set to OFF. If control

parameter Xpc = OFF, the cooling signal is set to 0% and the

damper output is maintained at 100 % above control point

(CTRP2).

Y[%]

100

MINPOS

0

Y3

Heating

Xph

Damper

Y1

CTRPH

1/4 Xp2 if Xpc = Off

Cooling

Xp2

CTRPC

Xpc

CTRP2

Y2

if Xpc = Off

Xwh / Xwc

NOTE: If the R7426B controller with floating output is used

for mixed air damper control, you must ensure that

the output load of maximum 450 mA is not

exceeded.

Temperature Cascade Control with Heating,

Energy Recovery System, and Cooling

For applications with energy recovery system (ERS) the

configuration parameter Y1CTRF has to be set to 1 to

perform a reverse acting Y1 output. The adjustment MINPOS

is inactive in this configuration and the control parameter Xpc

must be set to OFF if the outputs Y1 and Y2 should be

maintained at 0% above the control point (CTRP2) for

summer operation.

Within the range Xp2, the energy recovery system is controlled as shown in the diagram below. In the case of the

R7426C controller, a rotary energy recovery wheel can also

be controlled instead of a valve if the output signal of

0...10 Vdc or 2...10 Vdc is suitable for controlling the rotation

speed of this device.

Y[%]

100

Heating

Y3

ERS

Y1

1/4 Xp2

Cooling

Y2

Xwd

/

T2

0

CTRP2

W

R

cas

R

cas

lim

W

cas

W

lim

Offs = SOFFS for Standby Mode

0 for Comfort Mode

NOFFS for Night Mode

SUBMASTER

X Master

w

for

LimTyp=1

for

LimTyp=0

0

Xph Xp2

000

CTRP2CTRPH

CTRPC

Xpc=off

Xwh/Xwc/Xwd

Xpc

T2

Economizer Modes

The economizer modes are suitable for installations where

the main temperature sensor (T1) is installed in the exhaust

air or in the room with a constant offset between room and

X Master

0

w

exhaust air conditions. The offset value is programmable

within 0...5 K with the control parameter RetOffs which will

be added to the actual measured room temperature value to

simulate exhaust air conditions.

5 EN0B-0301GE51 R0104

Page 6

R7426B,C TEMPERATURE CONTROLLER

p

The economizer mode is disabled if the value of the control

parameter RetOffs is programmed to OFF, or if no outdoor

air temperature sensor is connected.

By comparing the outside air condition with the exhaust air

condition, the output for Y1 on the controller operates as

follows:

Mixed Air Dampers

RetOffs OFF; Y1CTRF = 0

AIR CONDITION Y1

Outside air temperature >

MINPOS

Exhaust air temperature

Outside air temperature <

Exhaust air temperature

Included in heating

sequence control (direct

acting)

Y[%]

100

MINPOS

0

Damper

Y3 Y2

Heating

Xph

Y1

CTRPH

T

OA

T1+RetOffs

< T

EA

1K

CTRP1

CTRP2

Xp1

Xp2

TOA > T

CTRPC

EA

Cooling

Xpc

Xwh / Xwc

T1/T2

A fixed hysteresis of 1K is used, to switch between MINPOS

and actual Y1 signal.

Energy Recovery System

RetOffs OFF; Y1CTRF = 1

AIR CONDITION Y1

Outside air temperature >

Exhaust air temperature

Outside air temperature <

Exhaust air temperature

100%

Energy Recovery System

included in heating

sequence control.

MINPOS is not active.

CONTROLLER FUNCTIONS

Outside Air Temperature Compensation

Outside air temperature compensation is performed when T3

is connected. The control parameter W

pensation changeover point for summer and winter compensation. The degree of summer and winter compensation is

defined by control parameters Wi and Su.

Winter compensation is performed if temperature

T3 < W

perature T3 > W

. Summer compensation is performed if tem-

comp

W1

compensated

C

W1

comp

.

Wi Su

W

comp

Smoothing Filter for Outside Air Temperature Input

A smoothing filter for the outside air temperature input T3 is

incorporated to eliminate sudden temperature variations. This

provides more stable operation of the control system. This

function will work only if the controller parameters have never

been changed by means of the PC tool.

Occupied/Unoccupied Function (SOFFS)

A potential free contact can be used between terminals 1 and

4 to switch the controller between occupied (contact closed)

or unoccupied (contact open) mode. The input is active

during Comfort and Standby mode.

In occupied mode, the temperature set point W1 is used for

the control point calculation. In unoccupied mode, the

SOFFS parameter value is added (cooling) to and subtracted

(heating) from the calculated control point for cooling and

heating.

The diagram below shows the occupied/unoccupied function

for sequence control.

defines the com-

comp

Positive

Negative

T3

C

Y

Y[%]

100

0

Energy

Recovery

Y3

Heating

Xph

Y1

CTRPH

TOA < T

CTRP1

CTRP2

Xp1

Xp2

T1+RetOffs

TOA > T

EA

1K

CTRPC

EA

Cooling

Xpc

Y2

Xwh / Xwc

T1/T2

%

100

unoccupied

occupied

SOFFS

Xph

CTRPH CTRPC

SOFFS

Xpc

CT

A fixed hysteresis of 1 K is used to switch between 0%

osition and actual Y1 signal.

Freeze Protection

If the contact connected to the freeze protection input is

open, the heating valve (Y3) will be driven into the fully open

position. The final control devices operated by the outputs

(Y1 and Y2) will be driven in the closed position.

EN0B-0301GE51 R0104 6

Page 7

R7426B,C TEMPERATURE CONTROLLER

In the case of controllers with RTC, the ON/OFF output will

be switched off.

A closed contact performs a frost recovery:

Conditions of

Outdoor Temp. T3

> 6C or T3 not

connected

Frost Recovery

Main temperature control

Setpoint W1 is temporarily raised by

< 6C

Xp1 and linearly decreased to its

normal value over approx. 10min.

Freeze protection operation has the highest priority over all

other control operations.

Dehumidification Control by Humidity

Deviation Input

Dehumidification control can also be performed using a

humidity controller. The deviation input signal X

from the humidity controller is compared with the cooling

deviation signal of the temperature control (X

with the highest cooling demand is used to control the

cooling output Y2.

received

w rh

). The signal

wc

Sequence control with two outputs for heating and one

output for cooling (YMode = 2)

Y[%]

100

Y3

Y1

0

OAIC

Heating

Xph

Y2

Cooling

Xpc

Xw

T

Sequence control with one output for heating and two

outputs for cooling (YMode = 3)

Y[%]

100

Y2 / OAIH

0

Heating

Y3

Cooling

OAIC

Y1

Xw

XpcXph

T

OUTPUT SEQUENCE OPERATION

The controllers are supplied from the factory configured for

sequence operation of heating, mixed air, and cooling

control.

NOTE: If a control range of 0...130 °F (C.04 = 1) is

selected, then only multi-stage heating (Ymode = 1)

is applicable.

The output sequence operation can be configured for the

following control applications in accordance with the

parameter setting Y1CTRF or YMode:

Sequence control for cooling with three outputs

(Y1CTRF = 0 and YMode = 1)

Y[%]

100

Y3

0

throttling range

Sequence control for heating with three outputs

(Y1CTRF = 1 and YMode = 1)

Y[%]

100

0

OAID

Y1

throttling range

Y2

Y2

OAID

Y1

Xw

Y3

Xw

OUTPUT FUNCTIONS

The R7426B controllers provide a choice of output signals

suitable for operating a range of final control devices

according to the parameter setting of YMode and YxMode

(x = 1, 2, or 3) control parameters.

3-position Output for Valve or Damper Actuators

(floating mode)

The controller converts the deviation signal to a proportional

output pulse which drives the actuators depending on the

Runtimex (x = Y1, Y2, or Y3) parameter value.

Parameter setting for Heating / Cooling Control Outputs :

YMode = 0, 1, 2 or 3; YxMode (x = 1, 2, or 3) = 0.

on

off

out1

close open

stop

An automatic synchronization function ensures correct

positioning of the actuators. This is performed by running all

actuators to the closed position periodically. The run time for

synchronization is derived by control parameter RuntimeYx

(x = 1, 2, or 3) multiplied by 1.25.

Synchronization by the controller is initiated:

after power up reset (initial start)

after 250 control steps as soon as control output is

below 5 %

if plant/system ON/OFF input is switched to OFF

out2

Y1/Y2/Y3

7 EN0B-0301GE51 R0104

Page 8

R7426B,C TEMPERATURE CONTROLLER

Electric Heat Current Valve (pwm output)

The pulse-width modulated output is suitable for driving

electric heat current valves and is controlled from the heating

signal. The interval or total cycle time is set by the control

parameter RuntimeY3.

The diagram below shows as example, 60% Output Signal

with Motor RuntimeY3 set to 50 sec: YMode = 0; Y3Mode =

3.

on

off

30 50 70 80 100 sec

out1/out2

Y3

2-stage ON/OFF Sequence Control

The R7426B controllers convert the output signal into a twostage ON/OFF sequence output signal suitable for operating

relays. Two relays can be connected to provide sequence

control of e.g. two electric heater stages.

Parameter setting for Output Switching Position:

YMode = 0; YxMode (x = 2 or 3) = 1

on

off

Step2 on

Step1 on

30

25 65 70

100

Power

out2

out1

%

Y2/Y3

4-stage ON/OFF Electric Heating or Cooling

For YMode = 2, the output sequence of Y3/Y1 is controlled

from the heating signal and the output Y2 is controlled from

the cooling signal. For YMode = 3, the output sequence of

Y3/Y1 is controlled from the cooling signal and the output Y2

is controlled from the heating signal.

The output of Y2 is operated in accordance with Y2Mode.

Parameter setting: YMode = 2 or 3, Y1Mode and Y3Mode =

4

on

off

Step1 on

25

Step2 on

40 45

Step3 on

60 65

Step4 on

8580

Power

Y1 out2

Y1 out1

Y3 out2

Y3 out1

100 %20 Y3/Y1

6-stage ON/OFF Sequence Control Heating or

Cooling

The output sequence of Y3/Y2/Y1 is controlled from one

output signal, Main Temperature Control or Cascade Control.

Parameter setting: YMode = 1,

Y1Mode, Y2Mode, and Y3Mode = 4

Y1CTRF = 0 (cooling) or 1 (heating)

Step6 on

Step5 on

Step2 on

Step1 on

Power

3-stage Binary ON/OFF Sequence Control

The R7426B controllers convert the heating signal into a

three-stage binary ON/OFF sequence as shown in the

following diagram.

Parameter setting for Output Switching Position:

YMode = 0; Y3Mode = 2

off

on

Step1 on

25

Step2 on

Step3 on

75

70 100 %20 5045

Power

out2

out1

Y3

on

off

6 signal sequence of

Y3/Y2/Y1 out1/out2

15 100 %10

25 30

70 85

75

90

Y3/Y2/Y1

15-stage Binary ON/OFF Electric Heating and

Cooling

The output sequence of Y3/Y1 is controlled from the heating

signal. The output sequence of Y2 is controlled from the

cooling signal.

The output of Y2 is operated in accordance with Y2Mode.

Parameter setting: YMode=5

Step15 on

Step14 on

Step2 on

Step1 on

on

off

4.5 100 %

4 signal sequence of

Y3/Y1 out1/out2

11

6.5 Y3/Y1

13

95.5

89

91

Power

97.5

EN0B-0301GE51 R0104 8

Page 9

R7426B,C TEMPERATURE CONTROLLER

Two-Position Damper Control

If the value of the control parameter YMode = 4, the damper

output signal Y1 operates as two-position control as follows:

If the controller mode OFF (Comfort- Standby- or Night-

mode), the output signal Y1 is set to 100%.

If the controller mode = OFF, the output signal Y1 is set to

0%.

The output sequence of Y2/Y3 operates as Temperature

Sequence Control with Heating and Cooling.

ON/OFF Output

The ON/OFF output is provided to switch fans, pumps, or

other MicroniK 200 controller without RTC.

If one of the following conditions occur the controller switches

the ON/OFF output from OFF to ON after a fixed 3-minute

time delay:

The controller mode OFF (Comfort, Standby, or Night

mode).

The night cycle program is active.

The optimum start program is active.

If one of the following conditions occur, the controller

switches the ON/OFF output from ON to OFF:

The controller mode = OFF.

The freeze protection input is active.

The following function will be active in flow water

temperature applications if the configuration parameter

Ctrltyp = Hi2:

The controller switches the ON/OFF output from ON to

OFF if the outside air temperature is above 8C and the

output signal Y1 = 0% for more than 5 minutes during

Comfort, Standby, or Night mode.

Analog Outputs on R7426C, only

Three output control signals are provided to control valve or

damper actuators or E/P transducers for pneumatic

actuators.

The full output range is 0...12 Vdc. The control range is

common to all outputs and is software-configurable using the

control parameter YRange to either 2...10 Vdc or 0...10 Vdc.

Each output can be selected for direct or reverse acting.

ADJUSTMENTS

Control Point / Setpoint Adjustment

(CPATYP)

The control or setpoint can be adjusted via the internal or an

external potentiometer connected to the CPA/SPA input. The

CPA/SPA type is selected using the control parameter

CPATYP (see page 2, Technical Data).

Calibration of Temperature Sensors

(T1CAL, T2CAL, and T3CAL)

In case of an offset as a result of long wiring lengths, the

temperature sensor inputs (T1, T2 and T3) can be adjusted

separately by the control parameters T1CAL, T2CAL, and

T3CAL.

WIRING

Wiring run

From controller to all

input and output

devices

Offset for temperature sensors due to wire resistance per

10 m distance from sensor to controller:

Type of wire

2

0.5mm

(AWG20)

1.0mm

(AWG17)

1.5mm

(AWG15)

(0.324F)

2

(0.162F)

2

(0.108F)

Type of

wires

local

standard

Temperature offset

Pt 1000 BALCO 500 NTC

0.18C

0.09C

0.06C

(0.54F)

0.15C

(0.27F)

(0.18F)

Length max.

1.0 mm

100 m 150 m

0.3C

0.1C

2

negligible

1.5 mm

2

9 EN0B-0301GE51 R0104

Page 10

R7426B,C TEMPERATURE CONTROLLER

CONNECTIONS

200mV/%rh

24 V

R7426B

15

16

17

24V

18

19

2

20

e

p

o

24V

21

22

s

o

l

c

e

p

o

23

24

24V

s

o

l

c

25

26

e

p

o

24V

27

28

s

o

l

c

R7426C

*

i

e

r

S

r

P

o

f

Occupancy

T1

T2

T3

Freeze

prot.

f

a

r

t

e

I

n

l

a

u

B

l

e

n

a

e

c

s

X

W

r

h

CPA/SPA

T1

1

2

3

4

V

4

2

T

U

/

O

n

1

Y

1

U

T

/

O

e

2

T

O

U

/

n

2

Y

T

1

U

/

O

e

2

T

U

/

O

n

3

Y

1

T

O

U

/

e

T2

T3

5

6

7

8

9

10

11

12

B

13

A

14

= 0V

Occupancy

*

a

i

e

r

S

P

r

o

f

Freeze

prot.

I

n

l

e

n

a

T1

T2

T3

t

200mV/%rh

24 V

e

c

r

f

a

e

s

u

B

l

15

16

17

18

19

20

21

22

23

24

25

26

27

28

X

W

r

h

24V

V

4

2

V

0

.

.

1

.

/

2

0

24V

V

4

2

V

0

.

.

.

1

/

2

0

24V

V

4

2

V

0

.

.

.

1

/

2

0

24V

V

4

2

*

R7426B1014,C1012

On/Off Output

Y

1

2

Y

3

Y

R7426B2012,C2010

ON/OFF

24V

10

CPA/SPA

T1

T2

T3

B

A

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

= 0V

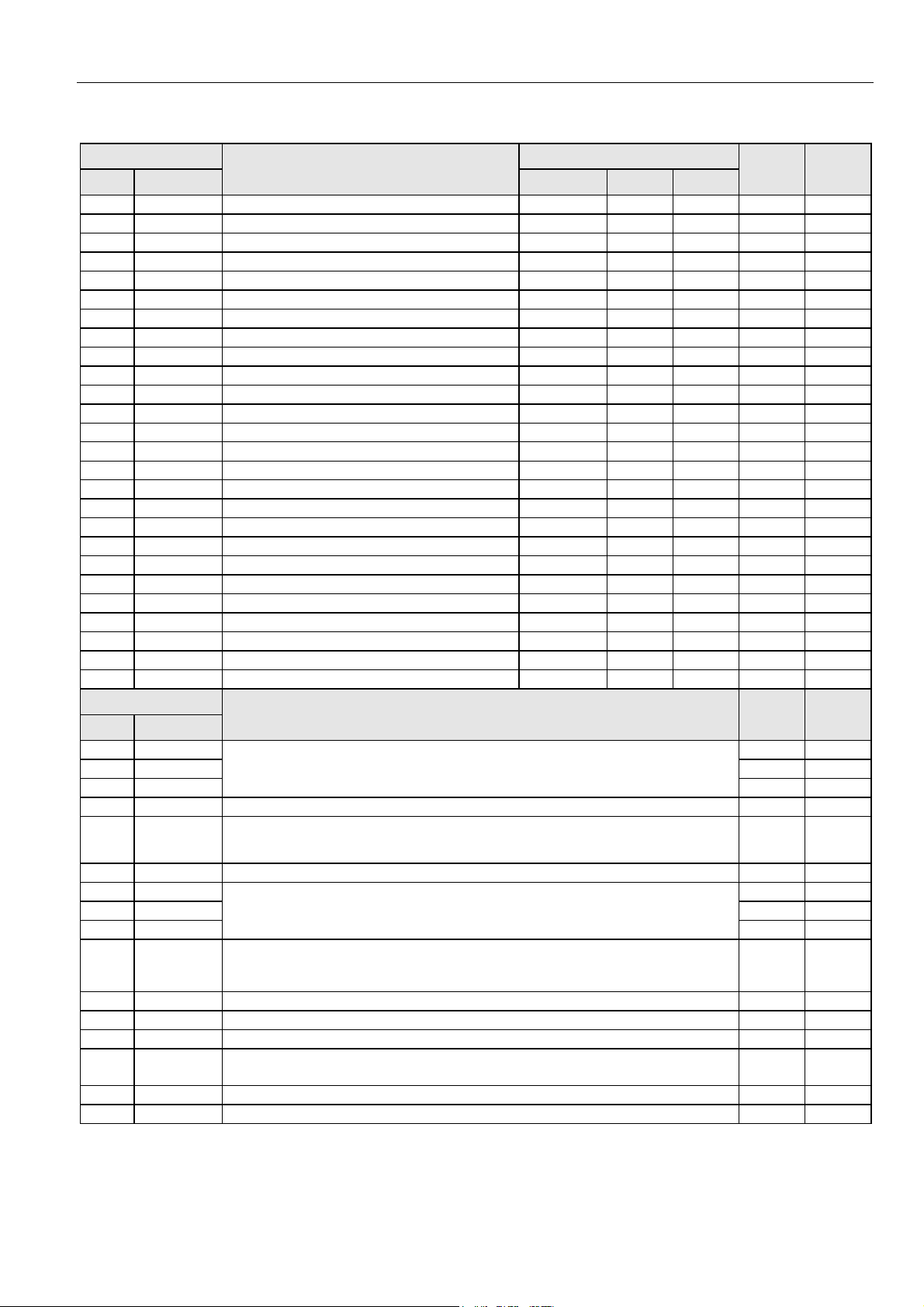

W 303

Jumper1)State Description

W303

1)

Default jumper position = closed

2)

Cut (open) jumper W303 only if the T3 input is fed from

open

closed

2)

T3 supplied by this controller

T3 supplied from another controller

another controller (parallel connection, max. 6 devices).

This disconnects the T3 input from the internal power

supply.

Fig. 3. Connections and Jumper coding

CAUTION

Outputs are not isolated from power supply

Observe correct phasing with 24Vac power

supply

EN0B-0301GE51 R0104 10

Page 11

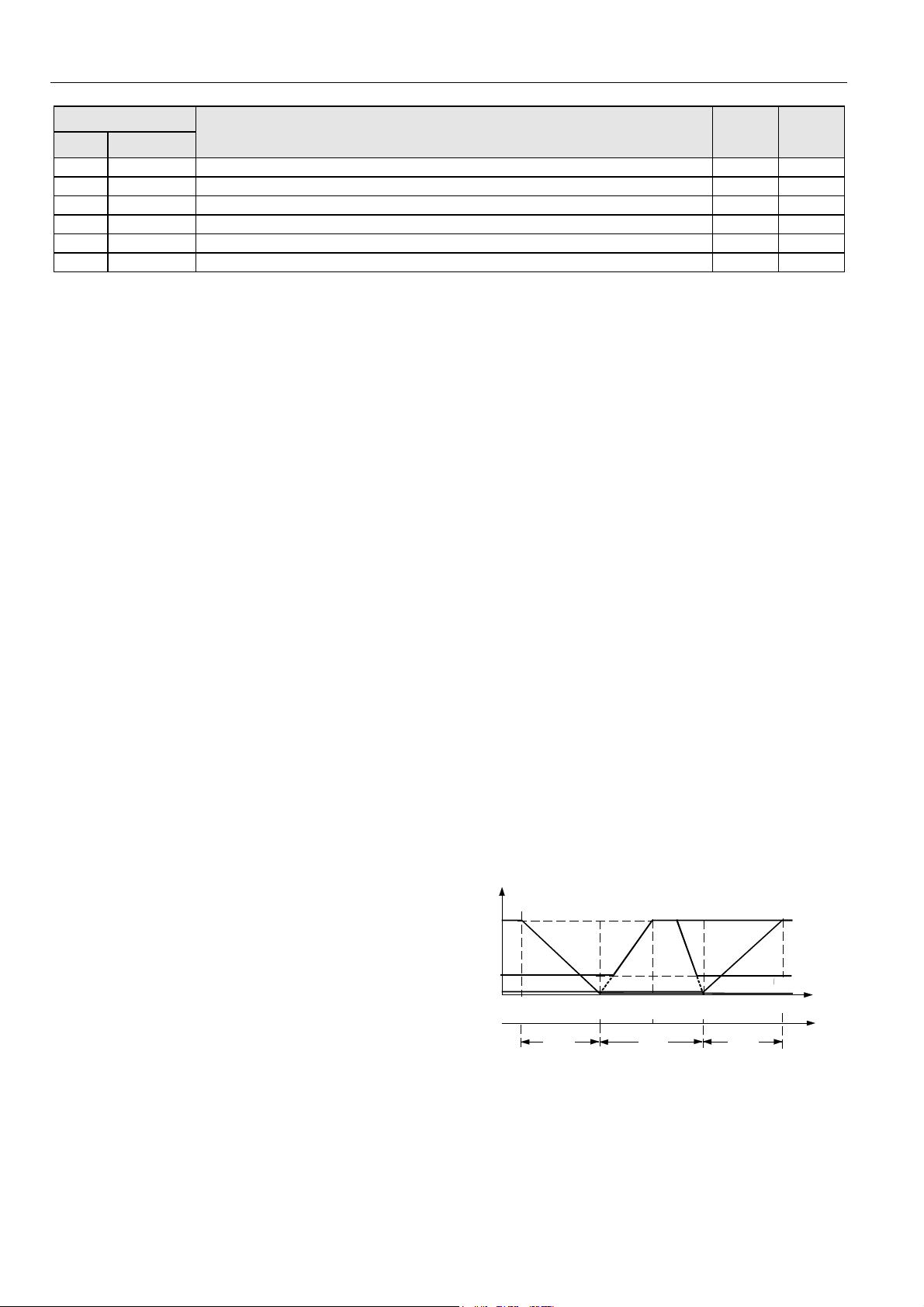

MOUNTING AND DIMENSIONS

87 +

/-0.

2

R7426B,C TEMPERATURE CONTROLLER

All dimensions in mm.

121 +/- 0.3

= =

==

3.5

105

152

Honeywell

SEL

SET

198 +/-0.3

170 +/-0.3

= =

43

==

3.5

wall mounting

approx. 45 x 35

(cut-out for cables)

Fig. 4. Mounting and dimensions

(when mounting on DIN rail)

4.5

180 +/-0.2

front panel mounting

110 +/-0.3

130 +/-0.3

11 EN0B-0301GE51 R0104

Page 12

R7426B,C TEMPERATURE CONTROLLER

HONEYWELL

Automation and Control Solutions

Honeywell GmbH

Böblinger Straße 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany Manufacturing location certified to

EN0B-0301GE51 R0104

Loading...

Loading...