Page 1

69-2467EFS-05

R7284B,P,U,G

Electronic Oil Primary,

EnviraCOM™ Enabled

INSTALLATION INSTRUCTIONS

APPLICATION

The R7284B,P,U,G Electronic Oil Primary is a line

voltage, safety rated, interrupted and intermittent ignition

oil primary control for residential oil fired burners used in

boilers, forced air furnaces and water heaters. The

R7284B,P,U,G used with a cad cell flame sensor

operates an oil burner, spark igniter, and optional oil

valve. The control works with a low voltage and optional

high voltage thermostat. The primary controls fuel oil,

senses flame, controls ignition spark (either interrupted

or intermittent) and notifies through the EnviraCOM™

bus a remote alarm circuit when in lockout.

The R7284 Series of Oil Primary Controls can be used

with both hydronic and forced air systems. When used

with hydronic systems, line voltage switching Aquastat®

Controllers normally provide for the starting and stopping

of the combustion sequences. With forced air systems,

both mechanical and electronic low voltage thermostats

control the starting and stopping of the combustion

process.

Some hydronic and forced air systems require a delayed

valve-on and burner motor-off delay. The R7284

operates an oil valve that prevents the flow of oil when

the burner motor is running prior to combustion (delayed

valve-on) and when the burner motor is running after

combustion (burner motor-off delay).

The R7284 models are intended for use only on oil

burning appliances which do not require prepurge and

post-purge as a safety related function as defined in

UL296. The valve-on delay and burner motor-off delay in

this control are intended only to help establish draft and

reduce oil after-drip related problems.

EnviraCOM™ enabled R7284’s can be used with

EnviraLink® remote monitoring systems and hand-held

diagnostics. Use only R7284P and U models for

networking with other EnviraCOM™ enabled devices.

FEATURES

The advanced interface has a two-line display used to

configure device parameters, retrieve diagnostic

information, and display system status.

The basic interface has a single LED used to display

error codes and system status.

In general, the “i” button cycles through the display

options and acts as an “enter” key (in setup modes).

Thermostat(s)

The oil primaries are compatible with both standard

thermostats and EnviraCOM™ communicating

thermostats.

Limited Recycle

This feature limits the number of recycle trials (for each

call for heat) to a maximum of three trials. If the flame is

lost three times and does not successfully satisfy a call

for heat, the R7284 locks out.

Pump Priming Cycle

To facilitate purging air from the oil lines and filters, the

R7284 can be placed in a purge routine by pressing and

releasing the up arrow button during the Trial For

Ignition.

In the advanced interface “PUMP PRIME” is displayed

on the display along with the time left on the Trial for

Ignition (TFI). Pressing the up arrow button adds a

minute to the TFI time for a maximum of 10 additional

minutes (press the up arrow button 10 times). Pressing

the down arrow button subtracts a minute from the TFI

time.

There is no visual indication for the basic interface

control and the purge timing is limited to five minutes.

Disable Function

Pressing and holding the “i” button will disable all control

functions until 3 seconds after the button is released.

User Interface

There are two user interfaces: basic and advanced. Both

interfaces consist of three buttons: , , and “i.”

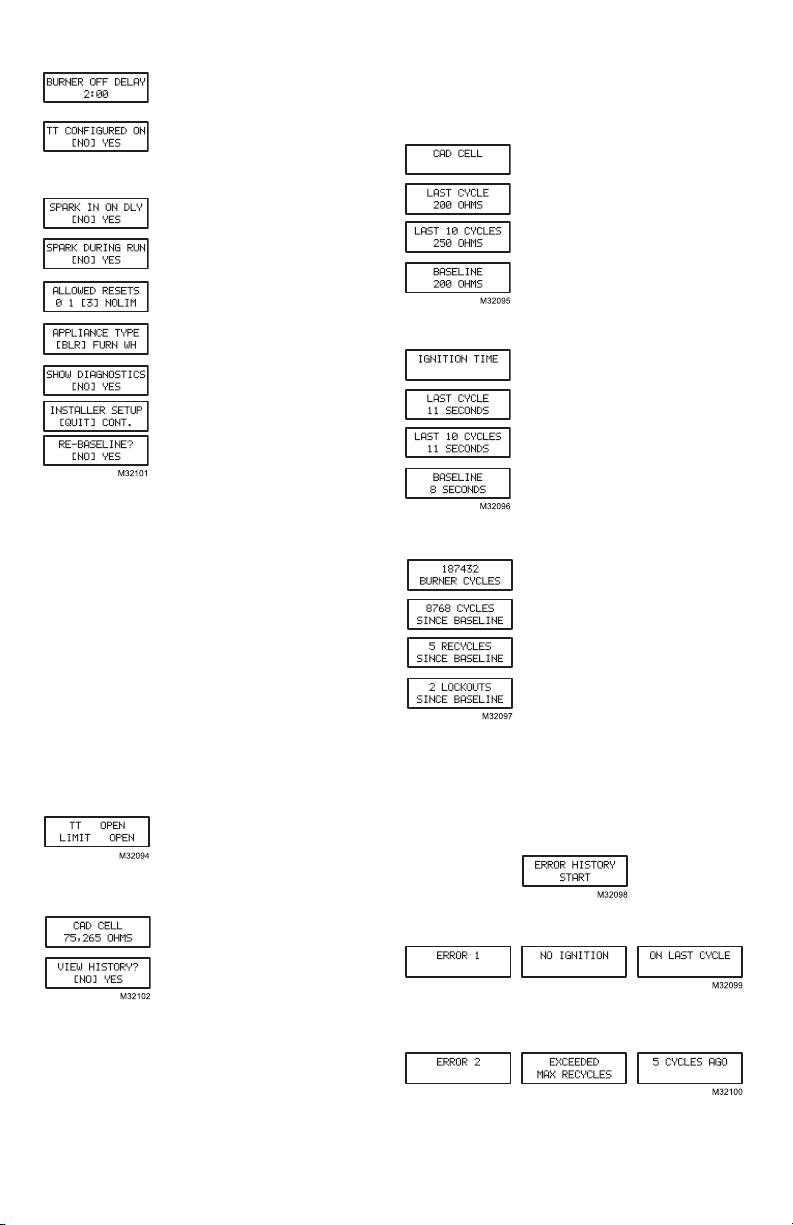

Lockout Modes

The R7284 has three types of lockout modes that are

entered when an error is encountered:

Page 2

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

WARNING

• Soft Lockout: Caused by a temporary internal error

such as low voltage. The control recovers

automatically after the error is no longer detected.

• Hard Lockout: Caused by a failure internal to the

control or by a system fault such as flame out of

sequence. A Hard Lockout will result in a no heat

condition. To reset from Hard Lockout press and hold

the “i” button for 2 seconds.

• Restricted Lockout: Caused by a number of

consecutive hard lockouts on the same heat cycle. To

reset from a Restricted Lockout press and hold the “i”

button for ten seconds.

Cad Cell Resistance

Cad cell resistance can be checked without using an ohm

meter.

Basic Interface:

Press and release the “i” button. The resulting flashes

indicate the resistance. See Table 3.

Advanced Interface:

The cad cell resistance is shown on the display.

Valve-on Delays/Blower Motor-off Delays

Select models may have fixed or adjustable delays for

valve open or blower motor off. The safety circuits will

check for flame during these delays and, if a flame is

present, will switch the control to lockout.

SPECIFICATIONS

Models:

Table 1 lists the major features for the R7284.

Timing:

Valve-on Delay: 0–30 seconds

Burner Off Delay: 0–8 minutes

Lockout: 15, 30 or 45 seconds.

Recycle: 60 seconds (fixed).

Ignition Carryover: 10 seconds (fixed).

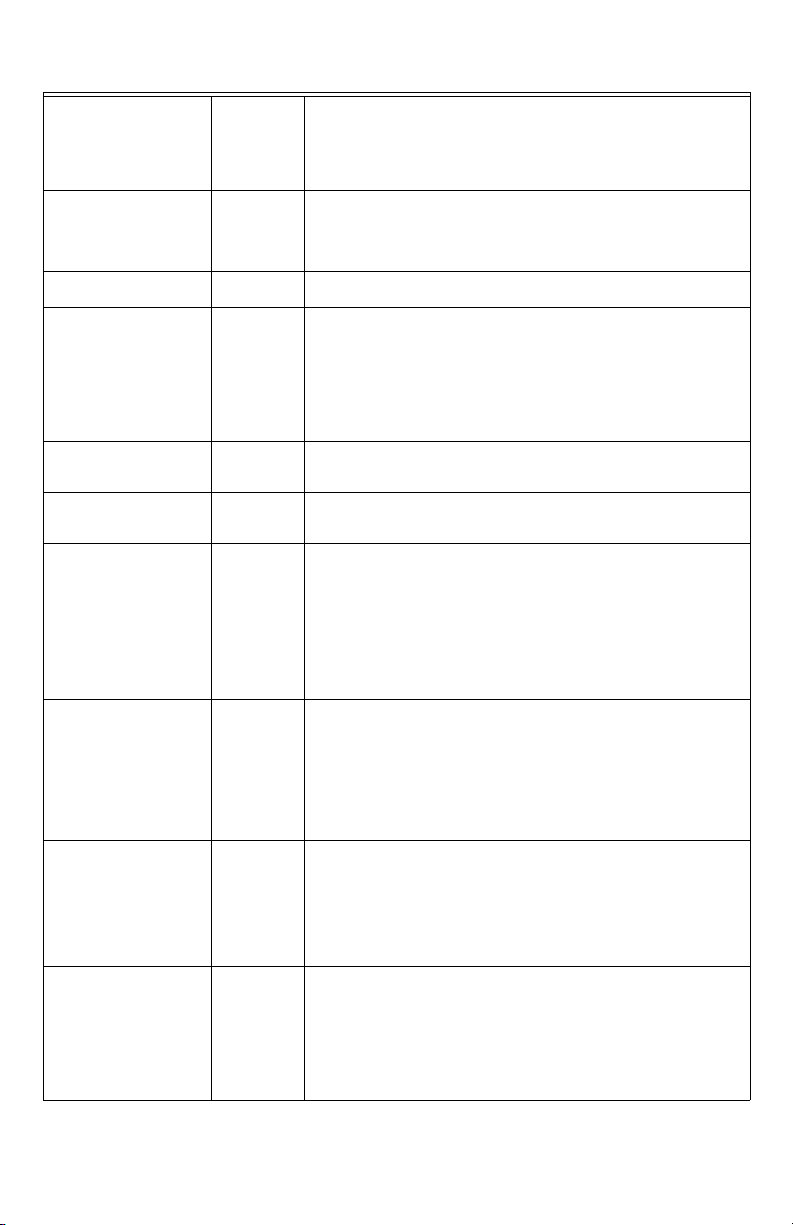

Table 1. R7284 Models.

Model Limit Valve Notes

R7284B No Yes Valve on delay only

R7284G No No No on/off delays, intermittent ignition (wire igniter together with motor)

R7284P Yes Yes On and off delays

R7284U Yes Yes On and off delays

NOTE: Some models have adjustable Valve-on Delay,

Burner Off Delay, and Lockout timings.

Electrical Ratings:

Inputs:

Voltage: 102 to 132 Vac, 120 Vac nominal.

Current: 0.5A plus burner motor, valve and igniter

loads.

Frequency: 60 Hz.

Outputs:

Relay Contacts:

Burner: 120 Vac, 10 full load amperes (FLA), 60 locked

rotor amperes (LRA).

Valve: 120 Vac, 1A.

Igniter: 120 Vac, 3 A.

Low Voltage Shutdown: 80 Vac

Thermostat Current Available: 100 mA.

EnviraCOM™ Current Available: 150 mA.

NOTE: Reduce burner FLA rating by igniter load. For

example, if the igniter draws 3A (120 Vac, 360

VA), reduce the burner motor FLA to 7A.

Typical Component Wire Color Code:

White: Neutral.

Black: Line.

Orange: Motor.

Blue or Blue w/White Stripe: Igniter.

Violet: Valve.

Red: Limit.

NOTE: The R7284 is provided with 1/4” quick-connect

terminals.

Environmental Ratings:

Operating/Shipping Temperature: -40°F to +150°F

(-40°C to +66°C).

Display text may not be visible below -4°F (-20°C)

Humidity: 0% to 95% relative humidity at 104°F (40°C),

noncondensing.

Accessories:

W8735S3000 Alarm Module

Approvals:

Underwriters Laboratories Inc.: Recognized (File MP268).

Canadian Underwriters Laboratories Inc.

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow

instructions can damage the product or cause a

hazardous condition.

2. Check ratings given in these instructions and on the

product to make sure the product is suitable for your

application.

3. Make sure the installer is a trained, experienced

service technician.

69-2467EFS—05 2

4. Use these instructions to check out the product

operation after installation.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage. More than one disconnect

may be involved.

Page 3

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

WARNING

WARNING

R7284

BURNER

M32085

M32178

CAD CELL CONNECTION

LINE VOLTAGE CONNECTIONS

Location

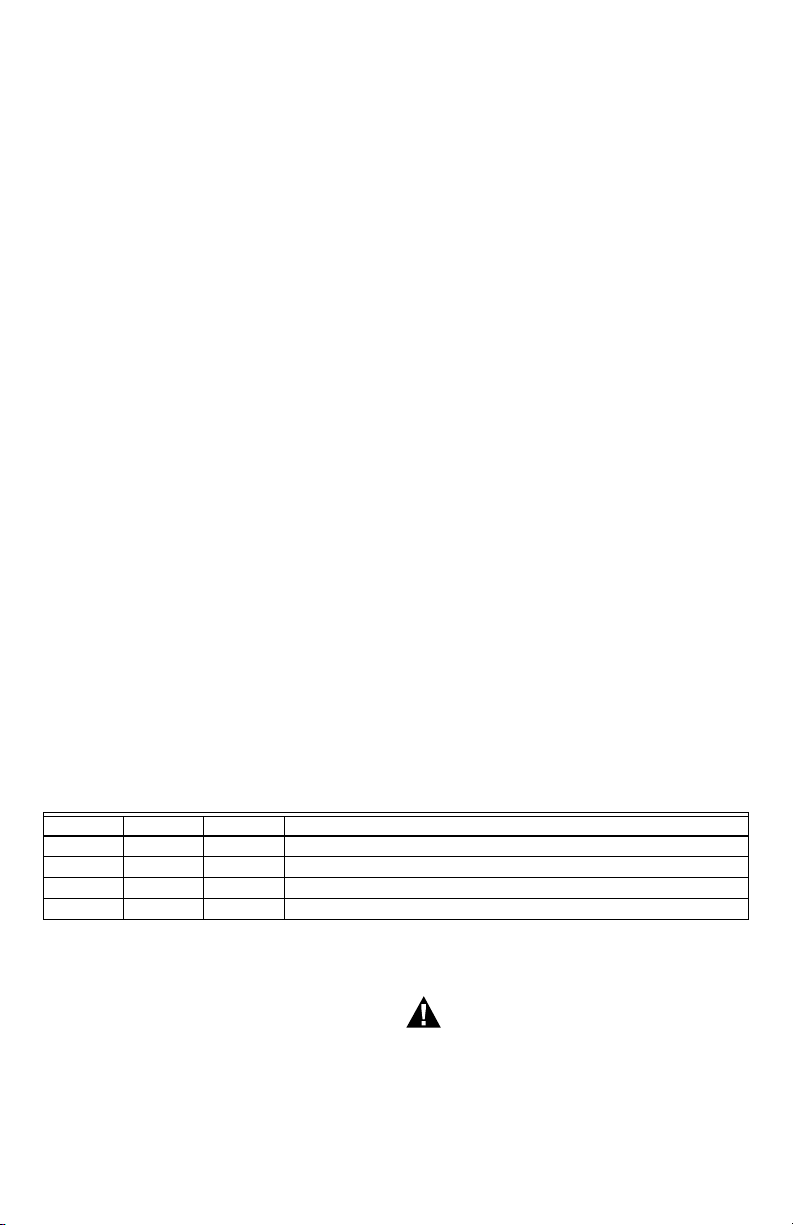

1. Mount on a 4 in. by 4 in. junction box, directly on the

main burner, or inside the appliance cabinet. In

replacement applications, mount in the same

location as the old control. See Fig. 1. Make sure

the operating temperatures are within the ambient

temperature range (see Specifications section).

2. Before mounting the control, make line voltage con-

nections as shown in Fig. 2 through 10. Splice lines

with solderless connectors. Do not exceed load ratings shown on the device label.

3. If necessary, use the control as a template to mark

and drill new mounting holes.

4. Mount the device using No. 6 screws (not included).

WIRING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

to prevent electrical shock or equipment damage.

More than one disconnect may be involved.

1. Make sure wiring complies with all local codes and

ordinances.

2. Check to make sure that line voltage wiring is

properly connected. Refer to oil primary label and

appliance wiring diagram for color codes.

3. After mounting make low voltage connections to the

screw terminals (see Fig. 2 through 10).

4. Strip leads 3/8 in. (10 mm) and insert under terminal

screw.

5. Connect thermostat leads to T-T (or 1, 2, 3 if

EnviraCOM™ is present), if required by installation.

CHECKOUT

Start System

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Make sure the combustion chamber is free of oil

and/or oil vapor before starting system.

1. Open hand valve in oil supply line.

2. Make sure system is powered. Check circuit

breaker or fuse and close system switch, if

provided.

3. Set thermostat to call for heat.

4. Make sure burner lights and operates until call for

heat ends. Note cad cell resistance while running.

5. Verify that burner turns off when thermostat call for

heat is satisfied.

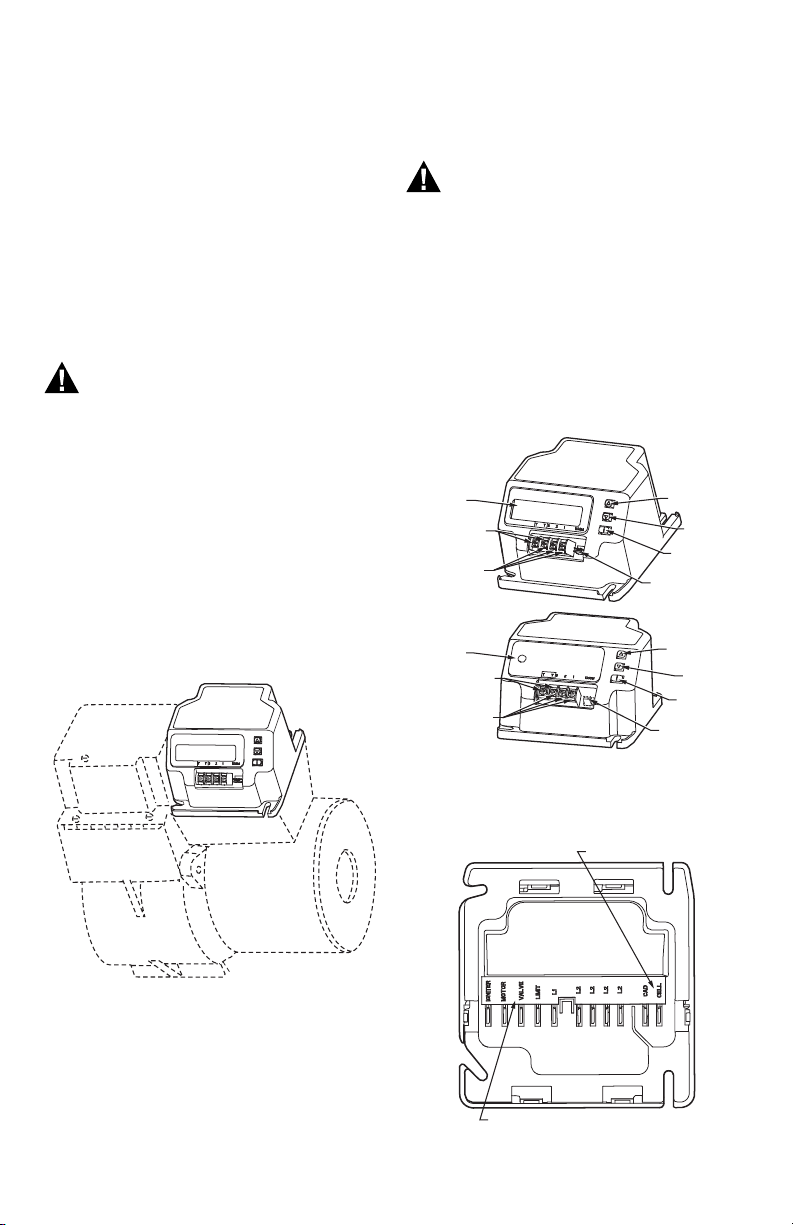

DISPLAY

THERMOSTAT

TERMINALS

ENVIRACOM

TERMINALS

DISPLAY

THERMOSTAT

TERMINALS

ENVIRACOM

TERMINALS

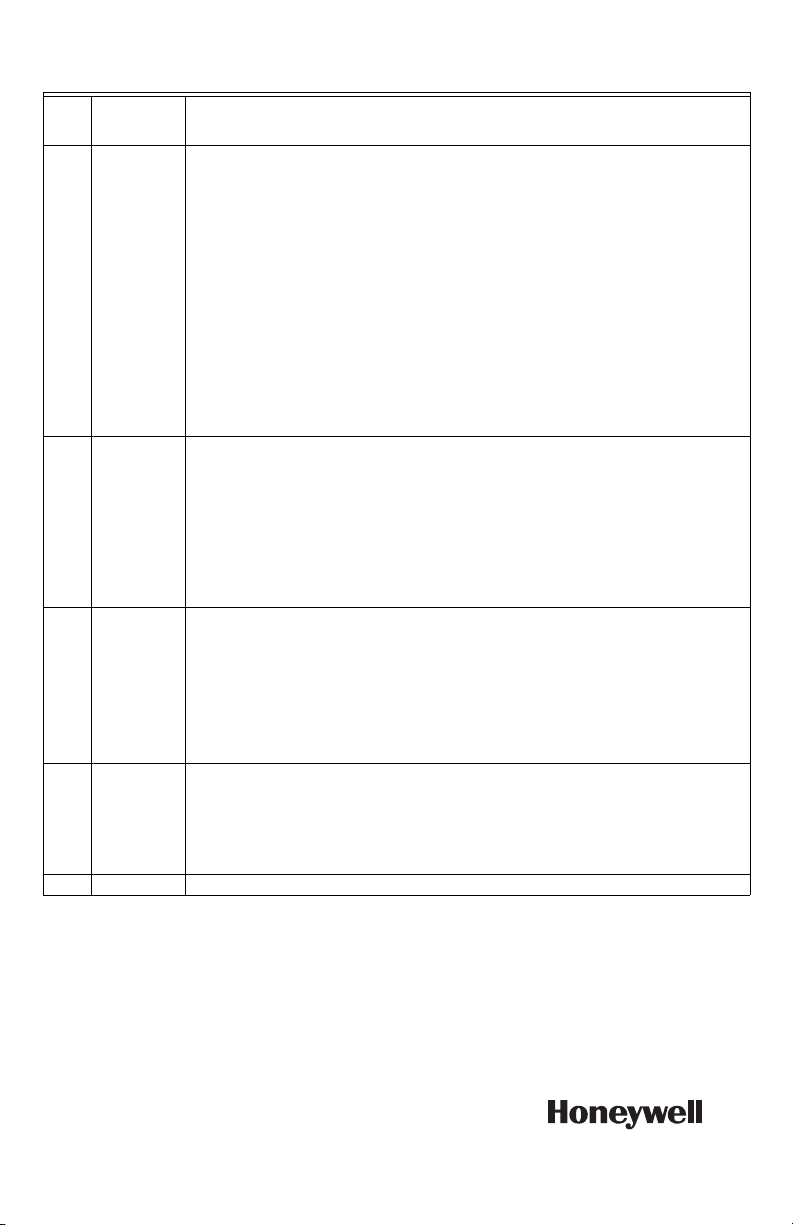

Fig. 2. R7284 terminals, connectors, LED, reset button

and DIP switch locations.

UP BUTTON

DOWN

BUTTON

i BUTTON

ENVIRACOM

DIAGNOSTIC

PLUG

UP BUTTON

DOWN

BUTTON

i BUTTON

ENVIRACOM

DIAGNOSTIC

PLUG

M32146

Fig. 1. Mounting R7284 on junction box.

Fig. 3. R7284 wiring connections.

3 69-2467EFS—05

Page 4

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

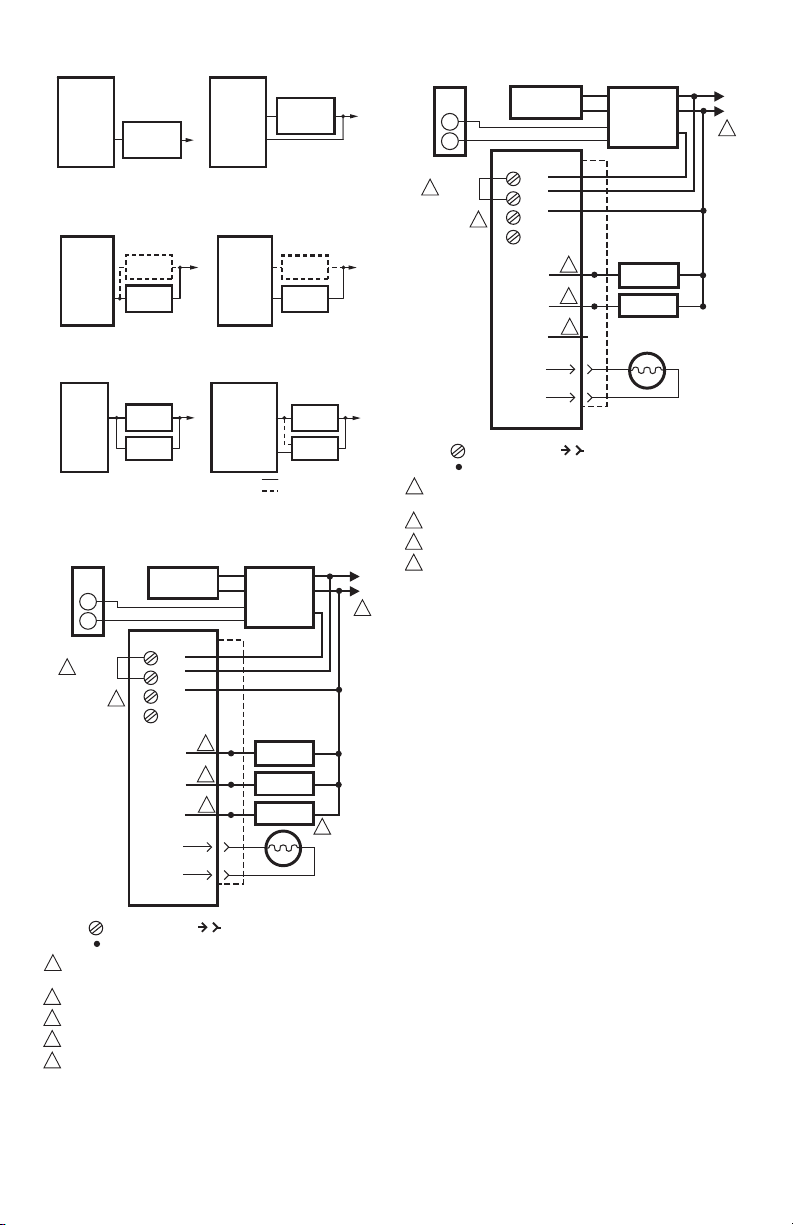

R7284P, U

L1

L1

LIMIT

R7284B, G

L1

AQUASTAT

OR OTHER

LIMIT

L1

……

……

AQUASTAT

OR OTHER

LIMIT

M32179

VALVE

R7284B, P, U

BURNER

MOTOR

L2

R7284A, G

BURNER

MOTOR

L2

……

……

BURNER

MOTOR

BURNER

MOTOR

VALVE

VALVE

M32180

R7284B, P, U

L2

IGNITER

IGNITER

INTERRUPTED IGNITION

INTERMITTENT IGNITION

R7284G

BURNER

MOTOR

L2

IGNITER

INTERMITTENT

IGNITION

……

……

BURNER

MOTOR

BURNER

MOTOR

BURNER

MOTOR

M32181

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

THE JUMPER MAY BE OMITTED IF THE R7284 IS CONFIGURED TO IGNORE

THE TT TERMINALS.

1

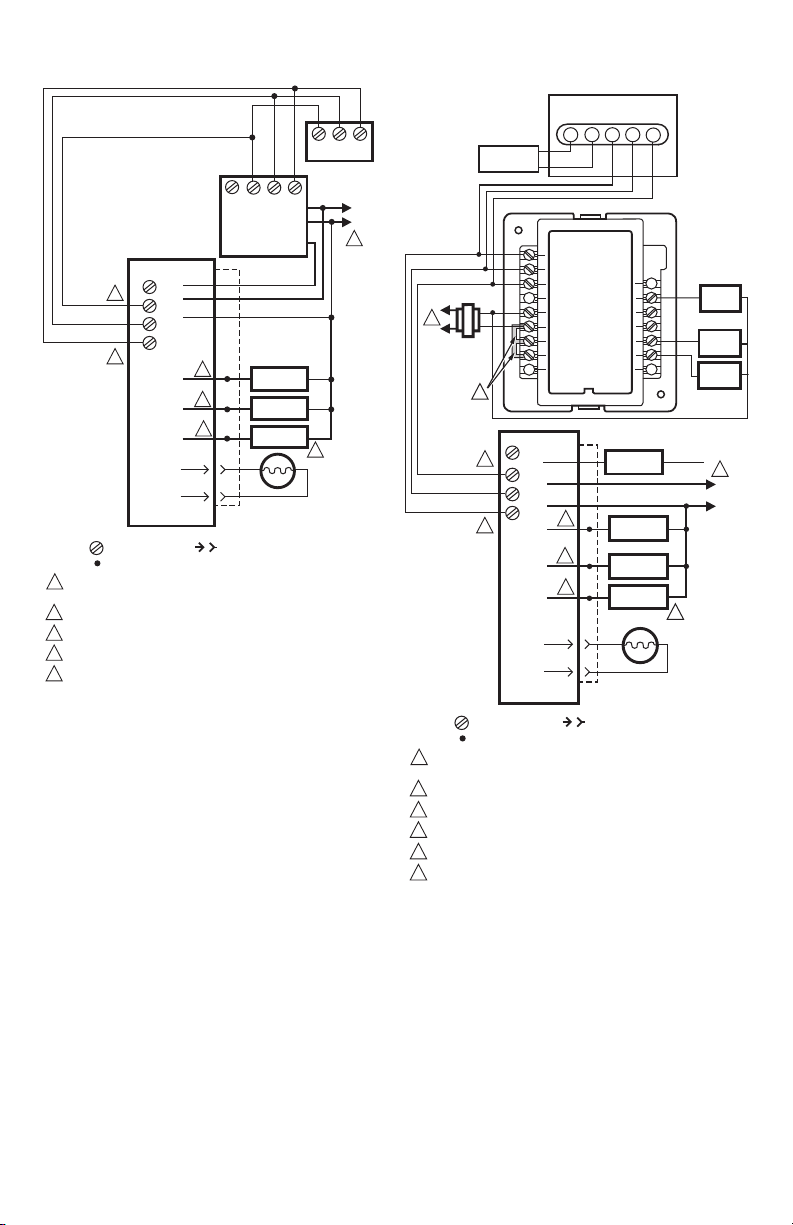

R7284

IGNITER

M32191

L1

1

CAD

CELL

2

3

4

3

4

2

2

2

BURNER

MOTOR

CIRCULATION

PUMP

L2

B2

C2

C1

BURNER

MOTOR

IGNITER

VALVE

CAD

CELL

L1

B1

LIMIT

JUNCTION

BOX

T

T

3

2

1

T

T

LEGEND:

SCREW TERMINAL

1/4 IN. QUICK CONNECT TERMINAL

SOLDERLESS WIRE CONNECTOR

THERMOSTAT

L8148A,C

JUMPER

AQUASTAT®

CONTROLLER

R

W

ENVIRACOM™

TERMINAL

Fig. 4. R7284 Limit wiring for line voltage thermostat,

Aquastat, or other Limit.

Fig. 5. R7284 wiring for optional oil valve.

Fig. 6. R7284 igniter wiring.

C1

CIRCULATION

R

W

THERMOSTAT

5

JUMPER

ENVIRACOM™

TERMINAL

LEGEND:

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

2

VALVE IS OPTIONAL ON SPECIFIC MODELS.

3

4

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

5

THE JUMPER MAY BE OMITTED IF THE R7284 IS CONFIGURED TO IGNORE

THE TT TERMINALS.

Fig. 7. Wiring R7284P,U without EnviraCOM™, for

69-2467EFS—05 4

PUMP

R7284

LIMIT

T

L1

T

3

L2

2

4

1

BURNER

MOTOR

IGNITER

VALVE

SCREW TERMINAL

SOLDERLESS WIRE CONNECTOR

CAD

CELL

typical oil-fired boiler.

AQUASTAT®

CONTROLLER

C2

T

T

L8148A,C

2

2

2

BURNER

MOTOR

IGNITER

VALVE

CAD

CELL

JUNCTION

BOX

1/4 IN. QUICK CONNECT TERMINAL

B2

B1

L1

L2

1

3

M32182

Fig. 8. Wiring R7284U without EnviraCOM™, for

typical oil-fired boiler.

Page 5

T

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

VALVE IS OPTIONAL ON SPECIFIC MODELS.

FACTORY INSTALLER JUMPERS.

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

DO NOT CONNECT THE JUMPER ACROSS THE TT TERMINALS OR

CONFIGURE THE INTERNAL TT SETTING TO "YES" WHEN THE OIL

PRIMARY AND AQUASTAT ARE CONNECTED VIA THE ENVIRACOM BUS.

1

M32184B

2

3

4

5

6

LEGEND:

SCREW TERMINAL

1/4 IN. QUICK CONNECT TERMINAL

SOLDERLESS WIRE CONNECTOR

L2

R7284

IGNITOR

L1

HOT

1

2

2

CAD

CELL

BURNER

MOTOR

L2

BURNER

MOTOR

IGNITOR

CAD

CELL

L1

JUNCTION

BOX

T

T

3

2

1

LIMIT

LIMIT

VALVE

L1

(HOT)

L2

COOL 1

RELAY

FAN

RELAY

OT

OT

2

1

3

C7089B

OUTDOOR

TEMPERATURE

SENSOR

T8635L

W8635A

C

R

R

H

R

C

1

2

3

Y2

W2

Y1

G

W1

COOL 2

RELAY

4

SYSTEM

TRANSFORMER

1

3

5

ENVIRACOM™

TERMINAL

VALVE

2

6

AQUASTAT®

CONTROLLER

R7284

LIMIT

T

5

4

ENVIRACOM™

TERMINAL

SCREW TERMINAL

LEGEND:

SOLDERLESS WIRE CONNECTOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

3

VALVE IS OPTIONAL ON SPECIFIC MODELS.

4

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

5

DO NOT CONNECT THE JUMPER ACROSS THE TT TERMINALS OR

CONFIGURE THE INTERNAL TT SETTING TO "YES" WHEN THE OIL

PRIMARY AND AQUASTAT ARE CONNECTED VIA THE ENVIRACOM BUS.

Fig. 9. Wiring R7284P,U with EnviraCOM™

connections, for typical oil-fired boiler.

IMPORTANT

When the R7284 Oil Primary is communicating

to the L7224/L7248 Aquastat via the EnviraCOM

bus, do not jumper the TT terminals or configure

the internal TT setting to "YES". Improper

burner operation will result.

L1

T

3

L2

2

1

BURNER

MOTOR

IGNITOR

VALVE

CAD

CELL

L7224/48

2

2

2

BURNER

MOTOR

IGNITOR

VALVE

CAD

CELL

JUNCTION

BOX

1/4 IN. QUICK CONNECT TERMINAL

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

1 2 3

12T/3

TH9421C

VisionPRO IAQ

L1

3

1

M32183A

L2

Fig. 10. Typical wiring diagram for EnviraCOM™

enabled thermostat and R7284P,U for an

oil-fired forced-air system.

IMPORTANT

System as shown in Fig. 10 is phase/polarity

sensitive. Make sure all input power is in the

same phase.

5 69-2467EFS—05

B2

B1

Page 6

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

ADVANCED USER INTERFACE

i

i

i

(CONT. SELECTED)

UP/DOWN

i

i

(YES SELECTED)

CAD CELL HISTORY

IGNITION TIME

HISTORY

CYCLE COUNTS

i

i

i

i

(NO SELECTED)

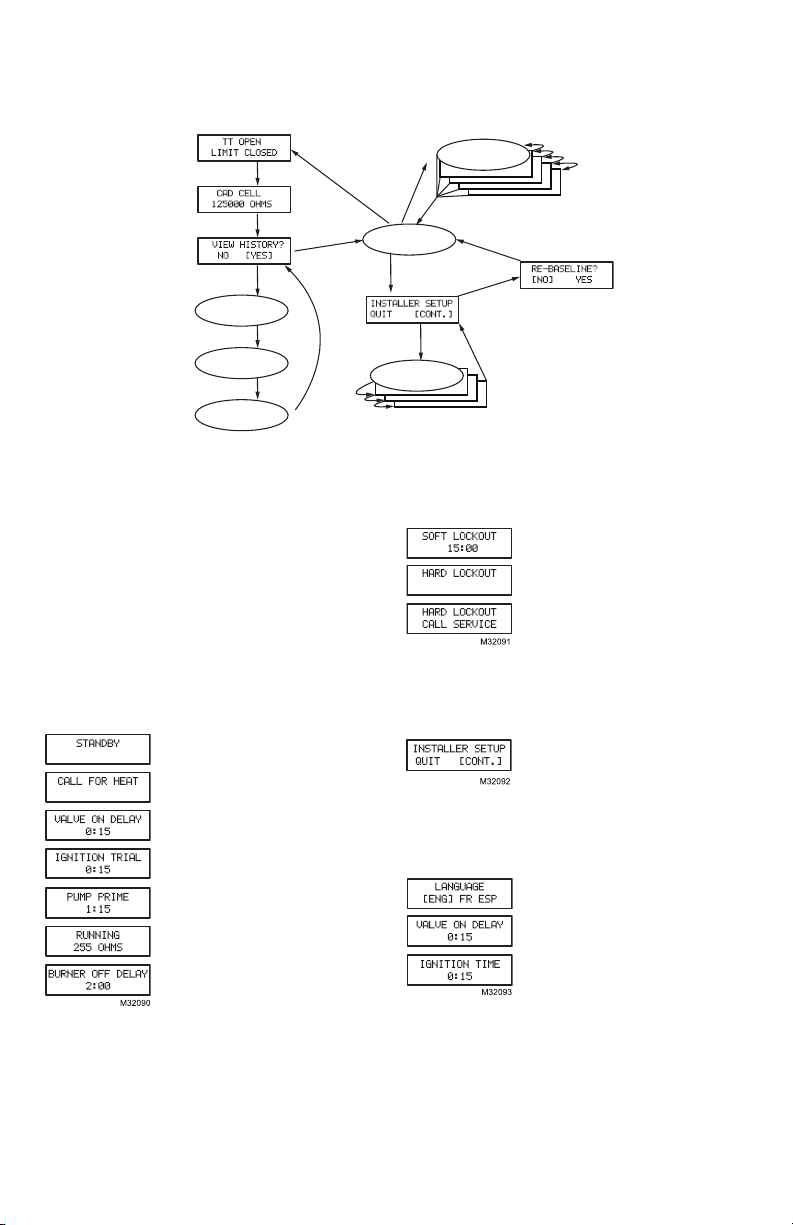

Fig. 11. User interface overview.

Home Screens

Pressing the “i” button longer than 2 seconds in states

other than Standby Interrupts control operation.

Once the held key is released the count down begins.

• Holding all 3 buttons longer than 2 seconds in any

state goes to Installer Setup (ISU).

• Pressing “i” in any state enters the Diagnostic screen

(if diagnostics are enabled).

• Pressing up or down in any screen enters Error History

(if diagnostics are enabled).

Below is a typical progression of screens through a

normal cycle.

Pressing up or down during the

Ignition Trial enters pump prime.

Each press of the up button adds a

minute, each press of the down

button subtracts a minute from the

pump prime time.

ERROR HISTORY

i

HOME SCREEN

HOLD ALL

3 BUTTONS

i

INSTALLER SETUP

SCREENS

If at any point there is an event generating a lockout, one

of the following screens will be displayed.

i

(EXIT SELECTED)

i

UP/DOWN

i

M32103A

Control is in Soft Lockout. Control will

recover when error clears or after

specified time.

Control is in Hard Lockout. Hold “i” for

at least 2 seconds to reset.

Hold the “i” button longer than 10

seconds to return to Standby.

Installer Setup

Installer setup is entered by pushing all three buttons

simultaneously for 2 seconds.

able in all models. Parameters not available for

adjustment will display “Locked” when an

attempt is made to modify them.

If QUIT is selected, an “i” button press

displays the Re-baseline option.

If CONT is selected, an “i” button

press goes to “Installer Setup”.

NOTE:Not all parameters are adjust-

Select between English, French, or

Spanish by using the up or down

buttons and the “i” button to select

Adjustment of the Valve On Delay in

five second increments.

Ignition (lockout) Time adjustment.

69-2467EFS—05 6

NOTE: The Ignition Time is only available for adjustment

during the first 100 cycles of operation. After 100

cycles the Ignition Time is locked in and can no

longer be adjusted.

Page 7

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

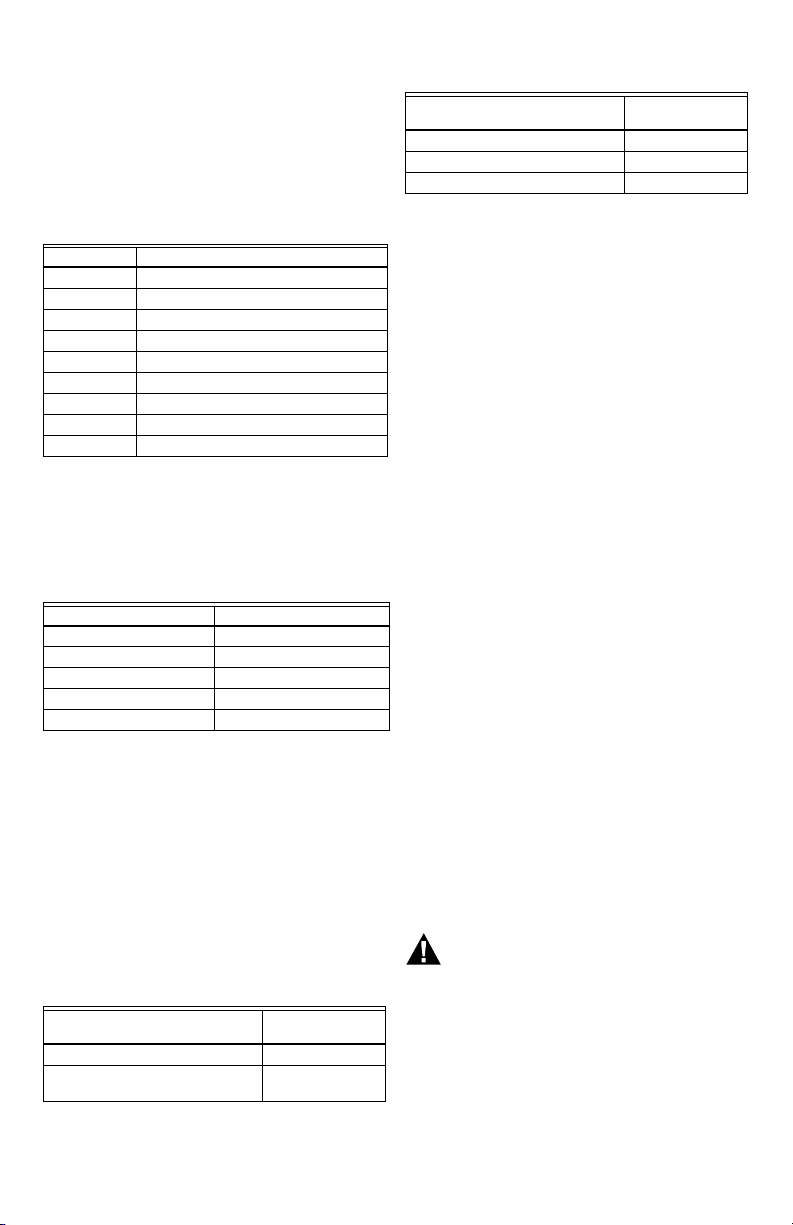

Adjustment of the Burner Off Delay.

Configuration of the TT terminals vs.

an “internal jumper.” Configure the TT

setting to "NO" when connecting the

oil primary to the L7224/L7248

Aquastat® via the EnviraCOM bus

terminals 1, 2, 3.

Controls sparking during On Delay

period.

Controls sparking during Run mode

(Interrupted vs. Intermittent ignition).

Number of resets allowed before

Restricted Lockout

Appliance configuration (boiler,

furnace, water heater) for

EnviraCOM™.

Enable advanced diagnostics mode

and error history.

Exit installer setup

If “QUIT” is selected, the user is

prompted with a screen asking if it is

desired to re-baseline the control.

Baselining the control is intended as a means to save

performance data at the time when the control is

operating optimally. The baseline values are a “trend” of

the first 500 cycles following an installation or a command

to “re-baseline” and is provided as a method to compare

present burner performance to that when the burner was

initially installed or serviced. Using the baseline data, it is

possible to monitor the burner system for degradation and

allow a service person to address any issues before they

result in a no-heat situation. After performing the service it

may be desired to reset the baseline through the installer

setup menu.

NOTE: Re-baselining will establish new baseline values

for CAD cell and Ignition Time going forward. It

will also reset the “Cycles Since Baseline”,

“Lockouts Since Baseline”, and “Recycles Since

Baseline” counters back to zero.

Displays the status of the TT and

Limit inputs. Note that “TT Remote”

means EnviraCOM™ is commanding

the R7284 to behave opposite the

status of the TT terminals.

Press “i” to go to the next screen

Current value of the CAD cell. Press

“i” to go to the next screen

If NO is selected, “i” returns to the

home screen

If YES is selected, “i” continues

through diagnostic screens.

The history screens can provide useful information about

the controls past performance, including its recent history

such as cycle trends (using the baseline function) and

total cycles since installation.

View History

From the Diagnostic screen scroll to the View History

screen and select YES. Scroll through the performance

data by using the up or down buttons.

Pressing “i” during any of the CAD cell screens moves to

the Ignition Time screens below.

Pressing “i” during any of the ignition time screens moves

to the Cycle Count screen below.

The next press goes back to the View History screen

where the user can exit to the home screen or loop back

through the performance history again.

The CAD Cell screen automatically

scrolls 4 screens.

Average CAD cell value during last

cycle

CAD cell trend over the last 10 cycles.

CAD cell trend over the first 500

cycles

The Ignition Time screen

automatically scrolls through 4

screens.

Last Ignition Time.

Ignition Time trend over the last 10

cycles. Ignition

Time trend over the first 500 cycles.

Total burner cycles.

Burner cycles since last service

(baseline reset).

Flame losses since last service

(baseline reset).

Ignition failures since last service

(baseline reset).

Error History Screens

For all Error History screens, pressing “i” returns to the

Normal Screen.

From the home screen, press the up button to display

most recent error.

Press the up button again to proceed to the next most

recent error or the down button to return to the previous

error screen.

These three screens transition every 3 sec.

If no more errors are logged, the display shows “Error

History End.”

7 69-2467EFS—05

Page 8

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

WARNING

BASIC USER INTERFACE

The basic user interface consists of 3 buttons and an

LED. Simple diagnostic information can be obtained

through the interaction of the buttons and LED.

R7284 Status (Basic Interface)

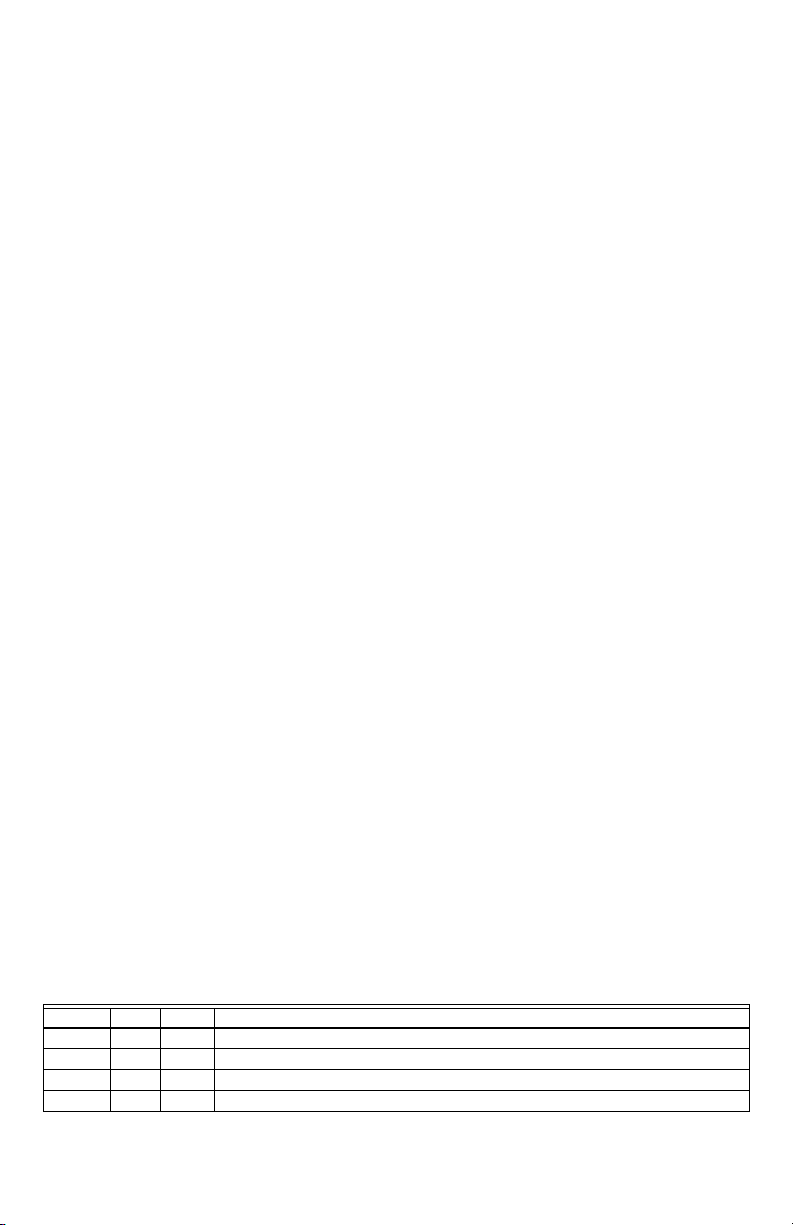

Table 2. LED Codes.

Description LED Code

Standby Pulse (1/4 sec. ON, 4 sec OFF)

Call for Heat Heartbeat (1/2 sec bright, 1/2 sec dim)

Flame proven On solid

Recycle 2 second ON, 2 second OFF flashing

Lockout 1/2 second on, 1/2 second OFF flashing

Interrupt OFF

“i” button Flame Strength Indication

Up button Most recent error

Down button Next most recent error

R7284 Flame Strength (Basic Interface)

During normal operation and when the R7284 is in the

Running state, the LED will show CAD cell resistance.

See Table 3.

Table 3. Flame Strength Indication.

Flame Strength Indication Number of 1/2 sec flashes

Cad Cell less than 400Ω 1

400Ω < Cad Cell < 800Ω 2

800Ω < Cad Cell < 1600Ω 3

1600Ω < Cad Cell < 6100Ω 4

Cad Cell > 6100Ω None

Error History (Basic Interface)

The last two errors are available for display on the LED:

• Pressing the up arrow button displays the most recent

error.

• Pressing the down arrow button displays the next most

recent error.

Once the up or down arrow is pushed, the LED will

display the most recent or next most recent alarm by

blinking the error code. See Table 4.

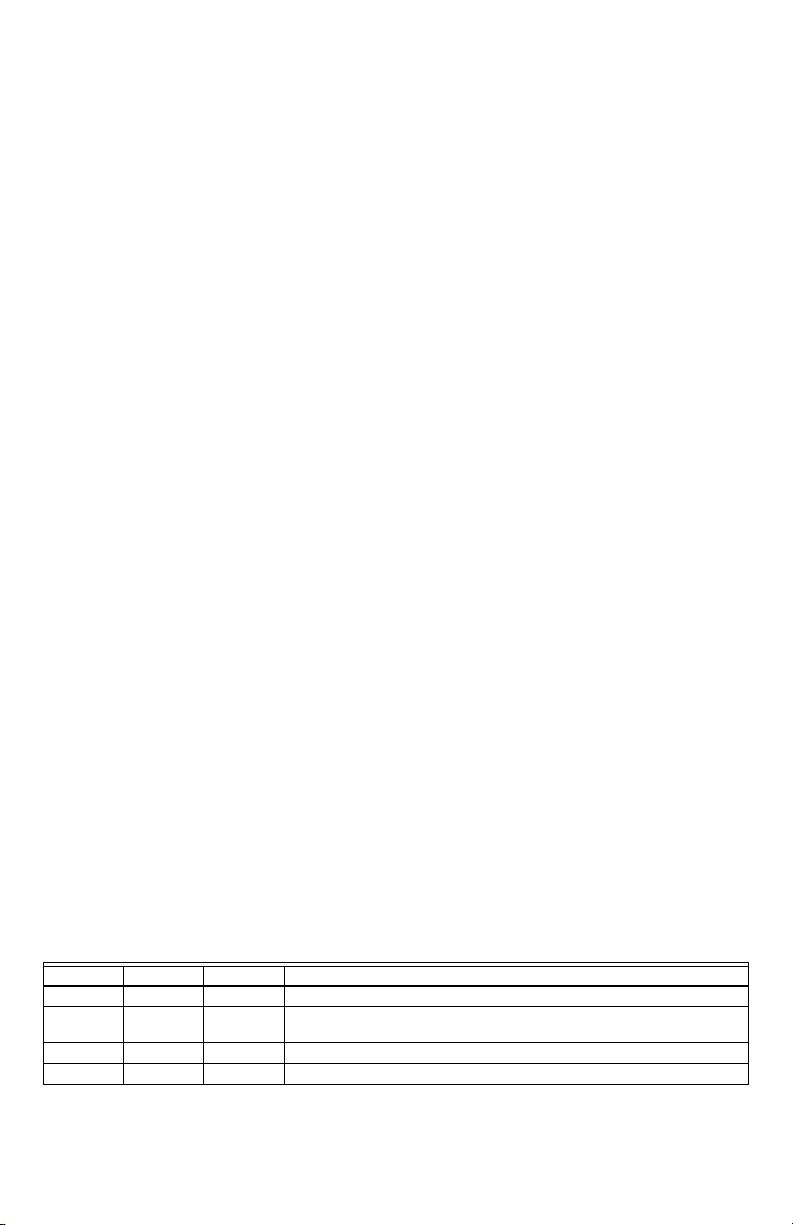

R7284 Error Codes (Basic Interface)

Table 4. Error Codes.

Error Codes

No ignition / Late ignition 1

Max flame losses / Cad Cell high

while running

Number of 1/4 sec

flashes

2

Table 4. Error Codes.

Error Codes

Flame out of sequence 3

Low Voltage / EnviraCOM™ error 4

Internal Error 5

Number of 1/4 sec

flashes

TROUBLESHOOTING AND MAINTENANCE

IMPORTANT

Due to the potential hazard of line voltage, only a

trained, experienced service technician should

preform the troubleshooting procedures.

This control contains no field-serviceable parts.

Do not attempt to take it apart. Replace entire

control if operation is not as described.

To completely troubleshoot an oil burner installation,

check the burner and oil primary control for proper

operation and condition.

Cad Cell Resistance Check

For proper operation, it is important that the cad cell

resistance is below 1600 ohms. On the basic model with

LED interface, during a normal call for heat, once the

control has entered the Run mode, press and release the

“i” button.

On the advanced model with display, follow the screen

diagnostic procedure to read the cad cell resistance.

Preliminary Steps

1. Check wiring connections and power supply.

2. Make sure power is on to controls.

3. Make sure limit control is closed.

4. Check contacts between igniter and the electrodes.

5. Check the oil pump pressure.

6. Check the piping to the oil tank.

7. Check the oil nozzle, oil supply and oil filter.

Check Oil Primary Control

If the trouble is not in the burner or ignition hardware,

check the oil primary control by using the following

equipment:

1. Screwdriver.

2. Voltmeter (0 to 150 Vac range).

3. Insulated jumper wire with both ends stripped.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Troubleshoot with the system powered. Be careful

to observe all precautions to prevent electrical

shock or equipment damage.

69-2467EFS—05 8

Page 9

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

Table 5. R7284 Operation.

External Action R7284 Action

Power applied to control. Internal safety check conducted. If no light or flame is detected and all internal

Thermostat or Aquastat® Control

calls for heat.

Call for heat is satisfied. 1. R7284B,G,P,U (if burner motor-off delay is disabled):

Reset control three times without

completing a call for heat

(number of resets is adjustable in

some controls)

conditions are correct, control enters Standby Mode.

1. Safety Period (5 seconds) internal and external check for flame or light. If

flame or light is detected, control remains in the Standby Mode.

2. When flame or light is not present:

a. R7284G will apply power to the burner motor and igniter.

b. R7284B,P,U (if valve-on delay is enabled) will apply power to the burner

motor and igniter, (if configured) enter/complete valve-on delay period

and then apply power to the valve.

3. Control enters Trial for Ignition period.

a. Monitors burner for flame.

b. When flame is not detected:

(1) Enters lockout mode (after lockout time of 15, 30, or 45 seconds).

(2) Shuts off valve, igniter and burner motor.

(3) Display models: display Lockout mode. LED models: flash LED 1/2

sec ON, 1/2 sec OFF.

(4) Depress “i” button for 2 seconds to return to power-up sequence.

c. When flame is detected, Carry-Over period begins:

4. Control enters Ignition Carry-Over period (continues to spark for 10 seconds

in interrupted mode).

a. Display models: display “Flame Proven.” LED models: turns on LED

b. If flame is lost and lockout time has not expired, R7284 returns to Trial for

Ignition period.

c. If flame is lost and lockout time has expired, R7284 enters Recycle Mode.

5. Carry-Over time expires; igniter turns off if interrupted ignition.

6. Enters Run Mode:

a. Flame is monitored until call for heat ends or flame is lost. If flame is lost:

(1) Control enters Recycle Mode.

(2) Recycle time starts (60 seconds).

(3) Burner and valve are turned off.

(4) Display models: display “Recycle.” LED models: flash LED 2 sec ON,

2 sec OFF.

(5) Returns to Idle Mode at end of Recycle Mode.

a. Burner motor and optionally oil valve and igniter shut off.

b. Display models: display “Standby”

LED models: LED turns OFF

c. Indicator light turns off.

2. R7284P,U (if burner motor-off delay is enabled):

a. Oil valve shuts off.

b. Burner motor runs for selected burner motor-off delay time.

c. Burner motor turns off.

d. Device returns to Idle Mode.

1. R7284 enters Restricted Mode.

2. Indicator light flashes and 1/2 second on, 1/2 second off.

3. Display models: display “Hard Lockout Call Service”

LED models: flash LED 1/2 second ON, 1/2 second OFF

4. Reset device by pressing and holding reset button for a minimum of 10

seconds.

9 69-2467EFS—05

Page 10

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

Table 6. Troubleshooting Information.

Condition: Burner does not start with a call for heat

Procedure Control Status Corrective Action

Review error history if

control in lockout

Check that limit switches

are closed

Check TT status Display models: display shows

Check for line voltage

power at R7284

Check status of cad cell Display models: display shows

-- Refer to Error Codes table of this section

Display models: display shows

status of limit switch.

status of TT.

Replace limit switch or clean contacts.

• Most hydronic systems require TT to be jumpered.

Display models can be configured to behave as

though the TT terminals are jumpered. LED models

require a jumper be added.

• Warm air systems will short TT terminals during a call

for heat. Check that TT is really shorted during the

call for heat.

-- Check breaker and investigate appliance wiring

cad cell resistance.

LED models: LED is on if cad

cell is too low to start.

• Replace cad cell

• If operation does not resume, remove leadwires from

R7284.

• If operation does not resume, replace control.

Condition: Burner does not stop when call for heat ends

Procedure Control Status Corrective Action

Check TT status Display models: display shows

Check limit status Display models: display shows

Check if other EnviraCOM

devices are commanding

the R7284 to run

status of TT.

status of limit.

Display models: display shows

"TT Remote" if an EnviraCOM

device is commanding it to run.

• Check if a TT jumper is installed. When the R7284

and L7224/L7248 electronic Aquastat are connected

via the EnviraCOM bus, neither a physical jumper

across the TT terminals or a configured TT jumper

should be present on the oil primary.

• Check if the R7284 is configured to ignore the TT

terminals.

• Verify thermostat contacts have opened. There

should be 24VAC across TT terminals when there is

not call for heat.

Measure voltage on Limit terminal. There should be no

voltage between Limit and Neutral when the contacts are

open. Replace limit switch if necessary.

Unplug all EnviraCOM devices from R7284. It should

turn off within 5 minutes.

Table 7. Display Alarm Information.

EnviraCOM™

Display Alarm

No Ignition

Check Igniter

No Ignition

Check Cad Cell

69-2467EFS—05 10

Alarm

Number Corrective Action

10 • The burner was not lit and spark was not detected. Check the

5 • The cad cell detected some amount of light during the ignition trial, but

electrodes, spring contacts (or high voltage wires), and ignition

transformer for proper operation.

• If spark ignition is functioning acceptably, proceed to “No Ignition”

corrective action.

not enough to enter run mode. Check the cad cell positioning and clean

the eye.

• Set the display to show the cad cell resistance.

• Shield the cad cell from light.

• If the display shows is less than 20,000 ohms, unplug the cad cell.

— If the display does not read 999999 ohms, replace control

— If it does read 999999 ohms, replace cad cell.

• Expose the cad cell to ambient light (generally enough light to read by

is adequate)

• If the display shows more than 2000 ohms, short the cad cell terminals.

— If the display shows more than 5 ohms, replace control

— If less than 5 ohms, replace cad cell.

• If the burner still does not light, proceed to “No Ignition” corrective

action.

Page 11

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

Table 7. Display Alarm Information.

No Ignition 20 • Check that the manual shut off valve is open.

Low Voltage

XX% low

59 • Supply voltage is low to the control.

Internal Error 18, 58 • An error has been detected inside the control. Replace control if the

Flame Proven

Out of Sequence

34 • The cad cell is permanently in a low resistance state. It should typically

• Check that the burner motor is spinning and the pump is generating

adequate pressure.

• Check the condition of the nozzle and replace if necessary.

• If a valve is present, check for proper operation.

• Check burner adjustments (refer to burner manufacturers instructions)

• Measure the voltage across screw terminals “2” and “3”

— If it's greater than 22VAC and the error does not clear, replace

control.

— If it's less than 22VAC, review appliance wiring.

error persists.

read much higher than 20,000 ohms when no flame is present.

• Set the display to display cad cell resistance.

• Shield the cad cell from light.

• If the display shows less than 20,000 ohms, unplug the cad cell,

— If display does not read 999999 ohms, replace control.

— If it does read 999999 ohms, replace cad cell.

Flame Proven

During On Delay

Flame Proven

During Off Delay

Exceeded Max Recycles 22 • Flame was lost more than the allowed number of times. The burner

EnviraCOM™ Error 91 • Communications error has been detected.

Cad Cell

High During Run

Flame Proven

Late in Trial

23 • Flame was proven during the valve on delay period. Check the oil valve

24 • Flame remained lit during the burner off delay. Check the oil valve for

4 • The cad cell resistance is higher than normal while running, the system

9 • The burner lit very late during the trial for ignition and is susceptible to

for proper operation.

• If the system does not have an oil valve, set the valve on delay to 0.

proper operation.

• If the system does not have an oil valve, set the burner off delay to 0.

lights, but does not remain lit.

• Check that the fuel tank is not empty.

• Check the fuel supply lines (and filter) for obstructions or air

— Use the pump priming feature to purge the system of airCheck

• Check that the burner motor is spinning and the pump is generating

adequate pressure.

• If present, check operation of the oil valve.

• If the problem persists, proceed to the “Cad Cell, High During Run”

corrective action.

• Remove all devices from the EnviraCOM™ connections, 3-pin plug

and screw terminals “1-2-3”.

— If the error does not clear within one minute, measure the voltage on

terminals “2” and “3”.

— If the voltage across terminals “2” and “3” is between 20VAC and

30VAC, replace control.

— If it is outside of that range, review appliance wiring. There should

be approximately 24VAC across “2” and “3”.

is in need of a tune up.

• Check for proper alignment of the cad cell and clean the eye if

necessary.

• Check if the pump is generating adequate pressure.

• Check burner adjustments (refer to burner manufacturers instructions).

• Check for excessive soot build up in the burner and flue.

• Check for flue blockage.

not lighting.

• Check cad cell for proper alignment and clean if necessary.

• Check burner adjustments (refer to burner manufacturers instructions)

• Check electrodes and spring contacts (if equipped) and adjust per

manufacturers recommendations.

• Check if the pump is generating adequate pressure.

• Check the fuel supply lines and filter for obstructions.

11 69-2467EFS—05

Page 12

R7284B,P,U,G ELECTRONIC OIL PRIMARY, ENVIRACOM™ ENABLED

Table 8. LED Flash Codes.

LED

EnviraCOM™

Flash

Code

1 10,5,20,59,9 The burner was not lit or lit near the end of the trial time.

2 22,4 Flame was lost more than the allowed number of times. The burner lights but does not remain

3 23,24,34 Flame was detected out of sequence.

4 59,91 • Supply voltage was low to the control or a communication error has occurred.

Alarm

Number Corrective Action

• Check that the manual shut off valve is open.

• Check that the burner motor is spinning and the pump is generating adequate pressure.

• Check the condition of the nozzle and replace if necessary.

• Check the fuel supply lines and filter for obstructions or air.

• Check the electrodes, spring contacts (or high voltage wires), and ignition transformer for

proper operation.

• If a valve is present, check for proper operation.

• Check burner adjustments (refer to burner manufacturers instructions) and spark was not

detected.

• Check the cad cell positioning and clean the eye.

• Expose the cad cell to ambient light (generally enough light to read by is adequate)

— If the LED does not turn on, short the cad cell terminals,

— If the LED does not turn on, replace the control,

— If the LED turns on, replace the cad cell.

• Shield the cad cell from light.

— If the LED does not turn off, unplug the cad cell,

— If the LED does not turn off, replace the control,

— If the LED turns off, replace the cad cell.

lit, or the cad cell is unusually high during a run cycle.

• Check that the fuel tank is not empty.

• Check the fuel supply lines (and filter) for obstructions or air

use the pump priming feature to purge the system of air

• Check for proper alignment of the cad cell and clean the eye if necessary.

• Check the burner motor is spinning and the pump is generating adequate pressure.

• If present, check operation of the oil valve.

• Check burner adjustments (refer to burner manufacturers instructions).

• Check for excessive soot build up in the burner and flue.

• Check for flue blockage.

• Check the oil valve for proper operation (if equipped).

• Expose the cad cell to ambient light (generally enough light to read by is adequate)

— If the LED does not turn on, short the cad cell terminals,

— If the LED does not turn on, replace the control,

— If the LED turns on, replace the cad cell.

• Shield the cad cell from light.

— If the LED does not turn off, unplug the cad cell,

— If the LED does not turn off, replace the control,

— If the LED turns off, replace the cad cell.

• Remove all devices from the EnviraCOM™ connections, 3-pin plug and screw terminals

“1-2-3”.

— Measure the voltage across screw terminals “2” and “3”

If it's between 22VAC and 30VAC and the error does not clear, replace control.

— If it's outside that range, review appliance wiring. There should be approximately 24VAC

across “2” and “3”.

5 18, 58 An error has been detected inside the control. Replace control if the error persists.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

69-2467EFS—05 M.S. Rev. 04-11

Printed in U.S.A.

Page 13

Régulateur primaire à mazout

électronique R7284B,P,U,G

compatible EnviraCOM™

NOTICE D'INSTALLATION

APPLICATION

Le régulateur à mazout électronique R7284B,P,U,G est

un régulateur primaire à mazout à allumage intermittent

et interrompu à tension secteur de sécurité pour les

brûleurs résidentiels à mazout, les générateurs d'air

chaud à air pulsé et les chauffe-eau. Le R7284B,P,U,G

utilisé avec un détecteur de flamme à cellule de cadmium

fait fonctionner un brûleur à mazout, un allumeur par

étincelle et une vanne à mazout en option. Le régulateur

fonctionne avec un thermostat basse tension et haute

tension en option. Le régulateur primaire contrôle le

mazout, détecte la flamme, contrôle l'étincelle d'allumage

(allumage intermittent ou interrompu) et donne l'alerte en

cas de verrouillage via le bus EnviraCOM™ et le circuit

d'alarme à distance.

Les régulateurs primaires à mazout de la série R7284

peuvent être utilisés avec les systèmes à air pulsé et à

eau chaude. Lorsqu'ils sont utilisés avec les systèmes à

eau chaude, les régulateurs Aquastat® à commutation à

tension secteur assurent normalement le démarrage et

l'arrêt des séquences de combustion. Avec les systèmes

à air pulsé, les thermostats basse tension mécanique et

électronique contrôlent le démarrage et l'arrêt du

processus de combustion.

Certains systèmes à eau chaude et à air pulsé

nécessitent une temporisation de mise en marche de la

vanne et une temporisation de mise à l'arrêt du moteur

du brûleur. Le modèle R7284 actionne une vanne à

mazout qui interrompt le débit de mazout lorsque le

moteur du brûleur est en marche avant la combustion

(temporisation de mise en marche de la vanne) et

lorsque le moteur du brûleur est en marche après la

combustion (temporisation de mise à l'arrêt du moteur du

brûleur).

Les modèles R7284 sont uniquement conçus pour une

utilisation sur les appareils à mazout ne nécessitant pas

de prébalayage et de post-balayage en tant que fonction

de sécurité telle que définie dans la norme UL296. La

temporisation de mise en marche de la vanne et la

temporisation de mise à l'arrêt du moteur du brûleur de

ce régulateur sont uniquement destinées à aider à établir

le tirage et à réduire les problèmes d'écoulement de

mazout après la fermeture de la vanne.

Les modèles R7284 compatibles avec EnviraCOM™

peuvent être utilisés avec les systèmes de surveillance à

distance EnviraLink® et les appareils de diagnostic de

poche. Utiliser uniquement les modèles R7284P et U

pour le fonctionnement en réseau avec d'autres

dispositifs compatibles EnviraCOM™.

CARACTÉRISTIQUES

Interface utilisateur

Il y a deux interfaces utilisateur : l'interface de base et

l'interface avancée. Les deux interfaces sont constituées

de trois boutons : , et « i ».

L'interface avancée a un affichage à deux lignes utilisé

pour configurer les paramètres du dispositif, récupérer

les informations sur le diagnostic et afficher le statut du

système.

L'interface de base a un voyant DEL unique utilisé pour

afficher les codes d'erreur et le statut du système.

De manière générale, le bouton « i » permet de défiler

parmi les options de l'affichage et sert de touche

« Entrée » (dans les modes de configuration).

Thermostat(s)

Les régulateurs primaires à mazout sont compatibles

avec les thermostats standard et les thermostats

communicants EnviraCOM™.

Remises en marche limitées

Cette fonction limite le nombre d'essais de remise en

marche (pour chaque appel de chaleur) à trois essais

maximum. Si la flamme est perdue trois fois et ne

satisfait pas à un appel de chaleur, le R7281 se

verrouille.

Cycle d'amorçage de pompe

Pour faciliter la purge d'air des conduites de mazout et

des filtres, le R7284 peut être placé en mode de

balayage en appuyant et en relâchant le bouton avec

une flèche ascendante durant l'essai d'allumage.

PUMP PRIME (Amorçage de pompe) s'affiche sur

l'interface avancée avec la durée restante de l'essai

d'allumage (TFI). Le fait d'appuyer sur le bouton avec

flèche ascendante ajoute une minute à la durée TFI

(appuyer 10 fois pour 10 minutes max. supplémentaires).

Le fait d'appuyer sur le bouton avec touche descendante

enlève une minute à la durée TFI.

Il n'y a pas d'indication visuelle pour la commande

d'interface de base et la minuterie de balayage est

limitée à cinq minutes.

Page 14

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

Fonction de désactivation

Le fait d'appuyer sur le bouton « i » sans relâcher permet

de désactiver toutes les fonctions du régulateur jusqu'à 3

secondes suivant le relâchement du bouton.

Modes de verrouillage

Le R7284 a trois types de modes de verrouillage qui sont

entrés en cas d'erreur :

• Verrouillage de premier niveau : Causé par une

erreur interne provisoire telle qu'une basse tension. Le

régulateur se remet en marche automatiquement une

fois que l'erreur n'est plus détectée.

• Verrouillage de deuxième niveau : Causé par une

panne interne du régulateur ou par une panne de

système telle qu'une flamme hors séquence. Un

verrouillage de deuxième niveau entraîne l'absence de

chauffage. Pour annuler un verrouillage de 2

appuyer sur le bouton « i » pendant 2 secondes.

• Verrouillage de restriction : Causé par un certain

nombre de verrouillages de 2

le même cycle de chauffage. Pour annuler un

verrouillage de restriction, appuyer sur le bouton « i »

pendant 10 secondes.

e

niveau consécutifs sur

e

niveau,

Résistance de la cellule de cadmium

La résistance de la cellule de cadmium peut être vérifiée

sans ohmmètre.

Interface de base :

Appuyer sur le bouton « i » et le relâcher. Les

clignotements qui suivent indiquent la résistance. Voir

le Tableau 3.

Interface avancée :

La résistance de la cellule de cadmium est illustrée sur

l'affichage.

Temporisation d'ouverture de vanne/temporisation de mise à l'arrêt du moteur de soufflante

Certains modèles peuvent avoir des temporisations fixes

ou réglables pour l'ouverture de la vanne et l'arrêt du

moteur de soufflante. Les circuits de sécurité vérifient la

flamme durant ces temporisations, et si une flamme est

présente, causent le verrouillage du régulateur.

CARACTÉRISTIQUES

Modèles :

Le Tableau 1 indique les caractéristiques principales du

R7284.

Tableau 1. Modèles R7284.

Modèle Limite Vanne Remarques

R7284B Non Oui Temporisation d'ouverture de vanne uniquement

R7284G Non Non Pas de temporisation de marche/arrêt, allumage intermittent (allumeur à fil avec moteur)

R7284P Oui Oui Temporisations de marche et arrêt

R7284U Oui Oui Temporisations de marche et arrêt

Minuterie :

Temporisation d'ouverture de vanne : 0-30 secondes

Temporisation d'arrêt du brûleur : 0-8 minutes

Verrouillage : 15, 30 ou 45 secondes.

Remise en marche : 60 secondes (fixe).

Report d'allumage : 10 secondes (fixe).

REMARQUE : Certains modèles ont une temporisation

Caractéristiques électriques :

Entrées :

Tension : 102 à 132 V c.a., 120 V c.a. nominaux.

Courant : 0,5 A plus charges du moteur du brûleur, de

Fréquence : 60 Hz.

Sorties :

Contacts de relais :

Brûleur : 120 V c.a., 10 A à pleine charge, 60 A à rotor

Vanne : 120 V c.a., 1A.

Allumeur : 120 V c.a., 3 A.

Coupure basse tension : 80 V c.a.

Courant de thermostat disponible : 100 mA.

Courant EnviraCOM™ disponible : 150 mA.

REMARQUE : Réduire l'ampérage à pleine charge du

Code de couleur de fil de composant typique :

Blanc : neutre.

Noir : secteur.

Orange : moteur.

Bleu ou bleu rayé blanc : allumeur.

Violet : vanne.

Rouge : limite.

REMARQUE : Le R7284 est fourni avec des bornes à

Caractéristiques environnementales :

Température de fonctionnement/d'expédition :

-40 °C à +66 °C (-40 °F à +150 °F).

Le texte d'affichage peut ne pas être visible à des

températures inférieures à -20 °C (-4 °F).

Humidité : 0 à 95 % d'humidité relative à 40 °C (104 °F),

sans condensation.

Accessoires :

Module d'alarme W8735S3000

Homologations :

Underwriters Laboratories Inc. : Reconnu (Dossier

MP268).

Underwriters Laboratories Inc. du Canada.

d'ouverture de vanne, d'arrêt de brûleur et

des minuteries de verrouillage réglables.

la vanne et de l'allumeur.

bloqué.

brûleur de la charge de l'allumeur. Par

exemple, si l'allumeur tire 3 A (120 V c.a.,

360 VA), réduire l'ampérage à pleine

charge du moteur du brûleur à 7 A.

connexion rapide de 1/4 po.

69-2467EFS—05 14

Page 15

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

R7284

BRÛLEUR

MF32085

INSTALLATION

Lors de l'installation de ce produit...

1. Lire attentivement ces instructions. Le fait de ne pas

les suivre risque d'endommager le produit ou de

constituer un danger.

2. Vérifier les caractéristiques nominales indiquées

dans cette notice et sur le produit pour s'assurer

que le produit correspond bien à l'application

prévue.

3. L'installateur doit être un technicien expérimenté

ayant reçu la formation pertinente.

4. Une fois l'installation terminée, utiliser ces

instructions pour vérifier le bon fonctionnement du

produit.

Risque de choc électrique.

Peut causer des dégâts et des blessures

graves, voire mortelles.

Débrancher l'alimentation en courant avant de

commencer l'installation pour prévenir des chocs

électriques ou des dommages matériels. Il peut

être nécessaire d'effectuer plus d'un

débranchement.

Emplacement

1. Monter un boîtier de raccordement de 4 x 4 po

directement sur le brûleur principal ou dans

l'armoire de l'appareil. Pour les applications de

remplacement, effectuer le montage au même

endroit que l'ancien régulateur. Voir la Fig. 1.

S'assurer que les températures de fonctionnement

sont comprises dans la plage de température

ambiante (voir la section Caractéristiques).

2. Avant de monter le régulateur, effectuer les

connexions de tension secteur comme illustré dans

les Fig. 2 à 10. Assembler les fils avec des

connecteurs sans soudure. Ne pas dépasser les

valeurs de charge nominales indiquées sur

l'étiquette du dispositif.

3. Si nécessaire, utiliser le régulateur comme modèle

pour marquer et percer les nouveaux trous de

montage.

4. Monter le dispositif avec des vis n° 6 fournies (non

incluses).

CÂBLAGE

Risque de choc électrique.

Peut causer des dégâts et des blessures

graves, voire mortelles.

Débrancher l'alimentation avant le câblage pour

éviter les chocs électriques et les dégâts de

l'équipement. Il peut être nécessaire d'effectuer

plus d'un débranchement.

1. Le câblage doit être conforme aux codes et aux

règlements locaux.

2. Vérifier que le câblage de la tension secteur est

bien connecté. Consulter l'étiquette du régulateur à

mazout et le schéma de câblage de l'appareil pour

les codes de couleur.

3. Après le montage, effectuer les connexions basse

tension aux bornes à vis (voir les Fig. 2 à 10).

4. Dénuder les fils de 10 mm (3/8 po) et insérer sous

la vis de borne.

5. Brancher les fils de thermostat à T-T (ou 1, 2, 3 si

EnviraCOM™ est présent), si l'installation l'exige.

Fig. 1. Montage du R7284 sur le boîtier de

raccordement.

VÉRIFICATION

Démarrage du système

Risque d'incendie ou d'explosion.

Peut causer des dégâts et des blessures

graves, voire mortelles.

S'assurer que la chambre de combustion est

exempte d'huile et/ou de vapeur d'huile avant de

mettre le système en marche.

1. Ouvrir le robinet manuel dans le conduit

d'alimentation de mazout.

2. S'assurer que le système est sous tension. Vérifier

le disjoncteur ou le fusible et fermer l'interrupteur du

système, si présent.

3. Régler le thermostat sur appel de chaleur.

4. S'assurer que le brûleur s'allume et fonctionne

jusqu'à la fin de l'appel de chaleur. Noter la

résistance de la cellule de cadmium lors du

fonctionnement.

5. Vérifier que le brûleur s'éteint une fois que l'appel

de chaleur du thermostat est satisfait.

15 69-2467EFS—05

Page 16

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

MF32146

AFFICHEUR

BORNES

ENVIRACOM

BORNES DE

THERMOSTAT

AFFICHEUR

BORNES

ENVIRACOM

BORNES DE

THERMOSTAT

BOUCHON DE

DIAGNOSTIC

ENVIRACOM

BOUTON i

BOUTON

BAS

BOUTON

HAUT

BOUCHON DE

DIAGNOSTIC

ENVIRACOM

BOUTON i

BOUTON

BAS

BOUTON

HAUT

CONNEXION DE LA CELLULE DE CADMIUM

MF32178

CONNEXIONS DE TENSION SECTEUR

VANNE

R7284B, P, U

L2

R7284A, G

MOTEUR DE

BRÛLEUR

L2

……

……

VANNE

VANNE

MF32180

MOTEUR DE

BRÛLEUR

MOTEUR DE

BRÛLEUR

MOTEUR DE

BRÛLEUR

L2

ALIMENTATION. FOURNISSEZ AU BESOIN UN DISPOSITIF DE COUPURE ET

UNE PROTECTION CONTRE LES SURCHARGES.

SE REPORTER À L’ÉTIQUETTE DE L’APPAREIL POUR CONNAÎTRE LE CODE

DE COULEUR DE FIL.

LA VANNE EST OPTIONNELLE POUR LES MODÈLES SPÉCIFIÉS.

LA BORNE ENVIRACOM™ 3 EST ÉGALEMENT LA PREMIÈRE BORNE

DU THERMOSTAT.

LE CAVALIER PEUT ÊTRE OMIS SI LE R7284 EST CONFIGURÉ POUR

IGNORER LES BORNES TT.

1

R7284

ALLUMEUR

MF32182

L1

1

2

3

4

5

3

4

5

2

2

2

MOTEUR DE

BRÛLEUR

POMPE DE

CIRCULATION

L2

B2

C2

C1

MOTEUR DE

BRÛLEUR

ALLUMEUR

VANNE

VANNE

CELLULE DE

CADMIUM

CELLULE DE

CADMIUM

L1

B1

BOÎTIER DE

RACCORDEMENT

T

T

3

2

1

T

T

LÉGENDE :

BORNE À VIS

BORNE DE CONNEXION RAPIDE DE 1/4 PO

CONNECTEUR SANS SOUDURE

THERMOSTAT

L8148A,C

CAVAL IE R

CONTRÔLEUR

AQUASTAT®

R

W

BORNE

ENVIRACOM™

LIMITEUR

Fig. 2. Emplacement des bornes, connecteurs,

voyants DEL, bouton de réinitialisation et

commutateurs du modèle R7284.

Fig. 4. Câblage de limiteur pour thermostat de tension

secteur, Aquastat ou autre limiteur du modèle R7284.

69-2467EFS—05 16

Fig. 3. Connexions de câblage du modèle R7284.

R7284B, G

……

AQUASTAT

L1

OU AUTRE

LIMITEUR

L1

R7284P, U

LIMITEUR

L1

……

AQUASTAT

OU AUTRE

LIMITEUR

MF32179

Fig. 5. Câblage du R7284 pour vanne à mazout en

R7284G

……

MOTEUR DE

BRÛLEUR

ALLUMEUR

ALLUMAGE

INTERMITTENT

MOTEUR DE

BRÛLEUR

option.

R7284B, P, U

L2

……

MOTEUR DE

BRÛLEUR

ALLUMEUR

ALLUMAGE INTERMITTENT

ALLUMAGE INTERROMPU

Fig. 6. Schéma de l'allumeur du R7284.

L1

Fig. 7. Câblage du R7284P,U sans EnviraCOM™, pour

chaudière à mazout typique.

MOTEUR DE

BRÛLEUR

ALLUMEUR

L2

MF32181

Page 17

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

L2

R7284

MF32191

L1

1

3

4

2

2

2

L2

B2

C2

C1

L1

B1

LIMITEUR

T

T

3

2

1

T

T

THERMOSTAT

L8148A,C

R

W

ALLUMEUR

ALIMENTATION. FOURNISSEZ AU BESOIN UN DISPOSITIF DE COUPURE ET

UNE PROTECTION CONTRE LES SURCHARGES.

SE REPORTER À L’ÉTIQUETTE DE L’APPAREIL POUR CONNAÎTRE LE CODE

DE COULEUR DE FIL.

LA BORNE ENVIRACOM™ 3 EST ÉGALEMENT LA PREMIÈRE BORNE DU

THERMOSTAT.

LE CAVALIER PEUT ÊTRE OMIS SI LE R7284 EST CONFIGURÉ POUR

IGNORER LES BORNES TT.

1

2

3

4

MOTEUR DE

BRÛLEUR

POMPE DE

CIRCULATION

MOTEUR DE

BRÛLEUR

ALLUMEUR

VANNE

CELLULE DE

CADMIUM

CELLULE DE

CADMIUM

BOÎTIER DE

RACCORDEMENT

LÉGENDE :

BORNE À VIS

BORNE DE CONNEXION RAPIDE DE 1/4 PO

CONNECTEUR SANS SOUDURE

CAVAL IE R

CONTRÔLEUR

AQUASTAT®

BORNE

ENVIRACOM™

ALIMENTATION. FOURNISSEZ AU BESOIN UN DISPOSITIF DE COUPURE

ET UNE PROTECTION CONTRE LES SURCHARGES.

SE REPORTER À L’ÉTIQUETTE DE L’APPAREIL POUR CONNAÎTRE LE

CODE DE COULEUR DE FIL.

LA VANNE EST OPTIONNELLE POUR LES MODÈLES SPÉCIFIÉS.

LA BORNE ENVIRACOM™ 3 EST ÉGALEMENT LA PREMIÈRE BORNE

DU THERMOSTAT.

NE PAS CONNECTER LES CAVALIERS SUR LES BORNES TT NI

CONFIGURER LE RÉGLAGE TT INTERNE SUR « OUI » LORSQUE LE

RÉGULATEUR PRIMAIRE À MAZOUT ET L’AQUASTAT SONT CONNECTÉS

VIA LE BUS ENVIRACOM.

1

MF32183A

2

3

4

5

LÉGENDE :

BORNE À VIS

BORNE DE CONNEXION RAPIDE DE 1/4 PO

CONNECTEUR SANS SOUDURE

ALLUMEUR

MOTEUR DE

BRÛLEUR

VANNE

MOTEUR DE

BRÛLEUR

ALLUMEUR

VANNE

CELLULE

DE

CADMIUM

CELLULE DE

CADMIUM

BOÎTIER DE

RACCORDEMENT

CONTRÔLEUR

AQUASTAT®

L2

R7284

L1

1

3

4

2

2

2

L2

B2

L1

B1

LIMITEUR

T

T

3

2

1

12T/3

123

L7224/48

TH9421C

VisionPRO IAQ

BORNE

ENVIRACOM™

T

5

Fig. 8. Câblage du R7284U sans EnviraCOM™, pour

chaudière à mazout typique.

Fig. 9. Câblage du R7284P,U avec connexions

EnviraCOM™, pour chaudière à mazout typique.

IMPORTANT

Lorsque le régulateur primaire à mazout R7284

communique avec l'Aquastat L7224/L7248 via le

bus EnviraCOM, ne pas connecter les bornes TT

ni configurer le réglage TT interne sur

« OUI ».Ceci compromettrait le bon

fonctionnement du brûleur.

17 69-2467EFS—05

Page 18

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

MF32184A

L1

(SOUS TENSION)

L1 (SOUS

TENSION)

RELAIS

VENTILATEUR

RELAIS

REFROID. 1

RELAIS

REFROID. 2

C7089B

CAPTEUR DE

TEMPÉRATURE

EXTÉRIEURE

TRANSFORMATEUR

DU SYSTÈME

ALLUMEUR

MOTEUR DE

BRÛLEUR

MOTEUR DE

BRÛLEUR

ALLUMEUR

VANNE

VANNE

BOÎTIER DE

RACCORDEMENT

LÉGENDE :

BORNE À VIS

BORNE DE CONNEXION RAPIDE DE 1/4 PO

CONNECTEUR SANS SOUDURE

BORNE

ENVIRACOM™

LIMITEUR

LIMITEUR

CELLULE

DE

CADMIUM

CELLULE DE

CADMIUM

ALIMENTATION. FOURNISSEZ AU BESOIN UN DISPOSITIF DE COUPURE ET

UNE PROTECTION CONTRE LES SURCHARGES.

SE REPORTER À L’ÉTIQUETTE DE L’APPAREIL POUR CONNAÎTRE LE CODE

DE COULEUR DE FIL.

LA VANNE EST OPTIONNELLE POUR LES MODÈLES SPÉCIFIÉS.

CAVALIERS INSTALLÉS EN USINE.

LA BORNE ENVIRACOM™ 3 EST ÉGALEMENT LA PREMIÈRE BORNE

DU THERMOSTAT.

NE PAS CONNECTER LES CAVALIERS SUR LES BORNES TT NI

CONFIGURER LE RÉGLAGE TT INTERNE SUR « OUI » LORSQUE LE

RÉGULATEUR PRIMAIRE À MAZOUT ET L’AQUASTAT SONT CONNECTÉS

VIA LE BUS ENVIRACOM.

1

2

3

4

5

L2

R7284

1

2

2

L2

L1

T

T

3

2

1

L2

OT

OT

2

1

3

T8635L

W8635A

C

R

R

H

R

C

1

2

3

Y2

W2

Y1

G

W1

4

1

3

5

2

6

6

IMPORTANT

Le système montré à la Fig. 10 est sensible à la

phase/polarité. S'assurer que toute la puissance

d'entrée est dans la même phase.

Fig. 10. Schéma de câblage typique pour thermostat

compatible EnviraCOM™ et R7284P,U pour un

69-2467EFS—05 18

système à air pulsé à mazout.

Page 19

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

MF32103A

i

i

i

i

i

i

i

i

i

i

i

HAUT/BAS

HAUT/BAS

(QUITTER SÉLECTIONNÉ)

(SUITE SÉLECTIONNÉ)

(NON SÉLECTIONNÉ)

(OUI SÉLECTIONNÉ)

APPUYER SUR LES

3 BOUTONS

i

i

i

ERREUR HISTORIQUE

ÉCRAN D’ACCUEIL

CELLULE CADMIUM

HISTORIQUE

COMPTAGE DE CYCLES

PÉRIOD ALLUMAGE

HISTORIQUE

ÉCRANS DE

CONFIGURATION DE

L’INSTALLATEUR

MF32090

MF32091

MF32092

INTERFACE UTILISATEUR AVANCÉE

Fig. 11. Présentation de l'interface de l'utilisateur.

Écrans d'accueil

Le fait d'appuyer sur le bouton « i » pour plus de deux

secondes en modes autres que veille interrompt le

fonctionnement du régulateur.

Une fois le bouton relâché, le compte à rebours reprend.

• Le fait d'appuyer sur les 3 boutons plus de 2 secondes

dans tout état fait passer le régulateur en mode de

configuration de l'installateur (ISU).

• Le fait d'appuyer sur le bouton « i » en tout état pour

afficher l'écran Diagnostic (si les diagnostics sont

activés).

• Le fait d'appuyer sur haut ou bas dans tout écran

permet d'afficher l'historique des erreurs (si les

diagnostics sont activés).

Voici ci-dessous une progression typique des écrans en

cours de cycle normal.

Le fait d'appuyer sur le haut ou le bas

durant l'essai d'allumage active

l'amorçage de la pompe.

Chaque pression du bouton haut

ajoute une minute, chaque pression

du bouton bas enlève une minute à la

durée d'amorçage de la pompe.

Si à tout moment, un événement générant un verrouillage

a lieu, l'un des écrans suivants s'affiche.

Le régulateur est en mode de

verrouillage de 1er niveau. Le

régulateur se remet en marche une

fois que l'erreur n'est plus détectée ou

après une durée spécifiée.

Le régulateur est en mode de

verrouillage de 2e niveau. Appuyer

sur le bouton « i » pendant au moins

deux seconds pour réinitialiser.

Appuyer sur le bouton « i » pendant

plus de 10 secondes pour revenir en

mode de veille.

Configuration de l'installateur

Pour passer en mode de configuration de l'installateur,

appuyer sur les trois boutons pendant 2 secondes

simultanément.

REMARQUE : Tous les paramètres ne sont pas réglables

19 69-2467EFS—05

Si QUIT (Quitter) est sélectionné, le

fait d'appuyer sur le bouton « i »

affiche l'option de retour aux valeurs

de référence.

Si CONT (Continuer) est sélectionné,

le fait d'appuyer sur le bouton « i »

permet de passer à la configuration

de l'installateur.

dans tous les modèles. Les paramètres

non disponibles pour le réglage s'affichent

comme verrouillés lorsqu'une tentative est

faite de les modifier.

Page 20

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

MF32093

MF32094

MF32102

MF32095

MF32096

Sélectionner entre anglais, français et

espagnol en utilisant les boutons haut

et bas et le bouton « i » pour

sélectionner.

Réglage de la temporisation de

marche de la vanne en incréments de

cinq secondes.

Réglage de la durée d'allumage

(verrouillage).

REMARQUE : La durée d'allumage ne peut être réglée

Ceci permet de sauvegarder les données de performance

lorsque le régulateur fonctionne de façon optimale. Les

valeurs de référence sont une tendance des premiers 500

cycles suivant l'installation ou une commande de

rétablissement des valeurs de base et sont fournie

comme une méthode permettant de comparer la

performance actuelle du brûleur à celle présente lors de

l'installation ou de l'entretien initiaux. En utilisant les

données de référence, il est possible de surveiller le

système de brûleur pour détecter les dégradations et

permettre à un personnel d'entretien de régler les

problèmes avant qu'une situation d'absence de chaleur

n'ait lieu. Après avoir effectué l'entretien, il est possible de

réinitialiser les valeurs de référence via le menu de

configuration de l'installateur.

que pour les 100 premiers cycles de fonctionnement. Après 100 cycles, la durée

d'allumage est enregistrée et ne peut plus

être réglée.

Réglage de temporisation d'arrêt du

brûleur.

Configuration des bornes TT par

rapport à un cavalier interne.

Contrôle l'étincelle durant la période

de temporisation de marche.

Configurer le réglage TT sur « NON »

lorsque le régulateur primaire à

mazout est connecté à Aquastat®

L7224/L7248 via les bornes 1, 2, 3 du

bus EnviraCOM.

Contrôle l'étincelle durant le mode de

fonctionnement (allumage interrompu

par rapport à allumage intermittent).

Nombre de réinitialisations permises

avec le verrouillage de restriction

Configuration de l'appareil

(chaudière, générateur d'air chaud,

chauffe-eau) pour EnviraCOM™.

Active le mode de diagnostic avancé

et l'historique des erreurs.

Quitter la configuration de

l'installateur

Si QUIT (Quitter) est sélectionné, une

invite sur l'écran demande à

l'utilisateur s'il veut rétablir les valeurs

MF32101

de référence du régulateur.

REMARQUE : Le rétablissement des valeurs de

Les écrans d'historique peuvent fournir des informations

utiles concernant les performances passées du

régulateur, y compris son historique récent, tel que les

tendances de cycle (utilisant la fonction de référence) et

les cycles totaux depuis l'installation.

référence permet d'établir de nouvelles

valeurs de référence pour la cellule de

cadmium et la durée d'allumage. Il permet

également de réinitialiser les compteurs de

« Cycles depuis la ligne de référence », de

« Verrouillage depuis la ligne de

référence » et de « Remises en marche

depuis la ligne de référence » à zéro.

Affiche le statut des entrées des TT et

du limiteur. Noter que « TT Remote »

(TT à distance) signifie

qu'EnviraCOM™ ordonne au R7284

de se comporter inversement au

statut des bornes TT.

Appuyer sur « i » pour passer à

l'écran suivant

Valeur courante de la cellule de

cadmium. Appuyer sur « i » pour

passer à l'écran suivant

Si NO (Non) est sélectionné, « i »

ramène à l'écran d'accueil

Si YES (Oui) est sélectionné, « i » fait

défiler par les écrans de diagnostic.

Voir Historique

Sur l'écran Diagnostic, défiler jusqu'à l'écran View History

(Voir historique) et sélectionner YES (Oui). Faire défiler

les données de performance en utilisant les boutons haut

et bas.

Le fait d'appuyer sur « i » au cours de tout écran de

cellule de cadmium permet de passer aux écrans de

durée d'allumage ci-dessous.

L'écran CAD Cell (Cellule de

cadmium) fait automatiquement

défiler 4 écrans.

Valeur moyenne de la cellule de

cadmium durant le dernier cycle.

Tendance de la cellule de cadmium

au cours des 10 derniers cycles.

Tendance de la cellule de cadmium

au cours des 500 premiers cycles.

L'écran Ignition Time (Durée

d'allumage) fait automatiquement

défiler 4 écrans.

Dernière durée d'allumage.

Tendance de durée d'allumage au

cours des 10 derniers cycles.

Tendance de durée d'allumage au

cours des 500 premiers cycles.

69-2467EFS—05 20

Page 21

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

MF32097

MF32099

MF32100

Le fait d'appuyer sur « i » au cours de tout écran de durée

d'allumage permet de passer aux écrans de compte de

cycle ci-dessous.

La pression suivante permet de revenir à l'écran de

visualisation de l'historique que l'utilisateur peut quitter

pour revenir à l'écran d'accueil ou à partir duquel il peut

de nouveau faire défiler l'historique de performance.

Cycles totaux de brûleur.

Cycles de brûleur depuis le dernier

entretien (réinitialisation aux valeurs

de référence).

Pertes de flamme depuis le dernier

entretien (réinitialisation aux valeurs

de référence).

Échecs d'allumage depuis le dernier

entretien (réinitialisation aux valeurs

de référence).

Écrans d'historique des erreurs

Pour tous les écrans d'historique des erreurs, le fait

d'appuyer sur « i » permet de revenir à l'écran normal.

MF32098

Sur l'écran d'accueil, appuyer sur le bouton haut pour

afficher l'erreur la plus récente.

Appuyer une fois de plus sur le bouton haut pour passer à

l'erreur la plus récente suivante ou sur le bouton bas pour

revenir à l'écran d'erreur précédent.

Les trois écrans alternent toutes les 3 secondes.

Si aucune autre erreur n'est enregistrée, l'affichage

indique « Error History End » (Fin de l'historique des

erreurs).

INTERFACE UTILISATEUR DE BASE

L'interface utilisateur de base consiste en 3 boutons et un

DEL. Les informations de diagnostic simples peuvent être

obtenues par l'interaction des boutons et du DEL.

Statut R7284 (Interface de base)

Tableau 2. Codes DEL.

Description Code DEL

Veille Impulsion (1/4 s sur marche, 4 s sur

Appel de

chaleur

Surveillance

de flamme

Remise en

marche

Verrouillage Clignotement de 1/2 seconde sur

Interruption ARRÊT

Bouton « i » Indication de force de flamme

Bouton haut Erreur la plus récente

Bouton bas Erreur la plus récente suivante

arrêt)

Pulsation (1/2 s lumineux, 1/2 s atténué)

Marche en continu

Clignotement de 2 secondes sur marche,

2 secondes sur arrêt

marche, 1/2 seconde sur arrêt

Force de flamme R7284 (Interface de base)

Durant le fonctionnement normal et lorsque le R7284 est

en mode de fonctionnement, l'interface DEL indique la

résistance de la cellule de cadmium. Voir le Tableau 3.

Tableau 3. Erreur la plus récente suivante.

Nombre de

Indication de force de flamme

Cellule de cadmium inférieure à 400Ω 1

400Ω < Cellule de cadmium < 800Ω 2

800Ω < Cellule de cadmium < 1600Ω 3

1600Ω < Cellule de cadmium < 6100Ω 4

Cellule de cadmium > 6100 Ω Aucun

clignotements

de 1/2 s

Historique des erreurs (interface de base)

Les deux dernières erreurs sont disponibles sur l'interface

DEL :

• Le fait d'appuyer sur le bouton à flèche ascendante

affiche l'erreur la plus récente.

• Le fait d'appuyer sur le bouton à flèche descendante

affiche l'erreur la plus récente suivante.

Une fois la flèche ascendante ou descendante pressée,

l'interface DEL affiche l'alarme la plus récente ou la plus

récente suivante en faisant clignoter le code d'erreur. Voir

le Tableau 4.

21 69-2467EFS—05

Page 22

RÉGULATEUR PRIMAIRE À MAZOUT ÉLECTRONIQUE R7284B,P,U,G COMPATIBLE ENVIRACOM™

AVERTISSEMENT

Codes d'erreur R7284 (Interface de base)

Tableau 4. Codes d'erreur.

Nombre de

Codes d'erreur

Pas d'allumage / Allumage retardé 1

Pertes de flamme max. / Résistance de

cellule de cadmium haute en

fonctionnement

Flamme hors séquence 3

Basse tension / erreur EnviraCOM™ 4

Erreur interne 5

clignotements

de 1/4 s

2

DÉPANNAGE ET ENTRETIEN

IMPORTANT

En raison des dangers potentiels liés à

l'alimentation secteur, seul un technicien

d'entretien formé et expérimenté doit effectuer

les procédures de dépannage.

Ce régulateur ne contient aucune pièce

réparable. Ne pas tenter de le démonter.

Remplacer le régulateur dans son intégralité s'il

ne fonctionne pas de la façon décrite.

Pour dépanner complètement une installation de brûleur

à mazout, vérifier que le brûleur et le régulateur primaire à

huile fonctionnent correctement et sont en bon état.

Vérification de la résistance de la cellule de cadmium

Pour un fonctionnement correct, il est important que la

résistance de la cellule au cadmium soit inférieure à 1600

ohms. Sur le modèle de base avec interface DEL, durant

un appel de chaleur normal, une fois le régulateur en

mode de fonctionnement, appuyer sur le bouton « i » et le

relâcher.

Sur le modèle avancé, suivre la procédure de diagnostic à

l'écran pour lire la résistance de la cellule de cadmium.

Étapes préliminaires

1. Vérifier les connexions de câblage et l'alimentation.

2. S'assurer que les régulateurs sont sous tension.

3. S'assurer que le limiteur est fermé.

4. Vérifier les contacts entre l'allumeur et les

électrodes.

5. Vérifier la pression de la pompe de mazout.

6. Vérifier la tuyauterie au réservoir de mazout.

7. Vérifier la buse de mazout, l'arrivée de mazout et le

filtre à mazout.

Vérification du régulateur à mazout primaire

Si le problème ne se trouve pas dans la quincaillerie du

brûleur ou de l'allumage, vérifier le régulateur à mazout

primaire avec l'équipement suivant :

1. Tournevis.

2. Voltmètre (plage de 0 à 150 V c.a.).

3. Fil de cavalier isolé avec les deux extrémités dénu-

dées.

Risque de choc électrique.

Peut causer des dégâts et des blessures

graves, voire mortelles.

Effectuer le dépannage avec le système sous

tension. Veiller à respecter toutes les précautions

pour éviter les chocs électriques et les dégâts de

l'équipement.

69-2467EFS—05 22

Page 23