Page 1

Put Bar Code Here

R7120D

WARNING

Burner Control Modules

INSTALLATION INSTRUCTIONS

APPLICATION

The R7120D is a microprocessor-based functional plug in

replacement for the Fireye D and E Series system utilizing the

existing wiring subbase. The R7120D is an integrated control

for automatically fired gas, oil, or combination fuel on/off or

modulating single burner applications. The R7120D system

consists of a relay module, amplifier, and purge card. Options

include keyboard display module (KDM), Data ControlBus™

Module, ModBus™ Module, remote display mounting. See the

Honeywell Programmer Control Cross Reference (form

number 70-8313 available on the web site

www.customer.honeywell.com) for correct parts and feature

selection options.

Functions provided by the R7120D include automatic burner

sequencing, flame supervision, system status indication,

system or self-diagnostics and troubleshooting.

R7120D models available:

R7120D1002 for Fireye D10 or E1XX

R7120D2000 for Fireye D20 or E2XX

R7120D3007 for Fireye D30 or E3XX

SPECIFICATIONS

Electrical Ratings (See Table 2):

Voltage and Frequency:

120 Vac (+10/-15%), 50/60 Hz (± 10%).

Power Dissipation: 10W maximum.

Maximum Total Connected Load: 2000 VA.

Fusing Total Connected Load: 15A Fast Blow, type SC or

equivalent.

Environmental Ratings:

Ambient Temperature:

Operating: -40°F to 140°F (-40°C to +60°C).

Storage: -40°F to 150°F (-40°C to +66°C).

Humidity: 85% relative humidity continuous, noncondensing.

Vibration: 0.5G environment.

Approvals:

cULus component listed: File No. MP268, Guide No.

MCCZ.

Federal Communications Commission: Part 15, Class B,

Emissions.

Required Components for operation (order separately):

Choice is based on configuration of the Fireye Control being

replaced:

Purge Timer

Flame Amplifier

Flame Detector

Contents

Application ........................................................................ 1

Specifications ................................................................... 1

Installation ........................................................................ 1

General Instructions ......................................................... 2

Safety Shutdown .............................................................. 10

Operation .......................................................................... 10

Settings and Adjustments ................................................. 12

System Checkout ............................................................. 13

Optional Components:

S7800A1001 Keyboard Display Module

S7810M1003 Modbus Module

S7820A1007 Cover for Remote Reset

INSTALLATION

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow applicable safety requirements when installing

a control on a burner to prevent death or severe injury.

66-1196EF-01

Page 2

R7120D BURNER CONTROL MODULES

WARNING

WARNING

CAUTION

WARNING

TERMINAL SCREW

M32654

Electrical Shock Hazard.

Can cause serious injury, death or equipment

damage.

Disconnect power supply before beginning installation.

More than one disconnect may be required.

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Installer must be a trained, experienced, flame safe-

guard service technician.

3. After installation is complete, perform the System

Checkout provided in these instructions.

IMPORTANT

1. Two flame detectors can be connected in parallel

with the exception of Flame Detectors C7915,

C7927,C7961 and C7952.

2. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used

in accordance with the instructions, can cause

interference with radio communications. It has been

tested and found to comply with the limits for a Class

B computing device of Part 15 of FCC rules.

3. This digital apparatus does not exceed the Class B

limits for radio noise for digital apparatus set out in

the Radio Interference Regulations of the Canadian

Department of Communications.

GENERAL INSTRUCTIONS

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Close all manual fuel shutoff valve(s) before starting

the replacement of these controls.

Electrical Shock Hazard.

Can cause serious injury, death or equipment

damage.

Disconnect power supply before beginning installation.

More than one disconnect may be required.

1. Disconnect the power supply from the main disconnect

before beginning installation to prevent electrical shock

and equipment damage. More than one disconnect can

be required.

2. Loosen the mounting screw to remove the Fireye Con-

trol from the wiring base.

3. Check all wiring at the subbase for correct connections,

tight terminal screws, correct wire, and proper wiring

techniques. Replace all damaged or incorrectly sized

wires.

4. Replace faulty controllers, limits, interlocks, actuators,

valves, transformers, motors and other devices, as

required. Do not bypass limits and interlocks.

5. Be sure loads do not exceed the terminal ratings. Refer

to the label on the R7120D.

6. See Table 1 for recommended grounding practices. The

R7120D is a microprocessor based control and proper

grounding is important for safe, reliable operation.

Installing Honeywell Flame Detectors

1. Fireye Infrared and Ultraviolet flame detectors SHOULD

NOT be used with the R7120D.

2. See the Honeywell instruction sheets for proper installa-

tion of the flame detector. NOTE: the wire for the Honeywell F terminal is connected to the Fireye Subbase

terminal S1. The G terminal wire is connected to the Fireye S2 terminal.

3. Applications that require shutter type flame detectors:

Connect one of the shutter leadwires to the terminal

screw found on the back of the R7120D. See Fig. 1.

Use extreme care while testing the system. Line voltage is

present on most terminal connections when power is on.

Ensure proper selection of configuration jumpers before

starting the burner operation.

66-1196EF—01 2

Electrical Hazard.

Can cause equipment damage or failure.

Do not perform a dielectric test with the relay module

installed. Internal surge protectors can break down,

allowing relay module to fail the dielectric test and

destroy the internal lightning and high current

protection.

Fig. 1. R7120D terminal screw.

Page 3

R7120D BURNER CONTROL MODULES

WARNING

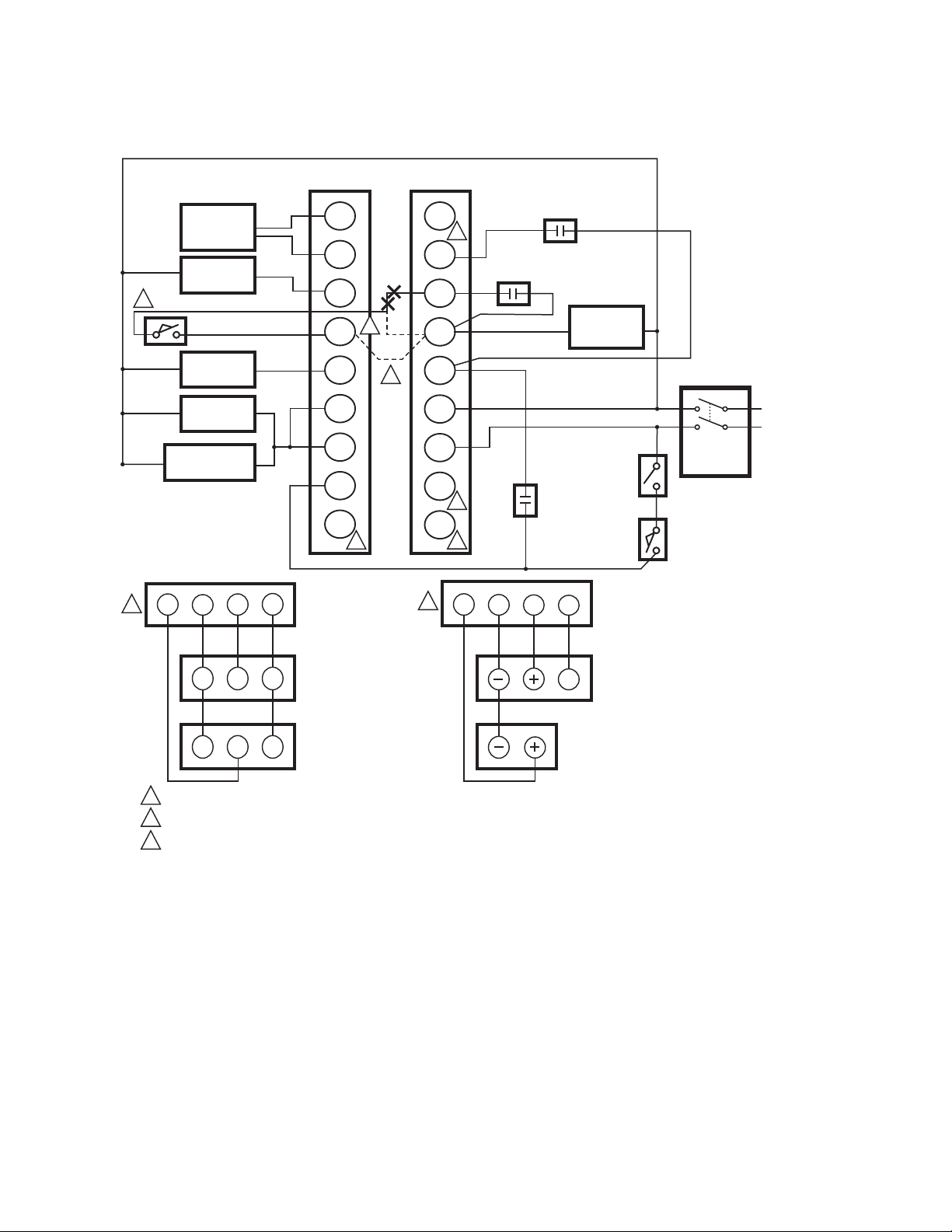

Replacing Fireye D10 or E1XX devices with R7120D

1. Locate the wire that is located on the D terminal that

goes to the High Fire (or Purge Rate) Switch.

2. Remove that wire and connect it to the M terminal.

Installing the R7120D Relay Module

1. Make sure no subbase wiring is projecting beyond the

terminal blocks. Route wiring against the back of the

subbase so it does not interfere with engagement of the

subbase terminals into the controller base.

2. Check the electrical tabs on the back of the chassis. If

they are bent out of position, reposition them with your

fingers so that they are in line.

3. Position the R7120 control into the mounting tabs of the

existing wiring base, and pivot the control into place. If a

shutter wire was installed for the Honeywell flame

detector, make sure the wire is not being pinched.

Refer to Fig. 8 for mounting information.

Table 1. Recommended Grounding Practices.

Ground Type Recommended Practice

Earth ground (subbase and relay

module).

Signal ground (Keyboard Display

Module, Data ControlBus™ Module,

Modbus Module.

1. Use to provide a connection between the subbase and the control panel of the

equipment. Earth ground must be capable of conducting enough current to blow the

15A, type SC, fast blow fuse (or breaker) in the event of an internal short circuit.

2. Use wide straps or brackets to provide minimum length, maximum surface area

ground conductors. If a leadwire is required, use 14 AWG copper wire.

3. Make sure that mechanically tightened joints along the ground path are free of

nonconductive coatings and protected against corrosion on mating surfaces.

Use the shield of the signal wire to ground the device to the signal ground terminal 3(c) of

each device. Connect the shield at both ends of the daisy chain to earth ground.

4. Gently press the control onto the subbase to engage the

terminal blades and secure with the one captivated

mounting screw at the center top of the R7120D control

housing.

5. Tighten the mounting screws enough to seat the R7120

to the wiring base but DO NOT OVERTIGHTEN.

6. If installed in an electrical panel, be sure there is ade-

quate clearance behind the closed door of the panel so

there is no interference with the R7120.

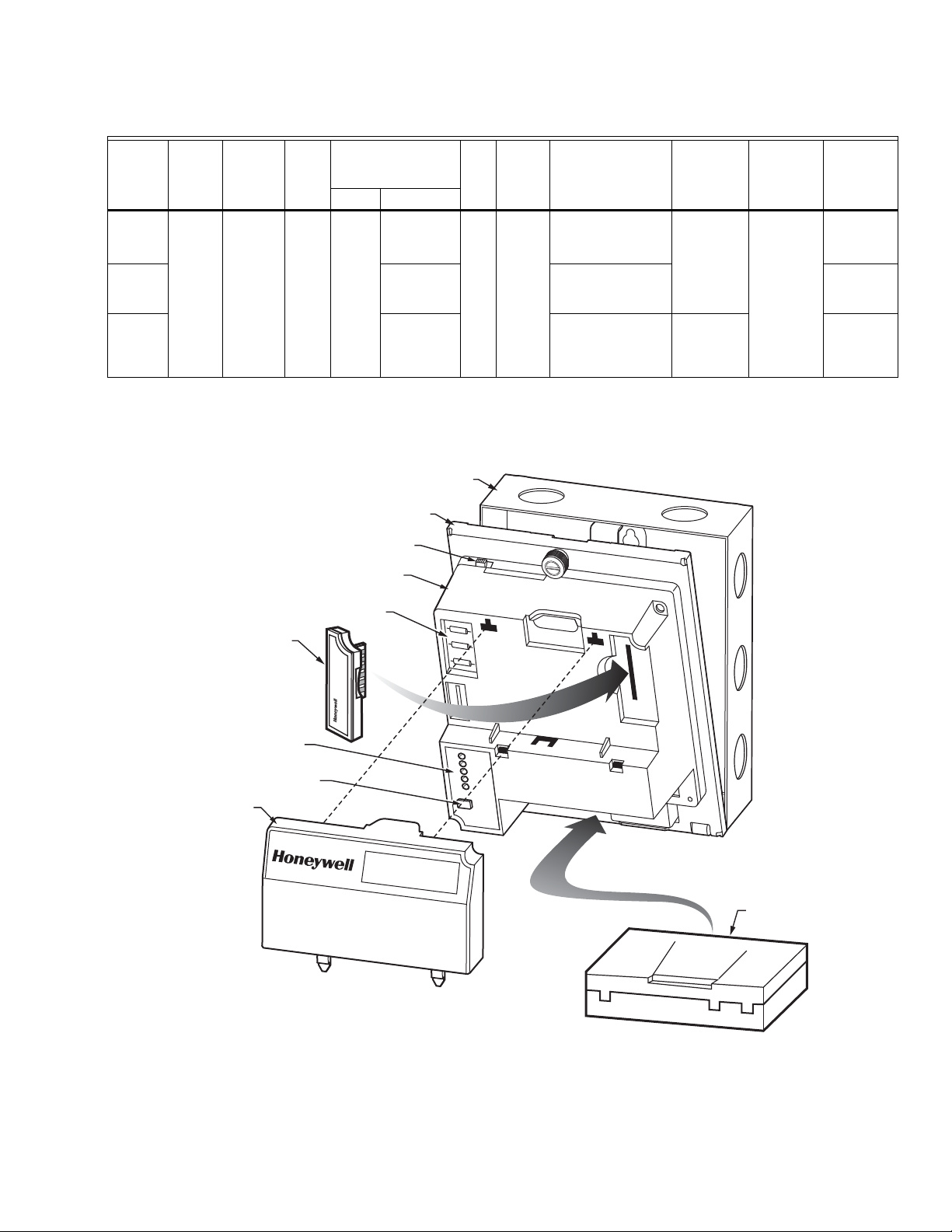

Mounting Other System Components

Refer to Fig. 9 for exploded view of installation, or the

applicable specification sheet for mounting other system

components.

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Follow applicable safety requirements when installing

a control on a burner to prevent death or severe injury.

3 66-1196EF—01

Page 4

R7120D BURNER CONTROL MODULES

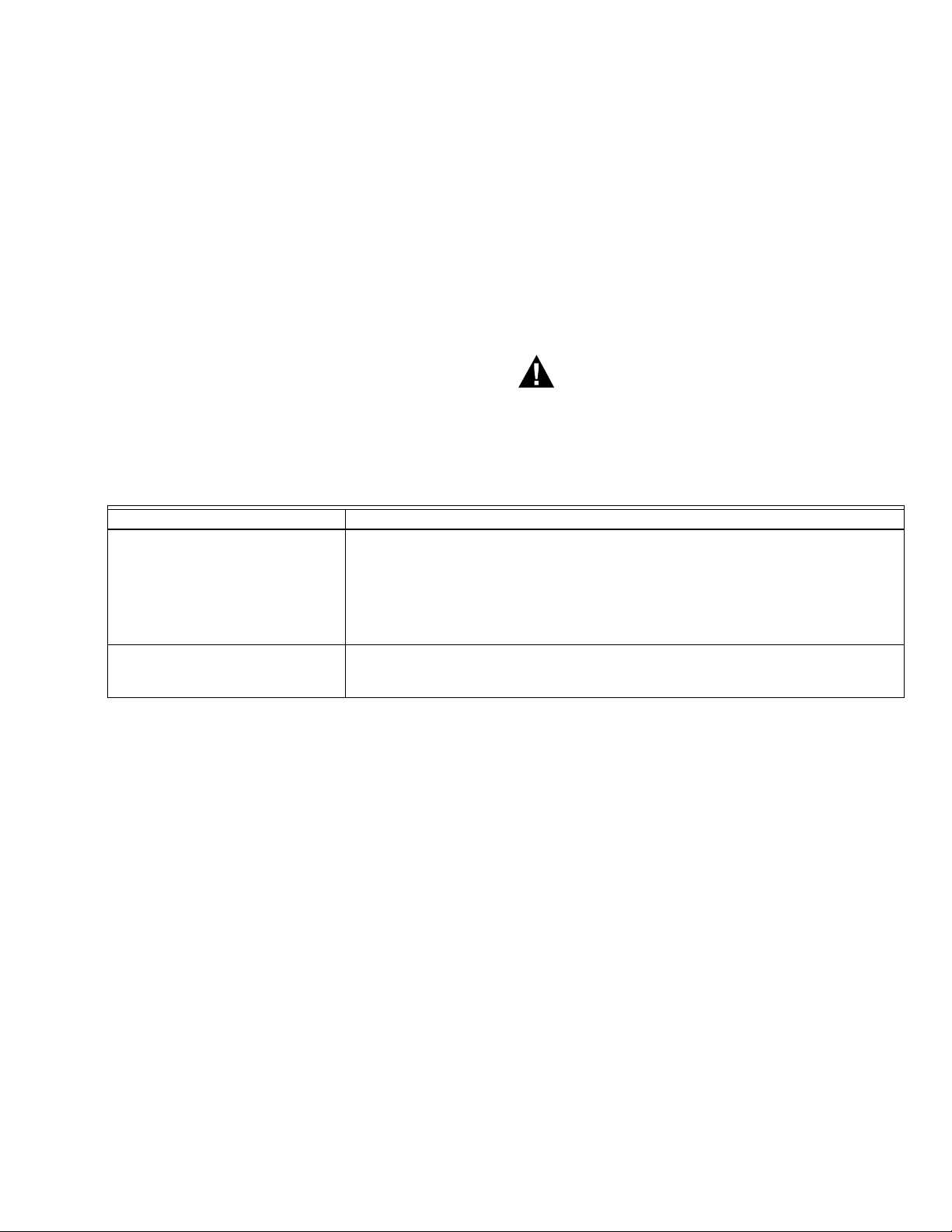

L1

RUN/TEST

SWITCH

RESET

PUSHBUTTON

STATUS LEDs

LIMITS CONTROLLER

2

6K1

3K1

KEYBOARD

DDL

DDL

COMMUNICATIONS

DISPLAY MODULE

RS485

1

2

CONFIGURATION

JUMPERS

SAFETY RELAY

CIRCUIT

R1

PII

13

LOW FIRE SWITCH

D

PURGE INTERLOCK

SWITCH

8

REMOTE

3

RESET

L1

(HOT) L2

1

MICROCOMPUTER

2K

3K

RUNNING/

LOCKOUT

INTERLOCK

9K2

4K

5K

6K

7K

8K

9K

1K

HIGH FIRE

COMMON

MODULATE

9K1

LOW FIRE

RELAY

DRIVE

CIRCUIT

3

8K1

8K2

120 Vac,

50/60 Hz

POWER SUPPLY

P

PLUG-IN PURGE

TIMER CARD

FLAME SIGNAL

1K1

X

10

11

12

TEST

4K1

7K1

2K2

TEST

JACK

F

PLUG-IN

FLAME

AMPLIFIER

RELAY

STATUS

FEEDBACK

AND LINE

VOLTAGE

INPUTS

CONTROL

POWER

INDICATES FEEDBACK SENSING

OF RELAY CONTACT STATUS

AND LINE VOLT INPUTS

FIELD WIRING

INTERNAL WIRING

G

17

R1

5

6

7

M

A

PILOT

PILOT/V2

MAIN VALVE

BLOWER

ALARM

L2

1

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

R7120D2000 DOES NOT HAVE A PURGE INTERLOCK

2

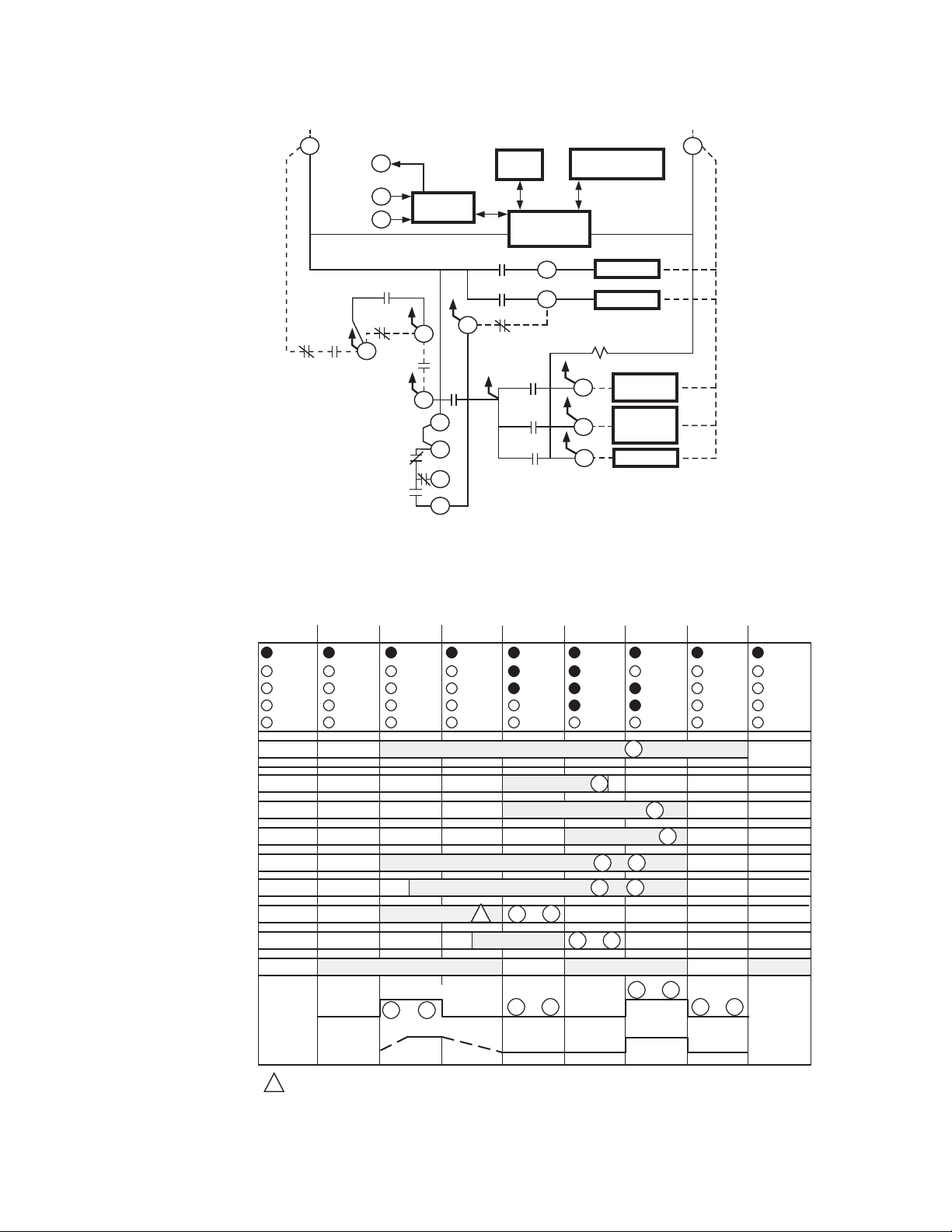

Fig. 2. Internal block diagram of the R7120D1002 and D2000.

66-1196EF—01 4

M32636

Page 5

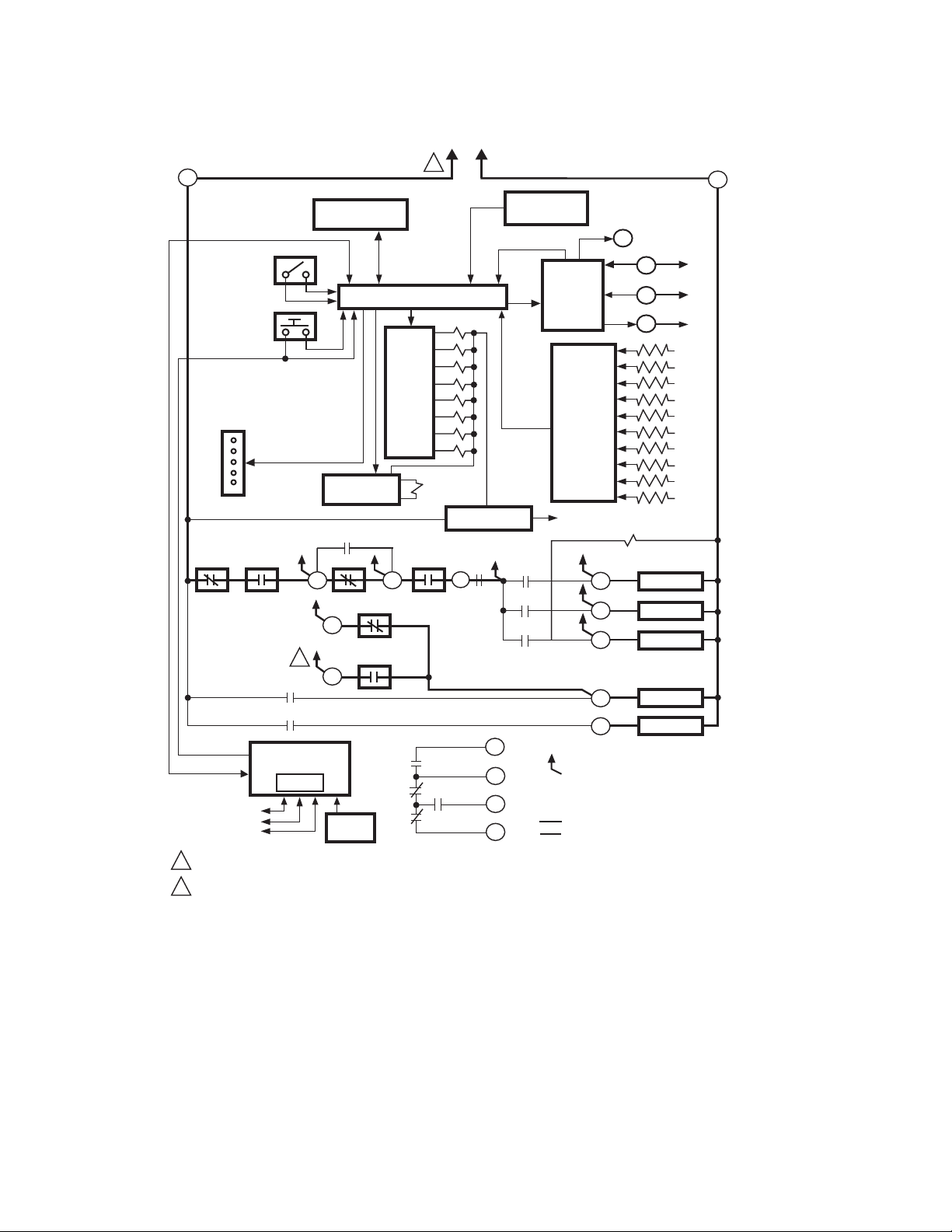

R7120D BURNER CONTROL MODULES

LED

DISPLAY

BURNER

OPERATING

CONTROLS

AND

INTERLOCKS

FLAME

SIGNAL

FIRING

RATE

MOTOR

INITIATE

(INITIAL

POWERUP

ONLY)

POWER

STANDBY

POWER

SAFE START CHECK

PREPURGE

HOLD

00

DRIVE TO

HIGH FIRE

POWER

PII CLOSED

M

SWITCHING

R7120D1002, D2000

PREPURGE

00 00 10 25 00 15 20

TIMED

PREPURGE

POWER

PILOT

FLAME

MAIN

LIMITS AND BURNER CONTROLLER CLOSED

LOCKOUT INTERLOCKS CLOSED

HIGH FIRE SW.

8TO

10

TO

MOTOR ACTION

HOLD

DRIVE TO

LOW FIRE

POWER

PILOT

FLAME

MAIN

BURNER/BLOWER MOTOR

13

1

2

X

TO

00

3

PFEP

10 SEC.

(4 SEC. IF

JR1

CLIPPED

POWER

PILOT

FLAME

MAIN

10 SEC. IGN./PILOT

15 SEC. PILOT 6

LOW FIRE SW.

M D

10 12

MFEP

RUN

POWER

PILOT

FLAME

MAIN

ALARM ALARM ALARM ALARM

MAIN VALVE

3TO

TO

FLAME PROVING

TO

POWER

PILOT

FLAME

ALARM

M

5

3

TO

13

L1

P

10 11

MAIN

TO

POSTPURGE

7

1

1

POWER

TO

10 12

STANDBY

POWER

SSC

1

PII MEANS PRE-IGNITION INTERLOCK.

R7120D1002 ONLY

2

FOR R7120D2000

3

- CLIP JR2 FOR INTERRUPTED PILOT WITH 15 SECONDS MFEP

- CLIP JR2 AND ADD JUMPER BETWEEN TERMINAL 8 AND M FOR INTERRUPTED PILOT WITH 30 SECOND MFEP

Fig. 3. Operating sequence for R7120D1002.

M32637

5 66-1196EF—01

Page 6

R7120D BURNER CONTROL MODULES

FLAME

DETECTOR

(UV)

LOCKOUT

ALARM

2

PURGE INTERLOCK

D10/EP100 OR D20/EP200

TYPICAL WIRING

S2

S1

A

2

8

X

P

D

M

1

LOW FIRE START

INTERLOCK

RUNNING

INTERLOCK

BURNER/

BLOWER

MOTOR

MAIN FUEL

VALVE(S)

PILOT

VALVE(S)

IGNITION

TRANSFORMER

11 12 10 X

1

AUTO

LO COM HI

B

R

W

W R B

1

USED ONLY ON D10 OR EP100 SERIES PROGRAMMERS.

LOCATE THE PURGE INTERLOCK WIRE CONNECTION ON TERMINAL D, REMOVE AND CONNECT TO TERMINAL M.

2

R120D2000, JUMPER WIRE ADDED BETWEEN 8 AND M PROVIDES 30 MFEP ON TERMINAL 6, IF JR2 IS REMOVED.

3

7

6

5

13

12

1

FLAME MONITOR

TERMINALS

135 OHM

FIRING RATE

MOTOR

135 OHM

CONTROLLER

3

3

L2/N

L1/L

11

1

10

1

1

11 12 10

AUTO

LO

COM

VALVE

PROOF OF

CLOSURE

X

HI

F

4-20mA

CONTROLLER

BURNER

SWITCH

FLAME MONITOR

TERMINALS

4-20 mA

MOTOR

MASTER

SWITCH

LIMIT

OPERATING

SWITCHES

L2

L1

M32638

Fig. 4. Internal block diagram of the R7120D3007 with pre-ignition interlocks.

66-1196EF—01 6

Page 7

R7120D BURNER CONTROL MODULES

INTERNAL

ELECTRONICS

M32639

CONFIGURATION

JUMPERS

PURGE

TIMER

FLAME

AMPLIFIER

ALARM

BLOWER

INTERMITTENT

PILOT

1R1

3K1

6K1

A

M

6

MAIN VALVE

7

LF

D

F

G

17

L1

L1

L2

L2

15 SECOND

INTERMITTENT

PILOT VALVE

5

4K1

7K1

2K2

1K1

P

AIRFLOW

3

13

LIMITS

CONTROLLER

1R1

X

10

PRE-

IGNITION

11

8K2

9K1

12

9K2

LED

DISPLAY

BURNER

OPERATING

CONTROLS

AND

INTERLOCKS

FLAME

SIGNAL

DAMPER

MOTOR

Fig. 5. Internal block diagram of R7120D3007.

INITIATE

(INITIAL

POWERUP

ONLY)

POWER

1

STANDBY

PII MEANS PRE-IGNITION INTERLOCK.

00 00 10 25 00 15 20

TIMED

PREPURGE

POWER

LIMITS AND BURNER CONTROLLER CLOSED

SAFE START CHECK FLAME PROVING

R7120D SWITCHING

10 11

MOTOR ACTION

Fig. 6. Operating sequence for R7120D3007.

R7120D 3007

PREPURGE

HOLD

DRIVE TO

LOW FIRE

POWER

PILOT

FLAME

MAIN

BURNER/BLOWER MOTOR

PII CLOSED

TO

POWER

PILOT

FLAME

MAIN

RUNNING INTERLOCKS CLOSED

PFEP

10 SEC.

00

(4 SEC. IF

JR1

10 SEC. IGN./PILOT

INTERMITTENT PILOT VALVE

1

LOW FIRE SW.

7 66-1196EF—01

CLIPPED

POWER

PILOT

FLAME

MAIN

3

10 12

TO

13TO

MFEP

POWER

PILOT

FLAME

MAIN

ALARM ALARM ALARM ALARM

5

MAIN VALVE

L1

3

TO

M

TO

D

RUN

POWER

PILOT

FLAME

MAIN

ALARM

M

6

13

PTO

10 11

TO

POSTPURGE

7

POWER

10 12

TO

STANDBY

POWER

SSC

M32640

Page 8

R7120D BURNER CONTROL MODULES

L1

L2

S2

S1

A

8

7

6

5

13

12

X

P

D

M

3

L2/N

L1/L

11

10

FLAME

DETECTOR

(UV)

BURNER/

BLOWER

MOTOR

VALVE

PROOF OF

CLOSURE

LIMIT

OPERATING

SWITCHES

BURNER

SWITCH

RUNNING

INTERLOCK

LOW FIRE START

INTERLOCK

MASTER

SWITCH

LOCKOUT

ALARM

MAIN FUEL

VALVE(S)

INTERMITTENT

PILOT

VALVE(S)

INTERUPTED

PILOT

VALVE(S)

M32641

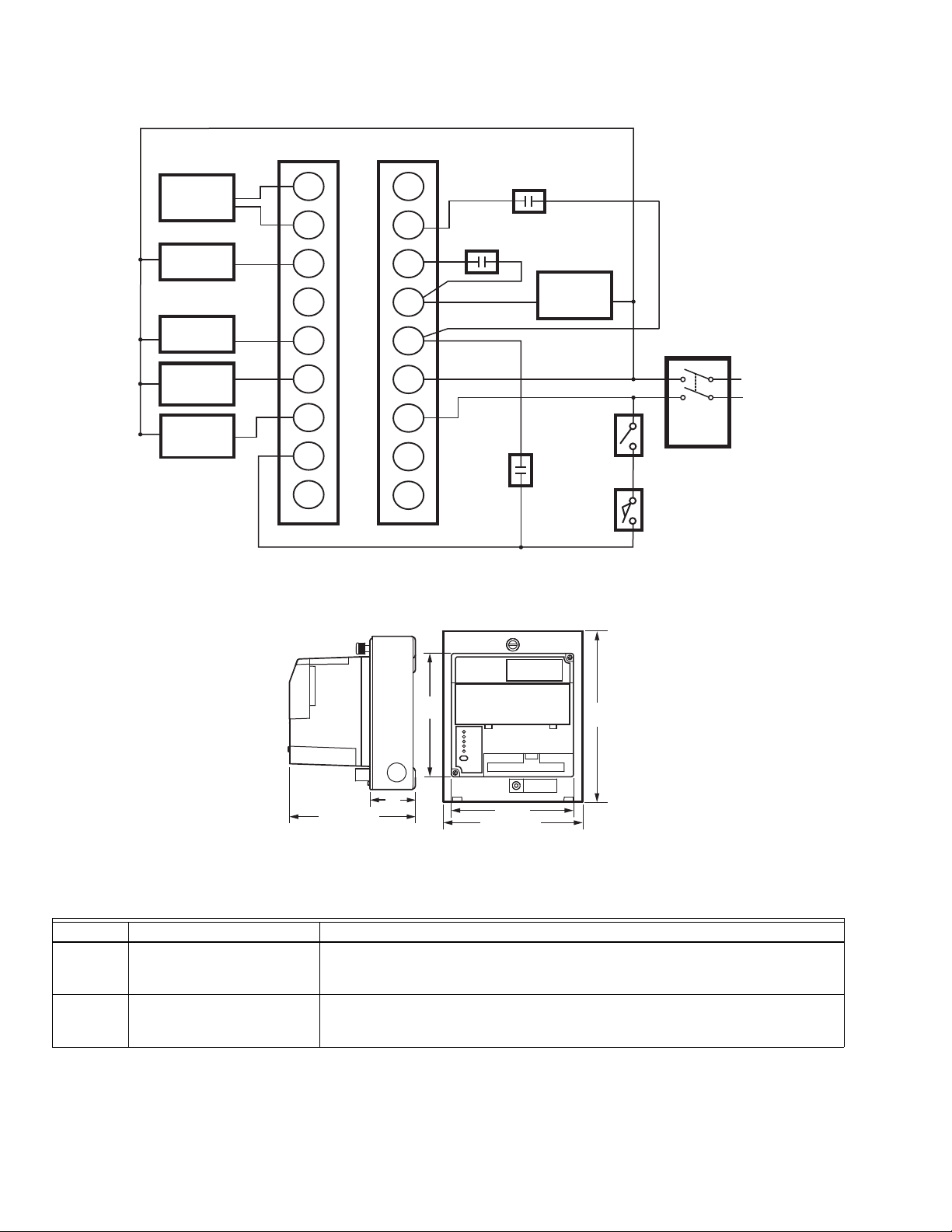

Fig. 7. Wiring hookup diagram for R7120D3007.

BURNER CONTROL

5

(127)

POWER

PILOT

FLAME

MAIN

ALARM

RESET

2

5-51/64 (147)

Fig. 8. Mounting dimensions of R7120D2000, R7120D1002, R7120D3007 Burner Control Module in in. (mm).

Terminal Typical Load Maximum Rating at 120 Vac, 60 Hz

5 or 6 Ignition

7 Main Fuel Valve(s) (solenoid/

66-1196EF—01 8

Transformer/Pilot

Valve/First Stage Fuel Valve

motorized/diaphragm) and

Vent Valve, if required

4.5A ignition and 50 VA pilot duty, or

2.5A ignition and 75 VA pilot duty.

250 VA pilot duty or 65 VA pilot duty in parallel with motorized valve(s) using a total of

1150 VA locked rotor (inrush), 460 VA to open, and 250 VA to hold or motorized valve(s)

using a total of 1500 VA locked rotor (inrush), 600 VA to open, and 250 VA to hold.

(51)

Table 2. Terminal Ratings.

5 (127)

5-45/64 (145)

7

(178)

M32698

Page 9

R7120D BURNER CONTROL MODULES

WIRING

SUBBASE

BURNER CONTROL

RELAY

MODULE

ADAPTER

PLATE

KEYBOARD

DISPLAY

MODULE

(OPTIONAL)

RESET

POWER

PILOT

FLAME

MAIN

ALARM

FLAME

AMPLIFIER

M32642

PURGE

TIMER

RESET

BUTTON

CONFIGURATION

JUMPERS

RUN/TEST

SWITCH

SEQUENCE

STATUS

LED PANEL

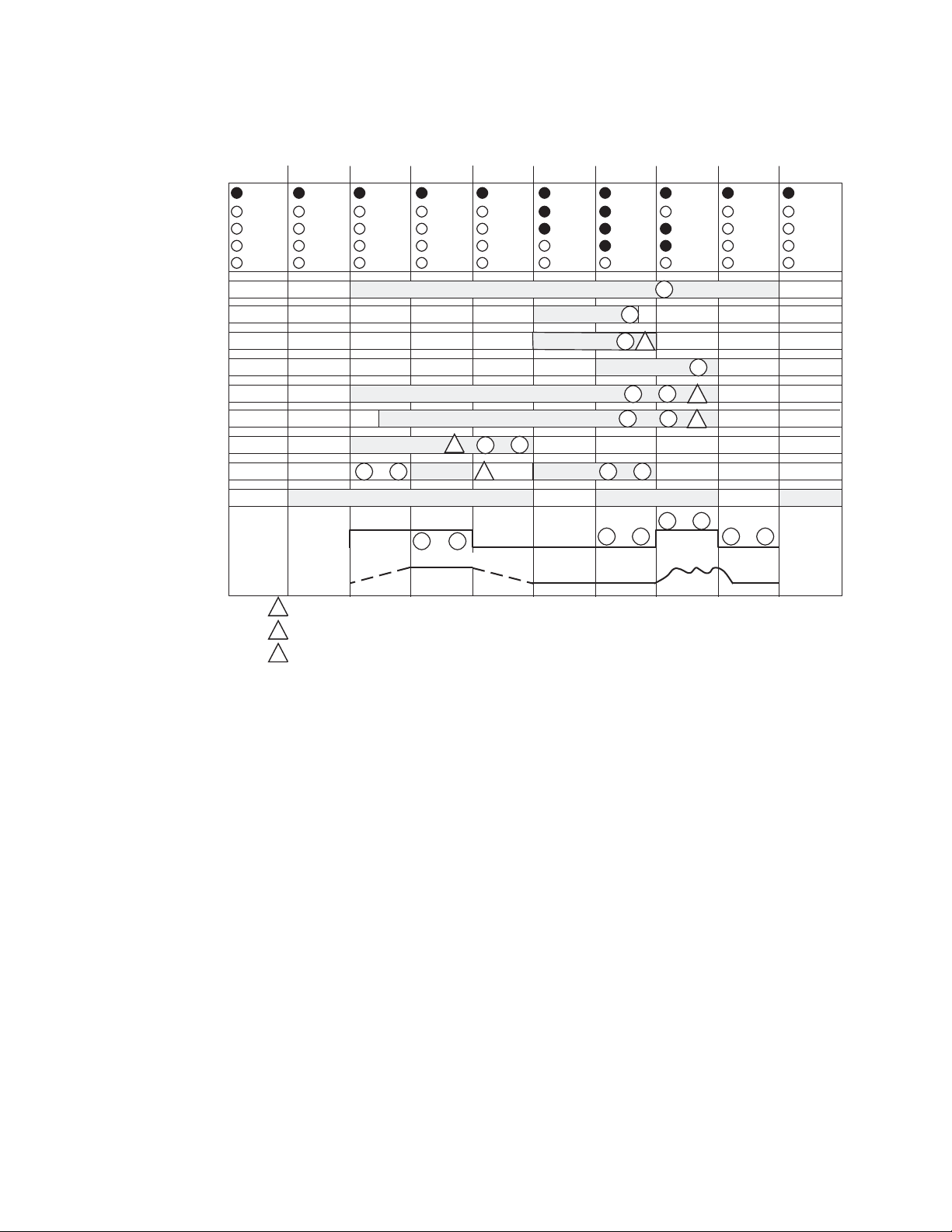

Table 3. Sequence Timing for Normal Operation.

Flame

Device Initiate Standby Purge

R7120D

10 sec. * ** 4 or 10

2000

Establishing

Period

10, 15

sec.

sec.a or

Post

Purge

Run

Timing Interlock Circuits

* 15 sec. Pre-Ignition,

Running, Low Fire

Firing

Rate

Circuit

4-wire

modulating

Energy

Approval

Saving

Pre-Purge

BodiesPilot Main

No UL/CSA

Modulating

intermittent.

R7120D

1002

10 or 15

sec

Pre-Ignition,

Lockout High and

FM/IRI

Modulating

Low Fire

R7120D

3007

10 sec. or

intermittent

Pre-Ignition,

Running, isolated

Low Fire.

2-wire

isolated

On-Off-On

UL/CSA

On-Off.

contacts

a

15 second MFEP with JR2 clipped, and 30 seconds with JR2 clipped and jumper from terminal M to terminal 8.

* STANDBY and RUN can be an infinite time period.

** PURGE will be determined by which ST7800A purge card is selected; 15 timings are available from 2 seconds to 30 minutes.

Code

Fig. 9. R7120D Relay Module, exploded view.

9 66-1196EF—01

Page 10

R7120D BURNER CONTROL MODULES

SAFETY SHUTDOWN

Safety Shutdown (Lockout) occurs if any of the following occur during the indicated period:

1. INITIATE Period:

a. Purge card is not installed or is removed.

b. Purge card is bad.

c. Configuration jumpers are changed (after 200 hours

of operation).

d. AC line power errors occur; see Operation section.

e. Four minute INITIATE period has been exceeded.

2. STANDBY Period:

a. Flame signal is present after 240 seconds.

b. Interlock check feature is enabled and the

Interlock String (including airflow switch) is closed

for 120 seconds with controller closed.

c. Ignition/pilot valve/intermittent pilot valve terminal is

energized.

d. Main valve terminal is energized.

e. Internal system fault occurs.

f. Purge card is not installed or is removed.

g. Purge card is bad.

3. PREPURGE Period:

a. Pre-Ignition Interlock opens anytime during PRE-

PURGE period (R7120D1002).

b. Flame signal is detected after first ten seconds

during PREPURGE (R7120D1002).

c. High Fire Switch fails to close within 4 minutes and

15 seconds after the firing rate motor is commanded

to drive to the high fire position at the start of PRE-

PURGE (R7120D1002).

d. Low Fire Switch fails to close within 4 minutes and

15 seconds after the firing rate motor is commanded

to drive to the low fire position at the end of PRE-

PURGE.

e. Running Interlock does not close within 30 seconds

(R7120D2000, R7120D3007).

f. Lockout Interlock does not close within 10 seconds

(R7120D1002).

g. Lockout Interlock opens during PREPURGE

(R7120D1002).

h. Ignition/pilot valve/intermittent pilot valve terminal is

energized.

i. Main valve terminal is energized.

j. Internal system fault occurs.

k. Purge card is removed.

l. Purge card is bad.

4. PILOT FLAME ESTABLISHING Period (PFEP):

a. Low Fire Switch opens.

b. Lockout Interlock opens (RM7140L).

c. Ignition/pilot valve/intermittent pilot valve terminal is

not energized.

d. Early spark termination terminal is energized after

five seconds.

e. No flame is present at the end of PFEP.

f. Main valve terminal is energized (R7120D2000,

R7120D3007).

g. Internal system fault occurs.

h. Purge card is removed.

i. Purge card is bad.

5. MAIN FLAME ESTABLISHING Period (MFEP):

a. Low Fire Switch Opens.

b. Lockout Interlock opens (R7120D1002).

c. Ignition/pilot valve/intermittent pilot valve terminal is

not energized.

d. Main valve terminal is not energized.

e. No flame is present at the end of MFEP.

f. Internal system fault occurs.

g. Purge card is removed.

h. Purge card is bad.

6. RUN Period:

a. No flame is present.

b. Lockout Interlock opens (R7120D1002).

c. Interrupted pilot valve terminal is energized

(R7120D2000, R7120D3007).

d. Main valve terminal is not energized.

e. Internal system fault occurs.

f. Purge card is removed.

g. Purge card is bad.

7. POSTPURGE Period:

a. Ignition/pilot valve/intermittent pilot valve terminal is

energized.

b. Main valve terminal is energized.

c. Internal system fault occurs.

d. Purge card is removed.

e. Purge card is bad.

OPERATION

Sequence of Operation

The R7120 has the following operating sequences; see Fig. 2

through 6 for internal diagrams, hookup drawings or operating

sequence charts. The R7120 LED provides positive visual

indication of the program sequence: POWER, PILOT, FLAME,

MAIN and ALARM.

Initiate

The R7120 enters the INITIATE sequence when the Relay

Module is powered. The R7120 can also enter the INITIATE

sequence if the Relay Module verifies voltage fluctuations of

+10/-15 percent or frequency fluctuations of ±10 percent

during any part of the operating sequence. The INITIATE

sequence lasts for ten seconds unless the voltage or

frequency tolerances are not met. When the tolerances are

not met, a hold condition is initiated for at least five seconds.

When the tolerances are met, the INITIATE sequence

restarts. If the condition is not corrected and the hold condition

exists for four minutes, the R7120 locks out. Causes for hold

conditions in the INITIATE sequence:

a. AC line dropout is detected.

b. AC line noise prevents a sufficient reading of the

line voltage inputs.

c. Low line voltage brownouts occur.

The INITIATE sequence also delays the burner motor starter

from being energized and de-energized from an intermittent

AC line input or control input.

Standby

The R7120 is ready to start an operating sequence when the

operating control determines a call for heat is present. The

burner switch, limits, operating control and all microcomputer

monitored circuits must be in the correct state for the R7120 to

continue into the PREPURGE sequence.

66-1196EF—01 10

Page 11

R7120D BURNER CONTROL MODULES

WARNING

Normal Start-Up Pre-Purge

The R7120 provides a pre-purge timing selectable with the

ST7800 Purge Timer cards, from two seconds to 30 minutes

with power applied and the operating control is indicating a

call for heat:

a. Running Interlocks, Pre-Ignition Interlocks, Burner

Switch, Run/Test Switch, Lockout Interlocks and all

microcomputer monitored circuits must be in the

correct operating state.

b. The blower motor output, terminal M, is powered to

start the PREPURGE sequence. The PREPURGE

timing for the R7120D1002 does not begin until the

High Fire Switch is closed.

NOTE: A jumpered High Fire Switch adds a 30-second hold

before the purge time starts.

c. The Pre-Ignition Interlock input must remain closed

throughout PREPURGE; otherwise, control returns to

the STANDBY state and holds (30 seconds) for the

R7120D2000, R7120D3007 or safety shutdown for the

R7120D1002 occurs.

d. The Lockout Interlock or Running Interlock inputs

(interlock circuit including Airflow Switch) must close

by ten seconds into PREPURGE; otherwise, a

recycle to the beginning of PREPURGE for the

R7120D2000, R7120D3007 will happen or a safety

shutdown for the R7120D1002 occurs.

e. When PREPURGE timing is complete, the firing rate

motor drives to the low fire position.

f. When the firing rate motor reaches low fire position,

the Low Fire Switch, terminal M to D, is energized to

enter the Ignition Trial state.

NOTE: A 30-second hold occurs for a jumpered Low Fire

Switch before the ignition trial period begins.

a. Terminal 7 is energized when the presence of flame is

verified at the end of the Pilot Flame Establishing

Period (PFEP).

b. Terminal 5 is turned off 10 seconds after terminal 7

is energized.

c. Terminal 6 action:

(1) R7120D1002: De-energized 15 seconds after

terminal 7 is energized.

(2) R7120D2000:

(a)Not turned off, or

(b)15 seconds after terminal 7 is energized and

JR2 is clipped, or

(c)30 seconds after terminal 7 is energized and

terminals 8 and M are jumpered and jumper

JR2 is clipped.

(3) R7120D3007: Remain energized as long as call

for heat is present.

Run

1.

Fifteen seconds after the main valve terminal 7 is

energized and flame is maintained, the R7120 goes to

Run.

2.

The firing rate motor releases to modulation

(R7120D1002,2000). Damper motor is energized

(R7120D3007).

3.

The R7120 is now in RUN and remains in RUN until the

controller input, terminal 13 opens, indicating that the

demand is satisfied or a limit opened.

Postpurge

The R7120 provides a 15-second POSTPURGE following the

completion of the RUN period (call for heat ends). The blower

motor output remains powered to drive all products of

combustion and any unburned fuel from the combustion

chamber. It also supplies combustion air to burn fuel being

purged from the fuel line downstream of the fuel shutoff valve.

Ignition Trials

1. Pilot Flame Establishing Period (PFEP):

a. With the firing rate motor at the low fire position:

(1) The pilot valve and ignition transformer,

terminals 5 and 6 are energized.

(a)The R7120D2000 has an interrupted or

intermittent pilot valve, terminal 6, depending

on the selection of configuration jumper 2.

(b) The R7120D1002 has a 15-second inter-

rupted pilot valve, terminal 6.

(c)The R7120D3007 has an intermittent pilot

valve, terminal 6.

NOTE: All of the R7120s have a ten-second interrupted pilot

valve/ignition, terminal 5.

(2) During PFEP, the Low Fire Switch must remain

closed. If it opens, a safety shutdown occurs.

(3) The Pre-Ignition Interlock input is ignored

throughout the Ignition Trial state.

b. Flame must be proven by the end of the 10-second

PFEP (four if JR1 is clipped) to allow the sequence

to continue. If flame is not proven by the end of

PFEP, a safety shutdown occurs.

2. Main Flame Establishing Period (MFEP):

1. The main fuel valve and intermittent pilot valve,

terminals 7 and 6, are de-energized and the firing rate

motor is commanded to the low fire position to begin the

POSTPURGE period.

2. After the 15-second POSTPURGE period is completed,

the blower motor (terminal 8) is de-energized and the

R7120 reenters Standby.

Run/Test Switch

Explosion Hazard.

Can cause serious injury or death.

Do not use the Run/Test switch during the Pilot Flame

Establishing Period for the R7120 when using Direct

Spark Function, because it turns on the main gas

valve, causing an accumulation of fuel in the burner.

The Run/Test Switch is located on the top side of the R7120,

see Fig. 1. The Run/Test Switch allows the burner sequence

to be altered as follows:

11 66-1196EF—01

Page 12

R7120D BURNER CONTROL MODULES

RUN/TEST SWITCH

NOTE: CONFIGURATION JUMPERS SHOWN FOR RM7800G/RM7840G.

SELECTABLE CONFIGURATION JUMPERS

M12301

1. In Pre-Purge Drive To High Fire Position

(R7120D1002), the Run/Test Switch, when placed in the

TEST position, holds in PREPURGE with the firing rate

motor in the High Fire position.

2. In the measured PREPURGE sequence, the Run/Test

Switch, when placed in the TEST position, causes the

PREPURGE timing to stop. The firing rate motor is in

the High Fire position.

3. In Pre-Purge Drive to Low Fire position, the Run/Test

Switch, when placed in the TEST position, holds the

burner sequence in PREPURGE with the firing rate

motor in the Low Fire position.

4.

In PFEP, the Run/Test Switch, when placed in the TEST

position, stops the timer during the first 8 seconds when a

10-second PFEP is selected or during the first 3 seconds

when a 4-second PFEP is selected, allowing pilot-turndown test and other burner adjustments to be made. This

activates a 15-second flameout timer that permits pilot

flame adjustment without nuisance safety shutdowns. The

Run/Test Switch is ignored during PFEP for the

R7120D1002 if terminals 5 and 7 or 7 and 6 are

jumpered.

5. During Run, the Run/Test Switch, when placed in the

TEST position, drives the firing rate motor to the Low

Fire position.

NOTE: When R7120 is switched to the Test mode, it stops and

holds at the next Run/Test Switch point in the operating

sequence. Make sure that the Run/Test Switch is in the

RUN position before leaving the installation.

SETTINGS AND ADJUSTMENTS

Selectable Site-Configurable Jumpers

The R7120 has site-configurable jumper options; see Fig. 10

and Table 4. If necessary, clip the site-configurable jumpers

with side cutters and remove the resistors from the Relay

Module.

Fig. 10. Selectable site-configurable jumpers.

Table 4. Site Configurable Jumper Options.

Jumper Number Description Intact Clipped R7120 Type

JR1 Pilot Flame Establishing

10 seconds 4 seconds All

Period (PFEP)

JR2

a

Pilot Valve

/Main Flame

Establishing Period (MFEP)

10 seconds/

Intermittent

15 or 30 seconds Interrupted

b

R7120D2000 only

JR3 Start-up Interlock Check Disabled Enabled All

a

Pilot Valve/First Stage Oil Valve (Valve/Start) terminal 5.

b

A 30 second MFEP can be accomplished by adding a jumper wire between terminals 8 and M.

SERVICE NOTE: Clipping and removing these site-configurable jumpers enhances the level of safety. Removal after 200 hours

of main valve operation will result in a hard lockout, Code 110.

66-1196EF—01 12

Page 13

R7120D BURNER CONTROL MODULES

WARNING

WARNING

SYSTEM CHECKOUT

Explosion Hazard.

Can cause serious injury or death.

Do not allow fuel to accumulate in the combustion

chamber for longer than a few seconds without igniting

to prevent danger of forming explosive mixture. Close

manual fuel shutoff valve(s) if flame is not burning at

end of specified time.

Electric Shock Hazard.

Can cause serious injury or death.

Use extreme care while testing system. Line voltage is

present on most terminal connections when power is on.

Open master switch before removing or installing R7120 Relay

Module or Keyboard Display Module connector.

Make sure all manual fuel shutoff valves are closed before

starting initial lightoff check and Pilot Turndown tests.

Do not put the system in service until you have satisfactorily

completed all applicable tests in this section and any others

recommended by the original equipment manufacturer.

Limit trial for pilot to ten seconds. Limit the attempt to light

main burner to two seconds after fuel reaches burner nozzle.

Do not exceed manufacturer nominal lightoff time.

IMPORTANT

1. If the system fails to perform properly, note the fault code,

fault message, equipment status, and sequence time on

the display. Then refer to the Troubleshooting section.

2. Repeat all required Checkout tests after all adjustments are made. All tests must be satisfied with the

flame detector(s) in their final position.

Equipment Recommended

S7800A Keyboard Display Module

Volt-ohmmeter (1M ohm/volt minimum sensitivity) with: 0-300

Vac capability. 0-6000 ohm capability. 0-10 Vdc capability.

Preliminary Inspection

Perform the following inspections to avoid common problems.

Make certain that:

1. Wiring connections are correct and all terminal screws

are tight.

2. Flame detector(s) is clean, installed and positioned

properly. Consult the applicable Instructions.

3. Combination of amplifier and flame detector(s) is

correctly used. See the amplifier specifications.

4. Plug-in amplifier and purge card are securely in place.

5. Burner is completely installed and ready to fire; consult

equipment manufacturer instructions. Fuel lines are

purged of air.

6. Combustion chamber and flues are clear of fuel and fuel

vapor.

7. Power is connected to the system disconnect switch

(master switch).

8. Lockout is reset (reset button) only if the Relay Module

is powered.

9. Run/Test Switch (if present) is in RUN position.

10. System is in STANDBY condition. STANDBY message

is displayed in the S7800 Keyboard Display Module.

11. All limits and interlocks are reset.

Flame Signal Measurement

See instructions provided with the amplifier.

Initial Lightoff Checks

Proved Pilot Systems

Perform this check on all installations that use a pilot. It should

immediately follow the preliminary inspection.

NOTE: Low fuel pressure limits, if used, could be open. If so,

bypass them with jumpers during this check.

1. Open the master switch.

2. Make sure that the manual main fuel shutoff valve(s) is

closed. Open the manual pilot shutoff valve. If the pilot

takeoff is downstream from the manual main fuel shutoff

valve(s), slightly open the manual main valve to supply

pilot gas flow. Make sure the main fuel is shut off just

upstream from the burner inlet, or disconnect power

from the automatic main fuel valve(s).

3.

Close the master switch and start the system with a call

for heat by raising the setpoint of the operating controller;

see the relay module sequence. The R7120 Relay Module should start the INITIATE sequence.

4. Let the sequence advance to PILOT IGN (status is dis-

played on the Keyboard Display Module, if used),

PILOT LED turns on, ignition spark should occur and

the pilot should light. If the pilot ignites, the FLAME LED

is energized. Go to step 7.

5. If the pilot flame is not established in ten seconds (four

seconds if configuration jumper JR1 is clipped), safety

shutdown occurs. Let the sequence complete its cycle.

6. Push the reset pushbutton, and let the system recycle

once. If the pilot still does not ignite, make the following

ignition/pilot adjustments:

a. Open the master switch and remove the Burner

Control Module from the subbase.

b. On the subbase, jumper 1 to the ignition terminal 4;

refer to the appropriate wiring diagram to determine

the proper terminal. Disconnect the leadwire to the

pilot valve if it is connected to the same terminal.

c. Close the master switch to energize only the ignition

transformer.

d. If the ignition spark is not strong and continuous,

open the master switch and adjust the ignition electrode spark gap setting to the manufacturer recom-

mendation.

e. Make sure the ignition electrodes are clean.

f. Close the master switch and observe the spark.

g. After a continuous spark is obtained, open the mas-

ter switch and add a jumper on the subbase from

terminal L1 power to the pilot terminal 3. Reconnect

the leadwire from the pilot valve if it was discon-

nected in step b.

h. Close the master switch to energize both the ignition

transformer and the pilot valve.

13 66-1196EF—01

Page 14

R7120D BURNER CONTROL MODULES

i. If the pilot does not ignite and if the ignition spark is

still continuous, adjust the pressure regulator until a

pilot is established.

j. When the pilot ignites properly and stays ignited,

open the master switch and remove the jumper(s)

from the terminals of the subbase.

k. Check for adequate bleeding of the fuel line.

l. Reinstall the Relay Module on the subbase, close the

master switch and then return to step 4.

7. When pilot ignites, measure the flame signal. If the pilot

flame signal is unsteady or approaching the 1.25 Vdc

minimum value, adjust the pilot flame size or detector

sighting to provide a maximum and steady flame signal.

8.

Recycle the system to recheck lightoff and pilot flame signal.

9. When the MAIN LED turns on, make sure the automatic

main fuel valve is open; then smoothly open the manual

main fuel shutoff valve(s) and watch for main burner

flame ignition. When the main burner flame is established, go to step 16.

10. If the main burner flame is not established within five

seconds or the normal lightoff time as specified by the

equipment manufacturer, close the manual main fuel

shutoff valve(s).

11. Recycle the system to recheck the lightoff and pilot

flame signal.

12.

Smoothly open the manual fuel shutoff valve(s) and try

lightoff again. (The first re-attempt may have been required

to purge the lines and bring sufficient fuel to the burner.)

13. If the main burner flame is not established within five

seconds or the normal lightoff time specified by the

equipment manufacturer, close the manual main fuel

shutoff valve(s). Check all burner adjustments.

14.

If the main burner flame is not established after two attempts:

a. Check for improper pilot size.

b. Check for excess combustion air at low fire.

c. Check for adequate low fire fuel flow.

d. Check for proper gas supply pressure.

e. Check for proper valve operation.

f. Check for proper pilot flame positioning.

15. Repeat steps 8 and 9 to establish the main burner

flame; then go to step 16.

16. With the sequence in RUN, make burner adjustments

for flame stability and Btu input rating.

17. Shut down the system by opening the burner switch or

by lowering the setpoint of the operating controller.

Make sure the main flame goes out. There may be a

delay due to gas trapped between the valve(s) and

burner. Make sure all automatic fuel valve(s) close.

18. Restart the system by closing the burner switch and/or

raising the setpoint of the operating controller. Observe

that the pilot is established during PILOT IGN and the

main burner flame is established during MAIN IGN

within the normal lightoff time.

19. Measure the flame signal. Continue to check for the

proper signal through the RUN period. Check the signal

at both High and Low Firing Rate positions and while

modulating, if applicable.

20. Run the burner through another sequence, observing

the flame signal for:

a. Pilot flame alone.

b. Pilot and main flame together.

c. Main flame alone (unless monitoring an intermittent

pilot). Also observe the time it takes to light the main

flame. Ignition of main flame should be smooth.

21. Make sure all readings are in the required ranges

before proceeding.

22. Return the system to normal operation.

NOTE: After completing these tests, open the master switch

and remove all test jumpers from the subbase terminals, limits/controls or switches.

Direct Spark Ignition Systems

This check applies to gas and oil burners not using a pilot. It

should immediately follow the preliminary inspection. Refer to

the appropriate sample block diagram of field wiring for the

ignition transformer and fuel valve(s) hookup.

NOTE: Low fuel pressure limits, if used, could be open. If so,

10. If the first stage burner flame is not established within

11. Check all burner adjustments.

12. Wait about three minutes. Close the master switch,

13. If the first stage burner flame is not established within

14. If necessary, repeat steps 11 through 13 to establish

15. When the first stage burner flame is established, the

16. Shut down the system by opening the burner switch or

17. If used, remove the bypass jumpers from the low fuel

18. If a second stage is used, make sure the automatic sec-

bypass them with jumpers during this check.

1. Open the master switch.

2. Complete the normal ready-to-fire checkout of the fuel

supply and equipment as recommended by the equipment manufacturer.

3. Close all manual main fuel shutoff valve(s). Check that

the automatic fuel valve(s) is closed. Make sure fuel is

not entering the combustion chamber.

4. Close the master switch and start the system with a call

for heat by raising the setpoint of the operating controller; see the relay module sequencing. The program

sequence should start the INITIATE sequence.

5.

Let the sequence advance through PREPURGE (if applicable). Ignition spark should occur when the PILOT LED turns

on. Listen for the click of the first stage fuel solenoid valve(s).

The Relay Module locks out and the ALARM LED turns on.

6. Let the Relay Module complete its cycle.

7. Open the manual fuel shutoff valve(s).

8. Push the reset button and the relay module recycles the

program sequence through PREPURGE (if applicable).

9. When the PILOT LED turns on, make sure that the first

stage burner flame is established. If it is, go to step 15.

four seconds, or within the normal lightoff time specified

by the equipment manufacturer, close the manual fuel

shutoff valve(s), and open the master switch.

open the manual fuel shutoff valve(s), and try to light off

the burner again. The first attempt may be required to

purge the lines and bring sufficient fuel to the burner.

four seconds, or within the normal lightoff time specified

by the equipment manufacturer, close the manual fuel

shutoff valve(s), and open the master switch.

the first stage burner flame. Then go to step 15.

sequence advances to RUN. Make burner adjustments

for flame stability and input rating. If a second stage is

used, go to step 18.

by lowering the setpoint of the operating controller.

Make sure the burner flame goes out and all automatic

fuel valves close.

pressure limit and subbase.

ond stage fuel valve(s) opened. Check the lightoff as

follows (or go to step 19):

a. Open the manual second stage fuel valve(s).

b. Restart the system by raising the setpoint of the

operating controller.

66-1196EF—01 14

Page 15

R7120D BURNER CONTROL MODULES

c. When the first stage burner flame is established,

watch for the automatic second stage fuel valve(s)

to open. Observe that the second stage lights off

properly.

d. Make burner adjustments for flame stability and

input rating.

e. Shut down the system by lowering the setpoint of

the operating controller. Make sure the burner flame

goes out and all automatic fuel valves close.

f. Go to step 19.

19.

Restart the system by closing the burner switch and/or raising the setpoint of the operating controller. Observe that the

burner flame is established during PILOT IGN, within the normal lightoff time specified by the equipment manufacturer.

20.

Measure the flame signal. Continue to check for the proper

signal through the RUN period. Check the signal at both

high and low firing rate positions and while modulating. Any

pulsating or unsteady readings require further attention.

21. Make sure all readings are in the required ranges

before proceeding.

NOTE: On completing these tests, open the master switch

and remove all test jumpers from the subbase terminals, limits/controls or switches.

22. Return the system to normal operation.

Pilot Turndown Test (All Installations Using a Pilot)

Perform this check on all installations that use a pilot. The

purpose of this test is to verify that the main burner can be lit

by the smallest pilot flame that can hold in the flame amplifier

and energize the FLAME LED. Clean the flame detector(s) to

make sure that it detects the smallest acceptable pilot flame.

If using AMPLI-CHECK™ or self-checking amplifier and

1M ohm/voltmeter, the flame signal fluctuates every time the

amplifier does a self-check or a shutter check.

NOTE: Low fuel pressure limits, if used, could be open. If so,

bypass them with jumpers during this test.

1. Open the master switch.

2. Close the manual main fuel shutoff valve(s).

3. Connect a manometer (or pressure gauge) to measure

pilot gas pressure during the turndown test.

4. Open the manual pilot shutoff valve(s).

5. Close the master switch and start the system with a call

for heat. Raise the setpoint of the operating controller.

The R7120D sequence should start, and PREPURGE

should begin.

6. After the PILOT LED turns on in interrupted pilot appli-

cations, set the Run/Test Switch to the TEST position to

stop the sequence. The FLAME LED comes on when

the pilot ignites.

NOTE: If the sequence does not stop, reset the system and

make sure you set the Run/Test Switch to TEST

within the first eight seconds of the PILOT IGN

sequence.

IMPORTANT

You have 0.8 second or three seconds, depending

on PFEP selected, to position the Run/Test Switch to

the TEST position to stop the sequence after the

start of the PILOT IGN period.

7. Turn down the pilot pressure very slowly, reading the

manometer (or pressure gauge) as it drops. Stop

instantly when the FLAME LED goes out. Note the pressure. The pilot is at the minimum turndown position.

Immediately turn up the pilot pressure until the FLAME

LED comes on again or the flame signal increases to

1.25 Vdc.

NOTE: If there is no flame for 15 seconds with the Run/Test

switch in the TEST position, the relay module locks out.

8. Repeat step 7 to verify the pilot gas pressure reading at

the exact point the FLAME LED light goes out.

9. Increase the pilot pressure immediately until the FLAME

LED comes on, and then turn it down slowly to obtain a

pressure reading just above the dropout point or until

the flame signal increases to 1.25 Vdc.

10. Set the Run/Test Switch in the RUN position (if used)

and let the sequence proceed. When the MAIN LED

turns on, make sure the automatic main fuel valve(s)

opens; then smoothly open the manual main fuel shutoff

valve(s) (or any other manually-opened safety shutoff

valve(s), if used) and watch for main burner ignition. If

the main burner flame is established, go to step 18.

NOTE: This step requires two people, one to open the man-

ual valve(s) and one to watch for ignition.

11. If the main burner flame is not established within five

seconds, or within the normal lightoff time specified by

the equipment manufacturer, close the manual main

fuel shutoff valve(s) and open the master switch. If the

lightoff is rough, the pilot flame size is too small.

12. Close the master switch to recycle the burner and stop

the sequence in the PILOT period by using the

Run/Test Switch.

13. Increase the pilot flame size by increasing its fuel flow

until a smooth main flame is accomplished.

14. Reposition the flame scanner sight tube or use orifices

until the pilot flame signal voltage is in the range of 1.25

to 1.50 Vdc.

15. When the main burner lights reliably with the pilot at

turndown, disconnect the manometer (or pressure

gauge) and turn up the pilot gas flow to that recommended by the equipment manufacturer.

16. If used, remove the bypass jumpers from the subbase

terminals, limits/controls, or switches.

17. Run the system through another cycle to check for

normal operation.

18. Return the system to normal operation.

Ignition Interference Test (All Flame Rods)

Ignition interference can subtract from (decrease) or add to

(increase) the flame signal. If it decreases the flame signal

enough, it causes a safety shutdown. If it increases the flame

signal, it could cause the FLAME LED to come on when the

true flame signal is below the minimum acceptable value.

Start the burner and measure the flame signal with both

ignition and pilot (or main burner) on, and then with only the

pilot (or main burner) on. Any significant difference (greater

than 0.5 Vdc) indicates ignition interference.

15 66-1196EF—01

Page 16

R7120D BURNER CONTROL MODULES

To Eliminate Ignition Interference

1. Make sure there is enough ground area.

2. Be sure the ignition electrode and the flame rod are on

opposite sides of the ground area.

3. Check for correct spacing on the ignition electrode:

a. 6000V systems—1/16 to 3/32 in. (1.6 to 2.4 mm).

b. 10,000V systems—1/8 in. (3.2 mm).

4. Make sure the leadwires from the flame rod and ignition

electrode are not too close together.

5. Replace any deteriorated leadwires.

6. If the problem cannot be eliminated, consider changing

the system to an ultraviolet flame detection system.

Hot Refractory Saturation Test (All Infrared Detectors)

Start the burner and monitor the flame signal during the warmup period. A decrease in signal strength as the refractory

heats up indicates hot refractory saturation. If saturation is

extreme, the flame signal drops below 1.25 Vdc and the

system shuts down as though a flame failure occurred.

If hot refractory saturation occurs, the condition must be corrected.

Add an orifice plate in front of the cell to restrict the viewing area,

lengthen the sight pipe or decrease the pipe size (diameter).

Continue adjustments until hot refractory saturation is eliminated.

Hot Refractory Hold-in Test (Rectifying Photocell, Infrared Detectors, Ultraviolet Detectors)

This condition can delay response to flame failure and also

can prevent a system restart if hot refractory is detected.

Infrared (lead sulfide) detectors can respond to infrared rays

emitted by a hot refractory, even when the refractory has

visibly ceased to glow. Infrared radiation from a hot refractory

is steady, but radiation from a flame has a flickering

characteristic. The infrared detection system responds only to

flickering infrared radiation; it can reject a steady signal from

hot refractory. The refractory steady signal can be made to

fluctuate if it is reflected, bent or blocked by smoke or fuel mist

within the combustion chamber. Be careful when applying an

infrared system to verify its response to flame only.

The ultraviolet detector can respond to hot refractory above

2300°F (1371°C).

1. Operate the burner until the refractory reaches its maxi-

mum temperature (infrared only). If the installation has a

multi-fuel burner, burn the heavier fuel that is most likely

to reflect, bend or obscure the hot refractory steady

infrared radiation.

2.

When the maximum refractory temperature is reached,

close all manual fuel shutoff valves, or open the electrical

circuits of all automatic fuel valves.

3. Visually observe when the burner flame or FLAME LED

goes out. If this takes more than three seconds, the

infrared detector is sensing hot refractory.

4. Immediately terminate the firing cycle. Lower the set-

point to the operating controller, or set the Fuel Selector

Switch to OFF. Do not open the master switch.

NOTE: Some burners continue to purge oil lines between

the valves and nozzles even though the fuel valves

are closed. Terminating the firing cycle (instead of

opening the master switch) allows purging the combustion chamber. This reduces a buildup of fuel

vapors in the combustion chamber caused by oil line

purging.

5. If the detector is sensing hot refractory, correct the con-

dition by one or more of the following procedures:

a. Add an orifice plate in front of the cell to restrict the

viewing area of the detector.

b. Resight the detector at a cooler, more distant part of

the combustion chamber. Make sure the detector

properly sights the flame.

c. Try lengthening the sight pipe or decreasing the

pipe size (diameter).

For details, refer to the detector Instructions and the

equipment Operating Manual. Continue adjustments until hot

refractory hold-in is eliminated.

Ignition Spark Response Test (All Ultraviolet Detectors)

Test to make certain that the ignition spark is not actuating the

FLAME LED:

Close the pilot and main burner manual fuel shut-off valve(s).

1.

2. Start the burner and use the Run/Test Switch (if avail-

able) to stop the sequence in the PILOT IGN period.

Ignition spark should occur, but the flame signal should

not be more than 0.5 Vdc.

3.

If the flame signal is higher than 0.5 Vdc and the FLAME

LED does come on, consult the equipment operating

manual and resight the detector farther out from the

spark, or away from possible reflection. It may be necessary to construct a barrier to block the ignition spark from

the detector view. Continue adjustments until the flame

signal due to ignition spark is less than 0.5 Vdc.

NOTE: The Honeywell Q624A and Q652B Solid State Spark

Generators prevent detection of ignition spark when

properly applied with C7027, C7035, C7044 or

C7061 Ultraviolet Flame Detectors. The Q624A and

Q652B are only for use with gas pilots.

Response To Other Ultraviolet Sources

Some sources of artificial light (such as incandescent or

fluorescent bulbs, mercury sodium vapor lamps and daylight)

produce small amounts of ultraviolet radiation. Under certain

conditions, an ultraviolet detector responds to these sources as

if it is sensing a flame. To check for proper detector operation,

check the Flame Failure Response Time (FFRT) and conduct

Safety Shutdown Tests under all operating conditions.

Flame Signal With Hot Combustion Chamber (All Installations)

1. With all initial start-up tests and burner adjustments

completed, operate the burner until the combustion

chamber is at the maximum expected temperature.

2.

Observe the equipment manufacturer warm-up instructions.

3. Recycle the burner under these hot conditions and

measure the flame signal. Check the pilot alone, the

main burner flame alone, and both together (unless

monitoring only the pilot flame when using an intermittent pilot, or only the main burner flame when using

DSI). Check the signal at both High and Low Firing Rate

positions and while modulating, if applicable.

66-1196EF—01 16

Page 17

R7120D BURNER CONTROL MODULES

Check the FFRT of the flame amplifier and relay module.

4. Lower the setpoint of the operating controller and

observe the time it takes for the burner flame to go out.

This should be within the maximum FFRT.

5. If the flame signal is too low or unsteady, check the

flame detector temperature. Relocate the detector if the

temperature is too high.

6. If necessary, realign the sighting to obtain the proper

signal and response time.

7. If the response time is still too slow, replace the Plug-In

Flame Signal Amplifier.

8. If the detector is relocated or resighted, or the amplifier

is replaced, repeat all required Checkout tests.

Safety Shutdown Tests (All Installations)

Perform these tests at the end of Checkout, after all other

tests are completed. If used, the external alarm should turn

on. Press the RESET pushbutton on the relay module to

restart the system.

1. Detection of flame 240 seconds after entry to STANDBY

from RUN, fault code 9. Detection of flame from 10 seconds up to 30 seconds into PREPURGE time.

a. Simulate a flame to cause the flame signal voltage

level to be at least 1.25 Vdc for 40 seconds after

entry to STANDBY from RUN and also simulate a

flame signal for 10 seconds to 30 seconds for PREPURGE.

b. *Flame Detected* fault is displayed on the Keyboard

Display Module. Fault code 9 or 15 or 18 is displayed

to denote the fault.

c. Safety shutdown occurs.

2. Failure to ignite pilot.

a. Close pilot and main fuel manual shutoff valve(s).

b. Cycle burner on.

c. Automatic pilot valve(s) should be energized but the

pilot cannot ignite.

d. *Pilot Flame Fail* fault is displayed on the Keyboard

Display Module. Fault code 28 is displayed four or ten

seconds, depending on the jumper configuration

selection for Pilot Flame Establishing Period (PFEP)

after the pilot valve(s) is energized to denote the fault.

e. Safety shutdown occurs.

3. Failure to ignite main (only interrupted pilot application).

a. Open the manual pilot valve(s); leave the main fuel

manual shutoff valve(s) closed.

b. Depress the RESET button.

c. Start the system.

d. The pilot should ignite and the flame signal should

be at least 1.25 Vdc but the main burner cannot light.

e. The flame signal should drop below 1.25 Vdc within

the FFRT of the amplifier and the relay module after

the interrupted pilot goes out.

f. *Main Flame Ign.* fault is displayed on the Key-

board Display Module. Fault code 19 is displayed to

denote the fault.

g. Safety shutdown occurs.

4. Loss of flame during RUN.

a. Open the main fuel manual shutoff valve(s) and

open manual pilot shutoff valve(s).

b. Depress the RESET button.

c. Start the system. Start-up should be normal and the

main burner should light normally.

d. After the sequence is in the normal RUN period for at

least ten seconds with the main burner firing, close

the manual main fuel shutoff valve(s) to extinguish

the main burner flame. (On intermittent pilot applica-

tions, also, close the pilot manual shutoff valve.)

e. The flame signal should drop below 1.25 Vdc within

the FFRT of the amplifier and the relay module after

the main flame and/or pilot goes out.

f. *Main Flame Fail* fault is displayed on the Keyboard

Display Module. Fault code 17 is displayed to

denote the fault.

g. Safety shutdown occurs, or will recycle if jumper JR2

is intact, then lock out on failure to light the pilot.)

IMPORTANT

If the relay module fails to shut down on any of these

tests, take corrective action; refer to Troubleshooting

and the relay module diagnostics and return to the

beginning of all Checkout tests.

When all Checkout tests are completed, reset all switches to

the original status.

17 66-1196EF—01

Page 18

R7120D BURNER CONTROL MODULES

66-1196EF—01 18

Page 19

R7120D BURNER CONTROL MODULES

19 66-1196EF—01

Page 20

R7120D BURNER CONTROL MODULES

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

66-1196EF—01 M.S. 07-11

Printed in U.S.A.

Page 21

Put Bar Code Here

Modules de régulation de brûleur

R7120D

NOTICE D'INSTALLATION

APPLICATION

Le R7120D est un dispositif de rechange fonctionnel

enfichable commandé par microprocesseur pour le système

Fireye série D et E utilisant la plaque de raccordement

existante. Le R7120D est un régulateur intégré pour brûleurs

à allumage automatique au gaz, au mazout ou au gaz et

mazout combinés dans les applications marche-arrêt ou à

brûleur unique à modulation. Le système R7120D comprend

un module de relais, un amplificateur et une carte de

balayage. Les options incluent un module à clavier et afficheur

(KDM), un module Data ControlBus™, un module ModBus™

et un système d’affichage à distance. Voir le guide des

références des contrôleurs de programmation Honeywell

(réf. 70-8313, disponible sur le site Web

www.customer.honeywell.com) pour les pièces correctes et la

sélection des caractéristiques.

Les fonctions fournies par le R7120D incluent la mise en

séquence automatique du brûleur, la surveillance de la

flamme, l'indication de l'état du système, les diagnostics du

système ou l'autodiagnostic et le dépannage.

Modèles R7120D disponibles :

R7120D1002 pour Fireye D10 ou E1XX

R7120D2000 pour Fireye D20 ou E2XX

R7120D3007 pour Fireye D30 ou E3XX

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques électriques (voir tableau 2) :

Tension et fréquence :

120 V c.a. (+10/-15 %), 50/60 Hz (± 10 %).

Dissipation d’énergie : 10 W maximum.

Charge connectée totale maximum : 2000 VA.

Fusible pour charge connectée totale : 15 A à fusion rapide,

type SC ou équivalent.

Caractéristiques environnementales :

Température ambiante :

Fonctionnement : -40 °F à 140 °F (-40 °C à 60 °C).

Stockage : -40 °F à 150 °F (-40 °C à 66 °C).

Humidité : 85 % d’humidité relative en continu, sans

condensation.

Vibration : 0,5 G environnement.

Homologations :

Composant répertorié cULus : fichier n° MP268; Guide n°

MCCZ.

Federal Communications Commission Émissions Section

15 Classe B.

Éléments requis pour le fonctionnement (à commander

séparément) :

La sélection est basée sur la configuration du contrôleur

Fireye remplacé :

Temporisateur de balayage

Amplificateur de flamme

Détecteur de flamme

Table des matières

Application ........................................................................1

Caractéristiques Techniques ............................................ 1

Installation ........................................................................ 2

Instructions Générales .....................................................2

Coupure De Sécurité ........................................................ 11

Fonctionnement ...............................................................11

Réglages Et Ajustements .................................................13

Vérification Du Système ...................................................14

Composants en option :

Module afficheur et clavier S7800A1001

Module Modbus S7810M1003

Couvercle S7820A1007 pour réarmement à distance

66-1196EF-01

Page 22

MODULES DE RÉGULATION DE BRÛLEUR R7120D

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

MISE EN GARDE

AVERTISSEMENT

INSTALLATION

Risque d’incendie ou d’explosion.

Peut causer des dégâts et des blessures graves,

voire mortelles.

Respecter toutes les exigences de sécurité

applicables lors de l’installation d’un régulateur sur un

brûleur pour éviter les blessures graves ou mortelles.

Risque de choc électrique.

Peut causer des dégâts et des blessures graves,

voire mortelles.

Débrancher l’alimentation avant de commencer

l’installation. Il peut être nécessaire d'effectuer plus

d'un débranchement.

Lors de l’installation de ce produit...

1. Lire attentivement ces instructions. Le non-respect des

instructions peut endommager le produit ou provoquer

une situation dangereuse.

2. L’installateur doit être un technicien formé, expérimenté

et qualifié en matière de surveillance de flamme.

3. Une fois l’installation terminée, effectuer la vérification

du système indiquée dans cette notice.

IMPORTANT

1. Deux détecteurs de flamme peuvent être connectés

en parallèle à l’exception des détecteurs de flamme

C7915, C7927, C7961 et C7952.

2. Cet équipement génère, utilise et peut émettre de

l’énergie de radiofréquence, et s'il n'est pas installé

et utilisé conformément aux instructions, peut causer

des interférences aux communications radio. Il a été

testé et est conforme aux limites des dispositifs

numériques de classe B, conformément à la partie

15 du règlement de la FCC.

3. Cet appareil numérique ne dépasse pas les limites

de classe B relatives au bruit radioélectrique des

appareils numériques indiquées dans le règlement

sur le brouillage radioélectrique du ministère des

Communications canadien.

Veiller à bien choisir les cavaliers de configuration avant de

lancer le fonctionnement du brûleur.

Risque de choc électrique.

Peut endommager ou causer une défaillance de

l’équipement.

Ne pas effectuer de test diélectrique lorsque le module

de relais est installé. Le suppresseur de surtension

interne peut tomber en panne, causant l’échec du test

diélectrique par le module du relais et la destruction de

la protection contre la foudre et les hautes intensités.

Risque de choc électrique.

Peut causer des dégâts et des blessures graves,

voire mortelles.

Débrancher l’alimentation avant de commencer

l’installation. Il peut être nécessaire d'effectuer plus

d'un débranchement.

1. Débrancher l’alimentation électrique au sectionneur

principal avant de commencer l’installation pour

empêcher les chocs électriques et les dégâts matériels.

Il peut être nécessaire d'effectuer plus d'un

débranchement.

2. Desserrer la vis de montage pour retirer le contrôleur

Fireye de la plaque de raccordement.

3. Vérifier tout le câblage de la plaque de raccordement et

s’assurer que les connexions sont correctes, les vis de

bornes serrées, les fils corrects et les techniques de

câblage adéquates. Remplacer tous les fils

endommagés ou de taille incorrecte.

4. Remplacer les contrôleurs défectueux, les limiteurs, les

dispositifs de verrouillage, les actionneurs, les vannes,

les transformateurs, les moteurs et les autres

dispositifs, selon le besoin. Ne pas contourner les

limiteurs et les dispositifs de verrouillage.

5. S’assurer que les charges ne dépassent pas les

caractéristiques nominales des bornes. Consulter

l’étiquette du R7120D.

6. Voir le tableau 1 pour les pratiques de mise à la terre

recommandées. Le R7120D est un contrôleur à

microprocesseur et une bonne mise à la terre est

importante pour assurer un fonctionnement sûr et fiable.

INSTRUCTIONS GÉNÉRALES

Risque d’incendie ou d’explosion.

Peut causer des dégâts et des blessures graves,

voire mortelles.

Fermer toutes les vannes de combustible manuelles

avant de procéder au remplacement.

Tester le système avec grande prudence. Une tension de

secteur est présente sur la plupart des connexions de bornes

lorsque le système est alimenté.

66-1196EF—01 2

Installation des détecteurs de flamme Honeywell

1. Les détecteurs de flamme à infrarouge et ultraviolets

Fireye NE DOIVENT PAS être utilisés avec le R7120D.

2. Consulter les modes d’emploi Honeywell pour

l’installation correcte du détecteur de flamme.

REMARQUE : le fil de la borne F Honeywell est

connecté à la borne S1 de la plaque de raccordement

Fireye. Le fil de la borne G est connecté à la borne S2

du Fireye.

3. Applications nécessitant des détecteurs de flamme à

obturateur : Connecter un des fils de l’obturateur à la vis

de borne au dos du R7120D. Voir la Fig. 1.

Page 23

AVERTISSEMENT

VIS DE BORNE

Fig. 1. Vis de borne du R7120D.

MF32654

Remplacement des dispositifs Fireye D10 ou E1XX par le R7120D

1. Repérer le fil situé sur la borne D et connecté à

l’interrupteur haute combustion (ou taux de balayage).

2. Retirer ce fil et le brancher à la borne M.

MODULES DE RÉGULATION DE BRÛLEUR R7120D

sorte qu’il n’interfère pas avec l’enclenchement des

bornes de la plaque de raccordement dans la base du

régulateur.

2. Vérifier les languettes électriques au dos du châssis. Si

elles ne sont pas bien positionnées, les repositionner

avec les doigts pour bien les aligner.

3. Placer le contrôleur R7120D sur les languettes de

montage de la plaque de raccordement existante et

faire pivoter le contrôleur en place. Si un fil d’obturateur

a été installé sur le détecteur de flamme Honeywell,

s'assurer qu'il n'est pas pincé. Consulter la Fig. 8 pour

les informations de montage.

4. Appuyer doucement le contrôleur sur la plaque de

raccordement pour engager les fiches de bornes et fixer

avec la vis de montage captive en haut et au milieu du

boîtier du contrôleur R7120D.

5. Serrer suffisamment les vis de montage pour asseoir le

R7120 sur la plaque de raccordement SANS TROP

SERRER.

6. Si l’installation se fait dans un tableau de distribution,

s’assurer qu’il y a un dégagement suffisant derrière la

porte fermée du tableau pour qu’il n’y ait pas

d’interférence avec le R7120.

Montage des autres composants du système

Consulter la Fig. 9 pour la vue éclatée de l’installation ou la

notice technique applicable pour le montage des autres

composants du système.

Installation du module de relais R7120D

1. S’assurer qu’aucun câblage de plaque de raccordement

ne se projette au-delà des borniers. Acheminer le

câblage contre le dos de la plaque de raccordement de

Tableau 1. Pratiques de mise à la masse recommandées.

Type de mise à la terre Pratique recommandée

Prise de terre (plaque de

raccordement et module de relais).

Signal à la terre (module afficheur à

clavier, module Data ControlBus™,

module Modbus).

1. Utiliser pour fournir une connexion entre la plaque de raccordement et le tableau de

commande de l’équipement. La prise de terre doit pouvoir fournir un courant

suffisant pour griller le fusible à fusion rapide de type SC de 15 A (ou le disjoncteur)

en cas de court-circuit interne.

2. Utiliser des brides ou des supports larges pour fournir des conducteurs de terre de

longueur minimum et de surface maximum. Si un fil est requis, utiliser un fil de

cuivre de calibre 14 (AWG).

3. S’assurer que les joints à serrage mécanique le long de la mise à la terre sont

exempts de revêtements non conducteurs et protégés contre la corrosion sur les

surfaces de contact.

Utiliser la gaine du fil de signal pour mettre le dispositif à la terre à la borne 3(c) de terre

de signal pour chaque dispositif. Connecter la gaine aux deux extrémités de la guirlande

à la prise de terre.

Risque d’incendie ou d’explosion.

Peut causer des dégâts et des blessures graves,

voire mortelles.

Respecter toutes les exigences de sécurité

applicables lors de l’installation d’un régulateur sur un

brûleur pour éviter les blessures graves ou mortelles.

3 66-1196EF—01

Page 24

MODULES DE RÉGULATION DE BRÛLEUR R7120D

CAVALIERS DE

CONFIGURATION

MICRO-ORDINATEUR

BOUTON

POUSSOIR DE

RÉARMEMENT

INTERRUPTEUR

DE TEST/

FONCTIONNEMENT

DEL D’ÉTAT

CARTE DE TEMPORISATEUR

DE BALAYAGE ENFICHABLE

CIRCUIT DE RELAIS

DE SÉCURITÉ

ALIMENTATION

MODULE AFFICHEUR

ET CLAVIER

HAUTE COMBUSTION

COMMUN

MODULATION

COMBUSTION

BASSE

INTERRUPTEUR

VERROUILLAGE BALAYAGE

AMPLIFICATEUR

DE FLAMME

ENFICHABLE

CIRCUIT

ENTRAÎN-

EMENT

RELAIS

ALIMENTATION

DE COMMANDE

PRISE

DE TEST

RÉARMEMENT

À DISTANCE

DDL

COMMUNICATIONS

DDL

INDIQUE UNE DÉTECTION DE SIGNAL

DE RETOUR DU STATUT DES CONTACTS

DU RELAIS ET DES ENTRÉES DE

TENSION SECTEUR

CÂBLAGE SUR SITE

CÂBLAGE INTERNE

VEILLEUSE

VEILLEUSE/V2

VANNE

PRINCIPALE

1K

9K

RETOUR

ÉTAT

RELAIS ET

ENTRÉES

SECTEUR

1K1

8K1

8K2

9K1

9K2

120 V c.a.,

50/60 Hz

SIGNAL DE FLAMME

TEST

INTERRUPTEUR COMBUSTION BASSE

PLACER SI NÉCESSAIRE UN DISPOSITIF DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

LE R7120D2000 N’EST PAS MUNI D’UN VERROUILLAGE DU BALAYAGE

RS485

1

2

3

L1

(SOUS TENSION) L2

L1

4K1

7K1

2K2

5

6

7

D

8

8K

7K

6K

5K

4K

3K

2K

F

G

17

SOUFFLANTE

6K1

M

ALARME

3K1

X

10

12

MF32636

1

2

2

1

L2

A

R1

11

LIMITEURS CONTRÔLEUR

VERROUILLAGE/

FONCTIONNEMENT

PII

3

13

R1

P

66-1196EF—01 4

Fig. 2. Schéma de principe interne du R7120D1002 et du D2000.

Page 25

AFFICHAGE

DEL

DÉMARRAGE

(MISE SOUS

TENSION