Page 1

R4140G,L and M

Flame Safeguard Programming Controls

INSTALLATION INSTRUCTIONS

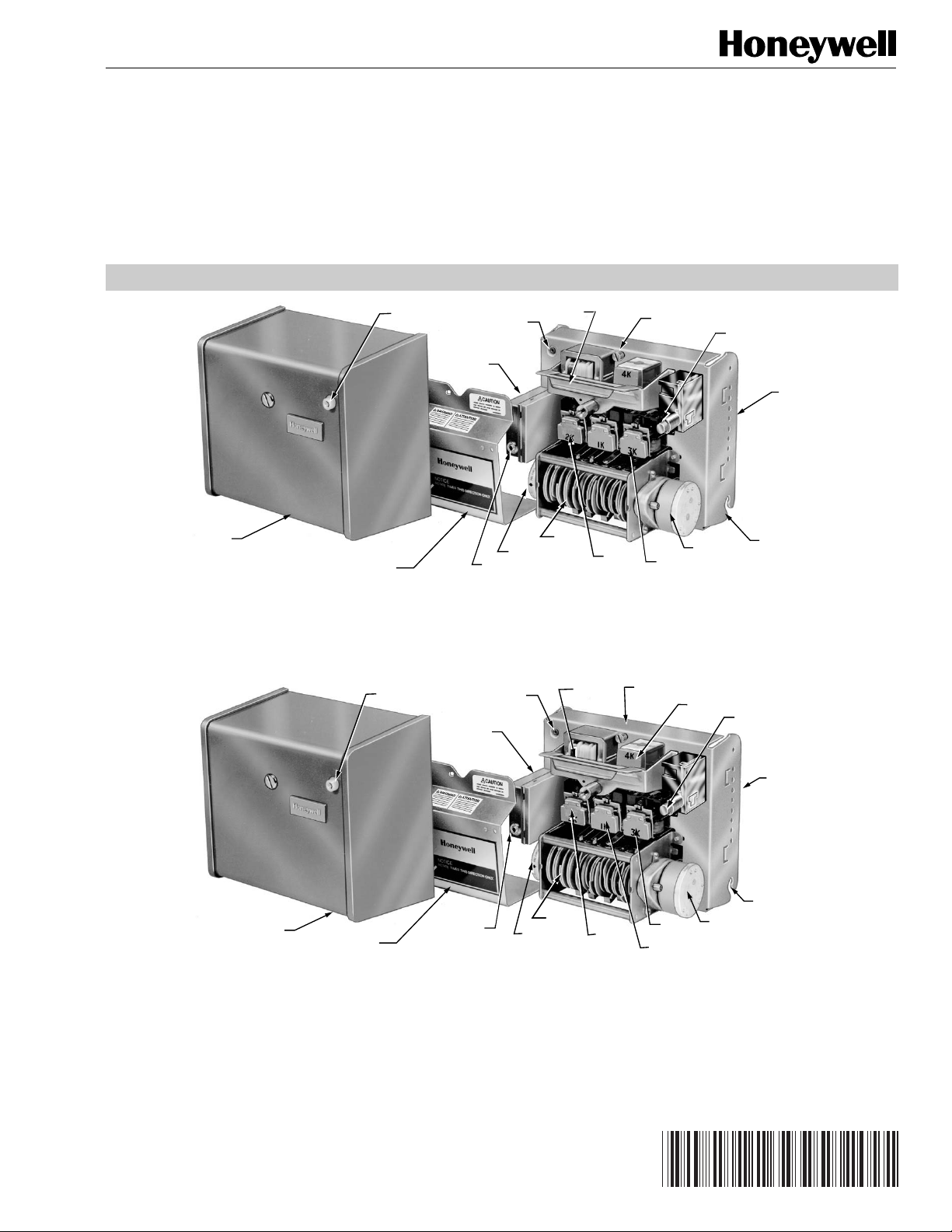

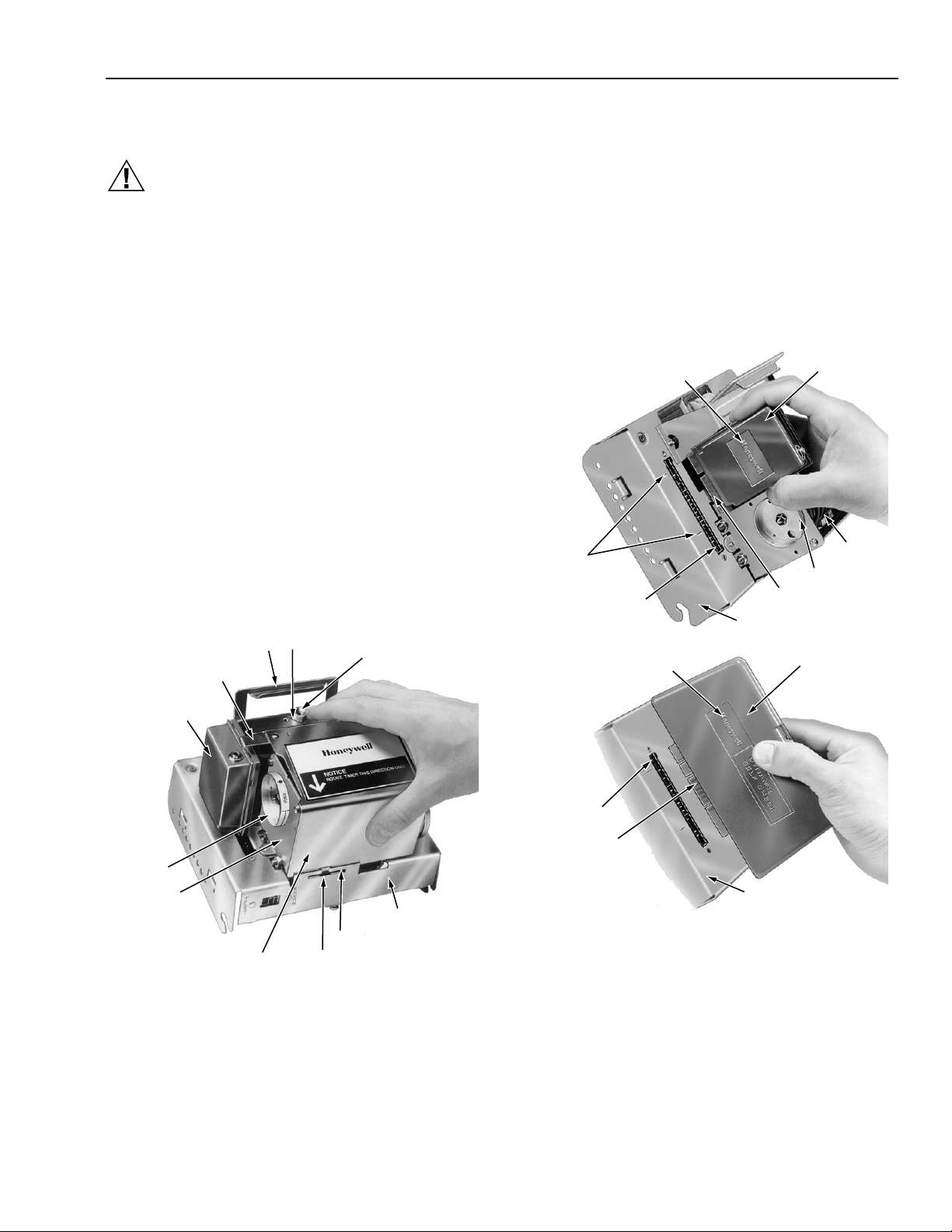

OPTIONAL

202050C

COVER

TIMER DIAL

HANDLE

TIMER

RELAY

2K

CHASSIS RETAINING

SCREW

RELAY

1K

RESET BUTTON

RELAY/TIMER

COVER

TIP JACK

PLUG-IN

FLAME SIGNAL

AMPLIFIER

FLAME SIGNAL

METER JACK

Fig. 1. Components of R4140G and R4140M Programmers.

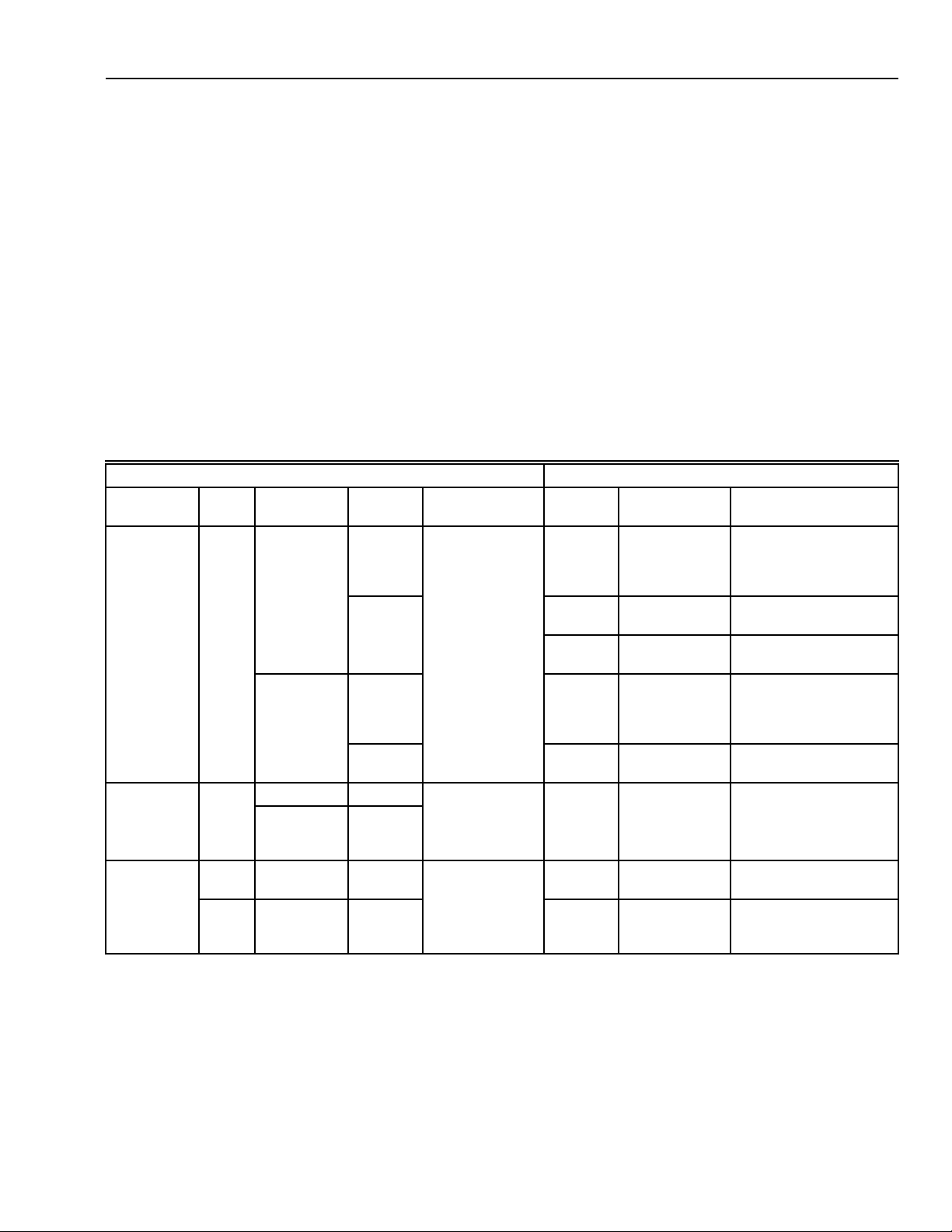

RESET BUTTON

TIP JACK

PLUG-IN

FLAME SIGNAL

AMPLIFIER

HANDLE

CHASSIS RETAINING

SCREW

TIMER

MOTOR

RELAY 4K

SAFETY SWITCH

BUTTON

CHASSIS

HINGE

BRACKET (2)

M10053

SAFETY SWITCH

BUTTON

OPTIONAL HEAVY DUTY

COVER (PART NO.

202050C OR 139695C)

RELAY/TIMER

COVER

Fig. 2. Components of R4140L Programmers.

IMPORTANT

Applications, Features, Specifications (including

dimension drawings), Operation (including

schematics and bar charts), and Wiring Diagrams

are included in these Specifications for models of

the R4140G, L, and M: R4140G—60-2337;

R4140L—60-2339; R4140M—60-2340.

Copyright © 1996 Honeywell Inc. • All Rights Reserved

FLAME SIGNAL

METER JACK

CHASSIS

HINGE

TIMER

TIMER DIAL

RELAY

2K

RELAY

3K

RELAY 1K

TIMER

MOTOR

BRACKET (2)

M7959

Contents

Installation ........................................................................... 2

Checkout ............................................................................. 11

Troubleshooting .................................................................. 18

Service Information ............................................................. 27

Testing and Maintenance .................................................... 28

60-0770-2

Page 2

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame

safeguard control technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

1. Disconnect power supply before beginning

installation to prevent electrical shock and

equipment damage.

2. All wiring must be NEC Class 1 (line voltage).

3. Loads connected to the control terminals must

not exceed those listed on the R4140 label or in

the Specifications section of the Specifications for

the R4140G,L or M.

4. Limits and interlocks must be rated to carry and

break current to the ignition transformer, pilot

valve, and main fuel valve(s) simultaneously.

5. All external timers must be listed or component

recognized by authorities having jurisdiction for

the specific purpose for which they are used.

Weather

The R4140 is not designed to be weather tight. If it is installed

outdoors, it must be protected.

Mounting the Wiring Subbase

NOTE: For installation dimensions, see Fig. 1 and 2 in the

Specifications for the R4140G,L or M.

The subbase can be mounted in any position except

horizontally with the knife-blade contacts pointing down.

The standard vertical position (shown in Fig. 5) is

recommended. Any other position decreases the

maximum ambient temperature rating.

Select a location on a wall or instrument panel. (The

0520A Subbase can be mounted directly in the

customer’s cabinet.) Be sure to allow clearances for

servicing and for removal of the R4140.

IMPORTANT

Do not mount the wiring subbase horizontally with

the knife-blade contacts pointing down.

For surface mounting, use the back of the subbase as

a template to mark the four screw locations. Drill the

pilot holes.

Insert the mounting screws and tighten them securely.

Wiring to Subbase

IMPORTANT

1. For on-off gas-fired systems, some authorities

having jurisdiction prohibit the wiring of any limit or

operating contacts in series between the flame

safeguard control and the main fuel valve(s).

2. Do not connect more than two C7012E,F or C7076A

Ultraviolet Flame Detectors (with self-checking

shutter) in parallel to the same terminals.

Use applicable installation instructions provided by the burner

manufacturer in addition to the corresponding instructions

given here. Before putting the system into service, check out

the installation using the procedures in the Checkout section

and any other procedures stipulated by the burner

manufacturer.

Location

Temperature

Install the R4140 where the surrounding temperatures

remain within the Ambient Operating Temperature Ratings in

the Specifications section of the Specifications for the

R4140G,L or M.

Humidity

Install the R4140 where the relative humidity never reaches

the saturation point. Condensation of moisture on the R4140

can cause enough leakage to short the flame signal to ground

and thus prevent the burner from starting.

Vibration

Do not install the R4140 where it could be subjected to

excessive vibration. Vibration shortens the life of the

electronic components.

CAUTION

Make sure the wiring to terminal 7 does not touch any

other terminal, especially terminal 8.

All wiring must comply with all applicable electrical

codes, ordinances, and regulations. Use NEC Class 1

(line voltage) wiring.

For normal installations, use moisture-resistant No. 14

wire suitable for at least 194°F (90°C).

For high temperature installations, use moisture

resistant No. 14 wire, selected for a temperature rating

above the maximum operating temperature, for all but

the ignition and flame detector F leadwires.

a. For the ignition, use Honeywell specification

no. R1061012 Ignition Cable or equivalent. This

wire is rated at 350°F (177°C) for continuous

duty, and up to 500°F (260°C) for intermittent

use. It has been tested to 25,000 volts.

b. For the flame detector F leadwire, use Honeywell

specification no. R1298020 or equivalent. This

wire is rated up to 400°F (204°C) for continuous

duty. It is tested for operation up to 600 volts and

breakdown up to 7500 volts.

IMPORTANT

Do not run high voltage ignition transformer wires in

the same conduit with the flame detector wiring.

For ignition installations in a contaminating

environment, use Honeywell specification no. R1239001

High Tension Ignition Cable or equivalent. This wire is

very resistant to severe conditions of oil, heat, and

corona, and is tested to withstand high voltages up to

60-0770—2

2

Page 3

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

25,000V rms in a salt bath for one minute without

breakdown. It is rated at 200°F (93°C) for continuous

duty, and up to 350°F (177°C) for intermittent use.

Refer to the appropriate wiring diagram in the

Specifications for the R4140G,L or M. Follow the burner

manufacturer’s wiring diagram, if provided.

Make sure the loads do not exceed the terminal ratings.

Refer to the label on the R4140 or to the Terminal

Ratings in the Specifications section of the

Specifications for the R41406,L or M.

Check the power supply circuit. The voltage and

frequency must match those of the R4140. Do not

connect the R4140 to a circuit that is subjected to line

voltage variations, such as would occur with on-off

switching of heavy loads. A separate power supply

circuit can be required for the flame safeguard control.

Add required disconnect means and overload

protection.

Check all wiring circuits and complete the Static

Checkout in Table 2 before installing the R4140.

Installing the Flame Detector

NOTE: Table 1 lists the flame detection systems available

for use with R4140 Programmers. Make sure you

are using the correct combination of amplifier and

flame detector(s).

Proper flame detector installation is the basis of a safe and

reliable flame safeguard installation. Refer to the instructions

packed with the flame detector and the burner manufacturer’s

instructions. Follow the instructions carefully for the best

possible flame detector application.

Keep the flame signal lead wires as short as possible from

the flame detector to the wiring subbase. Capacitance

increases with Ieadwire length, reducing the signal strength.

The maximum permissible leadwire length depends on the

type of flame detector, leadwire, and conduit. The ultimate

limiting factor in flame signal leadwire length is the signal

current. Refer to Table 4 in the Checkout section.

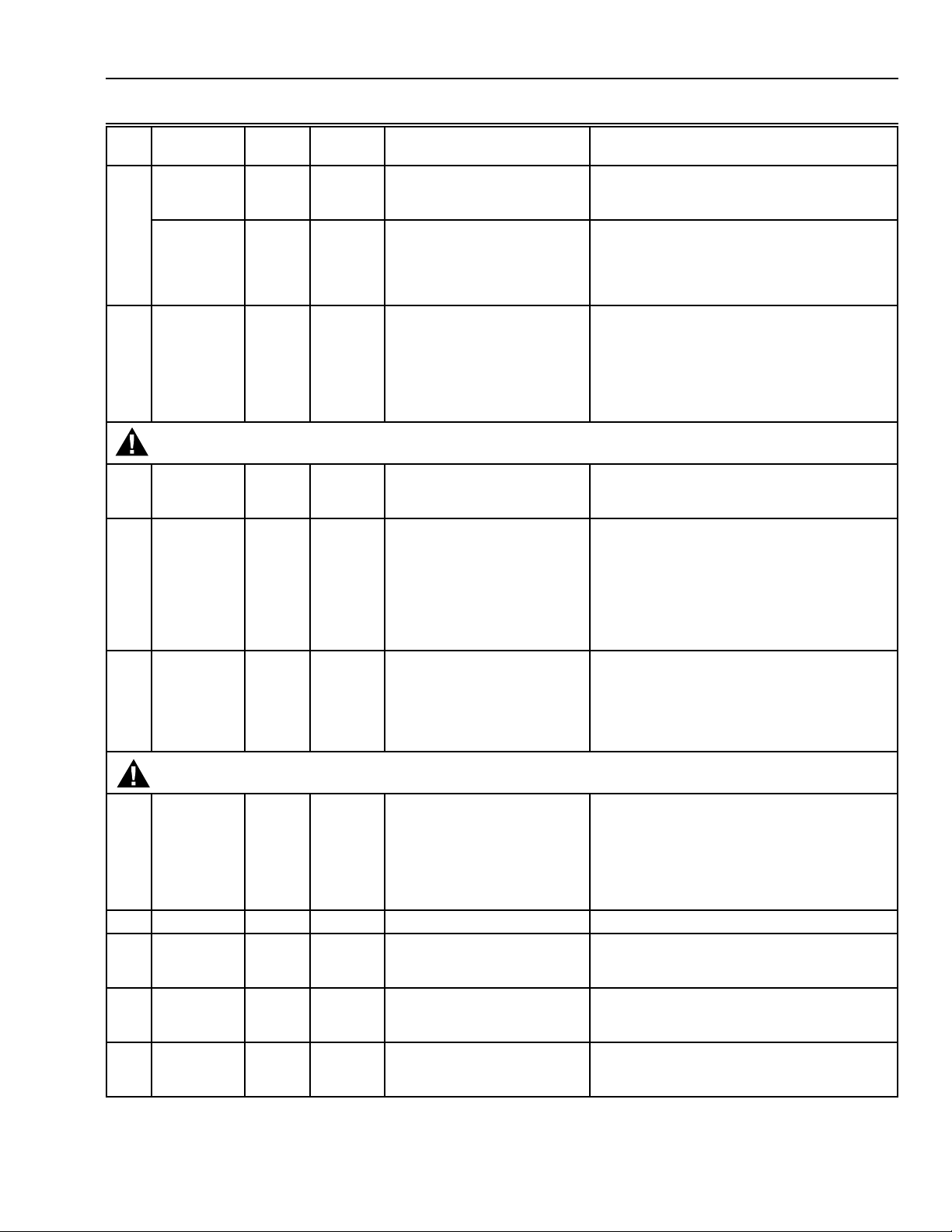

Table 1. Flame Detection Systems.

Plug-In Flame Signal Amplifiers Applicable Flame Detectors

Type Color

Checking Model

Rectification Green No R7247A 2 to 4 second Gas Rectifying

Self-

Flame Failure

Response Time Fuel Type Models

Holdersa C7004. C7007,

Flame Rods

C7011. Complete

Assemblies: C7005,

C7008, C7009, Q179.

Dynamic

Self-Check

R7247A,

R7247B

R7247B

b

b

Oil Rectifying

Photocells

Gas, Oil,

Coal

Ultraviolet

(Purple Peeper

Gas Rectifying

Flame Rods

c

C7003, C7010, C7013,

C7014.

C7012A or C.

Holdersa: C7004, C7007,

C7011. Complete

Assemblies: C7005,

C7008, C7009, Q179.

R7247C

Infrared Red No R7248A 2 to 4 second

Dynamic

R7248B

d

Gas, Oil,

Coal

Ultraviolet

(Purple Peeper

Gas, Oil, Infrared (Lead

b Coal Sulfide)

C7012E or F.

C7015.

AmpliCheck®

Ultraviolet Purple No R7249A 2 to 4 second Gas, Oil Ultraviolet

C7027, C7035, C7044.

(Minipeeper)

Blue Dynamic

Self-Check

R7476A

d

Gas, Oil,

Coal

Ultraviolet

(Adjustable

C7076.

Sensitivity)

a

Order flame rod separately; see Instructions for the holder.

b

Circuitry tests the flame signal amplifier at least 150 times a minute during burner operation and shuts down the burner if the

amplifier fails.

c

Use only Honeywell part no. 38316 Photocell.

d

Circuitry tests all electronic components in the flame detection system (amplifier and detector) 60 to 240 times a minute during

burner operation and shuts down the burner if the detection system fails.

3

60-0770—2

Page 4

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

Special Considerations for a C7012E or F

The R4140 provides two sources of power for a C7012E or F

Purple Peeper Ultraviolet Flame Detector (with self-checking

shutter). The power to the black leadwires of a C7012E can

be 120V, 208V, 220V, or 240 Vac, depending on the model of

the detector. The C7012F is available only in a 120V model.

This voltage must match the power supply of the R4140.

After checking all wiring circuits, perform this checkout before

installing the programmer on the subbase. These tests

ensure that the Q520A Wiring Subbase is wired correctly, and

that the external controllers, limits, interlocks, actuators,

valves, transformers, motors, and other devices are operating

properly.

Equipment Required

The power to the white leadwires must be 120 Vac; this is the

power supply for the operation of the self-checking shutter.

The 120V for the shutter is applied automatically at terminal

17 of the R4140 through switching action within the plug-in

R7247C Flame Signal Amplifier.

General Instructions

Using Redundant Parallel C7012E or F Detectors

For a flame that is difficult to sight, using two parallel C7012E

or F Flame Detectors reduces nuisance shutdowns. If only

one of the parallel detectors loses the flame signal, the other

continues to indicate the presence of the flame and keeps the

burner running. A flame simulating failure in either detector

causes the burner to shut down. Two C7012E detectors can

be wired in parallel to the same terminals on any R4140 (if

the voltage ratings match). Two C7012F Detectors can be

wired in parallel only on 120V models. To avoid exceeding the

rating of the solid state shutter switch in the R7247C Flame

Signal Amplifier, do not connect more than two C7012E or F

Detectors in parallel.

Static Checkout (See Table 2)

WARNING

1. Use extreme care while performing these tests;

line voltage is present on most subbase terminals

when power is on.

2. Open the master switch before installing or

removing a test jumper.

3. Be sure to remove the test jumper(s) after

completing each test before continuing to the

next test.

4. Replace all external devices not operating

properly. Do not bypass external devices.

5. Close all manual fuel shutoff valves before

starting these tests.

1. Voltmeter (W136A or equivalent) set on 0 to 300 Vac

scale.

2. Jumper wires (2) of No. 14 wire, insulated, 12 in.

(304.8 mm) long, with alligator clips at both ends.

Perform all applicable tests in Table 2, in the order

listed.

Make sure all manual fuel shutoff valves are closed.

Perform only those tests designated for the specific

programmer model being tested.

Raise the setpoint of the burner controller to simulate a

call for heat.

For each test, open the master switch and install the

jumper wire(s) between the subbase wiring terminals

listed in the Test Jumpers column.

Close the master switch before observing operation.

Read the voltage between the subbase wiring terminals

listed in the Voltmeter column.

If there is no voltage or if operation is abnormal, check

the circuits and external devices as described in the

last column.

Check all wiring in the circuits for correct connections,

tight terminal screws, correct wire, and proper wiring

techniques. Replace all worn or incorrectly sized wires.

쐅 Replace faulty controllers, limits, interlocks, actuators,

valves, transformers, motors, and other devices, as

required.

쐈 Normal operation must be obtained for each required

test before continuing the checkout.

쐉 Be sure to remove the test jumper(s) after completing

each test before continuing on to the next test.

Table 2. Static Tests of External Devices.

Test

No.

R4140

Models

Test

Jumpers Voltmeter

Normal

Operation

If Operation is Abnormal,

Check the Items Listed Below

WARNING

Make sure all manual fuel shutoff valves are closed.

1 All models None L1-L2 Line voltage at terminal L1. 1. Master switch is closed.

2. Power is connected to the master switch.

3. OverIoad protection (fuse, circuit breaker

etc.) has not opened the power line.

2 Models with

Preignition

Interlocks

Models with

Start

Interlocks

60-0770—2

None 4-L2 Line voltage at terminal 4. IMPORTANT

Low fuel pressure limits, if used, could be

open. Bypass them with jumpers for the

remaining Static Tests (if required).

None 16-L2 Line voltage at terminal 16. 1. Limits are closed. If open, determine

cause(s) and correct the condition(s).

2. Burner controller contacts are closed (call for

heat).

4

(Continued)

Page 5

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

Table 2. Static Tests of External Devices

Test

No.

3 Models with

4 All models L1-8 3-L2 1. Burner motor (fan or blower)

R4140

Models

Preignition

Interlocks

Models with

Start

Interlocks

Test

Jumpers Voltmeter

None 16-L2 Line voltage at terminal 16. 1. Preignition interlocks are closed. If open,

None 4-L2 Line voltage at terminal 4. 1. Start interlock(s), if used, is closed. If open,

starts.

2. Line voltage at terminal 3

within 12 seconds.

Normal

Operation

(Continued).

If Operation is Abnormal,

Check the Items Listed Below

determine cause(s) and correct the

condition(s).

determine cause(s) and correct the

condition(s).

2. If start interlock(s) is not used, jumper is

installed between terminals 4 and 16.

1. Burner motor circuit:

a. Manual switch of burner motor is closed.

b. Burner motor power supply, overload

protection, and starter are OK.

c. Burner motor is OK.

2. Running or Iockout interlocks (including the

Airflow switch) are closed.

WARNING

Make sure all manual fuel shutoff valves are closed.

5 Models with

5 second

ignition

6 All models L1-5 — 1. Ignition spark (if ignition

7 All models L1-6 — Same as test no. 6 for

L1-18 — Ignition spark (if ignition

transformer is connected to

terminal 18).

transformer is connected to

terminal 5).

2. Automatic pilot valve opens

(if connected to terminal 5).

NOTE: Refer to wiring diagram

of the programmer being

tested.

connections to terminal 6. (If

using direct spark ignition,

check the first stage fuel

valve(s) instead of the pilot

valve.)

1. Watch for spark or listen for buzz.

a. Ignition electrodes are clean.

b. Ignition transformer is OK.

1. Watch for spark or listen for buzz:

a. Ignition electrodes are clean.

b. ignition transformer is OK.

2. Listen for click or feel head of valve for

activation.

a. Actuator (if used) is OK.

b. Pilot valve is OK.

Same as test no. 6. (If using direct spark

ignition, check the first stage fuel valve(s)

instead of the pilot valve.)

WARNING

Make sure all manual shutoff valves are closed.

8 All models L1-7 — Automatic main fuel valve(s)

9 All models L1-9 — Alarm (if used) turns on. 1. Alarm is OK.

10 All R4140L

modeIs

11 All R4140G

modeIs

12 All R4140L

models

L1-8 and

10-11

L18 and

14-11

L1-8 and

14-11

13-L2 Firing rate motor drives open;

13-L2 Firing rate motor drives closed;

15-L2 Firing rate motor drives open;

opens. (If using direct spark

ignition on a model with

intermittent pilot/ignition on

terminal 6, check the optional

second stage fuel valve, if

used.)

zero volts at terminal 13 after

motor starts driving open.

line voltage at terminal 13 after

motor closes.

line voltage at terminal 15 after

motor opens.

1. Listen for and observe operation of the main

fuel valve(s) and actuator(s).

2. Valve(s) and actuator(s) are OK.

1. Low Fire switch is open.

2. Firing rate motor and transformer are OK.

1. Low Fire switch is closed.

2. Firing rate motor and transformer are OK.

1. High Fire switch is closed.

2. Firing rate motor and transformer are OK.

(Continued)

5

60-0770—2

Page 6

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

Test

No.

R4140

Models

13 All R4140L

modeIs

14 All R4140L

models

15 All R4140G

and R4140L

models

16 R4140M

models with

open damper

contacts

17 R4140M

models with

open damper

contacts

Final All models

Table 2. Static Tests of External Devices

Test

Jumpers Voltmeter

L18 and

13-L2 Firing rate motor drives closed;

14-11

line voltage at terminal 13 after

Normal

Operation

motor closes.

L1-15

and

14-11

13-L2 Firing rate motor drives closed;

line voltage at terminal 13 after

motor closes.

12-11 — 1. Raise setpoint of Series 90

Controller—firing rate motor

should drive toward open.

2. Lower setpoint of Series 90

Controller—firing rate motor

should drive toward closed.

L1-10 — If damper control is used,

actuator drives damper open.

L1-8 13-L2 If damper control is used,

spring return drives actuator

and damper closed; line

voltage at terminal 13 after

actuator closes.

CAUTION

After completing these tests, open the master switch and remove all test jumpers from the

subbase terminals. Also remove bypass jumpers from the low fuel pressure limits (if used).

(Continued).

If Operation is Abnormal,

Check the Items Listed Below

1. Low Fire switch is connected between

terminals 8 and 13. If not, proceed to test

no. 14.

2. Low Fire switch is closed.

3. Firing rate motor and transformer are OK.

1. Low Fire switch is connected between

terminals 15 and 13. If not, proceed to test

no. 15.

2. Low Fire switch is closed.

3. Firing rate motor and transformer are OK.

1. Series 90 Controller is OK.

2. Firing rate motor and transformer are OK.

1. Jumper wire is installed between

terminals 11 and 12.

2. Damper actuator is OK.

1. Low Fire switch is closed.

2. Damper actuator is OK.

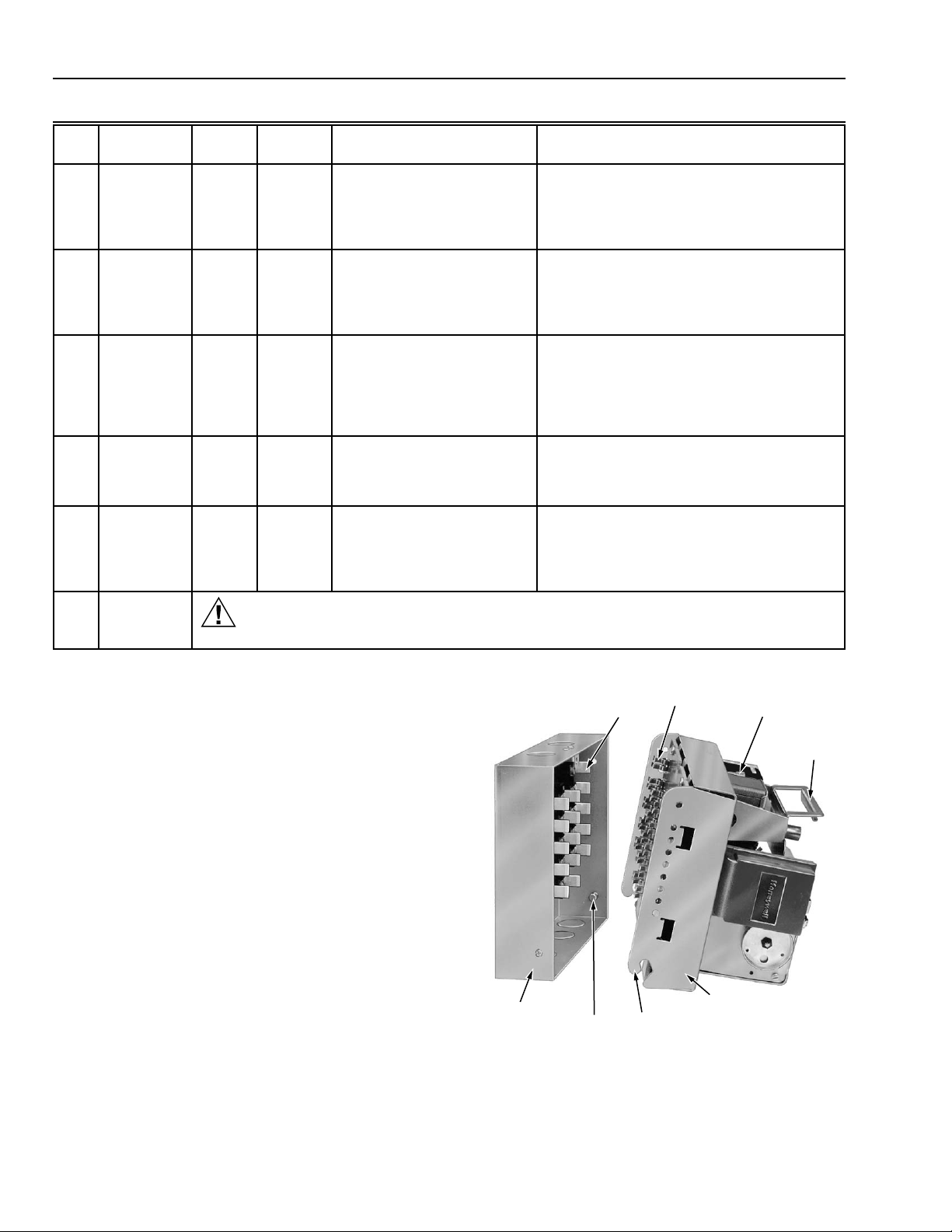

Installing the Programmer (Fig. 3)

Open the master switch.

Make sure no subbase wiring is projecting out beyond

the terminal blocks. Tuck in wiring against the back of

the subbase so it does not interfere with the contacts.

Grasp the handle of the programmer chassis and

engage the chassis hinge brackets with the pivot pins

at the bottom of the subbase.

Swing the chassis inward until the spring connectors

engage the knife-blade contacts. Push in until the

contacts are fully engaged.

Tighten the chassis retaining screw securely.

Removing the Programmer

Open the master switch.

Loosen the chassis retaining screw.

Pull outward on the handle.

Disengage the chassis hinge brackets from the

subbase pivot pins.

WIRING

SUBBASE

KNIFE-BLADE

CONTACTS (20)

PIVOT PIN (2)

SPRING

CONNECTORS

HINGE

BRACKET (2)

CHASSIS

RETAINING

SCREW

PROGRAMMER

CHASSIS

M7965

HANDLE

Fig. 3. Mounting the programmer on the subbase.

60-0770—2

6

Page 7

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

Removing and Replacing the Relay/Timer

Cover (Fig. 4)

CAUTION

If the programmer is mounted on the subbase, open

the master switch before removing or replacing the

relay/timer cover.

The relay/timer cover must be removed to install a plug-in

flame signal amplifier, to observe relay and timer operation, or

to inspect the contacts.

Removing the Cover

Grasp the relay/timer cover and squeeze until the V-notch

on the cover slides free of the stud on the handle.

Rotate the cover down and out to disengage the two tabs

from the slot in the bottom of the programmer chassis.

Pull out the cover.

Replacing the Cover

Insert the two tabs on the bottom of the cover between

the timer and the programmer chassis and engage

them with the slot in the bottom of the chassis. Make

sure the tabs are not jammed in the slot.

Rotate the cover up and in so the V-notch slides along

the stud on the handle. If the cover does not rotate

easily, the tabs are jammed.

Make sure the spring clip on the cover fits over the

plug-in amplifier.

Push in on the cover until the V-notch snaps into place

on the stud.

V-NOTCH

ON COVER

STUD ON

HANDLE

SPRING CLIP

ON COVER

HANDLE

NOTE: If installing a small amplifier, align its ends with

the two scribe marks alongside the receptacle

on the programmer.

Push in the amplifier until the circuit board is fully

inserted into the receptacle.

Make sure the amplifier is firmly in place, then replace

the relay/timer cover. Make sure the spring clip on the

cover fits over the amplifier.

NOTE: For further information about a self-checking

amplifier, refer to the Instructions packed

with the amplifier (form 60-2358 for an

R7247B or C, form 60-2357 for an R7248B, or

form 95-8270 for an R7476A).

ALIGNMENT

SCRIBE MARKS

FOR SMALL

AMPLIFIER

KEYED

RECEPTACLE

HONEYWELL

MONOGRAM

HONEYWELL

MONOGRAM

PROGRAMMER

CHASSIS

CIRCUIT

BOARD

AMPLIFIER

AMPLIFIER

TIMER

TIMER DIAL

PLUG IN

AMPLIFIER

TIMER

DIAL

TIMER

RELAY/

TIMER COVER

SLOT IN

CHASSIS

TABS (2)

ON COVER

BOTTOM OF

PROGRAMMER

CHASSIS

M7967

Fig. 4. Removing and replacing the relay/timer cover.

Installing a Plug-in Flame Signal Amplifier

(Fig. 5)

Remove the relay/timer cover.

Make sure the Honeywell monogram is on the outside,

then align the circuit board with the keyed receptacle on

the programmer.

KEYED

RECEPTACLE

CIRCUIT

BOARD

PROGRAMMER

CHASSIS

M7961

Fig. 5. Installing a plug-in flame signal amplifier.

Installation Instructions for Special Features

Some TRADELINE® models and international models (rated

for other than 120V, 60 Hz) can have one (or both) of the

following special features.

7

60-0770—2

Page 8

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

Installing Jumper on Back of Programmer (Fig. 6)

Some R4140G, L, and M models have provisions for

extending the main burner flame-establishing period

(MBFEP) at terminal 6 by installing a jumper on the back of

the programmer. If you are installing one of these models,

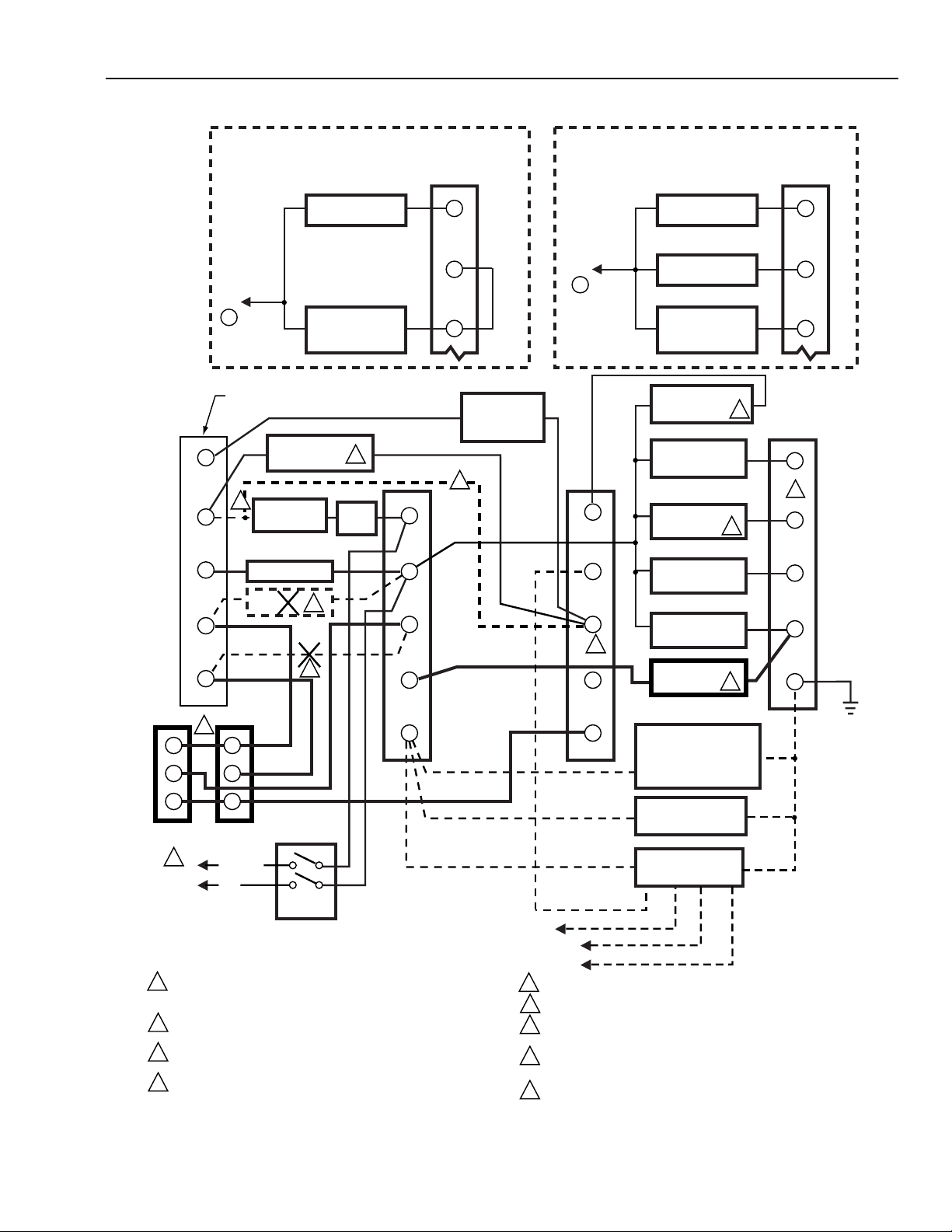

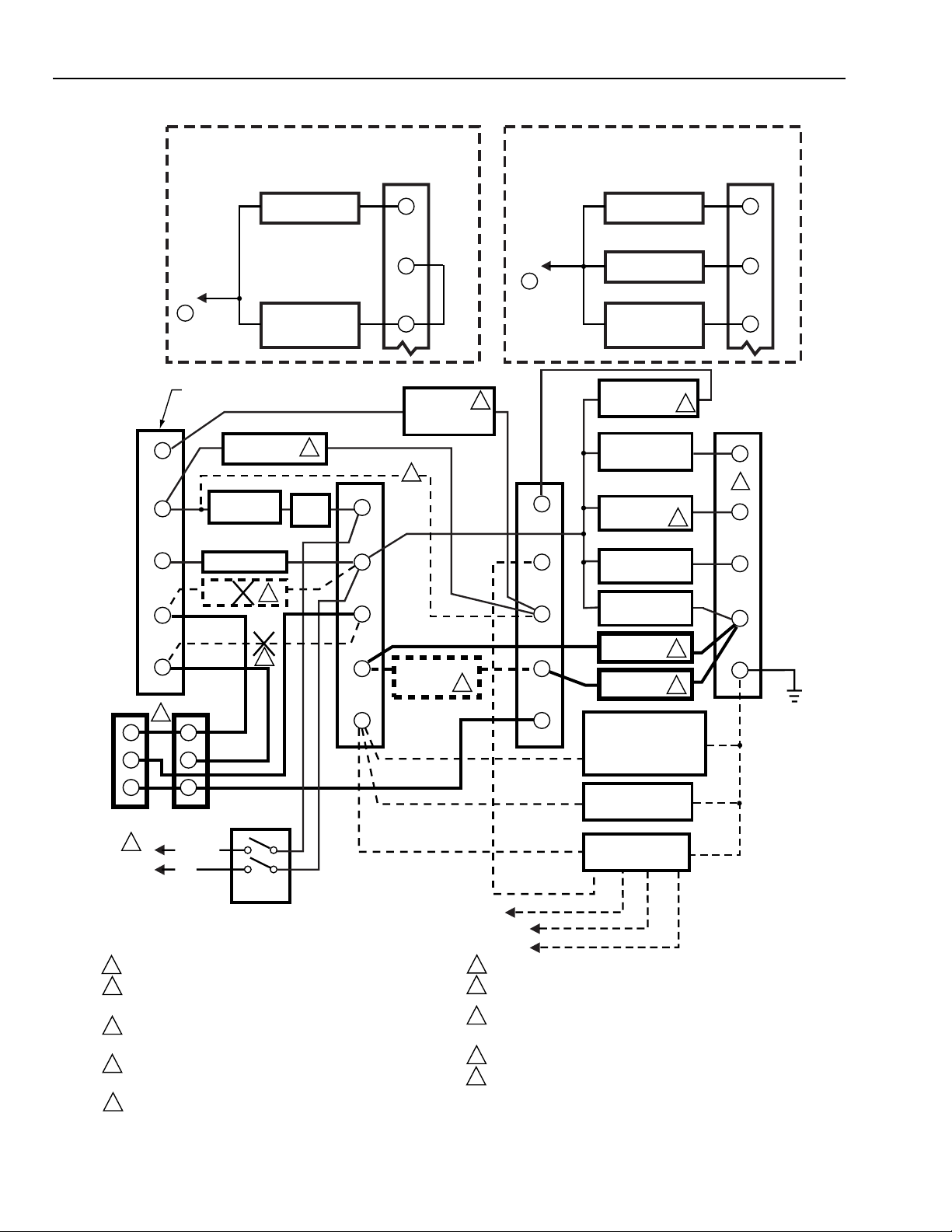

A system can be upgraded from on-off to modulating by

replacing an R4140M with an R4140G (Fig. 7). A system can

be upgraded to meet Factory Mutual and Industrial Risk

Insurers (formerly FlA) requirements by replacing an R4140M

or an R4140G with an R4140L (Fig. 8).

determine the required MBFEP. If you need the longer period

provided at terminal 6, install the jumper (included in a bag

assembly with the R4140) between the terminals labeled

JUMPER TO EXTEND MAIN IGN. TRIAL on the back of the

programmer. If you do not need the longer period, leave the

jumper off.

NOTE: Some R4140 models for use in Australia have

jumper terminals on the back of the programmer for

safety shutdown alarm options; these jumpers

cannot be used to extend the MBFEP. These R4140

models are shipped with a jumper link between the

N.O. screw terminals on the back of the

programmer. This results in alarm operation on

Requirements

UL On-Off Start and

UL On-Off (with

2-stage firing)

UL modulating

(with low highlow prepurge)

safety shutdown. N.C. screw terminals are provided

for an external auxiliary safety shutdown circuit.

Refer to the R4140 Specifications for these models.

FM/IRl

modulating (with

low-high-low

JUMPER TO

EXTEND MAIN

5

L1

6

7

8

18

L2

17

16

12

IGN. TRIAL

JUMPER

2

3

4

9

10

prepurge and

proven high fire

purge)

FM Factory Mutual requirements.

IRl Industrial Risk Insurers (formerly FlA) requirements.

UL Underwriters Laboratories Inc. requirements.

Table 3. R4140 Applications.

Application

Interlock

Circuits

Firing Rate

Switching

None R4140M

running

Start,

running, and

low fire

Start or

1-wirea (open

damper

contacts)

4-wire R4140G

pre-ignition,

running, and

low fire

Preignition,

4-wire R4140L

lockout, high

fire, and low

fire

a

Firing rate motor must close by itself (spring-return)

when power is removed.

Applicable

R4140

Several

R4140Ms

G

1

AN R4140L IS SHOWN; R4140G AND R4140M PROGRAMMERS HAVE

FEWER SPRING CONNECTORS. TERMINAL NUMBERS ARE NOT ON

THE PROGRAMMER, BUT ARE SHOWN FOR REFERENCE.

2

INSTALL JUMPER (INCLUDED IN BAG ASSEMBLY) TO OBTAIN THE

LONGER MAIN BURNER FLAME-ESTABLISHING PERIOD AVAILABLE

AT TERMINAL 6.

15

13

14

F

1

11

C8346

Fig. 6. Installing jumper to extend main burner flame-

establishing period.

Upgrading Systems

Conveniently, the R4140 family was developed in models of

varying complexity to allow the user to choose the simplest

programmer that meets their application requirements (Table 3).

IMPORTANT

Before replacing an R4140, make sure the

replacement model has the required:

— prepurge time.

— pilot/ignition timing on terminal 6.

— 5-second ignition on terminal 18 (if required).

— interlock circuits.

— safety features.

— electrical ratings.

— temperature ratings.

— approvals.

60-0770—2

8

Page 9

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

REPLACING AN R4140M WITH AN R4140G

TO

L2

WIRING SUBBASE

TERMINAL STRIP (4)

3

2

4

9

10

HIGH FIRE

COMMON

11

FOR DIRECT SPARK IGNITION (OIL OR GAS)

ON MODELS WITH INTERRUPTED

PILOT/IGNITION ON TERMINAL 6

START OR

PREIGNITION

INTERLOCKS

BURNER

CONTROLLER

120V ALARM

DAMPER

CONTROL

IGNITION

TRANSFORMER

MAIN FUEL

VALVE(S)

1

LIMITS

4

4

L1

L2

12

13

5

JUMPER

6

7

RUNNING

INTERLOCKS

(INCL. AIRFLOW

SWITCH)

2

FOR DIRECT SPARK IGNITION (OIL OR GAS)

ON MODELS WITH INTERMITTENT

PILOT/IGNITION ON TERMINAL 6

IGNITION

TRANSFORMER

TO

L2

18

17

16

2

15

1ST STAGE

FUEL VALVE

2ND STAGE

FUEL VALVE

(OPTIONAL)

5 SECOND IGNITION

(EARLY SPARK

TERMINATION)

10 SECOND

INTERRUPTED

PILOT/IGNITION

PILOT/IGNITION

MAIN FUEL

VALVES(S)

BURNER MOTOR

(BLOWER)

LOW FIRE

SWITCH

7

9

6

5

6

7

5

8

6

7

8

G

5

B

R

W

SERIES 90

CONTROLLER

1

120V, 60 HZ

POWER

SUPPLY

1

LEAVE INTERLOCKS CONNECTED BETWEEN TERMINALS 4 AND 16. (IF

INTERLOCKS ARE NOT USED, INSTALL A JUMPER WIRE BETWEEN

TERMINALS 4 AND 16.)

2

IF THE R4140G REPLACEMENT MODEL HAS "START" INTERLOCKS,

CONNECT THE BURNER CONTROLLER TO TERMINAL 16.

3

IF THE R4140G REPLACEMENT MODEL HAS "PREIGNITION" INTERLOCKS,

CONNECT THE BURNER CONTROLLER TO TERMINAL 4.

4

IF REPLACING AN R4140M WITH OPEN DAMPER CONTACTS, REMOVE

DAMPER CONTROL FROM TERMINALS 10 AND L2, AND REMOVE JUMPER

WIRE FROM TERMINALS 11 AND 12.

B

R

W

L1 (HOT)

L2

MODULATE

LOW FIRE

SERIES 90

FIRING RATE

MOTOR

MASTER

SWITCH

F

Fig. 7. Sample block diagram of field wiring for replacing an R4140M with an R4140G.

14

BLUE

BLUE

WHITE

WHITE

L2

L1

L2

5

ADD SERIES 90 CONTROLLER AND SERIES 90 FIRING RATE MOTOR.

5 SECOND IGNITION IS NOT AVAILABLE ON SOME MODELS.

6

REFER TO SPECIFICATIONS OF THE SPECIFIC R4140G MODEL TO

7

DETERMINE THE PILOT/IGNITION TIMING AVAILABLE ON TERMINAL 6.

FOR DIRECT SPARK IGNITION (OIL OR GAS), CONNECT THE

8

IGNITION TRANSFORMER AND FUEL VALVE(S) AS SHOWN IN THE

APPROPRIATE INSET.

9

ADD LOW FIRE SWTICH (IF NOT ALREADY CONNECTED).

RECTIFYING FLAME

ROD, RECTIFYING

PHOTOCELL, OR INFRARED (LEAD SULFIDE)

FLAME DETECTOR

C7027A, C7035A, OR

C7044A ULTRAVIOLET

FLAME DETECTOR

C7012A,C,E,F OR

C7076A ULTRAVIOLET

FLAME DETECTOR

BLACK

BLACK

WHITE

YELLOW

C8347

9

60-0770—2

Page 10

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

REPLACING AN R4140M OR G WITH AN R4140L

FOR DIRECT SPARK IGNITION (OIL OR GAS)

ON MODELS WITH INTERRUPTED

PILOT/IGNITION ON TERMINAL 6

IGNITION

TRANSFORMER

TO

L2

WIRING SUBBASE

TERMINAL STRIP (4)

HIGH FIRE

COMMON

B

R

W

PREIGNITION

INTERLOCKS

BURNER

CONTROLLER

120V ALARM

DAMPER

CONTROL

MODULATE

LOW FIRE

SERIES 90

FIRING RATE

MOTOR

3

4

9

10

11

5

B

R

W

SERIES 90

CONTROLLER

1

120V, 60 HZ

POWER

SUPPLY

1

LEAVE INTERLOCKS CONNECTED BETWEEN TERMINALS 3 AND 16.

LEAVE INTERLOCKS CONNECTED BETWEEN TERMINALS 4 AND 16.

2

IF THERE IS A JUMPER WIRE BETWEEN TERMINALS 14 AND 16, REMOVE

IT AND INSTALL INTERLOCKS.

IF REPLACING MODEL WITH "START" INTERLOCKS, DISCONNECT THE

3

BURNER CONTROLLER FROM TERMINAL 16 AND CONNECT IT TO

TERMINAL 4.

4

IF REPLACING AN R4140M WITH OPEN DAMPER CONTACTS, REMOVE

DAMPER CONTROL FROM TERMINALS 10 AND L2, AND REMOVE

JUMPER WIRE FROM TERMINALS 11 AND 12.

5

IF REPLACING AN R4140M, ADD SERIES 90 CONTROLLER AND SERIES 90

FIRING RATE MOTOR.

L1 (HOT)

L2

4

4

MASTER

SWITCH

MAIN FUEL

VALVE(S)

2

LIMITS

L1

L2

12

13

F

5

JUMPER

6

7

LOCKOUT

INTERLOCKS

(INCL. AIRFLOW

SWITCH)

3

ALTERNATE

LOW FIRE

SWITCH

FOR DIRECT SPARK IGNITION (OIL OR GAS)

ON MODELS WITH INTERMITTENT

PILOT/IGNITION ON TERMINAL 6

IGNITION

TRANSFORMER

TO

L2

1

18

17

16

15

9

14

BLUE

BLUE

WHITE

WHITE

L2

6

5 SECOND IGNITION IS NOT AVAILABLE ON SOME MODELS.

7

REFER TO SPECIFICATIONS OF THE SPECIFIC R4140L MODEL TO

DETERMINE THE PILOT/IGNITION TIMING AVAILABLE ON TERMINAL 6.

8

FOR DIRECT SPARK IGNITION (OIL OR GAS), CONNECT THE

IGNITION TRANSFORMER AND FUEL VALVE(S) AS SHOWN IN THE

APPROPRIATE INSET.

9

ADD LOW FIRE SWITCH (IF NOT ALREADY CONNECTED).

ADD HIGH FIRE SWITCH.

10

BLACK

L1

BLACK

L2

1ST STAGE

FUEL VALVE

2ND STAGE

FUEL VALVE

(OPTIONAL)

5 SECOND IGNITION

(EARLY SPARK

TERMINATION)

10 SECOND

INTERRUPTED

PILOT/IGNITION

PILOT/IGNITION

MAIN FUEL

VALVES(S)

BURNER MOTOR

(BLOWER)

LOW FIRE

SWITCH

HIGH FIRE

SWITCH

RECTIFYING FLAME

ROD, RECTIFYING

PHOTOCELL, OR INFRARED (LEAD SULFIDE)

FLAME DETECTOR

C7027A, C7035A, OR

C7044A ULTRAVIOLET

FLAME DETECTOR

C7012A,C,E,F OR

C7076A ULTRAVIOLET

FLAME DETECTOR

7

9

10

6

WHITE

YELLOW

5

6

7

5

8

6

7

8

G

C8349

60-0770—2

Fig. 8. Sample block diagram of field wiring for replacing an R4140M or G with an R4140L.

10

Page 11

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

CHECKOUT

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH.

Do not manually operate relays.

WARNING

Do not allow fuel to accumulate in the combustion

chamber. If fuel is allowed to enter the chamber for

longer than a few seconds without igniting, an

explosive mixture could result. It is recommended

limiting the trial for pilot to ten seconds, and limiting

the attempt to light the main burner to five seconds. In

any case, do not exceed the normal lightoff time

specified by the burner manufacturer; close the

manual fuel shutoff valves if the flame is not burning

at the end of the specified time.

CAUTION

1. Use extreme care while testing the programmer;

line voltage is present on most contacts when

power is on.

2. Open the master switch before removing the

programmer from the subbase, before reinstalling

the programmer, before installing or removing

any jumpers, and before making any

adjustments.

3. Make sure all manual fuel shutoff valves are

closed before starting the Initial Lightoff Check

and the Pilot Turndown Test.

4. If low fuel pressure limits are bypassed for any of

the tests, make sure you remove the jumpers

from these limits before putting the system into

service.

5. Do not put the system into service until you have

satisfactorily completed all applicable tests

described in this Checkout section and any

others required by the burner manufacturer.

IMPORTANT

a. If the system fails to perform properly, note the point

at which trouble occurs and refer to the

Troubleshooting section.

b. Before you reset the lockout switch, wait at least one

minute to allow the heater to cool.

c. Repeat ALL required Checkout tests after all

adjustments are made. ALL tests must be satisfied

with the flame detector(s) in its FINAL position.

Equipment Required

1. Voltmeter (Honeywell W136A or equivalent) with 0 to

300 Vac scale.

2. Microammeter (Honeywell W136A or equivalent) with

0 to 25 microampere range and SPL scale with

damping.

3. Part no. 196146 Meter Connector Plug or equivalent.

4. Jumper wires (2) of No. 14 wire, insulated, 12 in.

(304.8 mm) long, with alligator clips at both ends.

5. Watch or clock with second hand.

6. Manometer (or pressure gauge) to measure pilot gas

pressure.

7. Thermometer or thermocouple to measure temperature

at the flame detector(s).

8. Orifice plates (aperture disks) or filters, as necessary, to

adjust sensitivity of flame detector(s).

Checkout Summary

The following list summarizes the checkout tests required for

each type of installation. Instructions for each test are

included in this section; also consult the burner installation

instructions.

• Preliminary Inspection—all installations.

• Flame Signal Measurement—all installations.

• Initial Lightoff Check for Proved Pilot—all installations

using a pilot.

• Initial Lightoff Check for Direct Spark Ignition of Oil—oil

burners not using a pilot.

• Pilot Turndown Test—all installations using a pilot.

• Ignition Interference Test—all installations using flame rods.

• Hot Refractory Saturation Test—all installations using

infrared (lead sulfide) flame detectors.

• Hot Refractory Hold-in Test—all installations using rectifying

photocells or infrared (lead sulfide) flame detectors.

• Ultraviolet Response Tests—all installations using

ultraviolet flame detectors.

• Flame Signal with Hot Combustion Chamber—all

installations.

• Safety Shutdown Tests—all installations.

Refer to Fig. 1 or 2 for locations of component parts, and to

Fig. 7 or 8 for terminal locations.

Preliminary Inspection (All Installations)

Perform this inspection to avoid common problems. Make

certain that:

Wiring connections are correct and all terminal screws

are tight.

Voltage rating of the flame detector(s) matches the

voltage rating of the R4140.

Flame detector(s) is clean, installed and positioned

properly. Consult the appropriate Instructions.

Correct combination of amplifier and flame detector(s)

is used. Refer to Table 1 in the Installation section.

Spring clip on relay/timer cover is holding the plug-in

flame signal amplifier securely in the receptacle.

Burner is completely installed and ready to fire (consult

burner manufacturer’s instructions); fuel lines are

purged of air.

Combustion chamber and flues are clear of fuel and

fuel vapor.

Power is connected to the system disconnect switch

(master switch).

Lockout switch is reset (push in lockout switch reset

button, see Fig. 1 or 2).

쐅 Timer switch is in NORM position (Fig. 9).

쐈 The large dot between PURGE and PREPURGE on the

timer dial is at the index notch (Fig. 14). If not, manually

rotate the timer dial to the proper position. Rotate the

timer only in the direction shown by the arrow on the

relay/timer cover.

NOTE: The timer dial on the R4140L1030 cannot be

rotated manually, and there is no arrow on its

relay/ timer cover.

11

60-0770—2

Page 12

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

쐉 All limits and interlocks are reset.

씈 If you are installing a TRADELINE® model or an

international model (rated for other than 120V, 60 Hz)

check for one (or both) of these special features.

a. If the R4140 has provisions for extending the

main burner flame-establishing period (MBFEP)

at terminal 6, make sure the jumper is, or is not,

installed on the back of the programmer,

depending on the MBFEP desired.

RELAY/TIMER

COVER

INDEX NOTCH

PLUG-IN

AMPLIFIER

DOT ON

TIMER DIAL

TIMER

BOTTOM OF

PROGRAMMER

CHASSIS

W136A

TEST METER

RED (+) METER LEAD

SELECTOR

SWITCH

BLACK (-) METER LEAD

PLUG IN FLAME

SIGNAL AMPLIFIER

PLUG

196146 METER

CONNECTOR

PLUG

RED SPADE TIP

BLACK SPADE TIP

FLAME SIGNAL

METER JACK

M6424

Fig. 10. Measuring the flame signal.

Read the average stable current. For an R7247B or C

or an R7476A Dynamic Self-Check Amplifier, disregard

the peaks due to self-checking operation. The red

flame-indicating lamp on a self-checking amplifier

should blink:

— about 2-1/2 to 4 times a second on an R7247B.

— about 1 to 2 times a second on an R7247C or

R7476A.

— at the same rate that the flame is flickering (can

be as high as 20 times a second) on an R7248B.

M7966

TIMER SWITCH

Fig. 9. Location of timer switch and position of timer dial

at startup.

Flame Signal Measurement (Fig. 10 and

Table 4) for All Installations

Measure the flame signal at the appropriate times defined in the

following checkout tests. Read the flame signal in microamps at

the meter jack on the plug-in flame signal amplifier.

Use a Honeywell W136A Test Meter. (If a W136A is not

available, a microammeter with a 0 to 25 uA dc range

can be used.)

Set the selector switch on the test meter to:

— 25 uA for all standard amplifiers (R7247A, R7248A,

and R7249A) or for an R7248B Dynamic AmpliCheck® Infrared Amplifier or

— SPL for an R7247B or C or an R7476A Dynamic

Self-Check Amplifier. (If the test meter is not a

W136A, shunt the 0 to 25 uA dc range with a

50 microfarad capacitor.)

Use a part no. 196146 Meter Connector Plug, ordered

separately. Connect the red spade tip to the red (+)

meter lead and the black spade tip to the black (-)

meter lead.

Insert the plug into the flame signal meter jack and

allow a few seconds for the meter reading to stabilize.

If the lamp is on or off continuously while reading the flame

signal, replace the amplifier.

The meter reading must be as specified in Table 4 after

all tests are complete and all adjustments are made.

If the signal is unstable or less than the minimum acceptable

current, check the flame detector installation and circuitry.

Check the supply voltage at terminals L1-L2 on the

wiring subbase. Make sure the master switch is closed,

connections are correct, and the power supply is of the

correct voltage and frequency.

Check the detector wiring for defects including:

— incorrect connections.

— wrong type or size of wire.

— deteriorated wire.

— open circuits.

— short circuits.

— leakage paths caused by moisture, soot, or

accumulated dirt.

For a flame rod, make sure:

— there is enough ground area.

— the flame rod is properly located in the flame.

— temperature at the flame rod insulator is no

greater than 500°F (260°C).

— ignition interference is not present (see Ignition

Interference Test section).

60-0770—2

12

Page 13

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

For all other detectors, clean the detector lens, filter,

NOTE: Low fuel pressure limits, if used, could be open. If

viewing window, and inside of the sight pipe, as

applicable.

For a C7012A,C,E or F Purple Peeper Ultraviolet Flame

Detector, replace the 113236 and 115330 Electron

Tubes, unless the detector is a solid state model.

With the burner running, check the temperature at the

detector. If it exceeds the detector’s maximum rated

temperature:

— add additional insulation between the wall of the

combustion chamber and the detector,

— add a shield or screen to reflect radiated heat

away from the detector, or

— add cooling. (Refer to Sight Pipe Ventilation in the

Instructions for the detector.)

Make sure that the flame adjustment is not too lean.

Make sure the detector is properly sighting the flame.

If necessary, resight or reposition the detector.

If you cannot obtain proper operation, replace the plug-in

amplifier. If you continue to be unable to obtain proper

operation, replace the flame detector.

Initial Lightoff Check for Proved Pilot (All

Installations Using a Pilot)

Perform this check on all installations using a pilot. It should

immediately follow the preliminary inspection.

so, bypass them with jumpers during this check.

Open the master switch.

Make sure the manual main fuel shutoff valve(s) is

closed. Open the manual pilot shutoff valve. If the pilot

takeoff is downstream from the manual main fuel

shutoff valve, make sure the main fuel is shut off just

upstream from the burner inlet, or disconnect power

from the automatic main fuel valve(s).

Close the master switch and start the system with a call

for heat (raise the setpoint of the burner controller). The

burner motor (blower) should run, the programmer

timer should start, and prepurge should begin.

Let the timer dial advance through PREPURGE. When

the IGN part of the dial is opposite the index notch,

spark should occur and the pilot should ignite. If it

ignites, proceed to step .

If the pilot flame is not established in ten seconds,

safety shutdown occurs in about one-half minute. Let

the timer complete its revolution and stop.

Wait about one minute, reset the lockout switch, and let

the system recycle once. If the pilot still does not ignite,

make the following ignition/pilot adjustments:

a. Open the master switch and remove the

programmer from the subbase.

Table 4. Flame Signal.

Flame Detector Flame Signal Amplifier

Minimum Acceptable

Steady Currenta (uA)

Maximum Current

Expected (uA)

Rectifying Flame Rod R7247A (Green) 2 5

R7247B (Green Self Check)

Rectifying Photocell R7247A Green 2 5

R7247B Green Self Check

b

b

1-1/4 2-12

c

1-1/4 2-12

C7012A,C Ultraviolet (Purple Peeper) R7247A (Green) 2 6

R7247B (Green Self Check)

C7012E,F Ultraviolet (Purple Peeper)

e

R7247C (Green Self Check)

C7015A Infrared (Lead Sulfide Cell) R7248A (Red) 2-1/4

R7248B (Red Ampli-Check)

C7027A, C7035A, or C7044A Ultraviolet

R7249A (Purple) 3-1/2 7-1/2

b

d

b

24

e

2

3-1/2

f

f

7

5

5

(Minipeeper)

C7076A Ultraviolet (Adjustable Sensitivity)eR7476A (Blue Self Check)

a

This minimum or stronger signal is easily obtained when the detector is correctly installed and positioned to sense flame

properly.

b

When using an R7247B or an R7248B, circuitry tests the flame signal amplifier at least 150 times a minute during burner

operation and shuts down the burner if the

c

Do not permit signal to exceed five microamperes because it shortens the photocell life. Reduce the signal by using orifice

plates (aperture disks) or filters, as necessary.

d

If using an R7247C or an R7476A, circuitry tests all electronic components in the flame detection system (amplifier and

detector) 60 to 240 times a minute during burner operation and shuts down the burner if the detection system fails.

e

Shutter operation of the C7012E or F or C7076A causes fluctuations in the current reading. Read the average stable current,

disregarding the peaks.

f

The lead sulfide cells are available in two ranges of sensitivity: 104662B is lowest and 104662D is highest sensitivity. If a

This current must be obtained before completing checkout.

amplifier

fails.

d

2-1/2

e

5-1l2

sufficiently strong signal cannot otherwise be obtained, try a different cell of the same range. If necessary, substitute a cell of

higher sensitivity.

13

60-0770—2

Page 14

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

b. On the subbase, jumper terminal L1 to the

ignition terminal (5, 6, or 18). Refer to the

appropriate wiring diagram to determine the

proper terminal. Disconnect the leadwire to the

pilot valve if it is connected to the same terminal.

c. Close the master switch only to energize the

ignition transformer.

d. If the ignition spark is not strong and continuous,

open the master switch and adjust the ignition

electrode spark gap setting to the manufacturer’s

recommendation.

e. Make sure the ignition electrodes are clean.

f. Close the master switch and observe the spark.

g. Once a continuous spark is obtained, open the

master switch and add a jumper on the subbase

from terminal L1 to the pilot terminal (5 or 6).

Reconnect the leadwire from the pilot valve if it

was disconnected in step b.

h. Close the master switch to energize both the

ignition transformer and the pilot valve.

I. If the pilot does not ignite and if the ignition spark

is still continuous, adjust the pilot gas pressure

regulator until a pilot is established.

j. When the pilot ignites properly and stays ignited,

open the master switch and remove the jumper(s)

from terminals L1-5, L1-6, or L1-18 of the

subbase.

k. Check for adequate fuel line bleeding.

l. Reinstall the programmer on the subbase, reset

the lockout switch, and close the master switch.

When the pilot ignites, measure the flame signal. If

necessary, adjust the flame or detector to give a proper

flame signal.

Recycle the system to recheck lightoff and the pilot

flame signal.

When the MAIN part of the timer dial is opposite the

index notch, make sure the automatic main fuel

valve(s) opens; then smoothly open the manual main

fuel shutoff valve (and manually opened safety shutoff

valve, if used) and watch for main burner flame ignition.

When the main burner flame is established, proceed to

step 씊.

NOTE: This step requires two people—one to open

the manual valve(s) and one to watch for

ignition.

쐅 If the main burner flame is not established within five

seconds, or within the normal lightoff time specified by

the burner manufacturer, close the manual main fuel

shutoff valve(s) and open the master switch.

쐈 Purge the combustion chamber to remove any

unburned fuel. Check all burner adjustments.

쐉 Wait about three minutes. Reset the lockout switch,

close the master switch, and let the programmer

recycle to MAIN. Smoothly open the manual fuel shutoff

valve(s) and try lightoff again. The first attempt may

have been required to purge the lines and bring

sufficient fuel to the burner.

NOTE: This step requires two people—one to open

the manual valve(s) and one to watch for

ignition.

씈 If the main burner flame is not established within five sec-

onds, or within the normal lightoff time specified by the

burner manufacturer, close the manual main fuel shutoff

valve(s) and open the master switch. Check all burner

adjustments.

씉 Repeat steps 쐈 through 씈 to establish the main

burner flame.

씊 When the main burner flame is established, the timer

dial advances to the end of MAIN and stops. Make

burner adjustments for flame stability and input rating.

씋 Shut down the system by lowering the setpoint of the

burner controller. Make sure the main burner flame

goes out. If using an intermittent pilot, make sure the

pilot flame goes out. Make sure all automatic fuel

valves close.

씌 If used, remove the bypass jumpers from the low fuel

pressure limits.

씍 Restart the system by raising the setpoint of the burner

controller. Observe that the pilot is established during

IGN and the main burner flame during MAIN, within the

normal lightoff time specified by the burner

manufacturer.

씎 Measure the flame signal. Continue to check for the

proper signal (Table 4) through the MAIN part of the

timer dial, and into the Run period after the timer stops.

Check the signal at both high and low firing rate

positions and while modulating, if applicable.

씏 Run the burner through another sequence, observing

the flame signal for:

— pilot alone (unless using direct spark ignition)

— pilot and main burner flame together, and

— main burner flame alone (unless monitoring an

intermittent pilot).

Also observe the time to light the main burner.

IMPORTANT

Make sure all readings are in the required ranges

before proceeding.

Initial Lightoff Check for Direct Spark

Ignition of Oil (Oil Burners not Using a Pilot)

This check applies for oil burners not using a pilot. It should

immediately follow the preliminary inspection.

Refer to the appropriate sample block diagram of field wiring

in the R4140 Specifications for the ignition transformer and

fuel valve(s) hookup.

NOTE: Low fuel pressure limits, if used, could be open. If

so, bypass them with jumpers during this check.

Open the master switch.

Complete the normal ready-to-fire checkout of the oil

supply and equipment as recommended by the burner

manufacturer.

Close all manual fuel shutoff valves. Check that the

automatic fuel valves are closed. Make sure oil is not

entering the combustion chamber.

Close the master switch and start the system with a call

for heat (raise the setpoint of the burner controller). The

burner motor (blower) should run, the programmer

timer should start, and prepurge should begin.

60-0770—2

14

Page 15

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

Let the timer dial advance through PREPURGE. When

the IGN part of the dial is opposite the index notch,

watch for ignition spark and listen for the click of the

first stage oil solenoid. (If spark does not occur or the

first stage oil valve does not open, refer to Symptom E

in Table 5 in the Troubleshooting section.)

Let the programmer complete its revolution and stop.

Open the manual first stage oil valve.

Reset the lockout switch and recycle the programmer

through PREPURGE.

When the IGN part of the timer dial is opposite the

index notch, watch for the first stage burner flame to be

established. If it is, proceed to step 씊.

쐅 If the first stage burner flame is not established within

five seconds, or within the normal lightoff time specified

by the burner manufacturer, close the manual first

stage oil valve and open the master switch.

쐈 Purge the combustion chamber to remove any

unburned oil; then check all burner adjustments.

쐉 Wait about three minutes. Close the master switch,

open the manual first stage oil valve, and try lightoff

again. The first attempt may have been required to

purge the lines and bring sufficient oil to the burner.

씈 If the first stage burner flame is not established within

five seconds, or within the normal lightoff time specified

by the burner manufacturer, close the manual first

stage oil valve and open the master switch.

씉 If necessary, repeat steps 쐈 through 씈 to establish the

first stage burner flame. Then proceed to step 씊.

씊 When the first stage burner flame is established, the

timer dial advances to the end of MAIN and stops.

Make burner adjustments for flame stability and input

rating. If a second stage is used, make sure the

automatic second stage oil valve opened.

씋 Shut down the system by lowering the setpoint of the

burner controller. Make sure the burner flame goes out

and all automatic oil valves close.

씌 If used, remove the bypass jumpers from the low fuel

pressure limits.

씍 If a second stage is used, check the lightoff as follows;

otherwise, proceed to step 씎.

a. Open the manual second stage oil valve.

b. Restart the system by raising the setpoint of the

burner controller.

c. When the first stage burner flame is established,

watch for the automatic second stage oil valve to

open. Observe that the second stage lights off

properly.

d. Make burner adjustments for flame stability and

input rating.

e. Shut down the system by lowering the setpoint of

the burner controller. Make sure the burner

flames go out and all automatic oil valves close.

f. Proceed to step 씎.

씎 Restart the system by raising the setpoint of the burner

controller. Observe that the burner flame is established

during IGN, within the normal lightoff time specified by

the burner manufacturer.

씏 Measure the flame signal. Continue to check for the

proper signal (Table 4) through the MAIN part of the

timer dial and into the Run period after the timer stops.

Check the signal at both the high and the low firing rate

positions and while modulating, if applicable. Any

pulsating or unsteady readings require further

adjustments.

IMPORTANT

Make sure all readings are in the required ranges

before proceeding.

Pilot Turndown Test (All Installations using

a Pilot)

Perform this check on all installations using a pilot. It should

immediately follow the initial lightoff check. The purpose of

this test is to ensure that the main burner can be lighted by

the smallest pilot flame that can hold in the 2K (flame) relay.

Clean the flame detector(s) to ensure it can detect the

smallest acceptable pilot flame.

NOTE: Low fuel pressure limits, if used, could be open. If

so, bypass them with jumpers during this test.

Open the master switch.

Close the manual main fuel shutoff valve(s).

Connect a manometer (or pressure gauge) to measure

pilot gas pressure during the turndown test.

Open the manual pilot shutoff valve.

Close the master switch and start the system with a call

for heat (raise the setpoint of the burner controller). The

burner motor (blower) should run, the programmer

timer should start, and prepurge should begin.

When the IGN area of the timer dial is opposite the

index notch, set the timer switch to the TEST position to

stop the timer. Relay 2K should pull in when the pilot

ignites.

NOTE: If the timer does not stop, recycle the

programmer and set the timer switch as soon

as the beginning of the IGN area of the timer

dial reaches the index notch.

IMPORTANT

You have only six seconds to stop the timer after the

ignition starts.

Turn down the pilot pressure very slowly, reading the

manometer (or gauge) as it drops. Stop instantly when

relay 2K drops out. Note the pressure at the dropout

point. The pilot is at the turndown position. Immediately,

turn up the pilot pressure until relay 2K pulls in again.

NOTE: With the timer stopped in this position, the

lockout switch heats when 2K is not pulled in.

If 2K is out for a total of about one-half minute,

safety shutdown occurs.

Repeat step to verify the pilot gas pressure reading

at the exact point of relay 2K dropout.

Increase the pilot pressure immediately to pull in 2K,

and then turn it down slowly to obtain a pressure

reading just above the dropout point.

쐅 Set the timer switch to the NORM position and let the

timer proceed. When the MAIN area of the timer dial

reaches the index notch, make sure the automatic main

fuel valve(s) opens; then smoothly open the manual

main fuel shutoff valve (and manually opened safety

shutoff valve, if used) and watch for main burner

ignition. If the main burner flame is established,

proceed to step 씌.

15

60-0770—2

Page 16

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

NOTE: This step requires two people—one to open the

manual valve(s) and one to watch for ignition.

쐈 If the main burner flame is not established within five

seconds, or within the normal lightoff time specified by

the burner manufacturer, close the manual main fuel

shutoff valve(s) and open the master switch.

쐉 Purge the combustion chamber to remove any

unburned fuel. Check all burner adjustments.

씈 Wait about three minutes. Reset the lockout switch (if

tripped), close the master switch, and let the

programmer recycle to MAIN. Repeat steps 쐅 and 쐈

(try lightoff again).

씉 If the second attempt is unsuccessful, adjust the flame

detector position so that a larger pilot is required to hold

in flame relay 2K. This may require relocating the flame

detector to sense farther out on the pilot flame, or

adding an orifice plate.

씊 Measure the pilot flame signal after adjusting the flame

detector to make sure it is stable and above the

minimum (see Table 4).

씋 Repeat steps through 씊 until the main burner

positively lights with the pilot flame just holding in flame

relay 2K.

씌 Repeat the lightoff of the main burner several times

(steps through 쐅) with the pilot at turndown.

씍 When the main burner lights reliably with the pilot at

turndown, disconnect the manometer (or gauge) and

turn up the pilot to normal.

씎 If used, remove the bypass jumpers from the low fuel

pressure limits.

씏 Run the system through another cycle to check for

normal operation.

Ignition Interference Test (All Flame Rods)

Test to make certain that a false signal from a spark ignition

system is not superimposed on the flame signal.

Ignition interference can subtract from (decrease) or add to

(increase) the flame signal. If it decreases the flame signal

enough, it causes safety shutdown (relay 2K does not pull in

and the programmer acts as though the pilot or main burner, if

using direct spark ignition, was not ignited). If it increases the

flame signal, it could cause relay 2K to pull in when the true

flame signal is below the minimum acceptable value.

To Test for Interference

Start the burner and measure the flame signal with both

ignition and pilot (or main burner) on, and then with only the

pilot (or main burner) on. Any significant difference (greater

than 1/2 uA) indicates ignition interference.

To Eliminate Ignition Interference

Make sure there is enough ground area.

Be sure the ignition electrode and the flame rod are on

opposite sides of the ground area.

Check for correct spacing on the ignition electrode:

6,000 volt systems—1/16 to 3/32 in. (1.6 to 2.4 mm).

10,000 volt systems—1/8 in. (3.2 mm).

Make sure the leadwires from the flame rod and ignition

electrode are not too close together anywhere.

Replace any deteriorated leadwires.

If the problem cannot be eliminated, change to an

ultraviolet flame detection system.

Hot Refractory Saturation Test (All Infrared

Detectors)

Test to make certain that radiation from hot refractory does

not mask the flickering radiation of the flame itself.

Start the burner and monitor the flame signal during the

warmup period. A decrease in signal strength as the

refractory heats up indicates hot refractory saturation. If

saturation is extreme, the flame relay 2K drops out and the

system shuts down as though a flame failure occurred.

If hot refractory saturation occurs, the condition must be

corrected. Add an orifice plate ahead of the cell to restrict the

viewing area. If this does not work, resight the detector at a

cooler, more distant background. You can also try lengthening

the sight pipe or decreasing the pipe size (diameter). Continue

adjustments until hot refractory saturation is eliminated.

Hot Refractory Hold-In Test (Rectifying Photocells or

Infrared Detectors)

Test to make certain that hot refractory does not cause flame

relay 2K to stay pulled-in after the burner flame goes out. This

condition delays response to flame failure and also prevents

a system restart as long as hot refractory is detected.

First check the plug-in flame signal amplifier by starting a

burner cycle. As soon as the programmer stops for the run

period, lower the setpoint of the burner controller to shut

down the burner while the refractory is still at a low

temperature. Measure the time it takes for the flame relay 2K

to drop out after the flame goes out. (Watch or listen to the

flame relay to determine when it drops out.) If the flame relay

fails to drop out within four seconds, open the master switch

and replace the amplifier.

To check rectifying photocells for hot refractory hold-in,

operate the burner until the refractory reaches its maximum

temperature. Then terminate the firing cycle. (Lower the

setpoint of the burner controller, or set the fuel selector switch

to OFF. Do not open the master switch.) Visually observe

when the burner flame goes out. After the flame goes out,

measure the time it takes for the flame relay 2K to drop out.

(Watch or listen to the flame relay to determine when it drops

out.) If the flame relay fails to dropout within four seconds, the

photocell is sensing hot refractory. This condition must be

corrected as described in the last paragraph of this test

Infrared (lead sulfide) detectors can respond to infrared rays

emitted by a hot refractory, even when the refractory has visibly

ceased to glow. Infrared radiation from a hot refractory is

steady, but radiation from a flame has a flickering

characteristic. The infrared detection system responds only to

a flickering infrared radiation; it can reject a steady signal from

hot refractory. The refractory’s steady signal can be made to

fluctuate if it is reflected, bent, or blocked by smoke or fuel mist

within the combustion chamber. Take care when applying an

infrared system to ensure its response to flame only.

To check infrared (lead sulfide) detectors for hot refractory

hold-in, operate the burner until the refractory reaches its

maximum temperature. If the installation has a multifuel

burner, burn the heavier fuel, which is most likely to reflect,

bend, or obscure the hot refractory’s steady infrared radiation.

60-0770—2

16

Page 17

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

(Burn a solid instead of a liquid, or a liquid instead of a gas.)

When the maximum refractory temperature is reached, close

all manual fuel shutoff valves, or open the electrical circuits of

all automatic fuel valves. Visually observe when the burner

flame goes out. After the flame goes out, measure the time it

takes for the flame relay 2K to drop out. (Watch or listen to the

flame relay to determine when it drops out.) If the flame relay

fails to drop out within four seconds, the infrared detector is

sensing hot refractory. Immediately terminate the firing cycle.

(Lower the setpoint of the burner controller, or set the fuel

selector switch to OFF. Do not open the master switch.)

NOTE: Some burners continue to purge their oil lines

between the valve(s) and nozzle(s) even though the

fuel valve(s) is closed. Terminating the firing cycle

(instead of opening the master switch) allows

purging the combustion chamber, if available. This

reduces a buildup of fuel vapors in the combustion

chamber caused by oil line purging.

If the detector is sensing hot refractory, the condition must be

corrected. Add an orifice plate ahead of the cell to restrict the

viewing area of the detector. If this does not work, resight the

detector at a cooler, more distant part of the combustion

chamber. While resighting the detector, remember that it must

also properly sight the flame. For an infrared detector, you

can also try lengthening the sight pipe or decreasing the pipe

size (diameter). For details, refer to the C7015A Instructions,

form 60-2306. Continue adjustments until hot refractory holdin is eliminated.

Ultraviolet Response Tests (All Ultraviolet

Detectors) Ignition Spark Response Test

Test to be sure that ignition spark is not actuating flame

relay 2K.

Close the pilot and main burner manual fuel shut-off

valves.

Start the burner and run through the ignition period.

Ignition spark should occur, but relay 2K must not pull in.

The flame signal should not be more than 1/4 microamp.

If relay 2K does pull in, resight the detector farther out

from the spark, or away from possible reflection. It may

be necessary to construct a barrier to block the ignition

spark from the detector’s view. Continue adjustments

until the flame signal due to ignition spark is less than

1/4 microamp.

NOTE: Honeywell Q624A Solid State Spark Generator

prevents detection of ignition spark when properly

applied with flame detection systems using C7027,

C7035, or C7044 Minipeeper Ultraviolet Flame

Detectors. The Q624A is for use only with gas pilots.

Response to Other Ultraviolet Sources

Some sources of artificial light produce small amounts of

ultraviolet radiation. Under certain conditions, an ultraviolet

detector responds to them as if sensing a flame. Do not use

an artificial light source to check the response of an ultraviolet

detector. To check for proper detector operation, conduct flame

failure response tests (Safety Shutdown Tests 1, 2, and 3)

under all operating conditions.

Flame Signal with Hot Combustion Chamber

(All Installations)

With all initial startup tests and burner adjustments completed,

operate the burner until the combustion chamber is at

maximum expected temperature. (Observe the burner

manufacturer warmup instructions.) Recycle the burner under

these hot conditions and measure the flame signal. Check the

pilot alone, the main burner flame alone, and both together

(unless monitoring only the pilot flame when using an

intermittent pilot, or only the main burner flame when using

direct spark ignition). Check the signal at both the high and the

low firing rate positions and while modulating, if applicable.

Also check the flame failure response time. Lower the

setpoint of the burner controller and observe the time it takes

flame relay 2K to drop out after the burner flame goes out (2K

should drop out within four seconds).

If the flame signal is too low or unsteady, check the flame

detector temperature. Relocate the detector if the

temperature is too high. If necessary, realign the sighting to

obtain the proper signal and response time. If the response

time continues to be too slow, replace the plug-in flame signal

amplifier. If the detector is relocated or resighted, or the

amplifier is replaced, repeat all required checkout tests.

IMPORTANT

Repeat all required Checkout tests after all

adjustments are complete. All tests must be satisfied

with the flame detector(s) in its FINAL position.

Safety Shutdown Tests (All Installations)

Perform these tests at the end of Checkout after all other

tests are complete.

For all R4140 Programmers, safety shutdown should occur

on: (1) failure to ignite the pilot (or first stage burner when

using direct spark ignition), (2) failure to light the main burner

(unless monitoring an intermittent pilot), and (3) loss of flame

during the Run period. (If a self-checking flame detection

system is used, safety shutdown should also occur on a

failure in the detection system. However, because the

programmer acts the same if a flame failure has occurred, no

separate test is necessary.)

For an R4140L, safety shutdown should also occur upon (1)

detection of a flame (or a condition simulating a flame) before

or during prepurge, (2) opening of a preignition interlock

during prepurge, and (3) opening of a lockout interlock after

14 seconds.

On safety shutdown, the lockout switch should trip (pop out)

and lock out the programmer. The ignition and fuel valve

terminals should be de-energized. If used, the external alarm

should turn on. The timer should complete its revolution and

lock up at the start position. The lockout switch must be

manually reset to restart the system.

Failure to Ignite Pilot (or First Stage Burner if Using

Direct Spark Ignition).

a. Close all manual fuel shutoff valves; this includes

the manual pilot shutoff valve and all manual

main burner shutoff valves.

b. Make sure all interlocks are closed.

17

60-0770—2

Page 18

R4140G, L AND M FLAME SAFEGUARD PROGRAMMING CONTROLS

c. Reset the Lockout switch, if tripped.

d. Close the master switch.

e. Start the system with a call for heat. (Raise the

setpoint of the burner controller.)

f. Ignition spark should occur and the automatic

pilot valve (or automatic first stage valve) should

be energized, but the pilot (or first stage burner)

cannot ignite. No flame is detected so relay 2K

cannot pull in.

g. Safety shutdown should occur about one-half

Failure to Light Main Burner (Unless Flame Detector is

Loss of Flame During the Run Period.

Detection of a Flame (or a Condition Simulating a

Opening of a Preignition Interlock During Prepurge

minute after ignition spark occurs.

Monitoring

NOTE: If using direct spark ignition, perform Test

a. Open the manual pilot shutoff valve; leave the

b. Reset the Lockout switch.

c. Start the system.

d. The pilot should ignite and pull in relay 2K, but

e. Relay 2K should drop out within four seconds