Honeywell NAHA003WK01 Installation Instructions Manual

Tuesday 29 of SOD 1998. Faxination ->5123390477 Page 2 o£ f

INSTALLATION

INSTRUCTIONS

_ t /ll L'I //I

Twinning Kit NAHA003WK01

For Use With Furnace Models Using

Honeywell ST9120 Electronic Fan Controls

Please read these instructions completely before attempting installation.

Electrical shock hazard/Fire and/or explosion

hazard.

Turn off electric power supply at disconnect

switch or service panel before starting instal-

lation.

Turn off gas supply at field installed manual

gas valve before starting installation.

Failure to follow this warning can result in

property damage, p_rsonal Injury and/or

death.

Installation or repairs made by unqualified per-

sons can result In hazards to you and others.

Installation MUST conform with local building

codes or, In the absence of local codes, with

the National Fuel Gas Code NFPA 54/ANSI

A223.1,1990 or latest edition. In Canada, Na-

tional Standard CAN/CGA B149-t.

The information contained in this manual is in-

tended for use by a qualified service techni-

cian familiar with proper safety procedures

and equipped with the proper tools and test

instruments.

Failure to carefully read and follow all Instruc-

tions in this manual can result In furnace real-

function, property damage, personal injury

and/or death.

This"tw_nning kit is intended to permit two identical gas

furnaces to be installed.connected to the same duct work

Air conditioning can be added by using one air conditioning

evaporator coil sized for the total air flow capabilities of the

two furnaces.

Single and Two Stage Heating

Single or two stage heating is obtainable using twinning kit

NAHA003WK01. Follow the instructions located in the

Twinning Kit Installation section for proper hookup of desired

thermostat staging.

Furnace Installation

Refer to the Installation Instructions packed with the

furnaces for information about clearances, start-up and

maintenance, gas piping and vent installation.

CAUTION

Furnaces installed MUST be identical. They

may be installed on a raised platform or wood

floor which MUST be level. When side return

is required, separate return air drops MUST

be madeto both furnaces. Do not use rear of

furnace for the return air duct connection.

CAUTION

Make sure blower motors are wired to

operate on the same speed tap.

CAUTION

Two furnaces must be plumbed with a single

supply gas shut off valve.

NOTE: When twinning kit has been installed, locate the

adhesive backed wiring diagram included in the kit and apply

next lo Ihe existing wiring diagrams in the furnaces.

TWINNING KIT INSTALLATION

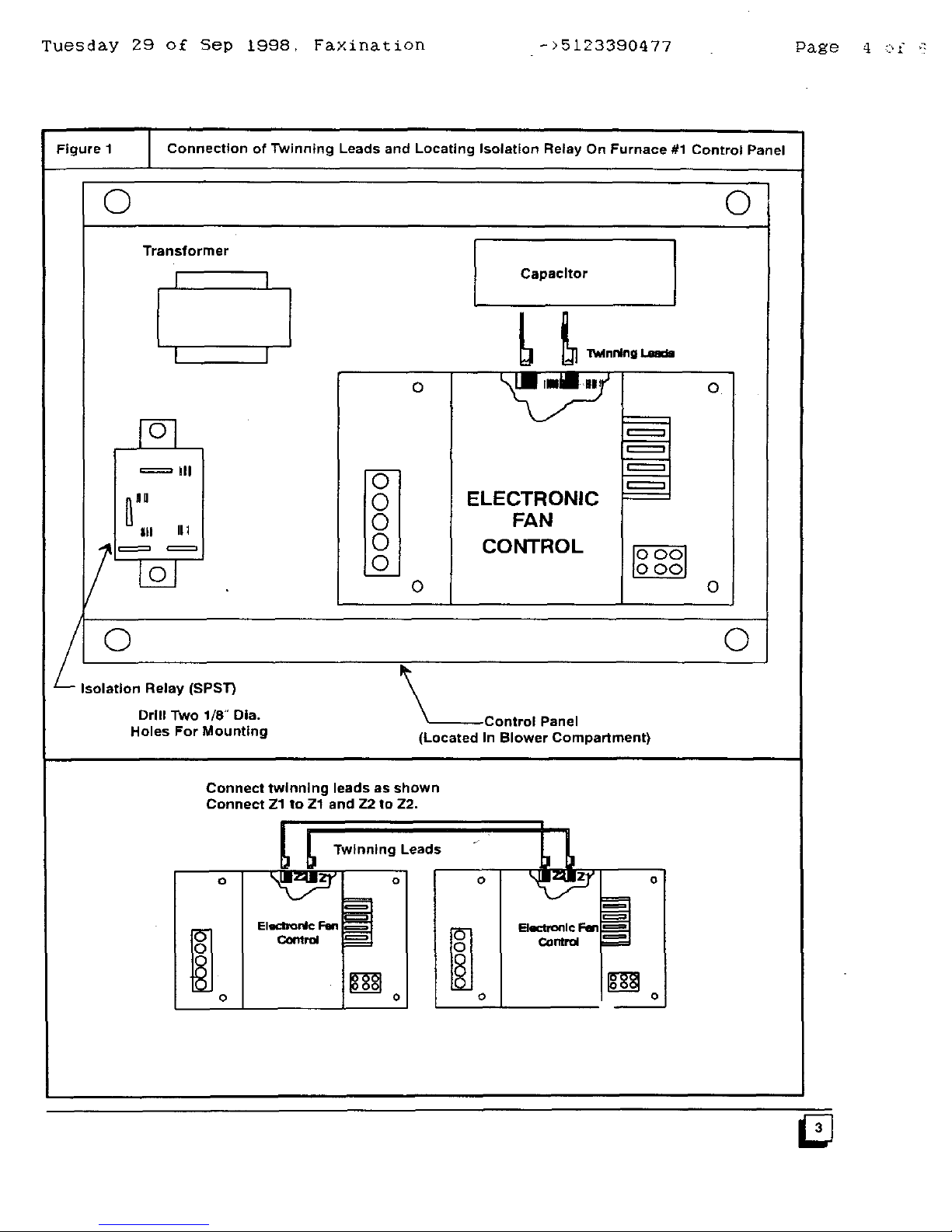

The twinning kit contains (2) 36" wires of two differenl colors

to interconnect the electronic fan controls of the two

furnaces. For proper operation, and to avoid damage to

the controls, be sure to match Z1 to Z1 and Z2 to Z2 on

each fan control (see Figure 1) The wires are color coded

to assist with this connection. Each wire is factory

terminated with a specia_ crimped edge connector which wi_

push into mating connection positions on the edge of the

circuit board on each fan con:roL The length of these wires

can be extended by cutting and splicing sufficient additional

wire to each lead.

An isolation relay is provided to protect the system s

thermostat from possible overloading due to the combined

valve end control load of the two appliances.

Printed in U,S,A. 441 06 1003 01 (2;98)

replaces 441 06 1003 00 (10,97

Tuesday 29 o£ Sep 1998. Faxination ->5123390477 Page 3 o£

Installation Procedures

I Remove line power from both appliances before

starting installation of the twinning kit.

2 Locale the Zl and Z2 connectic^s along one edge of

each control (see Figure 1). The demgnalions are

printed on top of the circuit board, and a black bar

shows the correct orientation of the metal body which

will be pust_ed in to make connection.

3 Remove furnace casing hole plugs and route the

[winning leads through bushings provided as required,

and lengthen if necessary by splicing. Be sure to

observe the polarity required so as lo match Z1 to Z1

and Z2 to Z2 (see Figure 2).

4. Push the terminal into the slot on the circuit board

edge. Be sure to align the body with the black bar to

line up the solder finger below the circuit board (see

Figure 1). The terminal will "bite into" the solder and

make the necessary connection. Repeat for each end

of both wires.

5 Locale and mount the isolation relay in the circulating

blower compartment on the same panel as the

electronic fen control in furnace #1 (see Figure 1).

6, Refer to single stage or two stage thermostat wiring as

noted below.

Single Stage Thermostat Operation

Reference Figure 3

1 Interconnect the thermostat wiring in parallel from the

thermostat to the terminaJ blocks on each fan control.

for the "G" and '+Y"connections only Interconnect the

winng from the "C" connections at the terminal blocks

on each fan control. Note: The "Y" connection ls not

required if air conditloning is not available.

2. Connect wire from "W" connection at the thermostat to

the "W" connection of the electronic fan control of

furnace #1

3 Connect wire from "R" connection at the thermoslat to

the "R" connection of the electronic fan control of

furnace #1.

4. Connect wire from the "W" connection of the electronic

fan control of furnace #1 to one side el the 24Vac coil of

the isolaUon relay (terminal #3)+ (Wire terminals for

connection to the isolation relay are provided in the kit)

5, Connect wire from the "C" connection of the electronic

fan control of furnace #1 to the other side of the 24Vac

coil of the isolation relay (terminal #1).

6. Connect one wire to each of the normally open

terminals of the isolation relay (terminals #2 and #4)

and connect to the "R" and "W" connections at the

electronic fan control of furnace #2.

7. -*S_t-the heat delay off timings on each control to the

same setting.

8. Set thermostat anticipator setting at 090

9. Recheck wiring connections, splices, and insulation

Re-apply line power to both appliances.

Two Stage Thermostat Operation

Reference Figure 3

1 Interconnect the Ihermostat wiring in parallel from the

thermostat to the terminal blocks on each fan control.

2,

for the "G' and 'Y' connections only. Interconnect [_,e

wir+ng from the C" connections at the terminal blocks

on each fan control. Note. The "'Y" connection _snot

reduired if air conditioning is not availab t=

Connect wire from "WI" of the thermostat to the W'"

connection of the electronic fan control of furnace Pl.

3. Connect wire from "W2" of the thermostat toone side

of the 24Mac coil of the isolation relay (terminal #3).

(VVire terminals for connection to the isolation relay are

provided in the kit)

4. Connect wire from'R" connection at the thermostat to

the "R" connection of the electronic fan control of

furnace #1.

5. Connect wire from the "C" connection of the electronic

fan control of furnace #1 to the other side of the 24Vac

coil of the isolation relay (terminal #1).

6. Connect one wire to each of the normally open

terminals of the isolation relay (terminal #2 and #4) and

connect to the 'R" and "W" connections at the

electronic fan control of furnace #2.

7. Set the heat delay off timings on each control Lothe

same setting.

8. Set thermostat anticipator setting at 0.75 for the tst

stage and 0.15 for the 2rid stage.

9. Recheck wiring connections, splices, and insulation.

Re-apply line power to both appliances.

Twinning+Kit Operation

1. Turn the heat/cool switching at the thermostat to

"OFF", or set so neither a call for heating nor cooling _s

being made.

2. Turn the fan switch to "ON" from "AUTO", or jumper

from '+R"to "G" at "furnace 1". Within several seconds,

the circulation blowers of each furnace will start at the

same speed connected to their respective 'heat =.

speed laps,

3. Turn the fan switch to ='OFF" from "AUTO" or remove

the jumper from "R" to"G". Both circulation blowers will

stop after several seconds.

4. Disconnect one wire from the high limit connection on

"furnace 1". Within several seconds, the circulation

blowers of each furnace will start at the same speed

connecled to their respective "heat" speed taps.

5. Re-connect the wire removed from the high limit

connection on "furnace 1". After the completion of the

heating "blower off" delay, both blowers will stop.

6. Repeat steps (4) and (5) with the limit connection in

"furnace 2" versus :furnace 1". The same operation

should result.

7.

8.

Operate the system through a normal call for heat,

burner on operation, and burner off operation. Each

furnace should fire and cycle both blowers, including

blower on and off delays, as in a normal single system.

Operate the system through a normal call for cooling.

The compressor operation should function normatiy.

with each furnace circulation blower operating at the

speeds connected to their respective "cool" speed

taps after cooling "blower on" delay. When the call for

cooling ends, Ihe circulation blowers will stop upon the

completion of the "cooling off" delay.

Tuesday 29 o£ Sep 1998, Faxination ->5123390477 Page 4 :>£ _

Figure 1 Connection of Twinning Leads and Locating Isolation Relay On Furnace #1 Control Panel

0 ©

Transformer

i I

I

I I

===:=' Ill

I_1 II1

0

ELECTRONIC

FAN

CONTROL

O

O

O

/O

Isolation Relay (SPST)

Drill Two 1/8" Dla.

Holes For Mounting

_--Control Panel

(Located In Blower Compartment)

©

Connect twinning leads as shown

Connect Zl to Zl and Z.2to Z2.

o

0

_ Twinning Leads

EIm:trordc Fen

0 o

Electranlc _ _==J

. .. C_ntrt:d

Y_

O O

Loading...

Loading...