for closed heating or cooling systems

4

6

GRÄSSLIN

2

bar

8

0

h

220V~50Hz

Z 52

UW

vom Kaltwassernetz

Nachfüllautomat Typ: NA 228

Construction

The automatic refilling unit comprises:

● Powder coated pressed steel housing

● Drinking water and system connection with shutoff ball valve

● Pressure switch for cut-in and cut-out pressures

● Electronic time relay

● Fault indicator lamp and cut-out button

● Pressure gauges for inlet and system pressures

● Discharge tundish

● Electrical plug for remote connection

● ON/OFF switch

● One metre connection cable without plug

● Water meter

● Bush for cable connection to a building management

system

● Operating-time meter

* For temperatures above 100ºC, the pressure at the highest point in the system when the

system is cold must be at least 1.0 bar above the operating pressure (static height plus 1.0 bar).

**A pressure reducing valve must be fitted before the refilling unit for pressures above 6.0 bar

10

5

SPX

1996

TÜV / DVGW

230V ~

50/60 Hz

15

bar

16

0

30 Watt

NA 228 S-A

A utomatic Refilling Unit

Product specification sheet

Application

The NA 228 S-A automatic refilling unit with DVGW-tested

backflow preventer permits the fixed connection of closed heating

or cooling systems to the drinking water supply network.

It integrates a backflow preventer, a check valve and a water

meter in a single unit. The automatic refilling unit maintains

pressure between prescribed upper and lower limits in closed

heating and cooling systems. It prevents back flow, back

syphonage or back pressure of the heating or cooling water

into the potable water network. Limitation of the refilling time is

also provided as well as the facility for fast and automatic

refilling of the system. In addition, build up of steam in the

system caused by loss of pressure is prevented.

Special Features

● Components DVGW approved

● Electrical changeover valve for control of the backflow preventer

● Supplementary hot-water-resistant check valve for

increased protection of the drinking water network

● Setting facility for fast filling or refilling of the system

● Pressure switch with separately adjustable cut-in and

cut-out pressures

● Time relay, for limitation of the refilling period

● Standardised discharge connection

● Remote volt-free connection

● Bush for cable connection to a building management system

● Circuit protection for volt-free connection

● Operating-time meter, measures the refilling time

● Water meter, measures the refills

Range of Application

The following operating data applies for the downstream system:

System pressure: Maximum 6.0 bar

Temperature: Maximum 120 ºC

Technical Data

Refilling: Flow rate 110 litres/h at ∆p = 2.0 bar

Fast filling: Flow rate finely adjustable between

110 litres/h and 1100 litres/h at ∆p = 2.0 bar

Duration of fill: Adjustable between 5 and 100 minutes

Cut-in pressure: Adjustable between 0.2 and 7.5 bar

Cut-out pressure: Adjustable between 0.5 and 8.0 bar

Pressure switching

differential: 0.3 to 0.5 bar (depending on pressure range)

Water inlet pressure: Minimum 3.0 bar, maximum 6.0 bar**

Remote connection: Volt-free contact

Supply voltage: 230V, 50/60 Hz

Power consumption: 30W

Connection size: R

1

/2" and Ø15

Subject to change 03/99

221

Automatic Refilling unit NA 228-SA

T

NETZ

EIN/AUS

zur Heizungsanlage

Fremdanschluß

- potentialfrei -

B

00 00 000 0

5

bar

0

Method of Operation

If the system pressure falls to below the lower set value, for

example through leakage losses, then the changeover valve is

opened by electrical impulse via the pressure switch and thereby

permits supply to the backflow preventer . The inlet pressure moves

the backflow preventer to the flow position and the system is

refilled until the pressure rises to the upper set limit. The time

period of the refill is monitored by the time relay and the operating

time counter. Once the upper limit value has been reached, the

pressure switch closes the changeover valve and the backflow

H

10

15

16

preventer goes to the shutoff position (open to atmosphere). The

time relay then returns to the initial position.

If the inlet pressure falls to the operating pressure of the

backflow preventer (2 bar) during the automatic refilling

operation, then the backflow preventer automatically goes to

the shutoff position (open to atmosphere). The shutoff position

of the backflow preventer is indicated in the viewing window

(green visible = shutoff position)

Option

NA 228 S-A

Connection size R

1

/2"

Soldered connection size (mm) Ø15

Weight (approx. kg) 16

Dimensions (mm)

H 380

B 370

T 160

Test Certificate Number 101/87/147

222

Braukmann Water Control . Honeywell AG

Subject to change 03/99

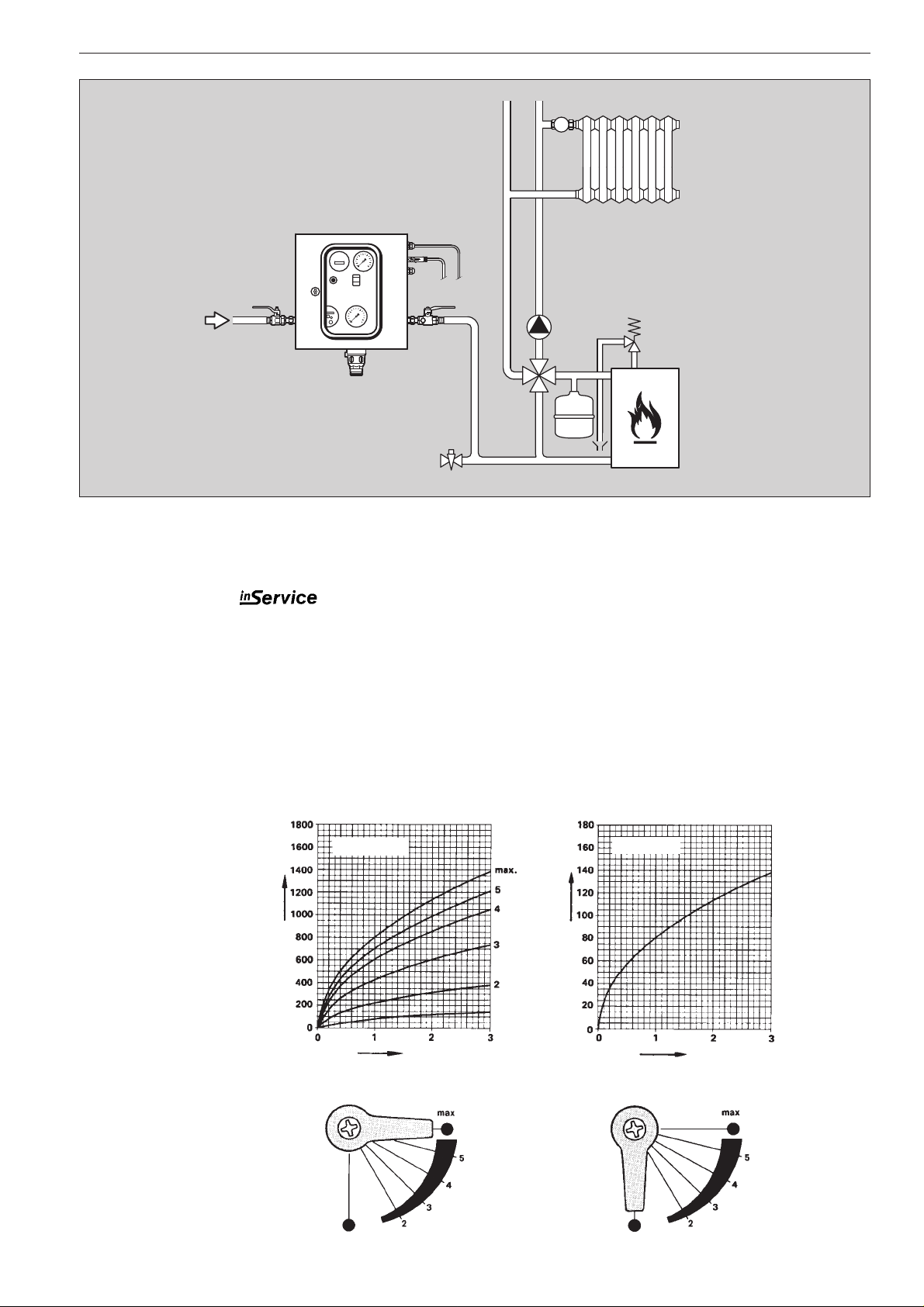

Installation example

Automatic Refilling unit NA 228-SA

Installation Guidelines

● Fix appliance to wall

● Fit shutoff valves

❍ With shutoff valves

is possible - main-

tenance and service without removal from the system

● Ensure good access

❍ Simplifies maintenance and inspection

● For supply pressures over 6.0 bar fit a pressure reducing

valve on the inlet

● Make hydraulic connections and check for leaks

● Check time setting on time relay

Flow Diagrams

Filling curves

Fast filling

Typical Applications

NA 228 S-A automatic refilling units permit a fixed connection

of closed heating and cooling systems to the drinking water

network.

Automatic refilling units are used:

● If the system pressure has to be maintained constant

● For fast and automatic refilling of the installation

● If build up of steam in the system caused by loss of

pressure must be prevented

● To limit the refilling time

Refilling

Setting

Flow rate V (litres/h)

∆p (bar)

Fast filling

Refilling Refilling

Subject to change 03/99 Braukmann Water Control . Honeywell AG

Refilling

Flow rate V (litres/h)

∆p (bar)

Fast filling

223

Automatic Refilling unit NA 228-SA

③

00 00 000 0

① ⑤

10

5

bar

15

0

16

Spare Parts - NA 228 S-A automatic refilling unit

(1997 and onwards)

②

Description Part No.

① Water meter 0903110

② Pressure switch 0903111

③ T ime relay 0903112

④ Operating time meter* 0903113

⑤ Changeover valve 0901407

⑥ Discharge tundish* 0901340

⑦ Pressure gauge M 07 K - A16

⑦

⑥

⑧ Pressure gauge M 228 S - A8

for system pressure*

* Not visible in illustration

Subject to change 03/99

Braukmann Water Control . Honeywell AG

P.O. Box 1347

D - 74819 Mosbach-Germany

Phone:

(49) 62 61/ 06261/8 10 · Fax: 06261/8 13 09 http://europe.hbc.honeywell.com

224

Loading...

Loading...