Page 1

1

a

s

w

t

s

l

e

a

r

D

K

I

N

R 295 SA

EA 2

-

D

2

r

b

a

V

G

W

10

5

15

bar

0

16

0

1

0

1

Nachfüllstation

Typ: NA225-A

CE

230V

50 / 60 HZ

20W IP65

0

1

0

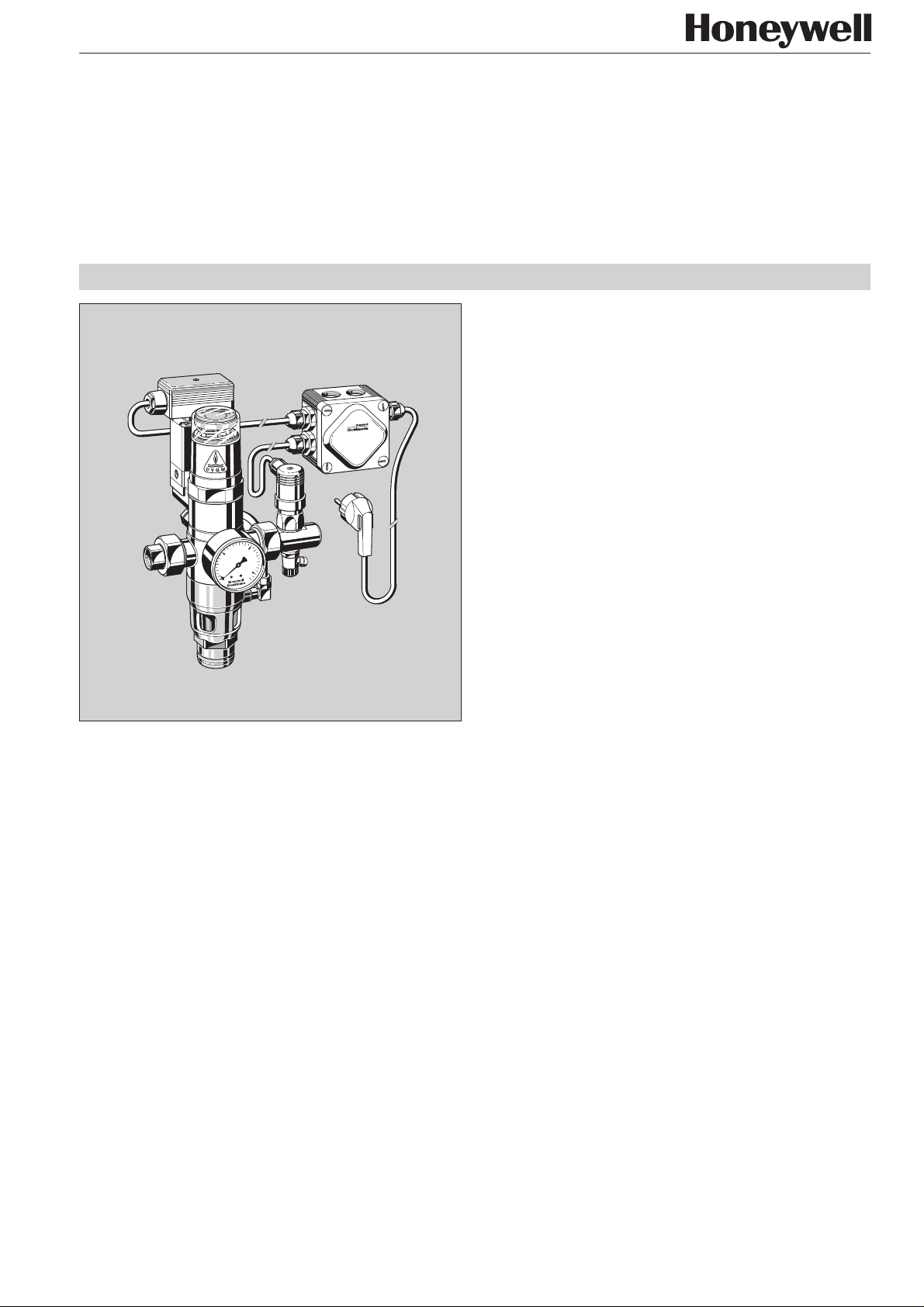

Construction

The refilling unit consists of:

● Threaded drinking water and system connections

● Changeover valve

● R 295 SA -

1

/2" backflow preventer

● Cut-in/cut-out pressure switch

● Electrical connector strip

● Time relay

● Discharge tundish

● Inlet pressure gauge

● Drain valve

● Cable wiring centre

● One meter electrical connection cable

NA 225-A

Automatic refilling unit

for heating and cooling systems

Product specification sheet

Purpose

The NA 225 - A refilling unit with DVGW tested backflow

preventer enables permanent connection of closed heating and

cooling systems to the drinking water network.

It combines a backflow preventer and non-return valve in one

appliance. The refilling unit maintains system pressure between

pre-determined upper and lower limits in closed heating and

cooling circuits. It prevents backflow, back syphonage or back

pressures of heating or cooling water into the drinking water

network and enables limitation of the refilling period. In addition,

it prevents generation of steam in a system caused by pressure

loss.

Special Features

● DVGW approved

● Pressure switch

● Drain valve for when cut-in and cut-out pressures are

to be changed

● Electronic time relay for limitation of the filling period

● Inlet pressure gauge

● Standardised discharge connection

Range of Application

The following operating conditions apply for the

downstream system:

System pressure Maximum 4.0 bar

Water temperature

at the refilling unit Maximum 40°C

Technical Data

Refilling Flow rate 110 litres/h at ∆p = 2 bar

Cut-in pressure 2.5 bar (set during manufacture)

Cut-out pressure 2,8 bar

Switching pressure

differential 0,3 bar

Inlet water pressure Minimum 3.0 bar, maximum 4.0 bar**

Electrical supply 230 V~ 50/60 Hz

Electrical loadv 30 W

** A pressure reducing valve must be fitted for inlet pr essur es above 4.0 bar

Subject to change 03/99

233

Page 2

Automatic refilling unit NA 225-A

H

Nachfüllstation

Typ: FA225

CE

230V •

50 / 60 HZ

20W IP65

Method of Operation

If the system pressure falls below the set limit, for example

because of leakage losses, then the changeover valve is

opened by an electrical impulse from the pressure switch and

thereby opens the hydraulic supply to the backflow preventer.

The inlet pressure brings the backflow preventer to the flow

position and the system is refilled up to the pre-set upper

pressure limit. The duration of fill is controlled by the time relay.

Once the upper fill pressure has been reached, the pressure

switch cuts out, the changeover valve closes and the backflow

preventer goes to the cutoff position. The time relay goes to the

outlet position.

If the inlet pressure during the filling operation falls to the

backflow preventer set pressure (2 bar), the backflow preventer

automatically goes to the shutoff position (open to atmosphere).

The shutoff position of the backflow preventer is indicated in

the viewing window (green visible = shutoff position).

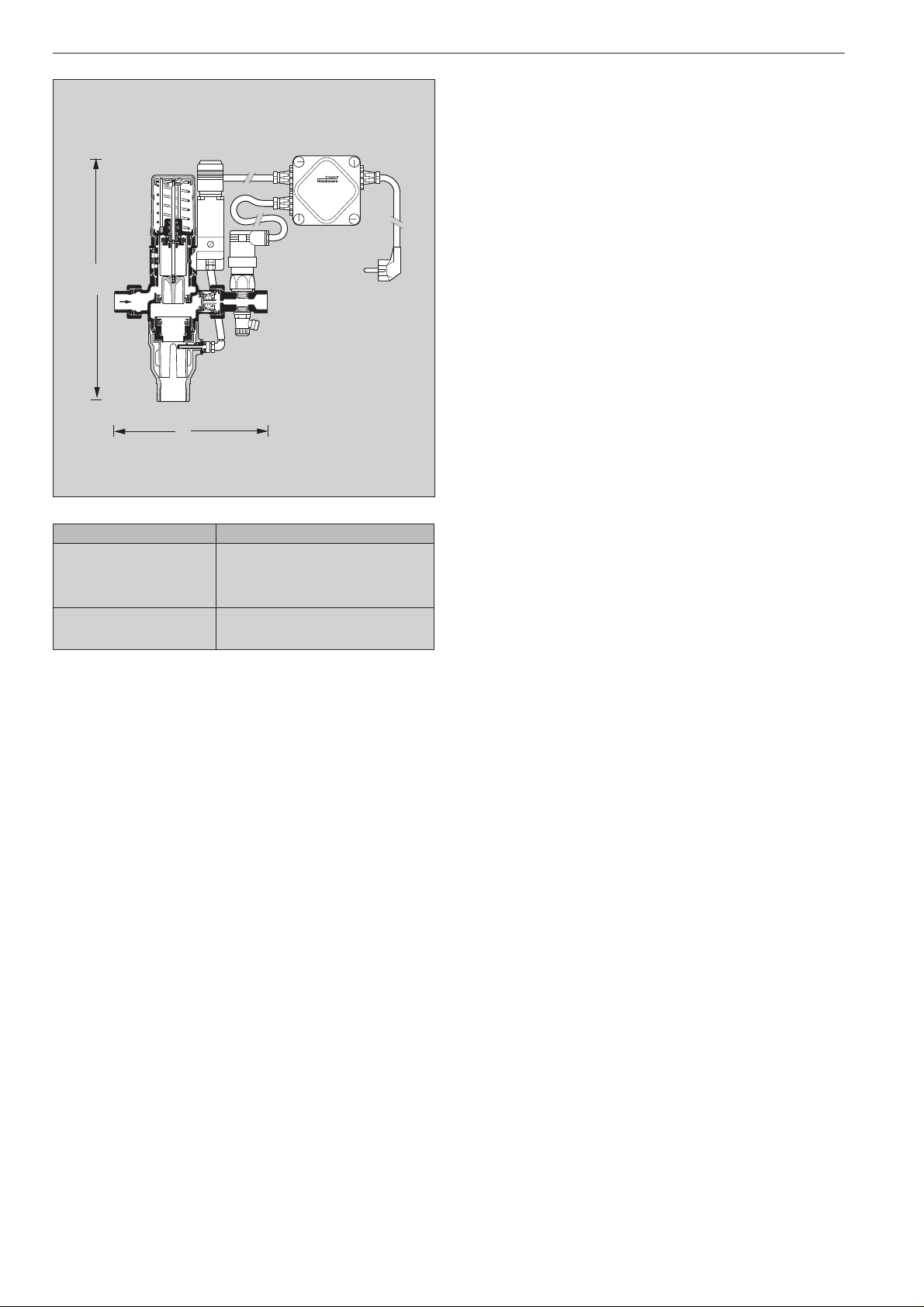

B

Weight Approx. kg 2,9

Dimensions (mm)

H 285

B 188

T65

Test No. for R 295 SA

backflow preventer DIN/DVGW 569 E

Versions

A = Normalausführung

Ordering Number

NA 225 - A

234

Braukmann Water Control . Honeywell AG

Subject to change 03/99

Page 3

Installation example (Heating system)

5

0

Automatic refilling unit NA 225-A

10

15

16

Installation Guidelines

● Install appliance in correct flow direction

● Fit isolating valves

❍ With isolating valves,

is possible maintenance and service without removal from the

pipework

● Ensure good access

❍ Simplifies maintenance and inspection

● A pressure reducing valve must be fitted for inlet pressures

greater than 4.0 bar

Flow Diagram (water)

Refilling

Typical Applications

The NA 225-A refilling unit enables a permanent connection of

closed heating or cooling systems to the drinking water

network.

Refilling units can be fitted:

● If the system pressure must be maintained

● If generation of steam caused by system pressure loss

must be prevented

● For limitation of the refilling duration

Flow rate (litres/h)

Subject to change 03/99 Braukmann Water Control . Honeywell AG

235

Page 4

Automatic refilling unit NA 225-A

Spare Parts - NA 225 - A refilling unit

1998 and onwards

Description Part Number

⑩

②

⑤

R

A

P

④

⑤

① Pressure switch 5670500

② Changeover valve 0903417

③ Pressure gauge M 07 K - A16

④ Valve insert R 295 SAA-1D

⑤ Seal 0901015

⑤

1

⑥ Hexagonal blanking plug S 06 M -

⑤

①

⑤

⑦

⑥

- With seal (Packs of 5)

⑦ Seal ring 5017500

⑧ Non-return valve RV 282 E -

⑨ Discharge tundish 0901340

/4

3

/4 A

⑦

10

5

15

16

0

⑤

⑧

③

⑩ Time relay 2595700

⑨

⑤

⑤

⑨

Subject to change 03/99

Braukmann Water Control . Honeywell AG

P.O. Box 1347

D - 74819 Mosbach-Germany

Phone:

(49) 62 61/ 06261/810 · Fax: 06261/813 09 http://europe.hbc.honeywell.com

236

Loading...

Loading...