Honeywell MultiPro User Manual

MULTIPRO PERSONAL PORTABLE GAS DETECTORS HAVE BEEN

DESIGNED FOR THE DETECTION AND MEASUREMENT OF

POTENTIALLY HAZARDOUS ATMOSPHERIC CONDITIONS

IN ORDER TO ASSURE THAT THE USER IS PROPERLY WARNED OF

POTENTIALLY DANGEROUS ATMOSPHERIC CONDITIONS, IT IS

ESSENTIAL THAT THE INSTRUCTIONS IN THIS REFERENCE

MANUAL BE READ, FULLY UNDERSTOOD, AND FOLLOWED.

MultiPro

Reference Manual

Part Number 13-278

Version 3

Copyright 2012

by

Honeywell Analytics, Inc.

Lincolnshire, Illinois 60069

All rights reserved.

No page or part of this operation manual may be reproduced in any form without written

permission of the copyright owner shown above.

Honeywell Analytics reserves the right to correct typographical errors.

1

Table of Contents

CERTIFICATION INFORMATION 5

OPERATING TEMPERATURE 5

IGNAL WORDS 5

S

ARNINGS AND CAUTIONS 5

W

DESCRIPTION 8

1.

1.1 Methods of sampling 8

1.2 Multi-sensor capability 8

1.3 Calibration 8

1.4 Alarm logic 9

1.4.1 Atmospheric hazard alarms 9

1.4.2 Low battery alarms 9

1.4.3 Sensor over range alarms. 9

1.4.4 LEL response failure due to lack of O2 alarm 9

1.4.5 Security beep/flash 10

1.4.6 Latching peak alarms 10

1.4.7 Fault detection 10

1.5 Other electronic safeguards 10

1.5.1 Heartbeat 10

1.6 Sensors 10

1.7 Optional sample draw pump 10

1.7.1 Special precautions when using the MultiPro pump 11

1.8 Data storage 11

1.8.1 Black box data recorder 11

1.8.2 Event logger 11

1.9 MultiPro design components 11

1.10 MultiPro standard accessories 12

1.10.1 Alkaline MultiPro detectors 12

1.10.2 Li-Ion MultiPro detectors 12

1.11 MultiPro kits 12

1.11.1 MultiPro Confined Space Kits 12

1.11.2 MultiPro Value Packs 12

2. BASIC OPERATIONS 12

2.1Turning the MultiPro On 12

2.1.1 Start up with pump 14

2.2Operating Logic 14

2.3Turning the MultiPro Off 15

2.4 Alarms 15

2.4.1 Warning Alarms 15

2.4.2 Danger Alarms 15

2.4.3 STEL Alarms 15

2.4.4 TWA Alarms 15

2.4.5 Low battery alarms 15

2.4.6 Sensor over range alarms 16

2.4.7 LEL failure due to lack of oxygen alarm 16

2.5 PC connection via infrared port 16

2.6 Error Messages 17

2.7 Contact Cover 17

SAMPLING 17

3.

2

3.1 Manual sample draw kit 17

3.1.1 Manual sample draw kit usage 17

3.2 Motorized sample draw pump 18

3.2.1 Starting the motorized sample pump 18

3.2.2 Turning off the pump 19

3.2.3 Pump low flow alarm 19

3.3 Sample draw probe 19

CALIBRATION 19

4.

4.1 Functional (Bump) testing 20

4.2 Fresh Air/Zero Calibration 21

4.2.1Fresh air/zero calibration failure 21

4.2.2 Forced fresh air / zero calibration 21

4.3 Span Calibration 22

4.3.1Span calibration failure: Toxic and LEL sensors 22

4.3.2Span calibration failure: Oxygen sensors 23

5. MAINTENANCE 23

5.1 Cleaning 23

5.2 Storage 23

5.3 Batteries 24

5.4 Replacing alkaline batteries 24

5.5 Maintaining Li-Ion battery packs 24

5.5.1Storage guidelines for the Li-Ion versions 24

5.5.2 Charging guidelines for Li-Ion battery 25

5.5.3Charging procedure for Li-Ion battery 25

5.5.4 Charging with the pump attached. 25

5.5.5 Battery troubleshooting 25

5.6 Sensor replacement 25

5.6.1 Sensor replacement (Not Duo-Tox) 25

5.7 Sample probe assembly 26

5.7.1 Changing sample probe filters 27

5.7.2 Changing sample probe tubes (wands) 27

5.8 MultiPro Pump Maintenance 27

5.8.1 Replacing pump filters 27

6. DIRECT PROGRAMMING 27

6.1 Entering the Advanced Menu 27

6.2 Set options 28

6.3 Set time 28

6.4 Set date 29

6.5 Set alarms 29

6.6 Set cal gas 29

6.7 Set cal due 29

6.8 Set bump test due 29

6.9 Setup accept 30

PPENDICES 31

A

Appendix A Toxic gas measurement – Warning, Danger, STEL and TWA alarms 31

1. Warning and Danger Alarms 31

2. Time Weighted Average (TWA): 31

3. Short Term Exposure Limits (STEL): 31

Appendix B Calibration Frequency Recommendation 33

3

Appendix C MultiPro Sensor Information 33

Appendix D Toxic Sensor Cross-Sensitivity 33

Appendix E Basic Parts List 33

MultiPro Remote Sampling Accessories 33

MultiPro Sensors 33

MultiPro Charging & Datalogging Accessories 33

Appendix F Honeywell Analytics Standard Gas Detection Warranty 35

4

Certification Information

UL Class I Division 1 Groups A,B,C,D Temp Code T4

UL Class II, Division 1 Groups E,F,G

UL Class III

CSA Class I, Division 1, Groups A,B,C,D Temp Code T4

(Per CSA C22.2 No. 152, only the combustible gas detection portion of this instrument

has been assessed for performance)

ATEX Certification:

II 2 G Ex ia d IIC T4

UL International DEMKO A/S 05 ATEX 0424116X

IECEx Certification:

Ex ia d IIC T4

IECEx UL 07.0003X

Operating Temperature

The MultiPro’s operating temperature range is printed on the label on

the back of the instrument. Use of Honeywell Analytics Gas Detectors outside of the

instrument’s specified operating temperature range may result in inaccurate and

potentially dangerous readings.

Signal Words

The following signal words, as defined by ANSI Z535.4-1998, are used in

the MultiPro Reference Manual.

indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

indicates a potentially hazardous situation, which if not

avoided, may result in moderate or minor injury.

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

Warnings and Cautions

1. The MultiPro personal, portable gas detector has been

designed for the detection of dangerous atmospheric conditions. An alarm

condition indicates the presence of a potentially life-threatening hazard and should

be taken very seriously.

2.

established procedures. The safest course of action is to immediately leave the

affected area, and to return only after further testing determines that the area is

once again safe for entry. Failure to immediately leave the area may result in

serious injury or death.

3.

whenever alkaline batteries are removed from the alkaline battery pack.

Removal of the alkaline batteries from the battery pack in a hazardous area may

impair intrinsic safety.

In the event of an alarm condition it is important to follow

The MultiPro must be located in a non-hazardous location

5

4.

Use only Duracell MN1500 or Ultra MX1500, Eveready Energizer

E91-LR6, Eveready EN91 batteries in the alkaline battery pack. Substitution of

batteries may impair intrinsic safety.

5.

To reduce the risk of explosion, do not mix old or used

batteries with new batteries and do not mix batteries from different manufacturers.

6.

Do not charge the MultiPro with any charger other than the

appropriate MultiPro charger. Standard versions of the MultiPro must be charged

with the UL/CSA-approved charger, which is part number 54-49-103-1. European

versions of the MultiPro must be charged with the ATEX-approved charger, which is

Honeywell Analytics part number 54-49-103-5.

7.

The MultiPro must be located in a non-hazardous location

during the charging cycle. Charging the MultiPro in a hazardous location may

impair intrinsic safety.

8.

MultiPro rechargeable battery packs are supplied with

Panasonic CGA103450 Lithium-Ion batteries. These batteries are not replaceable by

the user. The rechargeable pack must be obtained from Honeywell Analytics and

replaced as an assembly.

9.

The accuracy of the MultiPro should be checked periodically

with known concentration calibration gas. Failure to check accuracy can lead to

inaccurate and potentially dangerous readings. (The Canadian Standards

Association (CSA) requires an accuracy check using known concentration

calibration gas prior to each day’s use.)

10.

Fresh air/zero calibrations may only be performed in an

atmosphere that is known to contain 20.9% oxygen, 0.0% LEL and 0 PPM toxic gas.

11.

The accuracy of the MultiPro should be checked immediately

following any known exposure to contaminants by testing with known concentration

test gas before further use. Failure to check accuracy can lead to inaccurate and

potentially dangerous readings.

12.

The accuracy of the MultiPro should be checked immediately

following any physical shock. Failure to check accuracy can lead to inaccurate and

potentially dangerous readings.

13.

A sensor that cannot be calibrated or is found to be out of

tolerance should be replaced immediately. An instrument that fails calibration may

not be used until testing with known concentration test gas determines that

accuracy has been restored, and the instrument is once again fit for use.

14.

Do not reset the calibration gas concentration unless you are

using a calibration gas concentration that differs from the one that is normally

supplied by Honeywell Analytics for use in calibrating the MultiPro.

Customers are strongly urged to use only calibration materials when calibrating the

MultiPro. Use of non-standard calibration gas and/or calibration kit components can

lead to dangerously inaccurate readings and may void the standard Honeywell

Analytics warranty.

15.

Use of non-standard calibration gas and/or calibration kit

components when calibrating the MultiPro can lead to inaccurate and potentially

dangerous readings and may void the standard Honeywell Analytics warranty.

Honeywell Analytics offers calibration kits and long-lasting cylinders of test gas

specifically developed for easy MultiPro calibration. Customers are strongly

6

urged to use only Honeywell Analytics calibration materials when calibrating the

MultiPro.

16.

17.

Substitution of components may impair intrinsic safety.

For safety reasons this equipment must be operated and

serviced by qualified personnel only. Read and understand this reference manual

before operating or servicing the MultiPro.

18.

A rapid up-scale reading followed by a declining or erratic

reading may indicate a hazardous combustible gas concentration that exceeds the

MultiPro’s zero to 100 percent LEL detection range.

19.

The MultiPro is not designed for use in oxygen enriched

atmospheres.

20.

Do not use the MultiPro pump for prolonged periods in an

atmosphere containing a concentration of solvent or fuel that may be greater than 50%

LEL.

7

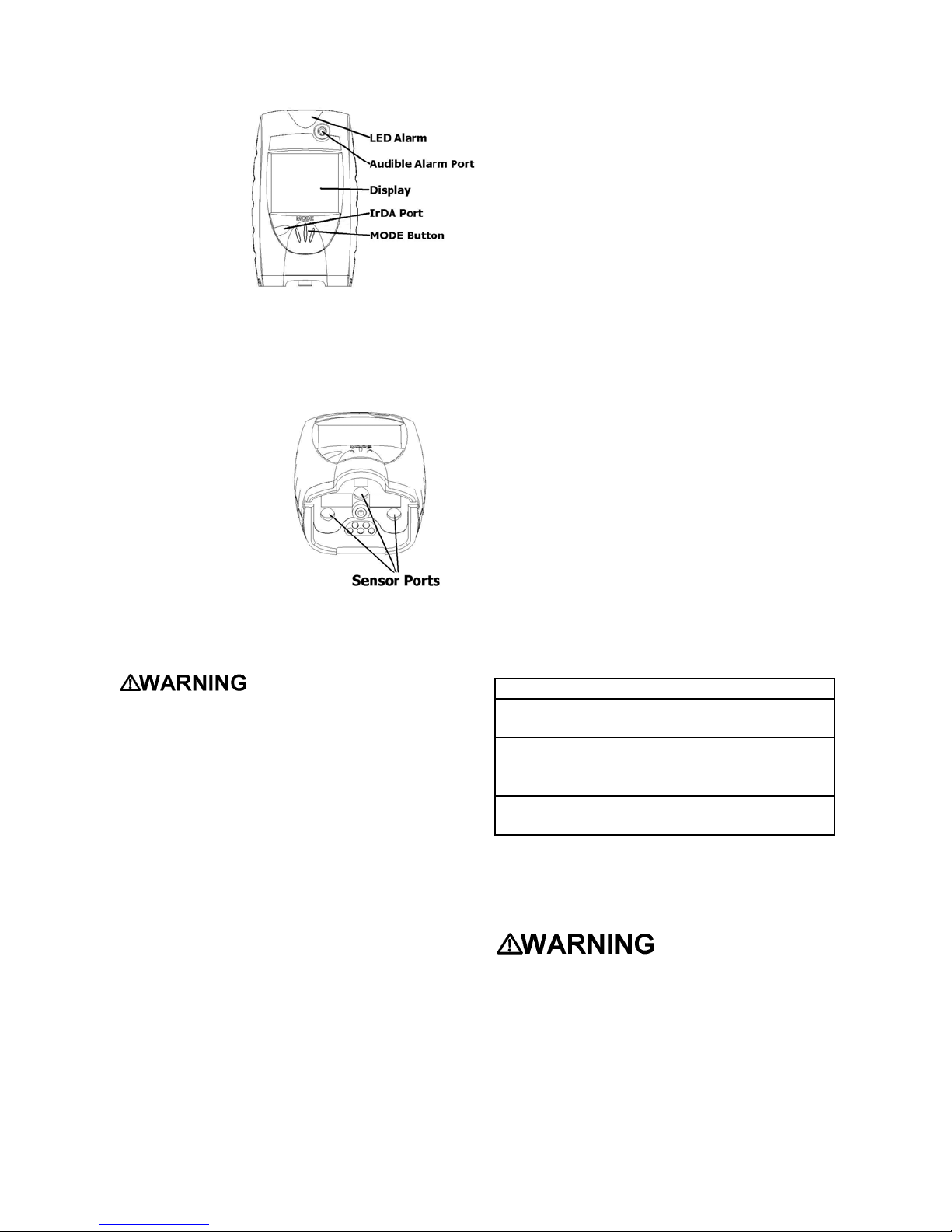

1. Description

The MultiPro is

a multi-sensor

gas detector

that can be

configured to

meet a wide

variety of user

requirements.

This chapter

provides an

overview of many of the features of the

MultiPro. More detailed descriptions of the

specific features of the MultiPro are contained

in the subsequent chapters of this manual.

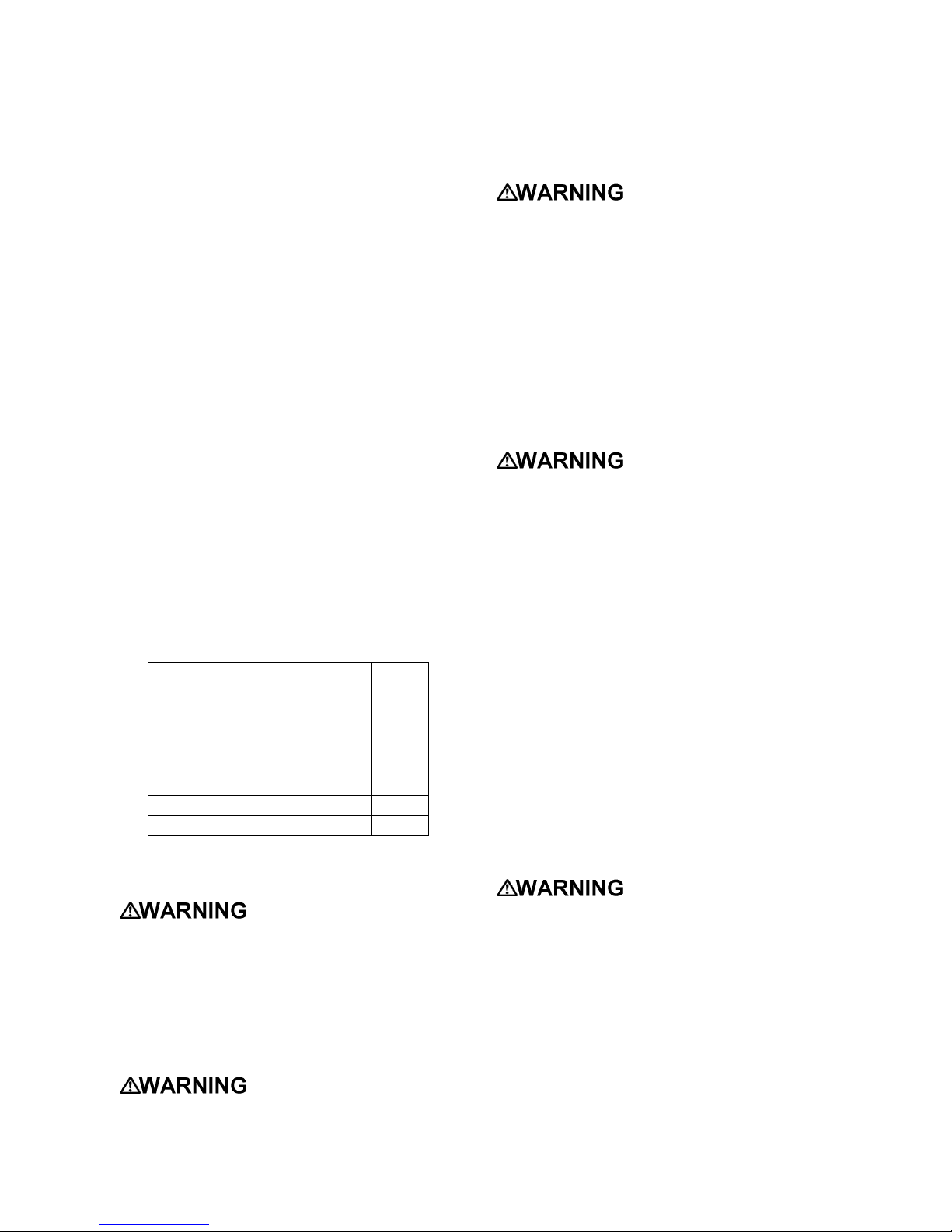

1.1 Methods of sampling

The MultiPro may be

used in either

diffusion or sampledraw mode. In

either mode, the gas

sample must reach

the sensors for the

instrument to

register a gas

reading. The

sensors are located at the bottom of the

instrument. There are three distinct sensor

ports that allow the sample to reach the

individual sensors.

The sensor ports must be

kept free of obstruction. Blocked sensor

ports can lead to inaccurate and

potentially dangerous readings.

In diffusion mode, the atmosphere being

measured reaches the sensors by diffusing

through the vents at the bottom of the

instrument. Normal air movements are

enough to carry the sample to the sensors.

The sensors react quickly to changes in the

concentrations of the gases being measured.

Diffusion-style operation monitors only the

atmosphere that immediately surrounds the

detector.

The MultiPro can also be used to sample

remote locations with the hand-aspirated

sample-draw kit or with the motorized,

continuous sample draw pump (both available

separately). During remote sampling, the gas

sample is drawn into the sensor compartment

through the probe assembly and a length of

tubing. Remote sampling operations only

monitor the atmosphere at the end of the

sample draw probe.

Use of the hand-aspirated sample draw

kits is covered in section 3.1.

Use of the motorized sample draw pump is

covered in section 3.2.

A detailed description of the MultiPro

probe assembly is given in section 5.7.

1.2 Multi-sensor capability

The MultiPro can be configured to

simultaneously monitor oxygen, carbon

monoxide, hydrogen sulfide and combustible

gases and vapors. All sensors are

replaceable in the field. Each of the MultiPro’s

sensor channels is configured for a specific

type of sensor.

Note: It is necessary to verify the accuracy of

the MultiPro by calibration with known

concentration test gas whenever a change is

made to the sensors installed in the

instrument.

Calibration procedures are discussed in detail

in Chapter 4.

The MultiPro uses electrochemical toxic gas

sensors that have been designed to minimize

the effects of common interfering gases.

These sensors provide accurate, dependable

readings for toxic gases commonly

encountered during confined space entry and

other industrial applications.

Different measurement units are used

depending on the gas being measured.

Type of Hazard Measurement unit

Oxygen (O2) Percentage by

volume

Combustible gas Percentage of lower

explosive limit

(%LEL)

Carbon Monoxide,

Hydrogen Sulfide

Table 1.2. Units of Measurement.

Parts per million

(PPM)

1.3 Calibration

The MultiPro detector features one-button

fresh air and span calibration.

The accuracy of the

MultiPro should be checked periodically

with known concentration calibration gas.

Failure to check accuracy can lead to

inaccurate and potentially dangerous

readings. (The Canadian Standards

Association (CSA) requires an accuracy

check using known concentration

calibration gas prior to each day’s use.)

8

Calibration procedures are discussed in

detail in Chapter 4.

Recommended calibration frequency is

discussed in Appendix B.

1.4 Alarm logic

MultiPro gas alarms can be adjusted with

BioTrak Software through a PC with an IrDA

port or directly with the MODE button (see

Chapter 6 for direct programming

instructions). Alarms may be set anywhere

within the nominal range of the specific sensor

type. When an alarm set point is exceeded a

loud audible alarm sounds, and the bright red

LED alarm lights flash.

1.4.1 Atmospheric hazard alarms

The combustible gas alarm is activated when

the percent LEL (Lower Explosive Limit) gas

concentration exceeds any pre-set alarm

level.

Two oxygen alarm set points have been

provided; a danger alarm for low

concentrations associated with oxygen

deficiency and a warning alarm for high

concentrations associated with oxygen

enrichment.

Four alarm set points have been provided for

each toxic gas sensor: Warning, Danger,

STEL (Short Term Exposure Limit) and TWA

(Time Weighted Average).

S

E

N

S

O

R

CO 35 100 100 35

H2S 10 20 15 10

Default Toxic Sensor Alarm Levels

Appendix A discusses alarm levels and

factory default alarm settings.

detectors have been designed for the

detection of deficiencies of oxygen,

accumulations of flammable gases and

vapors, and accumulations of specific

toxic gases. An alarm condition indicating

the presence of one or more of these

potentially life-threatening hazards should

be taken very seriously.

condition it is important to follow

established procedures. The safest course

W

A

R

N

I

N

D

A

N

G

E

R

S

T

E

L

G

MultiPro portable gas

In the event of an alarm

T

W

A

of action is to immediately leave the

affected area, and to return only after

further testing determines that the area is

once again safe for entry. Failure to

immediately leave the area may result in

serious injury or death.

A rapid up-scale reading

followed by a declining or erratic reading

may indicate a hazardous combustible gas

concentration that exceeds the MultiPro’s

zero to 100 percent LEL detection range.

1.4.2 Low battery alarms

The MultiPro may be equipped with either a

rechargeable Lithium Ion (Li-Ion) or an

alkaline battery pack. The MultiPro includes

multi-staged low battery alarms to let the user

know that the battery is running low.

For detailed information concerning the

low battery alarms, see section 2.4.5.

Use only Duracell MN1500

or Ultra MX1500, Eveready Energizer E91LR6, Eveready EN91 batteries.

Substitution of batteries may impair

intrinsic safety.

1.4.3 Sensor over range alarms.

The MultiPro will go into alarm if a sensor is

exposed to a concentration of gas that

exceeds its established range. In the case of

an LEL reading that exceeds 100% LEL, the

LEL channel will be automatically disabled by

the instrument and the instrument will remain

in constant alarm until it is turned off, brought

to an area that is known to be safe, and then

turned back on. The display will show “OL” in

place of the sensor reading for any channel

that has gone into over range alarm.

See section 2.4.5 for further details on

sensor over range alarms.

A sensor range chart is provided in

Appendix C.

In the event of an LEL

overrange alarm the MultiPro must be

turned off, brought to an area that is

known to be safe and then turned on again

to reset the alarm.

1.4.4 LEL response failure due to lack of

alarm

O

2

The MultiPro features automatic warning

against LEL sensor response failure due to

lack of oxygen. See section 2.4.7 for details.

9

1.4.5 Security beep/flash

The MultiPro includes a security beep function

that is designed to notify the user that the

instrument is powered up and running. Once

enabled the MultiPro will emit a short audible

beep and give a short flash on the LED at a

user-defined interval. The security beep/flash

function may be enabled and the interval may

be changed with BioTrak software or directly

with the MODE button (see Chapter 6 for

direct programming instructions).

1.4.6 Latching peak alarms

The MultiPro’s alarms are self-resetting unless

the alarm latch is enabled. With the MultiPro’s

alarm latch enabled, the audible and visible

alarms will continue to sound after the

atmospheric hazard has cleared. Press the

MODE button to reset the alarms. If the alarm

latch is disabled and the alarm condition is no

longer present, the instrument will

automatically return to normal operation, and

the visible and audible alarms cease without

further input from the user.

1.4.7 Fault detection

MultiPro software includes a number of

additional alarms designed to ensure the

proper operation of the instrument. When the

MultiPro detects that an electronic fault or

failure condition has occurred, the proper

audible and visible alarms are activated and

an explanatory message or message code is

displayed.

The MultiPro is designed to

detect potentially life threatening atmospheric

conditions. Any alarm condition should be

taken seriously. The safest course of action is

to immediately leave the affected area, and

return only after further testing determines that

the area is once again safe for entry.

1.5 Other electronic safeguards

Each time the detector is turned on, the

MultiPro automatically tests the LED alarm

light, audible alarm, internal memory and

pump status (if so equipped). The battery is

monitored continuously for proper voltage.

The MultiPro also monitors the connection of

sensors that are currently installed. The

detection of any electronic faults causes the

activation of the audible and visible alarms

and causes the display of the appropriate

explanatory message.

1.5.1 Heartbeat

At the center of the display is a heart symbol

that will blink every few seconds to show that

the instrument is functioning normally.

1.6 Sensors

The MultiPro can be configured to

simultaneously monitor oxygen, carbon

monoxide, hydrogen sulfide and combustible

gases and vapors. The sensor configuration

of the MultiPro may be specified at the time of

purchase, or changed in the field by

appropriately trained personnel.

Note: A CF Value may be required when

replacing the 54-49-24 CO/H2S sensor.

Instructions are included with the

replacement sensor.

Replacement sensor part numbers and

sensor ranges are given in Appendix B.

Sensor cross-sensitivity figures are given

in Appendix C.

A sensor that cannot be

calibrated or is found to be out of tolerance

must be replaced immediately. An instrument

that fails calibration may not be used until

testing with known concentration test gas

determines that accuracy has been restored,

and the instrument is once again fit for use.

Calibration procedures are discussed in detail

in Chapter 4.

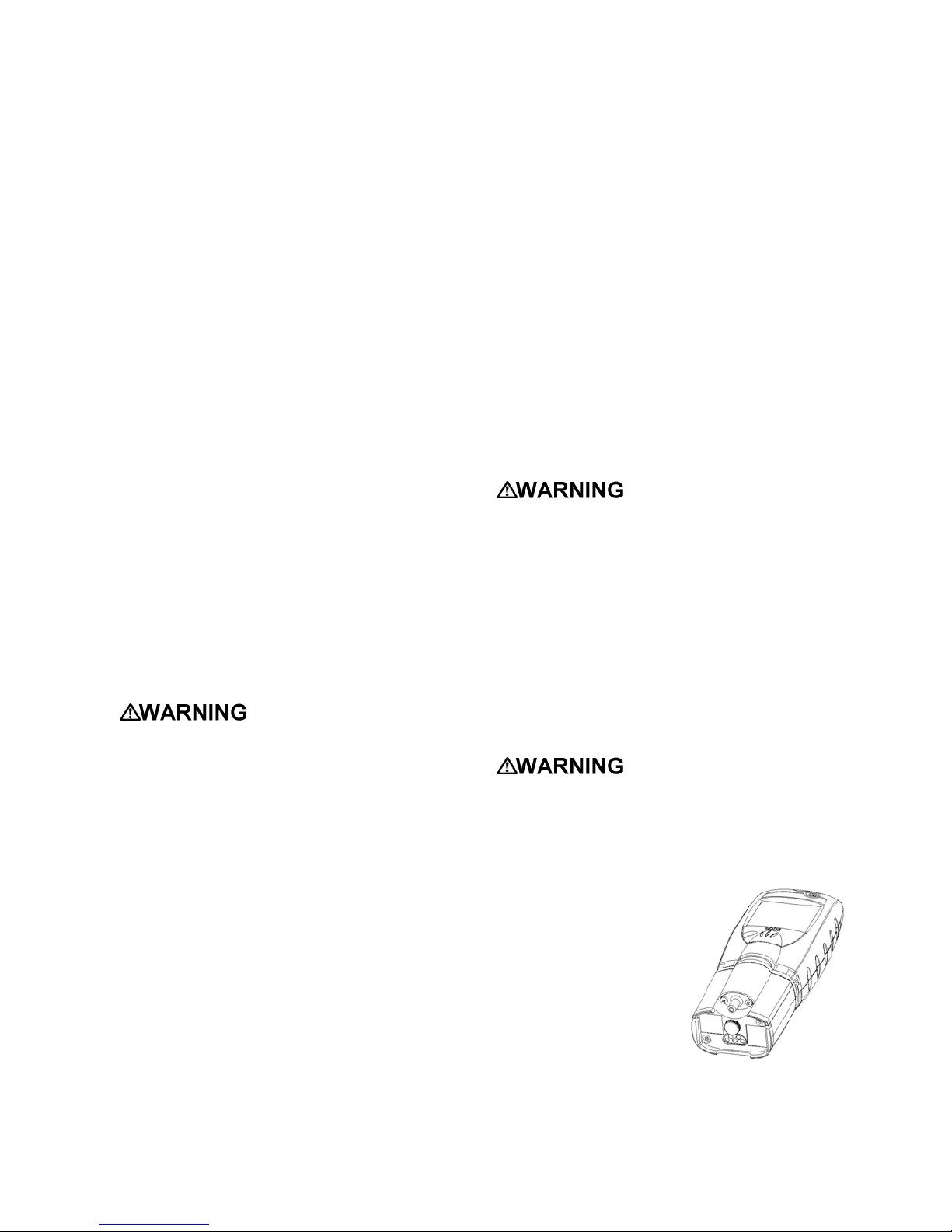

1.7 Optional sample draw pump

A motorized sample-draw pump is available

for the MultiPro for situations requiring

continuous "hands free" remote monitoring.

Use only part number 5449-102 sample draw pump with the

UL/CSA-approved version of the MultiPro.

Use only part number 54-49-102-5 sample

draw pump with the ATEX-approved

version of the MultiPro.

The pump contains a

pressure sensor that

detects restrictions in

airflow caused by water

or other obstructions

being drawn into the

unit and immediately

acts to turn the pump

off in order to protect

the sensors, pump, and

other MultiPro components from damage.

Pump status is continuously monitored by the

MultiPro microprocessor. When the pump is

10

Loading...

Loading...