Page 1

M436A/M836A,B Damper Motors

INSTALLATION INSTRUCTIONS

FEATURES

• Motors provide two-position zone control.

• Used to operate outdoor air dampers for combustion

or makeup air, changeover dampers for heating and

cooling systems, minimum position dampers for

ventilation and similar applications.

• Damper motors have an internal spdt switch for

controlling auxiliary equipment, additional motors, or

to provide a burner interlock switch.

• M436 Damper Motors require 120 or 240 Vac, 60 Hz

power; M836 Damper Motors require 24 Vac, 60 Hz

power.

• All models are supplied with a case and cover.

• Spring returns motor to start position in event of

power interruption or failure.

• Hexagonal output shafts on both ends of motor with

rotational direction stamped on motor case.

• M436A and M836A equipped with thermal breaker for

APPLICATION

M436A/M836A,B Damper Motors are spring return (SR)

motors used for residential and light commercial applications

in Series 40 and Series 80 circuits.

A 2-wire, line voltage thermostat or other line voltage, spst

controller must be used to control the M436A. A 24V spst

controller or thermostat without heat anticipation is required to

operate the M836A. The M836B requires 24V thermostat with

a 0.75 A heat anticipator adjustment.

Each damper motor is supplied with a shaft coupling assembly

and a crank arm assembly. With these accessories the motor

shaft may be connected to the damper shaft directly or

through a linkage.

overload protection during lifting stroke or when motor

stalls.

• M836A Damper Motor with 128499 Bracket directly

replaces M87A Damper Motor.

• These damper motors operate:

— Outdoor air dampers for combustion air in boiler

rooms.

— Backdraft dampers for exhaust fans.

— Outdoor air inlet dampers for industrial makeup air

units.

— Changeover dampers for heating and cooling sys-

tems.

— Minimum position damper for ventilation from outdoor

air.

— Two-position zone control dampers.

— Both motor types have an adjustable auxiliary switch

(spdt) for operating auxiliary equipment or cascading

motors, or to act as a burner interlock switch.

60-2119-05

Page 2

M436A/M836A,B DAMPER MOTORS

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

an individual unit may not exactly match the listed

specifications. Also, this product is tested and calibrated under closely controlled conditions and some

minor differences in performance can be expected if

those conditions are changed.

TRADELINE® Models:

TRADELINE® models are selected and packaged to provide

ease of stocking, ease of handling, and maximum replacement value. TRADELINE® model specifications are the

same as those of the standard models except as noted

below.

TRADELINE® Models Available:

M436A Damper Motor: 120 or 240 Vac, 60 Hz.

M836A,B Damper Motors: 24 Vac, 60 Hz.

Accessories: See Table 1. Crank arm, mounting bracket

#198545, and shaft coupling bag assemblies are included

with motors; brackets listed in Table 1 must be ordered

separately.

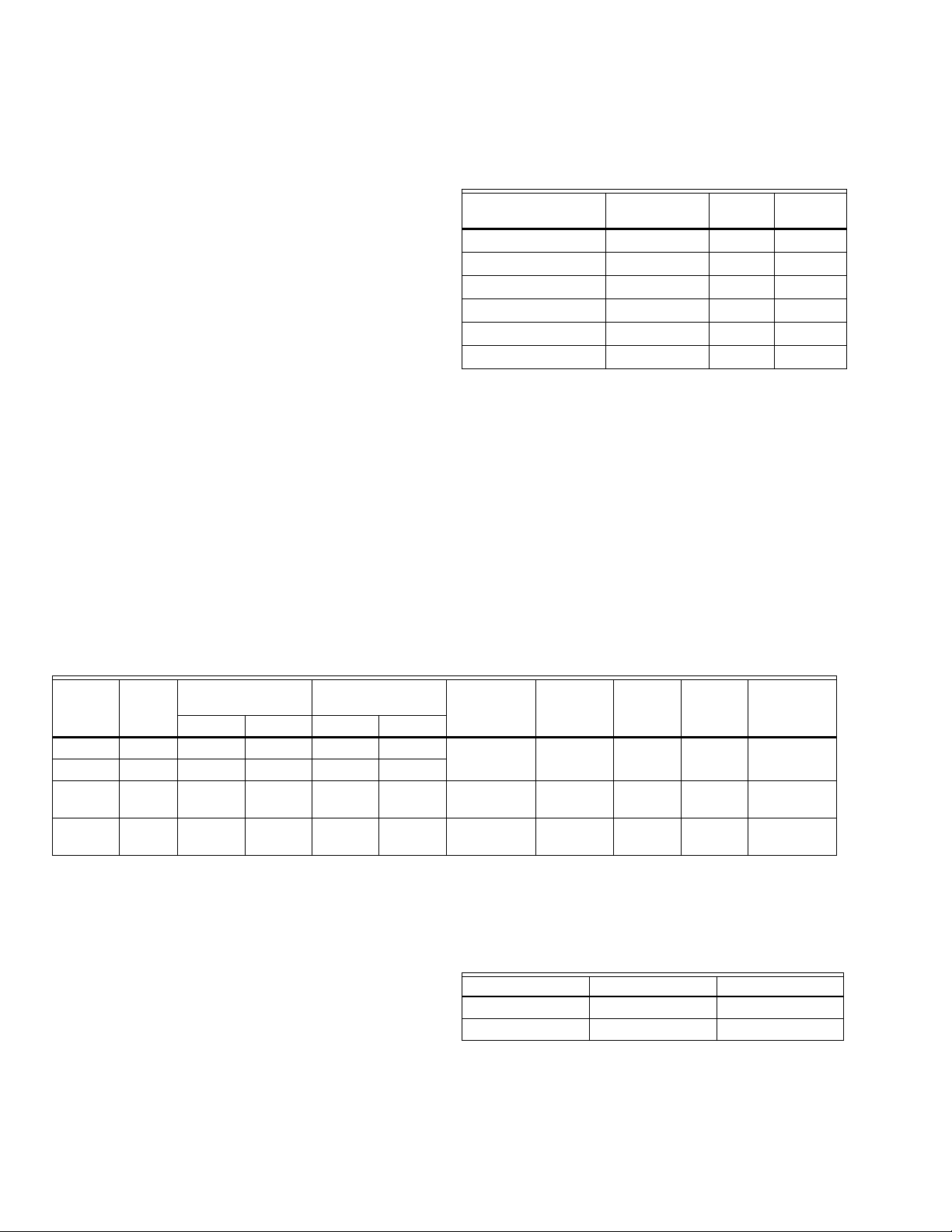

Table 1. Accessories Available

Type Bag Assembly

Bag Assembly

Part Number

Bracket

Included

Bracket

Height

Bracket 16254AC 128499 2.25 in.

Bracket - Mounting 7640JM 126809 N/A

Bracket 7640JN 126336 0.5 in.

Crank Arm 7640JL N/A N/A

Shaft Coupling 7640JE N/A N/A

Bracket 198545 198545 2.25 in.

Additional Features:

TRADELINE® pack with cross reference label and instruction

sheet.

Standard Models (See Table 2):

M436A Damper Motor: 120 or 240 Vac spring return motor for

use with two-wire thermostats or other spst controllers.

Includes internal adjustable spdt switch for controlling auxiliary equipment.

M836A Damper Motor: 24 Vac spring return motor for use with

spst controllers without heat anticipation. Includes internal

adjustable spdt switch for controlling auxiliary equipment.

M836B Damper Motor: 24 Vac spring return motor for use with

spst controllers. If circuit has thermostat heat anticipation,

set the anticipator at 0.75A. Includes internal adjustable

spdt switch for controlling auxiliary equipment.

Table 2. M436/M836 standard models.

Nominal Current

Model

Number

Voltage

(Vac)

(amperes)

M436A 120 0.37 0.12 27.0 8.5 20 30 30

240 0.19 0.06 27.0 8.5

M836A 24 1.85 0.6 27.0 8.5 20 30 30

M836B 24 1.34 0.73 20.3 11.2 15 30 25

a

Breakaway torque is available to overcome an occasionally frozen or seized damper or valve. The motor must not be used

Nominal Power

(watts)

Maximum

Load Torque

(lb-in.)

Breakawa

y Torque

(lb-in.)

Opening

a

Time

(nominal)

(nominal)

(nominal)

(sec)

b

Closing

b

Time

(sec)

25

(nominal)

25

(nominal)

25

(nominal)

Damper

Blade Area

(sq ft)Opening Holding Opening Holding

13

13

10

continuously at this rating.

b

40 sec maximum.

Ambient Temperature Rating: 32° to 125°F (0° to 52°C).

Finish: Gray.

Table 3. Auxiliary switch ratings (in amperes).

Power 120 Vac 240 Vac

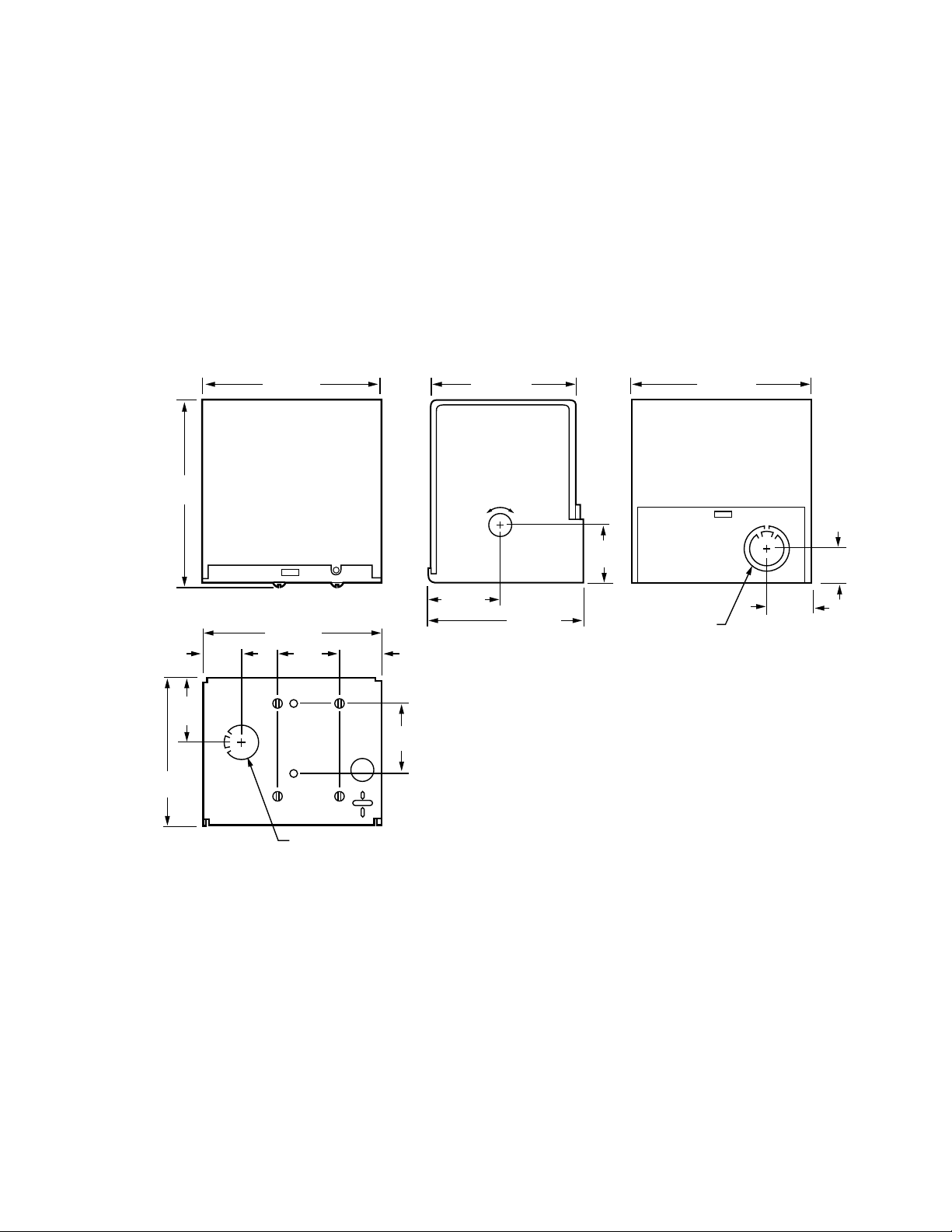

Dimensions: See Fig. 1.

Approvals:

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

Underwriters Laboratories Inc. Listed (M436A, M836A):

File No. E4436, Guide No. XAPX.

Auxiliary Switch Action:

Spdt, normally open (R-B) contacts close during the power

Auxiliary Switch Ratings (In Amperes): See Table 3.

Pilot Duty: 40 VA at 120 or 240 Vac.

stroke and open during the return stroke. Can be adjusted

to operate at any point between 5 and 70 degrees of motor

stroke.

60-2119—05 2

Page 3

M436A/M836A,B DAMPER MOTORS

1

(25)

1-1/2

(38)

4-5/8 (118)

4-5/8 (118) 4-5/8 (118)

1-5/8 (42)

1-5/8

(42)

3-3/4

(96)

3-17/32 (90)

25/32

(20)

29/32 (23)

3-3/4 (96)

1-3/4

(45)

1-3/8

(35)

4-1/2

(115)

1-1/8

(29)

COMBINATION

KNOCKOUT FOR

1/2 INCH AND

3/4 INCH CONDUIT

KNOCKOUT FOR 1/2 INCH CONDUIT

M9950

OPEN CLOSE

Angular Stroke: 75 degrees.

Weight: 4 lb, 10 oz (2.1 kg).

Optional Specifications:

M436 with crank arm.

M436A Damper Motor, 50 Hz for international applications.

Models for 220 or 240 Vac, with 50 second opening stroke,

25 second closing stroke. Includes ground and cover

screws and 7640JL Bag Assembly.

M836A Damper Motor, 50 Hz for international applications.

Model is for 24 Vac, with 50 second opening stroke and 25

second closing stroke. Includes ground and cover screws

and 7640JL Bag Assembly.

Accessories:

16254AC Bag Assembly, includes 128499 Mounting Bracket

and screws (see Fig. 2 and 6).

7640JE Bag Assembly, includes drive bushings, adapter, and

coupling for direct drive (see Fig. 4 and 7).

7640JL Bag Assembly, includes clamp and crank arm lever

for crank arm drive (see Fig. 5 and 6).

7640JM Bag Assembly, includes 126809 Mounting Bracket

and screws (see Fig. 3, 4 and 7).

7640JN Bag Assembly, includes 128336 Mounting Bracket

and screws (see Fig. 2 and 6).

4074BRU Bag Assembly, includes extension adapter and

screws for mounting Q607 Auxiliary Switch to M436A

Damper Motor.

Q298B Linkage, includes damper crank arms, bushings, 1/4

in. (6.5 mm) and ball joint assemblies (see Fig. 6).

Fig. 1. M436 and M836 Damper Motors dimensions in in. (mm).

3 60-2119—05

Page 4

M436A/M836A,B DAMPER MOTORS

CAUTION

4-3/16

(106)

3-9/16

(91)

1-31/64

(38)

2-3/32

(53)

11/32

(9)

1/2

(13)

3-5/8 (92)

M9944

5/16

(8)

1-3/4 (45)

2-11/32 (60)

19/32

(15)

13/64 (5) DIAMETER (2)

13/64 (5) DIAMETER

3-3/4 (96) 1-7/16

(37)

3-3/4

(95)

1-3/8

(35)

2-1/16

(52)

2-1/8

(54)

3-5/8 (92)

2-11/32 (60)

2-11/32

(60)

3-3/4

(95)

4-1/4

(108)

M16866

M9949

CLEARANCE HOLES FOR

MOUNTING SCREWS (4)

1-3/4

(46)

19/64 (8)

DIAMETER (2)

1-1/4 (32)

DIAMETER

7/16 (11)

CLEARANCE

HOLES (10)

2-3/8

(61)

4-23/32 (120)

2-3/8

(61)

1-3/16

(30)

2-35/64

(65)

1-1/2 (38) 1-3/8 (35)2-13/64 (61)

Fig. 4. 126809 Bracket dimensions in in. (mm).

INSTALLATION

Fig. 2. 128336, 128499 Mounting Brackets dimensions in

Fig. 3. 198545 Bracket dimensions in in. (mm).

60-2119—05 4

in. (mm).

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings and descriptions given on the product

to make sure the product is suitable for your application.

3. Installer must be a trained, experienced service techni-

cian.

4. After installation is complete, check out productopera-

tion as provided in this specification.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

1. Disconnect power supply before installation to

prevent electrical shock or equipment damage.

2. To prevent damage to the gear train, never turn the

motor shaft by hand or with a wrench.

3. Do not install the actuator in areas with acid fumes

or other deteriorating vapors that might attack the

metal parts of the motor.

4. Do not install the actuator in areas with escaping

gas or other explosive vapors that could be ignited

by a spark from the actuator or attached

accessories.

Location and Mounting

IMPORTANT

Mount M436 and M836 Damper Motors with the

shaft in the horizontal position.

Install the motor in a location where the ambient temperature

range is within 32° to 125°F, free from acid fumes or other

deteriorating vapors that might attack the metal parts of the

Page 5

motor. Also, make sure the location is free from escaping gas

M9946

BUSHING FOR

1/4 INCH (6.5 mm)

DAMPER SHAFT

BUSHING FOR

3/8 INCH (9.5 mm)

DAMPER SHAFT

CLAMP

ADAPTER

FOR

DAMPER

COUPLING

OPEN CLOSE

126809

BRACKET

M9945

1

1 CLAMP AND CRANKARM LEVER ARE DESIGNED TO FIT TIGHTLY

TOGETHER. IF NECESSARY, TAP THESE PARTS TOGETHER

PRIOR TO MOUNTING ON MOTOR TO ENSURE TIGHTNESS.

CRANKARM

LEVER

CLAMP

OPEN CLOSE

M9941

BRACKET

126809

BRACKET 128336

OR 128499

7640JL CRANK

ARM ASSEMBLY

Q298B

LINKAGE

1

1 ASSEMBLE 7640JL CRANK ARM ASSEMBLY TO MOTOR

AND Q298B LINKAGE TO DAMPER. ADJUST LENGTH

OF STEEL ROD AS NECESSARY. ONE Q298B CRANK

ARM IS NOT NECESSARY AND MAY BE DISCARDED.

or other explosive vapors that could be accidentally ignited by

a spark from the motor or its attached parts.

Install the motor in a location that allows enough clearance for

mounting accessories and for servicing.

Locate as near as possible to the equipment to be controlled.

The 198545 Mounting Bracket and 7640JE Bag Assembly are

for direct coupling to the damper shaft from either end of the

motor, depending upon the desired rotational direction.

The 198545 Mounting Bracket may also be used for offset

mounting with the 7640JL Bag Assembly and a standard

damper linkage, such as Q605. 128336 Mounting Bracket

must be used with 7640JL Bag Assembly and a standard

damper linkage.

Mounting brackets and crankarm drives are furnished with

TRADELINE® models of these motors or can be ordered

separately if required for the installation. Refer to the

Accessories section for specifications, Fig. 2 and 4 for

dimensions, and Fig. 5 through 8 for installation drawings.

M436A/M836A,B DAMPER MOTORS

Fig. 5. Exploded view showing how to mount 7640JE

Damper Shaft Coupling and 7640JM Mounting Bracket

Assembly to motor.

Fig. 6. Exploded view showing how to mount 7640JL

Crankarm Assembly to motor.

Fig. 7. Offset mounting with 7640JL Crankarm Assembly

and Q298B Linkage.

5 60-2119—05

Page 6

M436A/M836A,B DAMPER MOTORS

CAUTION

CAUTION

M9940

BRACKET 126809

(7640JM ASSEMBLY)

M9942

1

L1

L2

B

W

R

2

1

2

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

MAKES R TO B DURING MOTOR POWER (OPEN) STROKE.

L2

LINE VOLTAGE

TWO POSITION

CONTROLLER

TO

AUXILIARY

EQUIPMENT

L1

(HOT)

AUXILIARY

SWITCH

M436A

TO POWER SUPPLY

M9948

1

L1

L2

B

W

R

2

1

2

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

MAKES R TO B DURING MOTOR POWER (OPEN) STROKE.

L2

LOW VOLTAGE

TWO POSITION

CONTROLLER

TO

AUXILIARY

EQUIPMENT

L1

(HOT)

AUXILIARY

SWITCH

M836A

TO POWER SUPPLY

24 VOLT

TRANSFORMER

Fig. 8. Damper motor directly coupled to damper using

7640JM Mounting Bracket Assembly and 7640JE Drive

Coupling Assembly.

Wiring

Electrical Shock Hazard.

Disconnect the power supply before wiring to prevent

electrical shock or equipment damage.

Disconnect the power supply before beginning wiring to

prevent electrical shock or equipment damage. All wiring must

comply with local electrical codes, ordinances and

regulations. Refer to Fig. 9 and 10 for typical hookup

diagrams and to information furnished with the system

equipment.

Fig. 10. Typical wiring diagram for M836 Damper Motor.

ADJUSTMENT AND CHECKOUT

Auxiliary Switch Adjustment

Adjust the internal spdt auxiliary switch of the M436/M836

Damper Motor to operate at any point between 5 degrees and

70 degrees of the motor stroke. The switch has a 1 to 2

degree nonadjustable differential. The switch makes R to B

contact during the power stroke (motor shaft moves in the

direction of the OPEN arrow on the outside of the case).

Apply power to the motor so that the motor runs to the OPEN

position. Note the point of the motor stroke where the switch

operates (audible click or check for continuity across the R to

B terminals) If the switch operates correctly for the application,

proceed to check out the installation. If the switch needs to be

adjusted, perform the following steps:

1. Determine the number of degrees that the switch cam

must be adjusted to operate the switch at the desired

point of the motor stroke.

IMPORTANT

Do not adjust switch to operate closer than five

degrees from the ends of the motor stroke.

Fig. 9. Typical wiring diagram for M436 Damper Motor.

60-2119—05 6

2. Remove the motor cover.

Electrical Shock Hazard.

To prevent electrical shock or equipment damage,

disconnect the power supply before adjusting the

switch cam.

Page 7

M436A/M836A,B DAMPER MOTORS

OPEN CLOSE

M9947

M9951

OIL

HERE

OIL

HERE

(FELT

PAD)

OIL

HERE

OIL

HERE

3. Insert a narrow bladed common-point screwdriver in a

slot in the switch cam (white plastic) located near the

center of the motor. Refer to Fig. 10. Each slot in the

cam equals approximately 20 degrees of motor rotation.

4. Select a reference point and move the cam the correct

number of degrees, as follows:

a. To adjust the switch to operate nearer the open

(maximum rotation) motor position, move the cam in

the direction of the CLOSE arrow on the outside of

the motor case.

b. To adjust the switch to operate nearer the closed

motor position, move the cam in the direction of the

OPEN arrow on the outside of the motor case.

Repower the motor and check the point at which the switch

makes and breaks. Readjust as necessary.

and that the motor travels smoothly through the fully open and

fully closed positions. Cut any excess linkage rod length to the

correct size.

Make necessary minor adjustments until desired operation is

obtained and tighten all nuts and setscrews. A motor checkout

should prove that:

1. The motor operates the load.

2. The motor responds properly to the controller.

3. There is no linkage binding or motor stalling at any point

of travel.

If the motor does not operate properly, check for proper

voltage or mechanical linkage or damper binding.

Lubrication

To assure long motor life, annually lubricate the felt pads

located on each of the motor bearings and on the two shafts in

the gear train. See Fig. 11. Use Anderol® 465 Oil or an

equivalent. Light sewing machine oil is an acceptable

equivalent. Do not over lubricate. One drop at each lubrication

point is sufficient.

Fig. 11. Using screwdriver to adjust auxiliary switch cam.

Checkout

Operate the motor through the complete open-close stroke.

Be prepared to release one of the previously tightened linkage

connections, if necessary, to prevent damage. Check for

proper operation, making sure that the linkage does not bind

Fig. 12. M436/M836 Damper Motor lubrication points.

7 60-2119—05

Page 8

M436A/M836A,B DAMPER MOTORS

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2010 Honeywell International Inc.

60-2119—05 M.S. Rev. 10-10

Printed in U.S.A.

Loading...

Loading...