Honeywell L482A Installation Guide

L482A

Low Limit Controller

INSTALLATION INSTRUCTIONS

BEFORE INSTALLATION

No special tools are required to install the L482A Low Limit

Controller. Refer to the job drawings for specific wiring and

installation information.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check ratings given in instructions and on the product to

ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Mounting

IMPORTANT

1. The controller operates from the lowest temperature

along the entire 20 feet of the sensing element.

2. Locate controller case and bellows where ambient

temperature is always warmer than the set point.

3. For settings above the scale range midpoint it can be

necessary to locate the controller case close to a

steam pipe or other warm surface and make sure the

element does not extend across a cold surface.

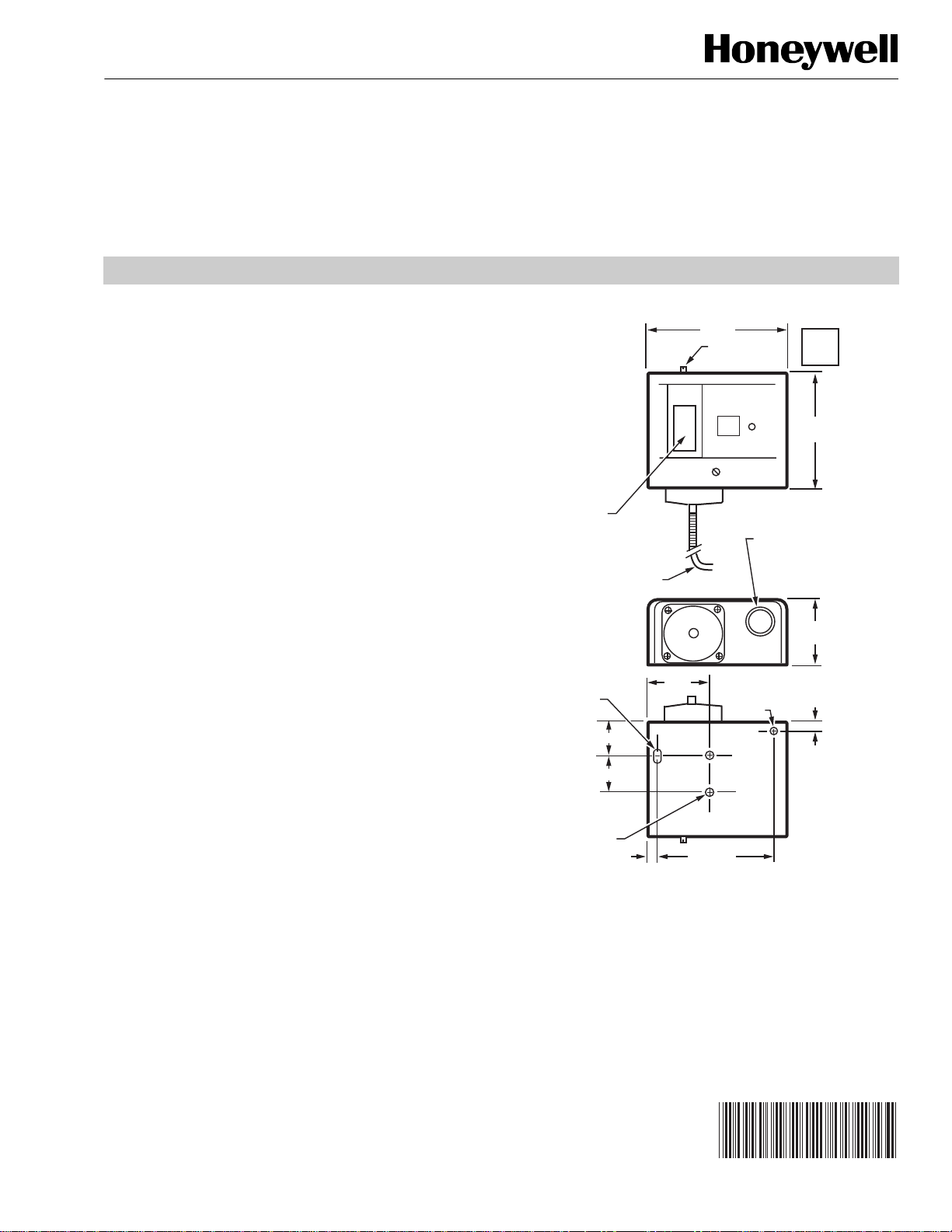

Controller

Surface mount the controller (Fig. 1) vertically on any

convenient location (including the duct itself). Orient the case

with the bellows positioned on the bottom.

SETPOINT

SCALE

20 FT BY 1/8 INCH

SENSING ELEMENT

3/8 X 3/16

(10 X 5)

DIAMETER

ELONGATED

MOUNTING

HOLE

1-1/8 (29)

1 (25)

MOUNTING

HOLES (2)

10-32 UNF-2B

THREAD

5/16 (8)

1-7/8

(48)

4 (101)

SETPOINT

ADJUSTMENT

SCREW

3-1/4 (83)

7/8 (22) HOLE

FOR 1/2 CONDUIT

WITH 1-3/32 (28)

KNOCKOUT RING

FOR 3/4 CONDUIT

3/16 (5)

DIAMETER

MOUNTING

HOLE

PUSH

TO

RESET

4-11/16

(119)

2-3/32

(53)

5/16

(8)

C606A

Fig. 1. L482A Low Limit Controller dimensions in in. (mm).

® U.S. Registered Trademark

Copyright © 2004 Honeywell International Inc.

All Rights Reserved

95-7432-1

996-496 Rev. A

L482A LOW LIMIT CONTROLLER

IF

Sensing Element

IMPORTANT

• The maximum allowable sensing element tempera-

ture is 250°F (121°C).

• Uncoil only the amount of element required for the

application.

• Bend element carefully and only as much as neces-

sary. Bends require a minimum radius of one inch

(25 mm).

• Bend only some distance from the controller.

• Pulling on the element damages it.

• For elements subject to vibration, provide protection

from any surface which the element contacts.

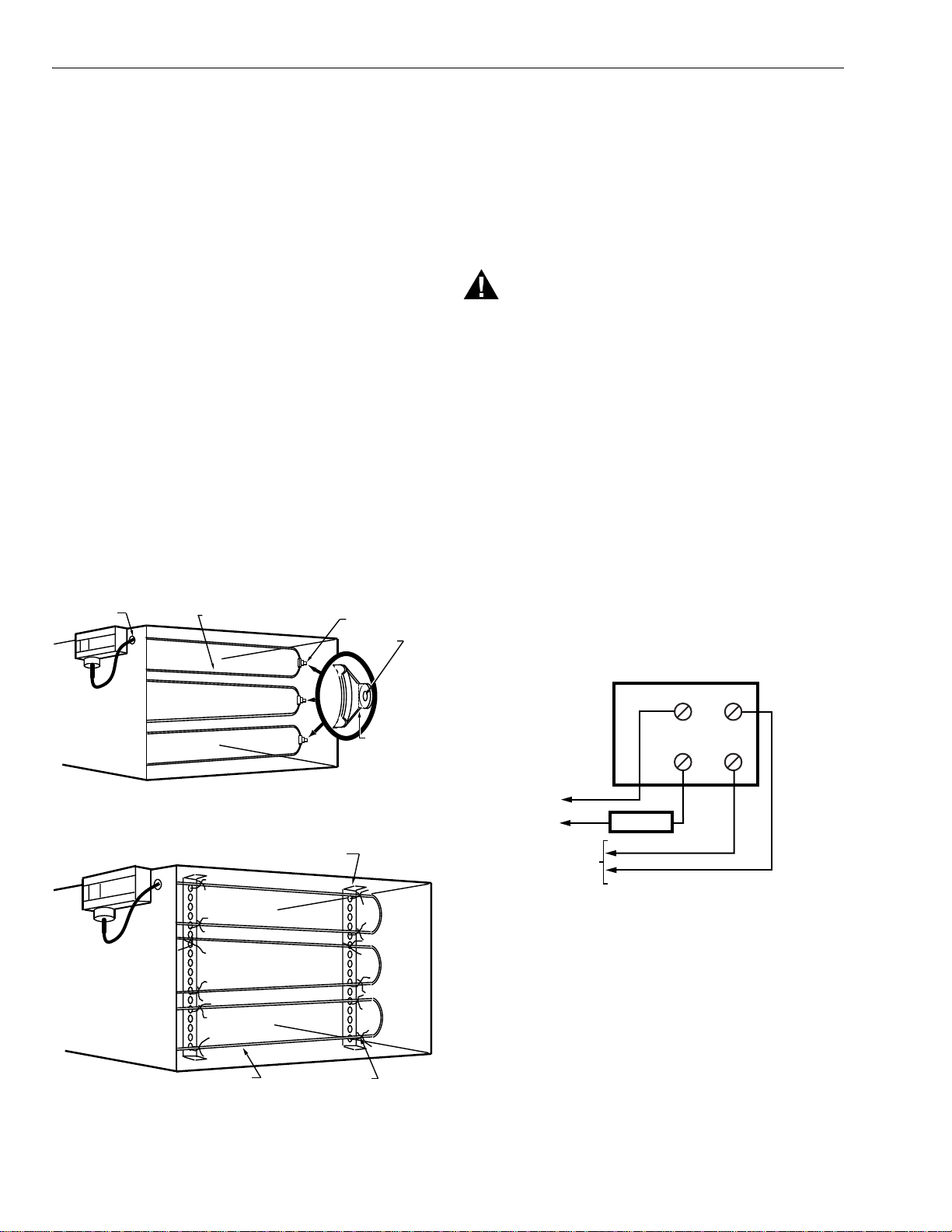

• Mount element horizontally as shown in Fig. 2 and 3.

1. Locate the sensing element where it can sense the

temperature of the air to be controlled.

NOTE: Locate the element away from hot or cold air

inlets.

2. Punch or drill a 1/4 in. hole in the duct and install

CCT1802 Grommet (Fig. 2) to protect the capillary.

3. Carefully insert the element through the grommet into

the duct. Use as much element as possible to provide

maximum protection.

4. Mount the element inside the duct or fasten to the coil if

freezing can occur.

a. Duct mounting: Use CCT2600 Clip (Fig. 2).

b. Coil fastening: Use perforated metal straps (Fig. 3).

GROMMET

ELEMENT

USE NO. 10

SHEET METAL

SCREWS

OPERATION

On a temperature drop to setpoint, LINE 1 to M1 contacts

close and LINE 2 to M2 contacts open. Reset to the normal

state is manual.

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment

damage.

Disconnect power supply before beginning installation

to prevent electrical shock or equipment damage.

IMPORTANT

– All wiring must agree with applicable codes,

ordinances and regulations.

– When switching both ac line voltage and an

automation input (Fig. 4), the input wires must

run no more than three feet in the same conduit.

See Fig. 6.

For typical L482A wiring, see Fig. 4 and 5.

NOTES:

– Screw terminals are provided for wiring

connections.

– Maximum wire size is 12 AWG.

– Use 8-32 x 1/4-inch screws for replacement if

necessary. Longer screws can interfere with the

switch mechanism and damage the switch.

CLIP

DETAIL

BEND HERE

NECESSARY

Fig. 2. Element mounted to duct with CCT2600 Clips.

PERFORATED METAL STRAPS

WIRE FASTENINGSELEMENT

Fig. 3. Element mounted in duct with

perforated metal straps.

C789

C790

LINE 2 LINE 1

M1

C791

L1

(HOT)

L2

TO STATUS

OR ALARM

INPUT OF

AUTOMATION

SYSTEM

M2

FAN RELAY

Fig. 4. Typical wiring diagram with automation input.

95-7432–1 2

996-496 Rev. A

Loading...

Loading...