Page 1

Galaxy Dimension

Installer Manual

Honeywell Security

Page 2

Page 3

Galaxy Dimension Installer Manual

Table of Contents

Contents

INTRODUCTION ....................................................................................... 1-1

Variants ................................................................................................................1-1

SECTION 1: QUICK SETUP .................................................................... 1-3

SECTION 2: SYSTEM ARCHTECTURE .................................................. 2-1

PCB Layout .......................................................................................................... 2-2

RS485 Expansion Module (GD-520 only) .........................................................2-3

System Installation and Wiring .........................................................................2-4

Connecting the Galaxy Dimension to the PSTN.............................................. 2-5

Connecting Additional Telecom Apparatus .......................................................................... 2-6

Line Monitoring .................................................................................................................... 2-6

Stand-by Battery .................................................................................................2-7

Battery Start-up ..................................................................................................................... 2-7

On-Board Power Supply Unit.............................................................................2-7

Memory ................................................................................................................2-8

RS485 Data Communication Bus (AB Lines) ................................................... 2-8

RS485 Wiring Configurations ............................................................................ 2-8

RS485 Wiring Recommendations .....................................................................2-9

Zones ................................................................................................................. 2-11

Zone Addresses ................................................................................................................ 2-11

Wiring Zones .....................................................................................................................2-13

Wiring Multiple Detectors ................................................................................2-15

Wiring Keyswitches ............................................................................................................ 2-15

Wiring Terminator Buttons ..................................................................................................2-16

Outputs ..............................................................................................................2-16

Output Applications ......................................................................................... 2-17

Trigger Header ..................................................................................................2-18

Trig 1-6 ............................................................................................................................... 2-18

Supply ................................................................................................................................2-18

SPI Header ......................................................................................................... 2-19

SECTION 3: PERIPHERALS ................................................................... 3-1

General................................................................................................................. 3-1

Wiring ................................................................................................................... 3-1

i

Page 4

Table of Contents

Galaxy Dimension Installer Manual

Configuring ......................................................................................................... 3-1

Addressing........................................................................................................................... 3-1

Connecting the RIO.............................................................................................................. 3-2

Configuring the RIO..............................................................................................................3-2

RIO Outputs.......................................................................................................................... 3-3

RF RIO .................................................................................................................. 3-4

Connecting the RF RIO ........................................................................................................ 3-4

Addressing the RF RIO ........................................................................................................ 3-5

RF RIO Programming ..........................................................................................................3-6

Configuring the RF RIO ........................................................................................................ 3-6

Power Supply Unit .............................................................................................. 3-7

Configuration ........................................................................................................................ 3-7

Installation Instructions ......................................................................................................... 3-8

Battery .................................................................................................................................. 3-9

Battery Test ........................................................................................................................... 3-9

Specifications ....................................................................................................................... 3-9

EN50131 Compliance ......................................................................................................... 3-9

Printer Interface Module ..................................................................................3-10

ISDN Module ...................................................................................................... 3-11

Programming the ISDN Module ......................................................................................... 3-11

Ethernet Module ...............................................................................................3-12

Configuring the Ethernet Module ....................................................................................... 3-12

Ethernet Communication ................................................................................................... 3-12

Galaxy Dimension and 2-Way Audio .............................................................. 3-13

Introduction.........................................................................................................................3-13

Audio Interface Module ......................................................................................................3-13

MUX Module ......................................................................................................................3-15

Remote Servicing Suite....................................................................................3-17

User Management Suite ................................................................................... 3-17

SECTION 4: KEYPADS ........................................................................... 4-1

The Galaxy Mk7 Keypad/KeyProx.....................................................................4-1

General ................................................................................................................................ 4-1

Power Consumption ............................................................................................................ 4-1

Wiring the Keypad/KeyProx ................................................................................................. 4-2

Keypad/KeyProx Installation Procedure............................................................................... 4-2

Self Diagnostics.................................................................................................................... 4-5

Keypad/KeyProx Operation ................................................................................................. 4-5

The Galaxy KeyProx ........................................................................................... 4-8

General ................................................................................................................................ 4-8

Addressing........................................................................................................................... 4-8

ii

Page 5

Galaxy Dimension Installer Manual

Operation ............................................................................................................................. 4-8

Card Types........................................................................................................................... 4-8

Table of Contents

The Galaxy Dimension TouchCenter................................................................4-9

General ................................................................................................................................ 4-9

TouchCenter Installation Procedure ..................................................................................... 4-9

Configuring a TouchCenter ................................................................................................ 4-10

Set-up Menu ......................................................................................................................4-10

TouchCenter - Operation ................................................................................................... 4-11

Specifications ..................................................................................................................... 4-11

SECTION 5: ACCESS CONTROL ........................................................... 5-1

Group Based Access Control............................................................................ 5-1

User and Access Templates .............................................................................. 5-1

Time Schedules .................................................................................................. 5-1

Door Control Module .......................................................................................... 5-2

MAX3 ....................................................................................................................5-7

SECTION 6: SYSTEM OPERATION ........................................................ 6-1

Menu Options...................................................................................................... 6-1

General ................................................................................................................................ 6-1

The Full Menu...................................................................................................................... 6-1

The Quick Menu .................................................................................................................. 6-1

Menu Access ....................................................................................................................... 6-1

Engineer Mode ....................................................................................................................6-2

Setting Options ................................................................................................... 6-5

Setting the System Using a PIN ............................................................................................ 6-5

Cancelling the Setting ..........................................................................................................6-5

Unsetting the System Using a PIN........................................................................................ 6-6

Engineer Unsetting ..............................................................................................................6-6

Keyswitch Setting Options .................................................................................................... 6-6

Setting the System with Cards/Tags/Fobs ............................................................................ 6-6

Cancelling and Resetting Alarms and Alerts ........................................................................ 6-7

Recording of Events ............................................................................................................. 6-7

Overriding of Faults and Tampers........................................................................................ 6-8

Setting Features ................................................................................................................... 6-8

Menu Options 11-19 ......................................................................................... 6-11

Option 11 – Omit Zones (Quick Menu Option 0) .............................................................. 6-11

Option 12 – Timed Set ....................................................................................................... 6-13

Option 13 – Part Set ...........................................................................................................6-13

Option 14 – Forced Set (Quick Menu Option 1) ................................................................6-13

Option 15 – Chime (Quick Menu Option 2) ....................................................................... 6-13

iii

Page 6

Table of Contents

Option 16 – Instant Set .......................................................................................................6-13

Option 17 – Silent Part .......................................................................................................6-14

Option 18 – Home Set ....................................................................................................... 6-14

Option 19 – All Set..............................................................................................................6-14

Galaxy Dimension Installer Manual

Display Options ................................................................................................ 6-15

Option 21 – Display Zones (Quick Menu Option 3) ........................................................... 6-15

Option 22 – Display Log (Quick Menu Option 4) ...............................................................6-16

Option 23 – System............................................................................................................6-17

Option 24 – Print (Quick Menu Option 5) ........................................................................... 6-18

Option 25 – Access Doors ................................................................................................. 6-19

Test Options ......................................................................................................6-23

Option 31 – Walk Test (Quick Menu Option 6)...................................................................6-23

Option 32 – Outputs ...........................................................................................................6-25

Modify Options ................................................................................................. 6-26

Option 41 – Time/Date (Quick Menu Option 7) ................................................................. 6-26

Option 42 – Codes (Quick Menu Option 8) .......................................................................6-27

Option 43 – Summer (Quick Menu Option 9) ....................................................................6-38

Option 44 – Trace ..............................................................................................................6-38

Option 45 – Timer Control .................................................................................................. 6-39

Option 46 – Group Omit ..................................................................................................... 6-43

Option 47 – Remote Access ..............................................................................................6-44

Option 48 – Engineer access ............................................................................................6-50

Engineer 1 .........................................................................................................6-51

Option 51 – Parameters.....................................................................................................6-51

Option 52 – Program Zones .............................................................................................. 6-71

Option 53 – Program Outputs ............................................................................................6-87

Option 54 – Links .............................................................................................................6-104

Option 55 – Soak .............................................................................................................6-107

Option 56 – Communications .......................................................................................... 6-108

Option 57 – System Print ..................................................................................................6-151

Option 58 – Keypad .........................................................................................................6-152

Option 59 – Quick Menu ..................................................................................................6-155

Engineer 2 .......................................................................................................6-156

Option 61 – Diagnostics...................................................................................................6-156

Option 62 – Full Test ........................................................................................................6-159

Option 63 – Options .........................................................................................................6-160

Option 64 – Assemble Zone............................................................................................6-164

Option 65 – Timers ..........................................................................................................6-168

Option 66 – Pre-checks ................................................................................................... 6-175

Option 67 – Remote Reset .............................................................................................. 6-176

Option 68 – Menu Access ............................................................................................... 6-177

Option 69 – Integrated Access Control ............................................................................6-178

iv

Page 7

Galaxy Dimension Installer Manual

Engineer 3 .......................................................................................................6-192

Option 71 – SPI Key .........................................................................................................6-192

Table of Contents

Appendix A: Library .............................................................................. A-1

Appendix B: SIA and Contact ID Event Codes .................................... B-1

Appendix C: SIA Event Structure ........................................................ C-1

Appendix D: Event Log Messages ....................................................... D-1

Appendix E: Site Data Storage..............................................................E-1

Preparing for Storage Mode ..............................................................................E-1

Enabling Storage Mode .....................................................................................E-1

Using Storage Mode ...........................................................................................E-2

Leaving Storage Mode .......................................................................................E-2

Appendix F: Specifications ................................................................... F-1

Panel Specifications........................................................................................... F-1

Appendix G: Declaration of Conformity .............................................. G-1

Compliance and Approvals .............................................................................. G-1

EN50131 Compliance......................................................................................... G-2

PD6662 Compliance........................................................................................... G-2

Public Switched Telephone Network (PSTN) approval.................................. G-2

Appendix H: Parts List Index................................................................ H-1

Index ..................................................................................................Index-1

v

Page 8

Table of Contents

Galaxy Dimension Installer Manual

vi

Page 9

Galaxy Dimension Installer Manual

Introduction

INTRODUCTION

This manual gives full instructions required to install and program a Galaxy Dimension control panel and

associated peripherals.

Variants

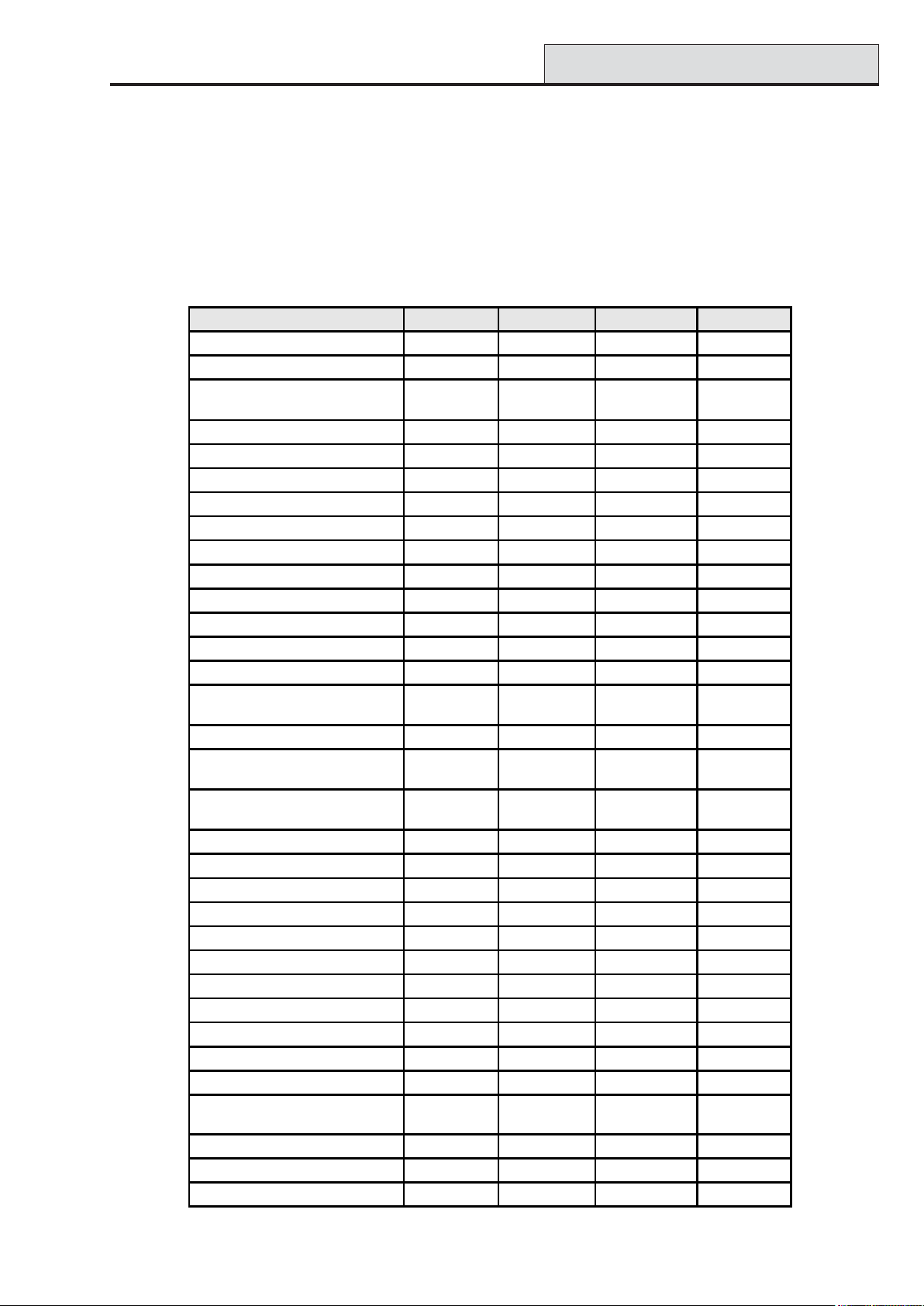

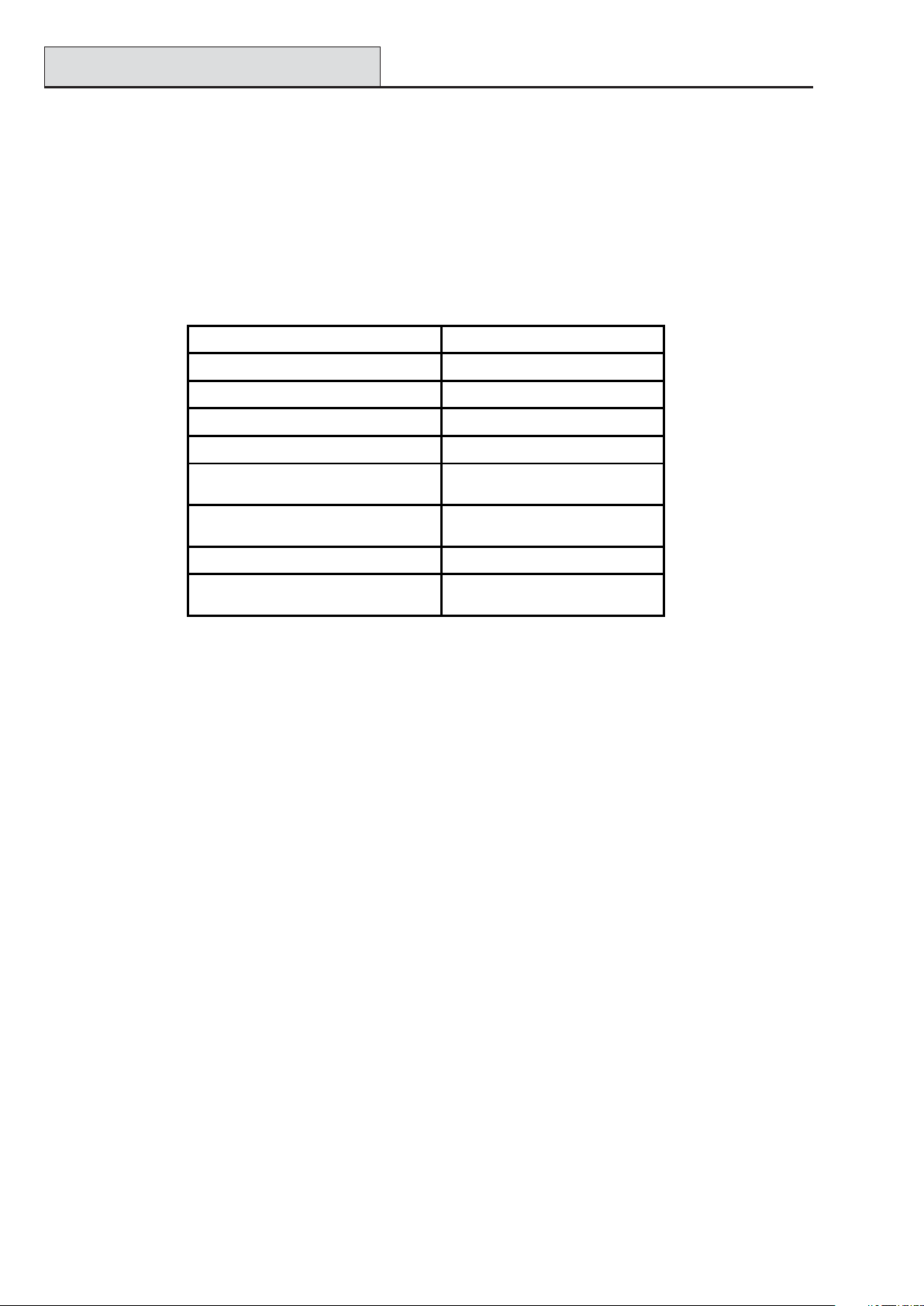

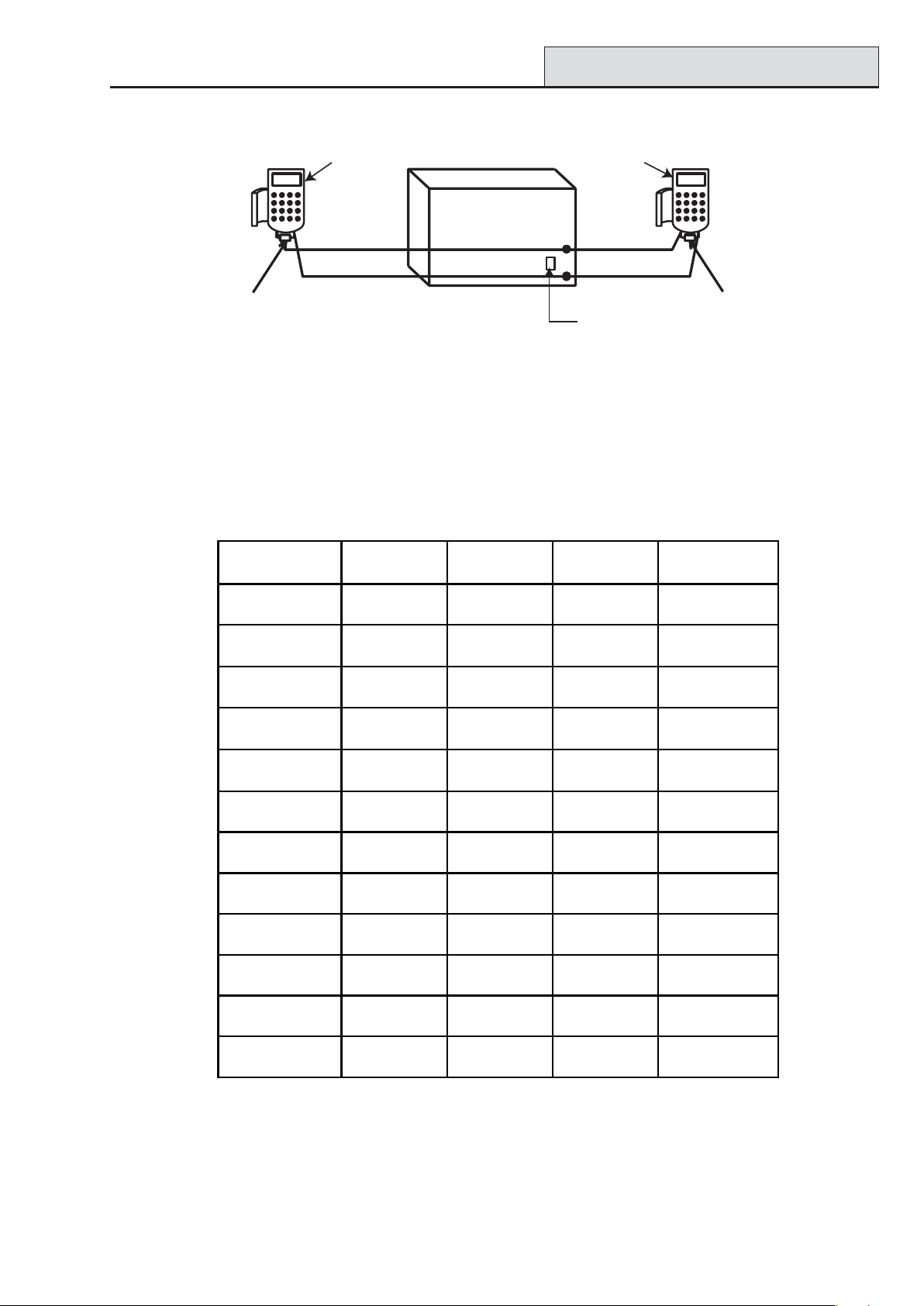

The Galaxy Dimension is available in four variants: GD- 48, GD-96, GD-264 and GD-520. The differences

between each variant are shown in the following table:

Features GD-48 GD-96 GD-264 GD-520

Zones 16-48 16-96 16-264 16-520

Outputs (400mA) 8-24 8-48 8-132 8-260

Trigger Outputs on Flying Lead

(100mA)

PSU 2.5A 2.5A 2.5A 2.5A

RS485 Databuses 12 2 4

Telecom onboard Yes Yes Yes Yes

RS232 Interface for online PC RS232 RS232 RS232 RS232

Printer Interface RS232 RS232 RS232 RS232

Ethernet option Yes Yes Yes Yes

GPRS option 3rd Party 3rd Party 3rd Party 3rd Party

Groups 8163232

Keypads 8161632

Keyprox 37 724

Multi-user Yes Yes Yes Yes

DCM's with 2 x wiegand

interfaces

DCM Controlled doors

Bus mounted prox readers

(MAX)

Access control groups (user

templates)

Weekly Timer Schedules 19 35 67 67

Annual Holiday Schedules 16 32 32 32

Users 100 250 999 999

Links 64 128 256 256

Remote software update Yes Yes Yes Yes

Upload/Download Yes Yes Yes Yes

Remote service Yes Yes Yes Yes

Network downloader Yes Yes Yes Yes

Alarm monitoring Yes Yes Yes Yes

Graphics mimic Yes Yes Yes Yes

TouchCe nte r 12 2 4

Mimic panel Yes Yes Yes Yes

66 6 6

4161632

8323264

4161632

50 50 100 100

Wireless Ademco 5800 Ademco 5800 Ademco 5800 Ademco 5800

Audio Verification Channels 8163232

SMS Yes Yes Yes Yes

Table 1-1. Galaxy Dimension General Specification

1-1

Page 10

Galaxy Dimension Installer Manual

1-2

Page 11

Galaxy Dimension Installer Manual

Quick Setup

SECTION 1: QUICK SETUP

To quickly set up a Galaxy Dimension control panel for programming follow these simple steps:

1. Connect a 1k Ω (1%) resistor across each of the zones on the panel and any RIO’s (if connected).

2. Ensure that the tamper return loop — the terminals marked as AUX TAMP/GND on the PCB — is a

complete loop.

3. Connect a keypad to the AB LINE terminals on the control panel.

Control Panel

(Line 1)

B1 B

A1 A

--

+12V +

Keypad

Table 1-2. Terminal Connections

4. Connect a 680 Ω End Of Line (EOL) resistor across the A and B terminals of the keypad.

5. Ensure that the keypad is fitted to the wall (see Keypad Installation Procedure, Section 4).

6. Connect the battery before replacing the control panel lid.

7. Connect the mains wiring to the control panel. Do not switch the mains ON.

8. Replace the control panel lid and secure the fastening screws.

9. Switch on the mains voltage (230 Va.c. / 50 Hz).

10. The following sequence of events occur:

• the keypad buzzer and control panel horn (if fitted) activate for 10 - 20 seconds,

• flashing is displayed on the keypad,

• the sounders stop and the keypad displays become blank,

• the green power LED lights and the following displays on the keypad

ConfiguringConfiguring

Configuring

ConfiguringConfiguring

Please WaitPlease Wait

Please Wait

Please WaitPlease Wait

• the default banner is then displayed on the keypad.

GALAXY <XXX> <VY.YY>GALAXY <XXX> <VY.YY>

GALAXY <XXX> <VY.YY>

GALAXY <XXX> <VY.YY>GALAXY <XXX> <VY.YY>

01:0101:01

01:01

01:0101:01

SUN 01 JAN SUN 01 JAN

SUN 01 JAN

SUN 01 JAN SUN 01 JAN

where: XXX is the panel type

Y.YY is the panel software revision

11. The system is now ready to be programmed. Refer to Section 6 System Operation for program-

ming details.

12. Default User code is 12345

Default Engineer code is 112233

1-3

Page 12

Galaxy Dimension Installer Manual

1-4

Page 13

Galaxy Dimension Installer Manual

Configuration

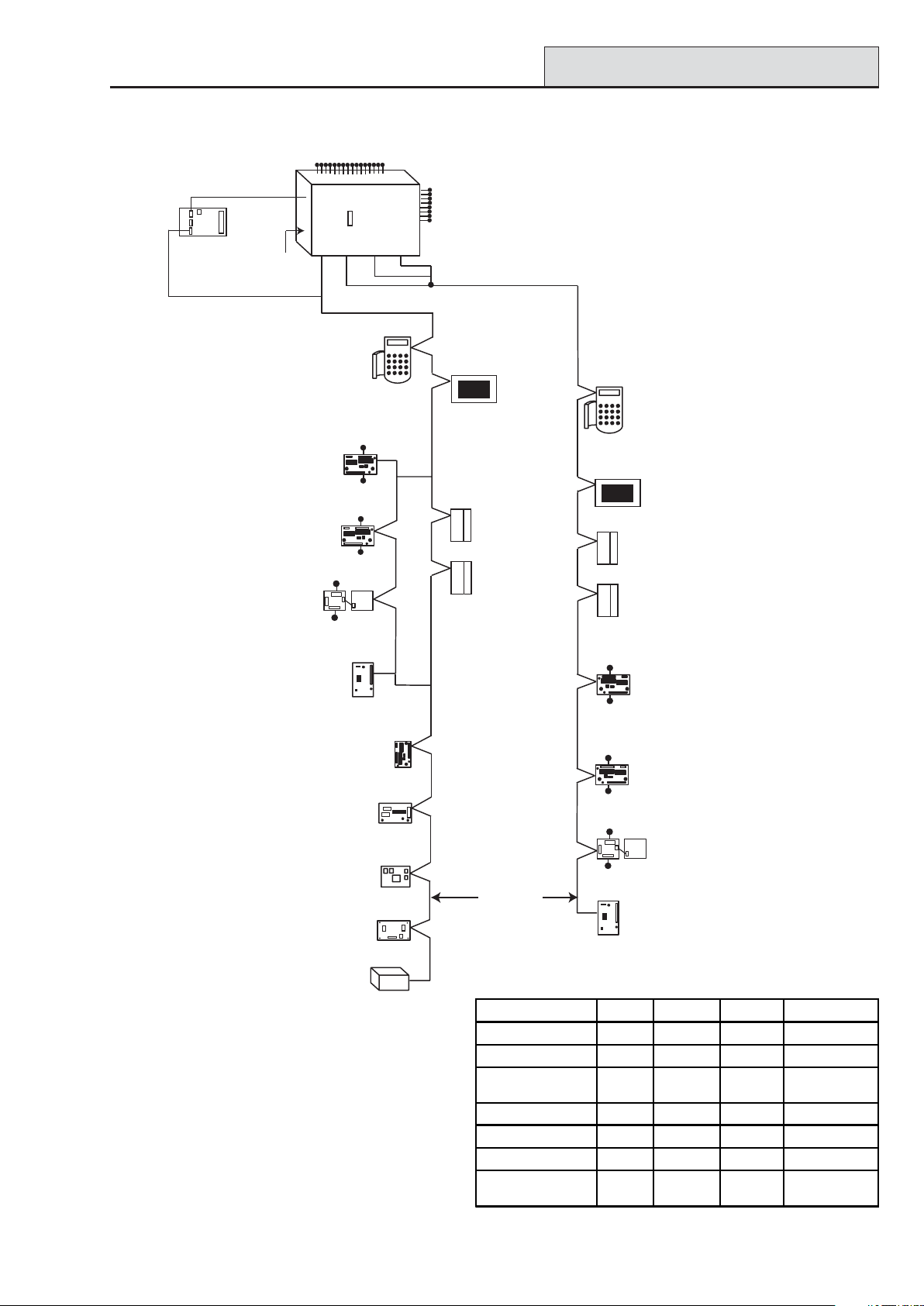

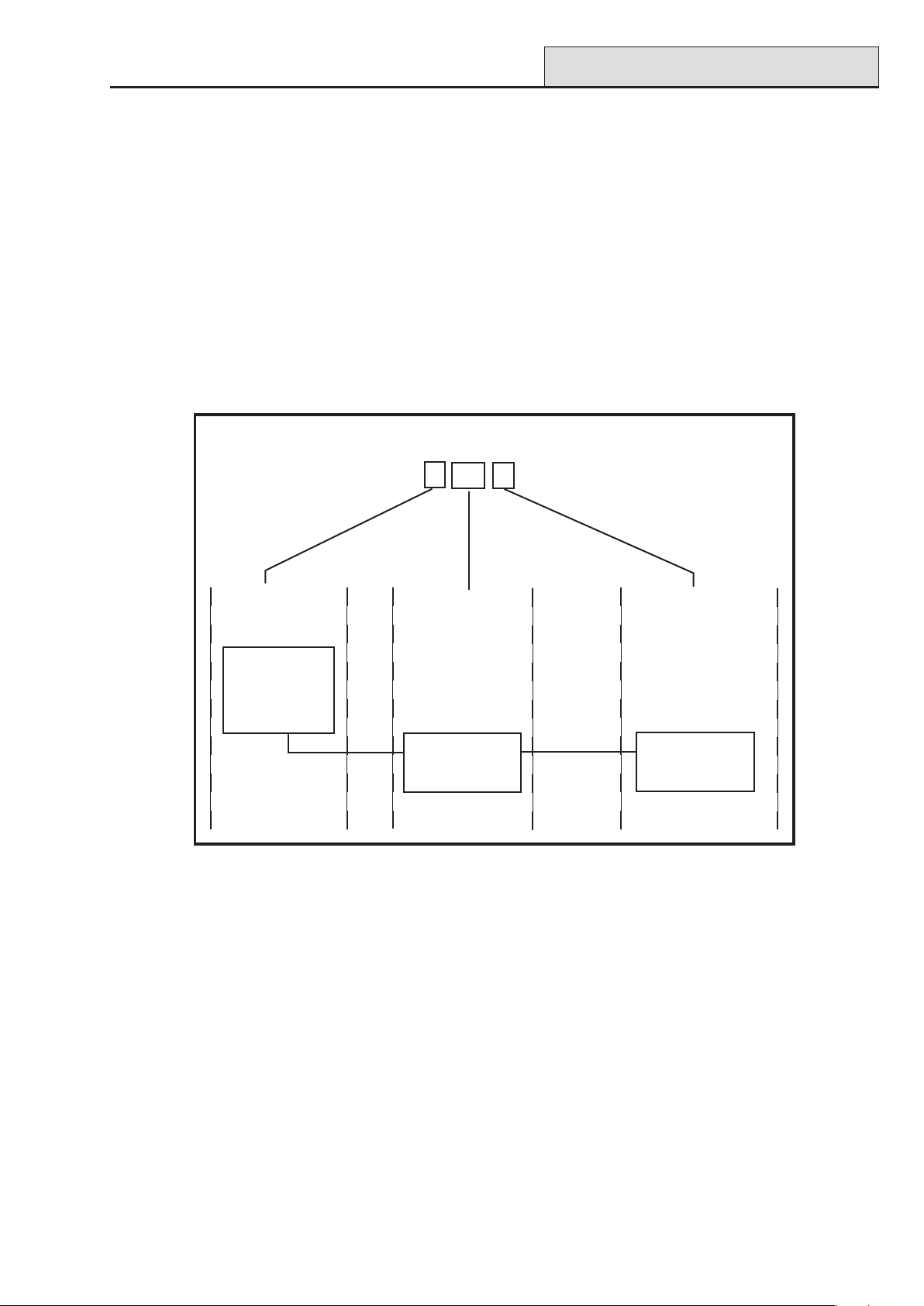

SECTION 2: SYSTEM ARCHTECTURE

16 zones on board

PSTN (comm 1)

Audio Interface

Module (1)

RS485 line

*

NOTE:

Valid addresses for the

keyprox are:

Line 1 (0, 1 & 2).

Line 2 (0, 1, 2, & 3 ).

This sets the address for both

the keypad and card reader

parts of the keyprox.

*

Certain keypad and

max addresses can

be replaced by a

combined keyprox unit.

NOTE:

RIOs, RF RIO's and

PSU's can be mixed on

the lines.

NOTE:

The Telecom, Printer Interface,

RS232, Ethernet and ISDN

modules can only be

connected to line 1.

If a Telecom module is attached,

keypad address E cannot be

connected to line 1(address E is

shown as 18 on the system).

If an RS232 module is attached,

keypad address D cannot be

connected to line 1 (address D is

shown as 17 on the system).

If an Ethernet module is attached,

keypad address B cannot be

connected to line 1 (address B is

shown as 15 on the system).

If an ISDN module is attached,

keypad address C cannot be

connected to line 1 (address C is

shown as 16 on the system).

RS232

Serial Port

(comm 6)

Power Unit P025

or

Power RIO P026

on board

telecom

area

Line

Smart PSU

P015

RF RIO Module

C076

Ethernet Module

E080 (comm 4)

Printer Interface

A134/A161

12

RIO

C072

OR

OR

4 outputs

8 zones

OR

RS232 Module

E054 (comm 2)

ISDN Module

E077 (comm 3)

Galaxy

Trigger

Header

Line

Line Line

4

3

Cable run 1 km (max)

*

K

eypads

CP027/

Keyprox

CP028

4 outputs

8 zones

4 outputs

8 zones

Telecom Module

E062 (comm 5)

8 outputs

on board

plus 6 outputs

on trigger header

Lines 2, 3 and 4 have

the same configuration

*

Max

MX03

OR

DCM

C080/81

Twisted Pair

Screened Cable

Touch

Center

CP040

OR

4 outputs

8 zones

4 outputs

8 zones

4 outputs

8 zones

*

Keypads

CP027/

Keyprox

CP028

Touch

Center

CP040

*

Max

MX03

DCM

C080/81

RIO

C072

OR

Smart PSU

P015

OR

Power Unit P025

or

Power RIO P026

OR

RF RIO Module

C076

GD-48 GD-96 GD-264 GD-520

Lines 12 2 4

Keypads 8 8 per line 8 per line 8 per line

Keyproxes 3 3 (line 1)

4 (line 2)

Touch Center 1 1 per line 1 per line 1 per line

MAX's 4 8 per line 8 per line 8 per line

DCM's 4 8 per line 8 per line 8 per line

RIO's/PSU's 4 4 (line 1)

6 (line 2)

Figure 2-1. Galaxy Dimension System Configuration

2-1

3 (line 1)

4 (line 2)

15 (line 1)

16 (line 2)

3 (line 1)

7 (lines 2, 3, 4)

15 (line 1)

16 (lines 2, 3, 4)

Page 14

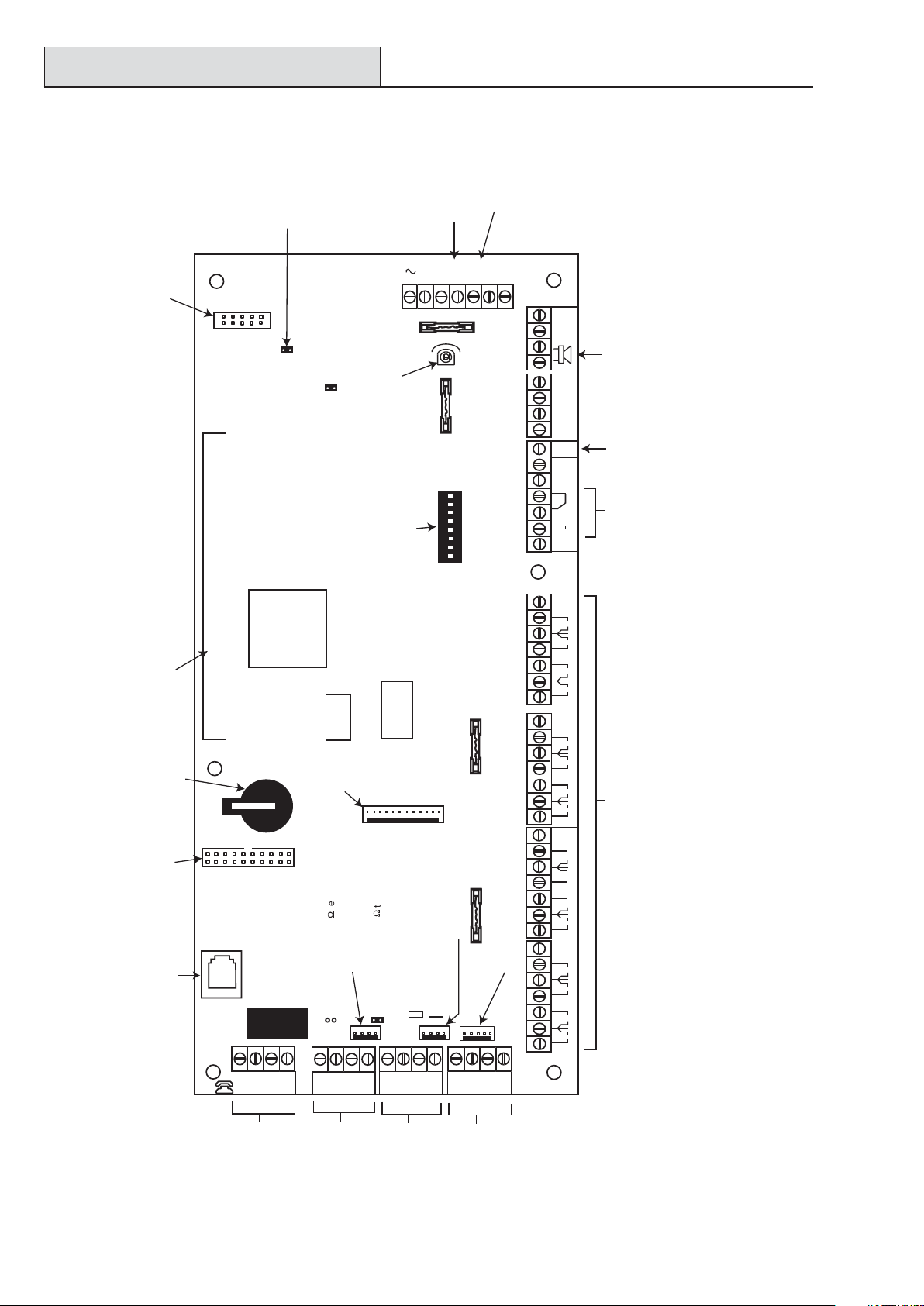

PCB Layout

PCB Layout

SPI

Program

Header

Jumper Lead

for off-wall

tamper switch

LK2

TAMPER

OFF WALL

BATTERY

START UP

LK4

BATT

Horn output

volume control

Pull-up switches

Leads for

lid tamper

AC

F1

AUX3

RIO

ON

microswitch

TAMP

LID

F2

SWITCH

7 8

6

4 5

2 3

1

SW3

Galaxy Dimension Installer Manual

Battery

terminals

14.5

-BAT

+BAT

G

N

D

AUX

TAMP

External

loudspeaker

AUX3

Relay

Output

N/C

C

N/O

4

2

RIO 1

13

+12V

4

3

RIO 0

2

1

Expansion card

interface

Memory

backup

battery

Debug

Header

Telecom

Socket

SKT2

MICRO

PROCESSOR

RAM1

Trigger

Header

termination

9

LK3 RS485 line 2, 680

FLASH

termination

9

Engineer socket

(RS485 Line1)

LK5 RS485 line 1, 680

LED1(for Telecoms)

AUX2

Engineer socket

(RS485 Line 2)

LED2 (for RS232)

AUX1

+12V

8

0V

7

6

0V

5

RIO 1

+12V

+12V

8

7

6

+12V

4

3

2

1

5

4

3

2

1

0V

0V

16 on-board zones

0V

0V

RIO 0

0V

0V

F3

F4

RS232 Port socket

OR

Zones 1-8 (RIO 1 line 1 (switch SW3-8 OFF))

Zones 1-8 (RIO 1 line 0 (switch SW3-8 ON))

NOTE: Zones 1-8 (RIO 0 line 1)

Fuse AUX2 controls

RS485 line 2, RIO 1 (zones 1-8)

Fuse AUX3 controls an independent

12V output which can be used for a

communicator or screw.

LINE

PHONE

ABAB

Telecom

Connect

A1

B1

B2

GND

+12V

RS485 line 1

A2

+12V

GND

RS485 line 2

TX

Figure 2-2. PCB Layout

2-2

NOTE: Fuse AUX1 controls

CTS

RX

RTS

RS485 line 1, RIO 0 (zones 1-8)

RS232 Port

Page 15

Galaxy Dimension Installer Manual

RS485 Expansion Module

The 7 transistorised outputs on the Galaxy Dimension can be configured to open collectors by setting the dip

switch SW3 to the OFF position.

NOTE: Output 2 on RIO 0 (relay output) is not affected.This is a form C relay that can switch up to 1 amp

at 24 volts DC.

The following table shows which outputs are controlled by which switches.

(SW3) RIO Output

10 1

20 3

30 4

41 1

512

613

714

Table 2-1. SW3 Transistorised Outputs Control

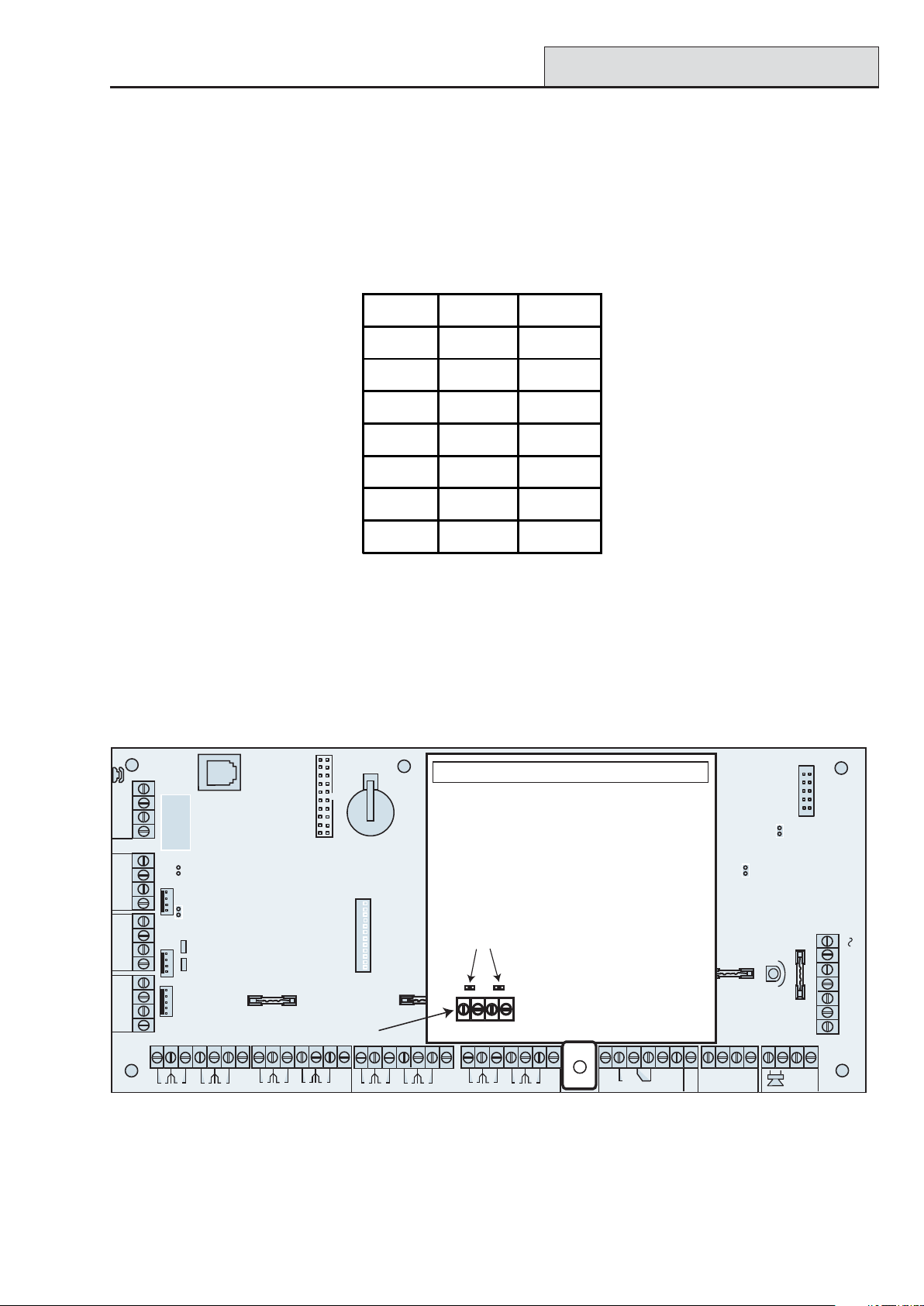

RS485 Expansion Module (GD-520 only)

The RS485 Expansion Module is attached to the GD-520 to give 2 extra RS485 (AB) lines.

This module can also be added to a GD-264 to convert it into a GD-520. Jumpers LK1 and LK2 can be

removed to disable the on-board end-of-line resistors.

SKT2

LINE

A

PHONE

B

AB

B1

A1

GND

+12V

B2

A2

GND

+12V

TX

RX

CTS

RTS

Twin

RS485

lines

LK1

A3

Jumpers

B3

A4

RS485

EXPANSION

MODULE

LK2

B4

ON

4 5

2 3

6

1

7 8

C

N/C

N/O

F1

-BAT

+BAT

14.5

AC

LID

TAMP

AUX

2

1

0V

+12V

4

3

0V

RIO 0

6

5

0V

+12V

8

7

0V

2

1

0V

+12V

4

3

RIO 1

0V

6

5

0V

+12V

8

7

0V

1

4

3

2

RIO 0

+12V

4

2

13

RIO 1

TAMP

G

N

D

Figure 2-3. RS485 Expansion Module

2-3

Page 16

Installation Recommendations

Galaxy Dimension Installer Manual

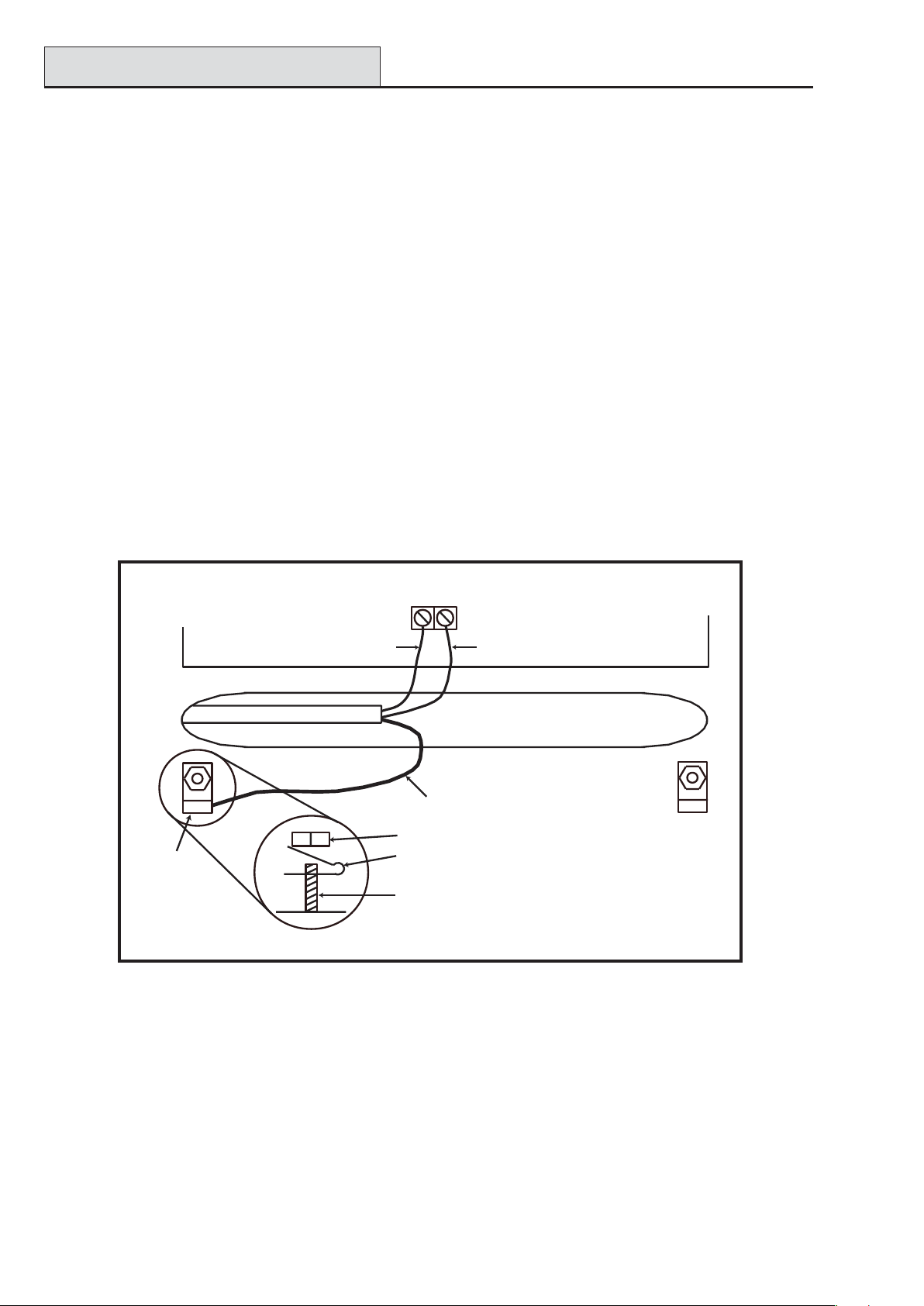

System Installation and Wiring

The installation and wiring must be performed by a competent engineer. For permanently connected equipment, a readily accessible disconnect device must be incorporated in the fixed wiring. The Galaxy Dimension

control panel must be connected to the a.c. mains supply (230/240 Va.c. 50 Hz) via a fused connection outlet

in accordance with EN60950-1: 2001

The fuse in the mains outlet must not exceed 3A.

WARNING: A means of isolation from the mains supply must be provided within 2 metres of

the control panel. Where live and neutral supplies can be identified, a fused spur

with a 3 amp fuse, must be fitted on the live circuit. Where live and neutral circuits

cannot be reliably identified, 3 amp fuses must be fitted to both circuits.

Route the mains cable through the hole on the right hand side of the enclosure base. Securely anchor the

cable to the box using the tie-wrap as shown in the following Figure:

Enclosure

base

AC connect

Attaching hole

PCB

Attaching hole

Keyhole

slot (top)

Figure 2-4. Securing the Mains Cable to the Enclosure Base

Mains

transformer

Earth wire

Terminal

block

Mains cable

Tie wrap

Secure the panel base to the wall using three 1.5" No. 8 round head steel screws through the holes provided.

The mains cable used must be a three core type (with green/yellow earth insulation) of adequate current

carrying capacity.

Connect the mains cable to the mains terminal block as follows:

• blue wire to the terminal marked N (Neutral)

• green/yellow wire to the terminal marked (Earth)

• brown wire to the terminal marked L (Live)

NOTE: No other connections to the mains connector are permitted.

All wiring must be in accordance with local regulations and the installation must conform to EN60950.

2-4

Page 17

Galaxy Dimension Installer Manual

System Wiring

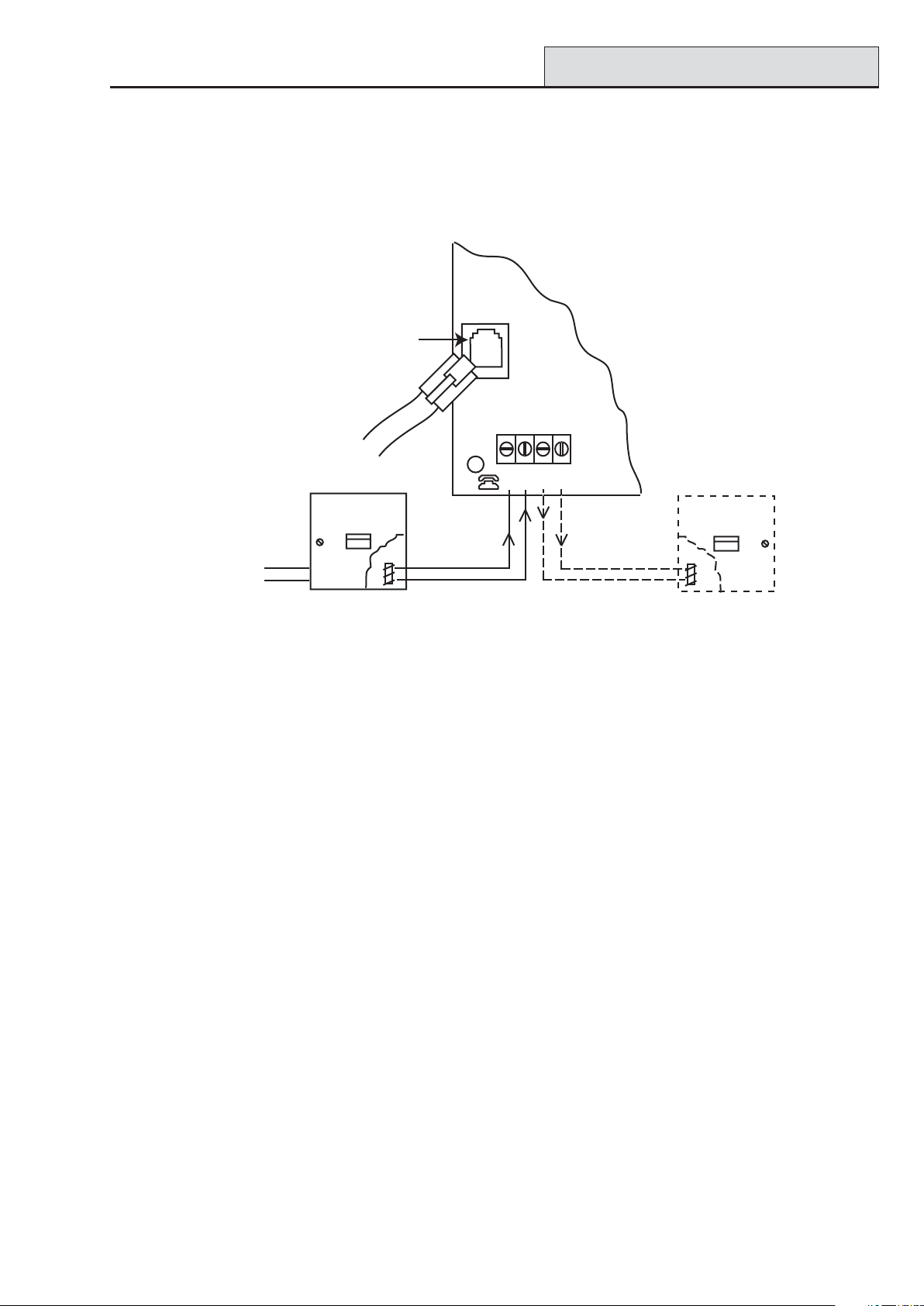

Connecting the Galaxy Dimension to the PSTN

The Telecommunications Network Voltage (TNV) port (terminals A and B on PCB) must be permanently

connected (hard-wired) to the PSTN via a master socket, refer to Figure 2-5.

Telecom

Socket

RJ11

Plug

PHONE

Master socket

LINE

ABAB

Secondary socket

Incoming

PSTN

Line

line 2

line 1

line 1

line 2

Figure 2-5. Connecting the Galaxy Dimension to the PSTN

NOTES: 1. Terminals 1 and 2 on the Master Socket must be hard-wired to LINE A and B

terminals on the Galaxy Dimension PCB. The connection is polarity independent.

2. It is strongly recommended that the Galaxy Dimension panel is the only device on the line.

3. If another device is to be connected to the line, connect the PHONE terminals on the PCB

to terminals 1 and 2 on a Secondary socket.

There are two methods of connecting the on-board Telecom Module to the PSTN:

Method 1

Using cable suitable for connection to 2.8 mm diameter screw terminals, strip back approximately 20 mm of

the outer sheath and then remove approximately 4 mm of the insulation from the wires to be connected to the

Galaxy Dimension PCB.

Connect terminals 1 and 2 on the Master socket across the LINE A and B terminals on the Galaxy Dimension

PCB, see Figure 2-5.

Method 2

Use a standard cable with RJ11 plug on one end and plug into the telecom socket on the Galaxy Dimension

PCB. Connect the other end of the cable to the Master socket as described in Method 1.

NOTE: Digital Subscriber Line (DSL) should not be used. If it is used, connect a suitable filter to the phone

line.

2-5

Page 18

System Wiring (cont’d)

Galaxy Dimension Installer Manual

Connecting Additional Telecom Apparatus

A secondary socket, allows additional telecom apparatus to be connected in series with the on-board telecom

module. Connect the PHONE terminals A and B on the PCB to the terminals on the secondary socket. See

Figure 2-5.

Line Monitoring

Under normal idle state conditions, the on-board Telecom Module monitors the PSTN line. The communication status is indicated by the state of the red LED (LED1) as shown in the following table:

LED STATE INDICATION

LED OFF No d.c. supply

ON - 01s, OFF - 0.9s Normal Communication

Single pulse at end of call Normal Communication

Flashing at end of alarm call Failed Communication

On during alarm monitoring,

Remote Servicing and SMS

Flickeri ng during alarm moni toring,

Remote servicing and SMS

Flashes in time with ringing signal Line Ringing

Pulses as each digit is dialled

Normal Communication

Poor Communication

Normal indication when

making call

Table 2-2. Comms Status

2-6

Page 19

Galaxy Dimension Installer Manual

Stand-by Battery

Stand-by Battery

The Galaxy Dimension control panels can accommodate up to 2 x 17 Ah batteries. Ensure that the battery

connector leads on the control panel Powers Supply Unit (PSU) are connected to the correct terminals on the

battery.

CAUTION: There is a risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

lenaPlortnoCyrettaB

TAB-lanimretev-

TAB+lanimretev+

Table 2-3. Battery/Control Panel connections

Battery Start-up

The system can be powered up via the Battery Start-up jumper if there is no AC power. To do this, short

out the Battery Start-up jumper for the duration of the configuration process only. Never leave the Battery

Start-up connected or else deep discharge of the Stand-by Battery will occur.

On-Board Power Supply Unit

The on-board Power Supply Unit (PSU) supplies and monitors power to the system and peripherals. The

following table shows the fuse name and value in amps.

The Galaxy Dimension control panel contains four fuses. Details are given in the following table.

FUSE NAME VALUE (AMPS) PROTECTS TYPE

AUX1 1.0 RS485 Line 1, RIO 0, Zones 1-8: +12V,

on-board comms

AUX2 1.0 RS485 Line 2, RIO 1, zones 1-8 +12V 20 mm, anti-surge

AUX3 1.0 +12V AUX3 terminal 20 mm, anti-surge

BATT 1.6 Battery 20 mm, anti-surge

Table 2-4. On-board PSU Fuses

Power Monitoring Characteristics: Low battery level: 11.2V

Deep discharge protection: 10.5V

Overvoltage protection: 14.7V

The PSU total capacity is 2.5A. Internally the PSU is split in two in order to ensure sufficient current is always

available for stand-by battery recharge. The PSU capacity is broken down as follows:

20 mm, anti-surge

• Battery: 1.25A

• Control PCB: 0.25A

• AUX +12V: 1.00A

The PSU is available for zones/outputs and peripherals.

2-7

Page 20

Memory

Galaxy Dimension Installer Manual

Memory

The Galaxy Dimension control panel is fitted with a memory chip with its own battery backup on the main

PCB. This allows the panel to retain the system configuration, programming details and the event log for up to

a year when both the mains power and standby battery have been disconnected. The memory backup battery

must be kept in place to retain the memory during a mains failure. Re-apply power, this is known as a warm

start.

To completely erase the system memory and return to the default settings, place a piece of thin card between

the retaining clip and the memory backup battery then remove all power to the PCB for one minute. Re-apply

power and remove the card. This is known as a cold start.

The memory backup battery shoud be replaced every 5 years.

CAUTION: There is a risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

CAUTION: Do not overstress the retaining clip when removing and installing the backup

battery. The clip must maintain a firm pressure on the backup battery at all times.

RS485 Data Communication Bus (AB Lines)

Communication between the Galaxy control panels and the modules attached to the system takes place on the

AB lines. The communication protocol is RS 485 format. The control panel constantly monitors the modules

attached to it. A break in the communication from any of the modules generates a module tamper alarm

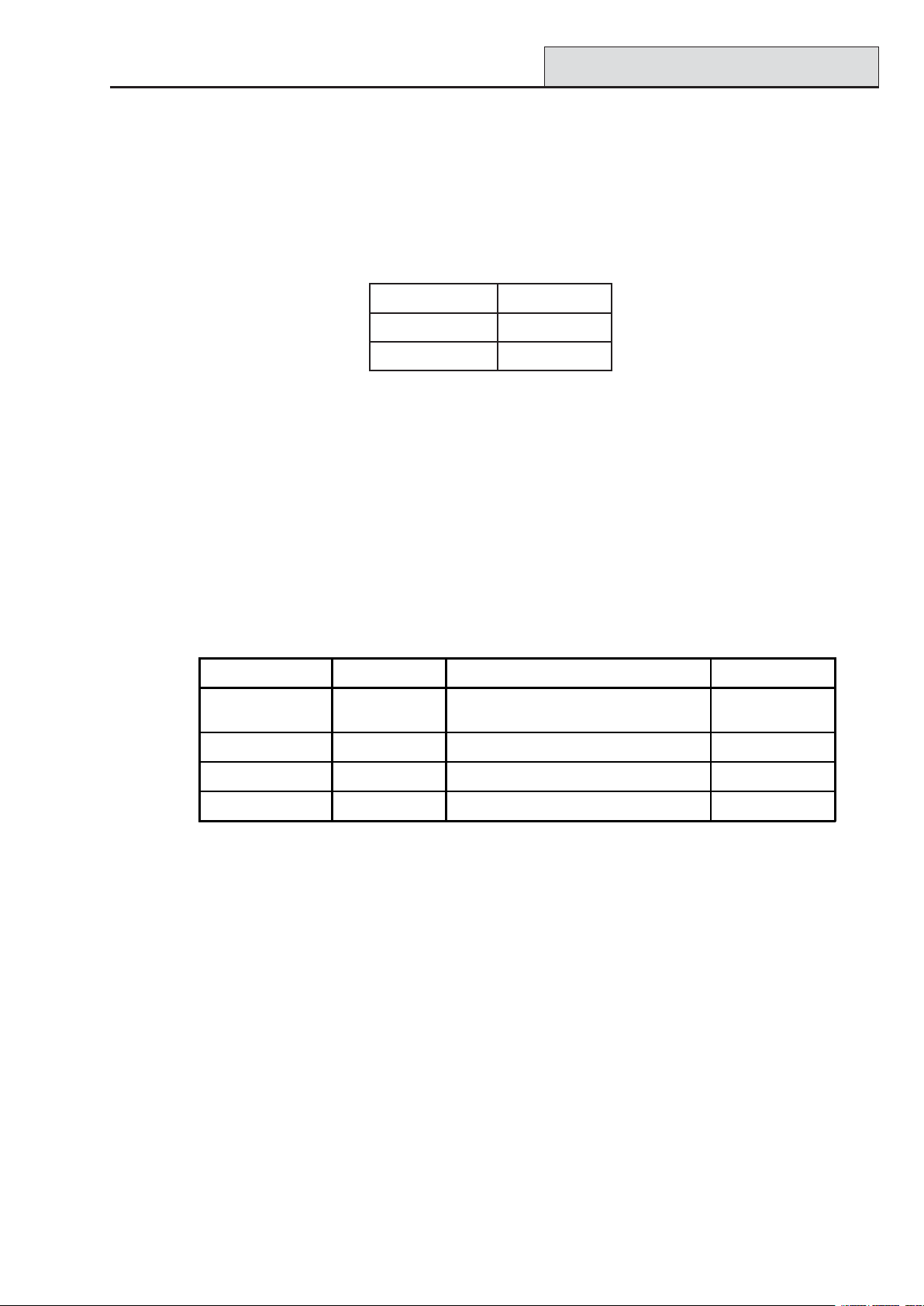

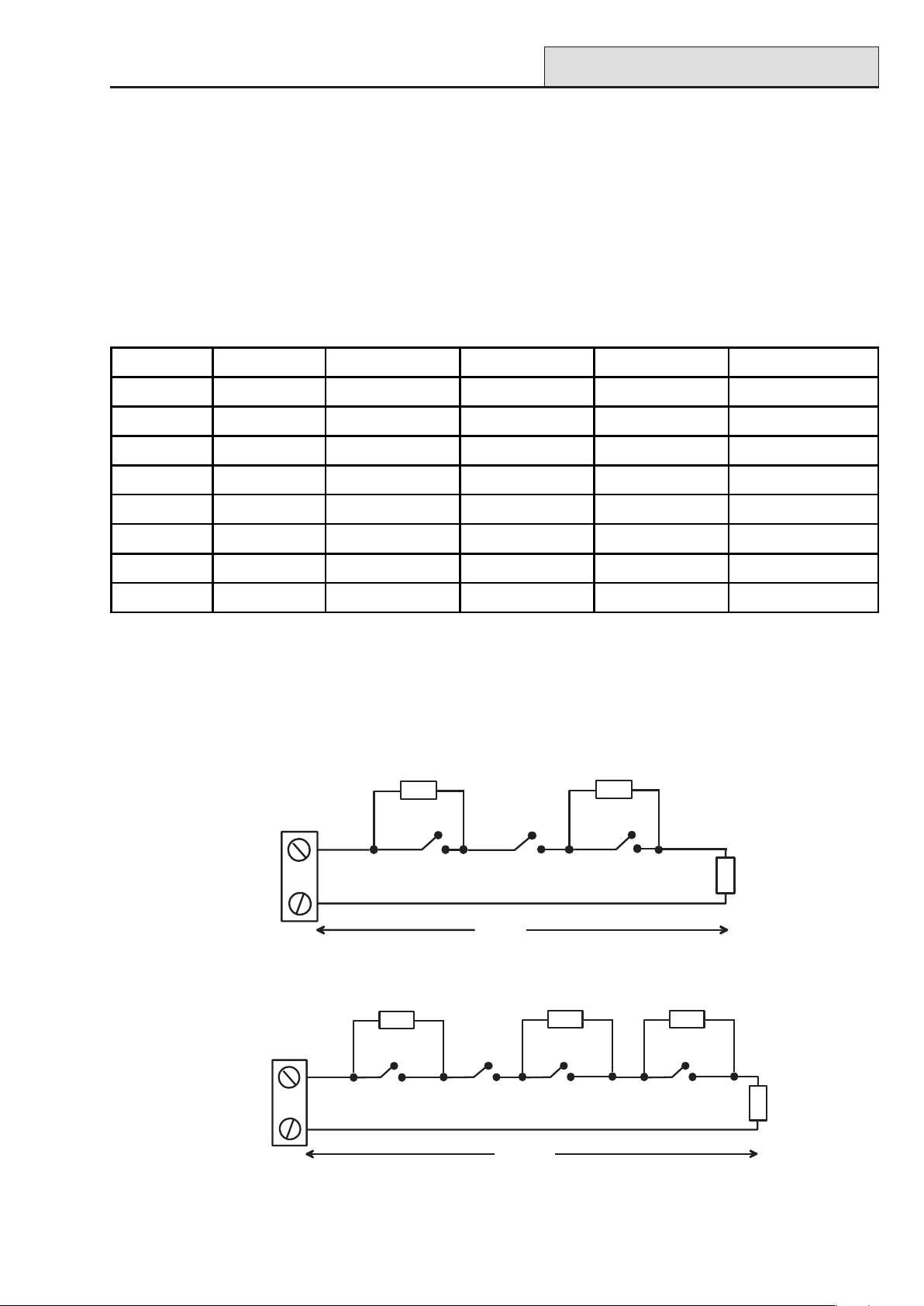

RS485 Wiring Configurations

The system must be wired in a daisy-chain configuration. That is the A line from the previous module is

connected to the A terminal of the current module and then on to the A line of the next module.

The RS485 (AB) line must have a 680 Ω resistor fitted across the A and B terminals of the last module on the

line. If two lines are connected, both ends must be terminated with 680 Ω resistors and the appropriate link

(LK3 or LK5) removed.

Keypad/Keyprox

OR

Galaxy

Control

Panel

680 Ω

A

A

B

Fit LK3/LK5 on PCB

Module

B

AB

680 Ω EOL

Figure 2-6. Daisy Chain Configuration

Each AB line can run in two directions from the control panel.

• Remove link LK3 (RS485 line1) or link LK5 (RS485 line2).

• Run two lines from the A and B terminals of the line.

• Terminate both Ends of Line (EOL) with a 680 ohm resistor.

NOTE: It is permissable to have different configurations on each line. For example, line 1 - Daisy chain;

line 2 - twin AB daisy chain.

2-8

Page 21

Galaxy Dimension Installer Manual

RS485 Recommendations

Keypad/Keyprox

OR

Module

Keypad/Keyprox

OR

Module

Galaxy

Control

A

680 Ω EOL

B

Panel

A

B

Remove

LK3/LK5

B

A

680 Ω EOL

Figure 2-7. Twin AB Line Daisy-Chain configuration

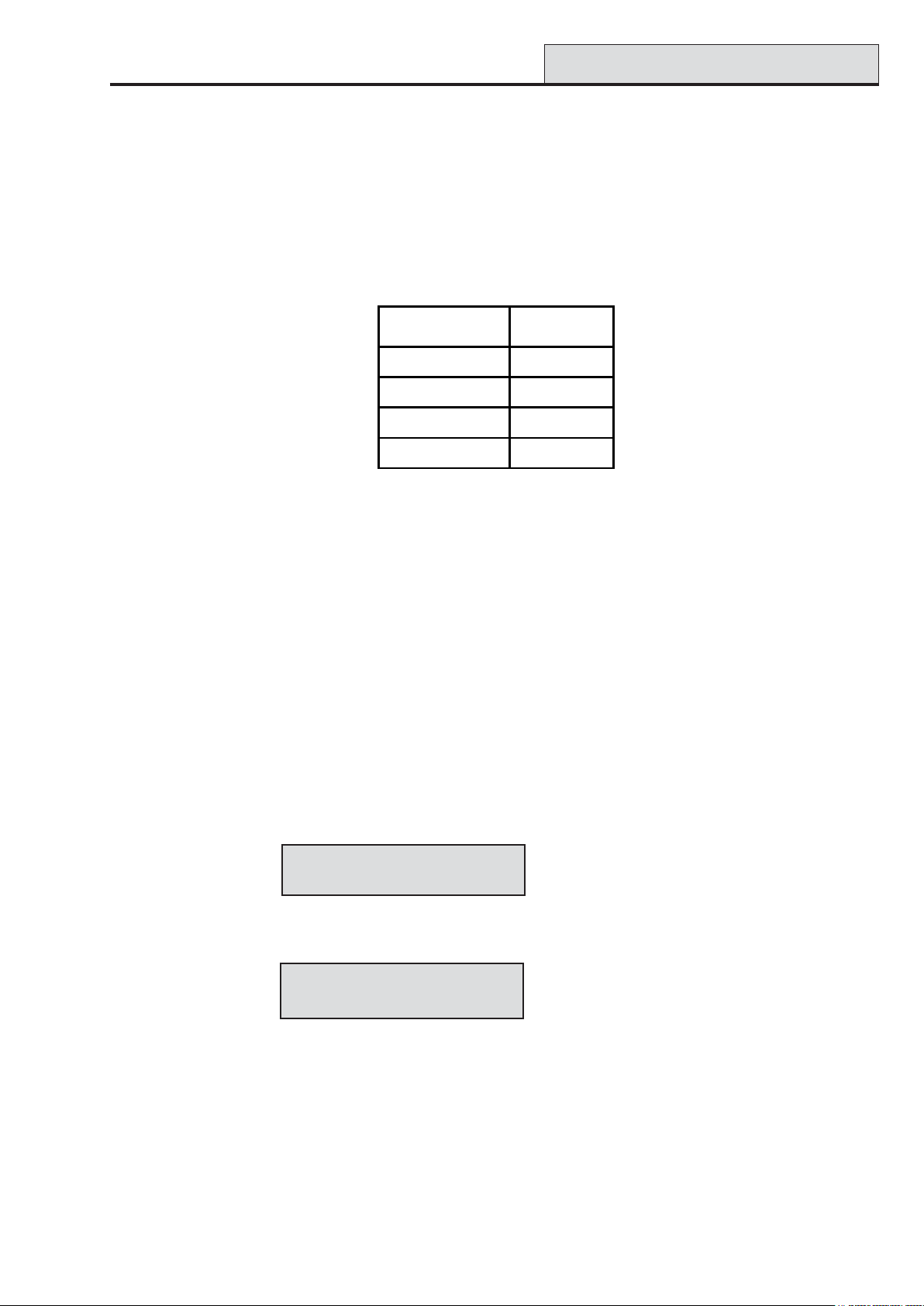

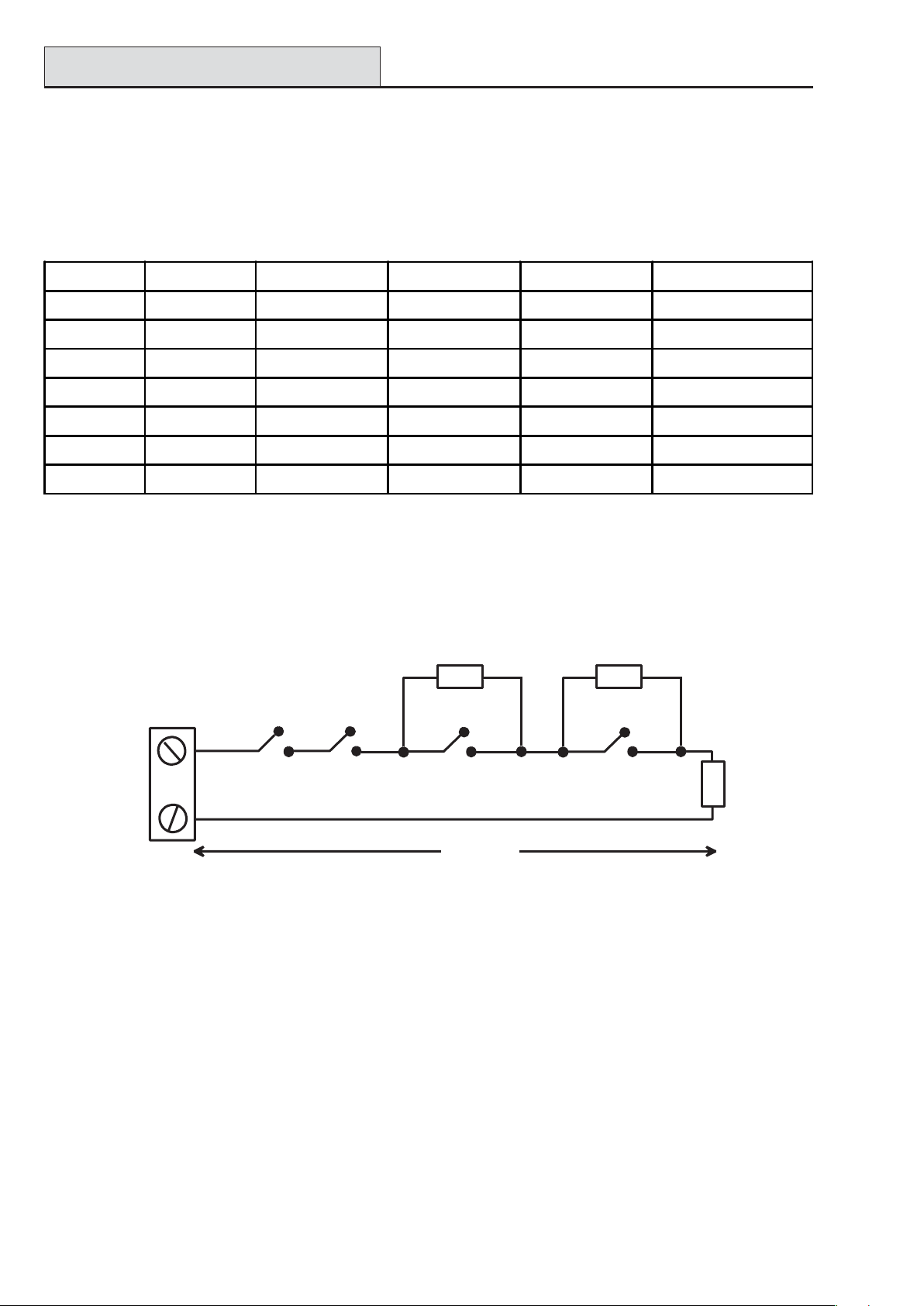

RS485 Wiring Recommendations

To ensure that the system communicates at the maximum level of efficiency, the following recommendations

must be adhered to:

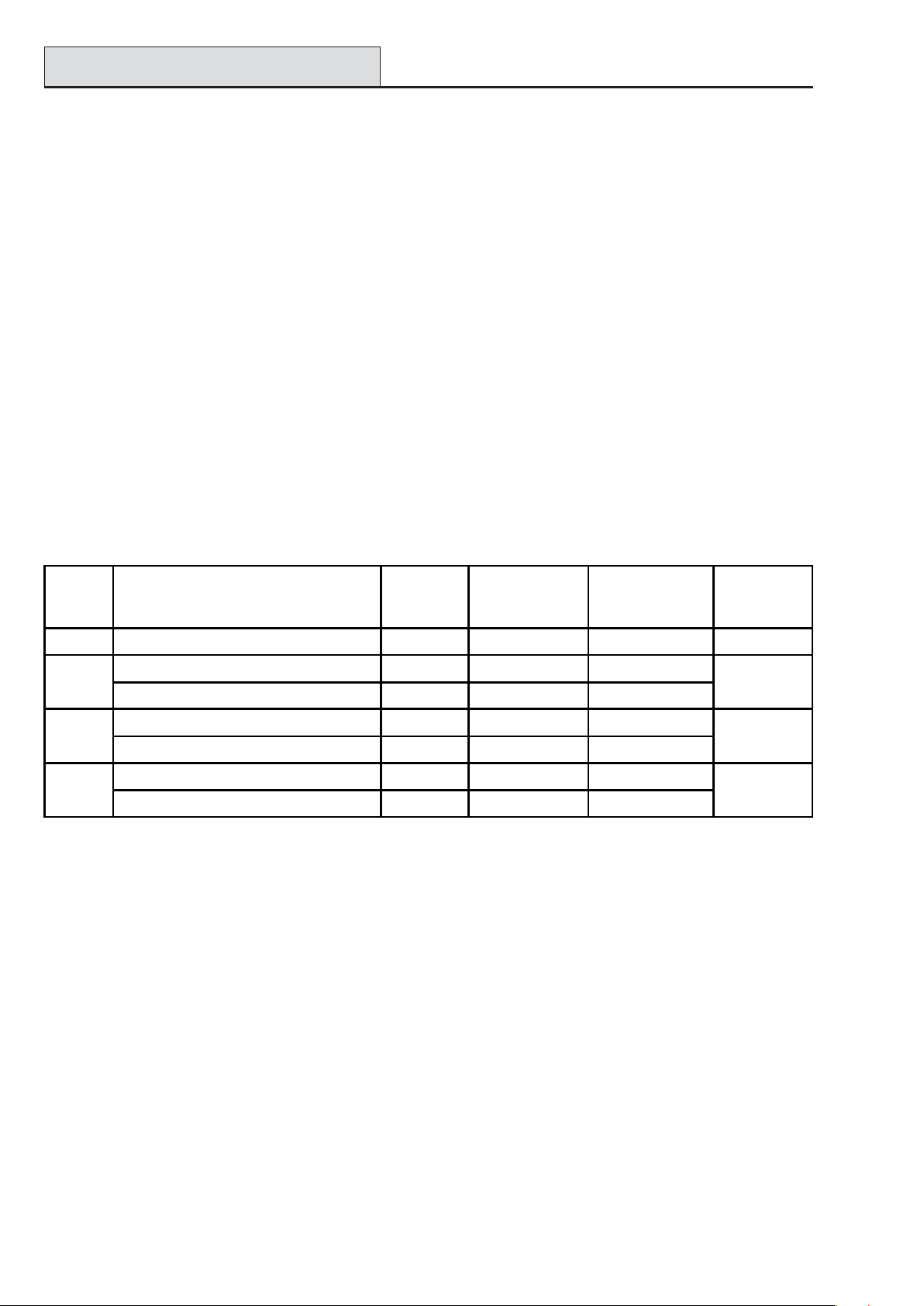

1. The maximum number of devices on each line are:

GD-48

(Line 1 only)

GD-96

(Lines 1-2)

GD-264

(Lines 1-2)

GD-520

(Lines 1-4)

Keypads

Keyprox

Touch Center

RIO's/SPSU's

RF RIO

MAX/DCM

RS232

Telecoms

Printer

ISDN

Ethernet

8 8 per line 8 per line 8 per line

3

1 1 per line 1 per line 1 per line

4

4

4 8 per line 8 per line 8 per line

1 1 (line 1 only) 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only) 1 (line 1 only)

3 (line 1)

4 (line 2)

4 (line 1)

6 (line 2)

4 (line 1)

6 (line 2)

3 (line 1)

4 (line 2)

15 (line 1)

16 (line 2)

15 (line 1)

16 (line 2)

3 (line 1)

7(lines 2, 3, 4)

15 (line1)

16 (lines 2, 3, 4)

15 (line 1)

16 (lines 2, 3, 4)

Audio Interface

1 1 (line 1 only) 1 (line 1 only) 1 (line 1 only)

Table 2-5. Communication Devices

2. The system must be wired in a daisy-chain configuration. Spur and star configurations must not

be used as they reduce the immunity to electrical interference.

3. The cable used must screened twisted pair (Part No W002) to connect the RS485 (AB) line. This

would be CAT5 or Belden 8723 equivalent.

2-9

Page 22

RS485 Recommendations

Galaxy Dimension Installer Manual

4. Shielded twisted pair cable, where used, is connected to the earthing pillar on the Galaxy control

panel using the P-clip and nut supplied (refer to Figure 2-8).

5. The RS485 (AB) line must have a 680 Ω resistor fitted across the A and B terminals of the last

module on the line. If twin lines are connected, both ends must be terminated with 680 Ω resistors and

the appropriate link on the control panel PCB must be removed (refer to figure 2-7).

6. There must only be a single AB pair of wires in each of the cables.

7. The minimum supply voltage level is 10.5 Vd.c. with 12.5 Vd.c. being the recommended working

minimum.

8. The power supply in the Galaxy control panel and remote power supplies must not be connected

in parallel.

9. The 0 V of all remote power supplies should be connected in common to the 0 V of the Galaxy

control panel.

10. Ensure that any extension loudspeakers are not wired in the same cable as an AB pair of wires.

11. Where possible, ensure that the AB cable is at least 30 centimetres away from any other cables.

12. Where possible, ensure that the AB cable does not run parallel to other cables for extended

distances (maximum 5 metres).

P-clip

AB connectors

A

data line

RS 485 cable

Nut

P-clip

Earthing pillar

(threaded)

B

data line

Cable screen

Figure 2-8. Connection of cable screen using P-Clip

2-10

Page 23

Galaxy Dimension Installer Manual

Zone Addresses

Zones

The default setting for the zones on the Galaxy Dimension are as follows:

Zone 1001 = Final

Zone 1002 = Exit

All remaining zones = Intruder

Zone Addresses

Each zone has a four digit address; 1004, 4136. The address is made up of three reference numbers as shown

in the following figure:

Example: 3057

3

05 7

Represents Panel

Line No.

GALAXY

PANEL

1 2 3 4

Represents

RIO Address

RIO

ADDRESS 05

Figure 2-9. Zone Addresses

For example, zone 3057 is the detector connected to line 3, RIO 05, zone 7.

Represents

Zone No. 1-8 on

RIO

ZONE 7

2-11

Page 24

RIO Switch

Galaxy Dimension Installer Manual

Zone Addressing with Onboard RIO Switch (Line 0 Switch)

The RIO switch (SW3, dipswitch 8) controls the ordering of the on-board RIO’s. This dipswitch must be set

before powering up the panel. Setting the switch to ON sets the on-board RIO1 to operate on line 0 and

allows a RIO addressed as 1 to be connected to line 1, giving a total of 15 RIO’s on a GD-264 and

GD-520. The RIO switch only needs to be activated when the full compliment of RIO’s is required, or when

replacing a Galaxy 512 panel with a power supply/RIO already using address 1.

NOTE: The RIO switch is not functional on other variants. It defaults to the Switch off configuration.

Switch off (default)

When the switch is set to this mode, the onboard RIO’s configure to the following addresses:

Onboard RIO0 Zone address range: 1001-1008 Outputs: 1001-1004

Onboard RIO1 Zone address range: 1011-1018 Outputs: 1011-1014

Switch on

When the switch is set to this mode, the onboard RIO’s configure to the following addresses:

Onboard RIO0 Zone address range: 1001-1008 Outputs: 1011-1014

Onboard RIO1 Zone address range: 0011-0018 Outputs: 0011-0014

Panel On-Board RIO Address Range Total

on-board

Zon e s

GD-48 1001 - 1008, 1011 - 1018 16 4 2 - 5 48

1001 - 1008, 1011 - 1018 (switch off) 16 4 2 - 5

GD-96

1001 - 1008, 0011 - 0018 (switch on) 16 5 1 - 5

GD-264 1001 - 1008, 1011 - 1018 (switch off) 16 14 2 - 9, A - F

1001 - 1008, 0011 - 0018 (switch on) 16 15 1 - 9, A - F

1001 - 1008, 1011 - 1018 (switch off) 16 14 2 - 9, A - F

GD-520

1001 - 1008, 0011 - 0018 (switch on) 16 15 1 - 9, A - F

Max No of

External RIO's

(Line 1)

Valid E xternal

RIO Addresses

(Line 1)

Total Zone

Addresses

(Switch ON)

96

264

520

Table 2-6. Zone Address Ranges

2-12

Page 25

Galaxy Dimension Installer Manual

Wiring Zones

Wiring Zones

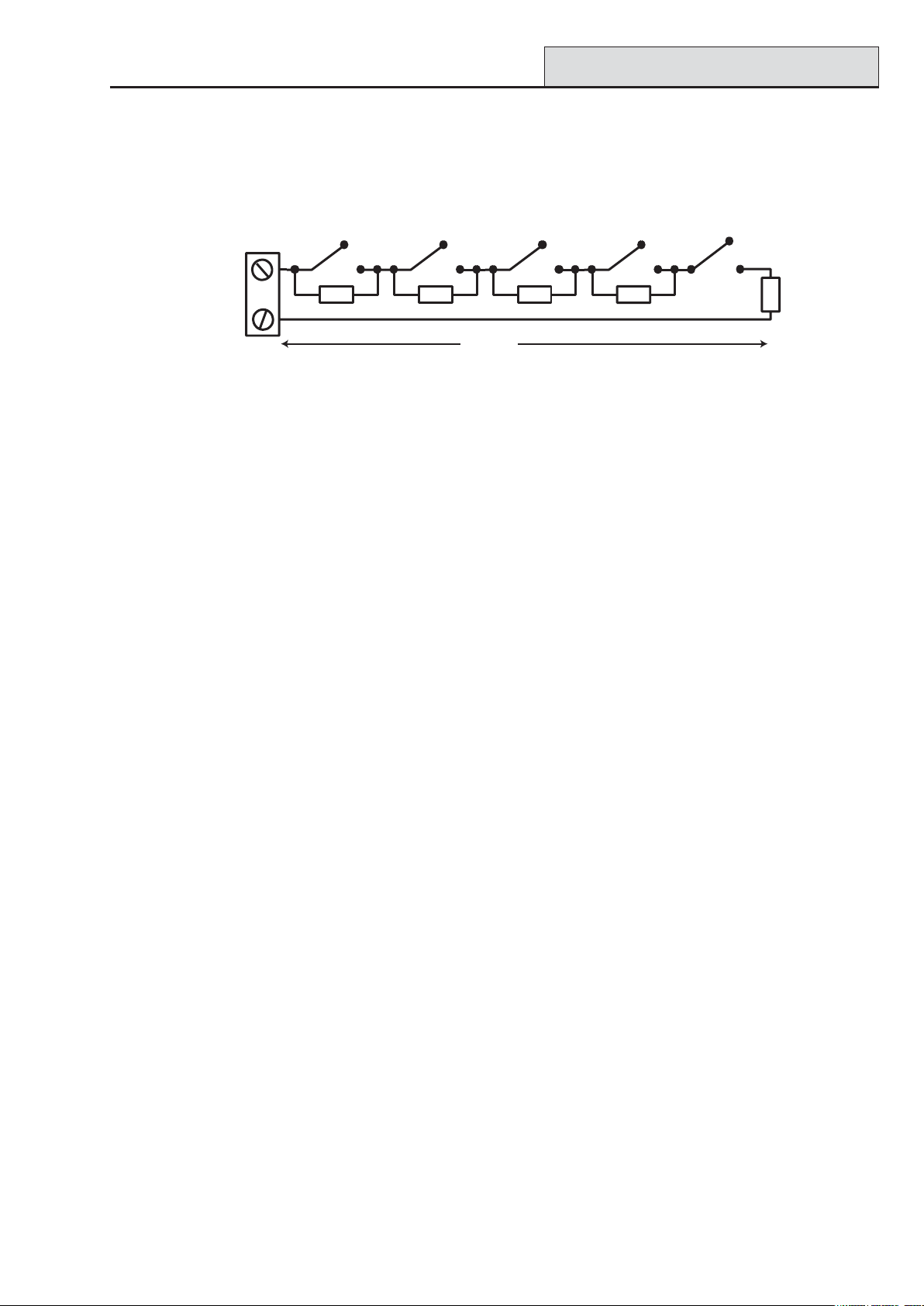

The zones on Galaxy Dimension panels can be Double Balanced (default) or End of Line. Zones can be

programmed with different resistance ranges for zone status activation (see Parameter 51.46 =

Parameters.Zone Resistance). Refer to Table 2-7 (Double Balanced) or Table 2-8 (End of Line) for

details of the zone resistance and resulting conditions.The system default is Option 9, giving fault monitoring on

1k double balanced wiring.

NOTE: The circuit debounce time (the period the zone must remain in a state to register a change in condi-

tion) is 300 milliseconds by default.

Option 01 - 1k Option 03 - 2k2 Option 05 - 4k7 Option 07 - 5K6 Option 09 - 1k Fault

Tamper S/C 0 - 800 0 - 1800 0 - 3700 0 -1400 0 - 800

Low Res 800 - 900 1800 - 2000 3700 - 4200 1400 - 2800 800 - 900

Normal 900 - 1200 2000 - 2500 4200 - 5500 2800 - 8400 900 -1200

High Res 1200 - 1300 2500 - 2700 5500 - 6500 8400 - 9800 1200 - 1300

Open 1300 - 12000 2700 - 12000 6500 - 19000 9800 - 12600 1300 - 3500

Fault - - - - 3500 - 4500

Masked 12000 - 19000 12000 - 15000 19000 - 22000 12600 - 22000 4500 - 19000

Tamper O/C 19000 - infinity 15000 - infinity 22000 - infinity 22000 - infinity 19000 - infinity

Table 2-7. Double Balanced Zone Resistance and Conditions

Option 09 - 1k Fault Double-balanced (default)

The wiring in Figure 2-10 should be used if the detector uses combined fault and mask signalling. A mask

condition is generated if an alarm and fault are signalled at the same time. Alternatively, if the detector has

seperate fault and mask indications then the wiring in Figure 2-11 should be used.

1k

Zone

Alarm N/C Fault N/C

Tamper N/C

100 m

Figure 2-10. Option 09 - Double balanced 1k Fault Monitoring Wiring

3k

1k

Zone

Figure 2-11. Option 09 - Double balanced 1k Fault/Mask Monitoring Wiring

NOTE: N/C = Normally Closed.

1k

Alarm N/C

Tamper N/C

2-13

100 m

3k

Fault N/C

12k

Anti-Mask N/C

1k

Page 26

Wiring Zones (cont’d)

Galaxy Dimension Installer Manual

When this wiring mode is employed, only one detector which can report fault conditions should be connected

to the zone. A maximum of two detectors or contacts of any type should be connected to a zone when this

mode is selected. It is recommended that zone cable lengths are kept below 100m in this configuration.

NOTE: The recommended maximum cable run from a zone to a detector is 500 metres in all other configu-

rations.

Option 02 - 1k Option 04 - 2k2 Option 06 - 4k7 Option 08 - 5k6 Option 10 -1k Fault

Tamper S/C 0 - 800 0 - 1800 0 - 3700 0 - 1400 0 - 800

Low Res 800 - 900 1800 - 2000 3700 - 4200 1400 - 2800 800 - 900

Normal 900 - 1200 2000 - 2500 4200 - 5500 2800 - 8400 900 - 1200

High Res 1200 - 1300 2500 - 2700 5500 - 6500 8400 - 9800 1200 - 1300

Fault - - - - 1300 - 4500

Masked 1300 - 12000 2700 - 12000 6500 - 19000 9800 - 19000 4500 - 19000

Open 12000 - infinity 12000 - infinity 19000 - infinity 19000 - infinity 19000 - infinity

Table 2-8. End of Line Zone Resistance and Conditions

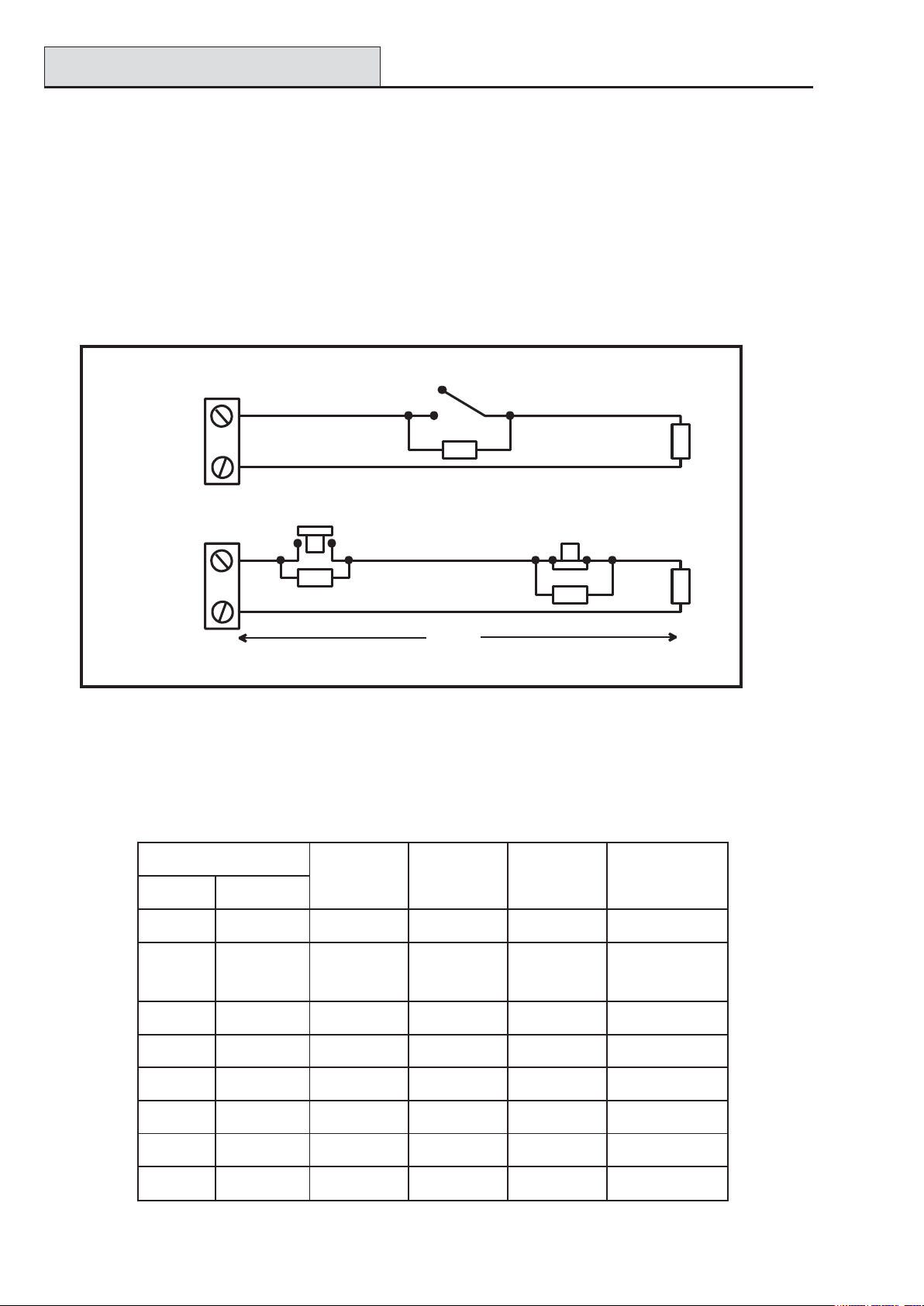

Option 10 - 1k Fault End-Of-Line

The wiring in Figure 2-12 should be used if the mode is end-of-line. Fault and mask indications can only be

signalled if the detector has seperate fault and mask indications.

3k

Zone

Alarm N/C

Tamper N/C

Fault N/C

100 m

Figure 2-12. Option 10 - End of Line Zone/Detector wiring

When this wiring mode is employed, only one detector which can report fault conditions should be connected

to the zone. A maximum of two detectors or contacts of any type should be connected to a zone when this

mode is selected. It is recommended that zone cable lengths are kept below 100m in this configuration.

12k

Anti-Mask N/C

1k

NOTE: The recommended maximum cable run from a zone to a detector is 500 metres in all other configu-

rations.

2-14

Page 27

Galaxy Dimension Installer Manual

Wiring Zones (cont’d)

Wiring Multiple Detectors

Multiple detectors can be wired into a single zone when using preset 1 as shown in the following Figure. The

maximum number of detectors that can be connected to a single zone is ten.

(10 max)

N/C TAMP

1k

1%

1k

Zone

N/C

Alarm

1k

1%

N/C

Alarm Alarm Alarm

N/C

1k

1%

500 m

N/C N/C

1k

1% 1%

Figure 2-13. Zone to Multiple Detector Wiring

Wiring Keyswitches

Latching or spring loaded keyswitches can be used to set and unset the Galaxy Dimension panels; option

52 = PROGRAM ZONES has provision to accommodate both types of transition.

If the keyswitch latches, the transition from 1 kΩ to 2 kΩ initiates the setting procedure of an unset system,

the transition from 2 kΩ to 1 kΩ instantly unsets a set system. If the system is already set, then the transition

from 1 kΩ to 2 kΩ has no effect. If the system is unset, the transition from 2 kΩ to 1 kΩ has no effect. This

is programmed as a Keyswitch in the PROGRAM ZONES option.

If the keyswitch is spring-loaded (returns to its normal position), the transition from 1 kΩ to 2 kΩ initiates the

setting procedure of an unset system and instantly unsets a set system, the transition from 2 kΩ to 1 kΩ - the

return to the normal position - has no effect. This is programmed as a Keyswitch in the PROGRAM

ZONES option.

2-15

Page 28

Terminator Zone Wiring

Galaxy Dimension Installer Manual

Wiring Terminator Buttons

Zones programmed as Push-Set (terminator) buttons can be open going closed (2 kΩ to 1 kΩ) or closed

going open (1 kΩ to 2 kΩ). The first activation of the terminator button initialises its status to the system.

NOTE: The first activation of a terminator may not set the system as this can be the initialisation routine. If

the system continues setting, push the button again. The system will set on the second push. This

initialisation only occurs on the first setting. All subsequent setting routines set on the first push of the

terminator.

The wiring of the terminator and keyswitch zone type is shown in the following figure:

Keyswitch

zone

Push-set

zone

Open - Closed

1k

1%

1k to unset, 2k to set

1k

1%

OR

500m

Closed - Open

1%

1k

Figure 2-14. Terminator and Keyswitch Zone Wiring

Outputs

The Galaxy Dimension control panel on-board outputs are detailed in the following table:

sserddAtuptuO

tluafeDelbanE0eniL

tluafeD

noitcnuF

epyTgnitaR

1k

1k

1%

1%

etatSlamroN

)pu-llup3k3htiw(

10011001slleBdesirotsis

20012001ebortSeloPelgniS

30013001APdesirotsisnarTAm0

40014001teseRdesirotsisnarTAm004,V21evitisoP

11011100teSdesirotsisnarTAm004,V21evitisoP

21012100redurt

31013100mrifnoCdesirotsisnarTAm004,V21evitisoP

41014100teseRdesirotsisnarTAm004,V

nIdesirotsisnarTAm004,V21evitisoP

narTAm004,V21evitisoP

A1,V03desigrene-eD

revOegnahC

)OCPS(yaleR

04,V21evitisoP

21evitisoP

Table 2-9. Outputs

2-16

Page 29

Galaxy Dimension Installer Manual

Output Applications

Output Applications

The outputs on the Galaxy panels, with the exception of the SPCO relay output, are transistorised outputs;

negative applied (positive removed) by default. These supply up to 400 mA and can be used to drive the

necessary output devices.

NOTE: The polarity of each output can be changed using option 53 = PROGRAM OUTPUTS

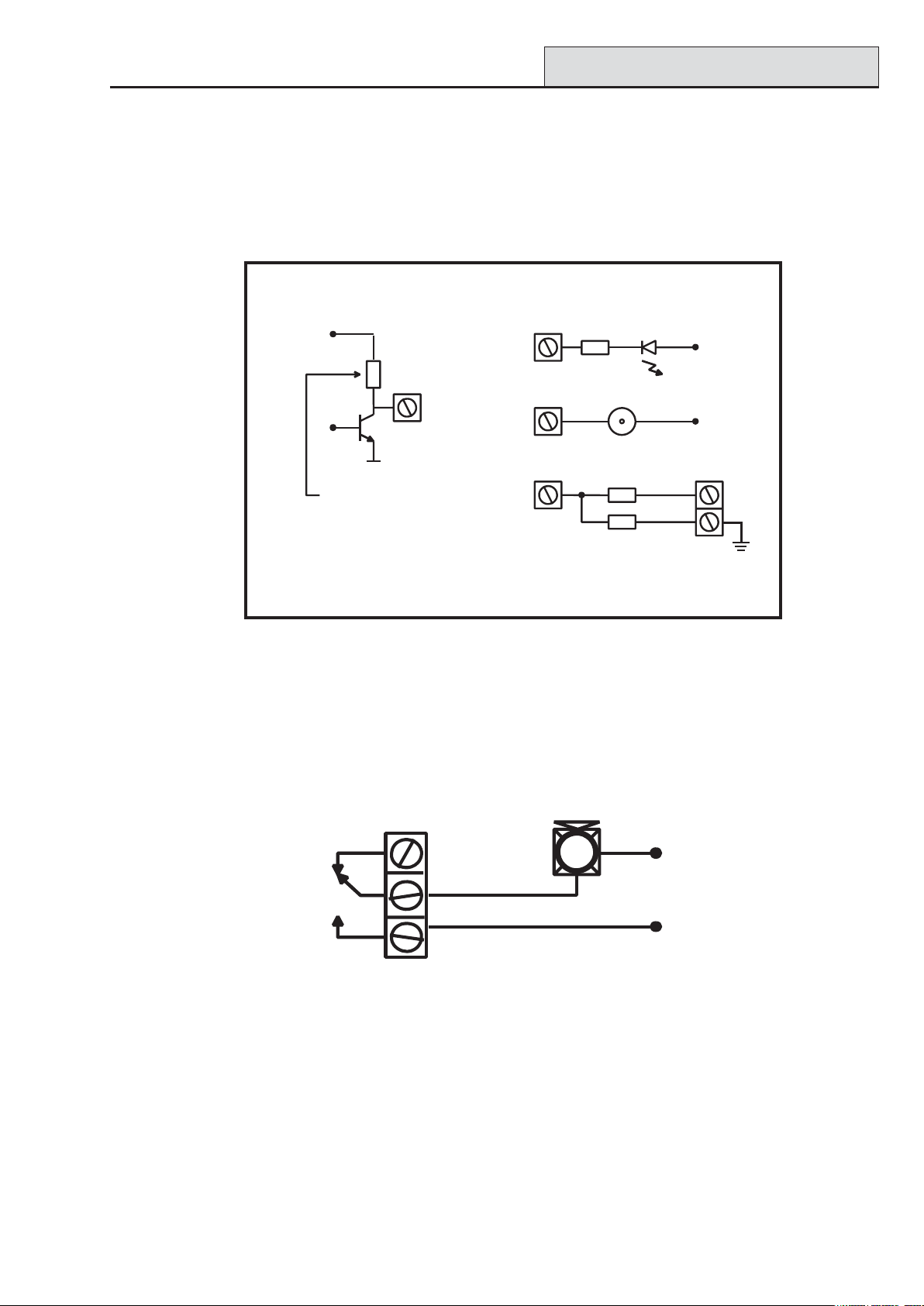

Transistorised Output

+12 V

3k3Ω

0 V

Switch out 3k3Ω

to give open collector

Output

Output must be

open collector

*

Typical Applications

A) LED

Output

1kΩ (typical)

B) Bell

Output

C) Output used to trigger zone

Output

NOTE: If the output used is one of the panel's

on-board outputs, then substitute this resistor

with a 680 Ω resistor.

LED

Bell

1%

*

1kΩ

1%

1kΩ

+12 V

+ 12 V

zone

Figure 2-15. Output Configuration and Typical Applications

Note: For the appropriate 3k3Ω pull-up resistor refer to DIP switch SW3 (Table 2-1).

The relay output is a single pole change over; this can be used to drive output devices that require a clean set

of contacts, isolated from the output voltage.

Horn

Normally

closed

+12 V

Single Pole

Change - 0ver

relay contacts

0 V

Normally open

Figure 2-16. Single Pole Change–Over Relay Output Configuration and Typical application

2-17

Page 30

Trigger Header

Galaxy Dimension Installer Manual

Trigger Header

The Trigger Header on the Galaxy Dimension is a set of pins that consist of programmable outputs for an

external communication module. The connection is via an optional ribbon cable.

Trig 1-6

There are six trigger outputs, that can be used as communication triggers, but can also be used for any other

purpose. By default these outputs are programmed as positive. They are designed to sink current (to 0V) not

source current (from 12V). The function of these outputs are as follows:

Output

Address

0001 Fire 100

0002 Panic 100

0003 Intruder 100

0004 Set 100

0005 Omit 100

0006 Confirm 100

Default

function

Current (mA)

Table 2-10. Trigger Output functions

The function of the trigger outputs can be programmed in menu option 53 = Program Outputs.

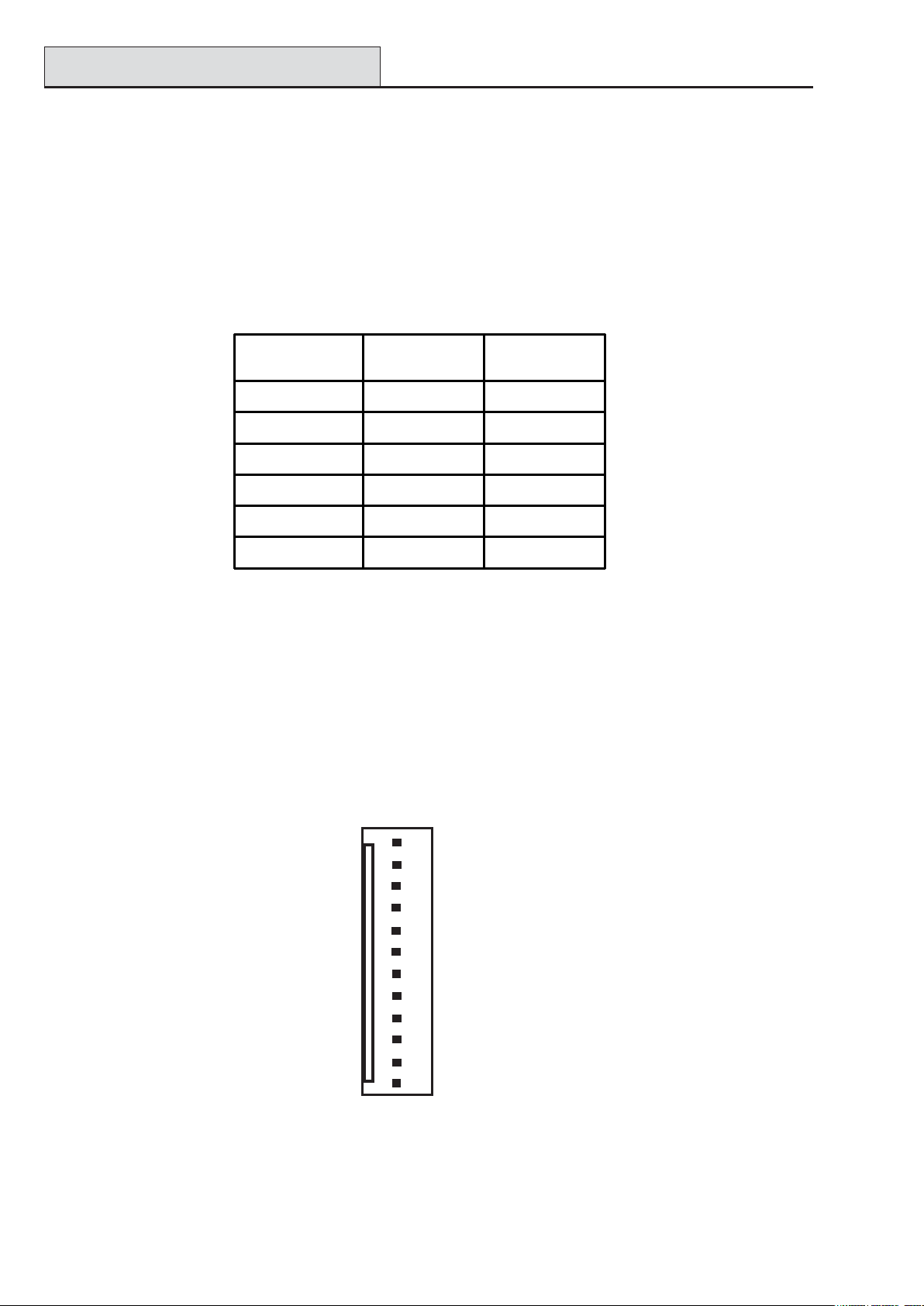

Supply

A 100 mA, 12V output is also provided. This output is fused by the on-board AUX3 FUSE (F2).

+12V

Not Used

Not Used

Trig 6

Trig 5

Trig 4

Trig 3

Trig 2

Trig 1

Not Used

Not Used

GND

Figure 2-17. Trigger Header

2-18

Page 31

Galaxy Dimension Installer Manual

SPI Key

Control

Panel

(part view)

SPI

Program

Header

Fitted

here

SPI Key

SPI Header

The SPI (Serial Peripheral Interface) key is an engineering peripheral used for copy/overwriting programming

data and carrying out software upgrades.

Fitting the SPI Key

The SPI key is fitted directly on to the Galaxy Dimension control panel.

CAUTION: Always power down the panel BEFORE removing or connecting the SPI key.

Failure to do so may result in damage to the SPI key. Never “hot-plug” the SPI

key.

The SPI Key has a 10-way connector. These locate on to the 10 pins of the SPI Program Header

(see Figures below).

NOTE: The SPI Key should only be fitted in the direction shown in Figure 2-19.

10-way

connector

Hinged

cap

Figure 2-18. SPI Key

Figure 2-19. Location of SPI Key on Program Header

1. Release the hinged cap to expose the 10-way connector.

2. Plug the SPI Key on to the Program Header on the Galaxy Dimension control panel.

Removing the SPI Key

CAUTION: Always power down the panel BEFORE removing or connecting the SPI key.

Failure to do so may result in damage to the SPI key. Never “hot-plug” the SPI

key.

1. Remove the SPI Key from the Program Header on the Galaxy Dimension control panel.

2. Secure the hinged cap to protect the 10-way connector.

2-19

Page 32

Galaxy Dimension Installer Manual

2-20

Page 33

Galaxy Dimension Installer Manual

RIOs

SECTION 3: PERIPHERALS

General

The following peripherals can be connected to the Galaxy Dimension panel:

All bus lines: Mk7 Keypad/Keyprox; TouchCenter; MAX3; Door Control Module (DCM); Remote Input

Output module (RIO); Power Supply Unit (PSU).

Bus line 1 only: Telecom; RS232; ISDN; Ethernet.

Wiring

Th following table shows the wiring between the Galaxy panel and the different peripherals.

Panel Keypad/-

Keyprox

+12V + + + X* +12V +12V +12V +

GND - - - 0V - - GND -

A A G A AAAA A

B B Y B BBBB B

Touch

Center

RIO/DCM PSU Telecom RS232 ISDN Ethernet

Table 3-1. Peripheral Wiring to Galaxy Panel

* Do not connect +12V terminals between panels and remote power supplies.

Configuring

New peripherals will be configured onto the system at system power up or on leaving programming mode.

Changes to peripheral addresses will only take effect when the peripheral is re-powered.

Addressing

The addresses on most peripherals is

set by either jumpers or a rotary

switch. These must be set before the

system is powered up. The table

opposite shows the available peripheral

addresses.

NOTES:

1 A single TouchCenter can be

fitted to each bus line.

2 If RIO 2 on-board is set to line 0

(dip switch 8), then the first

external RIO can use address 1

to give 8 extra zones where

needed.

Peripheral Line GD-48 GD-96 GD-264 GD-520

Mk7 Keypad 1

2

3-4

Mk7 Keyprox 1

2

3-4

To u c h C e n t e r

RIO/PSU 1

MAX/DCM Reader 1

Telecom 1 (E) (E) (E) (E)

RS232 1 (D) (D) (D) (D)

ISDN 1 (C) (C) (C) (C)

Ethernet 1 (B) (B) (B) (B)

1

1

2

3-4

2

3-4

2

3-4

0-2, B-F

-

-

0-2

-

-

0-2

-

-

2-5

-

-

0-3

-

-

Valid Addresses

0-2, B-F

0-2, B-F

-

0-2

0-3

-

0-2

0-3

-

2

2

-5

0-5

-

0-3

0-3

-

0-2, B-F

0-6, F

-

0-2

0-3

-

0-2

0-3

-

22-9, A-F

0-9, A-F

-

0-3

0-3

-

0-2, B-F

0-6, F

0-6, F

0-2

0-6

0-6

02

0-6

0-6

22-9, A-F

0-9, A-F

0-9, A-F

0-7

0-7

0-7

Table 3-2. Galaxy Dimension Peripheral Addresses

3-1

Page 34

RIO

Galaxy Dimension Installer Manual

Connecting the RIO

The RIO can only be connected to the system while engineer mode is accessed. The RS485 (AB) line of the

Galaxy RIO must be wired in parallel (daisy-chain configuration) with the RS485 (AB) line of any keypads

connected to the system. The RIO requires 12 Vd.c. (range 10.5 to 16.0 V) and 40 mA. This can be supplied from the control panel power supply or from a remote power supply if the distance causes a large

voltage drop on the cable.

NOTE: A Power RIO can be fitted in place of a RIO.

Connect the RIO terminals as follows:

+12 V (either control panel, keypad or remote power supply);

–0 V or ground (either control panel, keypad or remote power supply);

A to the A terminal of the previous module (or control panel if RIO is the first on the line);

B to the B terminal of the previous module (or control panel if RIO is the first on the line).

NOTE: If the RIO is the last module on the line, connect a 680 Ω EOL resistor across the A and B termi-

nals.

Configuring the RIO

The added RIO is configured into the system on exiting from engineer mode. If the message XX Mod Added

[<],[>] To View is displayed, the system has recognised that a new module is present. Press the A or B keys

to confirm that the RIO has been added. If this message is not displayed or the RIO is not on the list of added

modules, then the RIO is not communicating with the control panel or has been set to the same address as the

RIO already connected to the system.

The flash rate of the red LED (LED1) on the RIO indicates the status of the communication with the control

panel - refer to the following Table:

etaRhsalFgninaeM

FFO9.0/NO1.0snoitacinummoclamroN

FFOylppus.c.doN

FFO5.1/NO5.1metsysotniderugifnocneebtonsah

FFO2.0/NO2.0metsyshtiwnoitacinummoctsolsahOIR

FFO1.0/NO9.0snoitacinummocroopyreV

OIR

Table 3-3. RIO LED Flash Rates

Zones

The Galaxy RIO has eight programmable zones. These default to INTRUDER. Each zone is Double

Balance monitored with a 1 kΩ resistor in series with the zone detector and a 1 kΩ (1%) resistor in parallel

across the detector switch. The change to 2 kΩ (1%) resistance registers the zone as open/alarm.

3-2

Page 35

Galaxy Dimension Installer Manual

RIO Outputs

RIO Outputs

The RIO has four transistorised outputs. Each output is connected to +12 V via a 3k3Ω pull-up resistor

(refer to Table 3-4). When an output is activated, the load is switched to the negative supply voltage (ground

or 0 V) of the RIO. The current available from each output is 400 mA.

The default functions and pull-up resistors of each RIO output, when connected to a Galaxy are shown in the

following Table:

.oNtuptuOnoitcnuFrotsiseRpu-lluP

1slleB1R

2ebortS3R

3AP5R

4teseR7R

Table 3-4. RIO Output Default Functions

3-3

Page 36

RF RIO

Galaxy Dimension Installer Manual

RF RIO

The Galaxy Radio Frequency (RF) RIO module is an optional add-on to the existing Galaxy product range.

The module acts as an RF receiver for the Ademco 868MHz transmitter range.

Features

The RF RIO contains the following features:

• Support for up to 32 RF zones (dependent upon panel type)

• Support for up to 30 RF keyfobs

• 4 transistorised outputs

Panel Keypad

Panel Keypad

Outputs

Outputs

Outputs

1

1

1

2

2

2

4

4

4

3

3

3

Panel Keypad

BA -+BA - +

BA -+BA - +

BA -+ BA - +

Pull-up

Resistors

Tamper

link

Tamper

Switch

R7 R5 R3 R1

LED1

SW2

SW6

LK1

SW3

Programming

Switch

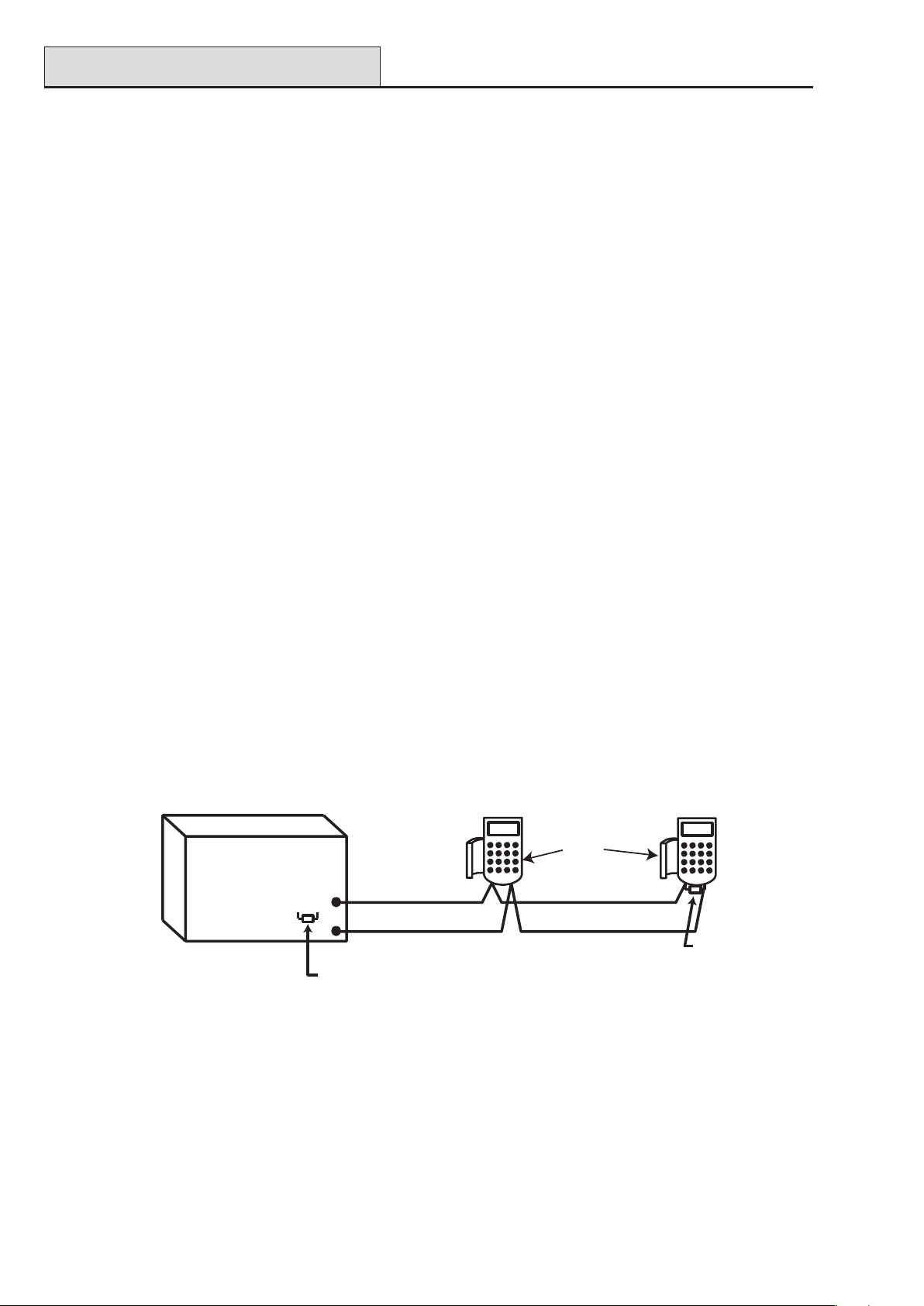

Connecting the RF RIO

SW1

Processor

Retaining Slot

Rotary

Address

Switch

Figure 3-1. RF RIO PCB Layout

Programming

Keypad

Socket

Rev 1.0

The RS 485 (AB) line of the RF RIO must be wired in parallel (daisy chain configuration) with the RS 485

(AB) line of the keypad connected to it. The RF RIO requires 12 V d.c. (range 10.5 to 16.0 V) and 55 mA.

This can be supplied from the control panel power supply or from a remote power supply if the distance

causes a large voltage drop on the cable.

3-4

Page 37

Galaxy Dimension Installer Manual

Connect the RF RIO terminals in accordance with the following Table:

lanimreTOIRFR...otdetcennoC

+)ylppusrewopetomerrodapyek,lenaplortnocta(V21+

RF RIO (cont’d)

- )ylppusrewopetomerrodapyek,l

A

B

enaplortnocta(dnuorgroV0

ehtsiOIRFRehtfilenap

iOIRFRehtfilenap

)enilehtnoeludomtsrif

)enilehtnoeludomtsrifehts

lortnocehtro(enilehtnoeludomsuoiverpehtfolanimretAehtoT

lortnocehtro(enilehtnoeludomsuoiverpehtfolanimretBehtoT

Table 3-5. RF RIO Connections

Note: If the RF RIO is the last Module on the line, connect a 680 Ω resistor across the A and B terminals.

Outputs

The RF RIO has four transistorised outputs. Each output is connected to +12 V via a 3k3Ω pull-up resistor

(refer to Table 3-6 RF RIO Connections). When an output is activated, the load is switched to the negative

supply voltage (ground or 0 V) of the RF RIO. Each output is capable of supplying 400 mA.

The default functions and pull-up resistors of each RF RIO output, when connected to a Galaxy are shown in

the following Table:

.oNtuptuOtluafeD

noitcnuF

1slleB34R

2ebortS73R

rotsiseRpu-lluP

3AP33R

4teseR32R

Table 3-6. Output Functions

NOTE: The number of pull-up resistors may vary with different hardware revisions.

RF RIO Tamper

Switch SW2 on the RF RIO acts as a tamper if the Tamper Link (LK1) is missing. Removing the lid from the

RF RIO enclosure activates the RF RIO tamper alarm if the system is not in Engineer Mode. The tamper

switch can be bypassed by fitting a 0 Ω link to LK1.

Addressing the RF RIO

The Galaxy RF RIO must be given unique addresses before it is connected to a power supply. This unique

address is selected using the 16-way Rotary Address Switch (SW1). The address selected will act as the

base address for the RF RIO. Subsequent addresses will be

base address + 1, base address + 2, base address + 3. For example:

Base address = 2 followed by 3, 4 and 5.

3-5

Page 38

RF RIO (cont’d)

Galaxy Dimension Installer Manual

Address Ranges

This option allows the programming of the RIO addresses, which are to be simulated by the RF RIO.

For example, if the RF RIO being programmed supports 32 zones (4 RIO addresses), and the base address,

programmed at the hexi-decimal rotary switch is 02, the available addresses would be 02, 03, 04, 05. However, you may want to only respond as RIO addresses 02, 04. The remaining addresses should be disabled

and will not respond to commands from the control panel. The base address is enabled by default. All other

addresses are disabled by default.

Module status on the RF RIO such as lid tamper,will be reported to the panel using the address set on the

rotary switch.

RF RIO Programming

Programming of the RF RIO is achieved by connecting a Galaxy Mk7 keypad directly to the RF RIO at the

Programming Keypad Socket or the Keypad Connector Block. The Keypad is not part of the Galaxy network and must be addressed as 0.

Note: To program RF devices, please refer to RF RIO Module, Installation and Programming

Instructions, (II1-0076) supplied with the RF RIO.

Configuring the RF RIO

The RF RIO is configured into the system in the same way as a standard RIO. Refer to standard RIO instructions for further details.

3-6

Page 39

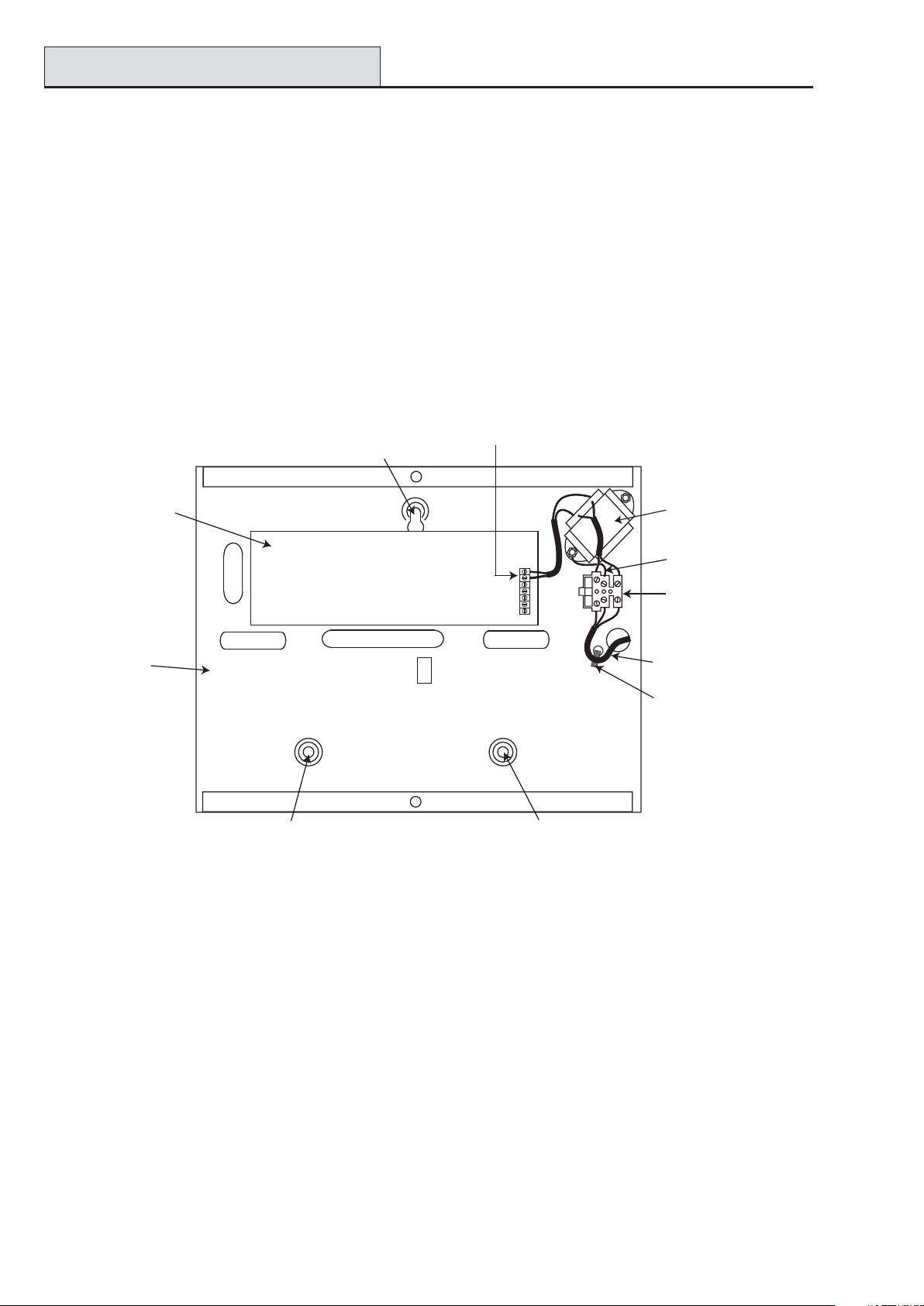

Galaxy Dimension Installer Manual

Power Supply Unit

Power Supply Unit

The Galaxy Dimension Power Supply Unit is available in 2 variants.

The Galaxy Power RIO consists of a Power Block and a Control Unit that includes an on-board RIO.

The Galaxy Power Unit consists of a Power Block and a Control Unit without the on-board RIO.

WARNING: There are lethal voltages present in the Power Block. Remove mains power from

the Power Block before handling it.

Each variant can be integrated with all Galaxy Dimension control panels. The number of Power Units or

Power RIO’s that can be used on a system is limited by the number of RIO’s that can be added to each panel.

Off-wall

Tamper

OW

LID

TAM P

Bell-Box

connection

Comms

Line

Outputs

+14.5

+12V2

+12V1

A(DO)

0V

B(DI)

OP3

OP2

OP1

TAM P

LK5

F1

F4

0V

F3

0V

OP4

LK4

LK3

LK2

LK1

3

1

1/2

2

HEATSINK

LK10

F2

Control Unit

5/6

3/4

5

6

4

Zones 1-8

13.8

From

0V

14.5

Powe r

0V

LED1

(comms)

LED2

(AC)

BT

AC/F

+BAT

-BAT

Rotary

Address

Switch

SLAVE

E/E

Block

To Control

Unit

Powe r

13.8V

0V

14.5V

0V

BT

AC/F

Power Block

NEUTRAL

LIVE

Mains

Terminal

Block

Header

BAT

AC

PWR

0V

FAULT OP

8

7/8

7

WARNING: The Power Block PCB

is connected to mains voltage. Always

disconnect mains supply for at least

1 minute before removing the box lid.

Figure 3-2. Power Supply Unit

Configuration

The Galaxy Power Supply Unit (PSU) consists of 2 modules, the Power Block and the Control Unit. The

PSU can be connected to the Galaxy Dimension control panel via the RS485 (AB) line. The PSU can be used

in place of a standard RIO to overcome power problems that arise when the additional RIO is fitted distant to

the control panel.

A 6-way jumper lead connects the Power Block to the Control Unit.

The PSU has 8 zones and 4 outputs. Each PSU takes one of the 4 RIO address (2 - 5). Addressing is identical to that described for RIO Modules.

The 4 outputs are switched 0V (0V active). Without the jumper links (LK1-4) fitted, the outputs will float in

the OFF state. They can apply a +12V signal, if required, by fitting the appropriate pull-up jumper supplied.

LK5 will short out the off-wall tamper if it is not used.

The SLAVE and E/E links must be in place for normal operation.

FAULT OP AC: This is an open collector transistor which is normally off. The output is activated by an AC

failure.

FAULT OP BAT:This is an open collector transistor which is normally off. The output is activated by a

Battery Low or Battery Fail condition.

FAULT OP POWER: This is an open collector transistor which is normally off. The output is activated by

low voltage present in +12V1, +12V2 or +14.5V.

3-7

Page 40

Power Supply Unit (cont’d)

Galaxy Dimension Installer Manual

Installation Instructions

The installation and wiring must be performed by a competent engineer. The Galaxy Dimension Power Supply

Unit must be connected to the a.c. mains supply (230/240 Va.c. 50Hz) via a fused connection outlet. The fuse

in the mains outlet must not exceed 3A.

The Galaxy Dimension Power Supply Unit comes installed in the metal enclosure base. The installation procedure of the panel base is as follows:

1. Route the mains cable through the hole on the right hand side of the enclosure base. Securely anchor

the cable to the box using the tie-wrap as shown in the following Figure:

Enclosure

base

Lid Tamper

Microswitch

Control

Unit

Attaching hole

Figure 3-3. Enclosure Base

6-way jumper lead

from power block

to control unit

Keyhole

slot (top)

Powe r

Block

Off-Wall

Tamper

Micro-switch

Terminal

block

Mains cable

Tie wrap

Attaching hole

2. Secure the panel base to the wall using three 1.5" No. 8 round head steel screws through the holes

provided.

The mains cable used must be a three core type (with green/yellow earth insulation) of adequate current

carrying capacity.

3. Connect the mains cable to the mains terminal block as follows:

• blue wire to the terminal marked N (Neutral)

• green/yellow wire to the terminal marked (Earth)

• brown wire to the terminal marked L (Live)

NOTE: No other connections to the mains connector are permitted.

All wiring must be in accordance with local regulations and the installation must conform to EN60950.

4. Power up by applying mains first. This unit can be powered up from the battery by momentarily shorting

LK10. Never leave LK10 connected, as deep discharge of the battery will occur. LK10 is for start-up

only.

3-8

Page 41