Honeywell Galaxy 3-48C, Galaxy 3-144, Galaxy 3-144C, Galaxy 3-520, Galaxy 3-520C installation Guide

Page 1

Galaxy

3-48C, 3-144, 3-144C, 3-520, 3-520C

Installation Manual

Honeywell Security

Page 2

Page 3

Galaxy 3 Series Installation Manual

Table of Contents

Content s

Introduction .............................................................................................1-1

Variants................................................................................................................1-1

Section 1: Quick Setup ..........................................................................1-3

Section 2: System Architecture............................................................2-1

PCB Layout..........................................................................................................2-4

RS485 Expansion Module (G3-520 only) .........................................................2-5

System Installation and Wiring.........................................................................2-6

Connecting the Galaxy 3 Series to the PSTN..................................................2-7

Connecting Additional Telecom Apparatus...................................................................2-8

Line Monitoring .................................................................................................................2-8

Stand-by Battery................................................................................................. 2-9

Battery Start-up .................................................................................................................2-9

On-Board Power Supply Unit.............................................................................2-9

Memory ..............................................................................................................2-10

RS485 Data Communication Bus (AB Lines) .................................................2-10

RS485 Wiring Configurations..........................................................................2-10

RS485 Wiring Recommendations ...................................................................2-11

Zones .................................................................................................................2-13

Zone Addresses..............................................................................................................2-13

Zone Addressing with Onboard RIO Switch...........................................................................................2-14

Wiring Zones ................................................................................................................... 2-14

Wiring Multiple Zones...................................................................................... 2-15

Wiring Keyswitches ........................................................................................................ 2-15

Wiring Terminator Buttons ............................................................................................ 2-16

Outputs ..............................................................................................................2-16

Output Applications .........................................................................................2-17

SPI Header........................................................................................................................2-18

Section 3: Optional Modules and Facilities..........................................3-1

Remote Input Output (RIO) Modules – C072 ....................................................3-1

Addressing ........................................................................................................................3-1

Connecting the RIO ...........................................................................................................3-2

Configuring the RIO ..........................................................................................................3-2

Outputs...............................................................................................................................3-3

i

Page 4

Table of Contents

Entry/Exit RIO.....................................................................................................................3-3

Entry/Exit RIO Zone Programming ...........................................................................................................3-4

Entry/Exit RIO Zone Operation .................................................................................................................3-4

Slave RIO ...................................................................................................................... ...........................3-4

Galaxy 3 Series Installation Manual

RF RIO – C076 .....................................................................................................3-5

Connecting the RF RIO.....................................................................................................3-5

Addressing the RF RIO.....................................................................................................3-6

Address Ranges ......................................................................................................................................3-6

RF RIO Programming........................................................................................................3-7

Configuring the RF RIO ....................................................................................................3-7

Output Module – C078 .......................................................................................3-8

Addressing ........................................................................................................................3-8

Connecting the Output Module .......................................................................................3-9

Configuring the Output Module ......................................................................................3-9

Outputs...............................................................................................................................3-9

Configuration Jumpers..................................................................................................3-10

Relay Module ................................................................................................................... 3-11

Technical Specification - Output Module .....................................................................3-11

Technical Specification - Relay Module .......................................................................3-11

Power Supply Unit ............................................................................................3-12

Configuration...................................................................................................................3-12

Installation Instructions ................................................................................................. 3-13

Battery ..............................................................................................................................3-14

Battery Test......................................................................................................................3-14

Specifications..................................................................................................................3-14

EN50131 Compliance ......................................................................................................3-14

Printer Interface Module-A134/A161 ..............................................................3-15

Telecom Module – E062................................................................................... 3-16

Connection to the PSTN.................................................................................................3-16

Programming the Telecom Module ..............................................................................3-16

RS232 Interface Module - E054.......................................................................3-17

Interface with a PC...........................................................................................................3-17

Serial Printer Interface ....................................................................................................3-18

ISDN Module – E077 .........................................................................................3-19

Programming the ISDN Module..................................................................................... 3-19

Ethernet Module - E080....................................................................................3-20

Configuring the Ethernet Module ................................................................................. 3-20

Ethernet Communication............................................................................................... 3-20

Remote Servicing Suite....................................................................................3-21

Event Monitoring .............................................................................................................3-21

Galaxy Gold ......................................................................................................................3-21

User Management Suite.........................................................................................................................3-21

ii

Page 5

Galaxy 3 Series Installation Manual

Table of Contents

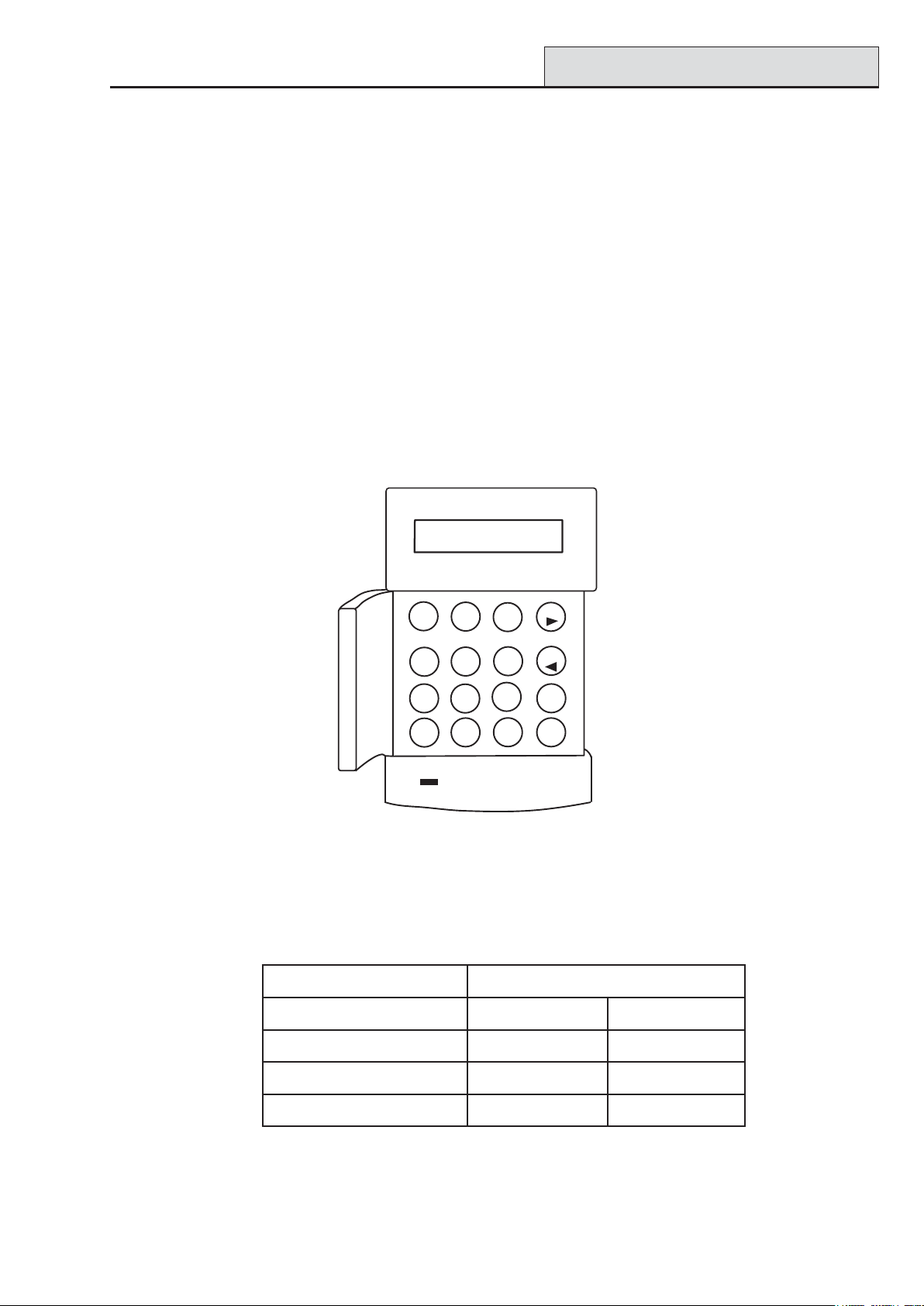

Section 4: The Galaxy Mk7 Keypad/KeyProx.......................................4-1

General.................................................................................................................4-1

Power Consumption.........................................................................................................4-1

Wiring the Keypad/KeyProx .............................................................................................4-2

Addressing ........................................................................................................................4-2

Keypad/KeyProx Installation Procedure .......................................................... 4-2

Volume Control..................................................................................................................4-4

Adding a Keypad/KeyProx to the System ...................................................................... 4 -4

Removing a Keypad/KeyProx from the System............................................................4-4

Self Diagnostics ................................................................................................................4-5

Keypad/KeyProx Operation.............................................................................................4-5

Number Keys ...........................................................................................................................................4-5

View Keys ................................................................................................................................................4-5

Enter Key ..................................................................................................................................................4-5

Escape Key ..............................................................................................................................................4-6

Hash Key..................................................................................................................................................4-6

Star Key....................................................................................................................................................4-6

Power LED ...............................................................................................................................................4-7

Display......................................................................................................................................................4-7

The Galaxy KeyProx...........................................................................................4-8

General ...............................................................................................................................4-8

Addressing ........................................................................................................................4-8

Operation ............................................................................................................................4-8

Card Types .........................................................................................................................4-8

Section 5: Door Control Module - MAX3...............................................5-1

Introduction.........................................................................................................5-1

Standalone.........................................................................................................................5-1

On-line ................................................................................................................................5-1

Installing the MAX3 ............................................................................................5-1

MAX3 Pack .........................................................................................................................5-1

Mounting the MAX3 ........................................................................................................... 5-1

Wiring the MAX3 .................................................................................................5 -2

Configuring a MAX3 Reader into the System................................................................5-3

Configuring as On-Line MAX3 .........................................................................................5-3

Configuring as a Stand-Alone MAX3.............................................................................. 5-4

Removing a MAX3 Reader from the System..................................................................5-5

On-Line Mode ...........................................................................................................................................5-5

Operating Instructions .....................................................................................................5-5

Card-Held Function...................................................................................................................................5-5

Card-Held System Setting........................................................................................................................5-5

MAX3 Log...........................................................................................................................5-6

Downloading the MAX3 Log.....................................................................................................................5-6

iii

Page 6

Table of Contents

Dual Access Cards............................................................................................................ 5- 7

Dual Focus (Card Held) ....................................................................................................5-7

Timed Anti-Passback ........................................................................................................5-7

Galaxy 3 Series Installation Manual

Appendix A : Door Control - MAX (MX01)............................................ A-1

Installation Instructions ................................................................................... A-1

Wiring the MAX ................................................................................................................. A-1

Mounting the MAX ............................................................................................................ A-2

Surface Mounting the MAX......................................................................................................................A-2

Flush Mounting the MAX .........................................................................................................................A-2

Configuring a MAX Reader into the System ................................................................. A-3

Configuring as a Stand-Alone MAX ............................................................................... A-3

Configuring as On-Line MAX.......................................................................................... A-4

Removing a MAX Reader from the System................................................................... A-5

Stand Alone Mode .................................................................................................................................. A-5

On-Line Mode ..........................................................................................................................................A-5

Programming Instructions for On-Line Readers ......................................................... A-5

Operating Instructions (On-Line Modes)...................................................................... A-6

Gaining Access ....................................................................................................................................... A-6

Card-Held Function..................................................................................................................................A-6

Max Log ............................................................................................................................. A-7

Max Events Print-Out............................................................................................................................... A-7

Appendix B: 3 Ampere Smart PSU - P015........................................... B-1

Grounding......................................................................................................................... B-1

Appendix C: Panel Comparisons......................................................... C-1

Appendix D: Declaration of Conformity .............................................. D-1

Compliance and Approvals .............................................................................. D-1

EN50131 Compliance ......................................................................................... D-2

PD6662 Compliance ........................................................................................... D-2

Public Switched Telephone Network (PSTN) approval .................................. D-2

Appendix E: Specifications ...................................................................E-1

Panel Specifications ...........................................................................................E-1

Appendix F: Parts List Index.................................................................F-1

Index............................................................................................................ 1

iv

Page 7

Galaxy 3 Series Installation Manual

Introduction

Introduction

This manual gives full instructions required to install a Galaxy 3 Series control panel and associated

peripherals.

Throughout this Installation Manual, references to menu options, unless otherwise indicated, are found in the

Galaxy 3 Series Programming Manual, part number IP1-0033.

Variants

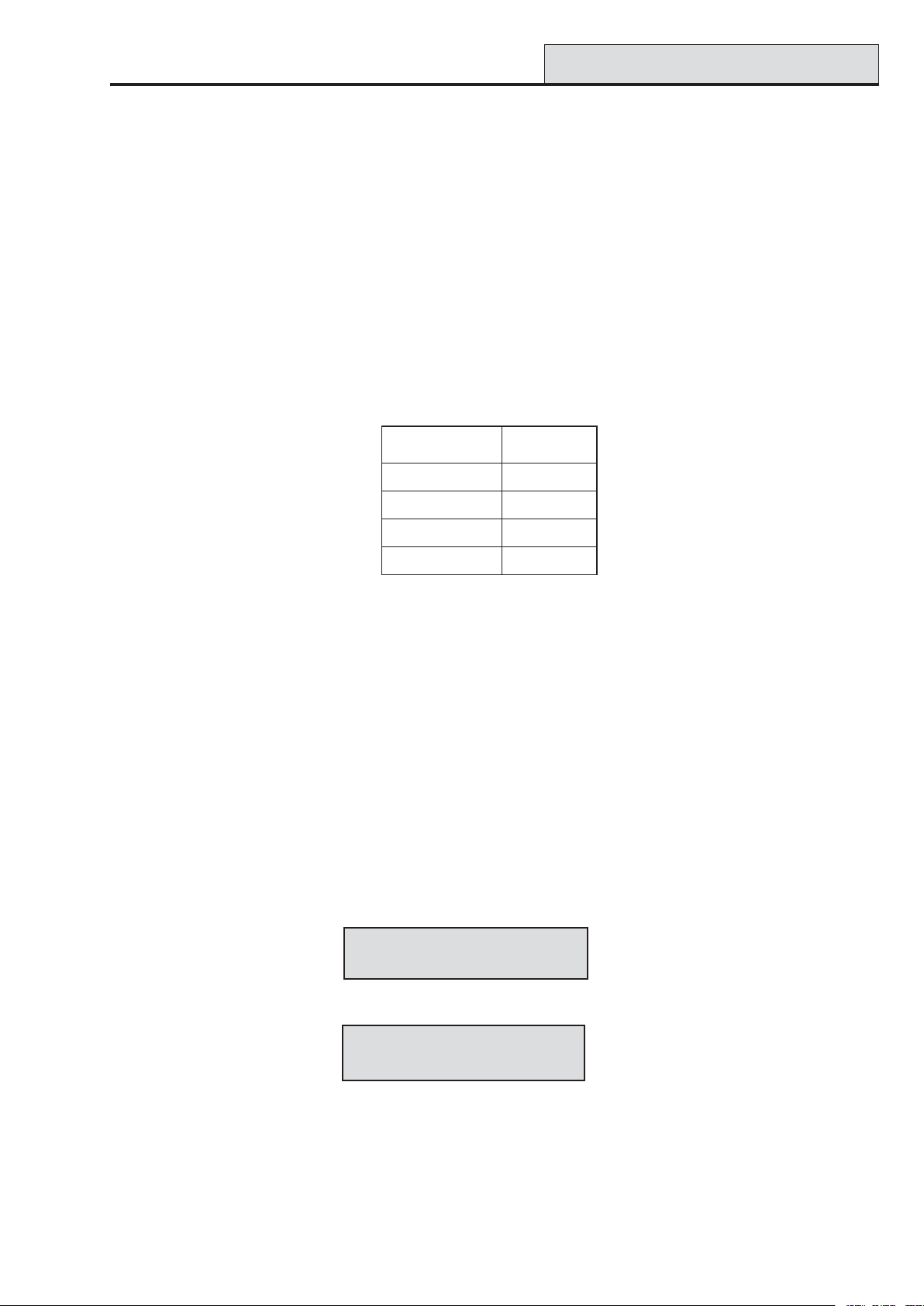

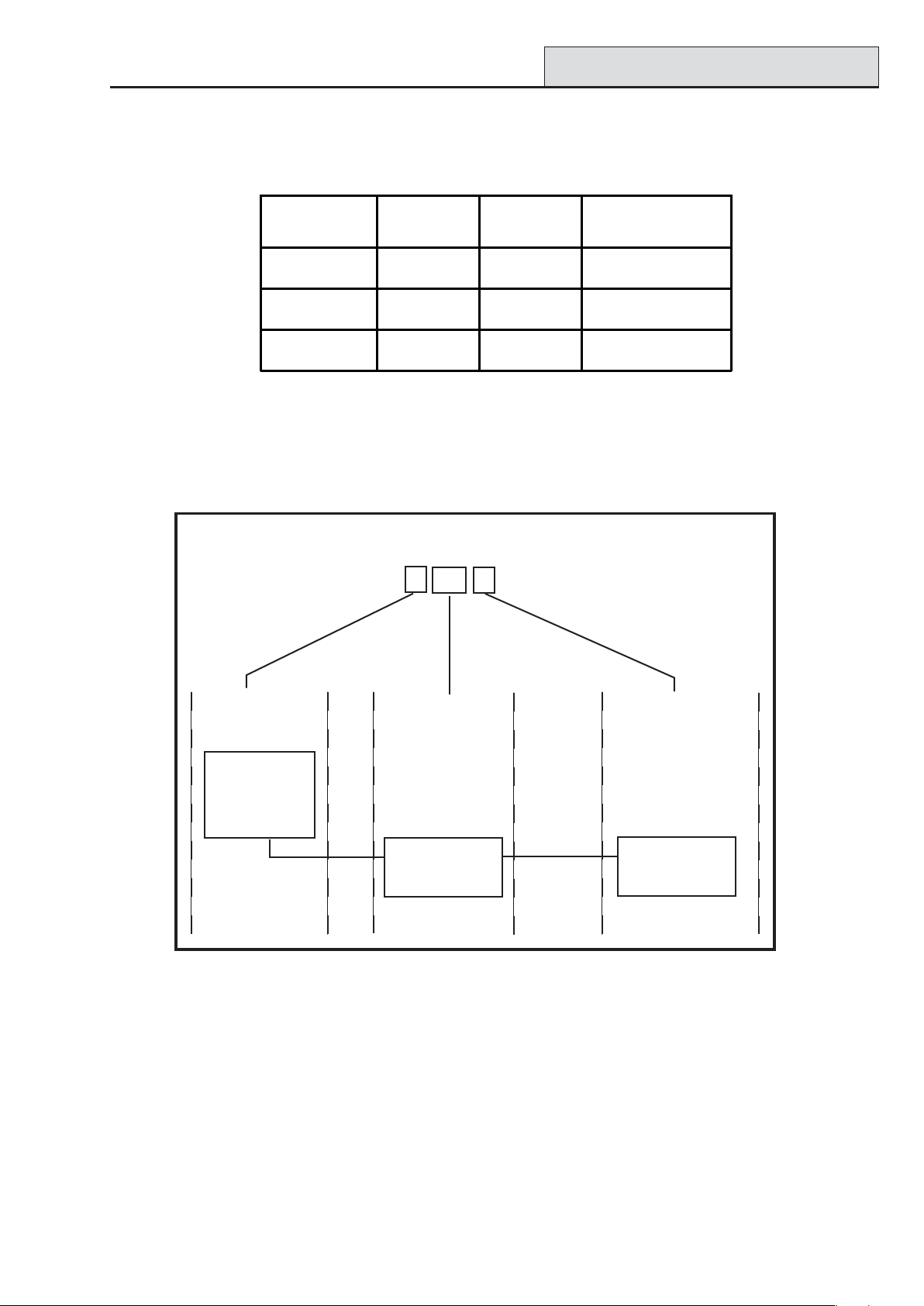

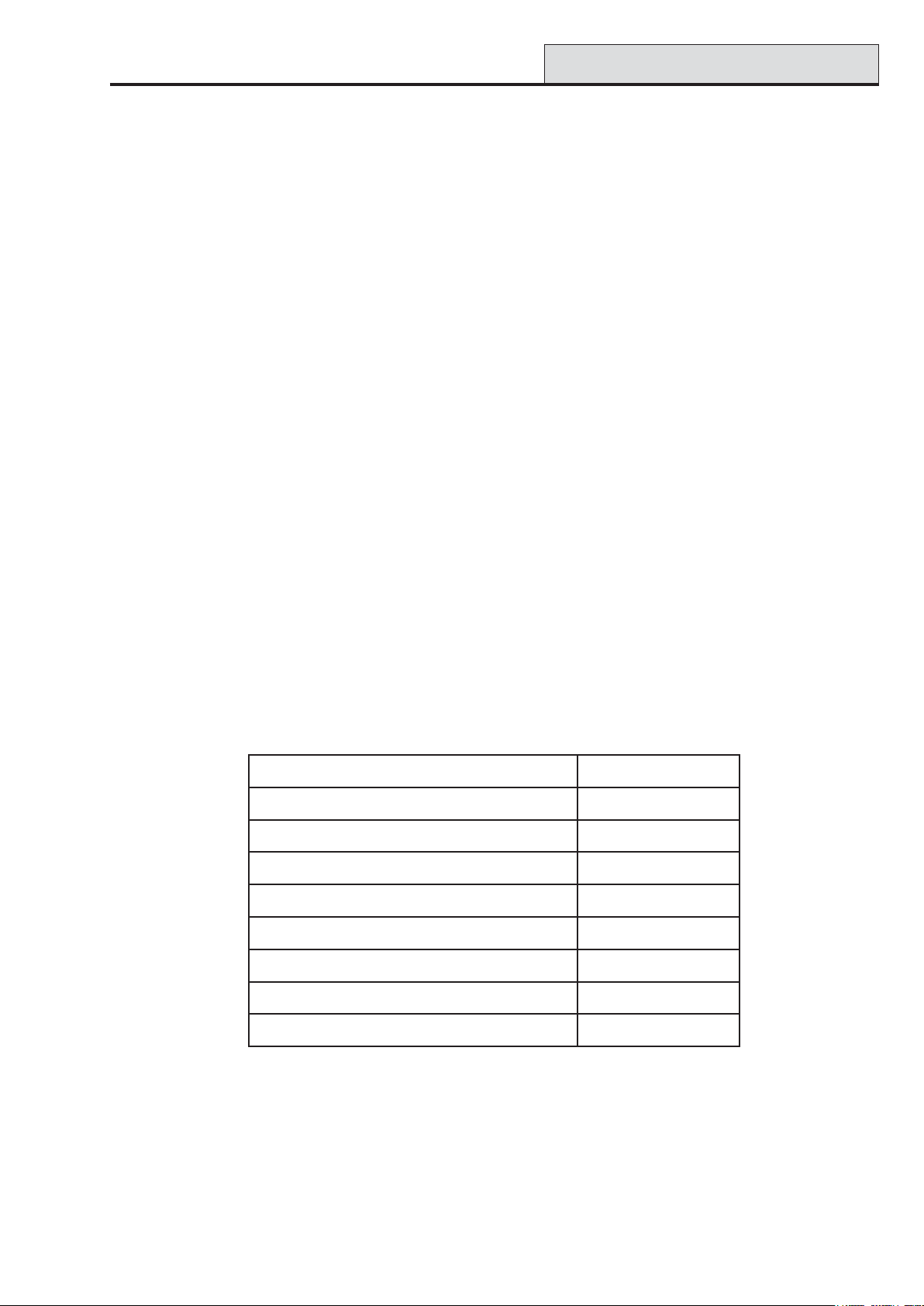

The Galaxy 3 Series is available in five variants: 3-48C; 3-144; 3-144C; 3-520; 3-520C. The differences

between each variant are shown in the following table:

VARIANT

3-48C YES NO 1

3-144 NO NO 2

3-144C YES NO 2

3-520 NO YE S 4

3-520C YES YES 4

ON-BOARD

COMMS

RS485 EXPANSION

MODULE

RS485 LINES

Table 1-1. Galaxy 3 Series Variants

NOTE: The RS485 Expansion module gives two extra lines (lines 3 and 4) on the 3-520 only .

1-1

Page 8

Galaxy 3 Series Installation Manual

1-2

Page 9

Galaxy 3 Series Installation Manual

Quick Setup

Section 1: Quick Setup

T o quickly set up a Galaxy 3 Series control panel for programming follow these simple steps:

1. Connect a 1k Ω (1%) resistor across each of the zones on the panel and any RIO’ s (if connected).

2. Ensure that the tamper return loop — the terminal marked as AUX T AMP on the PCB — is a complete

loop.

NOTE: This is factory set as a completed loop with a 0 V return.

3. Connect one of the keypads to the AB LINE terminals on the control panel. The Galaxy 3-48 has

one AB line; the Galaxy 3-144 has two AB lines; the Galaxy 3-520 has four AB lines (when an

RS485 Expansion Module is fitted).

NOTE: G3-48 - There is one AB LINE terminal on the control panel PCB.

NOTE: G3-144/G3-520 - There are two AB LINE terminals on the control panel PCB.

lenaPlortnoC

)1eniL(

1BB

1AA

--

++

dapyeK

T able 1-2. Terminal Connections

4. Connect a 680 Ω End Of Line (EOL) resistor across the A and B terminals of the keypad.

5. Ensure that the keypad is fitted to the wall (see Keypad Installation Procedure, Section 4).

6. Connect the battery before replacing the control panel lid.

7. Connect the mains wiring to the control panel. Do not switch the mains ON.

8. Replace the control panel lid and secure the fastening screws.

9. Switch on the mains voltage (230 Va.c. / 50 Hz).

10. The following sequence of events occur:

• the keypad buzzer and control panel horn (if fitted) activate for 10 - 20 seconds,

• flashing is displayed on the keypad,

• the sounders stop and the keypad displays become blank,

• the green power LED lights and the following displays on the keypad

ConfiguringConfiguring

Configuring

ConfiguringConfiguring

Please WaitPlease Wait

Please Wait

Please WaitPlease Wait

• the default banner is then displayed on the keypad.

GALAXY <XXX> <VY.YY>GALAXY <XXX> <VY.YY>

GALAXY <XXX> <VY.YY>

GALAXY <XXX> <VY.YY>GALAXY <XXX> <VY.YY>

01:0101:01

01:01

01:0101:01

SUN 01 JAN SUN 01 JAN

SUN 01 JAN

SUN 01 JAN SUN 01 JAN

where: XXX is the panel type

Y .YY is the panel software revision

11. The system is now ready to be programmed. Refer to Galaxy 3 Series Programming Manual:

IP1-0033 for programming details.

1-3

Page 10

Galaxy 3 Series Installation Manual

1-4

Page 11

Galaxy 3 Series Installation Manual

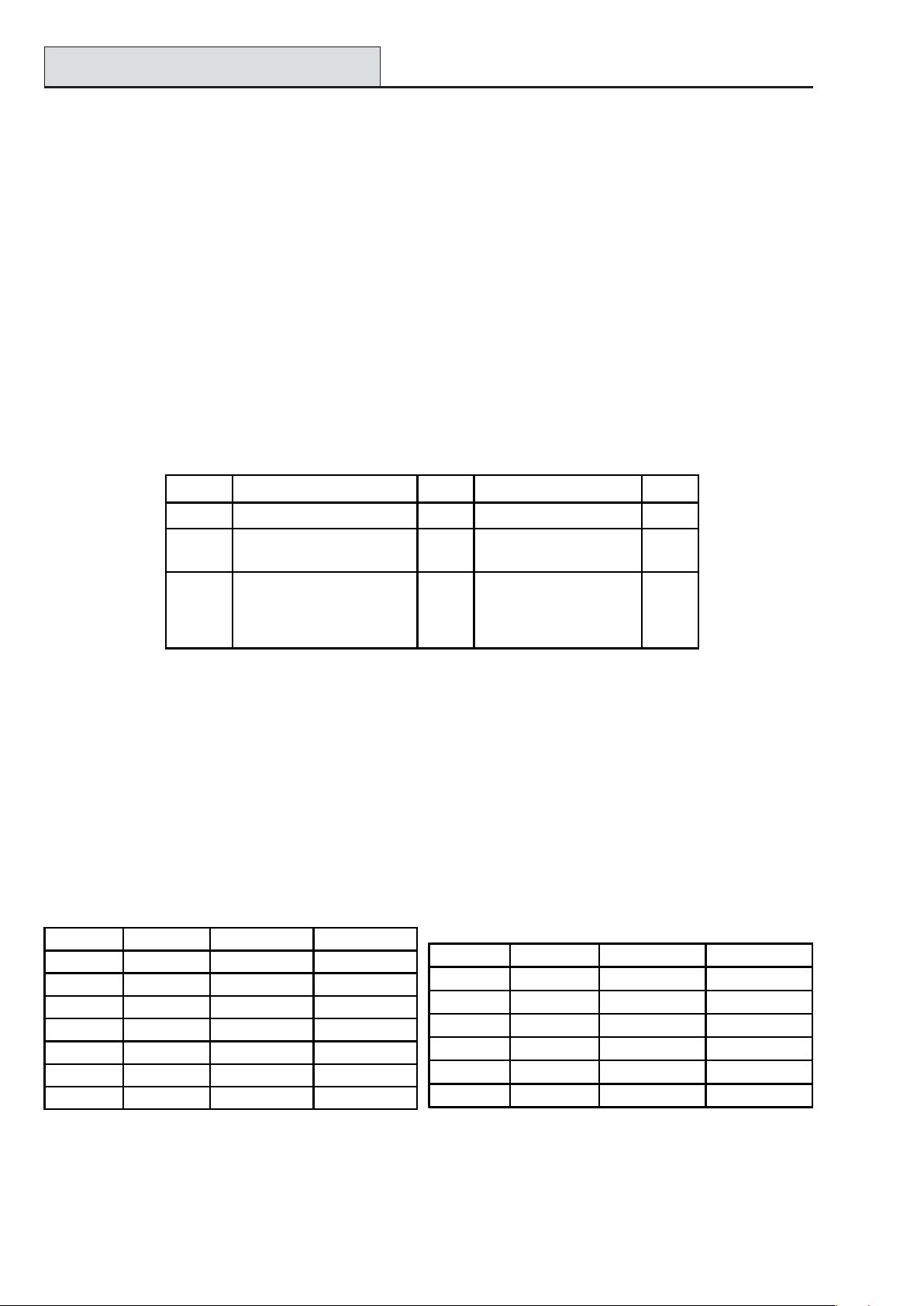

Section 2: System Architecture

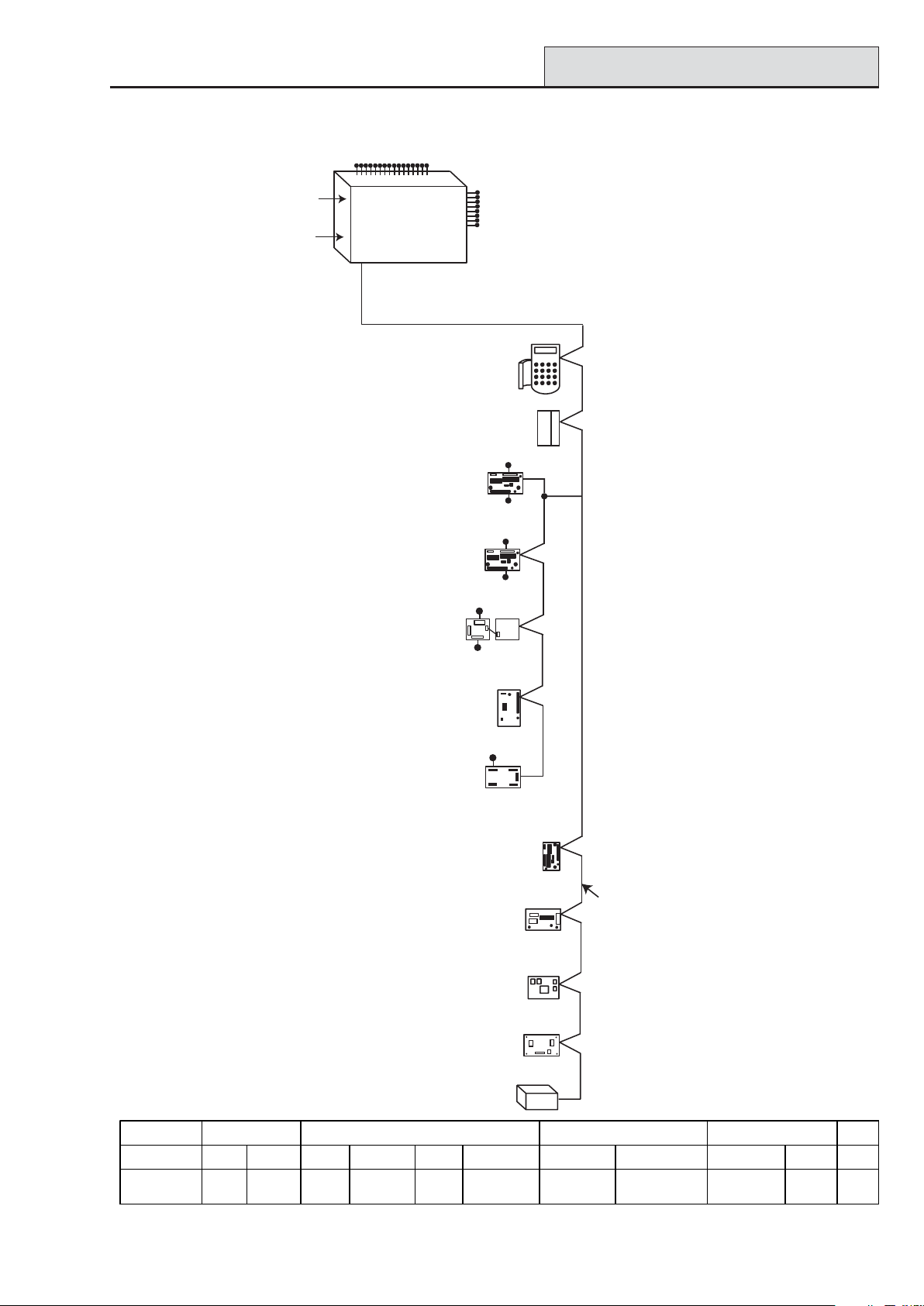

16 zones on board

G3-48 Configuration

PSTN

(comm 1)

RS232

Serial Port

(comm 6)

NOTE:

RIOs, RF RIO's and

PSU's can be mixed on

the lines. The maximum

number of combined

modules is given in the

table below.

on board

telecom

area

Line

NOTE:

Valid addresses for the

*

keyprox are:

Line 1 (0, 1 & 2).

This sets the address for both

the keypad and card reader

parts of the keyprox.

*

Certain keypad and

max addresses can

be replaced by a

combined keyprox unit.

Galaxy 3-48

1

Power Unit (4) P025

or

Power RIO (4) P026

Smart PSU (4)

P015

4 outputs

8 zones

OR

RF RIO Module (4)

C076

8 outputs

on board

Cable run 1 km (max)

K

eypads (8)

*

CP027/

Keyprox (3)

CP028

Max (4)

*

MX03

4 outputs

RIO (4)

C072

8 zones

OR

4 outputs

8 zones

OR

Output Module (4) C078

NOTE: Each Output Module can simulate

up to 4 RIO's (outputs only) depending

on DIP switch setting.

Valid addresses for the Output Module are

the same as standard RIO's.

NOTE:

The Telecom, Printer Interface,

RS232, Ethernet and ISDN

modules can only be

connected to line 1.

If a Telecom module is attached,

keypad address E cannot be

connected to line 1(address E is

shown as 18 on the system).

If an RS232 module is attached,

keypad address D cannot be

connected to line 1 (address D is

shown as 17 on the system).

If an Ethernet module is attached,

keypad address B cannot be

connected to line 1 (address B is

shown as 15 on the system).

If an ISDN module is attached,

keypad address C cannot be

connected to line 1 (address C is

shown as 16 on the system).

On-board RIOs/ Smart PSUs/EN51 PSU Keypads Keyprox MAX

Galaxy Panel Zones Outputs Poss. Address Zones Outputs Poss. Address Poss. Address Poss.

3-48 (line 1) 16 8 4 2 - 5 32 16 8 0, 1 & 2, B, C, D,

4 - 16 outputs

Telecom Module (1)

E062 (comm 5)

RS232 Module (1)

E054 (comm 2)

ISDN Module (1)

E077 (comm 3)

Ethernet Module (1)

E080 (comm 4)

Printer Interface (1)

A134/A161

Twisted Pair

Screened Cable

W002

E, F

30, 1 & 24

Figure 2-1. Galaxy 3-48 System Configuration

2-1

Page 12

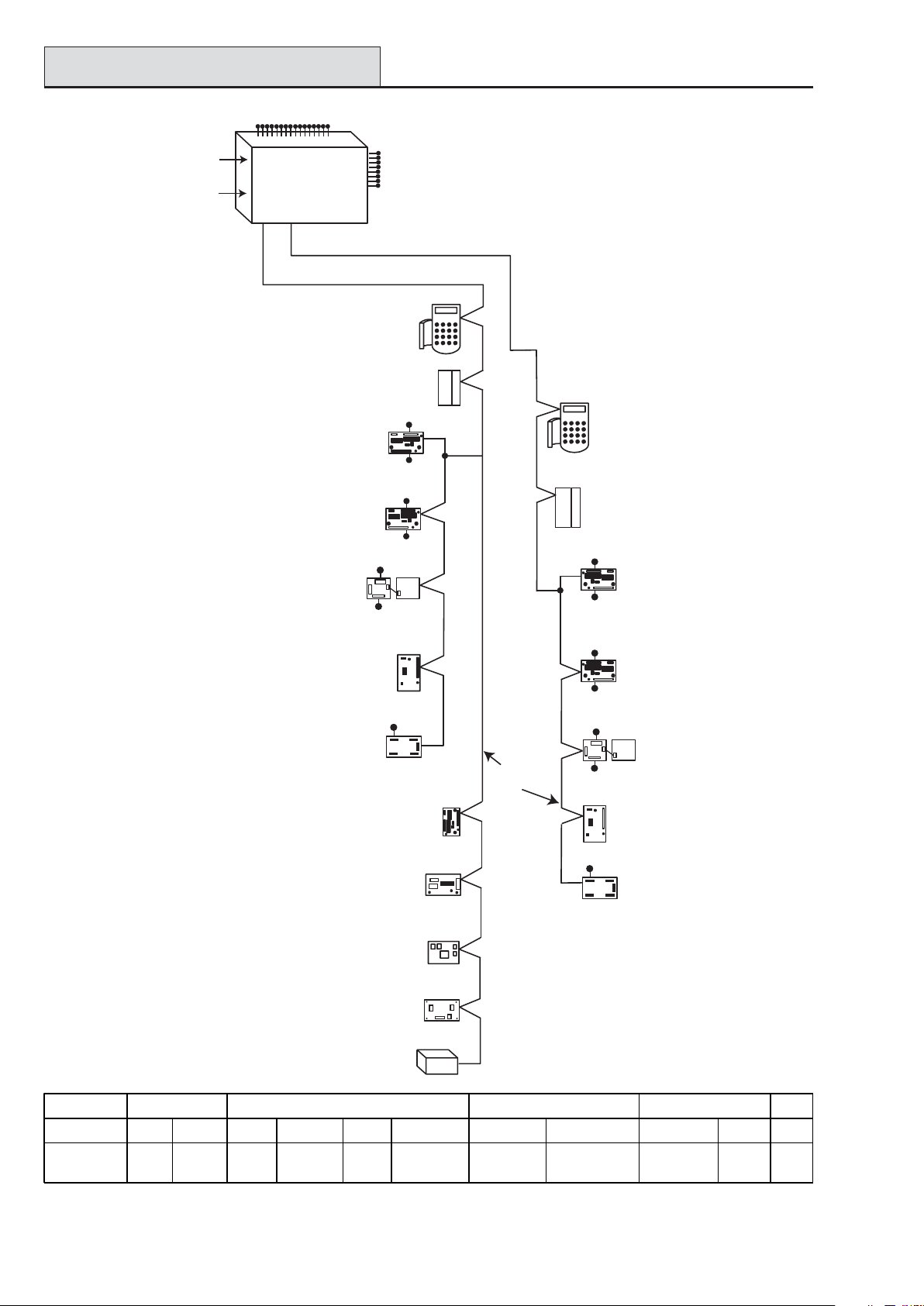

G3-144 Configuration

16 zones on board

Galaxy 3 Series Installation Manual

PSTN

(comm 1)

RS232

Serial Port

(comm 6)

NOTE:

RIOs, RF RIO's and

PSU's can be mixed on

the lines. The maximum

number of combined

modules is given in the

table below.

NOTE: Each Output Module can simulate

up to 4 RIO's (outputs only) depending

on DIP switch setting.

Valid addresses for the Output Module are

the same as standard RIO's.

NOTE:

The Telecom, Printer Interface,

RS232, Ethernet and ISDN

modules can only be

connected to line 1.

If a Telecom module is attached,

keypad address E cannot be

connected to line 1(address E is

shown as 18 on the system).

If an RS232 module is attached,

keypad address D cannot be

connected to line 1 (address D is

shown as 17 on the system).

If an Ethernet module is attached,

keypad address B cannot be

connected to line 1 (address B is

shown as 15 on the system).

If an ISDN module is attached,

keypad address C cannot be

connected to line 1 (address C is

shown as 16 on the system).

on board

telecom

Galaxy 3-144

area

Line

Line

12

NOTE:

Valid addresses for the

*

keyprox are:

Line 1 (0, 1 & 2).

Line 2 (0, 1, 2, & 3 ).

This sets the address for both

the keypad and card reader

parts of the keyprox.

*

Certain keypad and

max addresses can

be replaced by a

combined keyprox unit.

Smart PSU (8)

P015

Power Unit (8) P025

or

Power RIO (8) P026

Output Module (4) C078

8 outputs

on board

Cable run 1 km (max)

K

eypads (8)

*

CP027/

Keyprox (3)

CP028

Max (4)

*

MX03

4 outputs

RIO (8)

C072

8 zones

OR

4 outputs

8 zones

OR

4 outputs

8 zones

OR

RF RIO Module (8)

C076

4 - 16 outputs

Telecom Module (1)

E062 (comm 5)

RS232 Module (1)

E054 (comm 2)

ISDN Module (1)

E077 (comm 3)

Ethernet Module (1)

E080 (comm 4)

Printer Interface (1)

A134/A161

Twisted Pair

Screened Cable

W002

*

Max (4)

MX03

Keypads (8)

*

CP027/

Keyprox (4)

CP028

4 outputs

8 zones

4 outputs

8 zones

4 outputs

8 zones

RF RIO Module (8)

C076

4 - 16 outputs

RIO (8)

C072

OR

Smart PSU (8)

P015

OR

Power Unit (8) P025

or

Power RIO (8) P026

OR

Output Module (4)

C078

On-board RIOs/ Smart PSUs/EN51 PSU Keypads Keyprox MAX

Galaxy Panel Zones Outputs Poss. Address Zones Outputs Poss. Address Poss. Address Poss.

144 (line 1)

(line 2)

16 8 8

8

1 - 8

0 - 7

64

64

32

32

8

8

0 - 2, B, C, D, E, F

0 - 6, F

3

4

0-2

0-3

4

4

Figure 2-2. Galaxy 3-144 System Configuration

2-2

Page 13

Galaxy 3 Series Installation Manual

G3-520 Configuration

16 zones on board

NOTE:

Valid addresses for the

*

keyprox are:

Line 1 (0, 1 & 2).

Lines 2, 3 & 4 (0-6).

This sets the address for both

the keypad and card reader

parts of the keyprox.

Certain keypad and

*

max addresses can

be replaced by a

combined keyprox unit.

NOTE:

RIOs, RF RIO's and

PSU's can be mixed on

the lines. The maximum

number of combined

modules is given in the

table below.

NOTE: Each Output Module can simulate

up to 4 RIO's (outputs only) depending

on DIP switch setting.

Valid addresses for the Output Module are

the same as standard RIO's.

NOTE:

The Telecom, Printer Interface,

RS232, Ethernet and ISDN

modules can only be

connected to line 1.

If a Telecom module is attached,

keypad address E cannot be

connected to line 1(address E is

shown as 18 on the system).

If an RS232 module is attached,

keypad address D cannot be

connected to line 1 (address D is

shown as 17 on the system).

If an Ethernet module is attached,

keypad address B cannot be

connected to line 1 (address B is

shown as 15 on the system).

If an ISDN module is attached,

keypad address C cannot be

connected to line 1 (address C is

shown as 16 on the system).

Smart PSU (15)

P015

Power Unit (15) P025

or

Power RIO (15) P026

Output Module (4) C078

RF RIO Module (15)

C076

PSTN

RS232

Serial Port

Cable run 1 km (max)

K

eypads (8)

*

CP027/

Keyprox (3)

CP028

Max (8)

*

MX03

4 outputs

RIO (15)

C072

8 zones

OR

4 outputs

8 zones

OR

4 outputs

8 zones

OR

4 - 16 outputs

Telecom Module (1)

E062 (comm 5)

RS232 Module (1)

E054 (comm 2)

ISDN Module (1)

E077 (comm 3)

Ethernet Module (1)

E080 (comm 4)

Printer Interface (1)

A134/A161

on board

telecom

Galaxy 3-520

area

Line Line Line Line

1234

Lines 2, 3 and 4 have the same configuration

Cable run 1 km (max)

Max (8)

*

MX03

Twisted Pair

Screened Cable

W002

8 outputs

on board

Keypads (8)

*

CP027/

Keyprox (7)

CP028

4 outputs

8 zones

4 outputs

8 zones

4 outputs

8 zones

RF RIO Module (16)

C076

4 - 16 outputs

RIO (16)

C072

OR

Smart PSU (16)

P015

OR

Power Unit (16) P025

or

Power RIO (16) P026

OR

Output Module (4)

C078

On-board RIOs/ Smart PSUs/EN51 PSU Keypads Keyprox MAX

Galaxy Panel Zones Outputs Poss. Address Zones Outputs Poss. Address Poss. Address Poss.

520 (line 1)

(lines 2, 3, 4)

16 8 15

1 - 9, A - F

16

0 - 9, A - F

120

384

60

64

8

8

0 - 2, B, C, D, E, F

0 - 6, F

3

7

0-2

0-6

8

8

Figure 2-3. Galaxy 3-520 System Configuration

2-3

Page 14

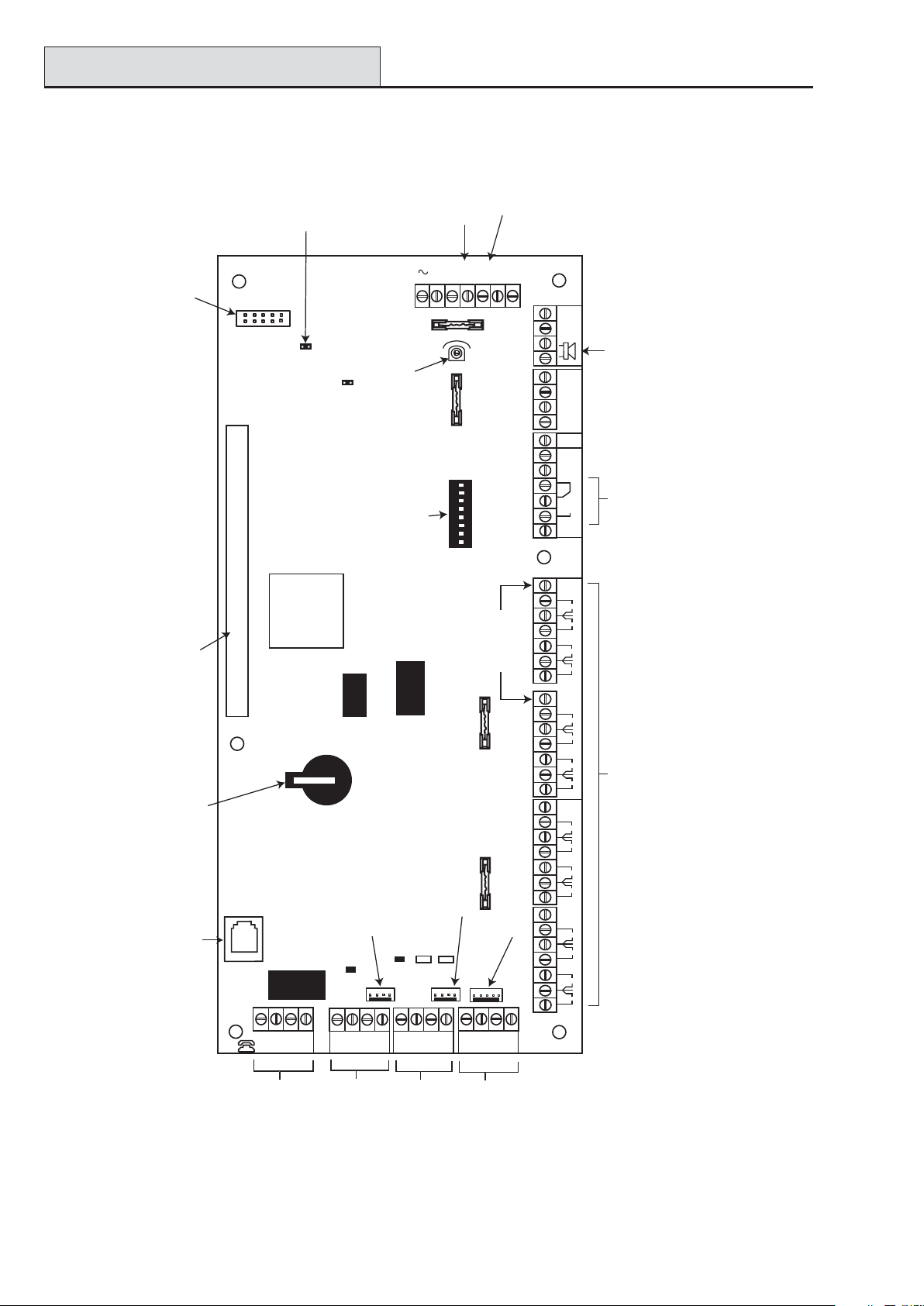

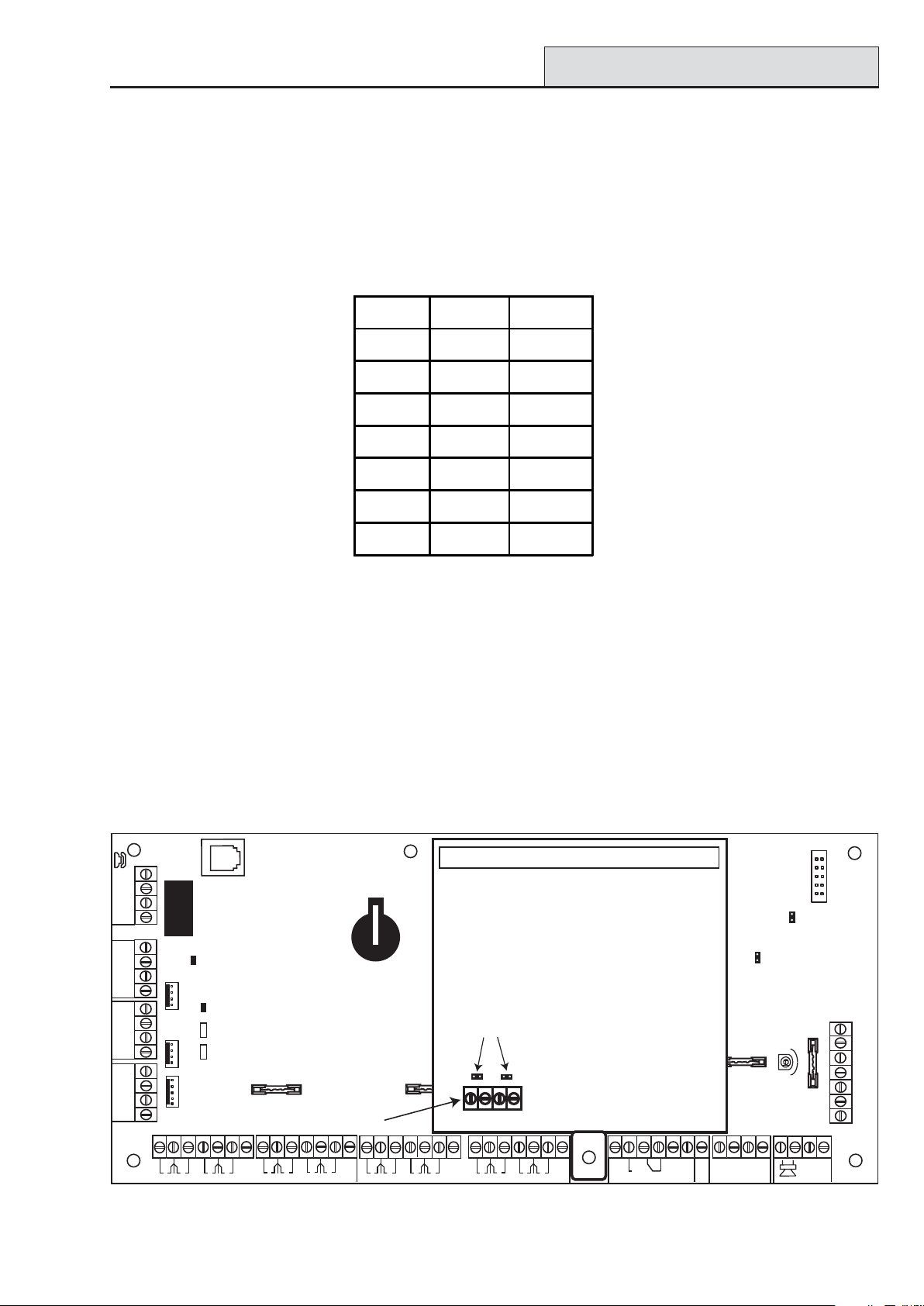

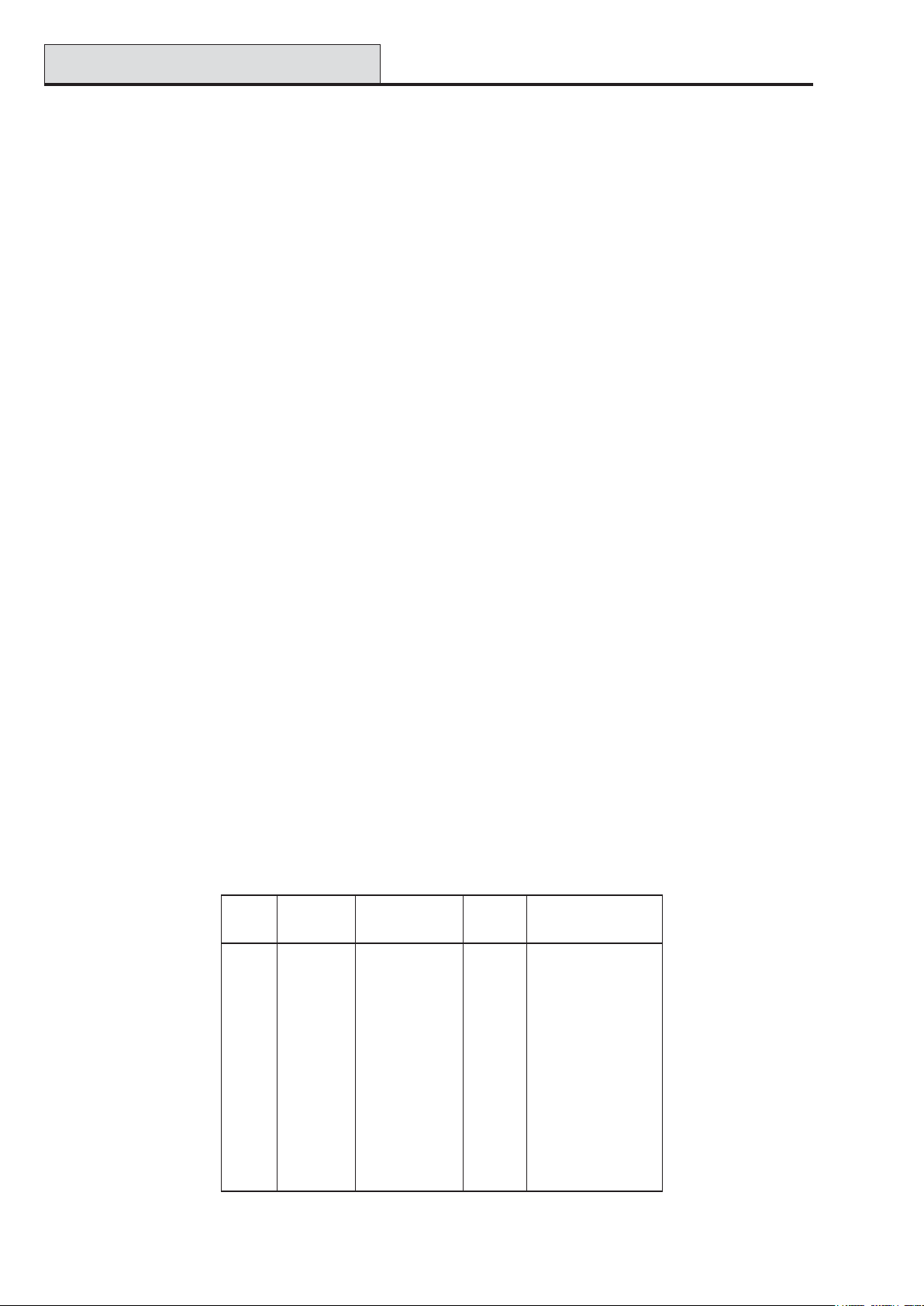

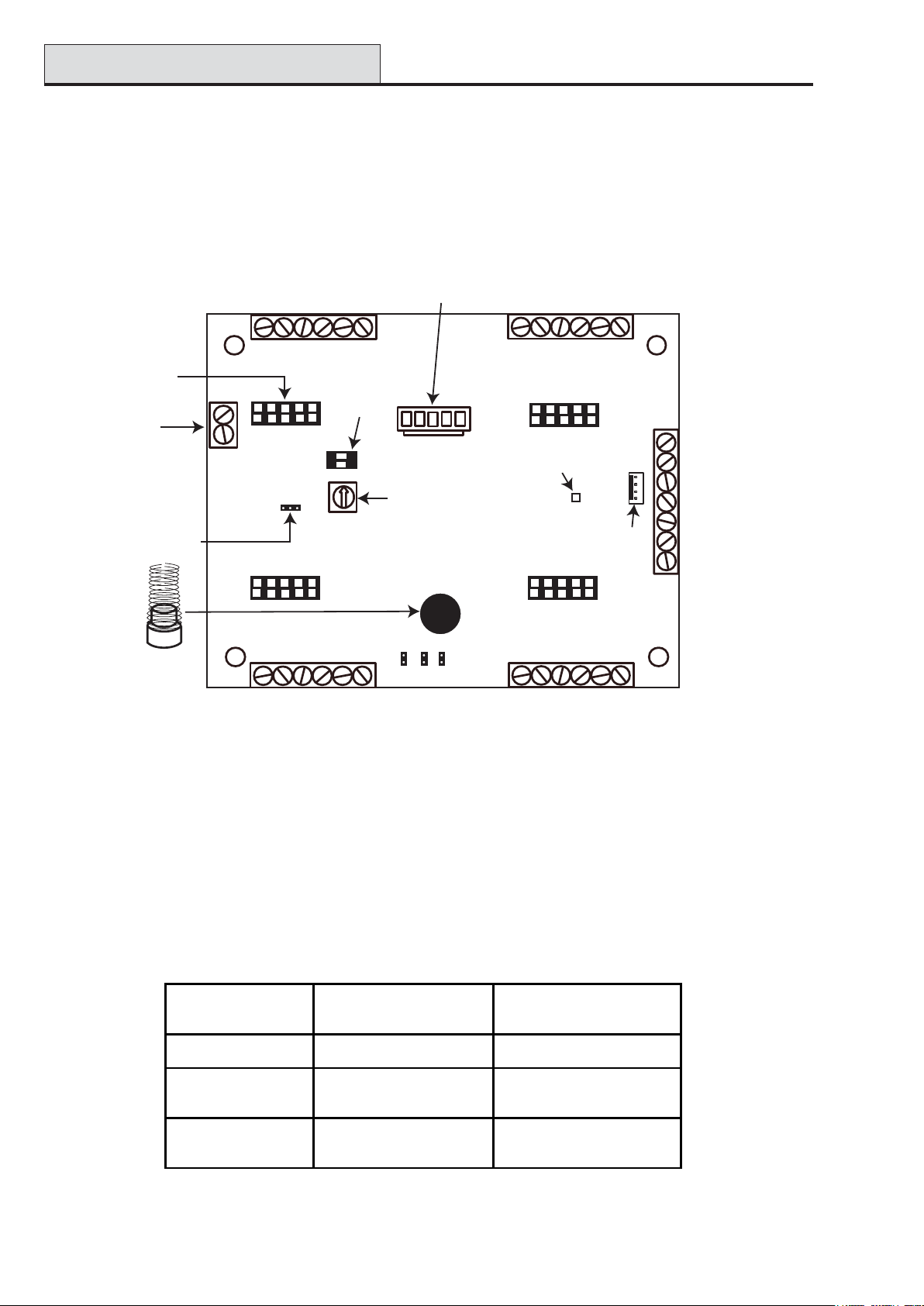

PCB Layout

ON

PCB Layout

SPI

Program

Header

Jumper Lead

for off-wall

tamper switch

TAMPER

OFF WALL

BATTERY

START UP

Galaxy 3 Series Installation Manual

Battery

TAMP

LID

-BAT

F2

SWITCH

7 8

6

4 5

2 3

1

SW3

terminals

14.5

+BAT

G

N

D

AUX

TAMP

External

loudspeaker

Relay

Output

N/C

C

N/O

4

2

RIO 1

13

+12V

4

3

RIO 0

2

1

BAT

Horn output

volume control

Pull-up switches

Leads for

lid tamper

AC

F1

BELL

RIO

ON

microswitch

Expansion card

interface

Memory

backup

battery

Telecom

Socket

LINE

ABAB

PHONE

MICRO

PROCESSOR

+12V

8

0V

7

6

+12V

+12V

8

7

6

5

+12V

0V

5

RIO 1

4

0V

3

2

0V

1

0V

0V

RIO 0

4

0V

3

2

0V

1

16 on-board zones

3-144/3-520 only

AUX2 (3-144/3-520 only)

FLASH

F3

SRAM

F4

Engineer socket

(RS485 Line 2)

LED2 (for RS232)

+12V

AUX1

RS232 Port socket

TX

CTS

RX

RTS

Engineer socket

(RS485 Line1)

LED1(for Telecoms)

GND

+12V

LK5

B2

A2

GND

LK3

A1

B1

OR

Zones 1-8 (RIO 1 line 1 (switch SW3-8 OFF))

Zones 1-8 (RIO 1 line 0 (switch SW3-8 ON))

NOTE: Zones 1-8 (RIO 0 line 1)

Fuse AUX2 controls

RS485 line 2, RIO 1 (zones 1-8)

NOTE: Fuse AUX1 controls

RS485 line 1, RIO 0 (zones 1-8)

Telecom

Connect

RS485

line 1

RS232 Port

RS485 line 2

(3-144/3-520 only)

Figure 2-4. PCB Layout

2-4

Page 15

Galaxy 3 Series Installation Manual

RS485 Expansion Module

The 7 transistorised outputs on the Galaxy 3 Series can be configured to open collectors by setting the dip

switch SW3 to the OFF position.

NOTE: Output 2 on RIO 0 (relay output) is not affected.

The following table shows which outputs are controlled by which switches.

(SW3) RIO Output

10 1

20 3

30 4

411

512

613

714

T able 2-1. SW3 T ransistorised Outputs Control

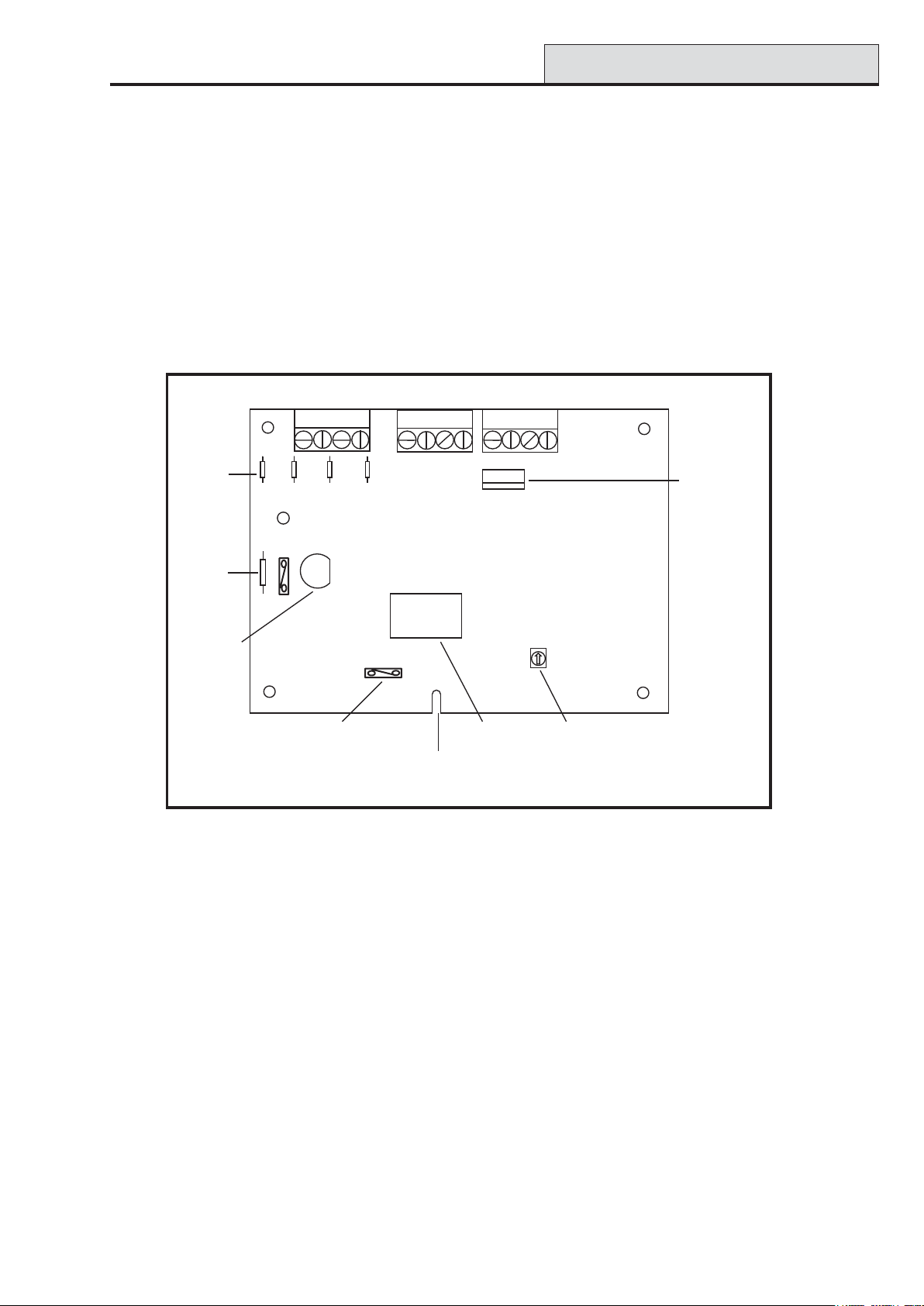

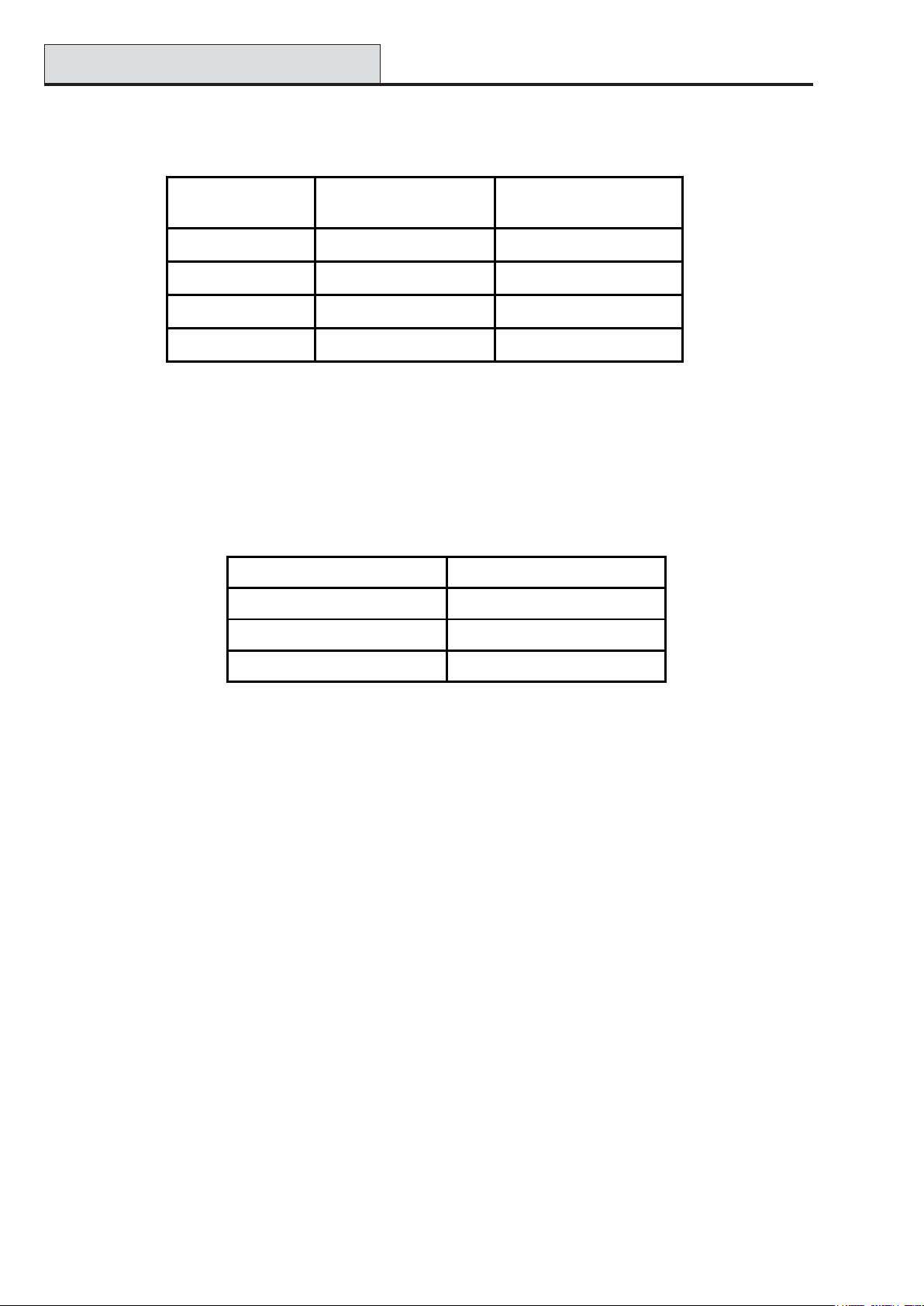

RS485 Expansion Module (G3-520 only)

The RS485 Expansion Module can be attached to the G3-520 to give 2 extra RS485 (AB) lines.

The Expansion module must be wired in a daisy-chain configuration. That is, the A line from the previous

module is connected to the A3 or A4 terminal of the Expansion Module.

The RS485 (AB) line must have a 680 ohm resistor fitted across the A and B terminals of the last module on

the line. If two lines are connected, both ends must be terminated with a 680 ohm resistor and the appropriate

link (LK1 or LK2) removed.

RS485

EXPANSION

MODULE

Jumpers

LK1

LK2

Twin

RS485

B3

A4

B4

lines

2

1

0V

+12V

4

3

0V

RIO 0

6

5

0V

+12V

8

7

0V

2

1

3

0V

A3

AUX

+12V

4

0V

RIO 1

6

5

0V

+12V

8

7

0V

1

4

3

2

RIO 0

+12V

4

2

13

RIO 1

TAMP

G

N

D

Figure 2-5. RS485 Expansion Module

2-5

Page 16

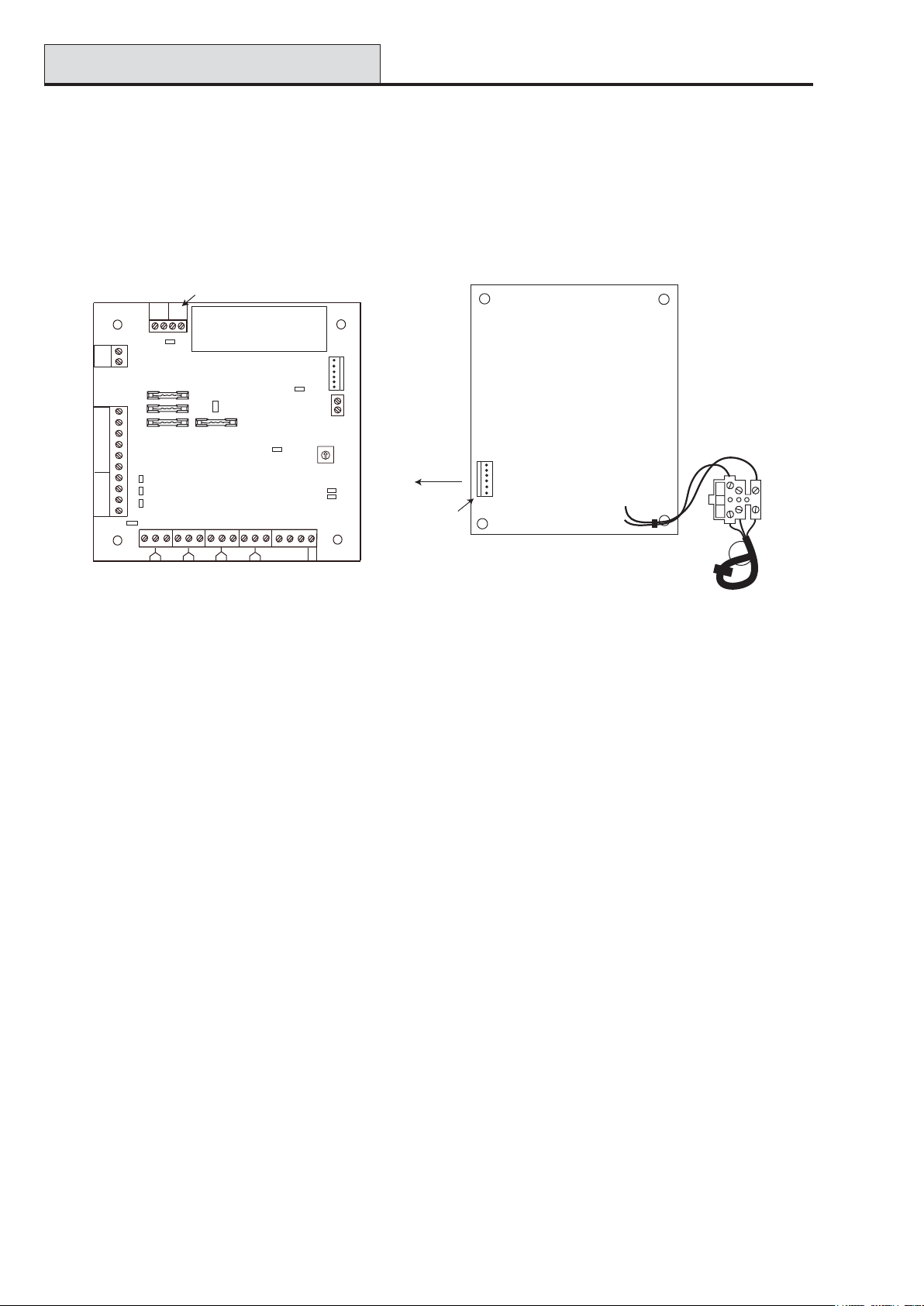

Installation Recommendations

Galaxy 3 Series Installation Manual

System Installation and Wiring

The installation and wiring must be performed by a competent engineer. For permanently connected equipment, a readily accessible disconnect device must be incorporated in the fixed wiring having contact separation

of at least 3 mm on each pole. The Galaxy 3 Series control panel must be connected to the a.c. mains supply

(230/240 Va.c. 50 Hz) via a fused connection outlet.

The fuse in the mains outlet must not exceed 3A.

WARNING: A means of isolation from the mains supply must be provided within 2 metres of

the control panel. Where live and neutral supplies can be identified, a fused spur

with a 3 amp fuse, must be fitted on the live circuit. Where live and neutral circuits

cannot be reliably identified, 3 amp fuses must be fitted to both circuits.

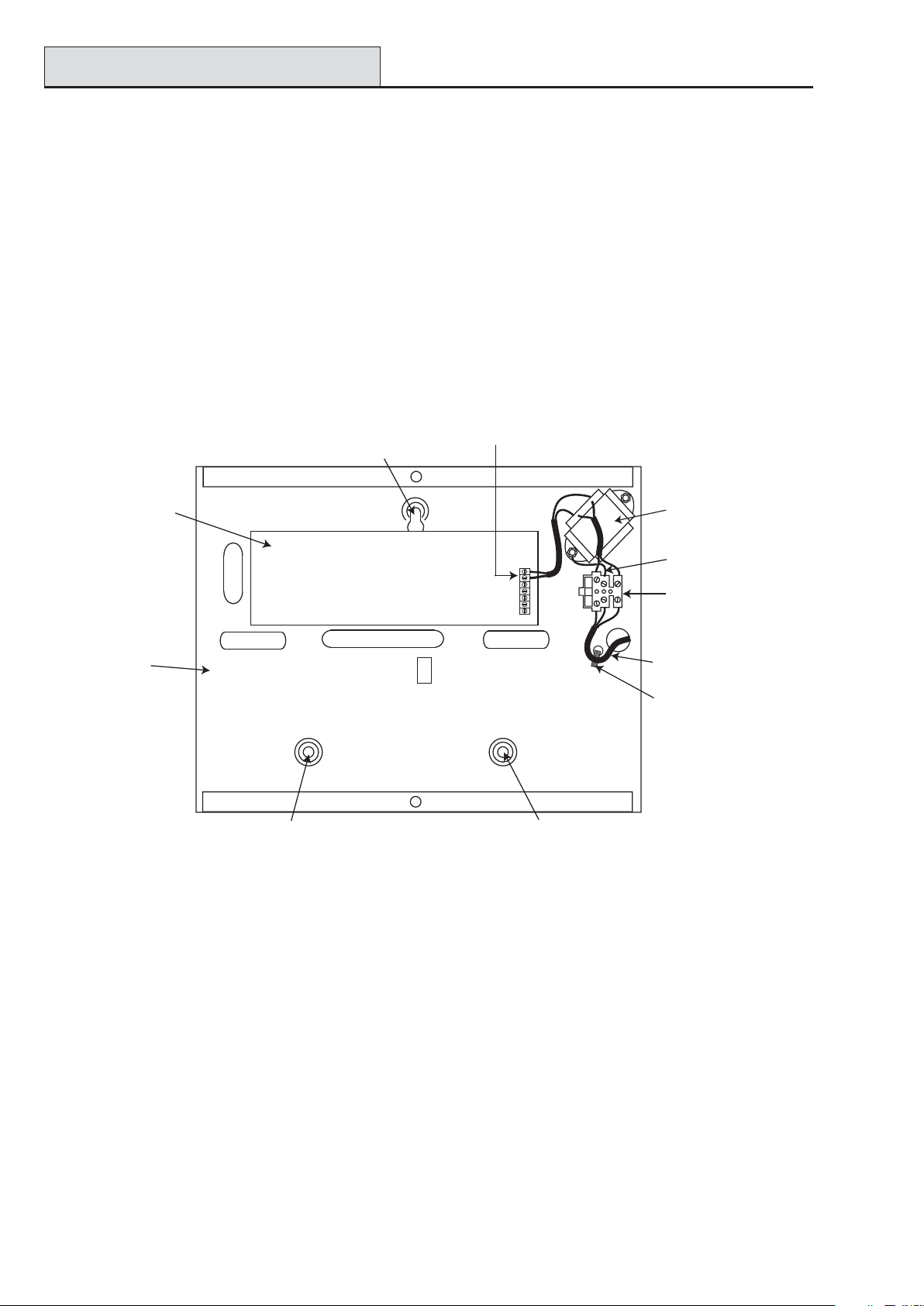

Route the mains cable through the hole on the right hand side of the enclosure base. Securely anchor the

cable to the box using the tie-wrap as shown in the following Figure:

Enclosure

base

AC connect

Attaching hole

PCB

Attaching hole

Keyhole

slot (top)

Figure 2-6. Securing the Mains Cable to the Enclosure Base

Mains

transformer

Earth wire

Terminal

block

Mains cable

Tie wrap

Secure the panel base to the wall using three 1.5" No. 8 round head steel screws through the holes provided.

The mains cable used must be a three core type (with green/yellow earth insulation) of adequate current

carrying capacity .

NOTE: The mains cable must satisfy the requirements stated in BS6500.

Connect the mains cable to the mains terminal block as follows:

• blue wire to the terminal marked N (Neutral)

• green/yellow wire to the terminal marked (Earth)

• brown wire to the terminal marked L (Live)

NOTE: No other connections to the mains connector are permitted.

All wiring must be in accordance with the latest edition of the IEE W iring Regulations, BS7671 (Requirements

for Electrical Installations).

2-6

Page 17

Galaxy 3 Series Installation Manual

System Wiring

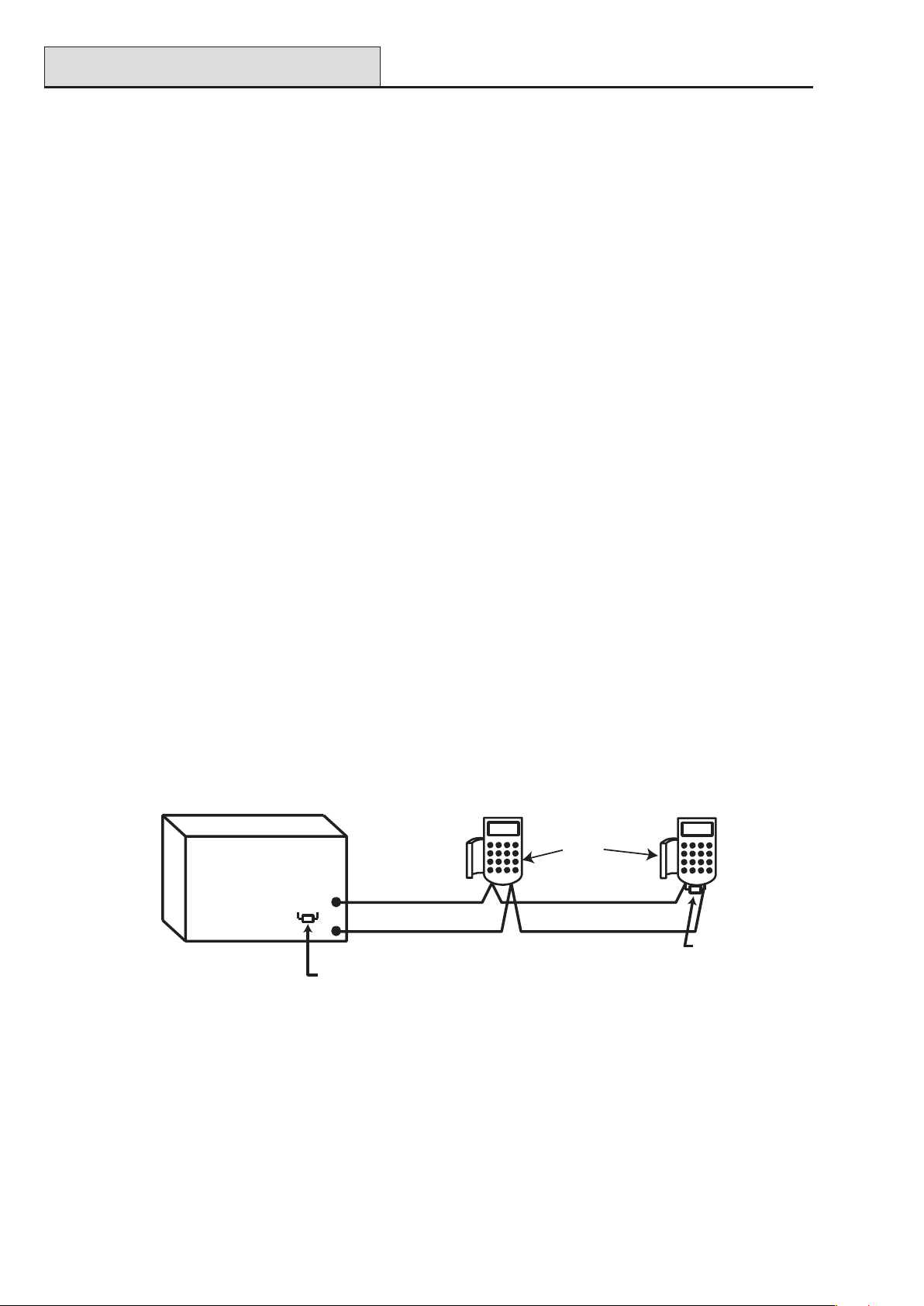

Connecting the Galaxy 3 Series to the PSTN

The T elecommunications Network V oltage (TNV) port (terminals A and B on PCB) must be permanently

connected (hard-wired) to the PSTN via a BT master socket, refer to Figure 2-7.

Note: If the BT master socket is the newer type (NTE5/CTE5), then the connection can be carried out by the

installation engineer . If the BT master socket is not an NTE5/CTE5, then the network operator must make the

connection.

Telecom

Socket

RJ45

Plug

PHONE

BT Master socket (

NTE5/CTE5

).

LINE

ABAB

BT Secondary socket (

NTE5/CTE5

).

Incoming

PSTN

Line

2

5

5

2

Figure 2-7. Connecting the Galaxy 3 Series to the PSTN

NOTES: 1. T erminals 2 and 5 on the BT Master Socket must be hard-wired to LINE A and B

terminals on the Galaxy 3 Series PCB. The connection is polarity independent.

2. It is strongly recommended that the Galaxy 3 Series panel is the only device on the line.

3. If another device is to be connected to the line, connect the PHONE terminals on the PCB

to terminals 2 and 5 on a second BT Master Socket.

There are two methods of connecting the on-board T elecom Module to the PSTN:

Method 1

Using cable suitable for connection to 2.8 mm diameter screw terminals, strip back approximately 20 mm of

the outer sheath and then remove approximately 4 mm of the insulation from the wires to be connected to the

Galaxy 3 Series PCB.

Connect terminals 2 and 5 on the BT Master socket across the LINE A and B terminals on the Galaxy 3

Series PCB, see Figure 2-7.

Method 2

Use a standard cable with RJ45 plug on one end and plug into the telecom socket on the Galaxy 3 Series

PCB. Connect the other end of the cable to the BT Master socket as described in Method 1.

2-7

Page 18

System Wiring (cont’d)

Galaxy 3 Series Installation Manual

Connecting Additional Telecom Apparatus

A BT secondary socket, allows additional telecom apparatus to be connected in series with the on-board

telecom module. Connect the PHONE terminals A and B on the PCB to the terminals on the BT secondary

socket. See Figure 2-7.

Line Monitoring

Under normal idle state conditions, the on-board T elecom Module monitors the RS485 line. The communication status is indicated by the state of the red LED (LED1) as shown in the following table:

ETATSDELNOITACIDNI

FFODELeludomotylppus.c.doN

s9.0-FFO,s10-NOnoitacinummoclamroN

llacfodnetaeslupelgniSnoita

llacmralafodnetagnihsalFnoitacinummoCdeliaF

yxalag,gnirotinommralagnirudnO

SMSdnadlog

,gnirotinommralagnirudgnirekcilF

SMSdnadlogyxalag

sehsalFgnigniReniL

langisgnignirhtiwemitni

dellaidsitigidhcaesasesluP

T able 2-2. Comms S tatus

cnummoclamroN

noitacinummoClamroN

noitacinummocrooP

nehwnoitacidnilamroN

llacgnikam

2-8

Page 19

Galaxy 3 Series Installation Manual

Stand-by Battery

St and-by Battery

The Galaxy 3 Series control panels can accommodate up to 2 x 17 Ahr batteries. Ensure that the battery

connector leads on the control panel Powers Supply Unit (PSU) are connected to the correct terminals on the

battery .

CAUTION: There is a risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

lenaPlortnoCyrettaB

TAB-lanimretev-

TAB+lanimretev+

T able 2-3. Battery/Control Panel connections

Battery St art-up

The system can be powered up via the Battery Start-up jumper if there is no AC power . T o do this, short

out the Battery Start-up jumper for the duration of the configuration process only . Never leave the Battery

Start-up connected or else deep discharge of the Stand-by Battery will occur .

On-Board Power Supply Unit

The on-board Power Supply Unit (PSU) supplies and monitors power to the system and peripherals. The

following table shows the fuse name and value in amps.

G3-144/G3-520: The Galaxy 3 Series control panel contains four fuses. Details are given in the table below .

NOTE: The G3-48 does not require fuse AUX2.

FU S E NAME VALUE (AMPS ) MONIT OR S TYPE

AUX1 1.0 RS485 Line 1, RIO 0, Zones 1-8: +12V,

on-board comms

AUX2 1.0 RS485 Line 2, RIO 1, zones 1-8 +12V 20 mm, anti-surge

BATT 1.6 Battery 20 mm, anti-surge

BELL 1.0 Outputs RIO 0 1-4, RIO 1 1-4, Horn output 20 mm, anti-surge

T able 2-4. On-board PSU Fuses

Power Monitoring Characteristics: Low battery level: 1 1.2V

Deep discharge protection: 10.5V

Overvoltage protection: 14.7V

G3-48

The PSU total capacity is 1.5A. Internally the PSU

is split in two in order to ensure sufficient current is

always available for stand-by battery recharge.

The PSU capacity is broken down as follows:

G3-144/520

The PSU total capacity is 2.5A. Internally the PSU is

split in two in order to ensure sufficient current is always available for stand-by battery recharge.

The PSU capacity is broken down as follows:

20 mm, anti-surge

• Battery: 0.75A

• Control PCB: 0.25A

• AUX +12V : 0.5A

The PSU is available for zones/outputs and peripherals.

• Battery: 1.25A

• Control PCB: 0.25A

• AUX +12V : 1.00A

2-9

Page 20

Memory

Galaxy 3 Series Installation Manual

Memory

The Galaxy 3 Series control panel is fitted with a memory chip with its own battery backup on the main PCB.

This allows the panel to retain the system configuration, programming details and the event log for up to a year

when both the mains power and standby battery have been disconnected. The memory backup battery must

be kept in place to retain the memory during a mains failure. Re-apply power, this is known as a warm start.

T o completely erase the system memory and return to the default settings, place a piece of thin card between

the retaining clip and the memory backup battery then remove all power to the PCB for one minute. Re-apply

power and remove the card. This is known as a cold start.

The memory backup battery shoud be replaced every 5 years.

CAUTION: There is a risk of explosion if the battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

CAUTION: Do not overstress the retaining clip when removing and installing the backup

battery. The clip must maintain a firm pressure on the backup battery at all times.

RS485 Data Communication Bus (AB Lines)

Communication between the Galaxy control panels and the modules attached to the system takes place on the

AB lines. The communication protocol is RS 485 format. The control panel constantly monitors the modules

attached to it. A break in the communication from any of the modules generates a module tamper alarm

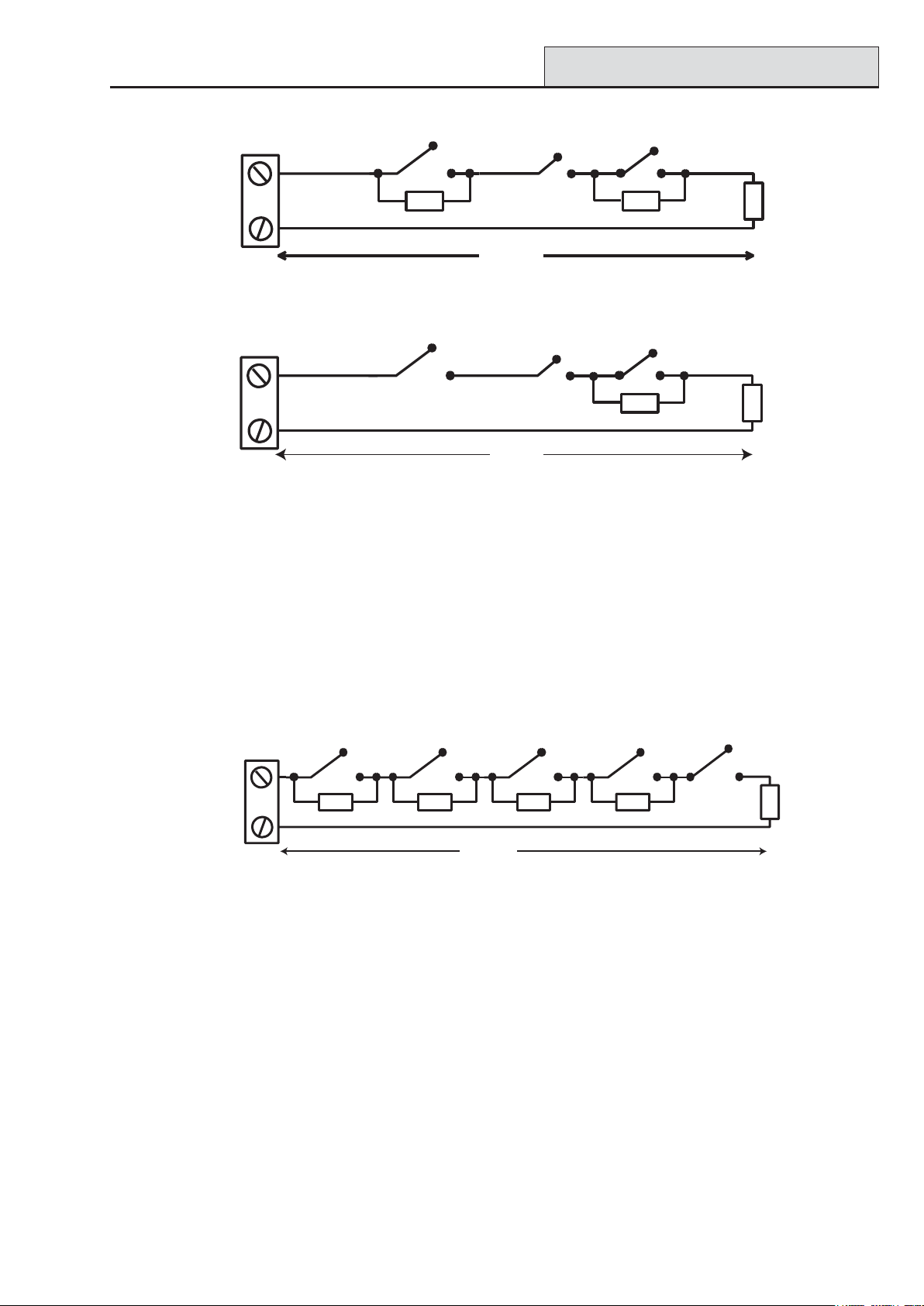

RS485 Wiring Configurations

The system must be wired in a daisy-chain configuration. That is the A line from the previous module is

connected to the A terminal of the current module and then on to the A line of the next module.

The RS485 (AB) line must have a 680 Ω resistor fitted across the A and B terminals of the last module on the

line. If two lines are connected, both ends must be terminated with 680 Ω resistors and the appropriate link

(LK3 or LK5) removed.

Keypad/Keyprox

OR

Galaxy

Control

Panel

680 Ω

A

A

B

Fit LK3/LK5 on PCB

Module

B

AB

680 Ω EOL

Figure 2-8. Daisy Chain Configuration

Each AB line can run in two directions from the control panel.

• Remove link LK3 (RS485 line1) or link LK5 (RS485 line2).

• Run two lines from the A and B terminals of the line.

• T erminate both Ends of Line (EOL) with a 680 ohm resistor .

NOTE: It is permissable to have different configurations on each line. For example, line 1 - Daisy chain;

line 2 - twin AB daisy chain.

2-10

Page 21

Galaxy 3 Series Installation Manual

RS485 Recommendations

Keypad/Keyprox

OR

Module

Keypad/Keyprox

OR

Module

Galaxy

Control

A

680 Ω EOL

B

Panel

A

B

Remove

LK3/LK5

B

A

680 Ω EOL

Figure 2-9. T win AB Line Daisy-Chain configuration

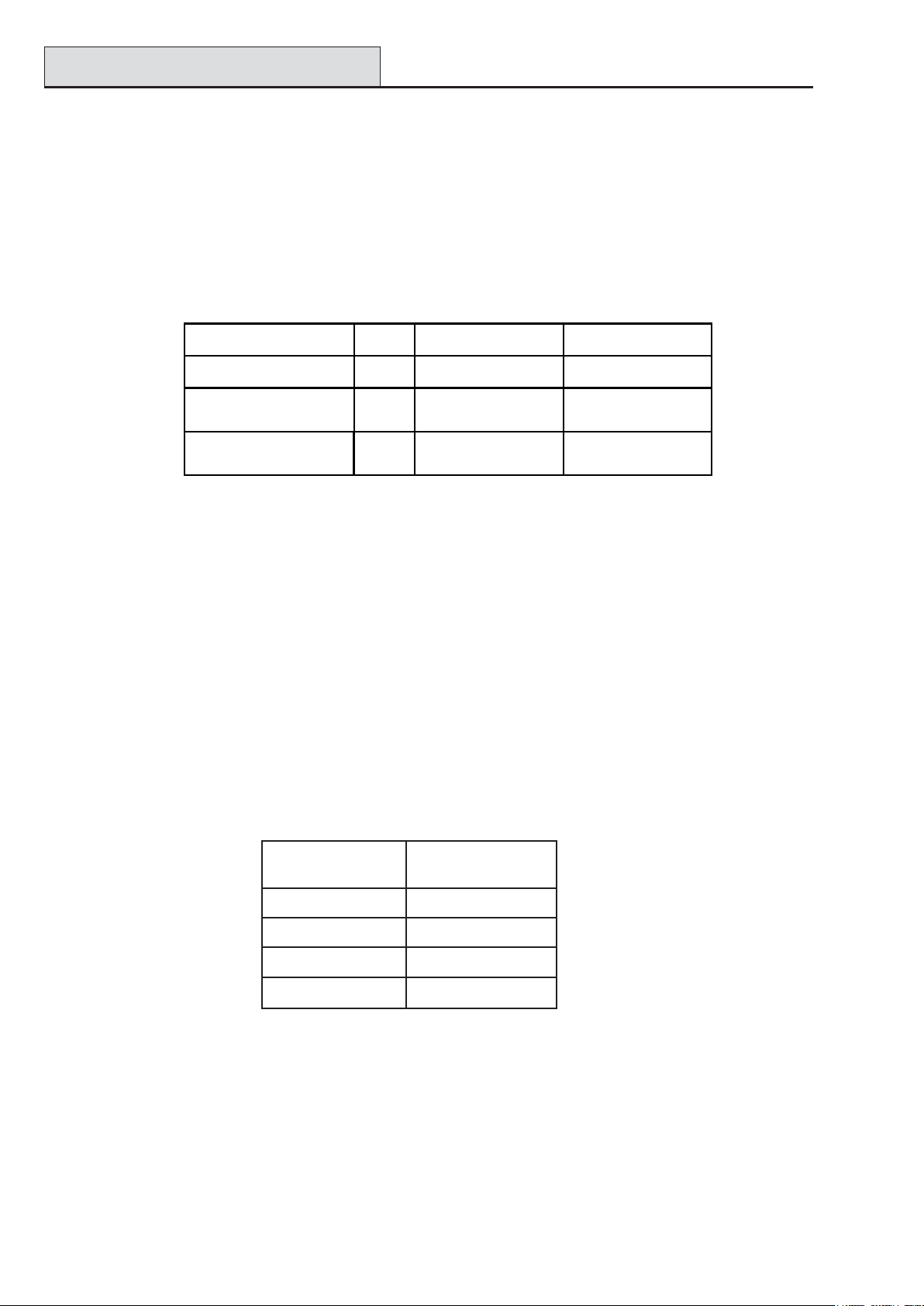

RS485 Wiring Recommendations

T o ensure that the system communicates at the maximum level of efficiency , the following recommendations

must be adhered to:

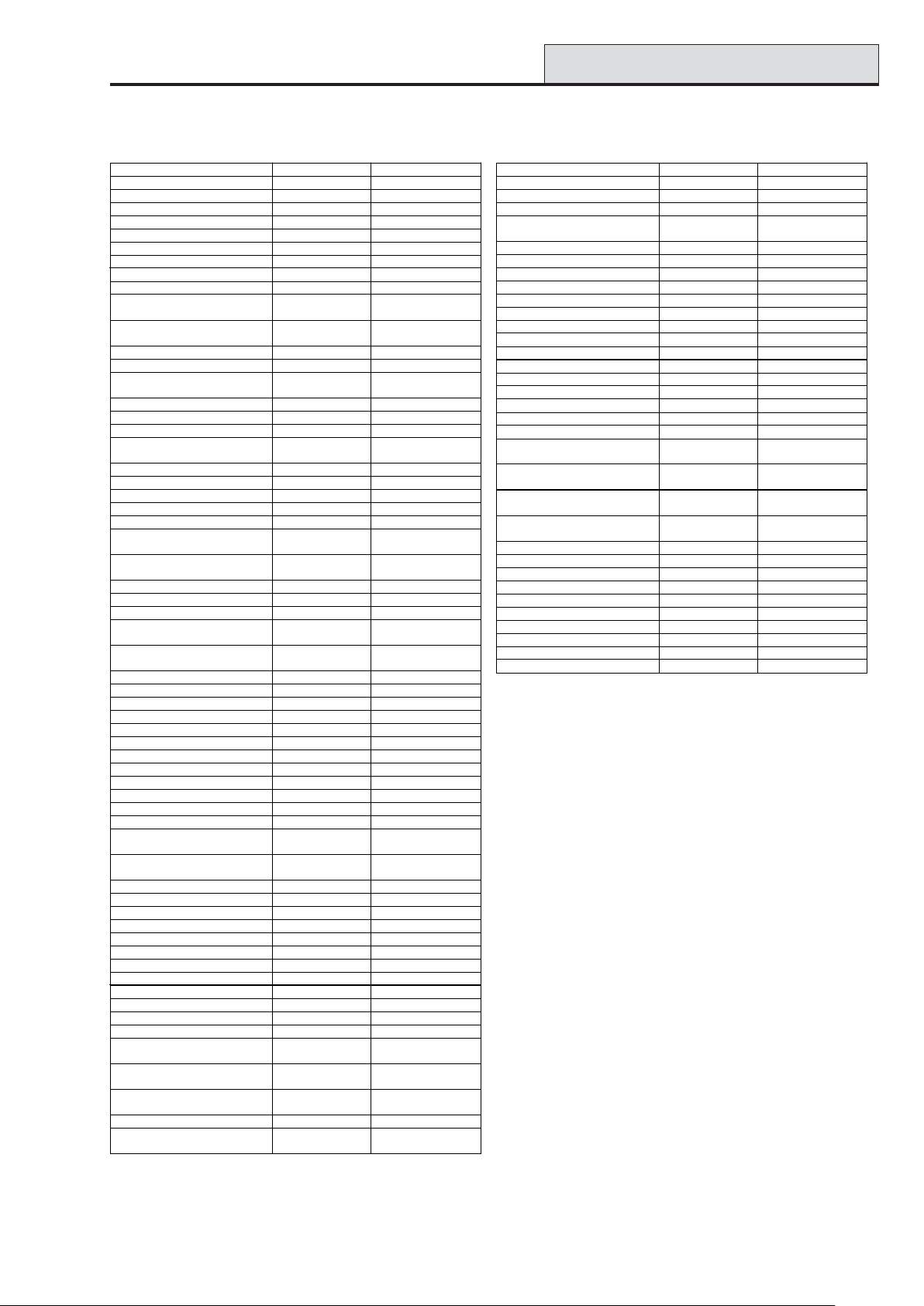

1. Each communication line can support 32 devices. The maximum number of devices on each line

are:

Keypads

Keyprox

RIO's/SPSU's

Output Mod ule

RF RIO

MAX

Galaxy 3-48

(Line 1 only)

8 8 per line 8 per line

3

4 8 per line

4 4 per line 4 per line

4 8 per line

4 4 per line 8 per line

Galaxy 3-144

(Lines 1-2)

3 (line 1)

4 (line 2)

Galaxy 3-520

(Lines 1-4)

3 (line 1)

7(lines 2, 3, 4)

15 (line1)

16 (lines 2, 3, 4)

15 (line 1)

16 (lines 2, 3, 4)

RS232

Telecoms

Printer

ISDN

Ethernet

1 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only)

1 1 (line 1 only) 1 (line 1 only)

T able 2-5. Communication Devices

2. The system must be wired in a daisy-chain configuration. Spur and star configurations must not

be used as they reduce the immunity to electrical interference.

3. The cable used to connect the RS485 (AB) line must be screened twisted pair (Part No. W002) or

Belden 8723 equivalent.

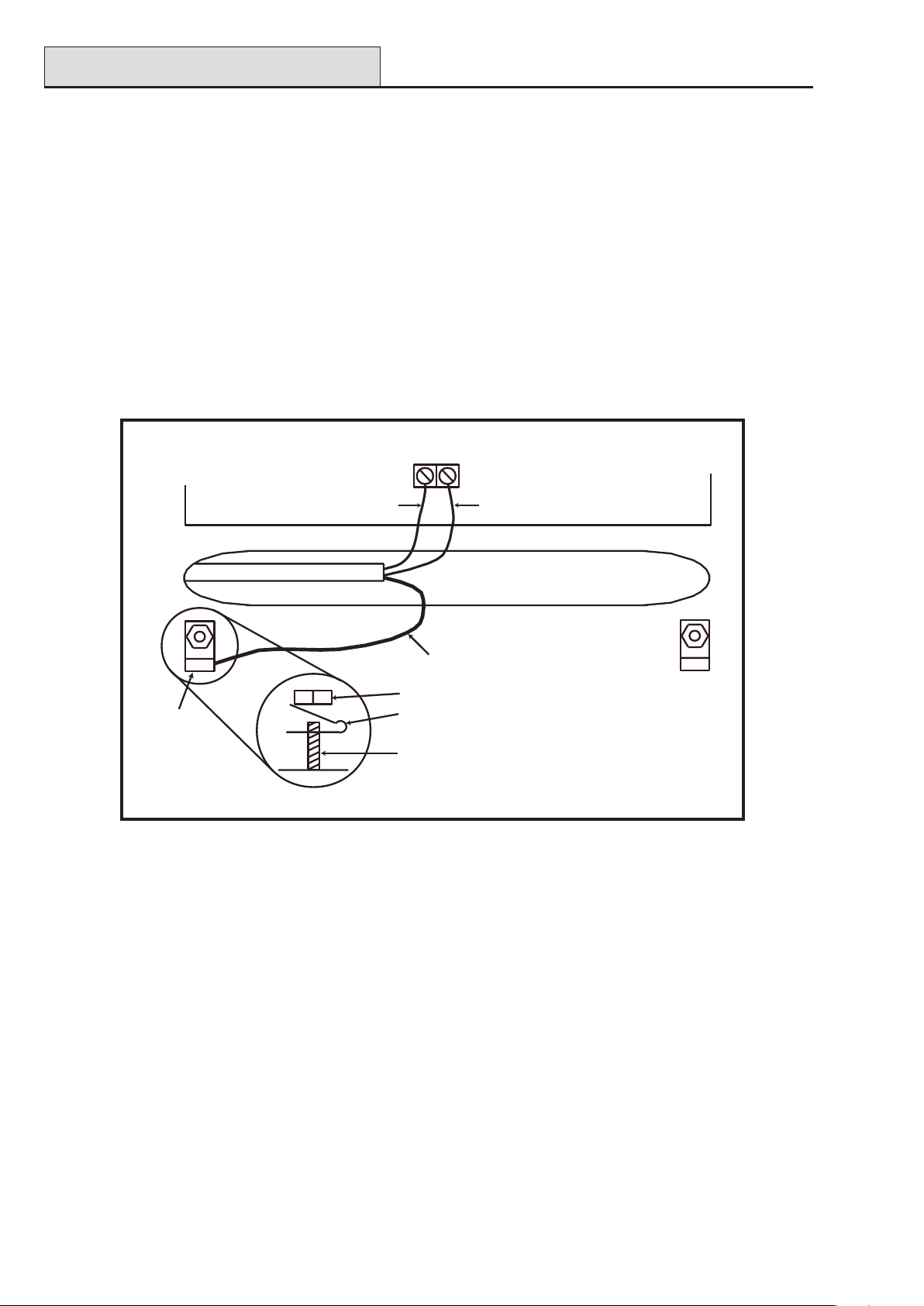

4. Shielded twisted pair cable, where used, is connected to the earthing pillar on the Galaxy control

panel using the P-clip and nut supplied (refer to Figure 2-10).

5. The RS485 (AB) line must have a 680 Ω resistor fitted across the A and B terminals of the last

module on the line. If twin lines are connected, both ends must be terminated with 680 Ω resistors and

the appropriate link on the control panel PCB must be removed (refer to figure 2-9).

2-11

Page 22

RS485 Recommendations

Galaxy 3 Series Installation Manual

6. There must only be a single AB pair of wires in each of the cables.

7. The minimum voltage level is 10.5 Vd.c. with 12.5 Vd.c. being the recommended working minimum.

8. The power supply in the Galaxy control panel and remote power supplies must not be connected

in parallel.

9. The 0 V of all remote power supplies should be connected in common to the 0 V of the Galaxy

control panel.

10. Ensure that any extension loudspeakers are not wired in the same cable as an AB pair of wires.

11. Where possible, ensure that the AB cable is at least 30 centimetres away from any other cables.

12. Where possible, ensure that the AB cable does not run parallel to other cables for extended

distances (maximum 5 metres).

AB connectors

P-clip

A

data line

RS 485 cable

Nut

P-clip

Earthing pillar

(threaded)

B

data line

Cable screen

Figure 2-10. Connection of cable screen using P-Clip

2-12

Page 23

Galaxy 3 Series Installation Manual

Zone Addresses

Zones

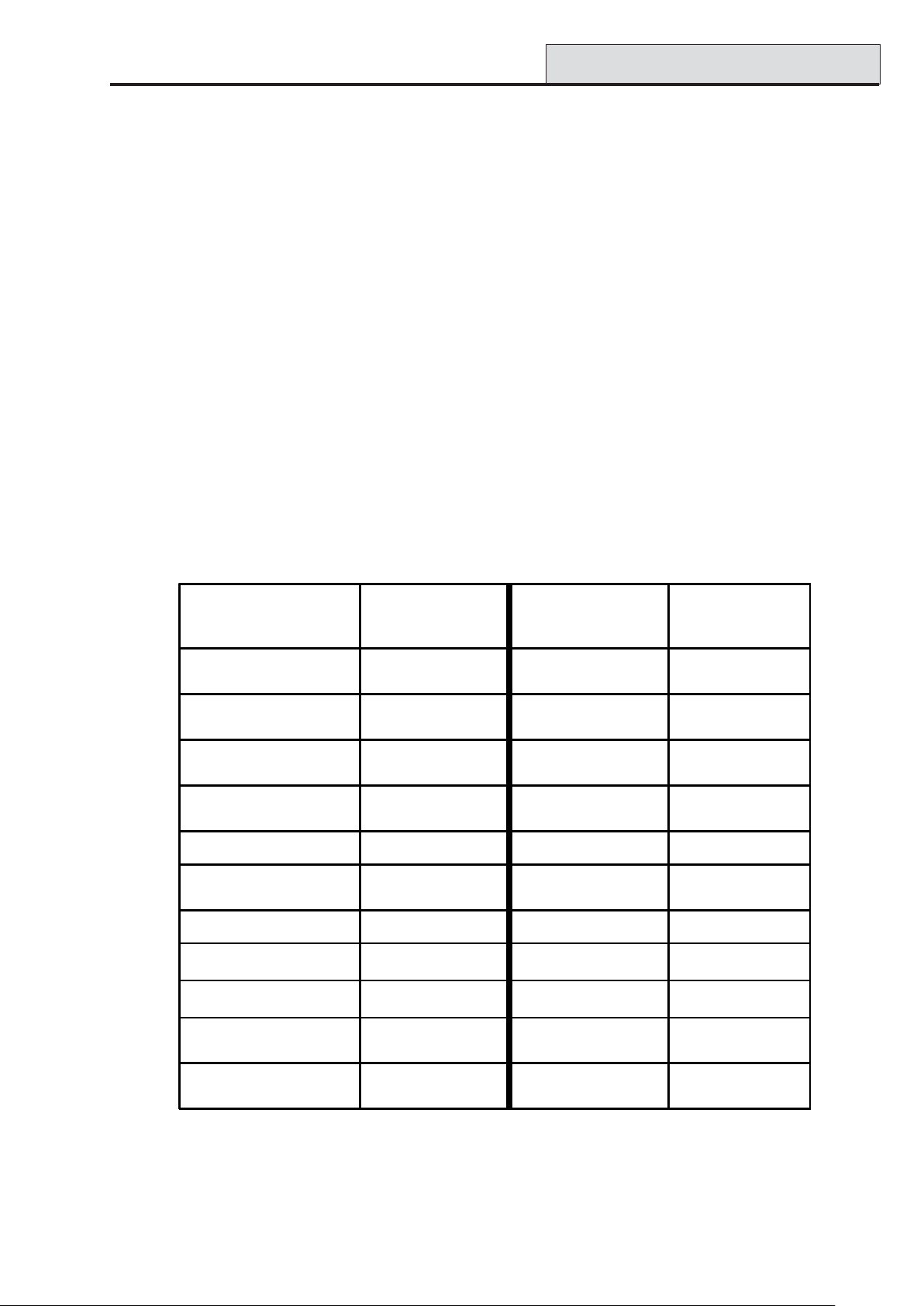

The default setting for the zones on the Galaxy 3 Series are shown in the following table:

Galaxy

Panel

3-48 Final Exit Intruder

3-144 Final Exit Intruder

3-520 Final Exit Intruder

Zone 1001 Zone 1002

Remaining

Zones

T able 2-6. Default Zone Functions

Zone Addresses

Each zone has a four digit address; 1004, 4136. The address is made up of three reference numbers as shown

in the following figure:

Example: 3057

3

05 7

Represents Panel

Line No.

GALAXY

G3 PANEL

1 2 3 4

Represents

RIO Address

RIO

ADDRESS 05

Represents

Zone No. 1-8 on

RIO

Figure 2-1 1. Zone Addr esses

For example, zone 3057 is the detector connected to line 3, RIO 05, zone 7.

ZONE 7

2-13

Page 24

RIO Switch

Galaxy 3 Series Installation Manual

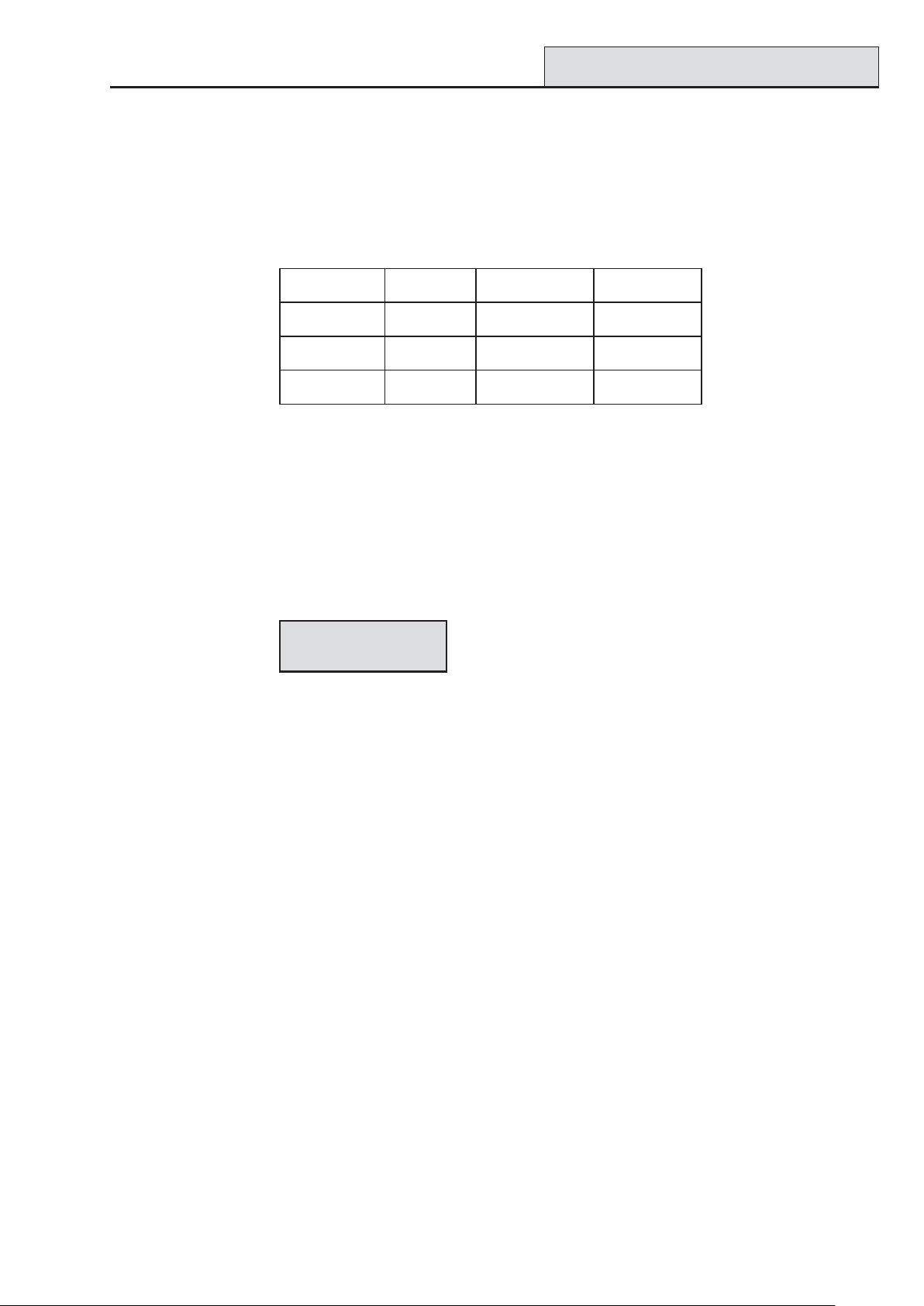

Zone Addressing with Onboard RIO Switch

The RIO switch (SW3, dipswitch 8) controls the ordering of the on-board RIO’ s. This dipswitch must be set

before powering up the panel.

NOTE: The RIO switch is not functional on the 3-48. It defaults to the Switch off configuration.

Switch off (default)

When the switch is set to this mode, the onboard RIO’s configure to the following addresses:

Onboard RIO0 Zone address range: 1001-1008 Outputs: 1001-1004

Onboard RIO1 Zone address range: 1011-1018 Outputs: 1011-1014

Switch on

When the switch is set to this mode, the onboard RIO’s configure to the following addresses:

Onboard RIO0 Zone address range: 1001-1008 Outputs: 1011-1014

Onboard RIO1 Zone address range: 0011-0018 Outputs: 0011-0014

PANEL ON-BOARD RIO RANGE TOTAL RIO's TOTAL

3-48 1001 - 1008, 1011 - 1018 16 Line 1 (4) 48

3-144 1001 - 1008, 1011 - 1018,

0011 - 0018 (switch on)

3-520 1001 - 1008, 1011 - 1018,

0011 - 0018 (switch on)

16 Line 1 (8)

Line 2 (8)

16 Line 1 (15)

Line 2 (16)

Line 3 (16)

Line 4 (16)

144

520

Table 2-7. Zone Address Ranges

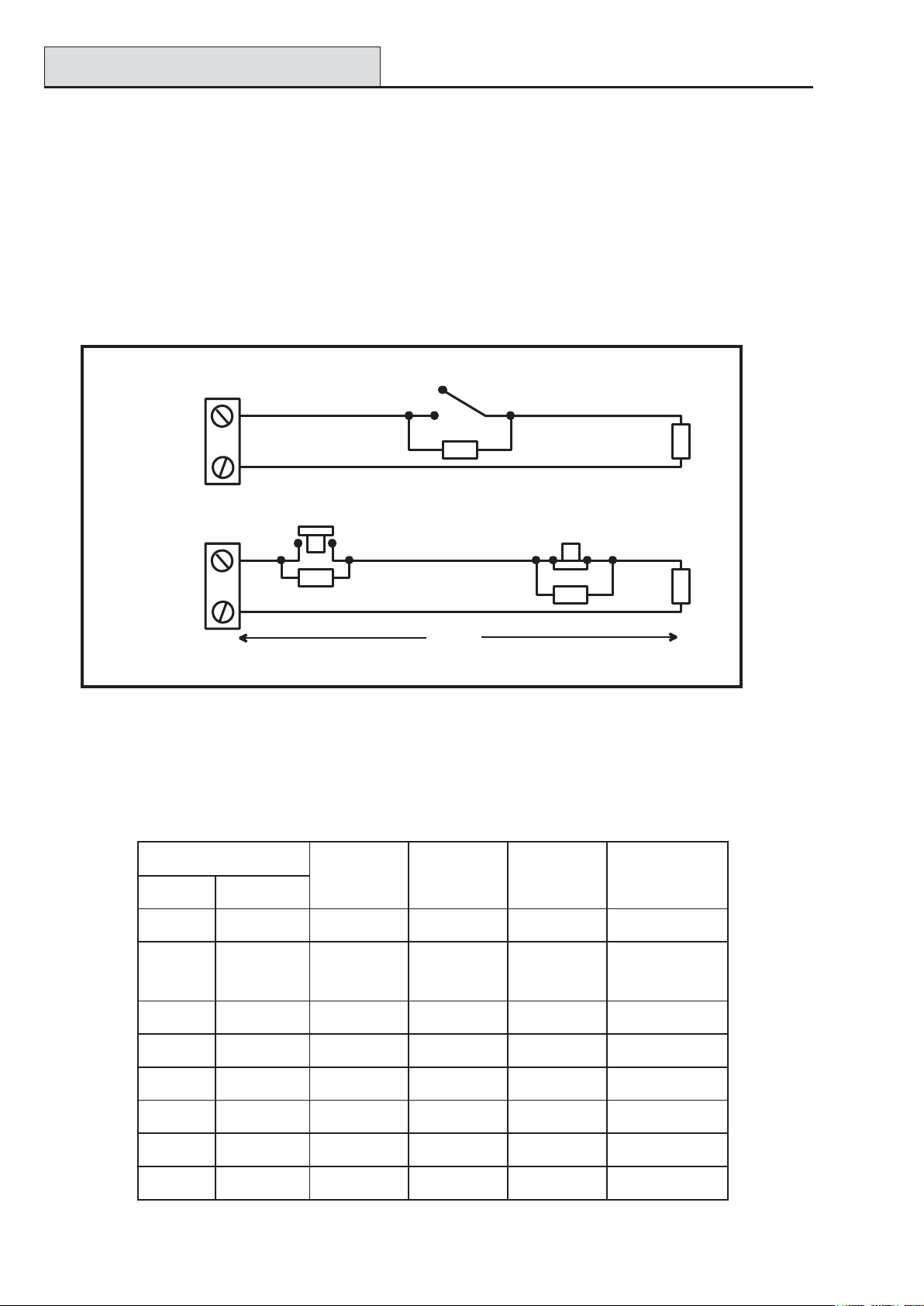

Wiring Zones

The zones on Galaxy 3 Series panels can be Double Balanced (default) or End of Line. Zones can be programmed with different resistance ranges for zone status activation (see Galaxy 3 Series Programming

Manual, IP1-0033, parameter 51.46 = Parameters.Zone Resistance). Refer to T able 2-8 (Double

Balanced) or T able 2-9 (End of Line) for details of the zone resistance and resulting conditions.

NOTE: The circuit debounce time (the period the zone must remain in a state to register a change in condi-

tion) is 300 milliseconds by default.

Preset 1 - 1k Preset 2 - 2k2 Preset 3 - 4k7

Tamper S/C 0 - 800 0 - 1800 0 - 3700

Low Res 800 - 900 1800 - 2000 3700 - 4200

Normal 900 - 1200 2000 - 2500 4200 - 5500

High Res 1200 - 1300 2500 - 2700 5500 - 6500

Open 1300 - 12000 2700 - 12000 6500 - 19000

Masked 12000 - 15000 12000 - 15000 19000 - 22000

Tamper O/C 15000 - infinity 150 00 - i nfi nity 220 0 0 - infini ty

Tamper S/C 0 - 800 0 - 1800 0 - 3700

Low Res 800 - 900 1800 - 2000 37 00 - 4200

Normal 900 - 1200 2000 - 2500 4200 - 5500

High Res 1200 - 1300 2500 - 2700 5500 - 6500

Masked 1300 - 12000 2700 - 12000 6500 - 19000

Open 12000 - infinity 12000 - infinity 19000 - infinity

Preset 1 - 1k Preset 2 - 2k2 Preset 3 - 4k7

T able 2-8. Double Balanced Zone

Resistance and Conditions

T able 2-9. End of Line Zone Resistance

and Conditions

2-14

Page 25

Galaxy 3 Series Installation Manual

Zone Wiring

Zone

Alarm

1k

1%

N/C

Tamper

N/C

500 m

Anti-mask

N/C

12k

1%

Figure 2-12. Preset 1 - Double balanced Zone/Detector wiring

Zone

Alarm

N/C

Tamper

N/C

500 m

Anti-mask

N/C

12k

1%

Figure 2-13. Preset 1 - End of Line Zone/Detector wiring

NOTE: N/C = Normally Closed

NOTE: The recommended maximum cable run from a zone to a detector is 500 metres.

1k

1k

1%

1%

Wiring Multiple Zones

Multiple detectors can be wired into a single zone as shown in the following Figure. The maximum number of

detectors that can be connected to a single zone is ten.

(10 max)

N/C TAMP

1k

1%

1k

Zone

N/C

Alarm

N/C

1k

1%

Alarm Alarm Alarm

N/C

1k

1%

500 m

N/C N/C

1k

1% 1%

Figure 2-14. Zone to Multiple Detector Wiring

Wiring Keyswitches

Latching or spring loaded keyswitches can be used to set and unset the Galaxy panels; option 52 = PROGRAM ZONES has provision to accommodate both types of transition.

If the keyswitch latches, the transition from 1 kΩ to 2 kΩ initiates the setting procedure of an unset system,

the transition from 2 kΩ to 1 kΩ instantly unsets a set system. If the system is already set, then the transition

from 1 kΩ to 2 kΩ has no effect. If the system is unset, the transition from 2 kΩ to 1 kΩ has no effect. This

is programmed as a Keyswitch in the PROGRAM ZONES option.

If the keyswitch is spring-loaded (returns to its normal position), the transition from 1 kΩ to 2 kΩ initiates the

setting procedure of an unset system and instantly unsets a set system, the transition from 2 kΩ to 1 kΩ - the

return to the normal position - has no effect. This is programmed as a Keyswitch in the PROGRAM

ZONES option.

2-15

Page 26

Terminator Zone Wiring

Galaxy 3 Series Installation Manual

Wiring T erminator Buttons

Zones programmed as Push-Set (terminator) buttons can be open going closed (2 kΩ to 1 kΩ) or closed

going open (1 kΩ to 2 kΩ). The first activation of the terminator button initialises its status to the system.

NOTE: The first activation of a terminator may not set the system as this can be the initialisation routine. If

the system continues setting, push the button again. The system will set on the second push. This

initialisation only occurs on the first setting. All subsequent setting routines set on the first push of the

terminator.

The wiring of the terminator and keyswitch zone type is shown in the following figure:

Keyswitch

zone

Push-set

zone

Open - Closed

1k

1%

1k to unset, 2k to set

1k

1%

OR

500m

Closed - Open

1%

1k

Figure 2-15. T erminator and Keyswitch Zone Wiring

Outputs

The Galaxy 3 Series control panel on-board outputs are detailed in the following table:

sserddAtuptuO

tluafeDelbanE0eniL

tluafeD

noitcnuF

epyTgnitaR

1k

1k

1%

1%

etatSlamroN

)pu-llup3k3htiw(

10011001slleBdesirotsis

20012001ebortSeloPelgniS

30013001APdesirotsisnarTAm0

40014001teseRdesirotsisnarTAm004,V21evitisoP

11011100teSdesirotsisnarTAm004,V21evitisoP

21012100redurt

31013100mrifnoCdesirotsisnarTAm004,V21evitisoP

41014100teseRdesirotsisnarTAm004,V

nIdesirotsisnarTAm004,V21evitisoP

narTAm004,V21evitisoP

A1,V03desigrene-eD

revOegnahC

)OCPS(yaleR

04,V21evitisoP

21evitisoP

T able 2-10. Outputs

2-16

Page 27

Galaxy 3 Series Installation Manual

Output Applications

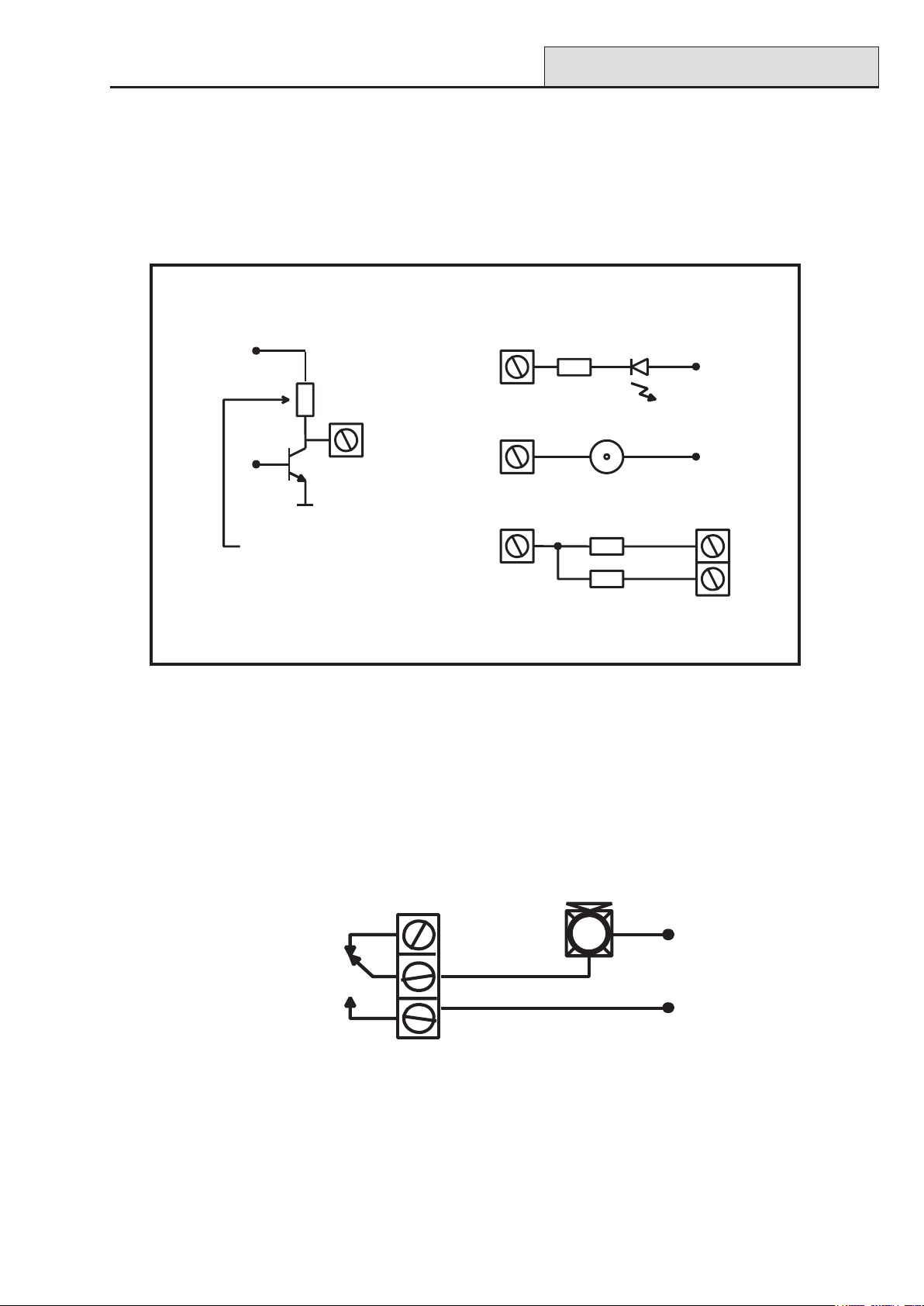

Output Applications

The outputs on the Galaxy panels, with the exception of the SPCO relay output, are transistorised outputs;

negative applied (positive removed) by default. These supply up to 400 mA and can be used to drive the

necessary output devices.

NOTE: The polarity of each output can be changed using option 53 = PROGRAM OUTPUTS

Transistorised Output

+12 V

3k3Ω

0 V

Cut 3k3Ω to give

open collector

A) LED

Output

B) Bell

Output

Output

C) Output used to trigger zone

Output

Output must be

open collector

Typical Applications

LED

1kΩ (typical)

Bell

1%

1kΩ

1%

1kΩ

Figure 2-16. Output Configuration and T ypical Applications

Note: For the appropriate 3k3Ω pull-up resistor refer to DIP switch SW3 (T able 2-1).

+12 V

+ 12 V

zone

The relay output is a single pole change over; this can be used to drive output devices that require a clean set

of contacts, isolated from the output voltage.

Horn

Normally

closed

+12 V

Single Pole

Change - 0ver

relay contacts

0 V

Normally open

Figure 2-17. Single Pole Change–Over Relay Output Configuration and T ypical application

2-17

Page 28

SPI Header

Galaxy 3 Series Installation Manual

SPI Header

The Serial Peripheral Interface (SPI) header on the Galaxy 3 Series PCB allows copying and overwriting of

programming information between panels using the SPI key .

The information is stored in a version independent format which allows panels of different versions to share

configuration information.

The panel software can also be updated using the SPI key using the menu structure, see Galaxy 3 Series

Programming Manual (IP1-0033), Option 71 = SPI Key .

2-18

Page 29

Galaxy 3 Series Installation Manual

RIOs

Section 3: Optional Modules and Facilities

Remote Input Output (RIO) Modules – C072

Galaxy RIO’s can be added to the Galaxy 3-144 and 3-520 control panels. Each additional RIO expands the

system by eight zones and four outputs.

Outputs

1

23

4

RS 485

BA

-

Power

-

+

S

+

3k3Ω pull-up

resistors

Tamper

Switch

Addressing

SW2

R1

1

R3

LK1

R5

R7

IC2

LED

SW4

5

3

2

4

Zones

6

Figure 3-1. Galaxy RIO

LK4

IC1

78

LK3

LK2

E/E

SLAVE

SW1

IC4

Rotary

Address

Switch

IC3

Rev 0.3

The Galaxy RIO must be given a unique address before it is connected to a power supply . This

address is selected using the 16-way Rotary Address Switch (SW1). Refer to Figure 3-1.

Galaxy Panel No of RIO's (MAX) Valid Addresses

3-48 4 2, 3, 4, 5

3-144

3-520

8 (line 1)

8 (line 2)

15 (line 1)

16 (lines 2-4)

1-8 (line 1)

0-7 (line 2)

1-9, A-F (line 1)

0-9, A-F (lines 2, 3, 4)

Table 3-1. V alid RIO Addresses

3-1

Page 30

Configuring the RIO

Galaxy 3 Series Installation Manual

Connecting the RIO

The RIO can only be connected to the system while engineer mode is accessed. The RS485 (AB) line of the

Galaxy RIO must be wired in parallel (daisy-chain configuration) with the RS485 (AB) line of any keypads

connected to the system. The RIO requires 12 Vd.c. (range 10.5 to 16.0 V) and 40 mA. This can be supplied from the control panel power supply or from a remote power supply if the distance causes a large

voltage drop on the cable.

NOTE: A 3 Ampere Smart PSU (part no. P015) can be fitted in place of a RIO.

Connect the RIO terminals as follows:

+12 V (either control panel, keypad or remote power supply);

–0 V or ground (either control panel, keypad or remote power supply);

A to the A terminal of the previous module (or control panel if RIO is the first on the line);

B to the B terminal of the previous module (or control panel if RIO is the first on the line).

NOTE: If the RIO is the last module on the line, connect a 680 Ω EOL resistor across the A and B

terminals.

Configuring the RIO

The added RIO is configured into the system on exiting from engineer mode. If the message XX Mod Added

[<],[>] T o View is displayed, the system has recognised that a new module is present. Press the A or B keys

to confirm that the RIO has been added. If this message is not displayed or the RIO is not on the list of added

modules, then the RIO is not communicating with the control panel or has been set to the same address as the

RIO already connected to the system.

The flash rate of the red LED (LED1) on the RIO indicates the status of the communication with the control

panel - refer to the following Table:

etaRhsalFgninaeM

FFO9.0/NO1.0snoitacinummoclamroN

FFOylppus.c.doN

FFO5.1/NO5.1metsysotniderugifnocneebtonsah

FFO2.0/NO2.0metsyshtiwnoitacinummoctsolsahOIR

FFO1.0/NO9.0snoitacinummocroopyreV

OIR

Table 3-2. RIO LED Flash Rates

Zones

The Galaxy RIO has eight programmable zones. These default to INTRUDER. Each zone is Double

Balance monitored with a 1 kΩ resistor in series with the zone detector and a 1 kΩ (1%) resistor in parallel

across the detector switch. The change to 2 kΩ (1%) resistance registers the zone as open/alarm.

3-2

Page 31

Galaxy 3 Series Installation Manual

RIO Outputs

Outputs

The RIO has four transistorised outputs. Each output is connected to +12 V via a 3k3Ω pull-up resistor

(refer to T able 3-3). When an output is activated, the load is switched to the negative supply voltage (ground

or 0 V) of the RIO. The current available from each output is 400 mA.

The default functions and pull-up resistors of each RIO output, when connected to a Galaxy are shown in the

following T able:

.oNtuptuOnoitcnuFrotsiseRpu-lluP

1slleB1R

2ebortS3R

3AP5R

4teseR7R

T able 3-3. RIO Output Default Functions

There are several links on the RIO which, if altered when the module is powered down, modify the RIO

operation:

• LK1 - short circuit this to by-pass the RIO lid tamper switch SW2

• LK2 - cut this to configure the module as an Entry/Exit RIO

• LK4 - cut this to configure the module as a Slave or Shunt RIO (If LK2 is already cut this

modifies the exit time on the Entry/Exit RIO from 30 to 90 seconds).

For further information refer to Galaxy Remote Input Output (RIO) Installer’s Guide (Part Number:

L/051 supplied with the RIO).

Entry/Exit RIO

A RIO is configured as an Entry/Exit RIO if resistor LK2 is cut, this allows a further sub-system to be

added to the Galaxy . The Entry/Exit RIO can be armed while the main system is unset, allowing protection

of specific areas; or disarmed when the main system is set allowing access to particular areas without unsetting

a group (shunting of zones). If the main system is set and the Entry/Exit RIO is not shunted, an activation on

the RIO will cause a full alarm on the main system. The Entry/Exit RIO configuration is shown in the

following Table:

enoZnoitcnuFtluafeDnoitcnuFdemmargorPtuptuO)dexiF(noitcnuFtluafeD

1redurtnInoitcnufynA1ydaeR

2redurtnInoitcnufynA2n

roHtixE/yrtnE

3redurtnInoitcnufynA3teS

4redurtnInoitcnufynA4mralA

5redurtnInoitcnufynA

6tixEelbammargorP-noN

7laniFgoL

8hc

tiwsyeKgoL

T able 3-4. Entry/Exit RIO Configurations

3-3

Page 32

Entry/Exit RIO

Galaxy 3 Series Installation Manual

Entry/Exit RIO Zone Programming

Zones 1 – 5 operate as normal zones. If a zone is programmed as Security, any activation - whether the

Entry/Exit RIO is armed or disarmed and the Galaxy is set or unset - results in the appropriate alarm condi-

tion being generated on the control panel.

If zones 1 – 5 are programmed as Intruder, then an alarm condition can be generated on the Entry/Exit

RIO when it is armed and the Galaxy is unset.

Zones 6 and 7 behave as an Exit and Final zone respectively . The functioning of these zones is fixed and is

independent of the programming of the Galaxy . Zone 7 can be programmed as Log in order to report and

record its activation in the Galaxy event log.

The function of zone 8 is fixed as a Keyswitch. This should also be programmed as Log in order to report

and record its activation in the Galaxy event log.

Entry/Exit RIO Zone Operation

The Entry/Exit RIO is armed by the transition of zone 8 (the keyswitch zone) from 2 k Ω to 1 kΩ (reverse to

normal operation). This starts an exit/entry time of 30 seconds. Closing the contact on zone 7 (the Final

zone) or expiry of the exit time set the RIO. Any activation of zones 1 – 5 when the Entry/Exit RIO is

armed activates the Alarm output (output 4).

The Entry/Exit RIO is disarmed by the transition of the keyswitch zone (zone 8) from 1 kΩ to 2 kΩ. The

disarming procedure can be started by activating the final zone, (zone 7), and gaining access to the keyswitch

zone via the exit zone (zone 6). Activating zones 1–5 during the disarming period result in an alarm condition

being generated. If the Entry/Exit RIO is disarmed while the main Galaxy is set, then activation of any of its

zones programmed as Intruder does not generated an alarm condition on the RIO or the control panel; the

zones are shunted.

The exit/entry time can be changed from 30 seconds to 90 seconds by cutting resistor LK4.

Slave RIO

A RIO is configured as a Slave or Shunt RIO if resistor LK4 is cut, this allows a further sub-system to be

added to the Galaxy .

The programming and operation of the Slave RIO is identical to that of the Entry/Exit RIO except for zones

6 and 7, which are Intruder type zones by default. Slave RIOs do not have an Exit or Final zone, or an

exit time; they are instantly unset and reset by the transition from 1 to 2 kΩ of zone 8.

enoZtluafeD

noitcnuF

1redurtnInoitcnufynA1ydaeR

2redurtnInoitcnufy

nA2teSotliaF

demmargorP

noitcnuF

tuptuOnoitcnuFtluafeD

)dexiF(

3redurtnInoitcnufynA3teS

4redurtnInoitcnufynA4mralA

5redurtnInoitcnufynA

6redurtnInoitcnufynA

7redurtnInoitcn

8hctiwsyeKgoL

ufynA

T able 3-5. Slave RIO Configuration

3-4

Page 33

Galaxy 3 Series Installation Manual

RF RIO

RF RIO – C076

The Galaxy Radio Frequency (RF) RIO module is an optional add-on to the existing Galaxy product range.

The module acts as an RF receiver for the Ademco 868MHz transmitter range.

Features

The RF RIO contains the following features:

• Support for up to 32 RF zones (dependent upon panel type)

• Support for up to 30 RF keyfobs

• 4 transistorised outputs

Panel Keypad

Panel Keypad

Outputs

Outputs

Outputs

1

1

1

2

2

2

4

4

4

3

3

3

Panel Keypad

BA -+BA - +

BA -+BA - +

BA - + BA - +

Pull-up

Resistors

Tamper

link

Tamper

Switch

R7 R5 R3 R1

LED1

SW2

SW6

LK1

SW3

Programming

Switch

Processor

Retaining Slot

SW1

Rotary

Address

Switch

Figure 3-2. RF RIO PCB Layout

Compatibility

The RF RIO is compatible with Galaxy Control Panels 3-144 and 3-520.

Programming

Keypad

Socket

Rev 1.0

Connecting the RF RIO

The RS 485 (AB) line of the RF RIO must be wired in parallel (daisy chain configuration) with the RS 485

(AB) line of the keypad connected to it. The RF RIO requires 12 V d.c. (range 10.5 to 16.0 V) and 55 mA.

This can be supplied from the control panel power supply or from a remote power supply if the distance

causes a large voltage drop on the cable.

3-5

Page 34

RF RIO (cont’d)

Galaxy 3 Series Installation Manual

Connect the RF RIO terminals in accordance with the following Table:

lanimreTOIRFR...otdetcennoC

+)ylppusrewopetomerrodapyek,lenaplortnocta(V21+

- )ylppusrewopetomerrodapyek,l

A

B

enaplortnocta(dnuorgroV0

ehtsiOIRFRehtfilenap

iOIRFRehtfilenap

)enilehtnoeludomtsrif

)enilehtnoeludomtsrifehts

lortnocehtro(enilehtnoeludomsuoiverpehtfolanimretAehtoT

lortnocehtro(enilehtnoeludomsuoiverpehtfolanimretBehtoT

T able 3-6. RF RIO Connections

Note: If the RF RIO is the last Module on the line, connect a 680 Ω resistor across the A and B terminals.

Outputs

The RF RIO has four transistorised outputs. Each output is connected to +12 V via a 3k3Ω pull-up resistor

(refer to T able 3-6 RF RIO Connections). When an output is activated, the load is switched to the negative

supply voltage (ground or 0 V) of the RF RIO. Each output is capable of supplying 400 mA.

The default functions and pull-up resistors of each RF RIO output, when connected to a Galaxy are shown in

the following Table:

.oNtuptuOtluafeD

noitcnuF

1slleB34R

2ebortS73R

rotsiseRpu-lluP

3AP33R

4teseR32R

T able 3-7. Output Functions

NOTE: The number of pull-up resistors may vary with different hardware revisions.

RF RIO T amper

Switch SW2 on the RF RIO acts as a tamper if the T amper Link (LK1) is missing. Removing the lid from the

RF RIO enclosure activates the RF RIO tamper alarm if the system is not in Engineer Mode. The tamper

switch can be bypassed by fitting a 0 Ω link to LK1.

Addressing the RF RIO

The Galaxy RF RIO must be given unique addresses before it is connected to a power supply . This unique

address is selected using the 16-way Rotary Address Switch (SW1). The address selected will act as the

base address for the RF RIO. Subsequent addresses will be

base address + 1, base address + 2, base address + 3. For example:

Base address = 2 followed by 3, 4 and 5.

Address Ranges

This option allows the programming of the RIO addresses, which are to be simulated by the RF RIO.

For example, if the RF RIO being programmed supports 32 zones (4 RIO addresses), and the base address,

programmed at the hexi-decimal rotary switch is 02, the available addresses would be 02, 03, 04, 05. However, you may want to only respond as RIO addresses 02, 04. The remaining addresses should be disabled

and will not respond to commands from the control panel. The base address is enabled by default. All other

3-6

Page 35

Galaxy 3 Series Installation Manual

addresses are disabled by default.

Module status on the RF RIO such as lid tamper,will be reported to the panel using the address set on the

rotary switch.

RF RIO (cont’d)

RF RIO Programming

Programming of the RF RIO is achieved by connecting a Galaxy Mk7 keypad directly to the RF RIO at the

Programming Keypad Socket or the Keypad Connector Block. The Keypad is not part of the Galaxy network and must be addressed as 0.

Note: To program RF devices, please refer to RF RIO Module, Installation and Programming

Instructions, (II1-0076) supplied with the RF RIO.

Configuring the RF RIO

The RF RIO is configured into the system on exiting from engineer mode. If the message

XX Mod Added [<],[>] T o View is displayed, the system has recognised that a new module is present. Press

the A or B keys to confirm that the RF RIO has been added. If this message is not displayed or the RF RIO

is not on the list of added modules, then the RF RIO is not communicating with the control panel.

The flash rate of the red LED (LED1) on the RF RIO indicates the status of the communication with the

control panel — refer to T able 3-8.

ETARHSALFGNINAEM

FFO9.-/NO1.0snoitacinummoclamroN

FFOylppus.c.doN

FFO5.1/NO5.1metsysotniderugifnocneebtonsah

FFO1.0/NO2.0metsyshtiwnoitacinummoctsolsahOIRFR

FFO1.0/NO9.0snoitacinummocroopyreV

Table 3-8. RF RIO LED flash rates

OIRFR

3-7

Page 36

Output Module

O N

1 2

Galaxy 3 Series Installation Manual

Output Module – C078

Galaxy Output Modules can be added to the Galaxy 3 Series control panels. Each additional Output Module

expands the system up to 16 outputs by simulating the outputs of four RIO’ s

The following figure shows the main components of the Output Module.

Secondary Output

Connectors (RM1-4)

for Relay Module

Normally Open

relay output

Jumper

Tamper switch

and spring

Primary Outputs

12

+

CN3

RM3

BUZZER

ext

CN1

1

+

Primary Outputs

11

int

2

10 9

1 2

3

4

Connector for

firmware upgrade

-

DIP

Switch

O N

ISP

Rotary

Address

Switch

MODE

-

Configuration

Jumpers

TEST

TAMPER

Bypass

{

Primary Outputs

16

15

+

+

Primary Outputs

5

RM4

LED

RM2RM1

67

14 13

Engineer

Socket

(RS485 line)

8

-

CN4

B

RS485 line

}

B

A

-

+

A

- (0V)

+ (12V)

- (0V)

Module

power

supply

}

+ (12V)

S (screen cable

connect)

CN2

-

Figure 3.3. Galaxy Output Module

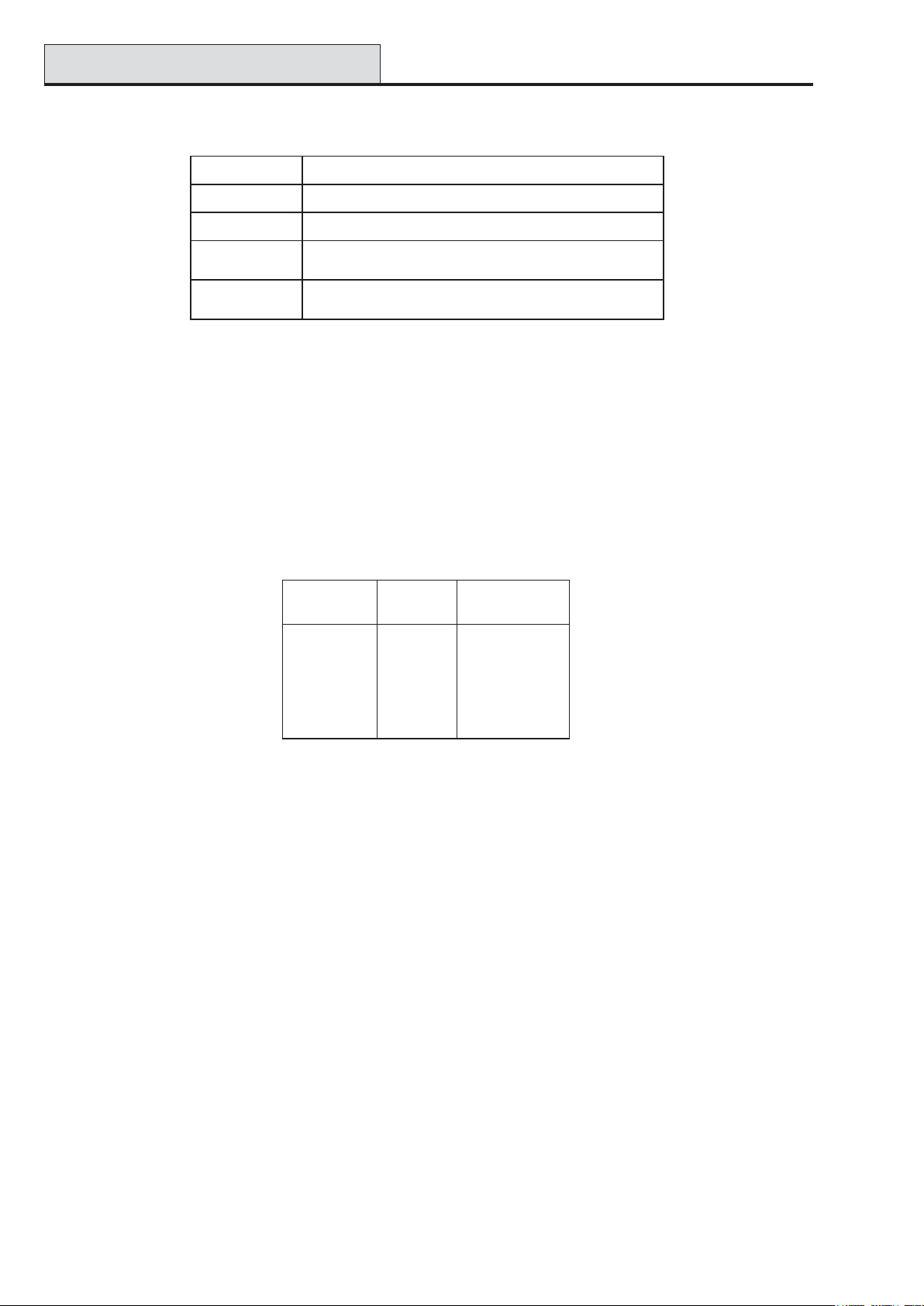

Addressing

The Galaxy Output Module must be given a unique address before it is connected to a power supply . This

base address is selected using the Rotary Address Switch. V alid addresses are shown in the following table.

NOTE: The zones represented by the Output Module addresses can be viewed on the panel, however they

are not used.

Gala xy Panel

No of Output Modules

(Maximum)

3-48 4 2, 3, 4, 5

3-144

3-520

8 (line 1)

8 (line 2)

15 (line 1)

16 (lines 2-4)

T able 3-9. Valid Output Module Addr esses

Valid Addresses

1-8 (line 1)

0-7 (line 2)

1-9, A-F (li ne 1)

0-9, A-F (lines 2, 3, 4)

3-8

Page 37

Galaxy 3 Series Installation Manual

Output Module (cont’d)

Connecting the Output Module

The Output Module can only be connected to the system while engineer mode is accessed. The RS485 (AB)

line of the Output Module must be wired in parallel (daisy-chain configuration) with the RS485 (AB) line of

any keypads connected to the system. The Output Module requires 12 Vd.c. (range 10.5 to 15.0 V) and

250 mA. This can be supplied from the control panel power supply or from a remote power supply if the

distance causes a large voltage drop on the cable.

Connect the Output Module terminals as follows:

+ (12 V) - either control panel, keypad or remote power supply;

– (0 V) - either control panel, keypad or remote power supply;

S (Screen cable connect) - to control panel

A to the A terminal of the previous module (or control panel if Output module is the first on the line);

B to the B terminal of the previous module (or control panel if Output Module is the first on the line).

NOTE: If the Output Module is the last module on the line, connect a 680 Ω EOL resistor across the A and

B terminals.

Configuring the Output Module