Page 1

TECHNICAL HANDBOOK

FSL100 SERIES FLAME DETECTORS

AND ACCESSORIES

Page 2

Revision History

ii

Revision

Comment

Date

Issue 01

First Issue

29/07/2015

Issue 02

First Revision

02/09/2016

Issue 03

Page 3

Disclaimer

iii

In no event shall Honeywell be liable for any damages or injury of any nature or kind, no matter how caused, that arise from the

use of the equipment referred to in this manual.

Strict compliance with the safety procedures set out and referred to in this manual, and extreme care in the use of the

equipment, are essential to avoid or minimise the chance of personal injury or damage to the equipment.

The information, figures, illustrations, tables, specifications, and schematics contained in this manual are believed to be correct

and accurate as at the date of publication or revision. However, no representation or warranty with respect to such correctness

or accuracy is given or implied and Honeywell will not, under any circumstances, be liable to any person or corporation for any

loss or damages incurred in connection with the use of this manual.

The information, figures, illustrations, tables, specifications, and schematics contained in this manual are subject to change

without notice.

Unauthorised modifications to the detection system or its installation are not permitted, as these may give rise to unacceptable

health and safety hazards.

In no event shall Honeywell be liable for any equipment malfunction or damages whatsoever, including (without limitation)

incidental, direct, indirect, special, and consequential damages, damages for loss of business profits, business interruption, loss

of business information, or other pecuniary loss, resulting from any violation of the above prohibitions.

Warranty

Honeywell Analytics warrants the FSL100 Series Flame Detection system and accessories against defective parts and

workmanship, and will repair or (at its discretion) replace any components that are or may become defective under proper

usage within 24 months from the date of commissioning by a Honeywell Analytics approved representative* or 30 months from

shipment from Honeywell Analytics, whichever is sooner.

This warranty does not cover consumable, batteries, fuses, normal wear and tear, or damage caused by accident, abuse,

improper installation, unauthorized use, modification or repair, ambient environment, poisons, contaminants or abnormal

operating conditions.

This warranty does not apply to sensors or components that are covered under separate warranties, or to any 3rd-party cables

and components

Any claim under the Honeywell Analytics Product Warranty must be made within the warranty period and as soon as reasonably

practicable after a defect is discovered. Please contact your local Honeywell Analytics Service representative to register your

claim.

This is a summary. For full warranty terms please refer to the Honeywell Analytics’ General Statement of Limited Product

Warranty, which is available on request.

* A Honeywell Analytics approved representative is a qualified person trained or employed by Honeywell Analytics, or a qualified

person trained in accordance with this manual.

Copyright Notice

Honeywell is the registered trademark of Honeywell Safety and Productivity Solutions (SPS).

FSL100 is a registered trademark of Honeywell Analytics (HA).

Other brand and product names mentioned in this manual may be trademarks or registered trademarks of their respective

companies and are the sole property of their respective holders.

Find out more at www.honeywellanalytics.com

Page 4

iv

This page deliberately left blank.

Page 5

CONTENTS

MAN0987_Iss 2_09/16

1

FSL100 Series Flame Detectors

Technical Handbook

Contents

1 Introduction ............................................................................................................................................................................ 3

1.1 Intended Readers ............................................................................................................................................................. 3

2 Safety Hazards, Warnings and Cautions ............................................................................................................................. 5

2.1 General Warnings and Cautions ....................................................................................................................................... 5

2.2 Important Information ........................................................................................................................................................ 5

2.3 FSL100 Safety Features ................................................................................................................................................... 6

3 Overview ................................................................................................................................................................................. 7

4 Mechanical Installation .......................................................................................................................................................... 9

4.1 Siting ................................................................................................................................................................................. 9

4.2 Mounting and Orientation .................................................................................................................................................. 9

4.3 Installing the FSL100 Flame Detectors ............................................................................................................................. 9

4.4 Cone of Vision ................................................................................................................................................................ 10

4.5 Shadow Effect ................................................................................................................................................................. 10

4.6 Mounting Below a Ceiling ............................................................................................................................................... 11

4.7 Vote Count ...................................................................................................................................................................... 12

4.8 Weather Protection ......................................................................................................................................................... 13

4.9 Hot Work ......................................................................................................................................................................... 13

5 Electrical Installation ............................................................................................................................................................ 15

5.1 Power Supply .................................................................................................................................................................. 15

5.2 Cabling Recommendations ............................................................................................................................................. 15

5.3 Earth (Ground) Regimes ................................................................................................................................................. 15

5.4 Wiring Diagram ............................................................................................................................................................... 16

5.5 Electrical Connection (General) ...................................................................................................................................... 17

5.6 Wiring to a Controller (General) ...................................................................................................................................... 17

5.7 Wiring to a Fire Control Panel ......................................................................................................................................... 18

5.8 Wiring to a PLC ............................................................................................................................................................... 19

5.9 Wiring to a 4-20 mA Non-Isolated (Sourcing) Current Output ......................................................................................... 19

5.10 Connecting the Manual Self-Test .................................................................................................................................... 19

5.11 FSL100 Latching Alarm Settings .................................................................................................................................... 20

6 Commissioning and Testing ................................................................................................................................................ 21

6.1 Commissioning ............................................................................................................................................................... 21

6.2 Functional Testing .......................................................................................................................................................... 22

6.3 Fault Analysis ................................................................................................................................................................. 22

6.4 Fault Testing ................................................................................................................................................................... 23

7 FSL100 Operation ................................................................................................................................................................. 25

7.1 The Display LEDs ........................................................................................................................................................... 25

7.2 Normal Operation ........................................................................................................................................................... 25

7.3 Fault Conditions .............................................................................................................................................................. 25

7.4 Relay Outputs ................................................................................................................................................................. 25

7.5 Analogue Output 0–20 mA (Stepped, Sinking, Non-Isolated) ......................................................................................... 25

7.6 Self-Testing..................................................................................................................................................................... 25

7.7 Manual Self-Test ............................................................................................................................................................. 26

8 Maintenance .......................................................................................................................................................................... 27

9 FSL100-SM21 Swivel Mount ................................................................................................................................................. 29

Page 6

CONTENTS

MAN0987_Iss 2_09/16

2

FSL100 Series Flame Detectors

Technical Handbook

9.1 How to Install the Detector Using the Swivel Mounting ................................................................................................... 29

9.2 Cleaning ......................................................................................................................................................................... 30

10 FSL100-TL Test Lamp Non-EX ............................................................................................................................................. 31

10.1 Safety Instructions .......................................................................................................................................................... 31

10.2 Before First Use .............................................................................................................................................................. 32

10.3 Test Lamp Operation ...................................................................................................................................................... 32

10.4 Battery Charging and Storage: ....................................................................................................................................... 32

10.5 Bulb Replacement .......................................................................................................................................................... 33

11 FSL100-TLX Test Lamp Hazardous Areas .......................................................................................................................... 35

11.1 Safety Instructions .......................................................................................................................................................... 35

11.2 Before First Use .............................................................................................................................................................. 36

11.3 Operation ........................................................................................................................................................................ 36

11.4 Battery Replacement ...................................................................................................................................................... 36

12 FSL100 Specifications .......................................................................................................................................................... 37

13 Accessory Specifications ..................................................................................................................................................... 39

14 FSL100 Certifications ........................................................................................................................................................... 41

14.1 EC Declaration of Conformity ......................................................................................................................................... 41

14.2 National and International Certificates of Compliance ................................................................ .................................... 41

14.3 Rating Label .................................................................................................................................................................... 41

14.4 North American approvals – cFMus class 3611 & FM class 3260 .................................................................................. 43

15 Ordering Information ............................................................................................................................................................ 43

16 Returns and Repairs Policy ................................................................................................................................................. 45

17 List of Figures ....................................................................................................................................................................... 47

18 List of Tables ......................................................................................................................................................................... 49

Page 7

MAN0987_Iss 2_09/16

3

FSL100 Series Flame Detectors

Technical Handbook

INTRODUCTION

1

Introduction

This technical manual is available in several languages and it covers the installation, operation and maintenance of the following

equipment:

FSL100-IR3 Flame Detector (Triple Infrared)

FSL100-UV Flame Detector (Ultraviolet)

FSL100-UVIR Flame Detector (Ultraviolet and Infrared)

FSL100-TL Test Lamp, Charger and Case (Safe Areas)

FSL100-TLX Test Lamp, Charger and Case (Intrinsically safe – IECEx, ATEX)

FSL100-SM21 Swivel Mounting

1.1 Intended Readers

This Manual should be read by everyone who operates or monitors the FSL100 Flame Detection system.

Only personnel who have been fully trained by Honeywell are authorised to Install, Set-up, Service, and Test, Repair, or

Recondition Honeywell flame detection systems.

Page 8

MAN0987_Iss 2_09/16

4

FSL100 Series Flame Detectors

Technical Handbook

INTRODUCTION

This page deliberately left blank.

Page 9

MAN0987_Iss 2_09/16

5

FSL100 Series Flame Detectors

Technical Handbook

SAFETY

Caution

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It is also

used to alert the user against unsafe working practices and potential damage to equipment.

Warning

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

WARNINGS AND CAUTIONS

1. Installation and commissioning must only be carried out by a Honeywell Analytics approved person or by a

qualified person trained in accordance with this manual, and only in accordance with the recognized

regulations and standards of the appropriate authority in the country concerned.

2. Do not make any unauthorised changes to the equipment as essential safety and certification requirements

may be invalidated.

3. Do not operate the detectors in normal conditions with covers open or removed. Access to the interior of the

detector must only be carried out by trained personnel.

4. Ensure the detector power is off and electrically isolated before opening the detector in a hazardous area.

Do not open the enclosure or touch live terminals when the system is energised.

5. Do not touch or contaminate the sensors or lenses as this may shorten their life and may affect their

sensitivity to UV / IR radiation. Clean contaminated sensors and lenses carefully using lint-free or micro-fibre

cloth dampened only with optical-grade cleaning solution.

6. These flame detectors do not require earthing (grounding), but must be installed correctly to avoid electrical

shocks and interference.

7. The FSL100 Flame Detector is only assessed under ATEX for ignition hazards.

8. Operators, site personnel and visitors should be made fully aware of the action to be taken in the event of an

alarm sounding.

Important

Read and understand the instruction manual before operating or servicing the equipment.

2

Safety Hazards, Warnings and Cautions

2.1 General Warnings and Cautions

2.2 Important Information

This manual is for use with FS100 Series Fire Detectors only.

Honeywell Analytics can take no responsibility for installation and/or use of its equipment if not done so in accordance with the

appropriate issue and/or amendment of the Operating Manual.

The reader of this Manual should ensure that it is appropriate in all details for the exact equipment to be installed and/or

operated. If in doubt, contact Honeywell Analytics for advice.

The following types of notices are used throughout this Operating Manual:

Page 10

MAN0987_Iss 2_09/16

6

FSL100 Series Flame Detectors

Technical Handbook

SAFETY

Every effort has been made to ensure the accuracy of this document; however, Honeywell Analytics can assume no

responsibility for any errors or omissions in this document or their consequences.

Honeywell Analytics would greatly appreciate being informed of any errors or omissions that may be found in the content of this

document.

For information not covered in this document, or if there is a requirement to send comments/corrections about this document,

please contact Honeywell Analytics using the contact details given on the back page.

Honeywell Analytics reserve the right to change or revise the information supplied in this document without notice and without

obligation to notify any person or organization of such revision or change. If information is required that does not appear in this

document, contact the local distributor/agent or Honeywell Analytics

2.3 FSL100 Safety Features

The FSL100 has the following safety features:

Hazardous area certified: ATEX Zone 2/22, FM Class 1, 2, 3 Div. 2

Performance certified: EN54-10 and FM 3260

Robust Glass Reinforced Polyester (GRP) housing, which is available in standard red housing or white housing options and

is:

o Light weight but impact resistant

o Weather sealed and incorporating pressure compensating breather

o Non-Incendive (flameproof), non-corrosive and UV resistant

Automatic Sensor self-test continuously monitors the sensors, electronics and firmware for proper operation

Manual Self test initiated by contact closure

Relay and mA sink outputs and selectable latching / non-latching alarm relay outputs

Local status LEDs

Optional (safe area or hazardous area) Function Test Lamps to enable simple coverage and operational checks of the

Honeywell FSL100 series Flame Detectors (with long range test source detection)

Page 11

MAN0987_Iss 2_09/16

7

FSL100 Series Flame Detectors

Technical Handbook

OVERVIEW

UV

Visible

Near IR

IR

Thermal IR

Far IR

3

Overview

The Honeywell Analytics FSL100 series of Flame Detectors comprises three models:

FSL100-IR3 Triple Infrared flame detector

FSL100-UV Ultraviolet flame detector

FSL100-UVIR Ultraviolet and Infrared flame detector

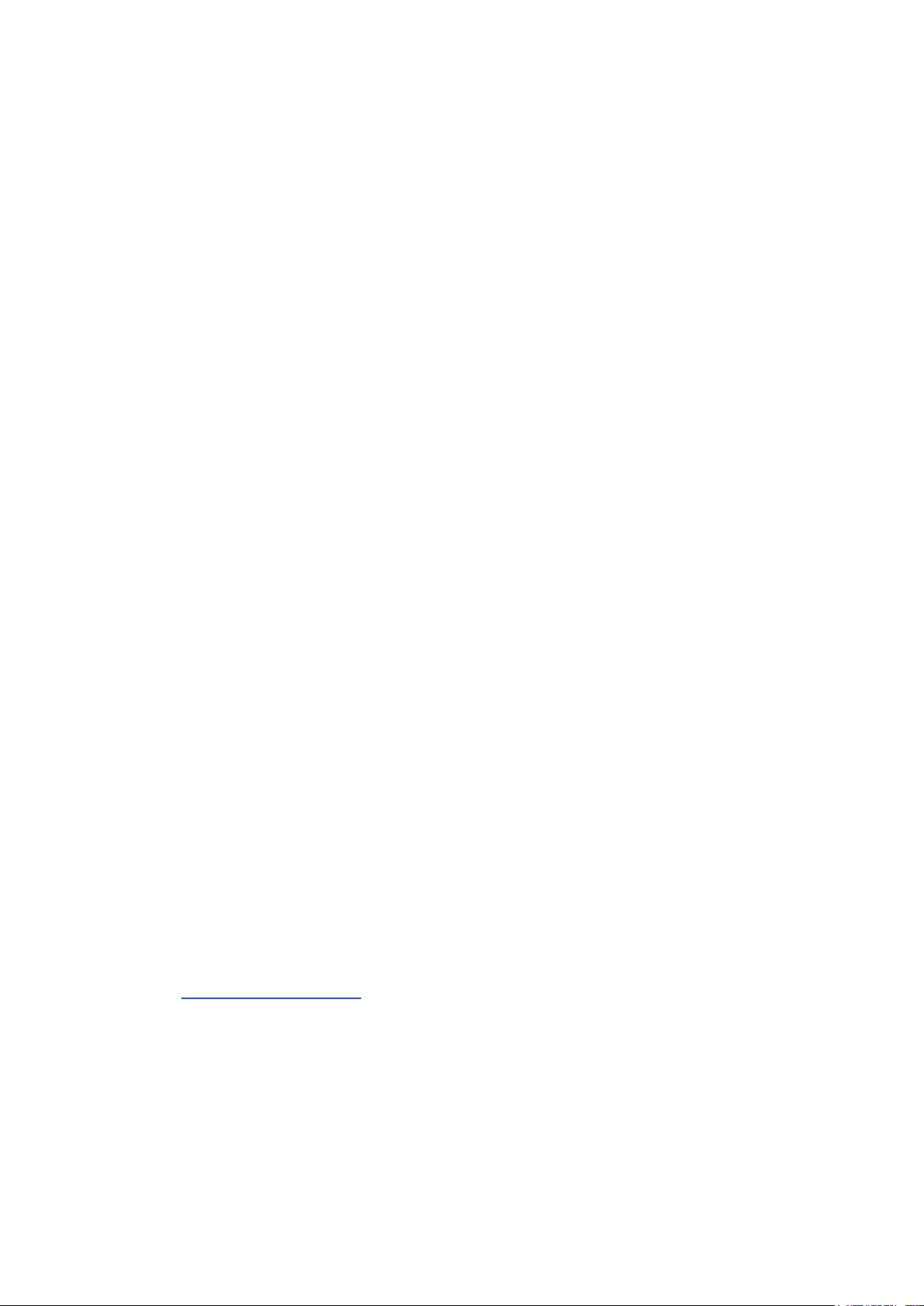

These flame detectors monitor an area by looking for the presence of invisible infrared or ultraviolet light that occur outside the

frequency range occupied by visible flames, and they can do this in the presence of interference (sunlight, smoke, dust, vapour

etc.) to determine whether or not a fire is actually present within their field of view.

All three detectors utilize a microprocessor for sophisticated electronic signal analysis. Detectors with IR sensors also analyse

the flame flicker effect. The Triple IR flame detector uses this method to give highly reliable nuisance alarm rejection and is also

less affected by optical contamination and smoke than are UV based flame detectors.

The diagram below shows the spread of invisible UV/IR radiation that is available for sampling outside the human visual range,

and shows how a UV/IR detector can be potentially 1 million times more sensitive than a human eye.

Frequency (Hz) Wavelength

Note: Monitoring a fire zone (i.e. a fume chamber) through its glass or acrylic walls could reduce or defeat the sensitivity of

certain types of flame detector.

For example, plain glass and acrylic are known to block IR but may transmit UV, whereas coated materials may block both.

Please consult Honeywell Analytics Technical Support for further information if you need this type of application

Figure 1. Comparison of Visible Radiation Range to UV/IR Radiation Range

Page 12

MAN0987_Iss 2_09/16

8

FSL100 Series Flame Detectors

Technical Handbook

OVERVIEW

This page deliberately left blank.

Page 13

MAN0987_Iss 2_09/16

9

FSL100 Series Flame Detectors

Technical Handbook

INSTALLATION

4

Mechanical Installation

This chapter describes the mechanical requirements for installing FSL100 Series Flame Detectors. Electrical

installation is discussed in the next chapter.

4.1 Siting

The number, type and placement of fire detectors and alarm control systems should be determined in consultation with

Honeywell Analytics specialist technical advisors and Site specialists.

Remember that the FSL100 series are flame detectors only; they cannot detect flammable gas or dust atmospheres. Please

contact Honeywell Analytics if you need a flammable atmosphere detection system.

Generally speaking, one or more FSL100 flame detectors should be positioned on walls or posts above the monitored object or

area, and they should overlap so that shadow areas cannot occur (see diagrams that follow).

4.2 Mounting and Orientation

In this chapter a number of general guidelines are given for the flame detector system design. Several of these guidelines are

discussed in more detail in the following chapters.

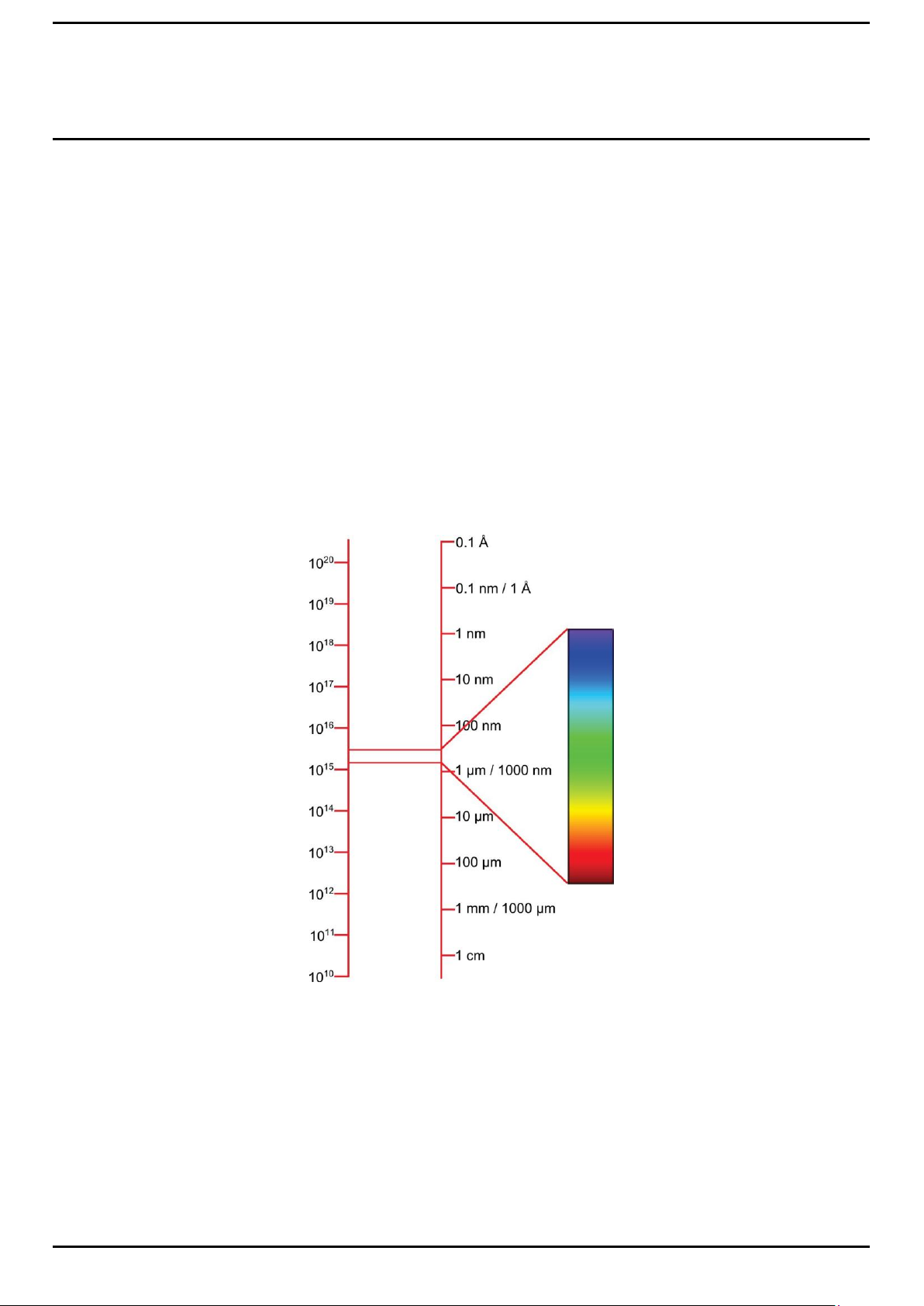

4.3 Installing the FSL100 Flame Detectors

There are 2 options for installing the FSL100 series of Flame Detectors:

1. You can use the optional Swivel Mount to mount them on walls, ceilings or posts (see Ch.10 FSL100-SM21 Swivel Mount).

2. You can mount them directly to a ceiling (i.e. in a fume chamber or in an engine room) or inside ducting.

Use the measurements below for mounting, remembering to allow clearance for the cables.

FSL100-SM21

Swivel Mounting

Wall Plate

Figure 2. Mounting Hole Dimensions

FSL100-SM21

Swivel Mounting

Back Plate FSL100 Detector

Page 14

INSTALLATION

MAN0987_Iss 2_09/16

10

FSL100 Series Flame Detectors

Technical Handbook

45

o

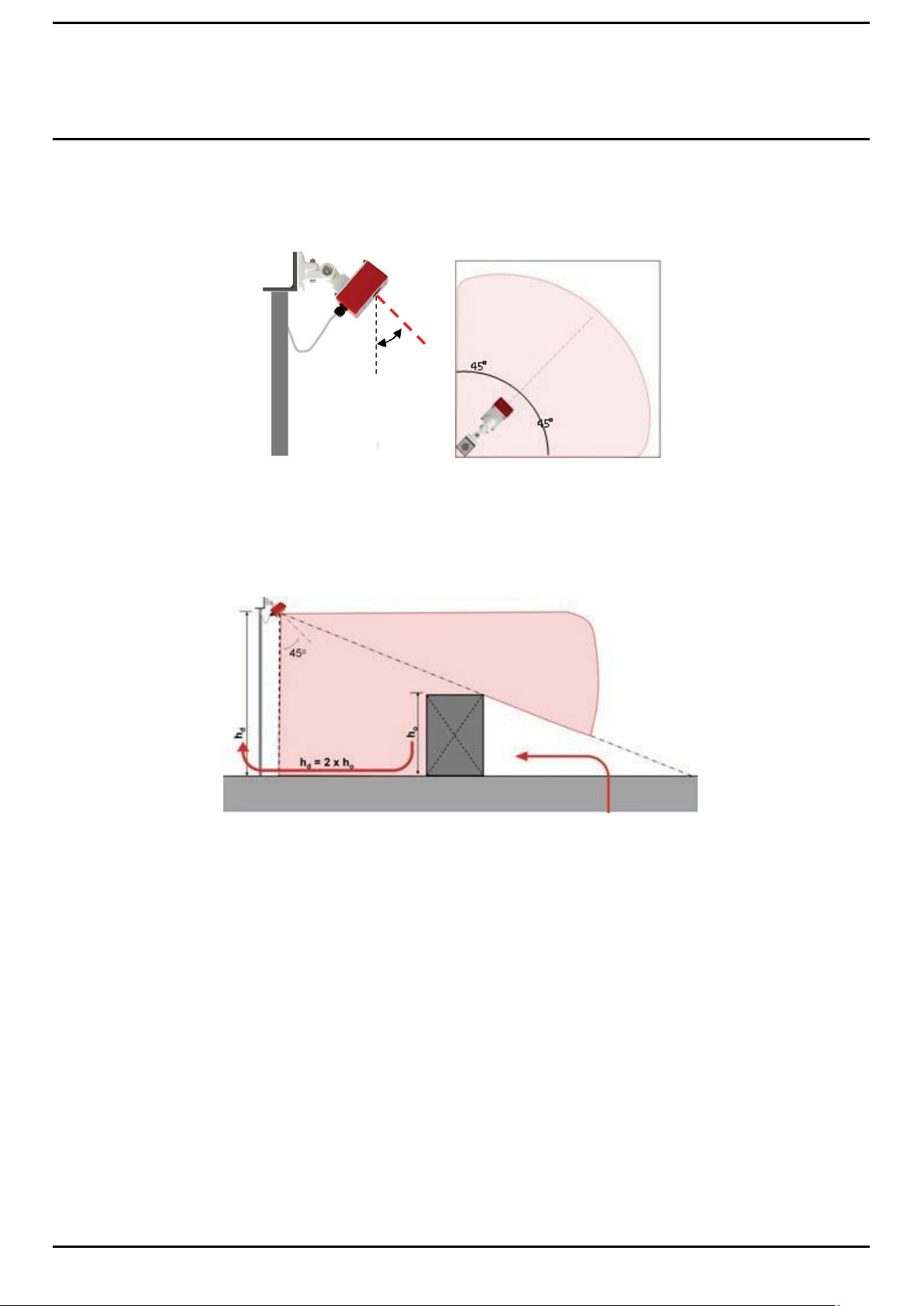

4.4 Cone of Vision

The FSL100 flame detector has a cone of vision of 90° so it can monitor an area extending from floor to ceiling and

extending to approximately 23 m (FSL100-UV and UVIR) or 35 m (FLS100-IR3).

Figure 3. Cone of View

4.5 Shadow Effect

If monitoring a solid object, the mounting height (hd) of the flame detector should be at least twice the height (ho) of the highest

object in the monitored zone:

Detector height (hd) = 2 x height of the highest object (ho) Shadow effect

Figure 4. Shadow Effect

Page 15

INSTALLATION

MAN0987_Iss 2_09/16

11

FSL100 Series Flame Detectors

Technical Handbook

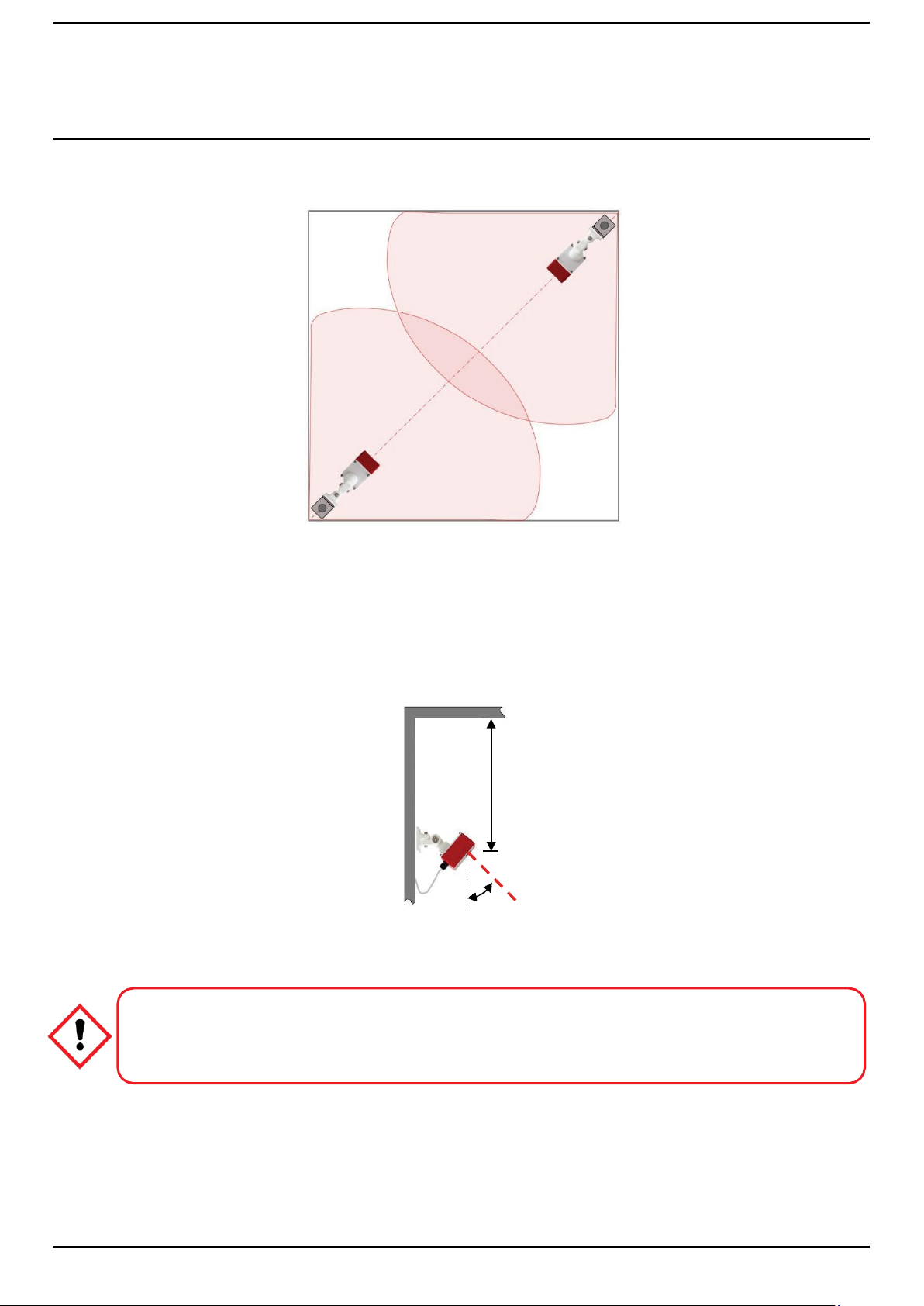

Caution

Reducing the height of a detector above the monitored item will increase the size of shadow areas, so a

minimum of two detectors will be required to cover the shadows. See Shadow Effect explanation above.

D m

45

o

To avoid the shadow effect (in zones that cannot be fully monitored by a solo flame detector) place a second flame detector in

the opposite corner.

Figure 6. Shadow Cancelling

4.6 Mounting Below a Ceiling

Smoke rises and can form a layer at ceiling height long before naked flames are visible. Dense smoke can block some of the

wavelengths of light given off by flames, and this can ultimately decrease the sensitivity and speed of the flame detector.

To avoid the risk of smoke blocking their fields of view, you should mount the FSL100-IR3 flame detectors at least 0.5 m (2 ft),

and the FSL100-UV and FSL100-UVIR detectors at least 1.5m (6 ft), below the ceiling (see dimension ‘D’ below).

Figure 7. Mounting Clearance

Page 16

INSTALLATION

MAN0987_Iss 2_09/16

12

FSL100 Series Flame Detectors

Technical Handbook

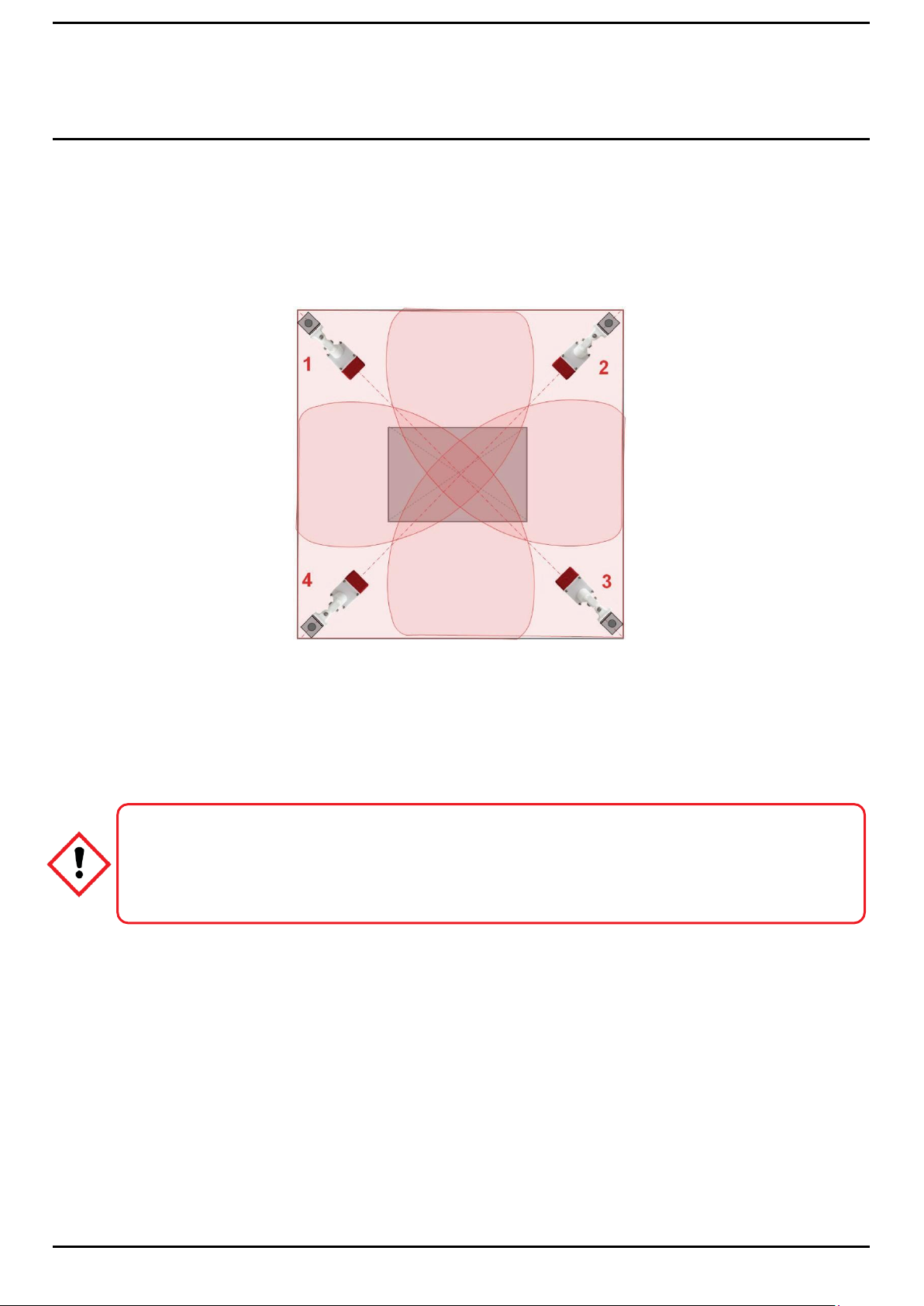

Caution

A flame detector is a line of sight detector so voting with just two flame detectors in not reliable. The redundant

flame detector in the opposite corner cannot be used for a 2 detector dependent output because a flame

occurring in a shadow area would not be seen by the second detector until the fire is well established. In this

case the second flame detector will give an alarm too late or not at all.

Monitored object

4.7 Vote Count

FSL100 flame detectors will not give an alarm until several different alarm criteria occur at the same time, and the probability of

a false alarm is very low. The flame detector is therefore suitable for relay activated actions (i.e. drenching) based on the signal

of one flame detector.

However, ‘voting’ may be demanded in a functional specification, in which case the ‘voting-system’ may be applied; i.e., the

flame detectors may be mounted in multiples, as shown in the example below where an alarm output would be dependent on

the controller receiving confirmatory alarm inputs from at least two of the available detectors.

Figure 8. Voting Arrangement Using Four Detectors

A good example of voting would be in a Server room or process room that uses inert gas drenching to replace oxygen in the

atmosphere, and the voting of any 2 out of the 4 flame detectors should be mandated before the relay output can be triggered.

Note: The fire control panel or PLC must be able to support the two detector voting system.

Page 17

INSTALLATION

MAN0987_Iss 2_09/16

13

FSL100 Series Flame Detectors

Technical Handbook

4.8 Weather Protection

It is recommended to place a hood or shield above the flame detector to protect it from sunlight, rain and snow. A stainless steel

metal plate of approximately 30 x 30 cm (12 x 12 in) can be mounted directly above the flame detector without inhibiting its field

of view. A similar plate can be used to shield it from potential false alarm sources such as smoke-stack flares.

4.9 Hot Work

Flame Detectors may alarm in the presence of hot work, for example a welding operation, and this must be taken into

account when doing Hot Work risk assessments and when issuing Hot Work permits.

Usually it is sufficient to inhibit or isolate the alarm system in that area and substitute a ‘Fire Marshall’ or safety man armed with

an appropriate fire extinguisher.

Page 18

INSTALLATION

MAN0987_Iss 2_09/16

14

FSL100 Series Flame Detectors

Technical Handbook

This page deliberately left blank.

Page 19

INSTALLATION

MAN0987_Iss 2_09/16

15

FSL100 Series Flame Detectors

Technical Handbook

Typical Cable Data

Maximum Cable Length (L)

Cable size

(cross sectional area)

Cable resistance

Ω/km (Ω/mile)

Metres

Feet

0.5 mm2 ≅ 20 AWG

36.8 (59.2)

245

808

1.0 mm2 ≅ 17 AWG

19.5 (31.4)

462

1516

1.5 mm2 ≅ 16 AWG

12.7 (20.4)

709

2326

5

Electrical Installation

5.1 Power Supply

Table 1. FSL100 Cable Data

Note: Safety margins should include an allowance for resistance changes due to changes in T ambient over time. I.e. Higher

temperature = higher resistance, while resistance may increase due to oxidation or loss of ductility over time.

5.2 Cabling Recommendations

The FSL100 Flame Detector is supplied fitted with a suitable gland. The use of industrial grade, screened and suitably armoured

field cable is recommended.

For example, three core copper cable, with screen (90% coverage) and suitable mechanical protection (i.e. insulated steel wire

armour) to suit M20 gland entry.

The maximum conductor size for the terminals is 1.5 mm2 (16 AWG).

Ensure the cable gland is installed correctly and fully tightened. All unused cable/conduit entries must be sealed with a suitable

certified sealing plug.

5.3 Earth (Ground) Regimes

Please note:

Controllers should be connected to protective earth (ground) via an isolator switch that cannot disconnect the earth line.

Field cable screens should be connected to instrument earth (ground) in the controller only. The other end of the field cable

screen shall be cut and isolated.

Field cable armour / conduit shall be insulated from the cable screening and earthed (grounded).

Avoid earth (ground) loops at all times.

Page 20

INSTALLATION

MAN0987_Iss 2_09/16

16

FSL100 Series Flame Detectors

Technical Handbook

Terminal

Input

Terminal

Input

1

+10 to +28 VDC Input

10

NC Alarm

2

–Ve Input

11

NC Fault

3

Not in use

12

MC Fault

4

Not in use

13

NO Fault

5

Not in use

14

+10 to +28 VDC Manual Self Test Input (>5 s)

6

Not in use

15

EOL Resistor

7

4–20 mA Sink Output

16

AL Resistor

8

NO Alarm

17

EOL Resistor

9

MC Alarm

18

AL Resistor

5.4 Wiring Diagram

Terminal 1 has a Blocking Diode for reverse polarity protection and a Multi-fuse for overcurrent protection.

Figure 9. FSL100 Wiring Diagram (Power On – Normal)

Table 2. FSL100 Terminal Allocation

Page 21

INSTALLATION

MAN0987_Iss 2_09/16

17

FSL100 Series Flame Detectors

Technical Handbook

Warning

The cable Earth (Ground) core must be connected to Protective Earth via the Controller power supplies, and the

cable screen must be connected to the controller’s common earth (ground) point.

The cable armour or conduit must be bonded to Protective Earth at regular intervals while being isolated from

the cable screen, cores and controller.

Avoid earth (ground) loops at all times.

5.5 Electrical Connection (General)

The flame detector has several wiring options; the most important are:

1. Wiring to a fire control panel using the ‘current increase’ principle.

2. Wiring to a PLC using a 0-20 mA output.

3. Wiring with an additional manual self-test.

4. Stand-alone wiring, with direct use of relays.

Options 1 to 3 are explained in this chapter, and Option 4 is shown in Chapter 5.4 Wiring Diagram.

5.6 Wiring to a Controller (General):

1. Use multi-core, shielded, twisted pair cable with earth (ground), depending on the panel and the type of connection. The

isolation resistance to ground must be at least 500K Ohm.

2. Core size must be 0.5 to 1.5 mm2 (20 to 16 AWG).

3. The length and diameter of the wires should be selected so that the flame detector will have sufficient power under all

conditions (normal and alarm) to ensure that the operating voltage is never below 10 VDC, especially when in alarm mode.

4. On the flame detector side of the cable leave a 10 cm (4 in) loop of spare cable to allow for alignment of the detector.

5. Grounding on the flame detector side: ensure that the screen cannot make an electrical connection with ground or with the

electronics in the detector housing. Ensure that the electronics in the flame detector housing are isolated from local ground

to avoid potential differences (ground loops).

6. Do not connect more than one flame detector per loop.

The flame detector has a cable gland fitted with an 8 mm insert. Use the cable gland with the insert for cables from 5.5 – 8 mm

diameter. Remove the insert for cables of 8 – 13 mm diameter.

Figure 10. FSL100 Cable Gland with and without Cable Entry Insert

Page 22

INSTALLATION

MAN0987_Iss 2_09/16

18

FSL100 Series Flame Detectors

Technical Handbook

Isola

alarm

shrin

te EOL and

resistors with

kable tubing

FLT

Alarm

EOL

Loop Power

Isolate EOL and

Alarm resistors

with Heatshrink

5.7 Wiring to a Fire Control Panel

The flame detector can be connected to a fire control panel using the current increase principle.

The flame detector is connected to the fire panel with 3 or 4 core cables, i.e. 2 cores for the power supply and 1 or 2 cores for

the loop. An additional core for the manual self-test may be used (see the FSL100 Terminal Connection Diagram).

The end of line resistor (EOL) is placed between the terminals 15 and 17. The alarm resistor (AL) is placed between terminals

16 and 18. The end of line and alarm resistors should be adapted to the fire control panel. They are approximately the same

size resistors that are used when connecting a manual call point to a fire control panel.

Controller

Alarm

EOL

Loop

Loop

Alarm

Alarm

Power

Screen end

isolated from

detector and

earth (ground)

Screen end

connected to

system earth

(ground)

Screened cable

Operating Principle:

The loop uses the alarm contact and the fault contact of the flame detector plus two resistors. In the event of a detector fault a

wire breakage is simulated. In the event of a fault followed by an alarm, a current Vn/AL is flowing through the loop. Thus an

alarm ‘overrides’ a fault signal, as can be seen in the figure.

Notes:

1. Please consult the fire control panel manufacturer for the values of the Alarm and EOL resistors.

2. The alarm and EOL resistor must be rated 2 W minimum each, and the total power dissipation of both alarm and EOL

resistor should not exceed 2 W. Use heat shrink tubing to insulate the legs of the EOL and the AL resistor when in-situ.

3. Do not connect more than one flame detector to a loop.

Figure 11. FSL100 to Controller Wiring

Power On, Normal

Page 23

INSTALLATION

MAN0987_Iss 2_09/16

19

FSL100 Series Flame Detectors

Technical Handbook

5.8 Wiring to a PLC

PLC

R = max

500Ω at

24 VDC

Screen end

isolated from

detector and

earth (ground)

Screen end

connected to

system earth

(ground)

Figure 12. Wiring to a PLC

Notes

1. 0-20 mA sinking analogue output, non-isolated.

5.9 Wiring to a 4-20 mA Non-Isolated (Sourcing) Current Output

The FLS100 detectors can be wired to a 4-20 mA non-Isolated (Sourcing) Output by using the controller’s alarm and fault

relays, as shown below.

Figure 13. Wiring to a 0-20 mA Non-Isolated (Sourcing) Current Output

The 4-20 mA sourcing output has the following values:

≥4 mA = Normal operation

≥20 mA = Alarm

0 mA = Fault (the 0 mA current will change to ≥20 mA (alarm) if flames are detected while the source is in fault)

Note:

This configuration has 2 wires connected to T1, but you should check if this is forbidden by your local regulations.

Page 24

INSTALLATION

MAN0987_Iss 2_09/16

20

FSL100 Series Flame Detectors

Technical Handbook

ON

OFF

5.10 Connecting the Manual Self-Test

A manual self-test switch can be incorporated by supplying a +10 to +28 VDC switched current to terminal 14 in the detector.

This switch can be integral or external to the Fire Control panel or the PLC.

Figure 14. Manual Self-Test Switch Locations

5.11 FSL100 Latching Alarm Settings

The FSL100 uses DIL switch 3 for field selectable alarm latching or unlatching. The default setting is latching ON, and DIL

switches 1, 2 and 4 are currently unused.

To change alarm status, change the DIL switch, and then power off for >1 second before switching back on again.

This setting is standard for fire control panels in conformity with the European standard EN54. However, you should always read

your controller’s handbook as some systems can control alarm latching status by software, in which case there is no need to

reset the detector by powering it off.

Figure 15. Latching Alarm Settings

Latching alarm Non-Latching alarm

Page 25

COMMISSIONING

MAN0987_Iss 2_09/16

21

FSL100 Series Flame Detectors

Technical Handbook

Caution

Always ensure that relay operated outputs and alarms are inhibited or isolated before carrying out any work on

Alarm systems.

Always ensure that Alarm Systems are returned to Normal Operation when work is completed.

6

Commissioning and Testing

Notes:

1. Commissioning, maintenance and functional testing of Honeywell Fire Detection systems must only be carried out by

qualified Honeywell approved persons or qualified persons trained in accordance with this manual.

2. All local laws and regulations for the commissioning and the cabling apply, including law and regulations for activating

alarm systems, extinguishing systems and other outputs.

3. For hazardous area applications appropriate regulations shall be followed.

4. The IR sensors can become saturated if exposed to high ambient IR radiation, so ensure that the FSL100 detectors are

shielded from potential sources such as boilers, radiators and IR lamps. The FSL100 detector returns to normal within 10

seconds once the IR source is removed.

6.1 Commissioning

Carry out the following steps before the flame detector is activated for the first time and in conjunction with the associated

Controller or PLC’s Technical Manual:

1. Satisfy yourself that the chosen FSL100 is the correct choice for this situation, location and controller.

2. Clean the FSL100 window using a microfiber glass cloth or optical wipe.

3. Check the terminals, seals and cable gland, and then close and secure the FSL100 housing.

4. Check position and alignment.

5. Check if there are potential false alarm sources in the field of view and shield if necessary.

6. Thoroughly tighten the cable gland and all fasteners.

7. Check the cabling in between the FSL100 and the controller.

8. Check the controller is electrically safe (isolator, protective earth (ground) etc.)

9. Check the cable screening is correctly bonded to the controller.

10. Check that armoured conduit is earthed (grounded) but isolated from the cable screen.

11. Test the manual self-test by shorting FSL100 terminals 1 & 14 for approximately 5 seconds.

12. Perform a functional test with the FSL100-TL or FSL100-TLX test lamp even if the manual test was ok.

13. If satisfied, and when all detectors are commissioned and tested, set the Controller or PLC to normal operation.

Page 26

COMMISSIONING

MAN0987_Iss 2_09/16

22

FSL100 Series Flame Detectors

Technical Handbook

Warning

A user-defined performance requirement may stipulate that an actual (real) fire performance test is carried out

from time-to-time. Ensure that a Safe System of Work is used to avoid the risk of death, injury or damage to

property.

Caution

Always ensure that relay operated outputs and alarms are inhibited or isolated before carrying out any work on

Alarm systems.

Always ensure that Alarm Systems are returned to Normal Operation when work is completed.

6.2 Functional Testing

The FSL100 flame detector has been tested in the factory and shall be tested as part of installation and commissioning. In

addition the flame detector should be functionally tested regularly (i.e. weekly) as part of a site fire alarm test. Check and clean

the FSL100 window prior to testing. Contamination lowers the sensitivity of the flame detector and can build up over time if not

monitored and cleaned regularly.

Honeywell supplies the FSL100-TL (safe area) and FSL100-TLX (hazardous area) test lamps for the FSL100 series of flame

detectors. Please read the test lamp instructions in this manual before you start the functional test.

6.3 Fault Analysis

False alarms may be triggered by transient events or because:

1. The sensor is activated by a known or unknown source in its field of view.

2. The sensor is activated by electromagnetic interference.

3. The sensor is activated by cabling faults or damage (may be intermittent).

4. The sensor electronics are faulty.

A single false alarm should not cause undue concern, but a series of false alarms should be carefully investigated to rule out the

causes listed above. You should also consider other factors such as season, weather, time of day, ambient temperature or

humidity, angle of the sun, etc.

Page 27

COMMISSIONING

MAN0987_Iss 2_09/16

23

FSL100 Series Flame Detectors

Technical Handbook

Caution

Always ensure that relay operated outputs and alarms are inhibited or isolated before carrying out any work on

Alarm systems.

Always ensure that Alarm Systems are returned to Normal Operation when work is completed.

6.4 Fault Testing

Refer to the manufacturer’s instructions before carrying out any testing as some controllers require sensors to be

decommissioned before removal or replacement.

1. Always follow a structured fault analysis and test regime.

2. Check the suspect FSL100 for signs of displacement, contamination, damage, loose or damaged cables, transient sources

etc.

3. Cover the FSL100 optics to ensure that no light or other radiation can reach the sensor and wait 30 seconds for the sensor

to return to normal. A continuing alarm state may be caused by the cabling or by the electronics. Ensure that the detector

window is uncovered after this test.

4. Check off the items listed in the section on Commissioning.

5. Check the power supplies; cables, voltage, current, ripples on the voltage signal etc.

6. Replace the flame detector with a known serviceable spare and re-test.

Page 28

COMMISSIONING

MAN0987_Iss 2_09/16

24

FSL100 Series Flame Detectors

Technical Handbook

This page deliberately left blank.

Page 29

MAN0987_Iss 2_09/16

25

FSL100 Series Flame Detectors

Technical Handbook

OPERATION

7

FSL100 Operation

7.1 The Display LEDs

The FSL100 series flame detectors have 3 LEDs on the display:

Steady green: powered up and in normal operation

Steady yellow: fault (blinking yellow: repeated self-test after a self-test fault)

Steady red: alarm

7.2 Normal Operation

The green LED is on when power is applied and the detector is in normal operation.

Fire Alarm

The green normal operation LED turns off and the red alarm LED turns on whenever the detector senses an alarm condition

and (under default settings) the alarm will remain latched (held on) until the event is cleared and either the alarm is reset at the

controller or the detector’s power is cycled.

Alternatively, if the latch setting has been changed to ‘unlatched’ the detector will return to normal operation once the alarm

trigger event has been removed.

Note: Optional alarm system relay outputs may be triggered during an alarm condition.

7.3 Fault Conditions

The yellow and green LEDs are illuminated when a fault condition occurs. The yellow LED turns off as soon as the fault is

cleared.

The green and yellow LEDs turn off and the red LED turns on if an alarm occurs during a non-critical fault condition (i.e. during

an IR or UV lamp test).

A blinking yellow LED shows that a self-test is in progress. The LED will become steady yellow if the FSL100 repeatedly fails

self-test.

7.4 Relay Outputs

The flame detector has 2 relay outputs:

1. Alarm relay (SPDT) that can be used to operate an alarm or relay controlled event. It can be changed from Latching

(default) to Unlatched. A latched alarm can be reset by using controller software or by cycling the detector power off and

on.

2. Fault relay (SPDT). The fault relay is energized when the detector is powered up and will be de-energized in the event of a

fault. The fault relay is non-latching.

7.5 Analogue Output 0–20 mA (Stepped, Sinking, Non-Isolated)

The analogue output has the following possible values:

0 mA power fault / microprocessor fault

2 mA optical fault

4 mA normal operation

20 mA Alarm

The output defaults to 20 mA if, during a fault, the FSL100 detects a fire.

7.6 Self-Testing

The FSL100 carries out a Power On Self Test (POST), and the 3 LEDs will flash sequentially until it is completed (10 Seconds)

The LED sequence is replaced by a steady green LED If the detector passes the test.

While powered up, an optical self-test is periodically and automatically executed to monitor the electronics and the sensor(s).

During this short test the yellow LED may flash and the FSL100 outputs are temporarily inhibited. The test may repeat several

times if a sensor fails the optical self-test.

The yellow fault LED will be steady and the fault relay will de-energize if the fault condition remains after the repeated self-tests.

Page 30

MAN0987_Iss 2_09/16

26

FSL100 Series Flame Detectors

Technical Handbook

OPERATION

Caution

Always ensure that relay operated outputs and alarms are inhibited or isolated before carrying out any work on

Alarm systems.

Always ensure that Alarm Systems are returned to Normal Operation when work is completed.

7.7 Manual Self-Test

The flame detector can test the sensor(s) and also the signal processing with help of the optional manual self-test circuit.

During a successful manual self-test the alarm relay is energized and the red alarm LED illuminates. If the detector is latched,

the alarm continues until the detector is powered off.

For the manual self-test a switch can be mounted in the controller or connected externally to a +10 to +28 VDC supply. (See Ch.

6.5 Connecting the Manual Self-Test.)

During commissioning this option can be tested by shorting the FSL100 terminals 1 & 14 for 5 seconds maximum.

1. The manual self-test can be used during commissioning to test the detector without the necessity to use a flame detector

test lamp.

2. The manual self-test is not a replacement for the functional test using a test lamp. After the commissioning is completed,

the flame detectors must be functionally tested by means of a test lamp.

Page 31

MAN0987_Iss 2_09/16

27

FSL100 Series Flame Detectors

Technical Handbook

MAINTENANCE

Warning – Explosion Hazard

Rubbing the GRP housing or mounting may cause static discharges that can result in an explosion in a

combustible atmosphere.

In hazardous areas use only a clean, damp cloth (moistened with water) to clean the mounting and detector.

8

Maintenance

Periodically inspect FSL100 and cabling for signs of physical damage. Do not use solvents or abrasive cleaners on the detector

housing or optics. Clean only with microfiber cloths moistened with water, or use optical grade wipes.

FSL100 has no user serviceable parts. Honeywell Analytics recommends that the unit is checked and serviced annually by an

approved Honeywell field technician.

Except for cleaning there is no specific preventive maintenance needed. Routine inspection of the following items is

recommended as follows:

1. Check the position and the alignment of the flame detectors.

2. Check there are no potential false alarm sources in the field of view.

3. Check there are no obstacles which restrict the field of view.

4. Clean the detector window with a microfiber cloth (see above).

5. Ensure that the cover of the housing (with detector window) is mounted correctly on the housing. The sensors must be

visible when you look through the detector window.

6. Check the cabling and conduits from the flame detectors to the controller for damage, insecurity, loose connections,

especially at earth (ground) points.

7. Check the cover and the gland are secure and undamaged to protect the IP rating.

8. Check that all fasteners and the cable gland are tight and secure.

9. Perform a functional test with help of an FSL100-TL or FSL100-TLX test lamp.

10. Ensure that once a year the inner side of the detector window is cleaned (i.e. during a field service technician’s annual

inspection).

Note:

1. The user is responsible for keeping the equipment in optimal condition. Contact Honeywell Analytics Technical Support if

you have any concerns about the serviceability or operation of the FSL100 Flame detectors, or if you need help with this

manual.

2. Do not use a liquid cleaning agent for cleaning the flame detector.

3. Your local Honeywell representative or distributor will be happy to advise you about keeping replacement Flame Detectors

or Test Lamps.

Page 32

MAN0987_Iss 2_09/16

28

FSL100 Series Flame Detectors

Technical Handbook

MAINTENANCE

This page deliberately left blank.

Page 33

MAN0987_Iss 2_09/16

29

FSL100 Series Flame Detectors

Technical Handbook

ACCESSORIES

2-Axis Swivel

Detector

Cable gland

always points

downwards

Warning – Explosion Hazard

Rubbing the GRP housing or mounting may cause static discharges that can cause an explosion in a

combustible atmosphere.

Use only a clean, damp cloth (moistened with water) to clean the mounting and detector.

Detector

Window

9

FSL100-SM21 Swivel Mount

The optional swivel mount is a convenient mounting device for fixing the FSL100 series of flame detectors to a variety of

surfaces or poles. The two axis swivel enables you to accurately align the detector’s field of view to the area of fire risk, or you

can use it to increase the detector’s stand-off from the mounting surface (i.e. for cooling and ventilation).

The FSL100-SM21 swivel mount is suitable for Hazardous Area applications, but see the Warning below.

9.1 How to Install the Detector Using the Swivel Mounting

Installation should be carried out by qualified persons only, and in conjunction with the instructions in this handbook.

Tools required:

13 mm wrench

7 mm wrench

#7 screwdriver

Wall plate

Figure 16. Swivel Mounting Fitment (Optional)

1. Unbolt either of the two swivel joints to make it easier to fix the detector to the mounting plate later on.

2. Mount the wall plate to a vibration free wall, ceiling or pole using 4 suitable fixings (not supplied).

3. Carefully undo the four plastic screws at the corners of the detector cover plate, and gently separate the cover from the

body. Be careful not to touch or damage the electronics inside.

4. Locate and remove the four steel bolts shown in the figure above. Use these bolts to secure the detector body to the swivel

mounting plate, ensuring that the screw heads are fully seated in the body recesses, that the swivel hub is closest to the

cable gland, and that the cable gland will point downwards when fully assembled.

5. Reconnect the swivel joint and tighten the bolt finger tight.

6. Connect the power/signal cable (see Wiring to a Controller (General)) and tighten the cable gland.

7. Place the cover of the detector on the housing and carefully tighten the four red plastic screws to 2 Nm (1.5 ft/lb) torque.

Note: The sensors should be clearly visible through the detector window.

8. Adjust the detector to the correct orientation and fully tighten the two swivel bolts.

9. Check that all is secure and correctly fitted, and then test (with a Honeywell approved test lamp) to ensure that the

operation is correct.

Page 34

ACCESSORIES

MAN0987_Iss 2_09/16

30

FSL100 Series Flame Detectors

Technical Handbook

Wall Plate

Detector Plate

Figure 17. SM21 Swivel Mount Attachment Plate Dimensions

9.2 Cleaning

Only experience of the operating environment will dictate how often you clean your detectors and mountings, but you should

remove contamination by wiping the mounting, detector and detector window regularly with a lightly dampened micro-fibre cloth.

Do not use dry cloth or dry paper in flammable atmospheres as this may cause static discharge that may result in an explosion.

Remember that airborne dusts can be more hazardous than flammable vapours.

Used cleaning cloths may be hazardous to health, so launder them carefully or dispose of them as hazardous waste.

Page 35

ACCESSORIES

MAN0987_Iss 2_09/16

31

FSL100 Series Flame Detectors

Technical Handbook

Warning – Safe Areas Only

The FSL100-TL test lamp is only compatible with the Honeywell Analytics FSL100 series flame detectors used

in safe areas. The test lamp is not approved for use with any other types of detector or location.

Always ensure that relay operated systems (drenchers, alarms, etc.) are inhibited or disabled before operating

this test lamp in the vicinity of any flame detector.

Always ensure that Alarm Systems are returned to Normal Operation when work is completed.

10

FSL100-TL Test Lamp Non-EX

The FSL100-TL (test lamp) is a rechargeable, hand-held IR and UV radiation source that is specifically designed to test

Honeywell FSL100 series flame detectors used in safe areas only. The detection range is approximately 4 meters (13 ft).

It is supplied in a custom carry case with a dedicated charging unit suitable for mains connection.

10.1 Safety Instructions

Read this manual carefully and study the warnings and cautions before using this equipment.

1. This test lamp is only suitable for testing Honeywell FSL100 series flame detectors in safe areas.

2. Do not use the test lamp in wet conditions.

3. Ensure testing of the flame detectors does not activate unwanted alarm signals.

4. Press the trigger to switch on, release it to switch off.

5. Batteries may be damaged if you use the test lamp continuously for longer than 10 minutes.

6. The grid may become hot during use. Be careful not to allow contact with skin or flammable objects.

7. Do not touch or remove the protective grid or stick fingers or objects through it.

8. Do not point directly at eyes from a short distance. Do not look directly into the light.

9. Store the test lamp in its box in a clean and dry location. A dirty reflector will reduce the test range.

10. Do not incinerate or mistreat the lamp or battery as the battery could leak or explode.

11. The test lamp should not be used when damaged. If a fault does occur, do not open the lamp other than to change the

battery. Return faulty lamps to Honeywell Analytics for repair.

12. Keep the test lamp and batteries away from children. Dispose of items in accordance with the WEEE directive.

Figure 18. FSL100-TL Test Lamp Kit

Page 36

ACCESSORIES

MAN0987_Iss 2_09/16

32

FSL100 Series Flame Detectors

Technical Handbook

Caution

Test outputs will be generated and relays will be activated during Cause and Effect Testing.

Ensure that relay activated output systems (i.e. emergency deluge / sirens etc.) are inhibited or isolated before

starting the test.

Ensure that the system is returned to normal operation once testing is complete

Caution – WEEE Directive

According to local laws and regulations batteries should be disposed of separately from household waste. Take

them to a collection point designated by local authorities when they are no longer needed.

10.2 Before First Use

The battery is fully charged when leaving the factory, but it should be fitted to the lamp and recharged prior to use.

1. Remove the battery compartment cover (on the top of the test lamp).

2. Fit the battery so that its terminals are making contact with the lamp terminals.

3. Refit the battery cover.

4. Attach the charging unit and charge the battery for ≅4 hours (6 hours max.).

5. The red LED should be lit during charging, although it may not come on straight

away if the battery is completely discharged.

10.3 Test Lamp Operation

This is usually a two-person operation; one at the detector and one at the controller. In addition you may need additional firewatchers while the alarms are inhibited.

1. Inhibit or isolate all affected relay outputs before beginning the test.

2. Aim the test lamp at the flame detector from a distance of ≅4 m (13 ft).

3. Operate the test lamp for ≅30 seconds and check that the alarm operated correctly. Do not use the test lamp for longer

than 1 minute continuously

4. Reset the alarm and test the next detector, waiting at least 30 seconds between tests to allow the lamp to cool down.

10.4 Battery Charging and Storage:

1. The red LED should be lit during charging, although it may not come on immediately if the battery is fully discharged.

2. Attach the charging unit to the lamp and charge the battery for ≅4 hours (6 hours max.).

3. Recharge the battery after prolonged use.

4. Recharge batteries every 3 months when in storage. Failing to do so will reduce battery life.

5. Store the test lamp and batteries in a cool, dry, ventilated place.

6. Do not allow the storage temperature to fall below 4 °C as this will reduce battery life.

Page 37

ACCESSORIES

MAN0987_Iss 2_09/16

33

FSL100 Series Flame Detectors

Technical Handbook

Caution

Do not touch the replacement bulb with bare skin as this will deposit contaminants that will lead to premature

failure of the bulb.

10.5 Bulb Replacement

In the event of a bulb failure, you may replace the bulb with Honeywell part number FSL100-TLBU only. However, Honeywell

recommend that this is only carried out by competent personnel, or that the Test Lamp is returned to Honeywell for repair.

1. Remove the battery cover and then remove the battery (Step 1).

2. Remove the protective ring from the front of the test lamp (Step 2).

3. Vertically cut the label on the rear seam (Step 3).

4. Remove qty. 5 screws (Step 4).

5. Carefully separate the two casing halves.

6. Hold the reflector in place and remove the bulb clip by squeezing the legs (Step 7).

7. Remove the bulb from the reflector and disconnect the lead from the connector.

8. Connect the new bulb lead to the connector.

9. Insert the bulb into the reflector.

10. Place the bulb clip over the bulb and lock it in into the bushing.

11. Reassemble the two casing halves and refit the 5 screws.

12. Refit the battery and battery cover.

13. Test the lamp.

14. Refit the protective ring.

Step 3

Step 4

Step 1

Step 2

Figure 19. FSL100-TL Bulb Replacement Exploded View

Step 7

Page 38

ACCESSORIES

MAN0987_Iss 2_09/16

34

FSL100 Series Flame Detectors

Technical Handbook

This page deliberately left blank.

Page 39

ACCESSORIES

MAN0987_Iss 2_09/16

35

FSL100 Series Flame Detectors

Technical Handbook

This page deliberately left blank.

Page 40

ACCESSORIES

MAN0987_Iss 2_09/16

36

FSL100 Series Flame Detectors

Technical Handbook

Caution – WEEE Directive

According to local laws and regulations batteries should be disposed of separately from household waste. Take

them to a collection point designated by local authorities when they are no longer needed.

-

11

FSL100-TLX Test Lamp Hazardous Areas

The FSL100-TLX (test lamp) is an Intrinsically Safe (IS), battery operated, hand-held IR and UV radiation source that is

specifically designed to test Honeywell FSL100 series flame detectors in both safe and hazardous areas. The detection range is

approximately 4 meters (13 ft).

Figure 20. FSL100-TLX Test Lamp

11.1 Safety Instructions

1. Suitable for use in safe areas and IECEx zone 1, but only when properly assembled and in serviceable condition.

2. This unit is intrinsically safe only while all covers and components are in place. Do not assemble, dissemble, remove covers

or replace batteries other than in a known safe area.

3. The test lamp is only approved for testing Honeywell FSL100 flame detectors.

4. Do not use the test lamp in wet conditions.

5. The lamp does not contain any user replaceable parts other than the batteries. In the event of faults contact Honeywell

Analytics Technical Support for help.

6. It is advisable to remove the batteries if storing the test lamp for any period of time. Battery leakage could damage the

equipment.

7. Keep the test lamp and batteries away from children. Dispose of items in accordance with the WEEE directive.

8. Do not mistreat or incinerate. The batteries could explode if exposed to intense heat.

Page 41

ACCESSORIES

MAN0987_Iss 2_09/16

37

FSL100 Series Flame Detectors

Technical Handbook

Caution – WEEE Directive

According to local laws and regulations batteries should be disposed of separately from household waste. Take

them to a collection point designated by local authorities when they are no longer needed.

Caution

Test outputs will be generated and relays will be activated during Cause and Effect Testing.

Ensure that relay activated output systems (i.e. emergency deluge / sirens etc.) are inhibited or isolated before

starting the test.

Ensure that the system is returned to normal operation once testing is complete.

11.2 Before First Use

Perform the following actions in a known safe area:

1. Remove the two screws securing the battery compartment cover.

2. Remove the battery cover.

3. Place the four supplied AA batteries correctly in the battery compartment.

4. Replace the battery compartment lid and secure with the 2 screws. Do not overtighten.

5. Place the test lamp in its protective case with the shoulder strap in its correct position.

11.3 Operation

This is usually a two-person operation; one at the detector and one at the controller. In addition you may need additional firewatchers while the alarms are inhibited.

1. Inhibit or isolate all affected relay outputs before beginning the test.

2. The test lamp will turn on/off by pushing/releasing the pushbutton.

3. Aim the test lamp at the flame detector from a distance of ≅4 m (13 ft).

4. Operate the test lamp for ≅30 seconds and check that the alarm operated correctly. Do not use the test lamp for longer

than 1 minute continuously.

5. Reset the alarm and test the next detector.

11.4 Battery Replacement

Replacement non–rechargeable 1.5 VDC AA Alkaline batteries can be purchased locally.

1. Remove the two screws securing the battery compartment cover.

2. Remove the battery cover.

3. Place the four AA batteries correctly in the battery compartment.

4. Replace the battery compartment lid and secure with the 2 screws. Do not overtighten.

5. Place the test lamp in its protective case with the shoulder strap in its correct position.

Page 42

MAN0987_Iss 2_09/16

38

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

FSL100 General Specifications

Power

DC 12–24 V (10–28 VDC)

Current Normal

25 mA at 24 VDC

Current In Alarm

+/- 75 mA at 24 VDC

Start Up Time

<10 sec

Alarm Output Setting

Selectable LEDs and relays latching/non latching, factory

setting: latching

Connects to

- a fire control panel by means of end of line (EOL) and alarm

resistor (current increase)

- a device that can take relay outputs

- a PLC with a 0–20 mA input

End Of Line And Alarm Resistor

To match the fire control panel, free terminals dedicated for

the resistors are available

Note: the alarm and EOL resistors must be rated 2 W minimum

each and the total power dissipation of both alarm and EOL resistors

should not exceed 2 W

Local LEDs

continuous green: normal operation

continuous yellow: fault (blinking yellow: repeated self-test after a

self-test fault)

continuous red: alarm

Alarm Relay

De-energized during normal operation, no alarm, SPDT, 30 VDC –

2 A, 60 W max.

Fault Relay

Energized during normal operation, no fault, SPDT, 30 VDC – 2 A,

60 W max.

Current Output

Standard available 0-20 mA (stepped, sinking, nonisolated) 0 mA power fault / microprocessor fault

2 mA optical fault

4 mA normal operation

20 mA Alarm

Maximum Range (IR)

(to alarm <10 s for a 0.1 m2 n-heptane fire)

35 m/115 ft. (FSL100-IR3)

Maximum Range (UV and UVIR)

(to alarm <10 s for a 0.09 m2 n-heptane fire)

23 m/75 ft. (FSL100-UV and FSL100-UVIR)

Alarm Response Time

8 to 30 s.

table continued…

SPECIFICATIONS

12

FSL100 Specifications

Page 43

MAN0987_Iss 2_09/16

39

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

FSL100 General Specifications

Cone Of Vision

90°

Ingress Protection

IP65

Temperature, Operating, ATEX/IECEx/FM

-25 °C to +70 °C (-13 °F to +158 °F)

Temperature, Operating, Safe Areas

-40 °C to +70 °C (-40 °F to +158 °F)

Temperature, Storage

-40 °C to +70 °C (-40 °F to +158 °F)

Humidity Range

0 – 95 %RH, non-condensing

Automatic and Manual Self-Test

Automatic Sensor Test (Built in Self-Test) and manual self-test

Detector Body

GRP, Non-Incendive. UV resistant, Self-Extinguishing V-0 (UL-94).

Swivel Mounting

PA66 (UV Resist.), 316 SS (Fixings)

Dimensions (Body only)

125 x 80 x 57 mm (4.9 x 3.15 x 2.25 inch)

Weight

465 gram (1.05 lb)

745 g (1.67 lb) with optional mounting

Cable Gland

cores 0.5 to 1.5 mm2 (20 to 16 AWG)

Pressure Compensating Element

The Pressure Compensating Element (PCE) helps prevent moisture

build up inside the detector housing caused by ambient fluctuation

Terminals

Suitable for cores 0.5 to 1.5 mm2 (20 to 16 AWG), tightening torque

0.4 Nm (0.3 ft/lb)

EN54-10 Certificate

FSL100-IR3 Flame Detector: Class 1

FSL100-UV Flame Detector: Class 2

FSL100-UVIR Flame Detector: Class 2

ATEX Certificate

FSL100-IR3 Flame Detector: ATEX zone 2/22

FSL100-UV Flame Detector: ATEX zone 2/22

FSL100-UVIR Flame Detector: ATEX zone 2/22

FM3260 Approval

FSL100-IR3 Flame Detector

FSL100-UV Flame Detector

FSL100-UVIR Flame Detector

FM3611 Approval

FSL100-IR3 Flame Detector: Non-Incendive, Class 1,2 & 3 Div 2

FSL100-UV Flame Detector: Non-Incendive, Class 1,2 & 3 Div 2

FSL100-UVIR Flame Detector: Non-Incendive, Class 1,2 & 3 Div 2

RoHS

FLS100 Series is RoHS compliant

SPECIFICATIONS

Table 3. FSL100 General Specifications

Page 44

MAN0987_Iss 2_09/16

40

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

FSL100-TL Safe Area Test Lamp Specifications

Lamp Housing

ABS (plastic) black

Ingress Protection rating

IP30 / NEMA 1

Adapter (charger)

100-240 Vac, 500 mA switching with plugs for US, EU, GB and AU

Battery

12 VDC / 2.8 Ah Sealed Lead Acid Battery

Lamp

H3, 12 VDC / 100 W

Temperature range

+4 to +40 ºC (+39 to +104 ºF)

Continuous Operation (Max)

10-15 minutes under optimal conditions

Operational range

Up to 4 m (13 ft)

Country of Origin/Intrastatistic Number

EU, 8531 10 30

Shipping dimensions (Lamp box)

310 x 220 x 210 mm (12.725 x 9 x 8.725 ins)

Shipping weight (Lamp)

2.1 kg (4.62 lbs)

Carrying case

Case: polypropylene, Inlay: polyurethane

Shipping dimensions (box)

440 x 340 x 280 mm (17.375 x 13.375 x 11 ins)

Shipping weight incl. test lamp

5 kg (11.1 lbs)

FSL100-TL Battery Specifications

Replacement Part No.

FSL100-TLBT

Battery Type

Rechargeable Sealed Lead-Acid Battery

Battery Voltage And Capacity

12 VDC / 2.7 Ah

Terminal Type

Spade

Dimensions

103 x 70 x 46 mm

FSL100-TLX Hazardous Area Test Lamp Specifications

Housing

Aluminium

Ingress Protection Rating

IP66

Power (Batteries)

6 VDC Nominal (4 X 1.5 VDC AA Alkaline Battery)

Operational Range

Up To 4 M (13 Ft)

Working Temperature Range

-25 To +50 °C (-13 to +122 °F)

Storage Temperature Range

-40 To + 80 °C

Country Of Origin/Intrastatistic Number

EU, 8531 10 30

Shipping Dimensions (Box)

32 X 30 X 13 cm (13 X 11 X 5 in.)

Shipping Weight

3 kg (7 lbs.)

IECEx Certificate

IECEx Zone 1

FSL100-SM21 Swivel Mount

Material Swivel / Bolts and Nuts

PA66 / 316 SS

Weight

280 grams (0.62 lbs)

SPECIFICATIONS

13

Accessory Specifications

Table 4. Accessory Specifications

Page 45

MAN0987_Iss 2_09/16

41

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

SPECIFICATIONS

This page deliberately left blank.

Page 46

MAN0987_Iss 2_09/16

42

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

Title

Standards

Certificates

ATEX

DEKRA Certification B.V.

DEKRA15ATEX0105X

IECEx

DEKRA Certification B.V.

IECEx DEK 15.0070X

FM

FM Approvals

Check www.approvalguide.com

CPR

SKG-IKOB Certificatie B.V.

0960-CPR-SKGIKOB.009676

14

FSL100 Certifications

14.1 EC Declaration of Conformity

A full EC declaration of conformity is available on either original hardcopy or electronic file (Honeywell Analytics website). This

document lists the European Standards with which FSL100 Series flame detectors comply.

14.2 National and International Certificates of Compliance

The FSL100 series of Flame Detectors holds the following National and International Certificates and Certification Codes:

Copies of the certificates are available on request.

Note 1: OEMs are responsible for ensuring that their systems are certified in accordance with these tables and any 3rd-party

requirements.

14.3 Rating Labels

Figure 22. EN54-10/ATEX/IECx Label

Figure 23. FM Label

Page 47

MAN0987_Iss 2_09/16

43

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

14.4 North American approvals – cFMus class 3611 & FM class 3260

All drawings and other details are listed in the “Document List FSL100-series flame detector”.

FM approvals for the:

FSL100-UV UV Flame Detector

FSL100-UVIR UVIR Flame Detector

FSL100-IR3 IR3 Flame Detector

Nonincendive per FM class 3611: Class I, II, III, Div. 2, Groups A, B, C, D, F, G

Nonincendive per C22.2 No. 213: Class I, Div. 2, Groups A, B, C, D

Dust-tight per C22.2 No. 25: Class II, III, Div. 2, Groups F, G

Ambient temperature : -25ºC to +70ºC

Temperature Code: T4 at Ta < +70ºC

Ingress Protection: IP65

Warnings:

1. The power supply of the flame detector must comply with NEC class 2, as described by the National Electrical Code

(ANSI / NFPA 70).

2. Cable used with the flame detector must be PLTC or ITC type as described by the National Electrical Code (ANSI /

NFPA 70); twisted shielded pairs.

3. When cleaning the swivel mount SM21, exclusively use a damp micro fiber cloth to avoid the mount from getting static.

4. The screws of the housing lid should be tightened with a torque of 2 Nm.

5. The screws of the wire terminals should be tightened with a torque of 0.4 Nm.

6. The alarm- and EOL resistor must be rated 2 W minimum each and the total power dissipation of both alarm- and EOL

resistor should not exceed 2 W.

7. Substitution of components may impair suitability for division 2.

8. Do not open when energized.

9. Explosion hazard. Do not remove or replace while circuit is powered or when a flammable or combustible atmosphere is

present.

10. Explosion hazard. Do not disconnect equipment when a flammable or combustible atmosphere is present.

11. Explosion hazard. Do not disconnect while circuit is powered unless the area is known to be non-hazardous.

-For language translation assistance, contact your local representative, or email: gasdetection@honeywell.com

-Pour la langue de traduction aide, contactez votre représentant local ou envoyez, un e-mail: gasdetection@honeywell.com

Avertissement:

Risque d'explosion. Ne pas débrancher tant que le circuit est sous tension, à moins qu'il ne s'agisse d'un emplacement non

dangereux.

Page 48

MAN0987_Iss 2_09/16

44

FSL100 Series Flame Detectors

Technical Handbook

CERTIFICATION

Fuel

FSL100-UV

FSL100-UVIR

FSL100-IR3

time

n-Heptane 30 x 30 cm (1 sqft)

23 m (75 ft)

23 m (75 ft)

35 m (115 ft)

within 10 sec.

Alcohol (Ethanol) 50 x 50 cm (20 inch by 20 inch)

18.3 m (60 ft)