Honeywell FSC-SM Installation Manual

FSC Safety Manager

Installation Guide

for use with the Honeywell FSC System

Releases 42x, 5xx and 600

FS20-500

.

Implementation

FSC Safety Manager

FSC Safety Manager

Installation Guide

for use with the Honeywell FSC System

Releases 42x, 5xx and 600

FS20-500

10/01

ii FSC Safety Manager Installation Guide 10/01

Copyright, Notices, and Trademarks

© Copyright 20 by Honeywell Inc.

Revision 0 – $SULO2, 201

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in

its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential

damages. The information and specifications in this document are subject to

change without notice.

TotalPlant, TDC 3000 and Universal Control Network are U.S. registered

trademarks of Honeywell Inc.

FSC is a trademark of Honeywell Safety Management Systems.

Other brand or product names are trademarks of their respective owners.

Honeywell

Industrial Automation and Control

Automation College

2820 West Kelton Lane

Phoenix, AZ 85023

(602) 313-5669

10/01 FSC Safety Manager Installation Guide iii

About This Publication

This publication includes both general and detailed installation information for the various major

components of the FSC Safety Manager (FSC-SM) for use with the Honeywell FSC system

Releases 42x, 5xx and 600. Specifically included are:

• general installation instructions for the FSC Safety Manager (FSC-SM) system,

• detailed installation instructions for installing the FSC Safety Manager Module (FSC-SMM),

and

• general installation instructions for the FSC-SM system.

Site planning information is contained in the TotalPlant Solutions (TPS) System Site Planning

Manual, which is in the System Site Planning binder. After installation of the FSC-SM, the

checkout procedure can be found in the FSC Safety Manager Service Manual, which is in this

binder.

This publication supports TotalPlant® Solutions (TPS) System network Releases 53x and 62x.

TPS is the evolution of TDC 3000X.

All references in this manual to "FSC Safety Manager" or "FSC Safety

Manager Module" pertain only for use with the Honeywell FSC system.

iv FSC Safety Manager Installation Guide 10/01

10/01 FSC Safety Manager Installation Guide v

Table of Contents

SECTION 1 – FSC SAFETY MANAGER SYSTEM INSTALLATION................................................ 1

1.1 Section Overview .........................................................................................................1

1.2 Equipment Warehousing.............................................................................................. 2

1.3 Move Preparation......................................................................................................... 3

1.4 Unpacking and Placement .........................................................................................13

SECTION 2 – SYSTEM COMPONENT INSTALLATION ................................................................21

2.1 Section Overview .......................................................................................................21

2.2 Installation Considerations......................................................................................... 22

2.3 Cabinet Installation..................................................................................................... 23

2.4 Cabling Considerations.............................................................................................. 24

2.5 Cabling Installation.....................................................................................................29

2.6 System Power Connections....................................................................................... 34

2.7 System Ground Connections .....................................................................................36

2.8 UCN Connections....................................................................................................... 39

SECTION 3 – SYSTEM COMPONENT CONFIGURATION ............................................................ 43

3.1 Section Overview .......................................................................................................43

3.2 System Configuration Overview................................................................................. 44

3.3 Module Configuration................................................................................................. 45

SECTION 4 – CONFIGURATION..................................................................................................... 47

4.1 Section Overview .......................................................................................................47

4.2 Configuration at FSC User Station............................................................................. 48

4.3 Configuration at TPS Universal Station...................................................................... 49

vi FSC Safety Manager Installation Guide 10/01

Figures

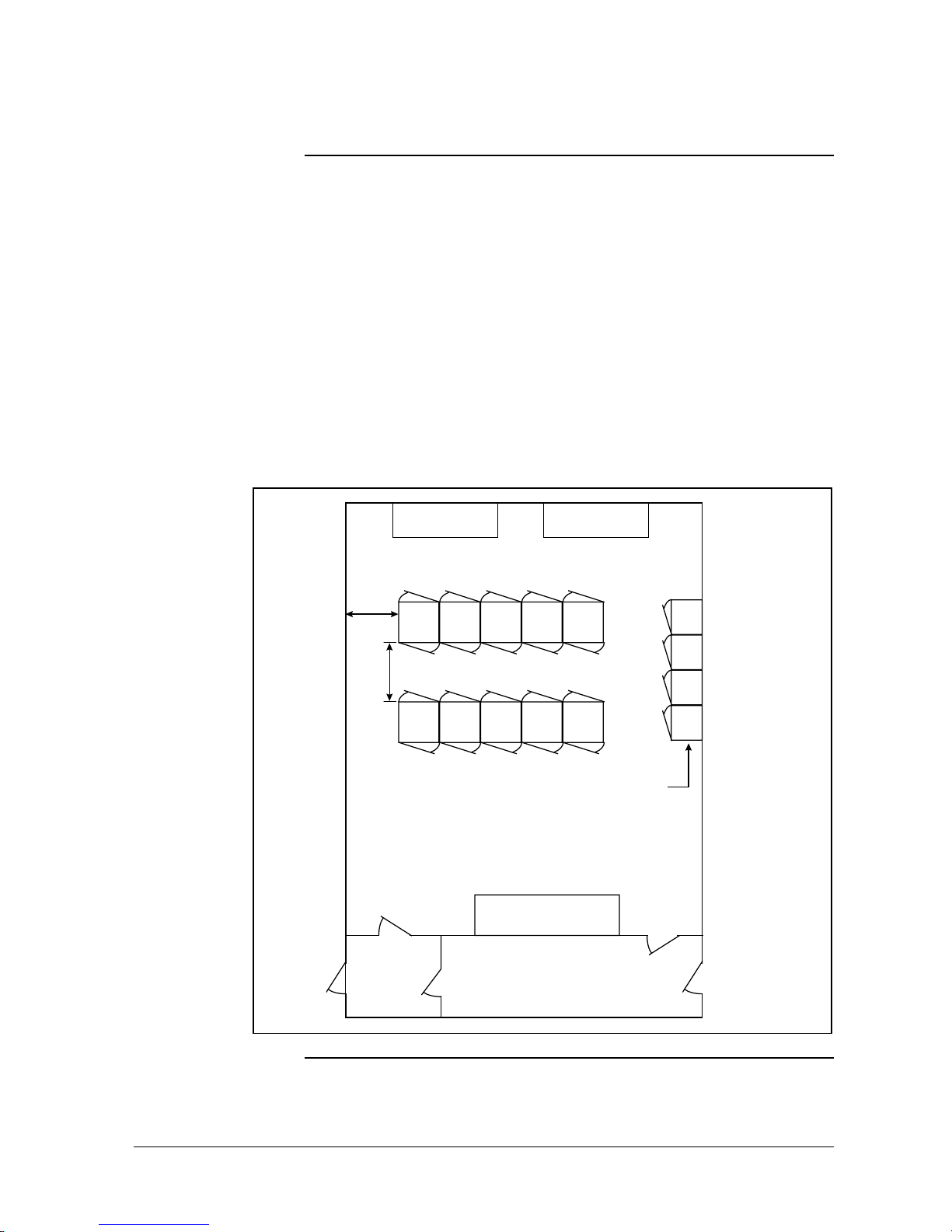

Figure 1-1 Typical Electronics Room Layout.............................................................................. 3

Figure 1-2 Location and dimensions of the cabinet bolt-down holes .........................................6

Figure 1-3 FSC-SM cabinet with back access (FTA-T).............................................................. 7

Figure 1-4 FSC-SM cabinet with front access (FTA-T).............................................................. 8

Figure 1-5 FSC-SM cabinet with front and back access (FTA-T) .............................................. 9

Figure 1-6 FSC-SM cabinet with front access (FTA-E)............................................................10

Figure 1-7 FSC-SM cabinet with back access (FTA-E) ........................................................... 11

Figure 1-8 FSC-SM cabinet with front and back access (FTA-E)............................................ 12

Figure 1-8 Placement of equipment onto lumber.....................................................................14

Figure 1-9 Placement using a mobile lifter............................................................................... 16

Figure 1-10 Lifting equipment by mobile lifter of crane ..............................................................17

Figure 1-11 Lifting equipment by mobile lifter of crane — part 2................................................ 18

Figure 1-12 Eyebolt crane method............................................................................................. 19

Figure 2-1 FSC-SMM front plate .............................................................................................. 29

Figure 2-2 Redundant FSC-SM UCN cabling .......................................................................... 30

Figure 2-3 Typical routing layout of internal wiring between I/O modules and

FTA-T via SICs ....................................................................................................... 31

Figure 2-4 Typical routing layout of internal wiring between I/O modules and

FTA-E via SICs ....................................................................................................... 32

Figure 2-5 FSC Safety Manager cabinet power connections................................................... 34

Figure 2-6 Connection of the UCN........................................................................................... 40

Figure 4-1 US System Status display....................................................................................... 51

Figure 4-2 US Engineering Main Menu display........................................................................52

Figure 4-3 US NIM Build Type Select Menu............................................................................. 53

Figure 4-4 US UCN Node Configuration display...................................................................... 54

Figure 4-5 US Node-Specific Configuration display................................................................. 55

Figure 4-6 US Process Point Building display.......................................................................... 56

10/01 FSC Safety Manager Installation Guide vii

Tables

Table 1-1 Move preparation checklist .......................................................................................4

Table 1-2 Move preparation checklist – part 2.......................................................................... 5

Table 1-3 Important unpacking considerations .......................................................................13

Table 1-4 Fork lift considerations............................................................................................ 14

Table 1-5 Mobile lifter considerations ..................................................................................... 15

Table 1-6 Roller method considerations ................................................................................. 18

Table 2-1 FSC system installation checklist............................................................................22

Table 2-2 Raceway shielding.................................................................................................. 24

Table 2-3 IEEE 518 wiring classification definitions................................................................ 25

Table 2-4 Tray spacing............................................................................................................26

Table 2-5 Tray/conduit spacing............................................................................................... 26

Table 2-6 Conduit spacing ......................................................................................................27

Table 2-7 Cabling guidelines...................................................................................................28

Table 2-8 System grounding considerations........................................................................... 36

Table 4-1 Start-up and reconfiguration procedures ................................................................ 49

Table 4-2 UCN configuration................................................................................................... 50

Table 4-3 UCN node configuration.......................................................................................... 53

Table 4-4 FSC-SMM data point configuration procedure........................................................57

viii FSC Safety Manager Installation Guide 10/01

Acronyms

AC...........................................................................................................................Alternating Current

CP......................................................................................................................................Central Part

CPU...................................................................................................................Central Processor Unit

DBM..................................................................................................... Diagnostic and Battery Module

DC...................................................................................................................................Direct Current

DCS............................................................................................................ Distributed Control System

EMI..........................................................................................................Electromagnetic Interference

EPROM.......................................................................... Erasable Programmable Read-Only Memory

ESD.................................................................................................................. Electrostatic Discharge

FLD .............................................................................................................. Functional Logic Diagram

FSC............................................................................................................................ Fail Safe Control

FSC-DS.......................................................................................................FSC Development System

FSC-SM ...............................................................................................................FSC Safety Manager

FSC-SMM ...............................................................................................FSC Safety Manager Module

FTA ...........................................................................................................Field Termination Assembly

HM................................................................................................................................. History Module

I/O ..................................................................................................................................... Input/Output

IEEE.............................................................................Institute of Electrical and Electronic Engineers

LCN....................................................................................................................Local Control Network

LED.......................................................................................................................Light Emitting Diode

NCF.............................................................................................................Network Configuration File

NIM...............................................................................................................Network Interface Module

PLC..................................................................................................... Programmable Logic Controller

SIC........................................................................................................ System Interconnection Cable

SM................................................................................................................................Safety Manager

SMM................................................................................................................Safety Manager Module

TAC......................................................................................................... Technical Assistance Center

TPS.........................................................................................................................TotalPlant Solution

TTL...........................................................................................................Transistor - Transistor Logic

UCN ............................................................................................................ Universal Control Network

US..............................................................................................................................Universal Station

VBD......................................................................................................................... Vertical Bus Driver

WD........................................................................................................................................Watchdog

10/01 FSC Safety Manager Installation Guide ix

References

For FSC-SM documentation:

Publication

Title

Publication

Number

Binder

Title

Binder

Number

FSC Safety Manager Installation

Guide

FS20-500 Implementation

FSC Safety Manager

TPS 3076

FSC Safety Manager Implementation

Guidelines

FS11-500 Implementation

FSC Safety Manager

TPS 3076

FSC Safety Manager Control

Functions

FS09-500 Implementation

FSC Safety Manager

TPS 3076

FSC Safety Manager Parameter

Reference Dictionary

FS09-550 Implementation

FSC Safety Manager

TPS 3076

FSC Safety Manager Configuration

Forms

FS88-500 Implementation

FSC Safety Manager

TPS 3076

FSC Safety Manager Service Manual FS13-500 Implementation

FSC Safety Manager

TPS 3076

For FSC documentation:

Publication

Title

Publication

Number

FSC Safety Manual PM.MAN.8047

FSC Hardware Manual PM.MAN.8048

FSC Software Manual PM.MAN.8025

x FSC Safety Manager Installation Guide 10/01

10/01 FSC Safety Manager Installation Guide 1

Section 1 – FSC Safety Manager System Installation

1.1 Section Overview

About this section

This section provides general installation information for the FSC Safety

Manager (FSC-SM) system. Topics included in this section are:

Subsection Topic See Page

1.1 Section Overview........................................................................................ 1

1.2 Equipment Warehousing............................................................................ 2

1.3 Move Preparation........................................................................................ 3

1.4 Unpacking and Placement........................................................................ 13

Tools and test

equipment

The following equipment is necessary for installation of the FSC Safety

Manager:

• Mobile lifter/lift truck — refer to Subsection 1.4 (Unpacking and

Placement),

• Carrier band MAP tester — refer to Subsection 2.2 (Installation

Considerations),

• Hand tools and multimeter, as in a typical electrician's tool kit,

• UCN Connector Torque Wrench Kit (part number: 4605459),

• Set of SAE (inch) "crow's foot" wrenches for the above torque wrench,

• ESD kit (Honeywell part number 30185-H).

ATTENTION

Installation of the FSC Safety Manager may only be

carried out by qualified and authorized personnel. Failure to comply with

the regulations and recommendations contained in this document may

cause severe damage to the equipment or serious injury to people.

REFERENCE — For detailed information regarding

• site planning and installation, refer to SM02-550 TPS System Site

Planning Manual in Binder TPS 3020-1 System Site Planning-1.

• post-installation checkout procedures, refer to the FSC Safety Manager

Service Manual in this binder.

2 FSC Safety Manager Installation Guide 10/01

1.2 Equipment Warehousing

Factory packing

For shipment, the FSC Safety Manager is packed with desiccant packages,

wrapped in a moisture barrier and optionally enclosed for shipment as

required by the user.

Transit/warehousing

specifications

The FSC Safety Manager can be shipped by a variety of means, but any

trucking should be done by enclosed air-ride vans. The equipment is

usually trucked on the final leg of the journey to the user warehouse or

site. There it is stored off the ground on a solid piece or combination of

lumber pieces (minimum height 10 cm / 4 in) and indoors until needed for

installation. During the whole process, the environment must be

monitored and corrected if the following equipment transit/storage ratings

are exceeded:

• Temperature range: –20°C to +70°C (–4°F to +158°F)

• Relative humidity: 5% to 95%, non-condensing

• Vibration: 1 G, frequency 10-150 Hz (IEC 68-2-6)

• Shock: 15 G for 11 ms (IEC 68-2-27)

A

TTENTION

In order to minimize exposure to humidity, keep the

factory wrapping intact during storage and transit. If it is necessary to

unseal the equipment for customs or receiving, add more desiccant and

reseal the package.

10/01 FSC Safety Manager Installation Guide 3

1.3 Move Preparation

Background

Several basic points need to be kept in mind when planning the movement

and unpacking of FSC Safety Manager cabinets. They include the

following:

• A single FSC Safety Manager cabinet is nominally 80 x 80 x 200 cm

(31½ x 32½ x 78¾ inches),

• Lifting eye bolts, which are removable, add about 5 cm (2 inches) to the

height, and

• Weight varies with options and can go as high as 385 kg (850 lb) per

cabinet.

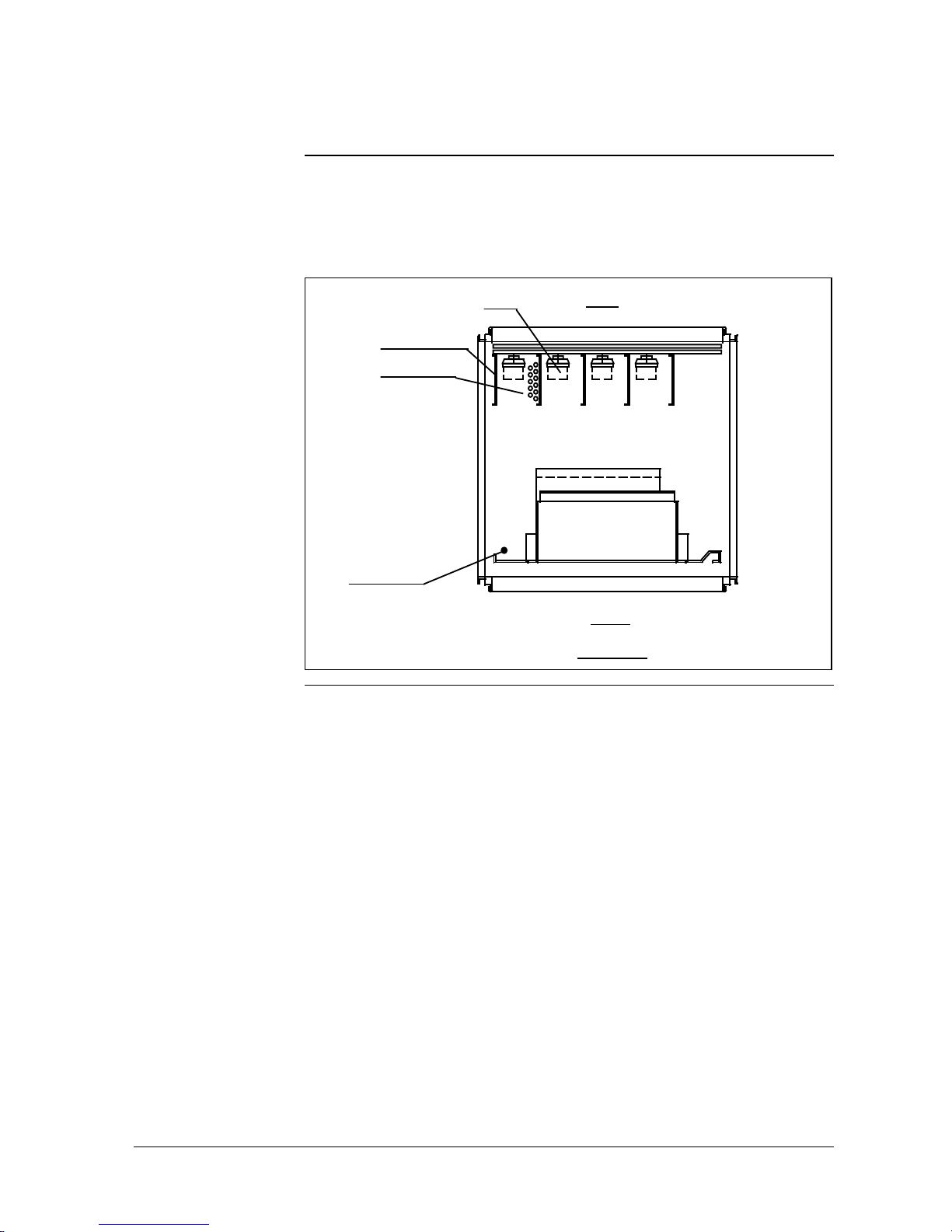

As illustrated in Figure 1-1, a typical factory-assembled complex uses up

to four such cabinets bolted together.

Figure 1-1 – Typical Electronics Room Layout

0-30 V

Terminal Panel

30-250 V

Terminal Panel

4 ft (1.25 m)

Min. Typical

Note:

These cabinets

are stand ar d width,

but are 21.75 inches

(55 cm) deep.

Control Cabine ts

Control Cabine ts

54 in (1.37 m)

(Reference)

Single-Access Control Cabinets

Expansion Area

Change House,

Lunchroom, Etc.

Power Distribution

Panel

Utility Room,

Maintenance

Equipment

Continued on next page

4 FSC Safety Manager Installation Guide 10/01

1.3 Move Preparation, Continued

Checklist

Table 1-1 provides a checklist to be used when planning the movement of

FSC Safety Manager cabinets.

Table 1-1 – Move preparation checklist

Check Action Notes

1

Travel Route Chart the equipment's route of travel regarding:

• loading doors — height and location,

• elevators — size, capacity, and availability,

• aisles — number, size, and layout,

• doorways — number and size,

• hallways — size, restrictions, and bends,

• stairs and ramps — may require some type of

lifting, and

• rigging of equipment — if needed.

2

Space Is there enough space to hold the equipment?

3

Floor Loading Will the floor in all areas be strong enough?

4

Power Distribution Check for proper transformer sizes, distribution

panels and sufficient outlets for support, test and

maintenance equipment.

5

Grounding Be sure that proper grounds are available.

6

Conduits and

Cable Trays

Make sure that conduits and cable trays are

large enough and the proper type to

accommodate all of the required cables.

7

Environment Are lighting and other environmental

requirements adequate?

8

Security Provide security clearances for the installation

crew if it is not composed of regular employees.

9

Responsibilities Are all responsibilities clearly defined and

understood?

10

Communications At minimum, three conveniently located

telephones are needed for:

• Honeywell Technical Assistance Center (TAC)

data terminal,

• Honeywell TAC voice, and

• Operator Emergency.

For additional information regarding actions described in the

Move Preparation Checklist, refer to SM02-550 — TPS System Site

Planning Manual in the Binder TPS 3020-1 System Site Planning-1.

10/01 FSC Safety Manager Installation Guide 5

1.3 Move Preparation, Continued

Preparation

Table 1-2 provides a checklist to be used when preparing the electronics

room for the FSC Safety Manager cabinets.

Table 1-2 – Move preparation checklist – part 2

Check Action Notes

1

Static Electricity Reduce the ESD-borne failures by:

• stripping the floors of any wax to prevent

static charge buildup,

• using anti-static spray on floors, furniture and

fabric in the work area, and

• placing a sign on or near the equipment that

states circuit boards are not to be handled

without wearing a ground strap.

2

Tack Rugs Placed at all entrances, tack rugs catch dust, grit

and abrasives from other areas.

3

Fire Prevention Consult with the local fire prevention authority to

select fire extinguishers suitable for electrical

fires.

4

Room Layout Prepare an electronics room layout diagram for

cabinet placement.

• Refer to Figure 1-1.

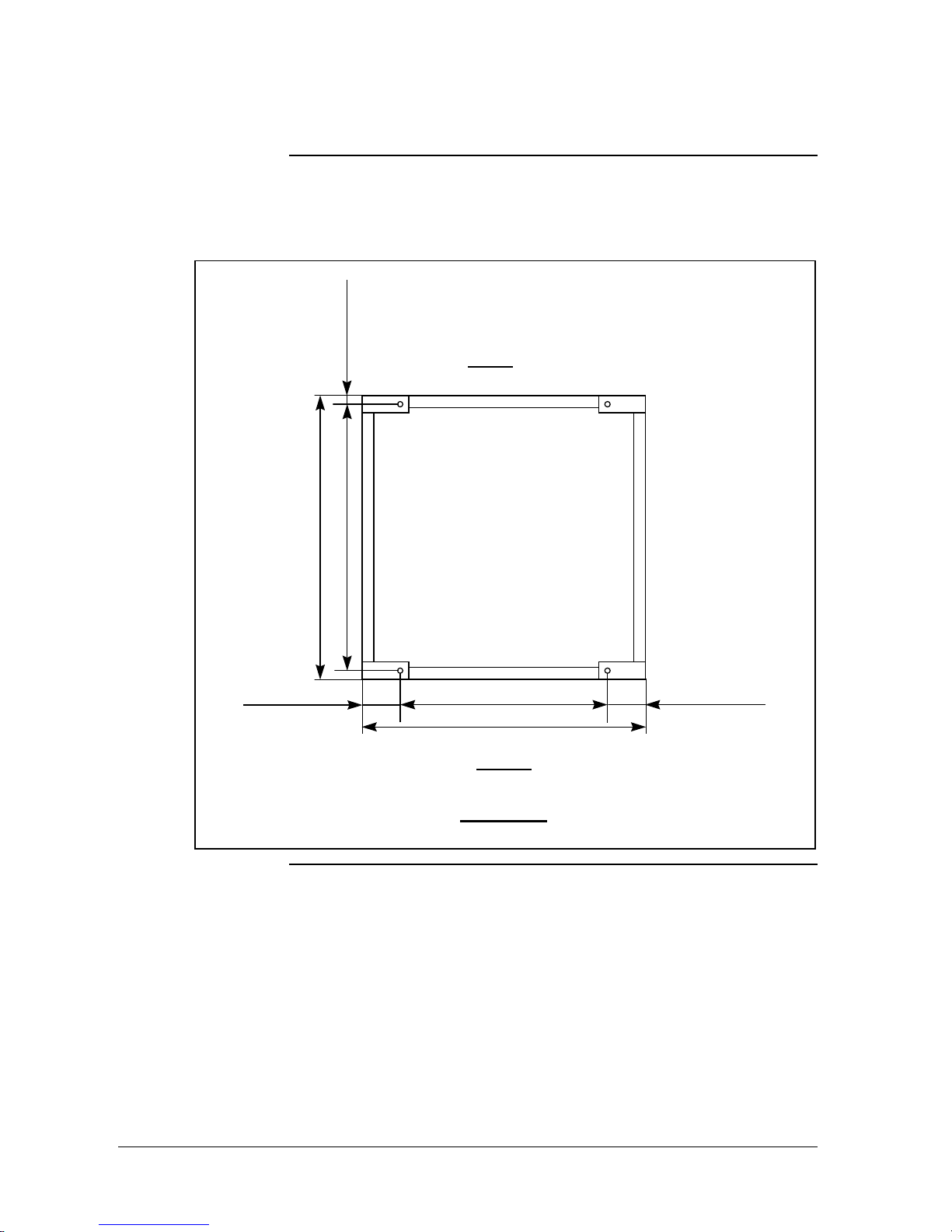

5

Cabinet

Bolt-Down

If this FSC Safety Manager cabinet is to be

bolted down, pre-drill holes in the floor.

A

TTENTION

Refer to Figure 1-2 for

placement and dimensions of the bolt-down

holes.

Continued on next page

6 FSC Safety Manager Installation Guide 10/01

1.3 Move Preparation, Continued

Bolt-down holes

Figure 1-2 provides the exact locations and dimensions of the cabinet

bolt-down holes.

Figure 1-2 – Location and dimensions of the cabinet bolt-down holes

600 mm (23.62")

800 mm (31.50")

100 mm (3.94")

750 mm (29.53")

100 mm (3.94")

25 mm (0.98")

700 mm (27.57")

REAR

FRONT

Bolt-down hole

diameter:

14 mm (0.55")

TOP VIEW

Continued on next page

10/01 FSC Safety Manager Installation Guide 7

1.3 Move Preparation, Continued

Cabinet entry

The process signal cables can enter the FSC Safety Manager cabinet

through the top or bottom of the cabinet. The FSC-SM cabinet is prepared

for field termination assembly to interface boards (FTA-E) or terminals

(FTA-T). These interface boards or terminals may be located in the

FSC-SM cabinet or in cross-wiring cabinets next to the FSC-SM cabinet.

Figures 1-3 through 1-8 illustrate the placement and dimensions for

process wiring for FTAs located in the FSC-SM cabinet.

The FSC-SM cabinet is also prepared for top or bottom entry as per user

specification. For bottom entry, sliding floor plates are provided which can

be adjusted to provide entry slots. For top entry, one sliding plate is

provided which can be adjusted to provide entry slots. For top or bottom

entry, the cables should be clamped firmly to the cabinet. The clamping

devices should be able to withstand a 45 kg (100 lb) pull. This prevents

damage inside the cabinet when pulling on cables outside the cabinet.

The FSC-SM cabinet includes a cable clamp rail at the bottom or at the

top.

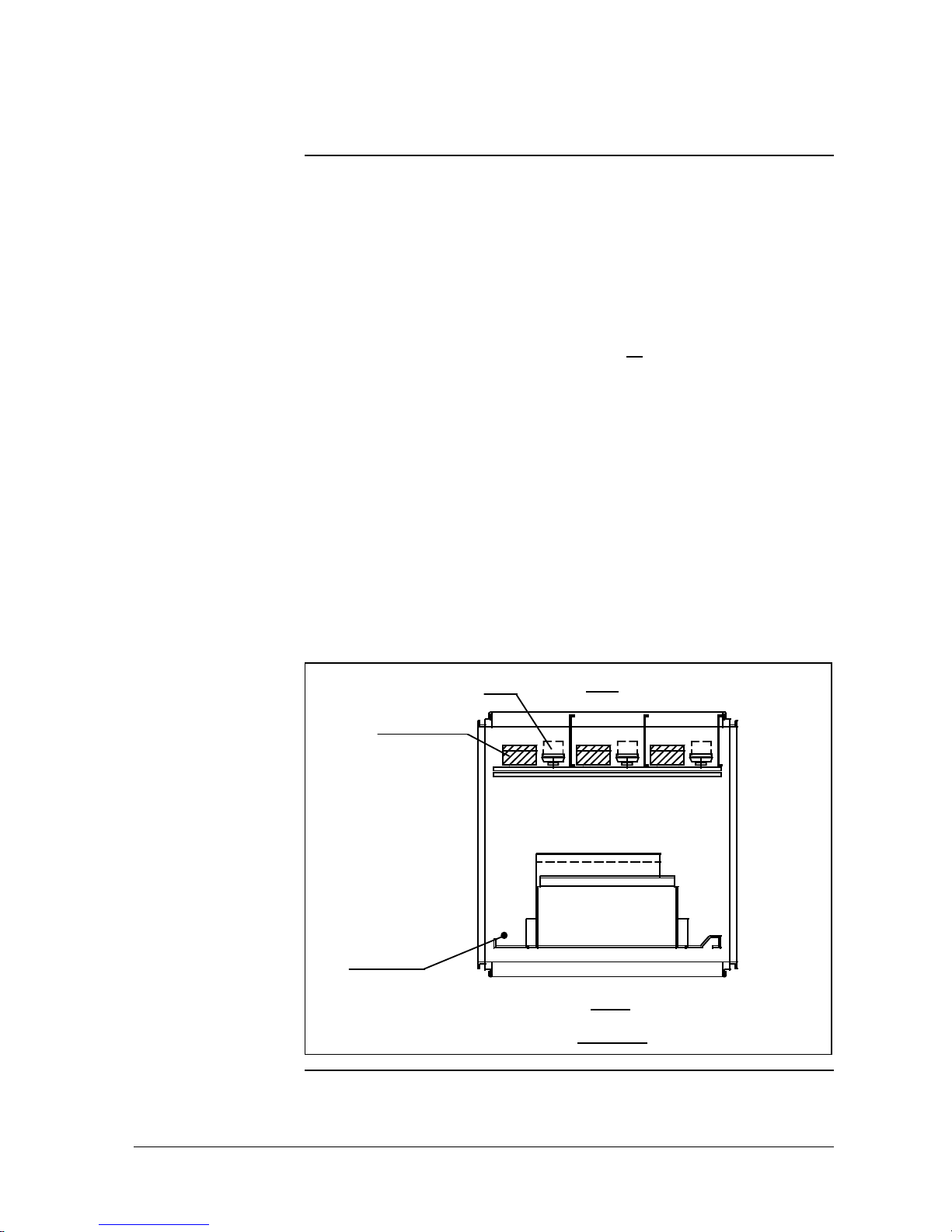

Figure 1-3 illustrates an FSC-SM cabinet bottom configured for back

access of the I/O field cables with FTA-T.

Figure 1-3 – FSC-SM cabinet with back access (FTA-T)

FSC I/O mounting rack

FRONT

TOP VIE W

Turning point

swing frame

REARFTA-T

Field cable duct

Continued on next page

8 FSC Safety Manager Installation Guide 10/01

1.3 Move Preparation, Continued

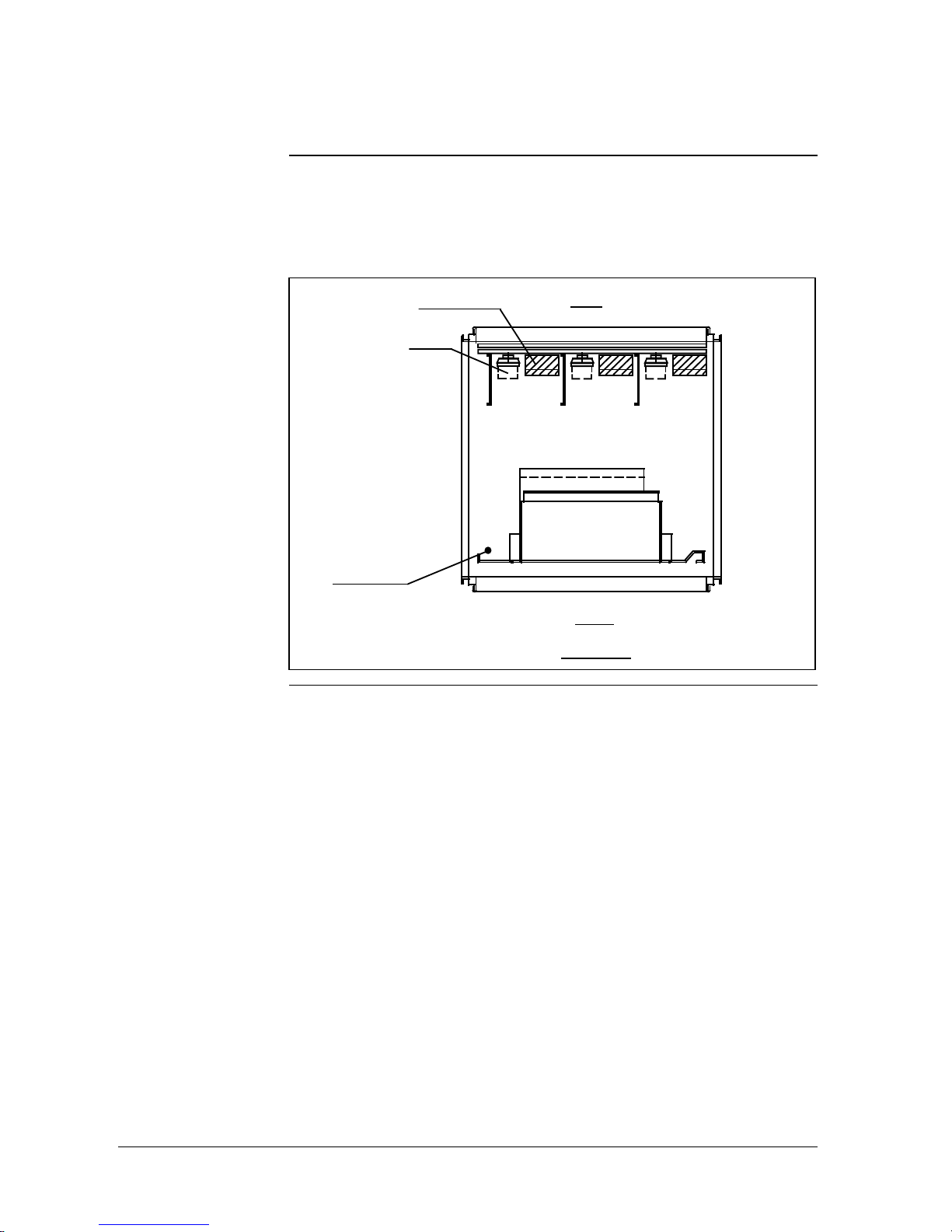

Cabinet entry,

continued

Figure 1-4 illustrates an FSC Safety Manager cabinet bottom configured

for front access of the I/O field cables with FTA-T.

Figure 1-4 – FSC-SM cabinet with front access (FTA-T)

FSC I/O mounting rack

Turning point

swing frame

FTA-T

Field cable duct

REAR

FRONT

TOP VIE W

Continued on next page

10/01 FSC Safety Manager Installation Guide 9

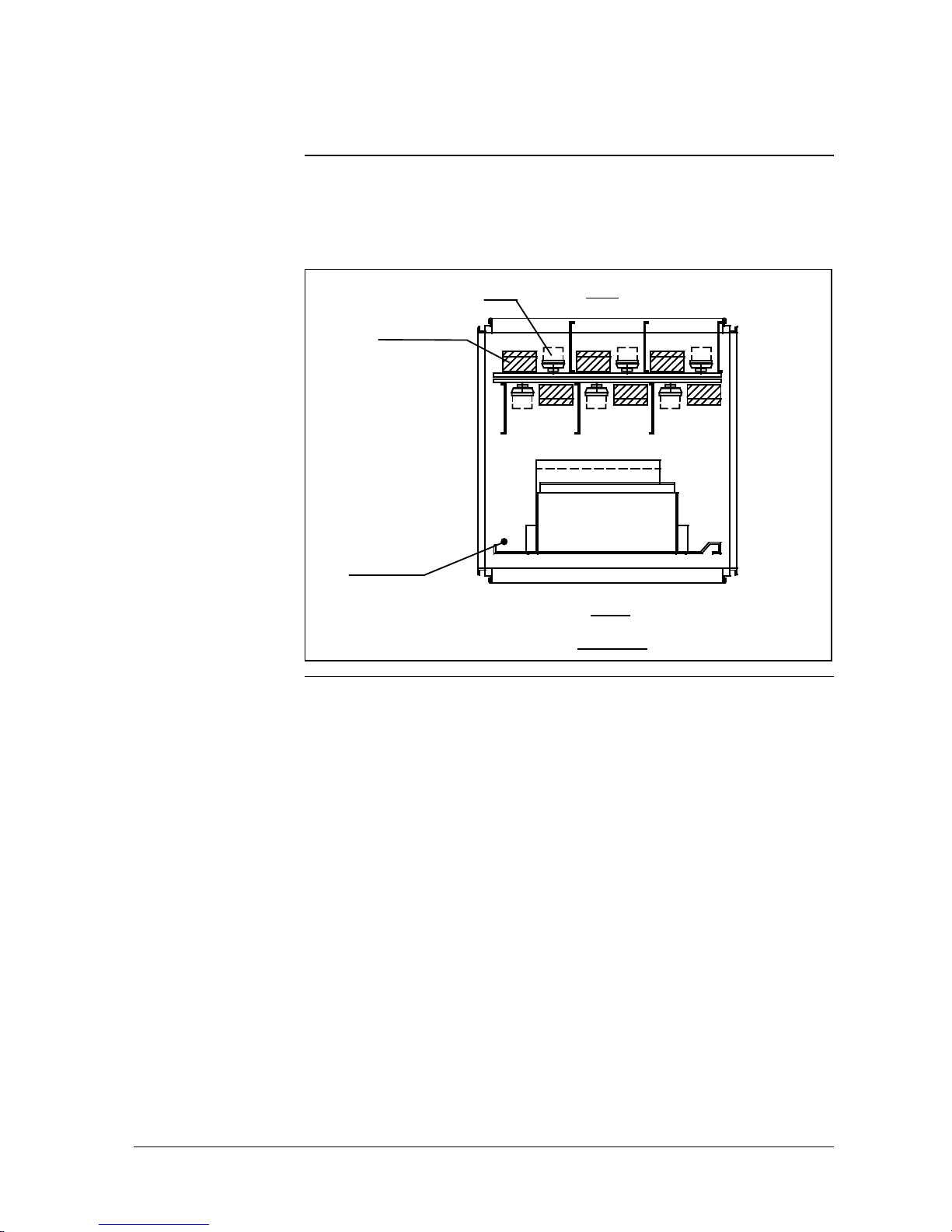

1.3 Move Preparation, Continued

Cabinet entry,

continued

Figure 1-5 illustrates an FSC Safety Manager cabinet bottom configured

for front and back access of the I/O field cables with FTA-T.

Figure 1-5 – FSC-SM cabinet with front and back access (FTA-T)

FSC I/O mounting rack

Turning point

swing frame

FTA-T

Field cable duct

REAR

FRONT

TOP VIE W

Continued on next page

10 FSC Safety Manager Installation Guide 10/01

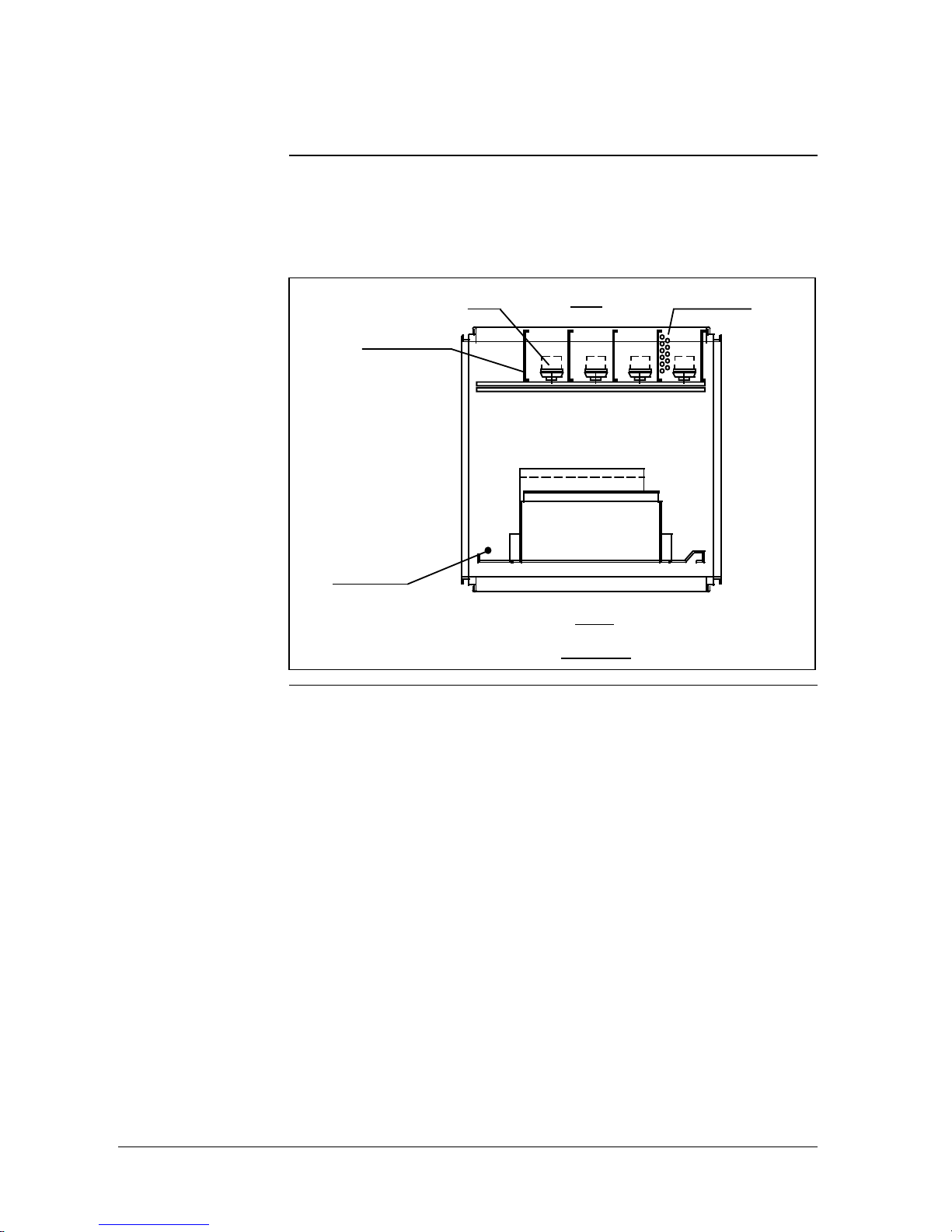

1.3 Move Preparation, Continued

Cabinet entry,

continued

Figure 1-6 illustrates an FSC Safety Manager cabinet bottom configured

for front access of the system cables with FTA-E.

Figure 1-6 – FSC-SM cabinet with front access (FTA-E)

FSC I/O mounting rack

FRONT

TOP VIE W

Turning point

swing frame

REARFTA-E

Field cable tray

System cables

Continued on next page

10/01 FSC Safety Manager Installation Guide 11

1.3 Move Preparation, Continued

Cabinet entry,

continued

Figure 1-7 illustrates an FSC Safety Manager cabinet bottom configured

for back access of the system cables with FTA-E.

Figure 1-7 – FSC-SM cabinet with back access (FTA-E)

FSC I/O mounting rack

FRONT

TOP VIE W

Turning point

swing frame

REARFTA-E

Field cable tray

System cables

Continued on next page

Loading...

Loading...