Page 1

F35F Media Air Cleaner

68-0178-2

WITH EXPANDAPAC™ MEDIA FILTER

PRODUCT DATA

FEATURES

APPLICATION

The F35F Expandapac Media Air Cleaner captures a

significant amount of the airborne particles, 1.0 microns and

larger from the air circulated through the unit.

• High efficiency Expandapac media filter with Ultra-

• Strong media will not tear when installing combs.

• Combs are located down stream from filter so they

• Efficiency and arrestance ratings based on the

®

technology captures particles as small as

Web

1.0 micron.

stay clean.

American Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) Standard 52.1-92.

—Initial Atmospheric Dust Spot Efficiency: 25.8%

—Average Atmospheric Dust Spot Efficiency: 32.0%

—Average Synthetic Dust Weight Arrestance: 92.0%

—ASHRAE Dust Holding Capacity: 55g

The above data is for a 16 x 25 in. filter.

Expandapac™ and Ultra-Web® are Trademarks of Donaldson Company, Inc.

Copyright © 1998 Honeywell Inc. • All Rights Reserved

Contents

Application........................................................................... 1

Features .............................................................................. 1

Ordering Information ........................................................... 2

Specifications ...................................................................... 3

Planning the Installation ...................................................... 4

Installation and Checkout .................................................... 7

Future Option ...................................................................... 9

Replacement Parts.............................................................. 9

Page 2

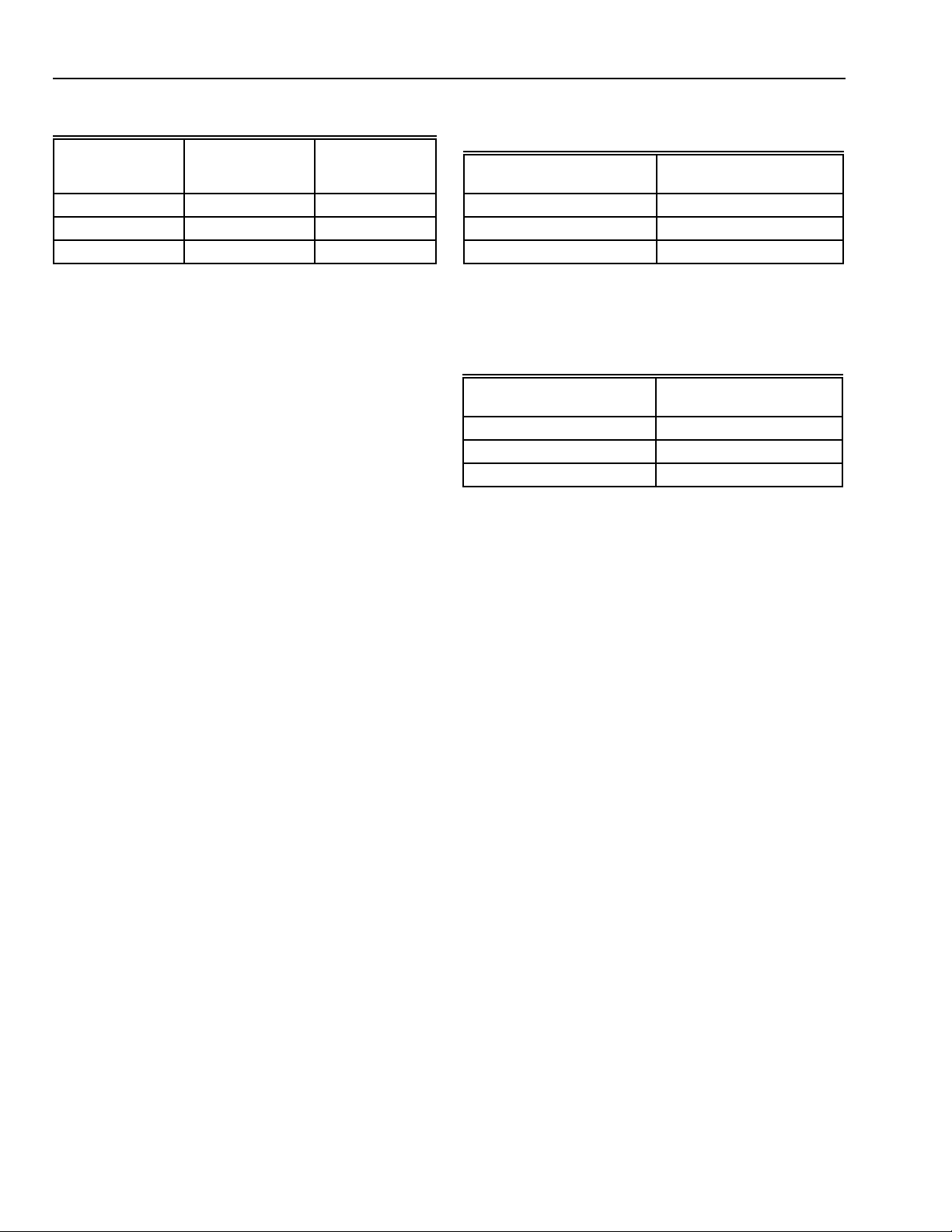

F35F Expandapac™ MEDIA AIR CLEANER

•Available in three sizes to fit most air ducts. • Compact packaging makes replacement media filters

easy to fit on service trucks or mail to customers.

Media Air

Cleaner Order

Number Size cfm

F35F1008 16 x 25 1400

F35F1016 20 x 20 1400

F35F1024 20 x 25 2000

Replacement Media Filter

Order Number Size

FC35A1001 16 x 25

FC35A1019 20 x 20

FC35A1027 20 x 25

• Applicable to all gas, oil, and electric forced warm air

furnaces and to compressor cooling up to five tons.

Can be used with heat pumps only if the filter is

changed regularly to prevent excessive pressure drop.

• Mounts in the return air duct.

• Cabinet can support weight of residential furnace and

evaporator coil.

• Requires no electrical connections.

• Mounts in any position.

• Requires no maintenance except periodic Expandapac

media filter replacement, which is easily replaced by

homeowner.

• Replacement filter comes with bag to dispose of old

filter.

• FC35B Kit available to upgrade an F25F to an F35F

(requires FC35A Replacement Media).

Upgrade Kit

Order Number Size

FC35B1018 16 x 25

FC35B1000 20 x 20

FC35B1026 20 x 25

• Easy to upgrade to the F50 Electronic Air Cleaner

when the homeowner’s needs change.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number, or specify—

1. Order number.

2. Duct size.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0178—2 2

Page 3

F35F Expandapac™ MEDIA AIR CLEANER

SPECIFICATIONS

IMPORTANT

The specifications in this publication do not include

normal manufacturing tolerances; therefore, an

individual unit may not exactly match the listed

specifications. This product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

Model:

F35F Expandapac Media Air Cleaner includes cabinet,

access door, Expandapac media filter, filter frame, and

combs.

Application:

Use with gas, oil, and electric forced warm air furnaces and

with compressor cooling. Can be used with heat pumps if

filter is changed regularly to prevent excessive pressure drop.

Arrestance Efficiency:

Efficiency ratings are based on National Bureau of Standards

Dust Spot Method using atmospheric dust and American

Society of Heating, Refrigerating and Air-Conditioning

Engineers Standard 52.1-92.

—Initial Atmospheric Dust Spot Efficiency: 25.8%

—Average Atmospheric Dust Spot Efficiency: 32.0%

—Average Synthetic Dust Weight Arrestance: 92.0%

—ASHRAE Dust Holding Capacity: 55g

The above data is for a 16 x 25 in. filter.

Filter Media:

Expandapac.

Temperature Rating:

-40°F to +125°F (-40°C to +52°C).

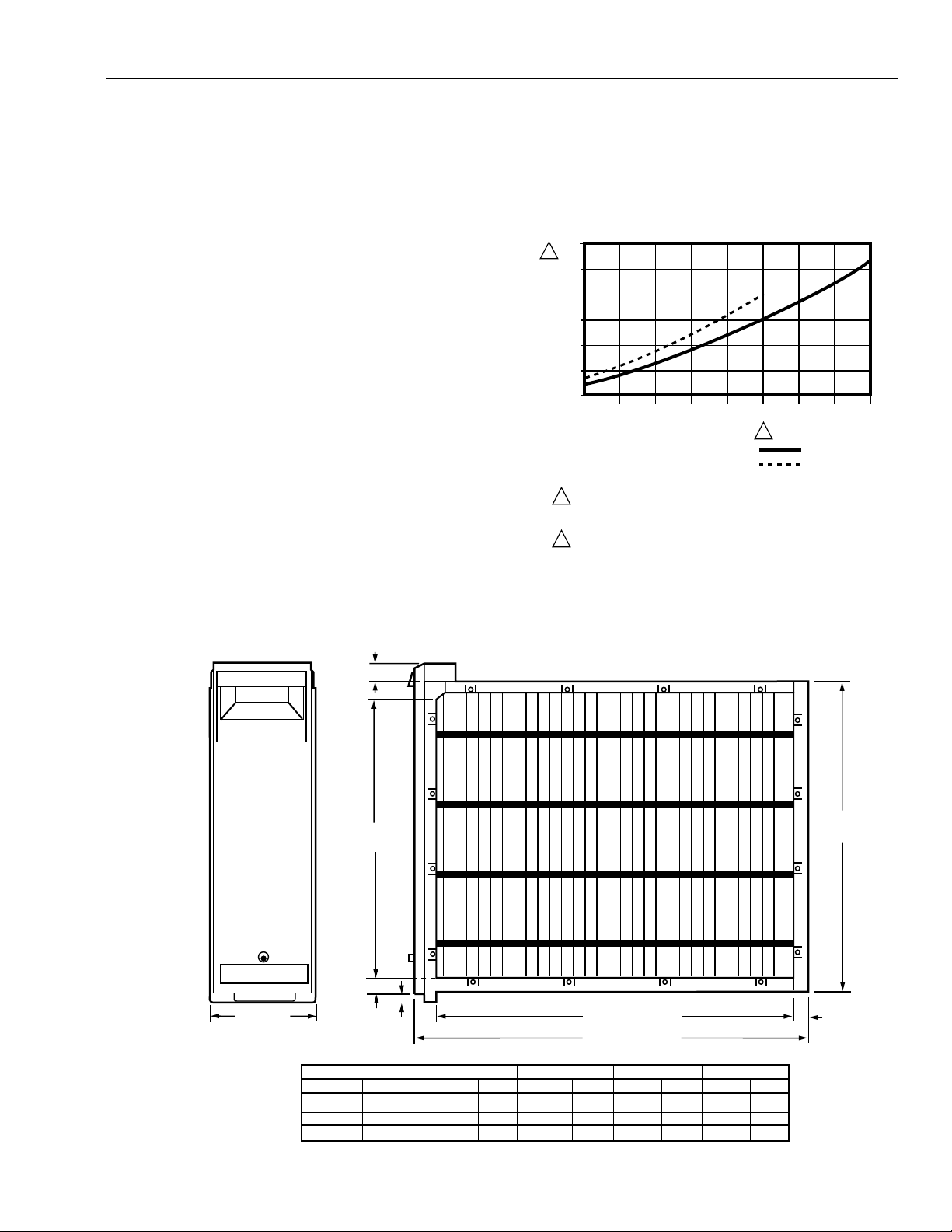

Capacity and Pressure Drop:

F35 FILTER PRESSURE DROP VS AIR FLOW RATE

0.30

1

0.25

0.20

0.15

0.10

0.05

PRESSURE DROP (IN. WC)

0.00

400

600 800 1000

1

WHEN FIRST INSTALLED. PRESSURE DORP INCREASES AS

FILTER BECOMES LOADED. FILTER SHOULD BE REPLACED

WHEN PRESSURE DROP REACHES 0.5 IN. WC (0.1 kPa).

2

MAXIMUM CAPACITY BASED ON 500 fpm FACE VELOCITY.

AIRFLOW (cfm)

Fig. 2. Capacity pressure drop of

F35 Expandapac Media Filter.

1200 1400 1600 1800 2000

2

20" X 25"

16" X 25"

AND 20" X 20"

M12002-A

The F35F removes particles as small as 1.0 microns.

Dimensions:

1-1/8 (29)

DIM A

(SEE TABLE)

7/8 (22)

6-3/4 (171)

F35 SIZE

IN.

16 X 25

20 X 25

20 X 20

5/8

(16)

MM

406 X 635

508 X 635

508 X 508

Fig. 1. Installation dimensions in in. (mm) of air cleaner.

DIM A

IN. MM IN. MM

14 7/16

18 7/16

18 7/16

367

468

468

DIM B

16 3/16

20 3/16

20 3/16

DIM C (SEE TABLE)

DIM D (SEE TABLE)

DIM C

IN. MM IN. MM

411

23 1/4

513

23 1/4

513

18 1/4

591

591

457

25 1/2

25 1/2

20 1/2

DIM D

648

648

521

DIM B

(SEE TABLE)

7/8 (22)

M6931

3

68-0178—2

Page 4

F35F Expandapac™ MEDIA AIR CLEANER

M939A

Mounting:

Mounts in any position in the return air duct next to the

furnace blower compartment. Airflow must be in the direction

of the arrow on the filter. Cabinet is sturdy enough to support

weight of a residential furnace and evaporator coil.

Underwriters Laboratories, Inc.:

UL 900, Class 2 listed.

Upgrade Path:

The F35 uses the same cabinet as the F50 Electronic Air

Cleaner. Upgrade requires installing the cell key, electronic

cells, protective screens, and power box installation and wiring.

Accessory:

S830A Clogged Filter Indicator.

Replacement Parts:

Replace Expandapac media filter annually or more often if

reduced airflow results in lower heating/cooling equipment

performance. See Replacement Parts section for Media Filter

and Frame/Comb replacement part numbers.

PLANNING THE INSTALLATION

Location

Install the media air cleaner where all the air passing through

the system is circulated through it. The best location is in the

return air duct next to the blower compartment so the media air

filter can help to keep the blower motor and evaporator coils

clean. Do not mount in the supply air duct.

Applications with a Humidifier

The media air filter is compatible with humidifiers. Avoid

applications where water mist can reach the media. If an

atomizing humidifier is used, the filter media will require

replacement more often because of minerals in the water.

Choose Mounting Position

The media air cleaner can be mounted in any position, but the

arrow on the cartridge must point in the same direction as the

airflow. See Fig. 3-10 for proper location of the media air

cleaner for a variety of furnace installations. Note that the

media air filter cabinet is sturdy enough to easily support the

weight of the furnace and evaporator coil. See Fig. 4.

For most efficient air cleaning, spread airflow evenly across

the face of the media. If the duct is a different size than the

media air cleaner cabinet, gradual transitions are required. If

the duct turns sharply just before the air filter, turning vanes

are required (Fig.12).

Choose a location that is readily accessible for checking and

replacing the filter. Allow at least 26 in. (660 mm) clearance in

front of the unit for removal of the filter.

Install the media air cleaner where the temperature will not

exceed the ratings in the Specifications section.

Applications with Air Conditioning

Mount the media air filter upstream of the evaporator coil in a

cooling system. The filter will help to keep the coil clean and

reduce maintenance.

Applications with a Charcoal Filter

Add an activated charcoal filter to the air handling system to

remove gaseous (nonparticulate) contaminants from the

circulated air. A common residential application is to remove

odors that cannot be removed by mechanical air filters. The

activated charcoal filter, if used, should be installed

downstream from the media air cleaner to protect the

charcoal filter from lint and other particles.

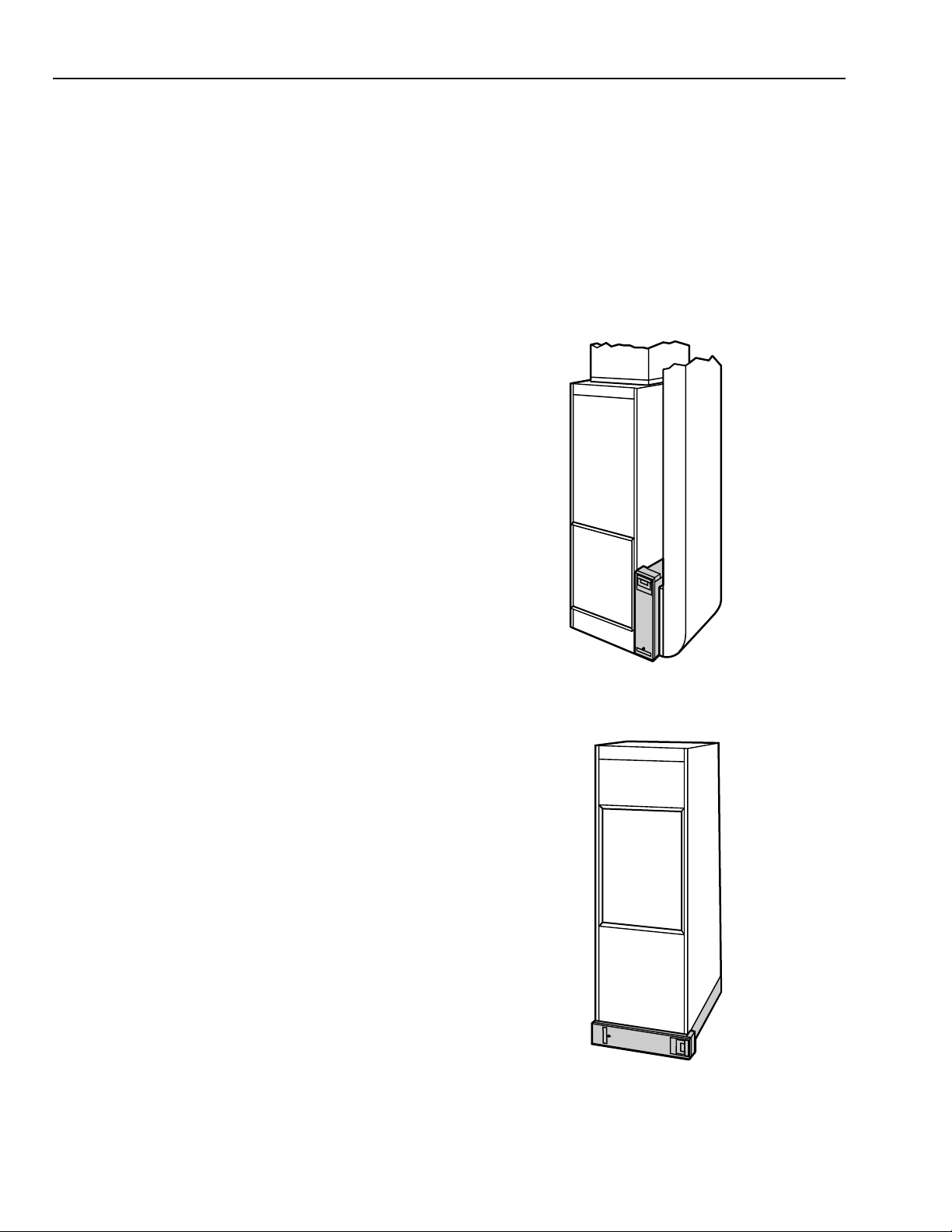

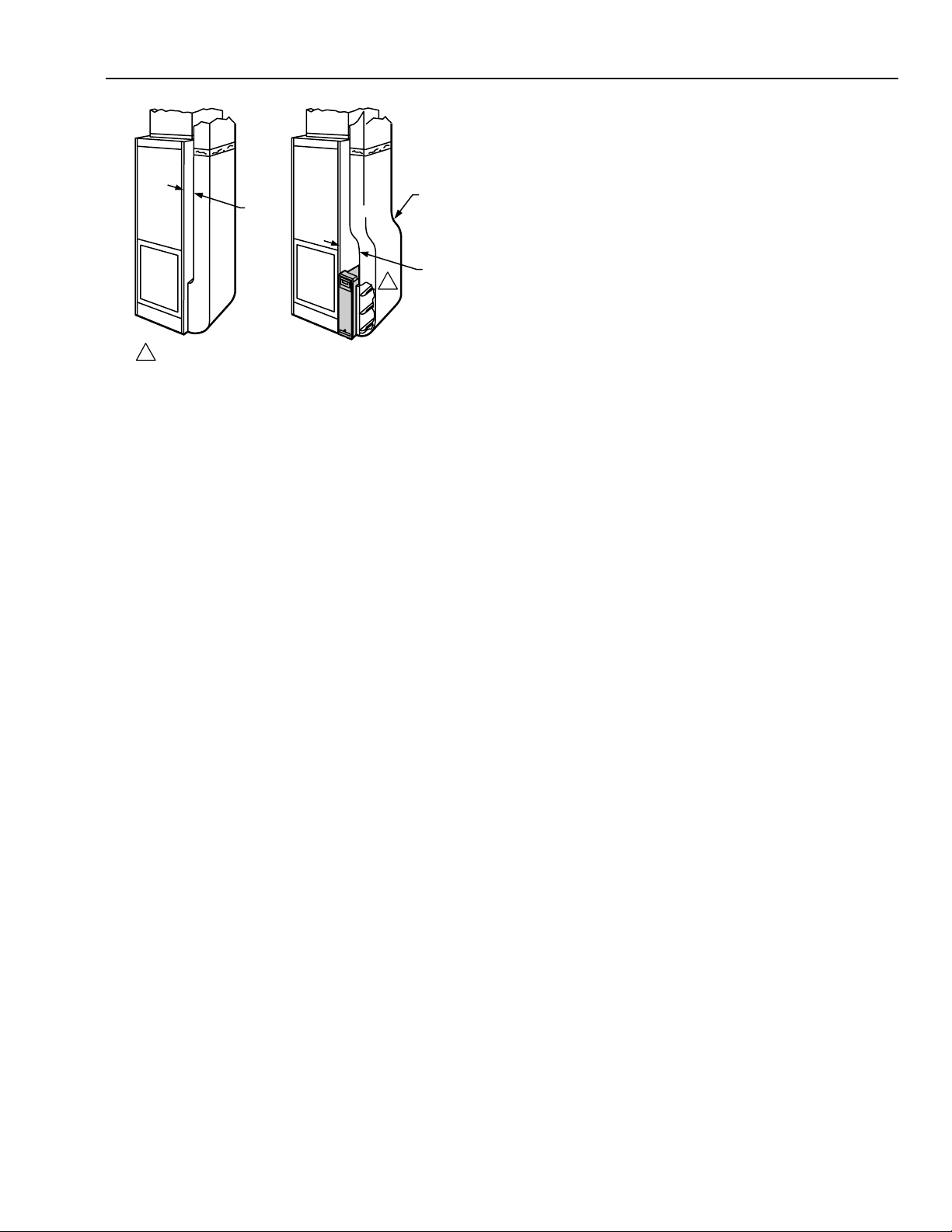

Fig. 3. Highboy furnace, with side installation.

Media air cleaner is mounted vertically

where return enters side inlet of furnace.

M940A

Fig. 4 Highboy furnace, with installation

beneath furnace. Media air cleaner is mounted

horizontally where return enters from below.

68-0178—2 4

Page 5

M6932-A

Fig. 5. Highboy furnace, with closet installation.

Media air cleaner is mounted vertically on

furnace between furnace and louvered

return air opening in closet door.

F35F Expandapac™ MEDIA AIR CLEANER

M943A

M942A

Fig. 6. Lowboy furnace, with media air cleaner

mounted horizontally in return plenum just

above furnace and opposite heating plenum.

Fig. 7. Counterflow furnace, with media

air cleaner mounted horizontally in return

duct or plenum just above furnace.

M944A

Fig. 8. Central fan installation, with media air cleaner

mounted horizontally in central return duct.

5

68-0178—2

Page 6

F35F Expandapac™ MEDIA AIR CLEANER

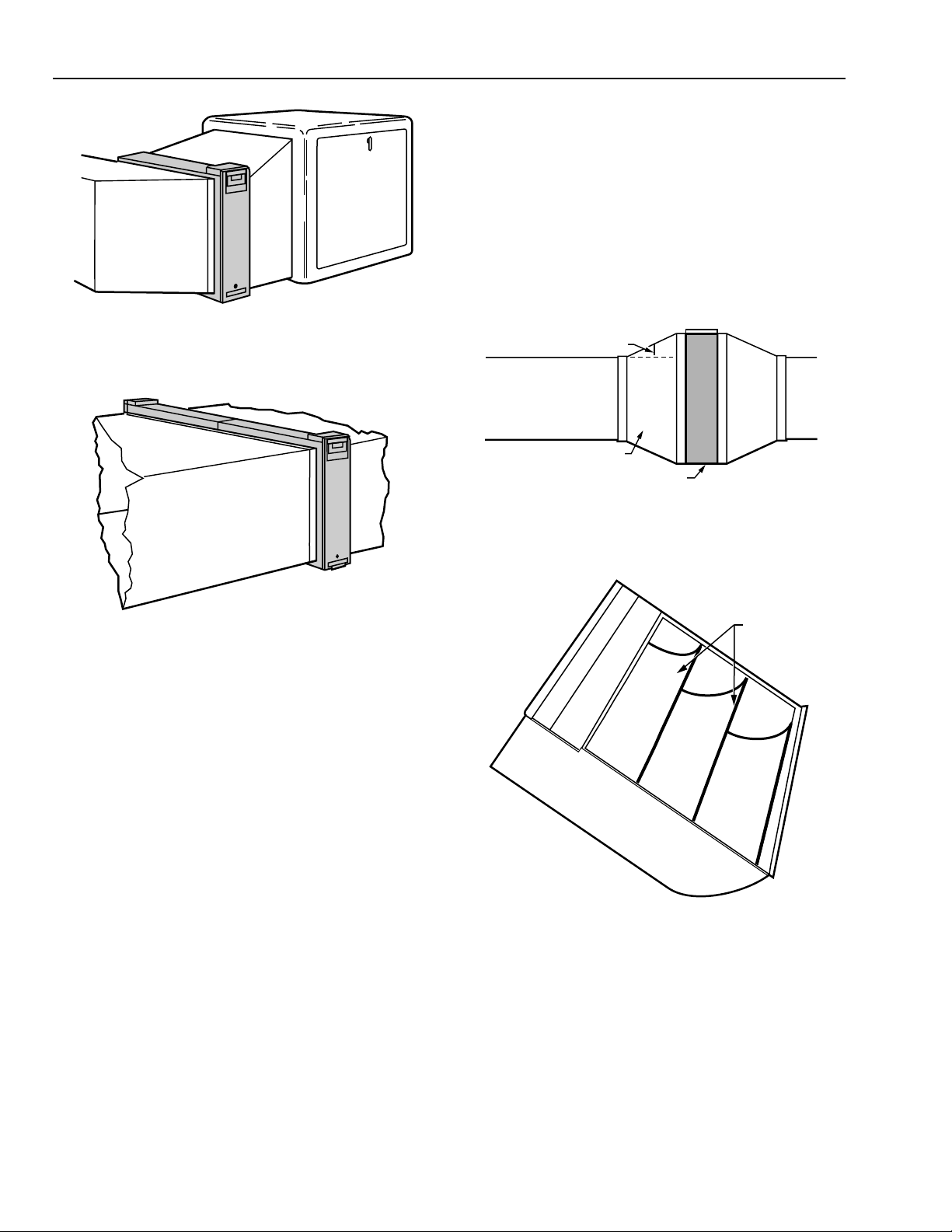

Turning Vanes

If the media air cleaner is installed next to an elbow or angle

fitting, add turning vanes inside the angle to distribute airflow

more evenly across the face of the media. See Fig 12.

Offsets

If the duct connection to the furnace in a side installation

allows less than 7 in. (178 mm) for mounting media air

cleaner cabinet, attach an offset to the elbow. See Fig. 13.

M945A

Fig. 9. Horizontal furnace, with media air cleaner mounted

vertically in return duct near furnace.

M946A

Fig. 10. Two or more media air cleaners

used in a high capacity system.

Determining Sheet Metal Requirements

The media air cleaner is adaptable to all new or existing

forced air heating and cooling systems used in residential

applications. Transitions or turning vanes may be required in

some applications for effective media air cleaner operation.

DUCT SIZE CHANGED GRADUALLY TO PREVENT TURBULENCE.

20 DEGREE EXPANSION PER SIDE PER

FITTING (4 IN. PER RUNNING FOOT

[100 MM PER 300 LINEAR MM])

RETURN AIR

DUCT

TRANSITION FITTING

MEDIA AIR FILTER CABINET

M947A

Fig. 11. Duct size changed gradually

to prevent turbulence.

TURNING

VANES

Transitions

Tr ansitions are needed when the duct is a different size than

the media air filter cabinet. Follow these guidelines when

fabricating:

1. Use gradual transitions to reduce air turbulence and

increase efficiency. See Fig. 11.

2. Use no more than 20 degrees (about 4 in. per running ft

[100 mm per 300 linear mm]) of expansion on each side

of a transition fitting.

68-0178—2 6

M5651

Fig. 12. Turning vanes installed in bend help

distribute airflow evenly over face of media.

Page 7

LESS

THAN

7 in.

(178 mm)

1 REQUIRED TURNING VANES HELP DISTRIBUTE AIRFLOW EVENLY.

Fig. 13. Typical use of duct offset to

make room for media air cleaner.

OFFSET

AT LEAST

7 in.

1

(178 mm)

INSTALLATION AND CHECKOUT

M948A

F35F Expandapac™ MEDIA AIR CLEANER

Make sure that shop-fabricated sheet metal components,

such as turning vanes, are available.

Fasten the Cabinet to the Furnace

Align the cabinet with the return air opening. Place blocks under

the cabinet, as necessary, to make sure the unit is seated

securely. Create an opening in the furnace to match the cabinet

opening. Attach the cabinet securely to the furnace. Attach the

unit directly or fit a starting collar in the furnace opening. Either

drill holes and fasten with sheet metal screws or rivets, or use

slip joints. If you are drilling holes, use a locking pliers to help

hold the unit in place during drilling.

Install Turning Vanes

Install turning vanes to help distribute air equally over the full

surface of the upstream side of the media. Install the vanes

whenever an abrupt 90 degree elbow is installed directly

against the media air cleaner cabinet.

Fasten Cabinet to Ductwork

Fasten the side of the cabinet to the ductwork using sheet

metal screws, rivets, or slip joints, as appropriate.

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the media air cleaner or cause a

hazardous condition.

2. Check the ratings given in the instructions and on the

media air cleaner to make sure the product is suitable

for your application.

3. Installer must be a trained, experienced service

technician.

Remove Furnace Filter and

Clean Blower Compartment

Before starting the installation, remove and discard the existing

furnace filter (if used). Thoroughly clean the blower

compartment. If possible, power vacuum the ductwork to

remove accumulated dust in an occupied home or remove

construction dirt in a new home. The media air filter cannot

remove dirt that has settled in the blower compartment and

distribution ducts.

Install the Cabinet

The following procedure describes a typical side installation

on an existing highboy furnace. Alternate procedures are

noted as appropriate. Other changes in installation

procedures may be necessary to complete your installation.

Review the Installation Plan

Temporarily place the cabinet on the floor, oriented as it will

be when installed. Measure to make sure the plan allows

adequate clearance (at least 26 in. [660 mm]) for easy

removal and replacement of the filter.

Connect Ductwork

Connect the vertical duct section to the elbow. If the vertical

drop of the duct is less than 7 in. (178 mm) from the side of

the furnace, shorten the horizontal trunk or attach an offset

fitting to the elbow. See Fig. 13. When ductwork is properly

aligned, connect the vertical duct to the horizontal trunk.

Seal Joints

Seal all joints in the return air system between the media air

cleaner and the furnace to prevent dust from entering the

clean airstream.

Assemble Expandapac Media Filter

1. Open the new media filter; expand it and set it upright

on a flat surface.

2. Insert one end panel tab into the retainers on the frame.

Fold in the end panel flanges and push the tab

completely in, making sure the end panel flanges are

inside the frame flanges. See Fig. 14.

3. Repeat step 2 on the opposite corner.

4. Flip over the assembly and repeat steps 2 and 3 on the

remaining two corners.

5. Lay the filter assembly down flat so the arrows point up.

Insert the combs as shown in Fig.15, aligning them with

the notches in the end panel flanges. Make sure the

combs are inserted completely.

7

68-0178—2

Page 8

F35F Expandapac™ MEDIA AIR CLEANER

END PANEL

TAB

END PANEL

FLANGE

FRAME

PANEL

FRAME PANEL

RETAINER

FRAME

FLANGE

Checkout

Visually check the installation. Make sure:

• Airflow is in the direction of the arrow on the

Expandapac media air filter.

•Turning vanes and transitions, if used, are properly

installed.

• Joints in sheet metal between media air cleaner and

furnace are sealed.

• All sheet metal connections are complete.

•Original furnace filter was removed and blower

compartment was cleaned.

Replace any access doors removed during the Installation or

Checkout.

Run the furnace or cooling system through one complete

cycle to make sure the system operates as desired.

Maintenance

Replace the media filter when pressure drop across the

media filter reaches 0.5 in. wc (0.1 kPa) or at least annually. If

the media air filter is installed downstream from an atomizing

humidifier or if the installation includes both heating and

cooling, more frequent replacement may be necessary.

Clogged media filter must be replaced promptly to avoid

restricting airflow and reducing efficiency of the heatingcooling system. Record the replacement date in the space

provided on the replacement media filter.

FRAME

PANEL

M6934

Fig. 14. Assemble Expandapac media filter in frame.

Install Expandapac Media Filter

Slide the assembled Expandapac media filter into the cabinet,

making sure the arrow on the cartridge points in the direction

of the airflow.

Replace the access door. Insert the tab on the bottom of the

door into the slot in the cabinet. Swing the door closed and

press it into place.

COMBS (3 OR 4,

DEPENDING ON

FILTER SIZE)

Replace the Expandapac Media Filter as follows:

1. Remove the cabinet door and pull out the dirty filter

assembly.

2. Remove all the combs and two frame panels. Set them

aside. Dispose of the dirty filter.

3. Open the new media filter; expand it and set it upright

on a flat surface.

4. Insert one end panel tab into the retainers on the frame.

Fold in the end panel flanges and push the tab

completely in, making sure the end panel flanges are

inside the frame flanges. See Fig. 15.

5. Repeat step 4 on the opposite corner.

6. Flip over the assembly and repeat steps 4 and 5 on the

remaining two corners.

7. Lay the filter assembly down flat so the arrows point up.

Insert the combs as shown in Fig.16, aligning them with

the notches in the end panel flanges. Make sure the

combs are inserted completely.

8. Insert the new filter assembly into the cabinet and close

the door.

See Replacement Parts in the Specifications section. If desired,

install the S830A Clogged Filter Indicator to allow visual

indication of when the media needs replacing. Install and adjust

the S830A by following the instructions provided with the unit.

M6935

Fig.15. Insert combs in media filter.

68-0178—2 8

Page 9

FUTURE OPTION

The F35F Expandapac Media Air Cleaner cabinet and filter

are designed to be easily upgraded to an F50 Electronic Air

Cleaner. An electronic air cleaner has the features to increase

the comfort and enjoyment of your home:

• Captures up to 95% of airborne particles, 0.5 microns

and larger that pass through the unit.

• Can save 10 to 15 percent in operating costs over the

life of your equipment. Honeywell offers an exclusive

10-year Clean Coil Guarantee.

• Protects your expensive HVAC equipment.

• No on-going filter replacements necessary because

cells can be washed and restored to top efficiency.

• Increases home comfort.

• Easy to maintain.

• And it’s by Honeywell, a leader in indoor air quality

products for over 30 years.

F35F Expandapac™ MEDIA AIR CLEANER

High Efficiency Cleaning F50 Electronic Air Cleaner.

REPLACEMENT PARTS

3

1

F35F part numbers are keyed to parts list.

F35F Replacement Parts List

No. Description 16 x 25 in. 20 x 25 in. 20 x 20 in.

1 Access Door 203306AB (1) 203305AG (1) 203305AG (1)

2 Expandapac Media Air Filter. Must be ordered in

multiples of 6.

3 Frame and Combs. Must be ordered in multiples of 6. FC35B1018 FC35B1026 FC35B1000

2

M11200

FC35A1001 FC35A1027 FC35A1019

9

68-0178—2

Page 10

F35F Expandapac™ MEDIA AIR CLEANER

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

Honeywell Latin American Region

480 Sawgrass Corporate Parkway

Suite 200

Sunrise FL 33325

68-0178—2 L.C. Rev. 2-98

68-0178—2 12

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

Honeywell Europe S.A.

3 Avenue du Bourget

1140 Brussels

Belgium

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Honeywell Asia Pacific Inc.

Room 3213-3225

Sun Hung Kai Centre

No. 30 Harbour Road

Wanchai

Hong Kong

www.honeywell.com/yourhome

Loading...

Loading...