Page 1

D22

Pressure reducing valve with piston balanced seat

Standard pattern for compressed air

Product specification sheet

Application

Pressure reducing valves of this type protect installations against

excessive pressure from the supply. They can be used for industrial or commercial applications within the range of their specification.

Because pressure reducing valves are subject to wear, they

cannot be used as the only means of protection and if the downstream system needs to be protected against excessive pressure

to prevent leakage, then a suitable safety valve must be fitted.

Special Features

• Screw with knob for setting pressure

• The adjustment spring is not in contact with the medium

• Compact construction

• Internal threaded connection

• Light weight

• Short installed length

• Inlet pressure balancing - fluctuating inlet pressure does not

influence outlet pressure

• Certified to Pressure Equipment Directive 97/23/EC, Reference No. CE 0035

• Reliable and proven

Construction

The pressure reducing valve comprises:

•Housing

•Valve piston

• Piston guide with G

• Diaphragm

• Adjustment spring

• Spring bonnet with adjuster

• Pressure gauge not included (see accessories)

Materials

• Brass housing

• Brass valve piston

• Brass piston guide

• High-quality synthetic material spring bonnet

• Spring steel adjustment spring

• NBR sealing washer

• NBR Diaphragm

EN0H-1011GE23 R1109 • Subject to change

• NBR O-rings

1

/4" pressure gauge connection

Range of Application

Medium Compressed air*, non-toxic and non-

flammable gases

Inlet pressure max. 40 bar

Outlet pressure 1,0 - 10,0 bar

Technical Data

Operating temperature max. 70°C

Nominal pressure PN40

Minimum pressure drop 1.0 bar

Connection size

*

As part of an installation being approved according to PED requirements, this

product must also be certified.

1

/4" - 2"

www.honeywell.com 55

Page 2

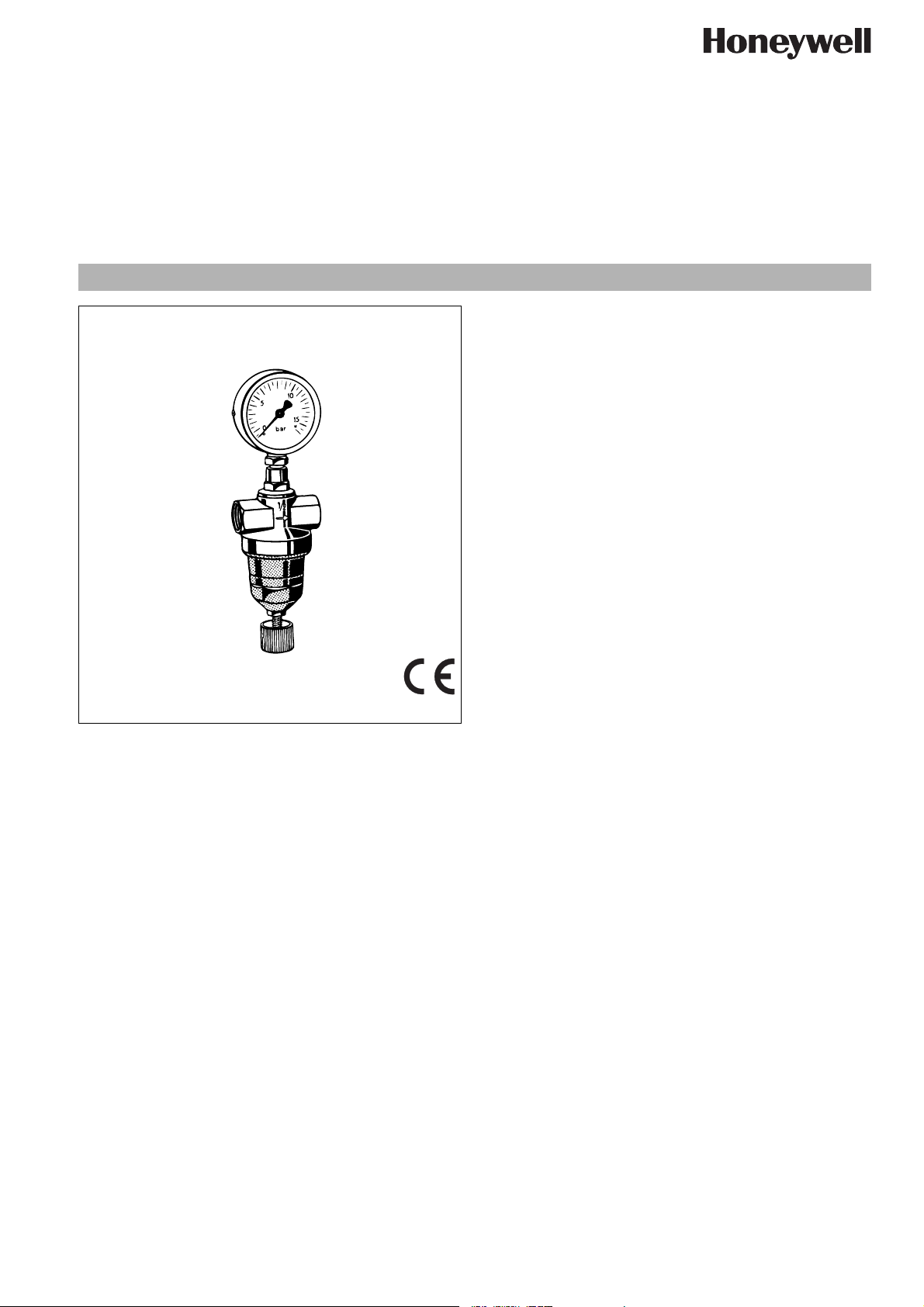

D22 Pressure reducing valve with piston balanced seat

Method of Operation

Spring loaded pressure reducing valves operate by means of a

force equalising system. The force of a diaphragm operates

against the force of an adjustment spring. If the outlet pressure

and therefore diaphragm force fall because water is drawn, the

then greater force of the spring causes the valve to open. The

outlet pressure then increases until the forces between the

diaphragm and the spring are equal again.

The inlet pressure has no influence in either opening or closing of

the valve. Because of this, inlet pressure fluctuation does not

influence the outlet pressure, thus providing inlet pressure balancing.

Options

D22-... A = Standard pattern

Special Versions available on request

Connection size

Connection size R

Nominal size

DN8 10152025324050

1

/4"

3

/8"

1

/2"

3

/4"1"1

1

/4"1

1

/2"2"

diameter

Weight approx. kg 0,3 0,3 0,45 0,6 1,35 1,8 2,9 3,8

Dimensions mm

L5050658095105115130

h 90 90 105 105 150 160 200 210

D3434364257577272

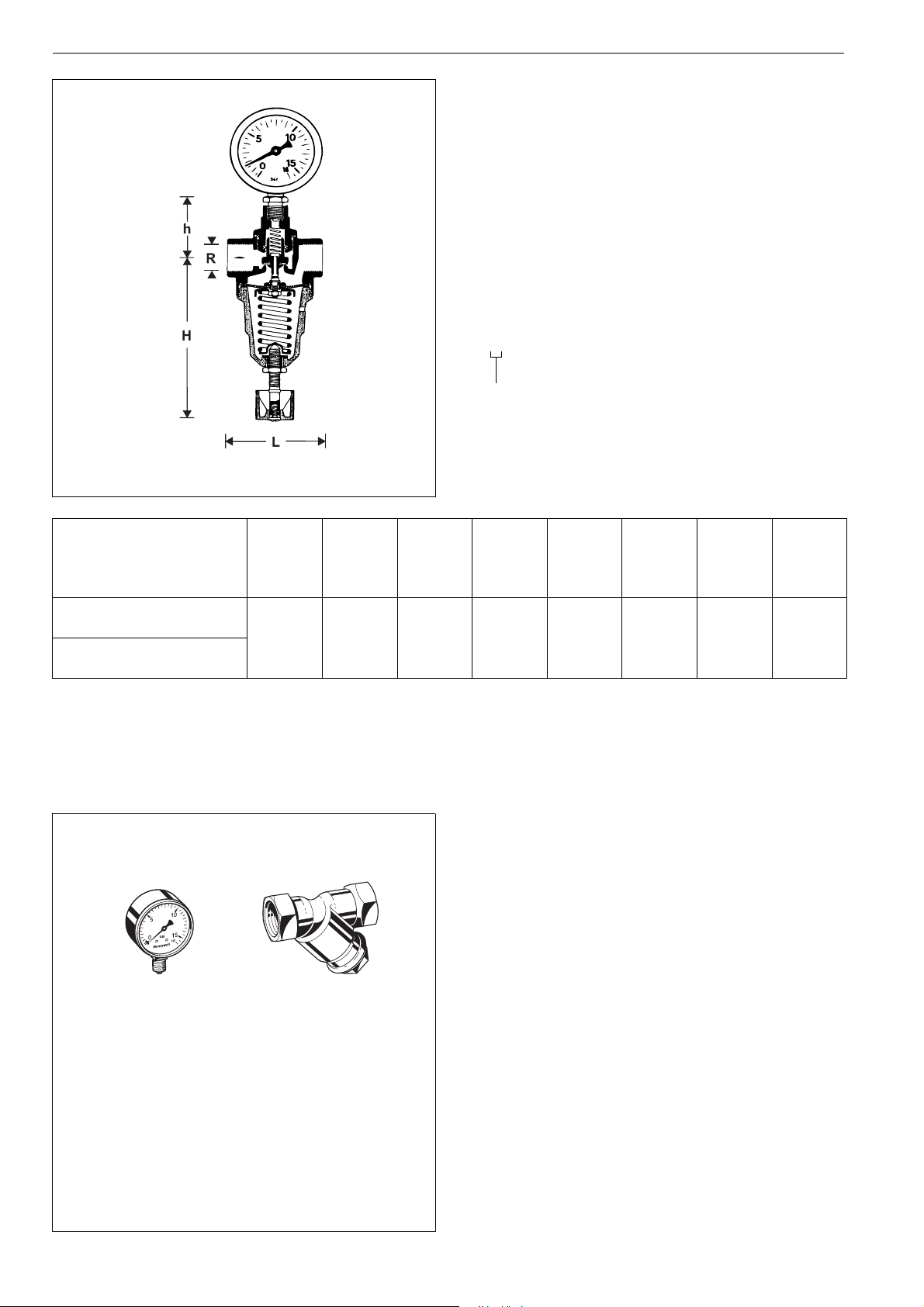

Accessories

FY30 Strainer

With double mesh strainer, brass housing

A = Mesh size approx. 0.35 mm

M38K Pressure gauge

Housing diameter 50 mm, below connection thread

G1/4". Ranges: 0 - 4, 0 - 10, 0 - 16 or 0 - 25 bar.

Please indicate upper value of pressure range when

M38K

FY30

ordering

56 www.honeywell.com

EN0H-1011GE23 R1109 • Subject to change

Page 3

Installation Example

D22 Pressure reducing valve with piston balanced seat

10

5

15

bar

0

16

Connection size R

1

/4"3/8"1/2"3/4"1"11/4"11/2"2"

DN8 10152025324050

W* mm 45 45 50 50 55 60 60 70

* Minimum distance from wall to centre line of pipework

Installation Guidelines

• Install in horizontal pipework with spring hood directed downwards.

• Install shutoff valves

• The installation location should be protected against frost

and be easily accessible

o Pressure gauge can be read off easily

o Simplified maintenance and cleaning

• Install downstream of the filter or strainer

Typical Applications

Pressure reducing valves of this type are suitable for household,

industrial and commercial applications within the range of their

specifications.

Pressure reducing valves should be installed:

• If the static pressure exceeds the maximum permissible value

for the system

• If pressure fluctuations in the downstream system must be

avoided

o This position ensures optimum protection for the pressure

reducing valve against dirt

• Provide a straight section of pipework of at least five times the

nominal valve size after the pressure reducing valve (in accordance with DIN 1988, Part 5)

EN0H-1011GE23 R1109 • Subject to change

www.honeywell.com 57

Page 4

D22 Pressure reducing valve with piston balanced seat

1

Spare Parts

Pressure Reducing Valve D22, from 1968 onwards

No. Description Dimension Part No.

1 Valve cone complete1/4"

for D22

+ 3

/8" 0903223

1

/2" 0903224

3

/4" 0903225

1" 0903226

1

1

/4" 0903227

1

1

/2" 0903228

2" 0903229

1

2 Diaphragm for D22

3 Spring bonnet

complete for D22

+ 3

/4"

/8" 2202500

1

+ 3

/2"

/4" 2202700

+ 11

1"

/4" 2203300

1

1

/2" + 2" 2204100

1

+ 3

/4"

/8" 0900272

1

+ 3

/2"

/4" 0900273

+ 11

1"

/4" 0900274

1

1

/2" + 2" 0900275

2

3

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Rolle, Z.A. La

Pièce 16, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1011GE23 R1109

Subject to change without notice

© 2009 Honeywell GmbH

Loading...

Loading...