Page 1

D06FI

Pressure reducing valve with balanced seat

Stainless steel pattern

Product specification sheet

Application

Pressure reducing valves of this type protect household water

installations against excessive pressure from the supply. They

can also be used for industrial or commercial applications within

the range of their specification.

By installing a pressure reducing valve, pressurisation damage is

avoided and water consumption is reduced.

The set pressure is also maintained constant, even when there is

wide inlet pressure fluctuation.

Reduction of the operating pressure and maintaining it at a

constant level minimizes flow noise in the installation.

6

4

8

2

bar

0

10

Construction

The pressure reducing valve comprises:

• Housing with pressure gauge connections on both sides

• Threaded male connections (options A & B)

• Valve insert complete with diaphragm and valve seat

• Fine filter with 0.16 mm mesh

• Spring bonnet with adjustment knob and setting scale

•Filter bowl

• Adjustment spring

• Pressure gauge not included (see accessories)

Materials

• Stainless steel housing

• Stainless steel threaded connections

• High-quality synthetic material valve insert

• Stainless steel fine filter mesh

• High-quality synthetic material spring bonnet with adjustment

knob and setting scale

EN0H-1035GE23 R1109 • Subject to change

• Clear synthetic or stainless steel filter bowl

• Spring steel adjustment spring

• Fibre-reinforced NBR diaphragm

• NBR seals

Special Features

• DVGW approved

•Up to size 1

1

/4" approved for low noise, Group 1 without limi-

tations

• The outlet pressure is set by turning the adjustment knob

• The set pressure is directly indicated on the set point scale

• The adjustment spring is not in contact with the potable water

• The valve insert is of high quality synthetic material and can

be fully exchanged

• Integral fine filter

• Also available without fittings

• Inlet pressure balancing - fluctuating inlet pressure does not

influence outlet pressure

• Light weight

• Meets KTW recommendations for potable water

Range of Application

Medium Water, compressed air* and nitrogen* in

consideration of valid standards (e.g.

DIN EN 12502)

Inlet pressure max. 16 bar with clear filter bowl

max. 25 bar with stainless steel filter

bowl

Outlet pressure 1.5-6.0 bar (preset to 3 bar)

Technical Data

Operating temperature max. 40 °C with clear filter bowl

max. 70 °C with stainless steel filter

bowl

Minimum pressure drop 1.0 bar

Connection size

*

As part of an installation being approved according to PED requirements, this

product must also be certified.

1

/2" to 2"

www.honeywell.com 23

Page 2

D06FI Pressure reducing valve with balanced seat

Method of Operation

Spring loaded pressure reducing valves operate by means of a

force equalising system. The force of a diaphragm operates

against the force of an adjustment spring. If the outlet pressure

and therefore diaphragm force fall because water is drawn, the

then greater force of the spring causes the valve to open. The

outlet pressure then increases until the forces between the

diaphragm and the spring are equal again.

The inlet pressure has no influence in either opening or closing of

the valve. Because of this, inlet pressure fluctuation does not

influence the outlet pressure, thus providing inlet pressure balancing.

Options

D06FI-... A = With threaded male connections, clear filter bowl -

up to 40 °C

D06FI-... B = With threaded male connections, stainless steel

filter bowl - up to 70 °C

Without fittings, with clear filter bowl - up to 40 °C

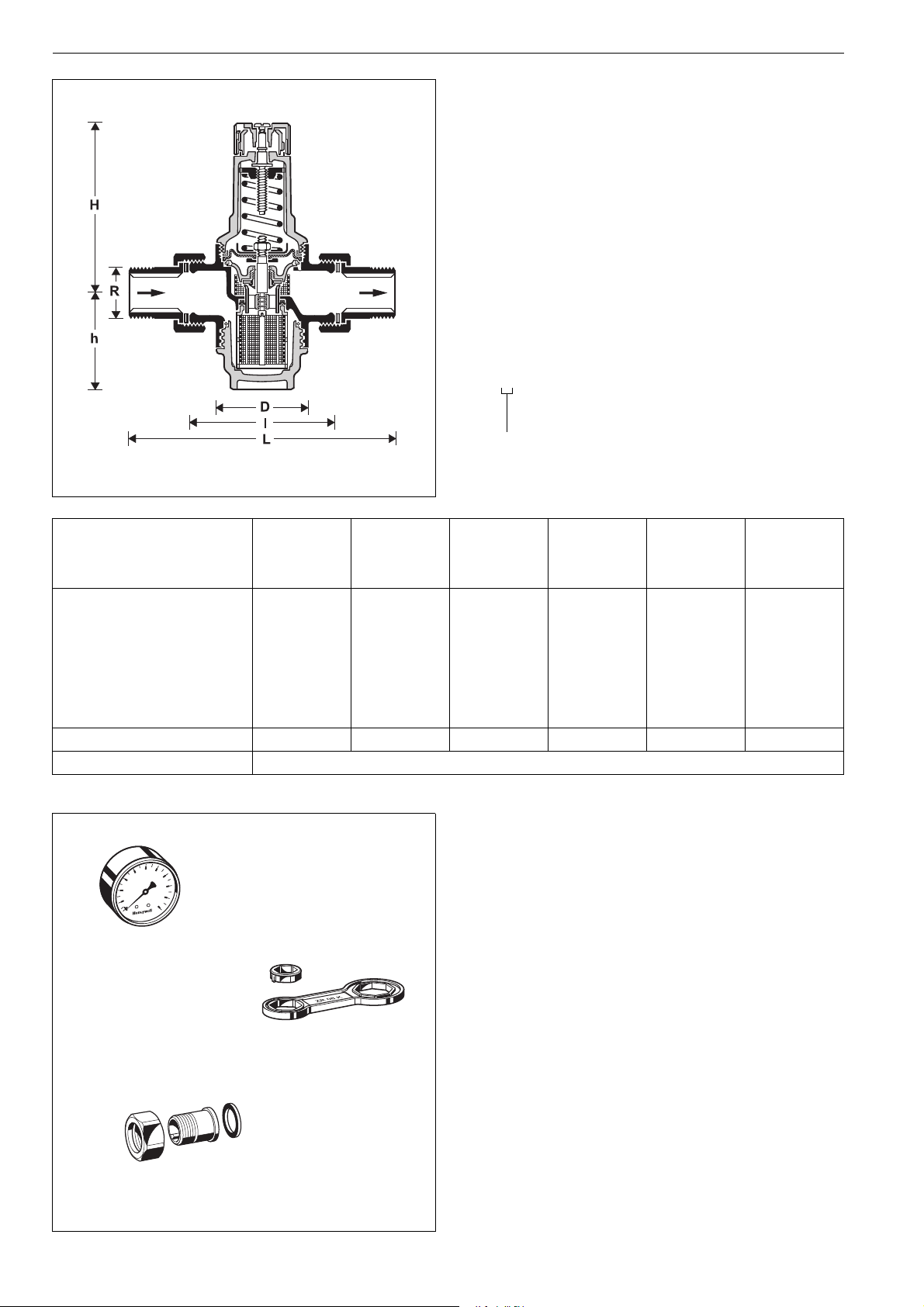

Connection size

Connection size R

1

/2"

3

/4"1"1

1

/4"1

1

/2"2"

Nominal size diameter DN 15 20 25 32 40 50

Weight (A-Version) kg 0.7 0.8 1.2 1.6 2.9 3.6

Dimensions mm

L 140 160 180 200 225 255

l 80 90 100 105 130 140

H 89 89 111 111 173 173

h58586464126126

D545461618282

-value m3/h 2.4 3.1 5.8 5.9 12.6 12.0

k

vs

DVGW-Approval No. DW-6330AT2314

* Compulsory testing in sizes R 1/2" to R 1 1/4"

Accessories

M07M Pressure gauge

6

4

8

2

r

ba

0

10

Housing diameter 63 mm, rear connection thread

1

/4". Ranges: 0 - 4, 0 - 10, 0 - 16 or 0 - 25 bar.

G

Please indicate upper value of pressure range when

ordering

M07M

ZR06K Double ring wrench

For removal of spring bonnet and filter bowl

VST06I-A

24 www.honeywell.com

ZR06K

VST06I-AConnection set

With stainless steel threaded connections

EN0H-1035GE23 R1109 • Subject to change

Page 3

Installation Example

1

Connection size R

/2"3/4"1"11/4"11/2"2"

DN 15 20 25 32 40 50

W* mm 55 55 60 60 70 70

* Minimum distance from wall to centre line of pipework

D06FI Pressure reducing valve with balanced seat

Installation Guidelines

• Install in horizontal pipework with filter bowl downwards.

• Install shutoff valves

• The device downstream should be protected by means of a

safety valve (installed downstream of the pressure reducing

valve).

• The installation location should be protected against frost

and be easily accessible

o Pressure gauge can be read off easily

o With clear filter bowl, degree of contamination can be easily

seen

o Simplified maintenance and cleaning

• For residential applications where maximum protection

against dirt is required, install a fine filter upstream of the

pressure reducing valve

• Provide a straight section of pipework of at least five times the

nominal valve size after the pressure reducing valve (in accordance with DIN 1988, Part 5)

Flow Diagram

[

l/s

10

3

]

[m

/h]

50

5

10

5

1

Typical Applications

Pressure reducing valves of this type are suitable for all types of

household water installations.

Pressure reducing valves can also be used for industrial and

commercial applications within the range of their specifications.

Pressure reducing valves should be installed:

• If the static pressure exceeds the maximum permissible value

for the system

• As protection against noise if the static pressure at take off

points exceeds 5.0 bar (DIN 4109: Noise protection in high

buildings)

• If several pressure zones are required when a pressurisation

system is used (pressure reducers on each storey of a building)

• If pressure fluctuations in the downstream system must be

avoided

• To achieve constant inlet and outlet pressures on pumped

pressure boosting systems

1

R 1

/2"

R 2"

1

/4"

R 1

R 1"

R 3/4"

1

R

/2"

0,5

1

EN0H-1035GE23 R1109 • Subject to change

0,1

Flow V

0,5

0,1

0,01

Pressure drop in valve ∆p

0,05 0,1 0,5 1 105

[

]

bar

www.honeywell.com 25

Page 4

D06FI Pressure reducing valve with balanced seat

1

2

4

Spare Parts

Pressure Reducing Valve D06FI, from 2007 onwards

No. Description Dimension Part No.

1 Spring bonnet

complete 1" + 1

2 Valve insert complete

D06FI (without filter)

1

/2" + 3/4" 0901515

1

/4" 0901516

1

1

/2" + 2" 0901518

1

/2" + 3/4"D06FI-1/2

1

1" + 1

/4"D0FI-1

1

1

/2" + 2" D06FI-11/2

3 Union seal washer1/2" 0901443

(10 pcs.)

3

/4" 0901444

1" 0901445

1

1

3

/4" 0901446

1

1

/2" 0901447

2" 0901448

4 Blanking plug

with O-ring R

1

/4"

S06K-1/4

(5 pcs.)

2

5 Replacement filter

1

/2" + 3/4" ES06F-1/2A

insert

5

6

7

D06F, D06FI 1" + 1

6 O-ring set for D06FI1/2" + 3/4" 0901246

(10 pcs.) 1" + 1

7 Clear filter bowl

with O-ring for D06FI 1" + 1

8 Stainless steel filter

bowl with O-ring

D06FI

1

/4" ES06F-1B

1

1

/2" + 2" ES06F-11/2A

1

/4" 0901499

1

1

/2" + 2" 0901248

1

/2" + 3/4"SK06T-1/2

1

/4"SK06T-1B

1

1

/2" + 2" SK06T-11/2

1

/2" + 3/4" SI06T-1/2

1

1" + 1

/4" SI06T-1

1

1

/2" + 2" SI06T-11/2

Honeywell GmbH

Haustechnik

Hardhofweg

D-74821 Mosbach

Telefon (0 18 01) 46 63 88

Telefax (08 00) 0 46 63 88

www.honeywell.de/haustechnik

Hergestellt im Auftrag von Environmental and

Combustion Controls Division of Honeywell

Technologies Sàrl, Rolle, Z.A. La Pièce 16,

Switzerland durch die autorisierte Vertretung

Honeywell GmbH.

EN0H-1035GE23 R1109

Änderungen vorbehalten

© 2009 Honeywell GmbH

Loading...

Loading...