Page 1

Place Bar Code Here

D05T Compact Design Pressure

Regulating Valves

INSTALLATION INSTRUCTIONS

APPLICATION

The Honeywell Braukmann D05T Pressure Regulating

Valve is a high quality pressure regulating valve that

maintains a constant outlet pressure over a wide range of

inlet supply pressures. It is ideally suited for new

residential and light commercial construction, drip

irrigation, and applications requiring highly sensitive and

accurate regulation.

The wide inlet pressure range of the D05T gives flexibility

without compromising reduced outlet pressure accuracy

or capacity. The superior balanced single seat design

maintains a constant outlet pressure over a wide range of

inlet pressures. The non-corroding unitized cartridge

insert contains all the working parts and is easily

replaceable.

The D05T is used for water or air regulation. It is not

suitable for steam.

SPECIFICATIONS

Model: D05T Pressure Regulating Valves

Construction Materials:

Body: Bronze.

Internal Parts: Stainless steel and engineered plastic.

Regulator Mechanism: Fabric-reinforced diaphragm.

Inlet Pressure: 400 psi maximum.

Reduced Pressure Range: 15 to 90 psi.

Outlet Pressure: Factory set at 60 psi.

Differential: 14 psi minimum (inlet to outlet).

Fluid Temperature (Maximum):

Air: 158°F (70°C).

Water: 180°F (82°C).

Ambient Temperature: 33°F to 140°F (1°C to 60°C)

Pipe Sizes: 3/4 in. and 1 in. available.

Connections: Can be configured as female thread-by-

thread, single- or double-union, NPT threaded or

sweat.

Strainer Screen Size: 0.032 in. (0.8 mm)

Gauge Tap: 1/4 in. NPT (available on all models).

Approvals:

ASSE (Std. 1003) Certified.

IAPMO, CSA, and City of L.A. Listed.

Dimensions: See Fig. 1.

Water Capacities (See Table 1):

The suitability of a given regulator size is dependent on

the pressure requirements of each installation. To

determine the pressure regulator valve size required

for a specific installation, determine the following:

1. Pressure differential between inlet and outlet pres-

sure in pounds per square inch (psi),

2. Capacity in gallons per minute (gpm), and

3. Allowable reduced pressure falloff in psi.

Given these variables, use Table 1 to determine the

proper size pressure regulator valve for your application.

Example:An installation has 135 psi inlet pressure, 60 psi

outlet pressure (75 psi pressure differential). If

12 gpm capacity is required with only 10 psi falloff allowable, a 1/2 in. D05T is required.

62-3028EF-01

Page 2

D05T COMPACT DESIGN PRESSURE REGULATING VALVES

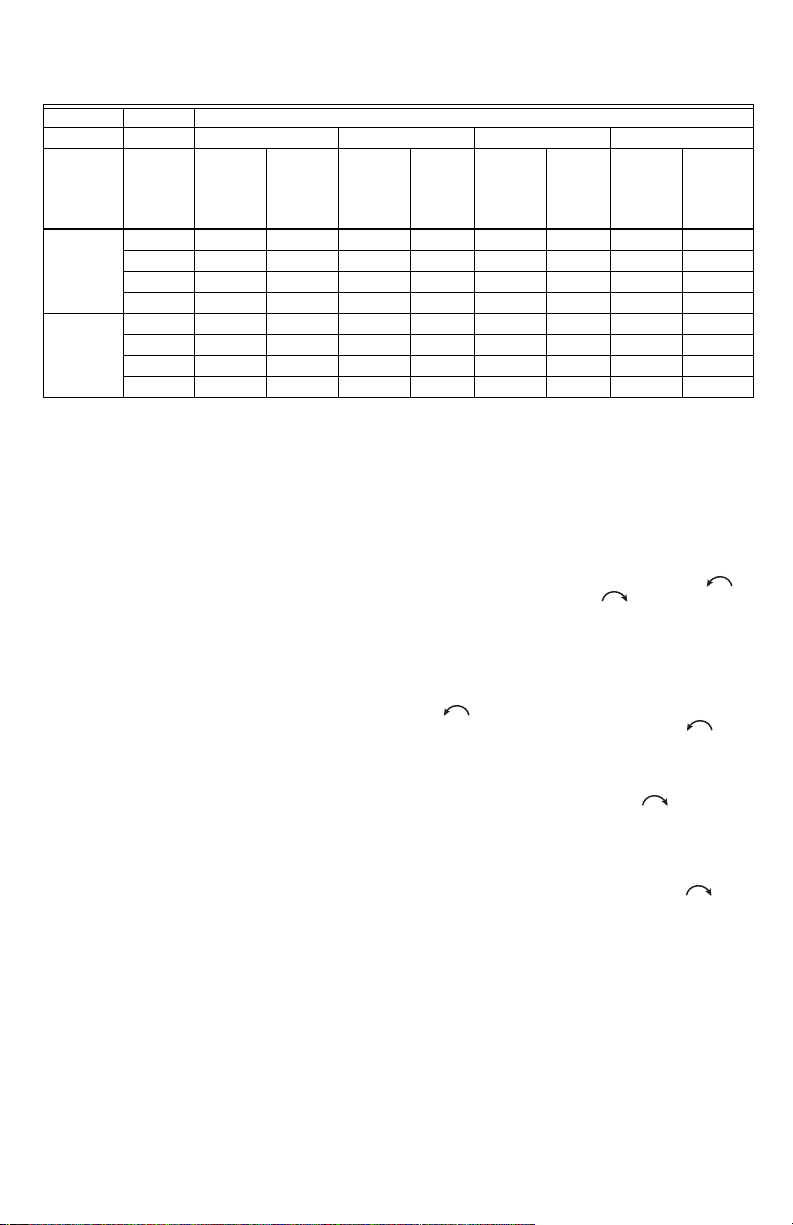

Table 1. Water Capacities.

Pressure Differential Between Inlet and Outlet

25 psi 50 psi 75 psi 100 psi or more

a

Flow

Capacity

Vel ocit y

(U.S.

gpm)

(ft/sec)

4. Open the supply valve.

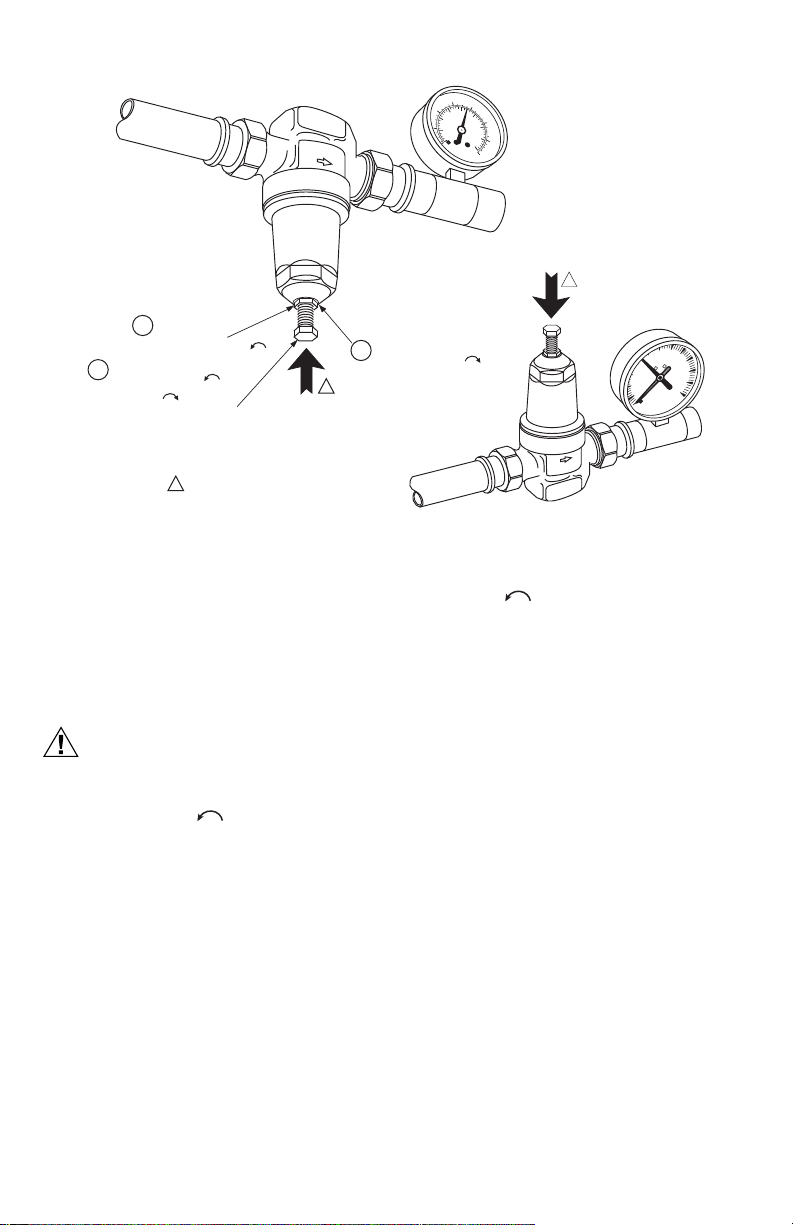

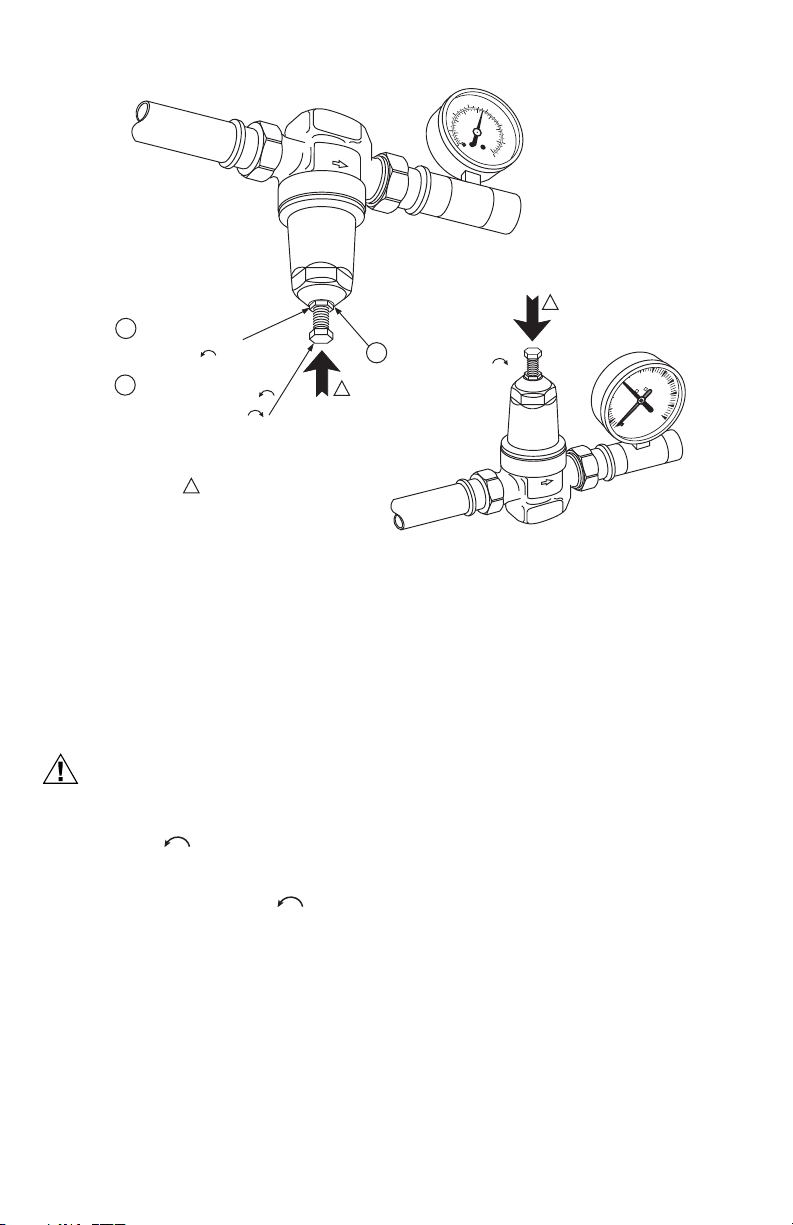

Changing the Outlet Pressure (See Fig. 1)

The D05T is factory set to 60 psi. To change the outlet

pressure, turn the adjusting bolt counterclockwise

to reduce pressure or clockwise to increase

pressure.

To adjust the outlet pressure to a desired setting:

1. Close the supply shutoff valve and open a down-

2. Loosen the locknut by turning counterclockwise

3. Turn the adjusting bolt counterclockwise sev-

4. Close all downstream valves and/or faucets and

5. Turn the adjusting bolt clockwise to gradually

6. Reopen a downstream valve. During flow, there will

7. Tighten the locknut by turning clockwise until

Pressure

Regulator

Valve

Size

3/4 inch 6 9.0 5.4 10.0 6.0 11.0 6.5 12.0 7.1

1 inch 6 11.5 4.2 13.0 4.7 14.5 5.3 16.0 5.8

a

Velocity in feet per second is based on schedule 40 pipe size. recommended pressure falloff for general use is

approximately 15 psi (104 kPa). Recommended velocities for the flow of water: Residential and general use, 5 to 10

feet per second; industrial use, 7 to 15 feet per second; boiler feed, 7 to 15 feet per second.

Reduced

Pressure

Falloff

(psi)

10 15.0 8.9 16.0 9.5 17.0 10.0 18.0 10.7

15 20.0 11.9 22.0 13.7 23.0 13.7 24.0 14.3

20 23.0 13.9 26.0 17.6 27.0 16.7 28.0 17.3

10 20.0 7.2 21.5 7.8 23.0 8.3 24.5 8.9

15 28.0 10.7 30.0 10.9 33.0 12.0 35.0 12.7

20 32.0 14.0 37.0 13.5 40.0 15.5 41.0 15.0

Flow

Capacity

(U.S.

gpm)

Velo city

(ft/sec)

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in these instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the product

operation as provided in these instructions.

Procedure

1. Flush the system clear of sediment or debris.

2. Close the supply valve and downstream isolating

valve (if used).

3. Install the D05T with the arrow on the body pointing

in the direction of water flow. (The D05T can be

mounted in any position.)

The D05T can be installed directly onto the pipe by using

the female NPT threads on each end. If space limitations

restrict turning the D05T, install single- or double-unions.

NOTE: Heat from soldering can damage internal parts of

the D05T. Always remove the tailpiece(s) from

the D05T during soldering, or disassemble the

D05T prior to heating the casting.

Flow

Capacity

a

stream faucet to relieve static pressure in the line.

two turns.

eral turns to make sure the setting is below the

desired setting.

slowly open the supply valve until fully open.

increase the pressure until the gauge indicates the

desired outlet pressure (under no flow condition).

normally be a pressure falloff of 3 to 15 psi depending upon the amount of water flow.

tight. Do not overtighten.

(U.S.

gpm)

Vel ocit y

(ft/sec)

Capacity

a

Flow

(U.S.

gpm)

Velocity

(ft/sec)

a

62-3028EF—01 2

Page 3

CAUTION

1

LOOSEN LOCKNUT

BY TURNING

COUNTERCLOCKWISE

TURN ADJUSTING BOLT

2

COUNTERCLOCKWISE

TO DECREASE OR

CLOCKWISE TO

INCREASE OUTLET PRESSURE

1

1

THE CLOCKWISE AND COUNTERCLOCKWISE

DIRECTIONS ARE DETERMINED BY LOOKING

DIRECTLY AT THE ADJUSTING BOLT

Fig. 1. Changing outlet pressure.

D05T COMPACT DESIGN PRESSURE REGULATING VALVES

600

800

400

100

75

125

1000

50

200

150

25

175

0

1200

0

200

PSI

HONEYWELL

kPa

1400

BRAUKMANN

1

TIGHTEN LOCKNUT BY

3

TURNING CLOCKWISE

150

200

100

water test

250

50

PSI

300

M32170

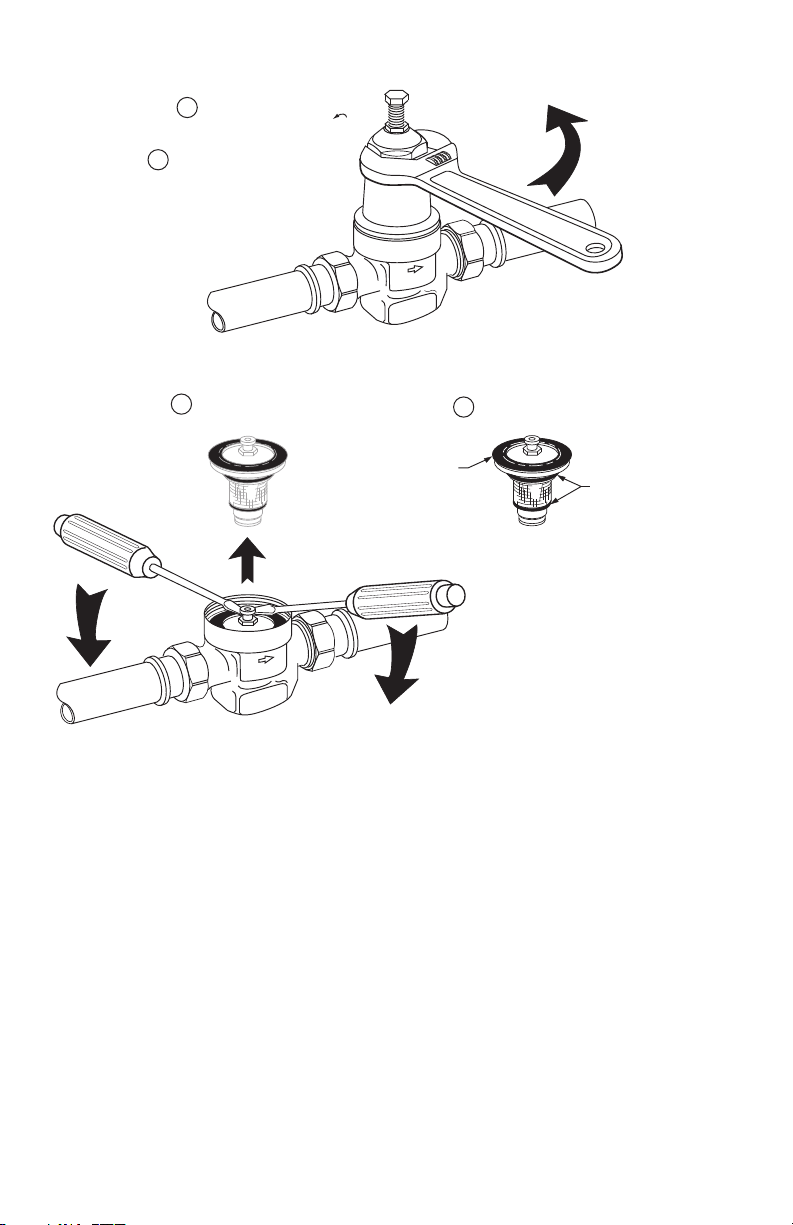

Replacing the Cartridge (See Fig.

2)

The working parts of the D05T, including diaphragm, valve

seat, strainer, and disk are all contained in a replaceable

cartridge. To replace the cartridge:

1. Shut off the supply valve and open a downstream

faucet to relieve the system pressure.

To prevent injury and/or equipment damage,

loosen locknut and turn adjusting screw

counterclockwise to remove spring tension.

2. Loosen locknut and turn adjusting screw counter-

clockwise to remove spring tension.

3. Remove the bonnet and washer using an adjust-

able wrench, socket, or box-end wrench.

4. Remove the cartridge using two screwdrivers as

levers.

5. Attach new O-rings and screen onto the new car-

tridge. Make sure O-rings are properly installed

above and below the screen.

6. Insert the new cartridge. Do not scratch the sides.

7. Place the washer on top of the cartridge.

NOTE: The inner lip must be pointing up to avoid

damaging the diaphragm.

8. Replace the spring, spring cup, and bonnet.

9. Readjust the outlet pressure to the desired setting

by using the procedure described in Changing the

Outlet Pressure section.

3 62-3028EF—01

Page 4

D05T COMPACT DESIGN PRESSURE REGULATING VALVES

2

REMOVE BONNET USING AN ADJUSTABLE

WRENCH, SOCKET, OR BOX END WRENCH

3

REMOVE CARTRIDGE USING TWO

SCREWDRIVERS AS LEVERS

4

ENSURE O-RINGS AND WASHER

ARE PROPERLY INSTALLED

O-RINGS

M761A

1

WASHER

(LIP UP)

LOOSEN LOCKNUT AND TURN ADJUSTING

SCREW COUNTER CLOCKWISE TO

REMOVE SPRING TENSION

Fig. 2. Replacing D05T cartridge.

62-3028EF—01 4

Page 5

D05T COMPACT DESIGN PRESSURE REGULATING VALVES

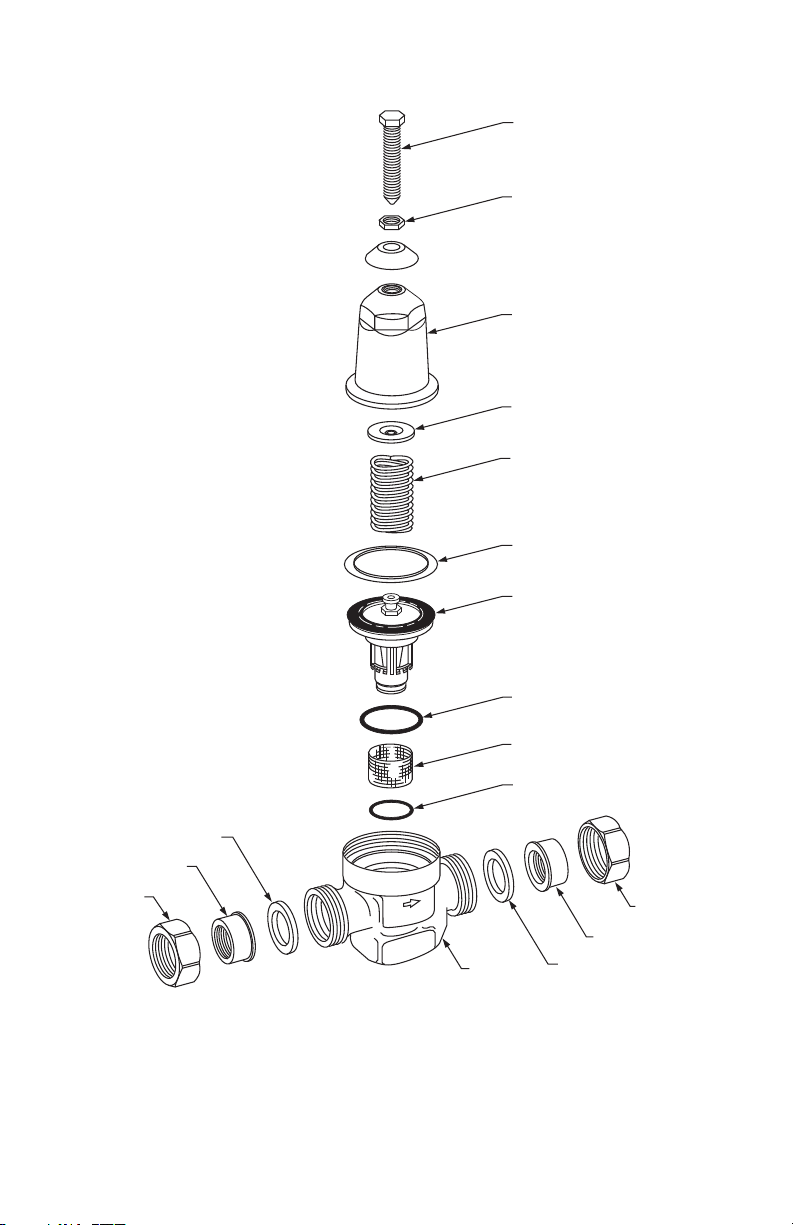

ADJUSTING SCREW

LOCKING NUT

BONNET

SPRING CUP

SPRING

WASHER

CARTRIDGE

TAILPIECE

NUT

GASKET

Fig. 3. D05T exploded view.

5 62-3028EF—01

BODY

O-RING

SCREEN

O-RING

GASKET

NUT

TAILPIECE

M32171

Page 6

D05T COMPACT DESIGN PRESSURE REGULATING VALVES

CAUTION

Cleaning the Cartridge Screen

To clean the cartridge screen:

1. Shut off the supply valve and open a downstream

faucet to relieve the system pressure.

To prevent injury and/or equipment damage,

loosen locknut and turn adjusting screw

counterclockwise to remove spring

tension.

2. Loosen locknut and turn adjusting screw counter-

clockwise to remove spring tension.

3. Remove the bonnet and washer using an adjust-

able wrench, socket, or box-end wrench.

4. Remove the cartridge using two screwdrivers as

levers as shown in Fig. 3.

5. Remove and clean the cartridge screen.

6. Replace the cartridge screen and make sure the O-

rings are installed properly.

7. Carefully clean the cartridge seat area.

8. Insert the cartridge. Do not scratch the sides.

9. Place the washer on top of the cartridge.

NOTE: The inner lip must be pointing up to avoid

damaging the diaphragm.

10. Replace the spring, spring cup and bonnet (see Fig.

3).

11. Readjust the outlet pressure to the desired setting

by using the procedure described in Changing the

Outlet Pressure section.

OPERATION

The Honeywell Braukmann D05T is a balanced, direct

acting pressure regulating valve. The D05T provides

constant downstream pressure regardless of varying inlet

pressures and downstream flow demands.

The spring force holds the valve in the open position until

downstream pressure, sensed by a port, is sufficient to

press on the underside of the diaphragm and close the

valve. As downstream pressure drops due to demand, the

force on the diaphragm is reduced and the valve opens.

Adjustment is made by manually turning the adjustment

screw clockwise to increase the spring force and

require a higher downstream pressure to close the valve.

Similarly, reducing the spring force lowers the outlet set

pressure.

Once the outlet pressure is set, the D05T regulates to

maintain that pressure downstream. See Fig. 4 for the

internal construction of the D05T.

62-3028EF—01 6

INLET OUTLET

M32172

Fig. 4. Internal construction of the D05T.

Page 7

D05T COMPACT DESIGN PRESSURE REGULATING VALVES

TROUBLESHOOTING

Table 2 provides a troubleshooting guide for the D05T Pressure Regulating Valves.

Table 2. Troubleshooting D05T Pressure Regulating Valves.

Problem Solution

Whistling noise. • Slightly increase or decrease the outlet pressure until the noise disappears.

Will not hold pressure. • Clean the filter cartridge as shown on page 2.

Chatters. • Replace the screen and O-rings.

Freezes up. • Replace bonnet or cartridge if damaged.

Pressure gauge measures a lower

pressure under flow conditions than

was originally set during static

conditions.

D05 Parts and Accessories

Order Number Description

Replacement Parts

203223 Bonnet Assembly for 3/4 in. Valves.

203224 Bonnet Assembly for 1 in. Valves.

272841 Gasket or 3/4 in. D05T/DS05 (quantity

272842 Gasket for 1 in. D05T/DS05 (quantity

K05A1009 Replacement Cartridge, Screen and

K05A1017 Replacement Cartridge, Screen and

K05B1007 Replacement Screen and O-ring for 3/

24).

24).

O-ring for 3/4 in. Valves.

O-ring for 1 in. Valves.

4 in. Valves.

• Open the gauge tap and blow out any dirt (D05G only).

• Replace the cartridge as shown on page 2.

• To avoid future freeze-up:

—Temporarily (slightly) open a downstream faucet if the D05T is going to be

exposed to temperatures below 32°F (0°C). The slight water flow will eliminate

freeze-up.

—Move the D05T to a location with an ambient temperature above 32°F (0°C)

if it is currently exposed to prolonged temperatures below 32°F (0°C).

• D05T is functioning properly. No action is necessary. The pressure

decrease is characteristic of all direct acting pressure regulating valves and

is referred to as fall-off.

K05B1015 Replacement Screen and O-ring for 1

Union Kits

K06U1077 Union Kit — 3/4 in., includes nut,

K06U1085 Union Kit — 1 in., includes nut, female

K06U1101 Union Kit — 3/4 in., includes nut,

K06U1119 Union Kit — 1 in., includes nut, sweat

in. Valves.

female NPT threaded tailpiece and

gasket.

NPT threaded tailpiece and gasket.

sweat tailpiece and gasket.

tailpiece and gasket.

7 62-3028EF—01

Page 8

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2010 Honeywell International Inc.

62-3028EF—01 T.D. Rev. 07-10

Printed in U.S.A.

Page 9

Place Bar Code Here

Régulateurs de Pression

Compacts D05T

NOTICE D'INSTALLATION

APPLICATION

Le régulateur de pression Braukmann D05T de

Honeywell est un régulateur de pression de qualité

supérieure maintenant une pression de sortie constant

sur une large plage de pressions d'entrée. Il est

parfaitement adapté aux constructions neuves

résidentielles et petits bâtiments commerciaux, aux

applications d'irrigation goutte à goutte, et aux autres

applications nécessitant une régulation très sensible et

précise.

La grande plage de pressions d'entrée du D05T offre

flexibilité sans compromettre la précision et la capacité

de la pression de sortie réduite. La conception

supérieure à siège unique équilibré maintient une

pression de sortie constante sur une large plage de

pressions d'entrée. La cartouche unitaire résistante à la

corrosion contient toutes les pièces actives et se

remplace facilement.

Le D05T est utilisé pour la régulation de l'eau et de l'air. Il

n'est pas compatible avec la vapeur.

CARACTÉRISTIQUES

Modèle: Régulateurs de pression D05T

Matériaux de construction:

Corps: Bronze.

Pièces internes: Acier inoxydable et plastique technique.

Mécanisme de régulation: Membrane renforcée de tissu.

Pression d'entrée : 400 psi maximum.

Plage de pression réduite: 15 à 90 psi.

Pression de sortie: étalonnée en usine à 60 psi.

Pression différentielle: 14 psi minimum (entrée à sor-

tie).

Tailles de conduit: 3/4 po et 1 po disponibles.

Connexions: Peut être configuré avec filetage femelle,

raccord simple ou double, à filetage NPT ou à souder.

Taille du filtre de tamis: 0,8 mm (0,032 po)

Prise de manomètre: 1/4 po NPT (disponible sur tous

les modèles).

Homologations:

Certifié ASSE (norme (1003).

Répertorié IAPMO, CSA et Ville de Los Angeles.

Dimensions: Voir la Fig. 1.

Contenances en eau (voir le Tableau 1) :

L'applicabilité d'une taille de régulateur donnée dépend

des exigences de pression de chaque application.

Pour déterminer la taille du régulateur requis pour une

installation spécifique, déterminer les points suivants:

12. Pression différentielle entre l'entrée et la sortie en

psi (livres/po2),

13. Capacité en gallons par minute (gal./min), et

14. Affaiblissement de pression réduite permis en psi.

En fonction de ces variables, utiliser le tableau 1 pour

déterminer la taille du régulateur de pression

correspondant à l'application.

Exemple:Une installation comporte une pression d'entrée

de 135 psi, une pression de sortie de 60 psi (différentiel de 75 psi). Si une capacité de 12 gal./

min est requise avec un affaiblissement permis

de 10 psi uniquement, un régulateur D05T de ½

po est requis.

Température de fluide (maximum):

Air : 70°C (158°F).

Eau : 82°C (180°F).

Température ambiante: 1 °C à 60 °C (33 °F à 140 °F)

62-3028EF-01

Page 10

RÉGULATEURS DE PRESSION COMPACTS D05T

Tableau 3. Contenances en eau.

Pression différentielle entre l'entrée et la sortie

25 psi 50 psi 75 psi 100 psi ou plus

Taille du

régulateur

pression

3/4 po 6 9.0 5.4 10.0 6.0 11.0 6.5 12.0 7.1

a

La vitesse en pied/s est basée sur une taille de conduit de schedule 40. L'affaiblissement de pression recommandé

pour un usage général est d'environ 15 psi (104 kPa). Vitesses recommandées pour le débit d'eau : Usage général et

résidentiel, 5 à 10 pi/s (1,5-3,0 m/s); usage industriel, 7 à 15 pi/s (2,1-4,6 m/s); alimentation de chaudière, 7 à 15 pi/s

(2,1-4,6 m/s).

Affaiblisse-

de

1 po 6 11.5 4.2 13.0 4.7 14.5 5.3 16.0 5.8

ment de

pression

réduite (psi)

Débit (gal.

US/min)

10 15.0 8.9 16.0 9.5 17.0 10.0 18.0 10.7

15 20.0 11.9 22.0 13.7 23.0 13.7 24.0 14.3

20 23.0 13.9 26.0 17.6 27.0 16.7 28.0 17.3

10 20.0 7.2 21.5 7.8 23.0 8.3 24.5 8.9

15 28.0 10.7 30.0 10.9 33.0 12.0 35.0 12.7

20 32.0 14.0 37.0 13.5 40.0 15.5 41.0 15.0

Vitesse

(pi/s)

a

Débit (gal.

US/min)

Vitesse

(pi/s)

Débit (gal.

a

US/min)

Vitesse

(pi/s)

Débit (gal.

a

US/min)

Vitesse

(pi/s)

a

INSTALLATION

Lors de l'installation du produit...

1. Lire attentivement ces instructions. Le non-respect

des instructions peut endommager le produit ou

provoquer une situation dangereuse.

2. Vérifier les caractéristiques nominales indiquées

dans cette notice et sur le produit pour s'assurer

que le produit correspond bien à l'application prévue.

3. L'installateur doit être un technicien expérimenté

ayant reçu la formation adéquate.

4. Une fois l'installation terminée, vérifier que le pro-

duit fonctionne comme indiqué dans cette notice.

Procédure

1. Purger le système de tout sédiment ou débris.

2. Fermer le robinet d'arrivée et le robinet d'isolement

en aval (le cas échéant).

3. Installer le D05T avec la flèche sur le corps pointant

dans la direction du débit d'eau. (Le D05T peut être

monté dans n'importe quelle position.)

Le D05T peut être installé directement sur le conduit en

utilisant un filetage NPT femelle à chaque extrémité. Si

des restrictions au niveau de l'espace empêchent de

tourner le D05T, installer des raccords simples ou

doubles.

REMARQUE : La chaleur dégagée par le soudage peut

endommager les pièces internes du D05T.

Toujours retirer le ou les embouts du D05T

durant le soudage, ou démonter le D05T

avant de chauffer le moulage.

4. Ouvrir le robinet d'alimentation.

Modification de la pression de sortie (voir la Figure 1)

Le D05T est réglé en usine à 60 psi. Pour modifier la

pression de sortie, tourner le boulon de réglage dans le

sens antihoraire pour réduire la pression et dans le

sens horaire pour augmenter la pression.

Pour régler la pression de sortie à un réglage désiré:

1. Fermer le robinet d'alimentation et ouvrir un robinet

en aval pour dissiper la pression statique dans le

conduit.

2. Desserrer l'écrou de blocage en le tournant de deux

tours dans le sens antihoraire .

3. Tourner le boulon de réglage de plusieurs tours

dans le sens antihoraire pour s'assurer que

le réglage est inférieur au réglage désiré.

4. Fermer tous les robinets et/ou vannes en aval et

ouvrir lentement le robinet d'alimentation jusqu'à ce

qu'il soit complètement ouvert.

5. Tourner le boulon de réglage dans le sens horaire

pour augmenter graduellement la pression

jusqu'à ce que le manomètre indique la pression de

sortie désirée (dans des conditions sans débit).

6. Ouvrir de nouveau la vanne en aval. Durant le

débit, il y aura normalement un affaiblissement de

la pression de 3 à 15 psi en fonction du débit d'eau.

7. Serrer l'écrou de blocage en le tournant dans le

sens horaire jusqu'à ce qu'il soit bien serré.

Ne pas trop serrer.

62-3028EF—01 10

Page 11

MISE EN GARDE

1

DESSERRER L’ÉCROU DE

BLOCAGE EN TOURNANT

DANS LE SENS

ANTIHORAIRE

TOURNER LE BOULON DE RÉGLAGE

2

DANS LE SENS ANTIHORAIRE

POUR RÉDUIRE LA PRESSION DE

SORTIE OU DANS LE SENS

HORAIRE POUR L’AUGMENTER

1

LES SENS HORAIRE ET ANTIHORAIRE SONT

DÉTERMINÉS EN REGARDANT DIRECTEMENT

LE BOULON DE RÉGLAGE

RÉGULATEURS DE PRESSION COMPACTS D05T

600

800

400

100

75

125

1000

50

200

150

25

175

0

1200

0

200

PSI

HONEYWELL

kPa

1400

BRAUKMANN

SERRER L’ÉCROU DE

3

BLOCAGE EN TOURNANT

DANS LE SENS HORAIRE

1

Fig. 5. Modification de la pression de sortie.

1

150

200

100

water test

250

50

PSI

300

MF32170

Remplacement de la cartouche (voir la Figure 2)

Les pièces actives du D05T, y compris la membrane, le

siège de vanne, le tamis et le disque, sont toutes

contenues dans une cartouche remplaçable. Pour

remplacer la cartouche:

1. Fermer le robinet d'arrivée et ouvrir un robinet en

aval pour dissiper la pression du système.

Pour éviter les blessures et/ou les dégâts

matériels, desserrer l'écrou de blocage et

tourner la vis de réglage dans le sens

antihoraire pour dissiper la tension du

ressort.

2. Desserrer l'écrou de blocage et tourner la vis de

réglage dans le sens antihoraire pour dissiper la tension du ressort.

3. Retirer le chapeau et la rondelle avec une clé

réglable, une douille ou une clé polygonale.

4. Retirer la cartouche en se servant de deux tourne-

vis comme leviers.

5. Attacher des joints toriques et un tamis neuf sur la

cartouche neuve. S'assurer que les joints toriques

sont bien installés au-dessus et en dessous du

tamis.

6. Insérer la cartouche neuve. Ne pas rayer les côtés.

7. Placer la rondelle sur la cartouche.

REMARQUE : La lèvre interne doit pointer vers le

8. Replacer le ressort, la coupelle du ressort et le cha-

peau.

9. Régler de nouveau la pression de sortie au réglage

désiré en utilisant la procédure décrite dans la section Modification de la pression de sortie.

haut pour éviter d'endommager la

membrane.

11 62-3028EF—01

Page 12

RÉGULATEURS DE PRESSION COMPACTS D05T

DESSERRER L’ÉCROU DE BLOCAGE ET

1

TOURNER LA VIS DE RÉGLAGE DANS

LE SENS ANTIHORAIRE POUR DISSIPER

LA TENSION DU RESSORT

RETIRER LE CHAPEAU AVEC UNE CLÉ

2

RÉGLABLE, UNE DOUILLE OU UNE CLÉ

POLYGONALE

RETIRER LA CARTOUCHE EN UTILISANT

3

DEUX TOURNEVIS COMME LEVIERS

RONDELLE

(LÈVRE VERS

LE HAUT)

S’ASSURER QUE LES JOINTS TORIQUES

4

ET LA RONDELLE SONT BIEN INSTALLÉS

JOINTS TORIQUES

Fig. 6. Remplacement de la cartouche D05T.

62-3028EF—01 12

MF761A

Page 13

RÉGULATEURS DE PRESSION COMPACTS D05T

VIS DE RÉGLAGE

ÉCROU DE BLOCAGE

CHAPEAU

COUPELLE DU RESSORT

RESSORT

RONDELLE

CARTOUCHE

ÉCROU

EMBOUT

JOINT

Fig. 7. Vue éclatée du D05T.

13 62-3028EF—01

CORPS

JOINT TORIQUE

TAMIS

JOINT TORIQUE

ÉCROU

EMBOUT

JOINT

MF32171

Page 14

RÉGULATEURS DE PRESSION COMPACTS D05T

CAUTION

Nettoyage du tamis de la cartouche

Pour nettoyer le tamis de la cartouche:

1. Fermer le robinet d'arrivée et ouvrir un robinet en

aval pour dissiper la pression du système.

Pour éviter les blessures et/ou les dégâts

matériels, desserrer l'écrou de blocage et

tourner la vis de réglage dans le sens

antihoraire pour dissiper la tension du

ressort.

2. Desserrer l'écrou de blocage et tourner la vis de

réglage dans le sens antihoraire pour dissiper la tension du ressort.

3. Retirer le chapeau et la rondelle avec une clé

réglable, une douille ou une clé polygonale.

4. Retirer la cartouche en se servant de deux tourne-

vis comme leviers, comme illustré dans la figure 3.

5. Retirer et nettoyer le tamis de la cartouche.

6. Replacer le tamis de la cartouche et s'assurer que

les joints toriques sont bien installés.

7. Bien nettoyer la zone du siège de la cartouche.

8. Insérer la cartouche. Ne pas rayer les côtés.

9. Placer la rondelle sur la cartouche.

REMARQUE : La lèvre interne doit pointer vers le

10. Replacer le ressort, la coupelle du ressort et le cha-

peau (voir la figure 3).

11. Régler de nouveau la pression de sortie au réglage

désiré en utilisant la procédure décrite dans la section Modification de la pression de sortie.

haut pour éviter d'endommager la

membrane.

FONCTIONNEMENT

Le D05T Braukmann de Honeywell est un régulateur de

pression à action directe équilibré. Il fournit une pression

descendante constante indépendamment des variations

des pressions d'entrée et des exigences de débit

descendant.

La force du ressort maintient le régulateur en position

ouverte jusqu'à ce que la pression descendante, captée

par un orifice, soit suffisante pour appuyer sur le côté

inférieur de la membrane et fermer le régulateur. Au fur et

à mesure que la pression descendante chute suite à la

demande, la force sur la membrane est réduite et le

régulateur s'ouvre. Le réglage se fait en tournant

manuellement la vis de réglage dans le sens horaire

pour augmenter la force du ressort et nécessiter

une pression descendante supérieure pour fermer la

vanne. De même, la réduction de la force du ressort

réduit la pression de sortie.

Une fois la pression de sortie réglée, le D05T assure une

régulation pour maintenir cette pression descendante.

Voir la figure 4 pour la construction interne du D05T.

62-3028EF—01 14

ENTRÉE SORTIE

MF32172

Fig. 8. Construction interne du D05T.

Page 15

RÉGULATEURS DE PRESSION COMPACTS D05T

DÉPANNAGE

Le tableau 2 fournit un guide de dépannage des régulateurs de pression D05T.

Tableau 4. Dépannage des régulateurs de pression D05T.

Problème Solution

Bruit sifflant. • Augmenter ou réduire légèrement la pression de sortie jusqu'à ce que le

La pression ne se maintient pas. • Nettoyer la cartouche du filtre comme illustré à la page 2.

Murmure. • Remplacer le tamis et les joints toriques.

Congélation. • Remplacer le chapeau ou la cartouche s'ils sont endommagés.

Le manomètre mesure une pression

mesurée dans des conditions de débit

inférieure à celle réglée lors de

conditions statiques.

Pièces et accessoires du D05

Description Commande

du numéro

Pièces de rechange

203223 Chapeau pour vannes de 3/4 po.

203224 Chapeau pour vannes de 1 po.

272841 Joint pour D05T/DS05 de 3/4 po

272842 Joint pour D05T/DS05 de 1 po

K05A1009 Cartouche, tamis et joint torique de

K05A1017 Cartouche, tamis et joint torique de

K05B1007 Tamis et joint torique de rechange

(quantité 24).

(quantité 24).

rechange pour vannes de 3/4 po.

rechange pour vannes de 1 po.

pour vannes de 3/4 po.

bruit disparaisse.

• Ouvrir la prise du manomètre et dégager toute saleté en soufflant (D05G

uniquement).

• Nettoyer la cartouche comme illustré à la page 2.

• Pour éviter la congélation:

—Ouvrir provisoirement (légèrement) un robinet en aval si le D05T va être

exposé à des températures inférieures à 0°C (32°F). Le léger débit d'eau

permettra d'éliminer le gel.

—Mettre le D05T dans un endroit où la température ambiante est supérieure à

0°C (32°F) s'il est actuellement exposé à des températures prolongées

inférieures à 0°C (32°F).

• Le D05T fonctionne correctement. Aucune action n'est requise. La

réduction de la pression est typique à tous les régulateurs de pression à

action directe et est appelée affaiblissement.

K05B1015 Tamis et joint torique de rechange

Nécessaires de raccords

K06U1077 Nécessaire de raccord — 3/4 po,

K06U1085 Nécessaire de raccord — 1 po, inclut

K06U1101 Nécessaire de raccord — 3/4 po,

K06U1119 Nécessaire de raccord — 1 po, inclut

pour vannes de 1 po.

inclut écrou, embout fileté NPT

femelle et joint.

écrou, embout fileté NPT femelle et

joint.

inclut écrou, embout à souder et joint.

écrou, embout à souder et joint.

15 62-3028EF—01

Page 16

RÉGULATEURS DE PRESSION COMPACTS D05T

Solutions de régulation et d’automatisation

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35, Dynamic Drive

Toronto (Ontario) M1V 4Z9

customer.honeywell.com

® Marque de commerce déposée aux É.U.

© 2010 Honeywell International Inc.

Tous droits réservés

62-3028EF—01 T.D. Rev. 07-10

Imprimé aux États-Unis

Loading...

Loading...