Page 1

Cellular Network Interface

–2(

CNI2

)

Operating and Installation Guide

V

ersion:

1.01

Issued

:

May 3, 2010

--

Preliminary

--Not Released

--

Preliminary

--

Not Released

--

Preliminary

--

Copyright

©

2010Honeywell |

Mercury Instruments

,

Cincinnati, Ohio

,

USA.

Page 2

CNI2

O

perating and Installation

Guide

1

Contents

REVISION HISTORY

................................

................................

................................

................

10

TRADEMARKS AND COPYR

IGHTS

................................

................................

.......................

11

SYMBOLS AND ICONS.

................................

................................

................................

..........

12

IMPORTANT BATTERY IN

FORMATION

................................

................................

.................

14

CNI2 OVERVIEW

................................

................................

................................

.....................

15

CNI2 FEATURES

................................

................................

................................

.....................

15

CERTIFICATIONS

................................

................................

................................

....................

15

MECHANICAL ASSEMBLIE

S

................................

................................

................................

..

16

INSTRUMENT MOUNTING

OPTIONS

................................

................................

...............................

16

WALL MOUNTING

................................

................................

................................

............................

16

METER INDEX BASE

................................

................................

................................

........................

17

VERTICAL PIPE MOUNTI

NG

................................

................................

................................

............

20

ENCLOSURE SEALING

................................

................................

................................

....................

21

INTERNAL BATTERYPOW

ER O

PTIONS

................................

................................

.........................

21

INTERNAL CIRCUIT BOA

RDS

................................

................................

................................

..........

24

CNI2 Board

................................

................................

................................

................................

....24Serial Port M

ultiplexer Board

................................

................................

................................

..........

25RS-

485 Serial Data Converter

................................

................................

................................

........

26

Serial Multiplexer & RS

-

485 Boards

................................

................................

...............................

27

Summary of Serial Data Connection Scenarios

................................

................................

..............

28

CNI2 INDEX BASE

................................

................................

................................

............................

30

OPTIONAL REMOTE PULS

E TRANSMITTER

................................

................................

..................

33

ANTENNA OPTIONS

................................

................................

................................

.........................

34

TAMPER DETECT & CALL

SWITCH OPTIONS

................................

................................

................

36

ELECT

RICAL ASSEMBLIES

................................

................................

................................

...

37

CIRCUIT BOARD CONNEC

TORS & JUMPERS

................................

................................

................

37

Cellular Radio Module

................................

................................

................................

....................

38

SIM Card Socket

................................

................................

................................

............................

38

Reset Jumper JP4

................................

................................

................................

.........................

38

Power Connectors J1 & J2

................................

................................

................................

.............

38

Terminal Block TB2

................................

................................

................................

........................

39

Terminal Block TB4

................................

................................

................................

........................

39

JP3 & JP6 Jumper Settings

................................

................................

................................

............

39

Connector J4

................................

................................

................................

................................

.40Terminal Block TB1

................................

................................

................................

........................

41

Connector J9

................................

................................

................................

................................

.41Connector J11

................................

................................

................................

...............................

41

Connector J12

................................

................................

................................

...............................

41

Connector J7

................................

................................

................................

................................

.42RS-232 MULTIPLEXER BOAR

D

................................

................................

................................

........

43RS-

485 CONVERSION BOARD

................................

................................

................................

........

45

UNCORRECTED PULSE OU

TPUT BOARD

................................

................................

......................

46

SIGNAL INPUTS & OUTP

UTS

................................

................................

................................

...........

47

Alarm Inputs

................................

................................

................................

................................

..47Pulse Counting Inputs

................................

................................

................................

....................

49

Outputs

................................

................................

................................

................................

..........

49

POWER SUPPLY OPTIONS

................................

................................

................................

.............

50

Extending Battery Life

................................

................................

................................

....................

50

Low Battery Detection

................................

................................

................................

....................

50

AC MAINS POWER CONFI

GURATION

................................

................................

.............................

51

Page 3

CNI2

O

perating and Installation

Guide

2

SOLAR POWER CONFIGUR

ATION

................................

................................

................................

..52SERIAL PORT CONNECTI

ONS

-

TB2

................................

................................

...............................

52

SIM SOCKET CONNECTIO

N

................................

................................

................................

............

5

3

PROGRAMMING INF

ORMATION

................................

................................

............................

56

STARTING THE MP32

®

CONFIGURATIONPROGRA

M

................................

................................

....57CONFIGURING THE PROG

RAMMING PORT

................................

................................

...................

58

STARTING THE CNI2 PR

OGRAMMING APPLICATIO

N

................................

................................

....59MAIN SCREEN

................................

................................

................................

................................

..60Saving and Retrieving Configurations

................................

................................

............................

60

Remote Unit ID (RUID)

................................

................................

................................

.................

60

Primary Destination

................................

................................

................................

........................

60

Originate Calls

................................

................................

................................

...............................

61

Allow Connection Requests

................................

................................

................................

...........

61

Respond to Voice Calls / Respond to SMS

................................

................................

.....................

61

Time Interval Size

................................

................................

................................

..........................

61

Firmware Version

................................

................................

................................

...........................

62

Compare Device Configuration to Template

................................

................................

...................

62

INPUT / OUTPUT CONFI

GURATION

................................

................................

................................

63

Alarm Input Parameters

................................

................................

................................

.................

63

“Special Purpose” Input Parameters

................................

................................

...............................

65

Pulse

-

Counting Input Parameters

................................

................................

................................

..67Output Parameters

................................

................................

................................

........................

69

Output

Under Host Control

................................

................................

................................

.........

69

Output Follows Input

................................

................................

................................

..................

69

“Special Purpose” Output

................................

................................

................................

...........

70

OPTIONS SCREEN

................................

................................

................................

...........................

71

Applications Selection

................................

................................

................................

....................

71

Metretek SIP

................................

................................

................................

..............................

71

Metretek SIP via InvisiConnect

................................

................................

................................

...71Metretek InvisiConnect

................................

................................

................................

...............

72

Mercury MINI

-

MAX or Mercury Pulse Accumulator

................................

................................

.....72Metretek SMS Modem

................................

................................

................................

................

72

Transparent Modem

................................

................................

................................

...................

73

Allow Transparent Mode

................................

................................

................................

................

73

When Answering if No Port Select…….

................................

................................

..........................

74

Low Battery Alarm

................................

................................

................................

.........................

75

Queue Size

................................

................................

................................

................................

....

75

Queue Full Alarm

................................

................................

................................

...........................

76

Sample Rates

................................

................................

................................

................................

76

SERIAL PORT CONFIGUR

ATION

SCREEN

................................

................................

.....................

77

Port Select ID

................................

................................

................................

................................

77

Port Enable

................................

................................

................................

................................

....77Max BPS. Data Bits,

Parity, Stop Bits

................................

................................

.............................

77

Flow Control

................................

................................

................................

................................

..78Hardware Handshaking

................................

................................

................................

..............

78

Sof

tware Handshaking

................................

................................

................................

...............

79

No (None) Handshaking

................................

................................

................................

.............

79RS-

485 Half Duplex

................................

................................

................................

...................

79

Delay before Sending Packets

................................

................................

................................

.......

79

Always Send CONNECT Message

................................

................................

................................

.

80

Always “RING” Port

................................

................................

................................

........................

80

Use Non

-

verbose Result Codes

................................

................................

................................

.....80Enable Blocking

................................

................................

................................

.............................

80

Use Alternate CONNECT Message

................................

................................

................................

80

Connect on DTR High

................................

................................

................................

....................

81

Page 4

CNI2

O

perating and Installation

Guide

3

Disconnect on DTR Low

................................

................................

................................

................

82

CELLULAR SETTINGS SC

REEN

................................

................................

................................

......83CDMA Service (Aeris, Verizon, Sprint)

................................

................................

...........................

83

CDMA Packet (Internet) Service

................................

................................

................................

.83CDMA Circuit Switched Data (CSD) Service

................................

................................

...............

83

Over

-

the-Air-Activation (OTAA)

................................

................................

................................

..84OTAA Programming Number

................................

................................

................................

.....85Packet Service Connection Command

................................

................................

.......................

86

Session Timeout

................................

................................

................................

........................

86

Ping Interval

................................

................................

................................

...............................

86

Source Port Starting / Ending Numbers

................................

................................

......................

86

PAP User Name and Password

................................

................................

................................

..86Max

imum Packet Size

................................

................................

................................

................

87

Auxiliary Radio Type

................................

................................

................................

..................

87

GSM Service (AT&T, T

-

Mobile, Rogers)

................................

................................

.........................

88

GSM Packet (Internet) Service

................................

................................

................................

...88GSM Circuit Switched Data (CSD) Service

................................

................................

.................

89

Installation of the SIM Card

................................

................................

................................

........

90

GPRS Access Point Name

................................

................................

................................

.........

91

Packet Service Connection Command

................................

................................

.......................

91Session Timeout

................................

................................

................................

........................

91

Ping Interval

................................

................................

................................

...............................

91

Source Port Starting / Ending Numbers

................................

................................

......................

91

PAP User Name and Password

................................

................................

................................

..91PIN Number

................................

................................

................................

...............................

92

Maximum Packet Size

................................

................................

................................

................

92

Auxiliary Radio Type

................................

................................

................................

..................

92

iDENService (Nextel, Harmony)

................................

................................

................................

.....93HSPAService

................................

................................

................................

................................

.93CALL SCHEDULING SCRE

EN

................................

................................

................................

..........

94

Call Retry Strategy

................................

................................

................................

.........................

94

Primary Call Retry Count

................................

................................

................................

...............

94

Primary Call Retry Interval

................................

................................

................................

.............

95

Secondary Call Retry Interval

................................

................................

................................

.........

95

Try Alternate Destination

................................

................................

................................

................

95

Enable Repetitive Call Schedule

................................

................................

................................

....95SERVER MODE SCREEN

................................

................................

................................

.................

96

PROGRA

MMING THE CNI2

................................

................................

................................

..............

97

Loading a Configuration with the Programming Cable

................................

................................

....97OVER

-

THE

-

AIR (OTA) PROGRAMMIN

G

................................

................................

...........................

99

What is Over

-

the-Air Programming?

................................

................................

...............................

99

Over

-

the-Air Configuration Changes

................................

................................

..............................

99

Over

-

the-Ai

r “Firmware” Changes

................................

................................

................................

101

LED STATUS INDICATOR

S

................................

................................

................................

..

102

CALL PROGRESS AND ST

ATUS

................................

................................

................................

....

102

ERROR CODES

................................

................................

................................

..............................

103

LEDS AFTER OVER

-

THE

-

AIR REPROGRAMMING

................................

................................

........

107

TECHNICAL INFORMATIO

N

................................

................................

................................

.

108

“SAMPLE RATE” EXPLAI

NED

................................

................................

................................

.........

108

“DEBOUNCE” EXPLAINED

................................

................................

................................

.............

109

What is Switch “Bounce”?

................................

................................

................................

............

109

What is “Debouncing”?

................................

................................

................................

................

109

FORM

-

C OPERATION

................................

................................

................................

....................

111

USING THE OUTPUT

................................

................................

................................

......................

112

Page 5

CNI2

O

perating and Installation

Guide

4

AT MODEM EMULATION M

ODE

................................

................................

................................

....

113

ATV (response type) Command

................................

................................

................................

...

113

ATE (echo)

Command

................................

................................

................................

.................

114

ATH (hangup) Command

................................

................................

................................

.............

114

ATZ (reset) Command

................................

................................

................................

.................

114ATA (answer) Command

................................

................................

................................

..............

114

ATD (dial) Command

................................

................................

................................

...................

114

+++ (escape) Command

................................

................................

................................

..............

115

AT Command Chaining

................................

................................

................................

................

115

AT+ICLK? (time and date) Command

................................

................................

..........................

115

Response to AT Commands while in SLEEP Mode

................................

................................

......116

DC-2009 DATA COLLECTION

SOFTWARE SETUP

................................

.............................

117

INTRODUCTION

................................

................................

................................

.............................

117

SETTING UP THE S

IP SERVER FOR PACKET

(INTERNET) CONNECTIO

NS

...............................

117

SETTING UP DC

-

2009 FOR CSD CONNECT

IONS

................................

................................

.........

119

SETTING UP A CALL SC

HEDULE

................................

................................

................................

..

121

DEFINING THE CNI2

–

MANUAL MODE

................................

................................

.......................

124

CONFIGURING THE CNI2

................................

................................

................................

..............

127

CONFIGU

RING THE CNI2’S PULS

E-COUNTING INPUTS

................................

..............................

128

CONFIGURING THE CNI2

’S CALL INFORMATION

................................

................................

........

130

CONFIGURING THE CNI2

’S ALARMS

................................

................................

............................

131

Customer Alarm

-1................................

................................

................................

........................

132

Customer Alarm

-2................................

................................

................................

........................

132

Magnetic or ”CALL” Switch Alar

m

................................

................................

................................

132

TAMPER Detect Alarm

................................

................................

................................

................

133

AC-OFF Alarm

................................

................................

................................

.............................

133

AC-ON Alarm

................................

................................

................................

...............................

133

Unit Reset Alarm

................................

................................

................................

..........................

133

Call Retry Alarm

................................

................................

................................

...........................

133

Queue Full Alarm

................................

................................

................................

.........................

133

Clock Resync Alarm

................................

................................

................................

.....................

133

Remote Daily Volume Low Input

-

1,2,3,4

................................

................................

......................

134Remote Daily Volume High Input

-

1,2,3,4

................................

................................

......................

134

Remote TTI Consumption Low Input

-

1,2,3,4

................................

................................

................

134

Remote TTI Consumption High Input

-

1,2,3,4

................................

................................

...............

134

Low Battery Alarm

................................

................................

................................

.......................

134

DEFINING THE CNI2

–

AUTOMATICMODE

................................

................................

.................

135

STARTING DC

-

2009

................................

................................

................................

.......................

135

OBTAINING THE CNI2’S

CELLULAR PHONE NUMBE

R

................................

................................

.

135

OBTAINING THE CNI2’S

HARDWARE STATUS AND

CELLULAR INFORM

ATION

........................

136

MAINTENANCE

................................

................................

................................

.....................

142

BATTERY REPLACEMENT

................................

................................

................................

.............

142

CLEANING AND C

HEMICAL COMPATIBILIT

Y LIST

................................

................................

.......

142

MAINTENANCE CHECKLIS

T

................................

................................

................................

..........

142

ESD HANDLING PRECAUT

IONS

................................

................................

..........................

144

CONTROL DRAWINGS

-

HAZARDOUS AREA

................................

................................

.....

145

HAZARDOUS AREA CLASS

IFICATION (NORTH AM

ERICAN CLASS I, DIVI

SION 2)

....................

145

SPECIFICATIONS

................................

................................

................................

..................

150

CERTIFICATIONS

................................

................................

................................

...........................

150

MECHANICAL

................................

................................

................................

................................

.

151

Operati

onal Temperature range

................................

................................

................................

...

151

Page 6

CNI2

O

perating and Installation

Guide

5

Terminal Block Screws

................................

................................

................................

................

151

Environmental Ratings

................................

................................

................................

.................

151

Enclosure Mounting

................................

................................

................................

.....................

151

Mounting Direction

................................

................................

................................

.......................

151

Humidity Range

................................

................................

................................

...........................

151

Cable Glands

................................

................................

................................

...............................

151

Weight of CNI2 with Wall Mount Option: (w/o batteries)

................................

...............................

151

Weight of CNI2 with Meter Mount Opt

ion: (w/o batteries)

................................

.............................

151

Battery Pack Shipping Weight

................................

................................

................................

......

151

ELECTRICAL

-

POWER

................................

................................

................................

..................

153

Battery Voltage: (without load applied)

................................

................................

........................

153

Approved Battery Pack Assemblies

................................

................................

..............................

153

Battery Life

................................

................................

................................

................................

..

153

Current Requirements during Transmission

................................

................................

.................

153

Sleep current (data logger mode, no communicationsoption boards)

................................

...........

153

Sleep current (transparent modem mode, no communications option boards)

.............................

153

Boost Capacitor

................................

................................

................................

...........................

154

Low-Voltage Detector

................................

................................

................................

..................

154

Power Input #3 (TB1) Connector Type

................................

................................

.........................

154

Power Input #1 & #2 (J1 and J2) Connector Type

................................

................................

........

154

ELECTRICAL

-

GENERAL

................................

................................

................................

...............

155

Pulse Count Retention Memory

................................

................................

................................

....

155

Flash Pro

gram Memory

................................

................................

................................

................

155

Static RAM Memory

................................

................................

................................

.....................

155

Clocks

................................

................................

................................

................................

.........

155

Logic Supply Vo

ltage

................................

................................

................................

...................

155

Auxiliary Supply Voltage

................................

................................

................................

..............

155

ELECTRICAL

–

DIGITAL OUTPUTS

................................

................................

...............................

156

Number of outputs

................................

................................

................................

.......................

156

Output Configuration

................................

................................

................................

....................

156

Source resistance

................................

................................

................................

........................

156

Operating Modes

................................

................................

................................

.........................

156

J7, J9, J11, J12 Connector Type

................................

................................

................................

..

156

TB4 Connector Type

................................

................................

................................

....................

156

Recommended Output Cable

................................

................................

................................

.......

156

ELECTRICAL

–

DIGITAL INPUTS

................................

................................

................................

...

157

Number of inputs

................................

................................

................................

.........................

157

Input Configuration

................................

................................

................................

......................

157

Input rate (sampling mode)

................................

................................

................................

..........

157

Minimum input pulse width (

sampling mode)

................................

................................

................

157

Sample rate (sampling mode)

................................

................................

................................

......

157

Debounce Count (sampling mode)

................................

................................

...............................

157

Input rate (edge

-

detection mode)

................................

................................

................................

.

157

Minimum pulse width (edge

-

detection mode)

................................

................................

...............

157

Wetting current per inp

ut

................................

................................

................................

..............

157Wetting voltage

................................

................................

................................

............................

157

Input resistance

................................

................................

................................

...........................

157

J7, J9, J11, J12

Connector Type

................................

................................

................................

..

157

Recommended Input Cable

................................

................................

................................

..........

157

ELECTRICAL

–

SERIAL PORT (TB2)

................................

................................

..............................

158

Number of input lines

................................

................................

................................

...................

158

Input levels

................................

................................

................................

................................

..

158

Number of output lines

................................

................................

................................

.................

158

Output levels

................................

................................

................................

................................

158

Bit rate

................................

................................

................................

................................

.........

158

TB2 Connector Type (RXD, TXD, GND)

................................

................................

.......................

158

Page 7

CNI2

O

perating and Installation

Guide

6

TB2 Connector Type (all other signals)

................................

................................

........................

158

FUNCTIONAL

................................

................................

................................

................................

..

159

Modes of Operation

................................

................................

................................

.....................

159

Cellular Network Communications Options (varies with model)

................................

.....................

159

Paging Mechanisms

................................

................................

................................

.....................

159

Status Indicators

................................

................................

................................

..........................

159

Firmware and Configuration Programming

................................

................................

...................

159

CELLULAR RADIO AND A

NTENNA INFORMATION

................................

................................

.......

160

GSM24

................................

................................

................................

................................

........

160

CDMA24

................................

................................

................................

................................

......

160

iDen270

................................

................................

................................

................................

.......

160

Receive Frequencies

................................

................................

................................

...................

160

Transmit Frequencies

................................

................................

................................

..................

160

Antenna Connector

................................

................................

................................

......................

160

Antenna (internal quad

-

band) (GSM24, CDMA24)

................................

................................

........

160

Antenna (internal quad

-

band) (iDEN270)

................................

................................

.....................

160

ASCII CHAR

T

................................

................................

................................

................................

..

161

Page 8

CNI2

O

perating and Installation

Guide

7

Figures

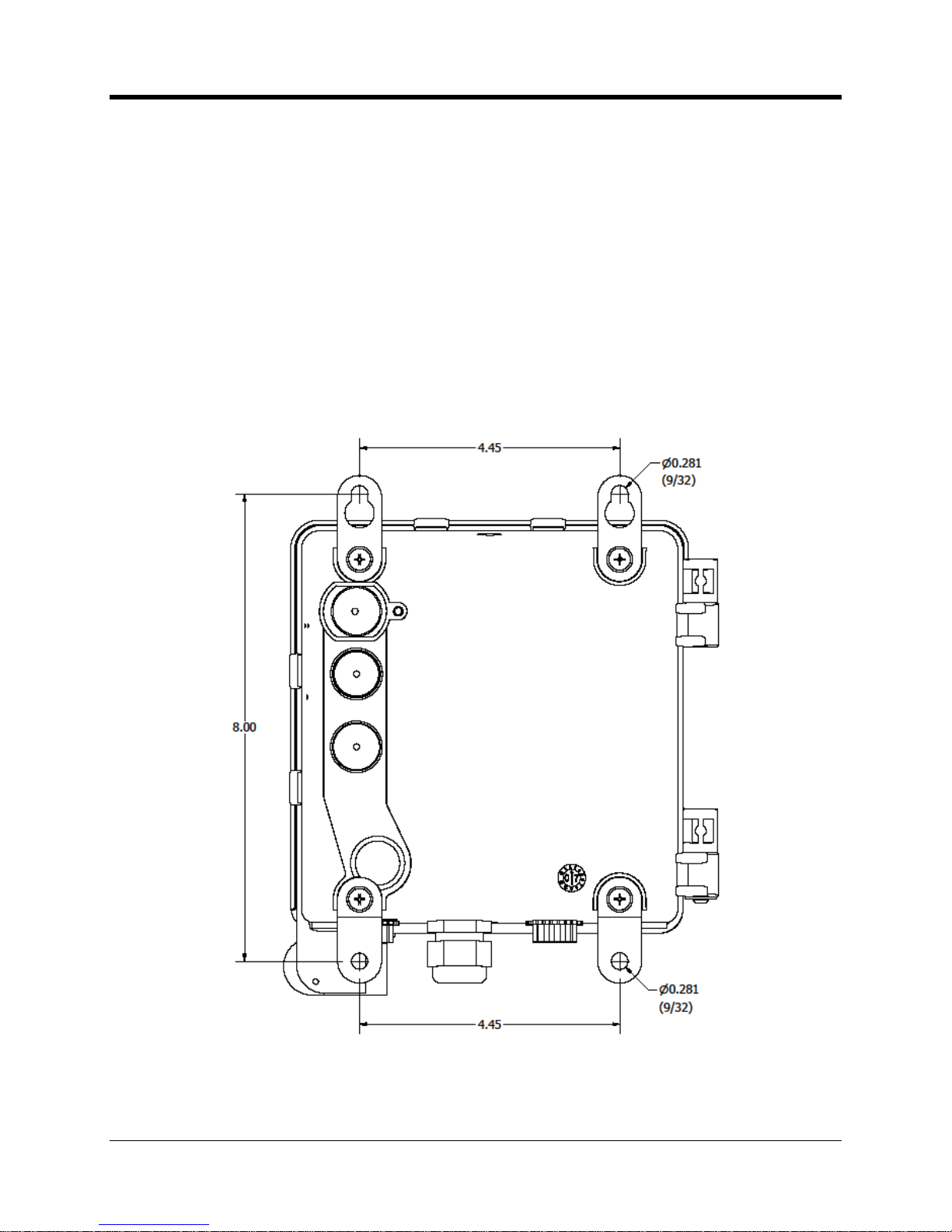

Wall Mounting Tabs and Dimensions

................................

................................

........................

16

Wall Mount Hangers Asse

mbly Sequence

................................

................................

................

17

CNI2 with Universal Mounting Bracket (UMB)

................................

................................

...........

18

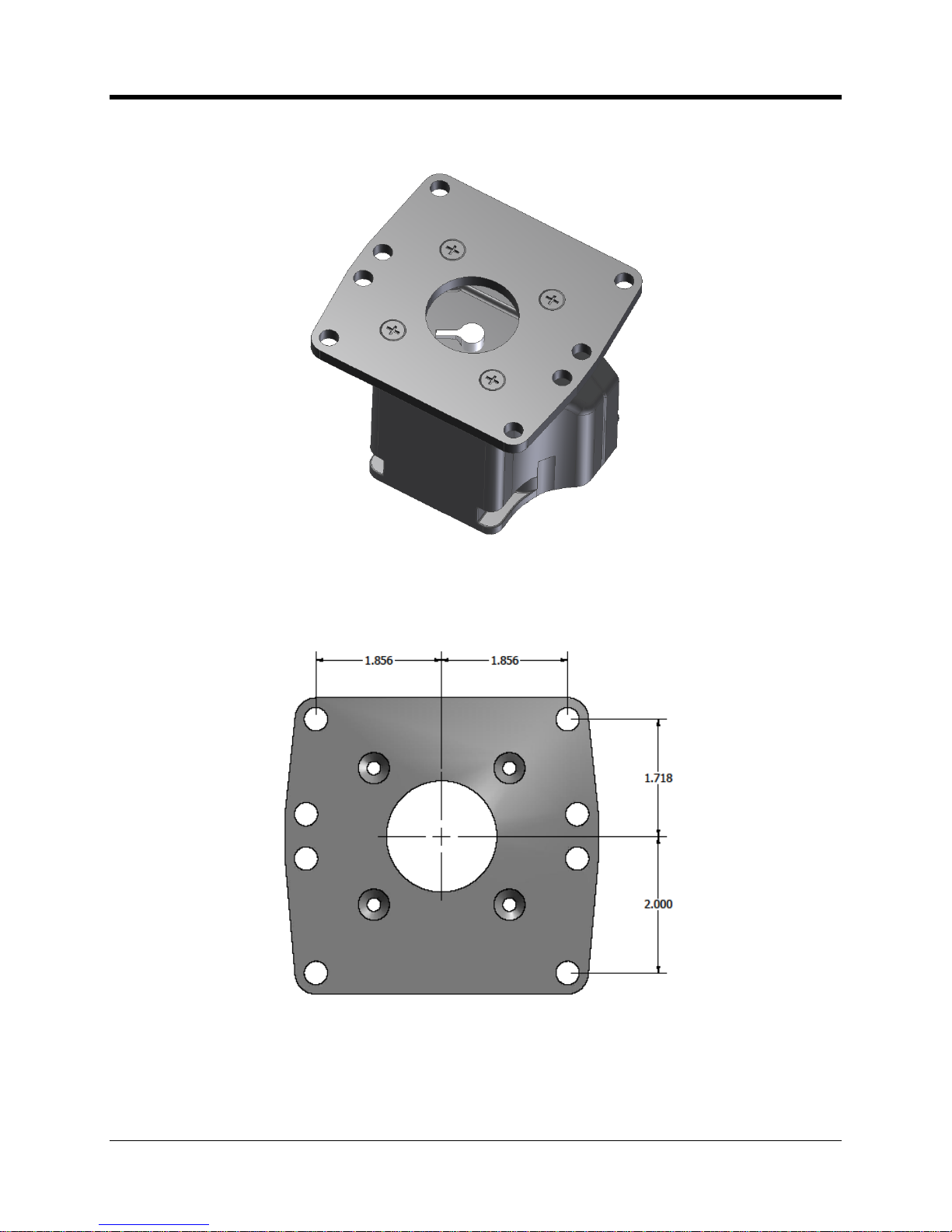

Bottom View of the Universal Mounting Bracket (UMB)

................................

.............................

19

Universal Mounting Bracket (UMB) Hole Pattern

................................

................................

.......

19

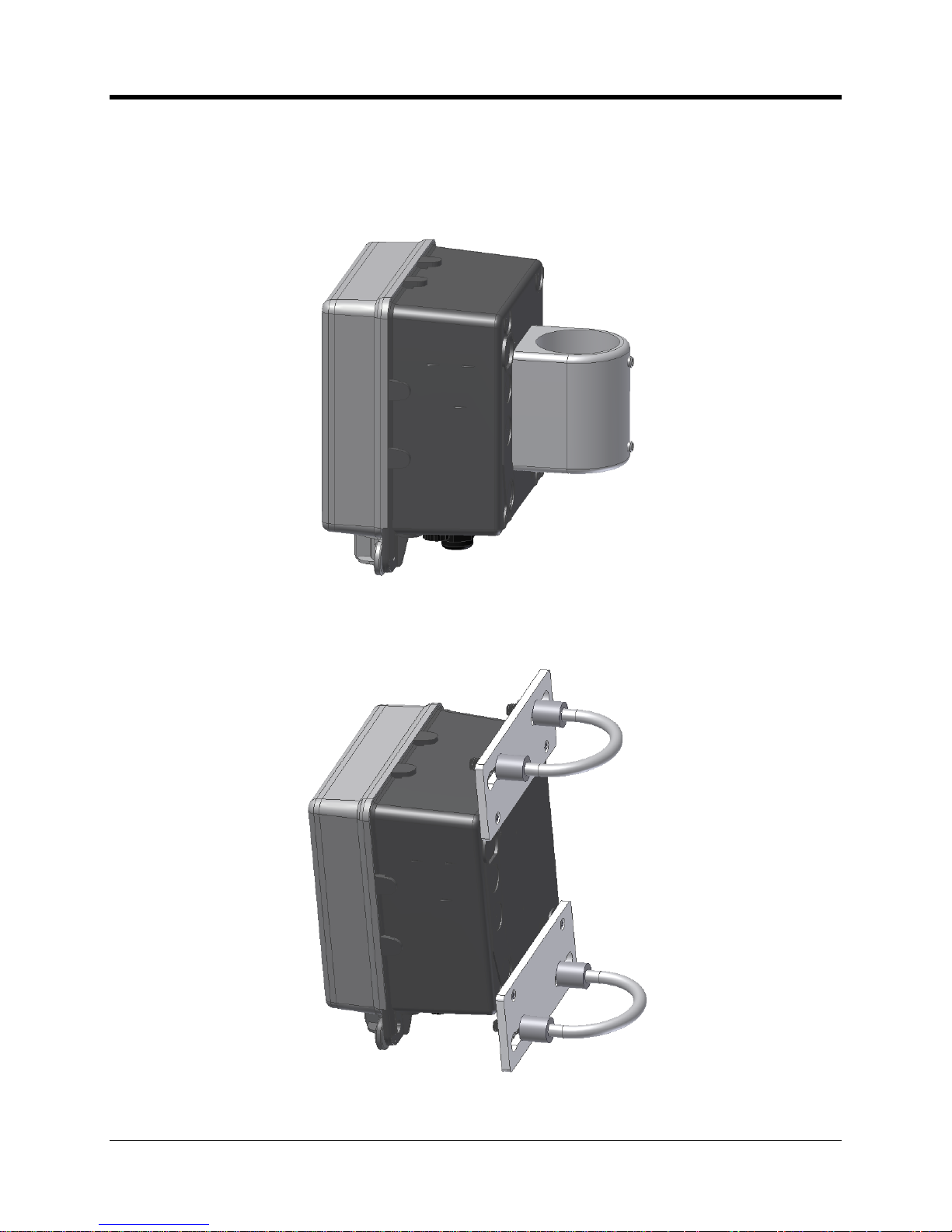

Pipe Mounting using Collar

................................

................................

................................

.......

20

Pipe Mounting using U

-

Bolts

................................

................................

................................

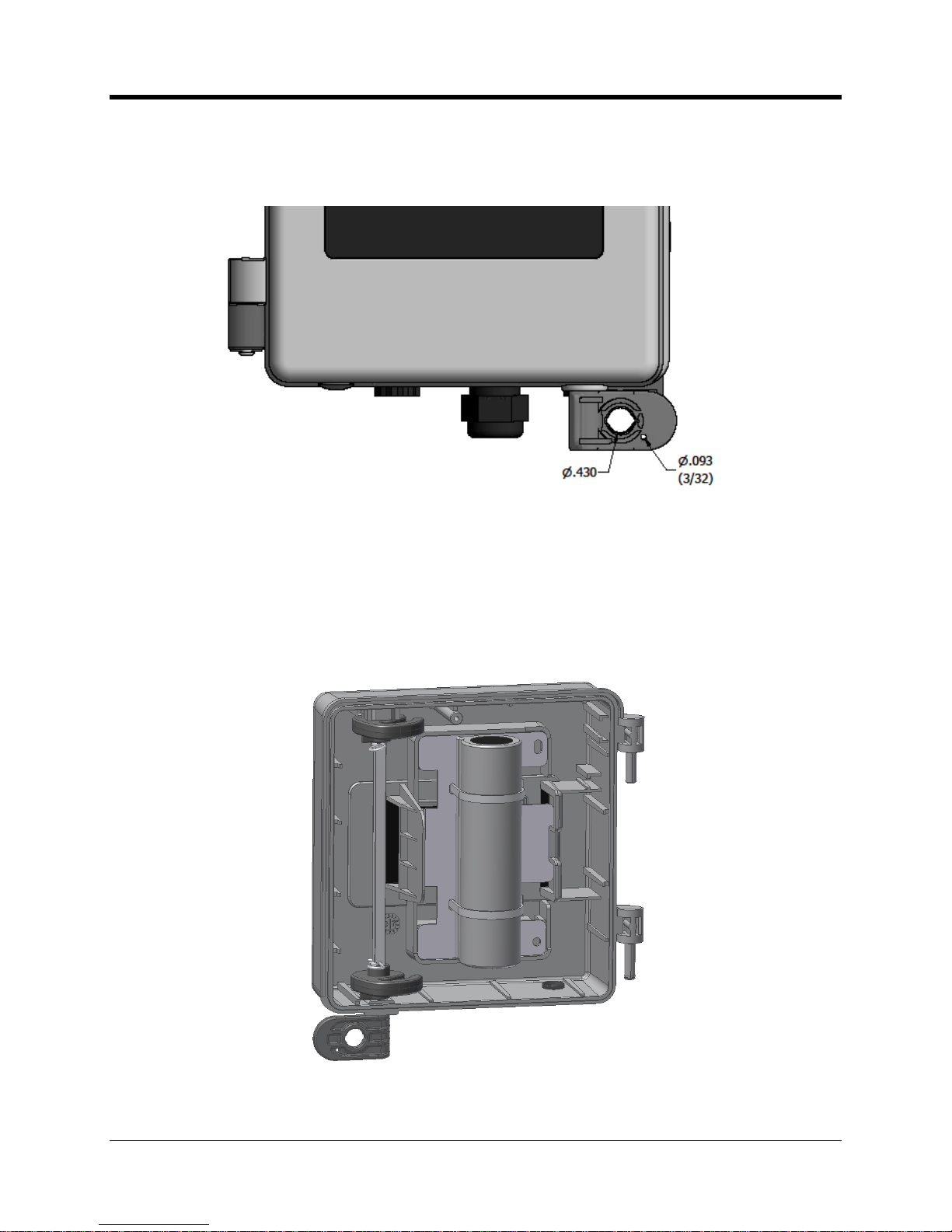

.....20Enclosure Sealing Options

................................

................................

................................

........

21

Lithium Battery Pack Mounting

................................

................................

................................

..21Alkaline Battery Pack Mounting

................................

................................

................................

.22Disposable Alkaline Battery Pack

................................

................................

..............................

23

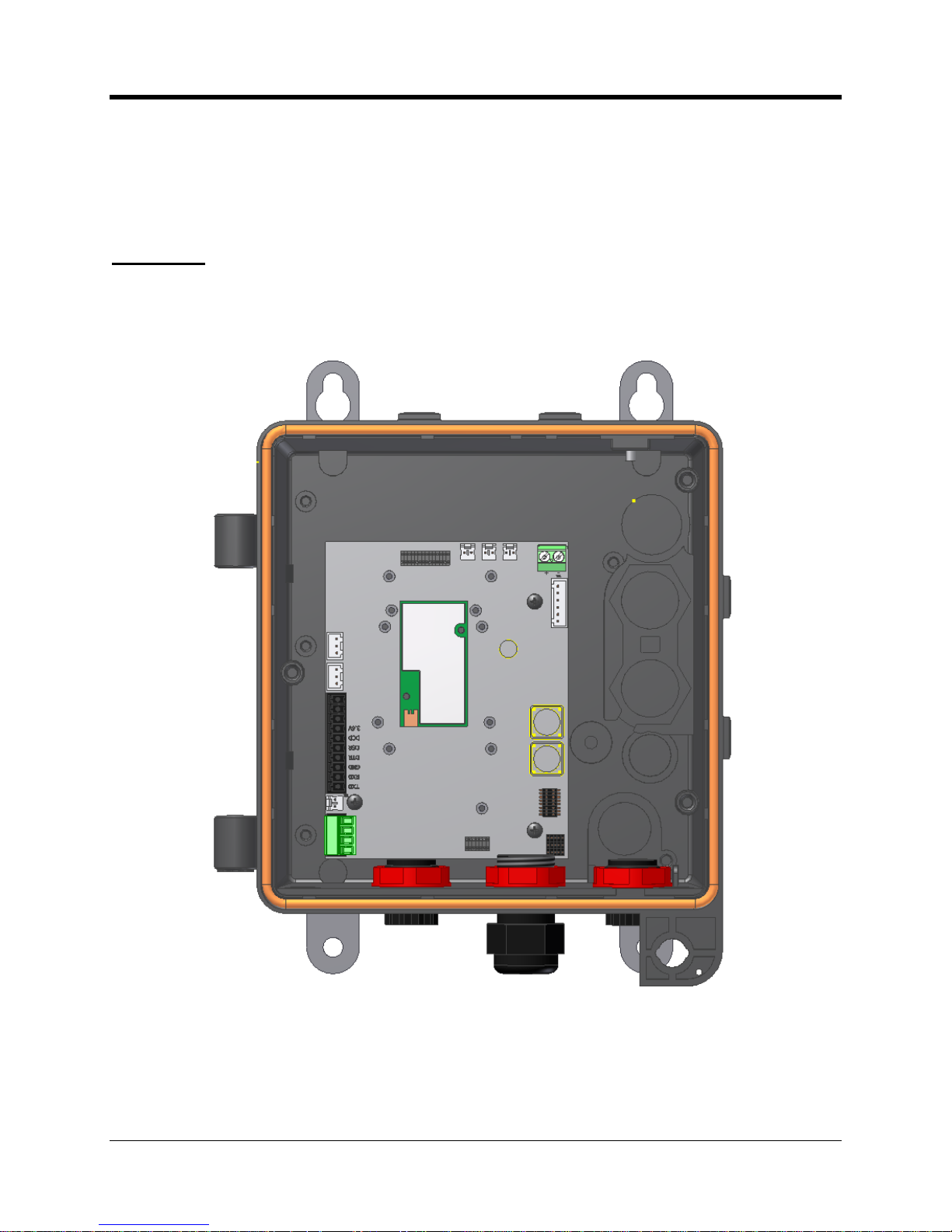

CNI2 Board Orientation

................................

................................

................................

.............

24

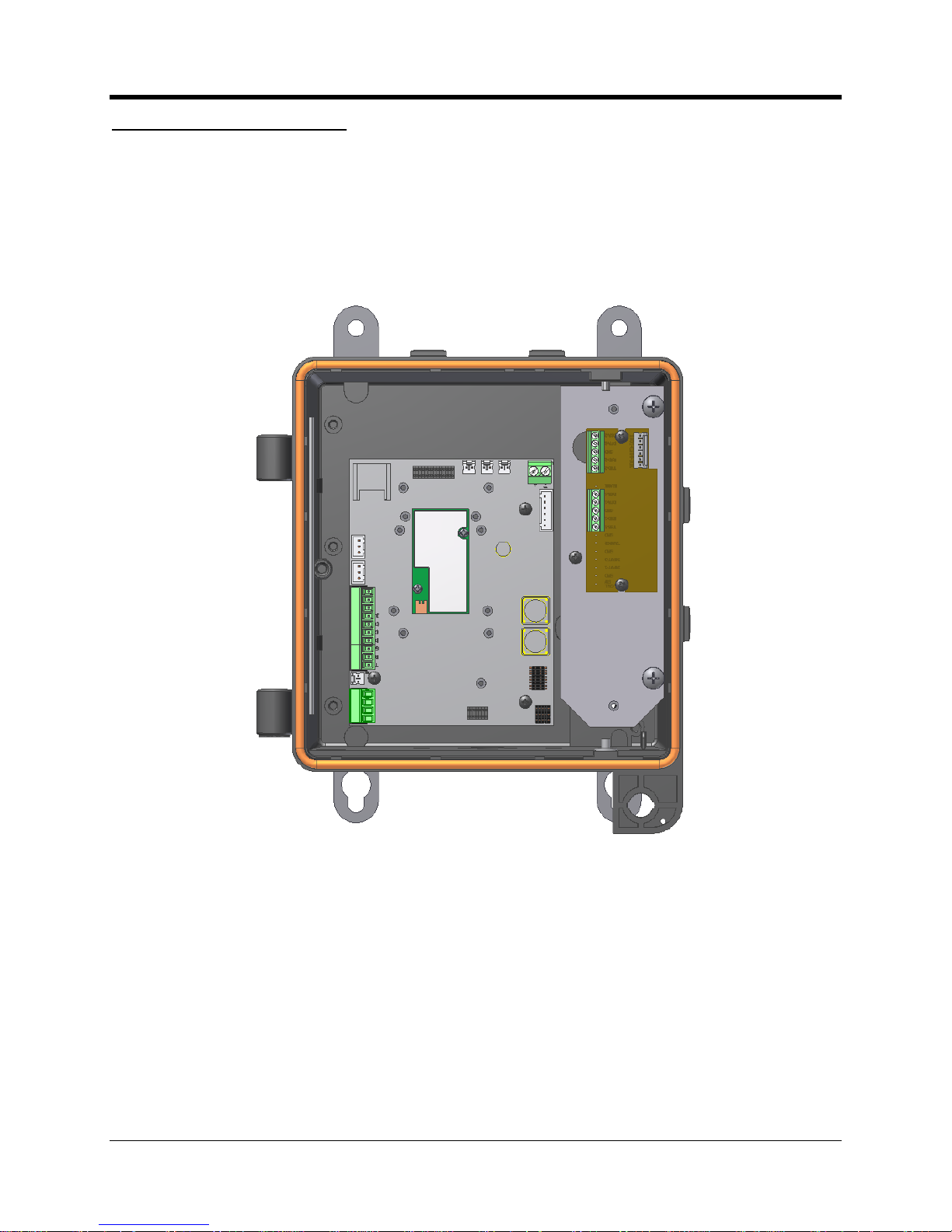

CNI2 Board and Multiplexer Board

................................

................................

............................

25

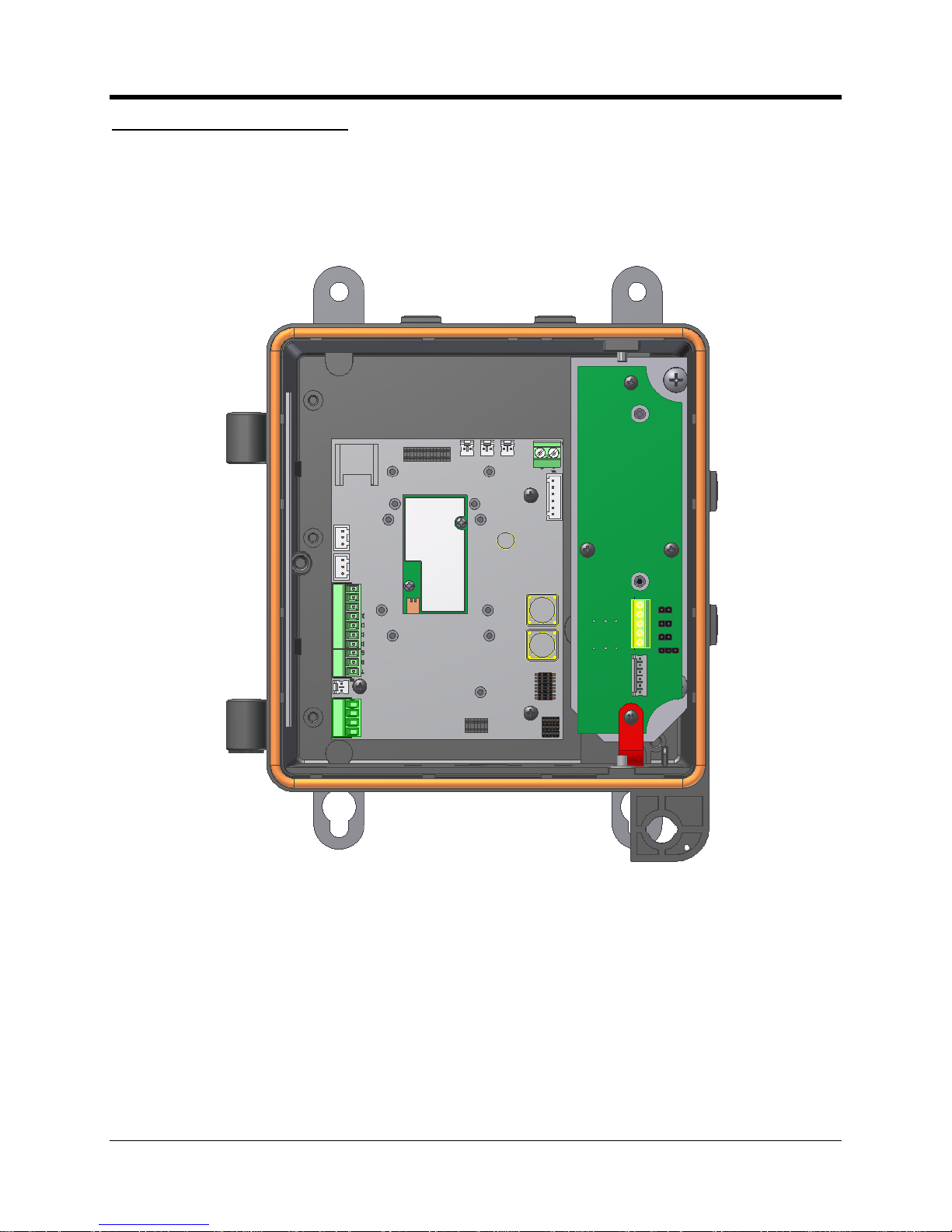

CNI2 Board and RS

-

485 Board

................................

................................

................................

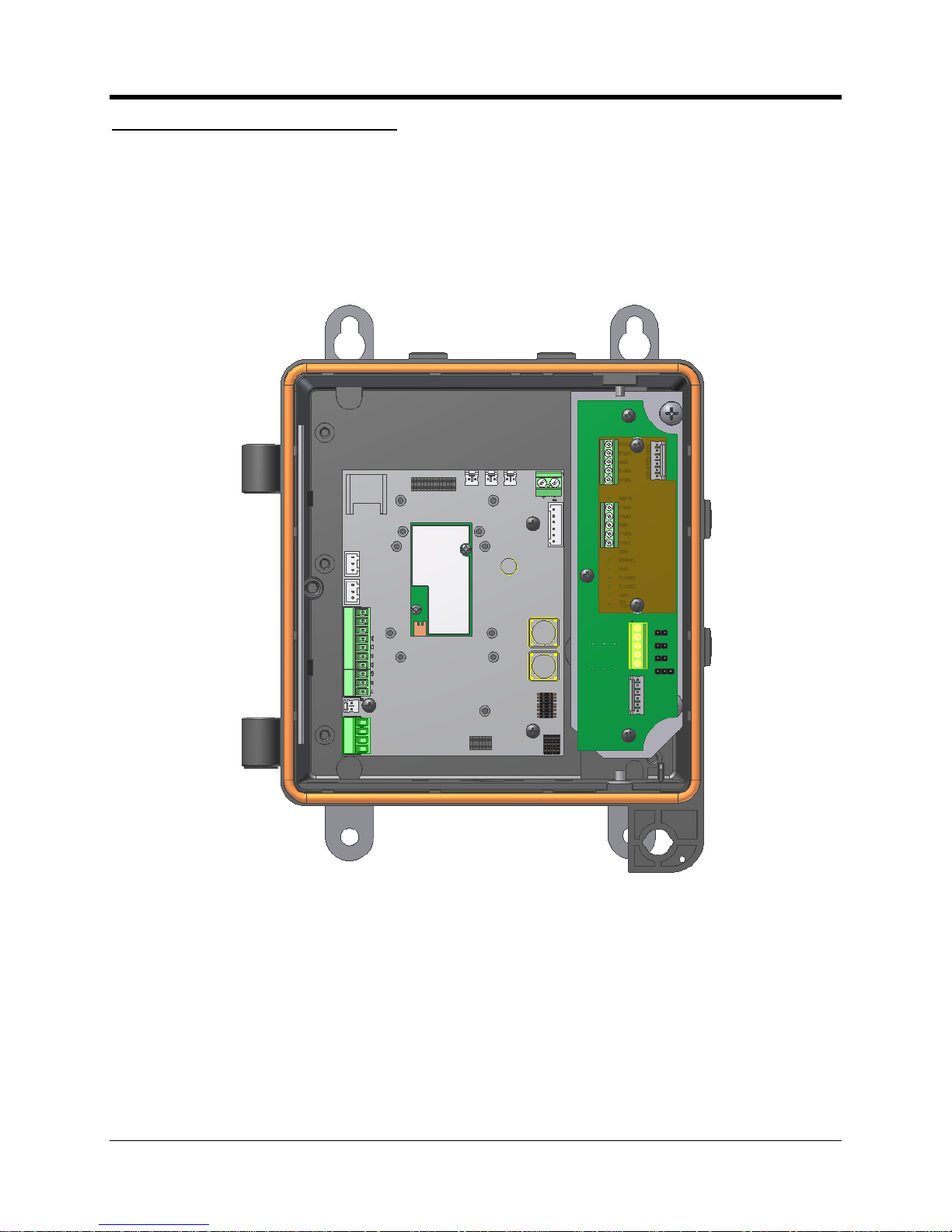

.26CNI2 Board with RS

-

485 Board and Multiplexer Board

................................

.............................

27

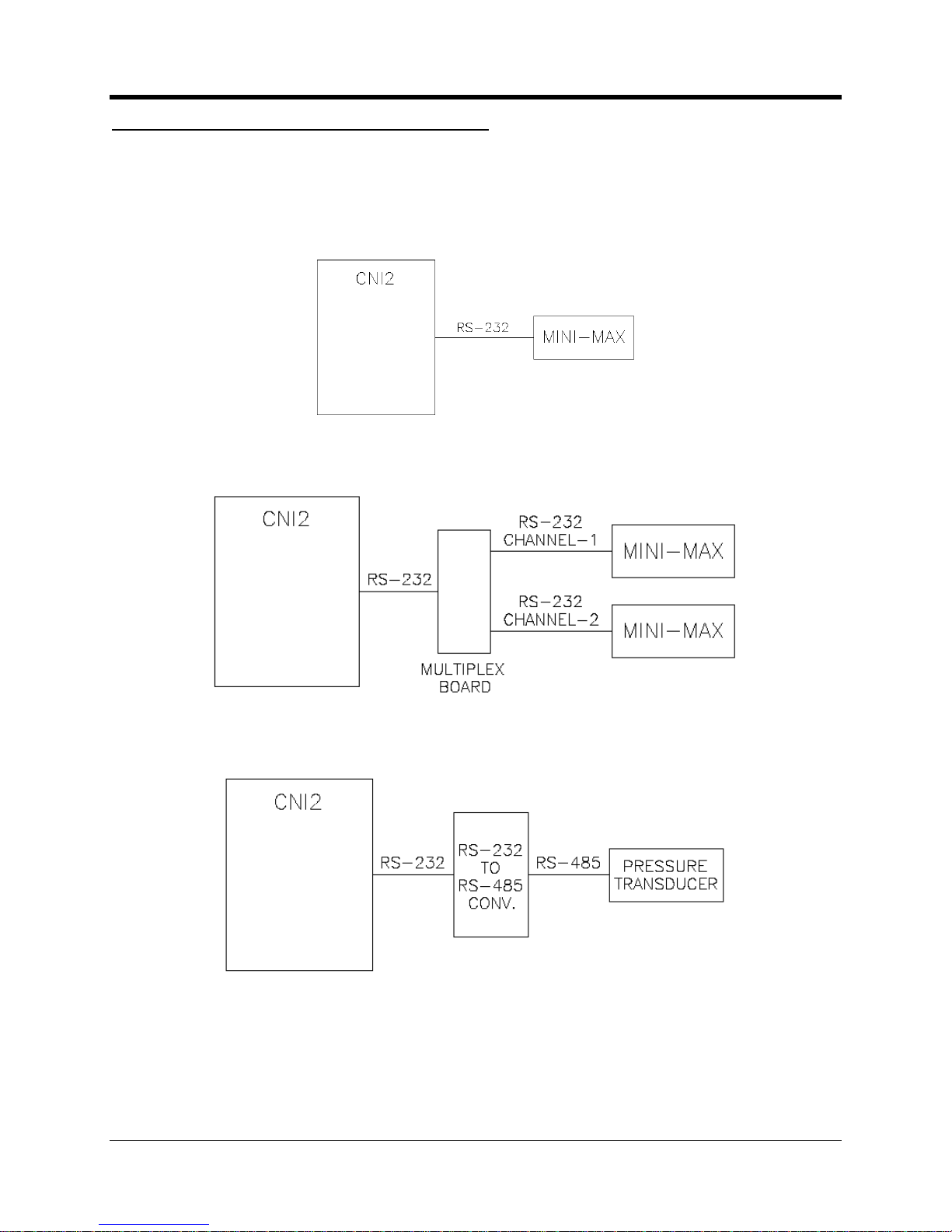

CNI2 with single RS

-

232 connection to external instrument

................................

......................

28

CNI2 wit

h multiplexer board to support two serial data links

................................

......................

28

CNI2 with conversion board to interface to RS

-

485 capable instrument

................................

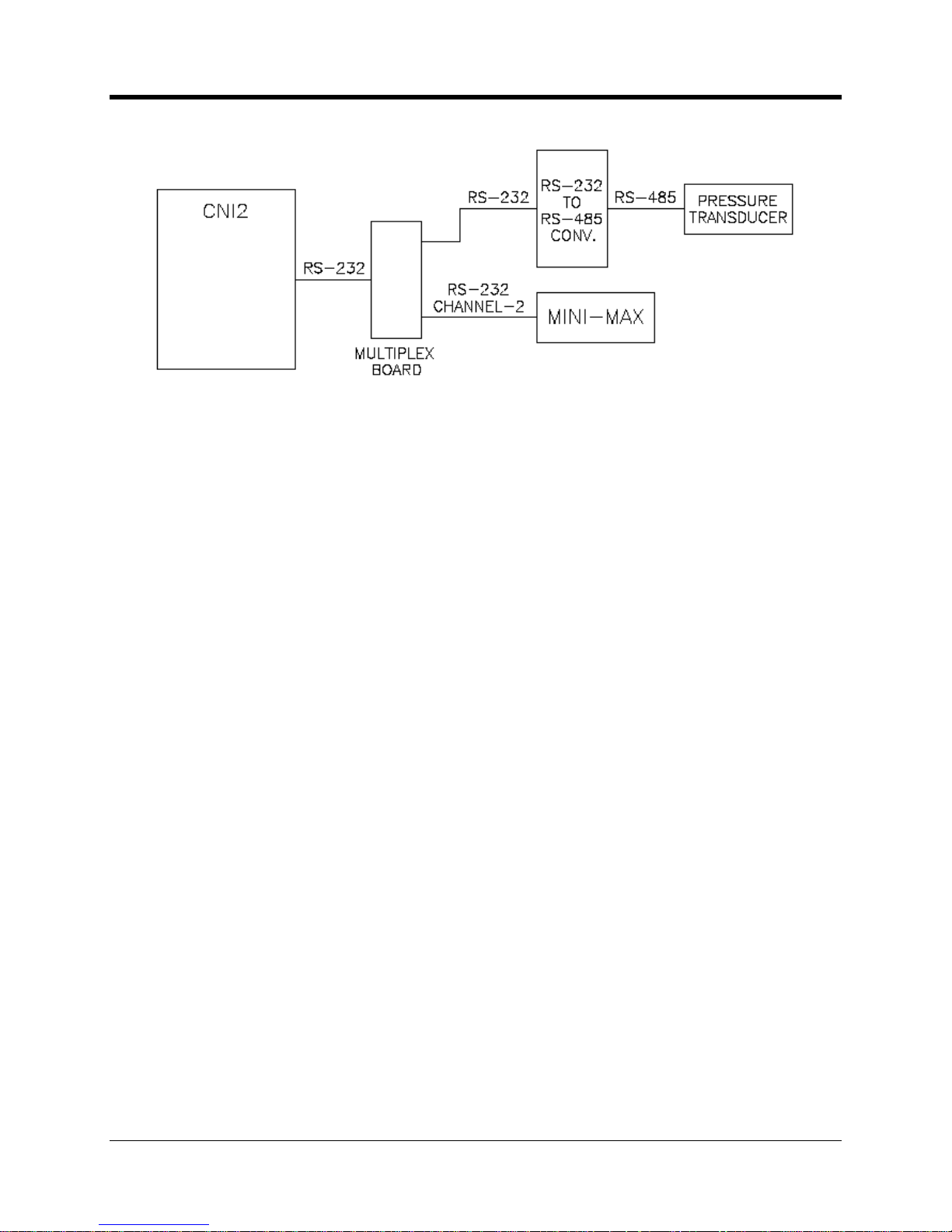

....28Configuration using both RS

-

232 & RS

-

485 options

................................

................................

..29Index Base with Magnetic Switches

................................

................................

..........................

30

Pulse Output Board

................................

................................

................................

...................

31

Internal View of the Index Base

................................

................................

................................

.31Rotation Gears within the Index Base

................................

................................

.......................

32

Remote

Pulse Transmitter

................................

................................

................................

.........

33

Location of the Internal Antenna

................................

................................

...............................

34

Antenna Connection to Radio Module

................................

................................

.......................

34

Bottom View with External RF Connector

................................

................................

..................

35

Location of the TAMPER and CALL Switches

................................

................................

...........

36

CNI2 Circu

it Board Layout

................................

................................

................................

.........

37

J1 and J2 Power Connectors

................................

................................

................................

....38Configuration Jumpers

................................

................................

................................

..............

39

Jumper Block JP6 Settings

................................

................................

................................

.......

40

Jumper Block JP3 Settings

................................

................................

................................

.......

40

Capacitor Connection to TB1 (prewired)

................................

................................

...................

41

Serial RS

-

232 Multiplexer Board

................................

................................

...............................

43

Wiring to the Serial RS

-

232 Multiplexer Board

................................

................................

..........

44RS-

485 Conversion Board Connectors

................................

................................

.....................

45

Uncorrected Pulse Output Board

................................

................................

...............................

46

Alarm Input Connectors

................................

................................

................................

............

47

Alarm / Pulse Input Terminal Block TB4

................................

................................

....................

48

CNI2 Power Connections

................................

................................

................................

..........

50

AC Power Adapter

................................

................................

................................

....................

51

External Power Tie

-

In Block

................................

................................

................................

......51Typical Solar Power System

................................

................................

................................

.....52Serial

Port Terminal Block TB2

................................

................................

................................

.53Typical SIM Card

................................

................................

................................

......................

53

Installation of the SIM Card

................................

................................

................................

.......

54

Page 9

CNI2

O

perating and Installation

Guide

8

Serial and USB Programming Cables

................................

................................

.......................

56

MP32

®

Login Screen

................................

................................

................................

.................

57

MP32

®

Device Selection Screen

................................

................................

...............................

57

Programming Port Configuration Screen

................................

................................

...................

58

CNI2 Main Configuration Screen

................................

................................

...............................

59

Standard A

larm Descriptions

................................

................................

................................

.....63Configuration of an Alarm Input

................................

................................

................................

.64Configuration of a “Special Purpose” Input

................................

................................

................

66

Configuration of a Pulse Counting Input

................................

................................

....................

67

Configuration of a “Special Purpose” Output

................................

................................

.............

70

Options Screen

................................

................................

................................

.........................

71

“Route To” Port Selection in Transparent Mode

................................

................................

........

75

Serial Port Configuration Screen

................................

................................

...............................

77

Hardware Flow Control

................................

................................

................................

.............

78

DTR Detection Jumper

................................

................................

................................

..............

82

CDMA Cellular Configuration Screen

................................

................................

........................

85

Installation of the SIM Card

................................

................................

................................

.......

90

GSM Cellular Configuration Screen

................................

................................

..........................

90

Call Scheduling Screen

................................

................................

................................

.............

94

Server Mode Screen

................................

................................

................................

.................

96

Attaching the Programming Cable

................................

................................

.............................

97

OTA Device Selection Screen

................................

................................

................................

.

100

Example of Error Code “35” Display

................................

................................

........................

103

LED Error Codes 11 thru 19

................................

................................

................................

....

104

LED Error Codes 21 thru 39

................................

................................

................................

....

105

LED Error Codes 41 thru 59

................................

................................

................................

....

106

LED Er

ror Codes 61 thru 79

................................

................................

................................

....

107

Example of Timed Sampling

................................

................................

................................

...

108

Example of Switch Bounce

................................

................................

................................

......

109

Example of Debouncing Process

................................

................................

............................

110

Typical Form

-

A and Form

-

C (KYZ) Connections

................................

................................

.....

111

Example of Detection of a

Form

-

C Fault

................................

................................

.................

111

Accuracy Errors Using the “Output

-

Follows

-

Input” Feature

................................

.....................

112Delay Errors Using “Output

-

Follows

-

Input” Feature

................................

................................

.

112

Typical CNI2 “AT” Responses

................................

................................

................................

.

113

Received Data (RXD) Detection Jumper

................................

................................

.................

116

Starting the DC

-

2009 System Configuration

................................

................................

............

117

Changing the Data Collection Configuration

................................

................................

............

118

Configuring the SIP Se

rver

................................

................................

................................

......

119

Configuring DC

-

2009 for CSD Connections

................................

................................

............

120

Configuring a Call Schedule

................................

................................

................................

....

121

Defining a Call Profile Name

................................

................................

................................

...

122

Defining a Call Profile

................................

................................

................................

..............

123

Starting the CNI2 Configuration Process

................................

................................

.................

124

Remote Unit Selection Screen

................................

................................

................................

125

Device Type Selection Screen

................................

................................

................................

125

Add Remote Unit Screen

................................

................................

................................

........

126

Remote Unit Configuration General Information Screen

................................

..........................

127

Device Configuration Screen

................................

................................

................................

...

128

Data Input Configuration Screen

................................

................................

.............................

129

Call Information Screen

................................

................................

................................

...........

130

Page 10

CNI2

O

perating and Installation

Guide

9

Hardware Ala

rm Configuration Screen

................................

................................

....................

131

Viewing the Cellular and Hardware Status

................................

................................

..............

136

Cellular and Hardware Status Screen

................................

................................

.....................

137

Starting the Call Diagnostic Dump Utility

................................

................................

.................

138

Using the Call Diagnostic Dump Utility

................................

................................

....................

139

Status and Cellular Information on the Call Dump Screen

................................

.......................

139

Cellular Information Fields

................................

................................

................................

.......

140

Previous Error Codes on th

e Call Dump Screen

................................

................................

.....

140

Power Input Connector Polarities

................................

................................

............................

154

ASCII Conversion Chart

................................

................................

................................

..........

161

Page 11

CNI2

O

perating and Installation

Guide

10

Version 1.00

April 23, 2010

-

Initial release of draft document.

Version 1.01

May 3

, 2010

-

Redefined section breaks.

-

Redefined some text styles to allow automatic inclusion into the table of contents.

-

Added

figure titles to all illustrations

and added a list of figures after the table of contents.

-

Moved battery regulations

statements

and warnings

to

the

beginning of

the

document.

-

Added an auto

-

date field to the cover sheet.

-

Refined and added to the section that deals with programming the unit

.

REVI

SI

ON HISTORY

Page 12

CNI2

O

perating and Installation

Guide

11

“Windows” refers to

Microsoft Windows 2000, XP, Vista and Windows

-7that

are either

registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

“MV90

®

” is

either

a registered tra

demark

or

trademark

of

Itron

Corporation.

“DC-

2009

®

”

“MP32

®

”

and “

InvisiConnect

®

”

are either registered trademarks or trademarks of

Honeywell International.

Other brands and product names are trademarks or registered trademarks of their respective

holder

s.

“Metretek” is a reference to a business that produced

data logging and telemetry products

between 1977 and 2008. Metretek was acquired by Mercury Instruments in 2008. The

Metretek name appears in this document as a reference to legacy products and pr

otocols,

which are still in use today.

For additional information or questions regarding Mercury Instruments, please contact

a Product

Support Specialist

or visit our website.

Honeywell |

Mercury Instruments

3940 Virginia Ave. • C

incinnati, Ohio 45227 USA

Phone 513

-

272-1111 • Fax 513

-

272-0211

www.mercuryinstruments.com

TRADEMARKS

AND COPY

RIGHTS

Page 13

CNI2

O

perating and Installation

Guide

12

The following symbols may be found within the text of this document, or

may

be marked direct

ly

on the equipment.

Denotes an information item

Denotes a user action item

Denotes an example line

Caution or Danger:

Alerts the operator to special precautionary actions that may be required,

or danger hazards that exis

t or have the potential to exist.

Shock Hazard:

Alerts the operator to an electrical shock hazard condition that exists or could

potentially exist.

Earth Terminal:

Symbol that indicates earth ground. A copper rod buried in the ground is a

common examp

le of an earth ground connection, although these can take various forms.

Reference your local electrical code regulations for detailed information.

Direct Current:

Internationally recognized symbol that represents voltage in the form of direct

current. A

common example of a direct current (DC) source is an automotive car battery.

Hazardous

Wa

ste Disposal

:

Alerts the operator that the equipment or component thus labeled

is not to be disposed of without special consideration to the hazardous waste that it

contains.

Compliance is necessary to ensure that national, state, and local community legal statutes are

not violated.

SYMBOLS

AND

ICONS.

Page 14

CNI2

O

perating and Installation

Guide

13

Warning

This product contains a radio

-

frequency transmitter,

Motorola Model g24

-

L, FCC ID # IHDT56HQ1,

(GSM

-

Equipped CNI2)

The co

mbined cable loss and antenna gain must not exceed +6.8 dBi (850 band),

+1.9 dBi (900 band), +7.7 dBi (1800 band) or +2.2 dBi (1900 band). Total system

output must not exceed 2.0W EIRP in the 1900 band in order to comply with the

EIRP limit of 24.232.

The

product must be installed in a manner that

provide

s

a minimum separation

distance of 20cm (8”)

or more between the antenna and

users and persons and

must not be co

-

located or operat

e

in conjunction with any other antenna or

transmitter

to satisfy expos

ure requirements.

.

Warning

This product contains a radio

-

frequency transmitter,

Motorola Model

c24,FCC ID # IHDT56JE1

,

(CDMA

-

Equipped CNI2)

The combined cable loss and antenna gain must

not exceed +5.3dBi (800 band).

The combined cable loss and

antenna gain must not exceed +4.2dBi and total

system output must no

t exceed 2.0W EIRP in the

PCS (

1900

)

band in order to

comply with the EIRP limit of 24.232

(b).The

product must be installed in a manner that

provide

s

a minimum separation

distance of 2

0cm (8”)

or more between the antenna and

users and persons and

must not be co

-

located or operat

e

in conjunction with any other antenna or

transmitter

to satisfy exposure requirements.

.

FCC Warning:

This device complies with Part 15 of the FCC Rules. O

peration is subject to the

following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Page 15

CNI2

O

perating and Installation

Guide

14

Caution

Disposal of lithium battery cells is strictly regulated in most areas as hazardous waste

material. Consult your regional waste disposal authority to ensure full compliance

with legal statutes when disposing of cells.

Warning

Transp

ort of primary cell lithium batteries (even when fully discharged) of this type is

strictly forbidden on passenger aircraft. Cargo shipment of batteries via UPS, FedEx,

etc., requires special shipping containers, packing, and paperwork to be completed.

Domestic Requirements

Class

-

9 is a general class designation by the DOT and has specific packaging instructions.

Lithium primary cells are ‘Class

-

9’ if they contain more than 5.0 grams of lithium. This is

applicable to

the lithium battery pack

s

intended

for

use

with the

CNI2

.

Specific requirements are applicable to Class

-

9 shippers:

Product handlers must be tested and certified. Packaging must meet Group II requirements and

boxes must be tested by UN specification. Packaging must be clearly marked to

indicate:

Lithium batteries, UN3090, PG II, Number of packages, Emergency phone number, Shipper

certification.

MSDS information must also be included within the package.

Additional requirements may apply, or come into force in the future. Please co

nfirm all

requirements in advance with your shipper.

IMPORTANT BATTERY IN

FORMATIO

N

Page 16

CNI2

O

perating and Installation

Guide

15

The Honeywell

CNI2 is a pulse accumulator (data logger) and serial data communications

product with an integral cellular radio transceiver. Pulse signal inputs (dry contact) and ala

rm

inputs can be supplied from an external electronic corrector

or other measurement device

. An

index base option with both a mechanical index display and pulse switch output is available.

Serial data communications with a cor

rector

or similar instrument

are also possible using either

an RS

-

232 or RS

-

485 connection.

A variety of power o

ptions are also available

. These include alkaline battery, lithium battery, or

an external source such as solar or AC mains.

Numerous pulse counting inp

uts and alarm trigger inputs are supported.

Optional meter index base enables direct mounting onto a gas meter.

Several mounting options provide flexibility to mount to a wall, pipe, meter, etc.

Cellular radio service options include conventional GSM and C

DMA. Additional radio

options are also available to service special market

needs

.The internal antenna feature conceals the nature of the wireless device. Where signal

strength is a concern, external antenna options are also supported.

Various power opt

ions are available, including alkaline battery, lithium battery, or

connections for external sourced power. External power can be either AC mains or

solar.

The enclosure is field proven durable and UV resistant against weather effects.

Over

-

the-air firmw

are update capability allows for new feature enhancements as they

become available.

CSA Hazardous area certification, Class I, Div

-

2, Group

-

DPTCRB cellular network approvals

FCC Part 15

(B), 22, 24

Measurement Canada

Metrology

Operational

temperature range

-

22 to +158 F (

-

30 to +70 C)

CNI2

OVERVIEW

CNI2

FEATURES

CERTIFICATIONS

Page 17

CNI2

O

perating and Installation

Guide

16

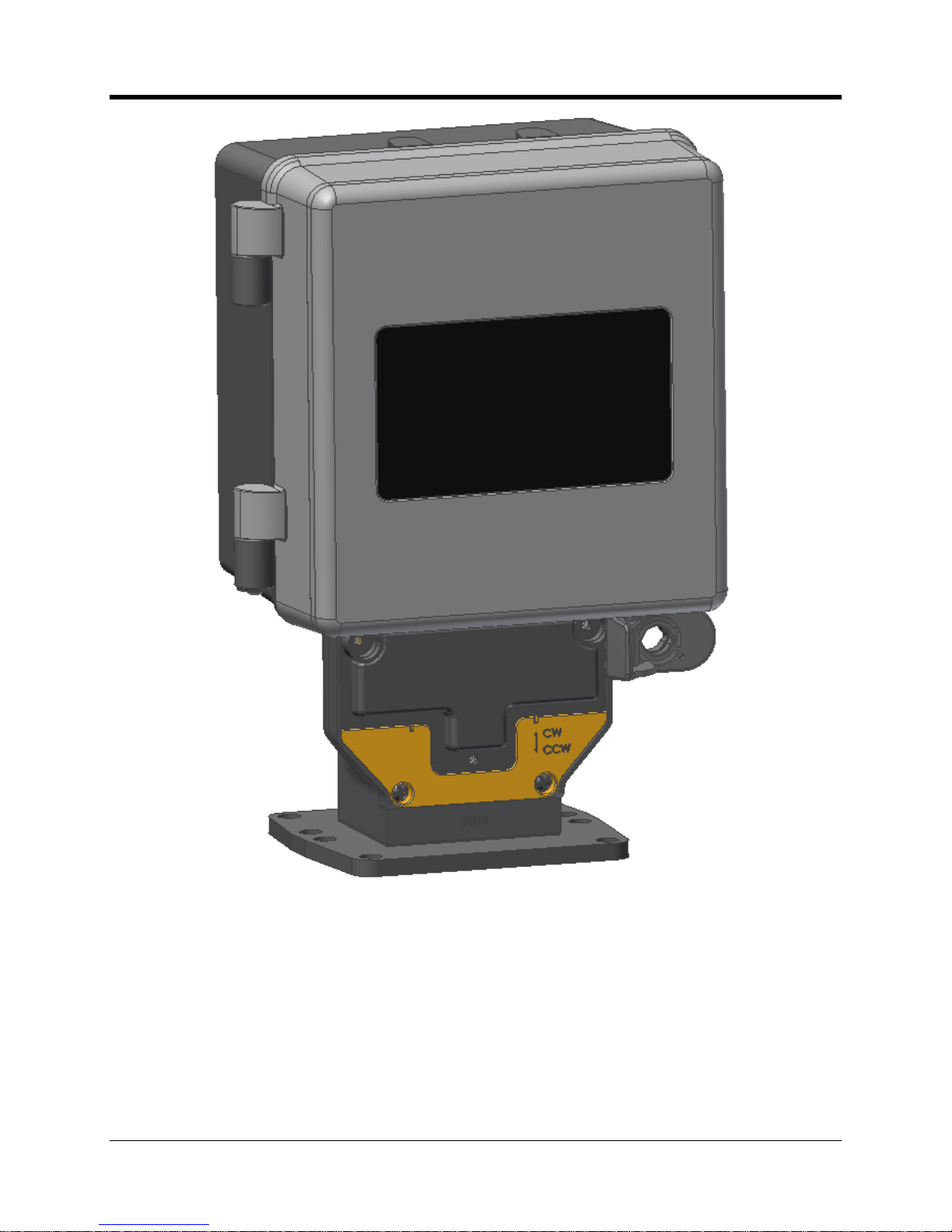

INSTRUMENT MOUNTING

OPTIONS

A number of options are available for conveni

ent