Page 1

CM921

WIRELESS PROGRAMMABLE THERMOSTAT

PRODUCT SPECIFICATION SHEET

The CM921 thermostat is designed to provide automatic time

and temperature control of heating or cooling systems in

villas and apartments.

It can be used as part of a system in conjunction with combiboilers, oil-burners and gas fired boilers, circulation pumps,

thermal actuators, zone values and electric heating systems

(<10A). In combination with other CM921 room units and

HC60NG receivers it can be used to control multi-zone

applications (up to 4 zones).

The radio frequency controlled CM921 system pack consists

of a room unit CMT921A and a relay box R6660D (HC60NG).

No wiring to the room unit is required. The installer only

needs to wire the relay box to the controlled device (e.g.

boiler) and mount the room unit in a suitable location where

RF communication is reliable. The CM921 uses reliable RF

communication technology in the 868MHz band.

The CM921 extra large LCD display, dynamic text display

and controls layout are identical to the CM901 ‘wired’

thermostat. The unit is ideal for consumers who want reliable

and precise temperature control from a modern looking,

simple to program and easy-to-use product.

FEATURES

CM921 can be installed without disrupting your room décor

•

as no wiring connection is required between the room unit

and the boiler

• Attractive, slim, ultra-modern styling makes it ideal for

location in any type of home

• 1-day heating programming

• A dynamic text display on the LCD that gives enhanced

feedback to the user / installer

• LCD Backlighting to illuminate the display for easier viewing

in low light conditions

• Reliable RF communication utilising 868 MHz band with 1 %

duty cycle limit to minimise communication disturbance

• Every room unit can be bound with several relay boxes (e.g.

to control several electric heating panels)

• Armchair programmed

• Holiday button that provides energy savings by reducing

to a constant temperature for 1 to 99 days when people are

on holiday, returning to normal operation (AUTO or

MANUAL) on the day of their return.

• EEPROM memory holds the user program indefinitely

• OFF position has an integral frost protection setting at

minimum 5°C (installer adjustable) so that pipes in the

house will never freeze in winter.

• Communication compatibility with other Honeywell product

such as HR80, HM80 and HCE80.

• CM921 can be used to control a zoning system with up to 4

zones

• Maximum system efficiency and extended boiler life due to

unique zoning system synchronisation

• Automatic Summer / Winter time change adjusts the time

automatically to daylight saving time.

• Standard room units and receiver boxes are used for zoning

applications algorithm

• When used with the table top stand the room unit can be

positioned anywhere in the room where RF communication

is reliable

• 24...230V 10A resistive, 3A inductive SPDT relay provides

compatibility with most domestic central heating systems

reducing the need to stock many different models.

• The HC60NG may be surface or wallbox mounted.

• Installer Set-Up Mode allows extra functions to be set at the

discretion of the installer to match the consumer

applications and needs:

• Optimisation

• Pump Exercise

• Upper / Lower Setpoint Limit Adjust

• Temperature offset

• Minimum ON time

• Cycle rate

• Heat / Cool Operation

• Proportional Band Width

• Fail-safe mode for communication loss

EN0H 8557 UK07 R0 09/06

1

Page 2

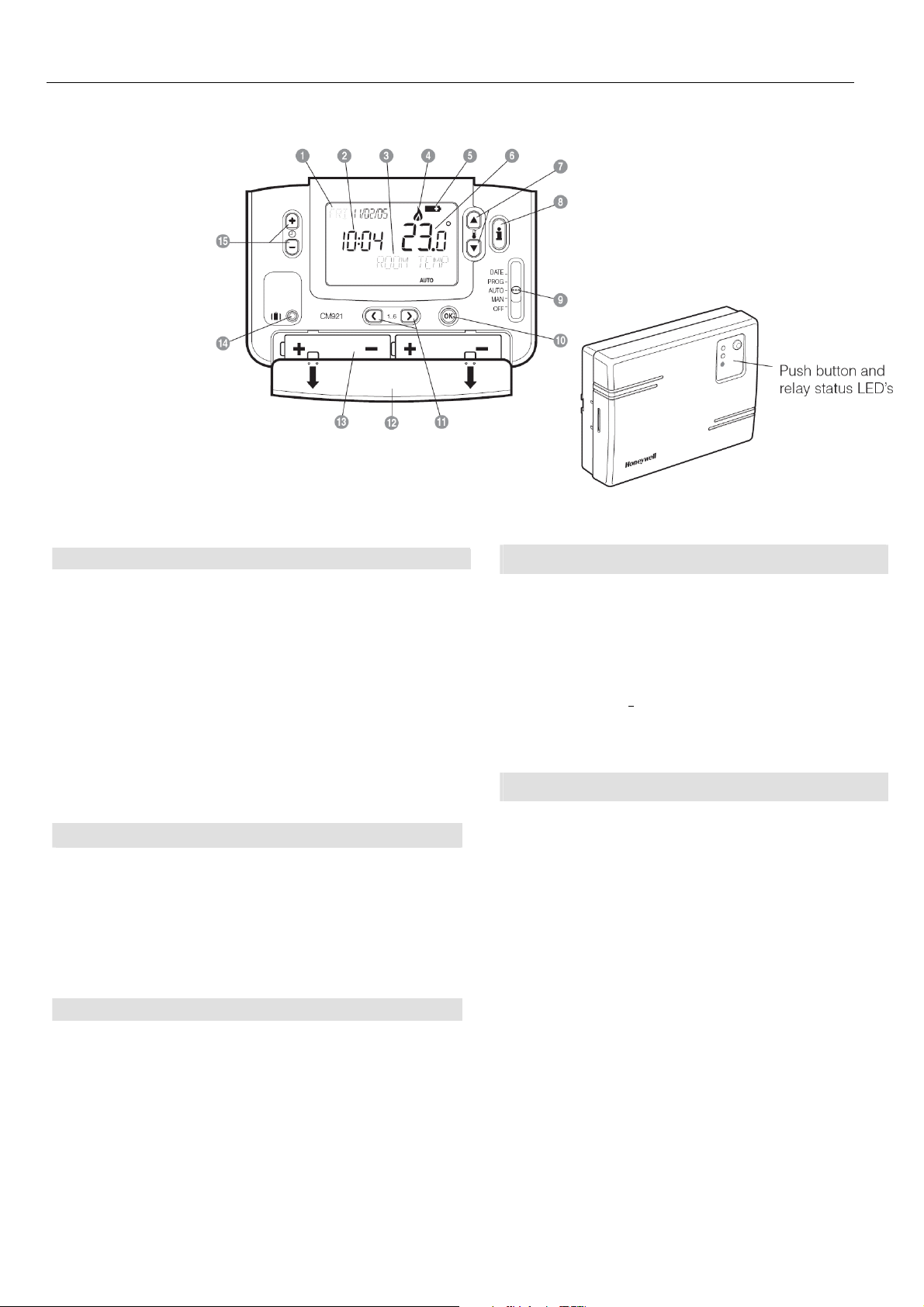

CONTROLS/DISPLAY LAYOUT

Room Unit Layout:

1. Day & Date Display

2. Time Display

3. Dynamic Text Display

(DTD)

4. Burner On Indicator

5. Battery Low Indicator

6. Temperature Display

7. Temperature Change

Buttons

8. Information Enquiry

Button

9. Slider Switch

10. Green OK Button

11. Program Buttons

12. Battery Cover

13. Battery Compartment

14. Holiday Button

15. Time Change Buttons

SPECIFICATIONS

CM921 CHRONOTHERM

ELECTRICAL

Room unit power

supply

Battery life : Minimum 2 years

Battery

replacement

Receiver power

supply

Switch type : SPDT potential free

Output rating : 24-230 V AC, 10 A resistive, 3 A inductive

Wiring (receiver

only)

Wire access : from the rear (wall box mounting), right

: 2 x 1.5 V IEC LR6 (AA) Alkaline cells

: Program retained in EEPROM

: 230V AC +10% - 15%, 50Hz

0.6 p.f.

: Cable terminals for mains and relay wiring

for max 2.5 mm

2

wire

and bottom

RF

RF operation band : ISM (868.0-868.6) MHz, 1% duty cycle

RF communication

: 30 m in a residential building environment

range

RF communication

technology

: short, high rate transmissions to minimise

air time and avoid collisions

Blocking immunity : Receiver class 2 (ETSI EN300 220-1

version 1.3.1)

RF binding method : Factory pre-bound with the room unit.

ENVIRONMENTAL & STANDARDS

Operating

temperature

Shipping & storage

temperature

Humidity : Humidity range 10 to 90% rh, non-

IP class : 30

Meeting the

following

standards

: 0 to 40oC when relay load < 8 A

: 0 to 30oC when relay load > 8 A

o

: -20 to 55

C

condensing

: EN60730-1(Nov 2000), EN55014-1(1997),

EN55014-2(2000), ETSI EN300 220-3

(2000), ETSI EN301 489-3(2000)

TEMPERATURE CONTROL

Sensing element : 100K (@ 25 oC ) NTC thermistor

Control form : Fuzzy Logic Algorithm

Minimum ON

time

10% of cycle time (min one minute),

adjustable to 2 to 5 min (see installer set

up)

Cycle rate : Selectable by application (see installer

set up)

+

Temperature

control accuracy

0.5 K (nominal) @ 20oC, 50% load 3K

:

Δ/hour

Fail-safe mode : Off or cycling depending on the CM927

system set-up

TIME SETTING/PROGRAMMING

Time display : 24 hour or 12 hour AM/PM format

Time keeping

accuracy

Program : 1-day with 6 daily time and temperature

Time setting

resolution

Temperature

setting range

Room

Temperature

display range

: Typically better than 10 minutes per year

level changes

: Time of day - 1 minute

Program – 10 minute steps

o

: Program : 5 to 35

: 5

o

C to 16 oC). Frost protection does not

C in 0.5 oC steps Frost

o

C or equal to lower limit (5

work in cooling mode

o

: From 0

C to 50 oC

2

EN0H 8557 UK07 R0 09/06

Page 3

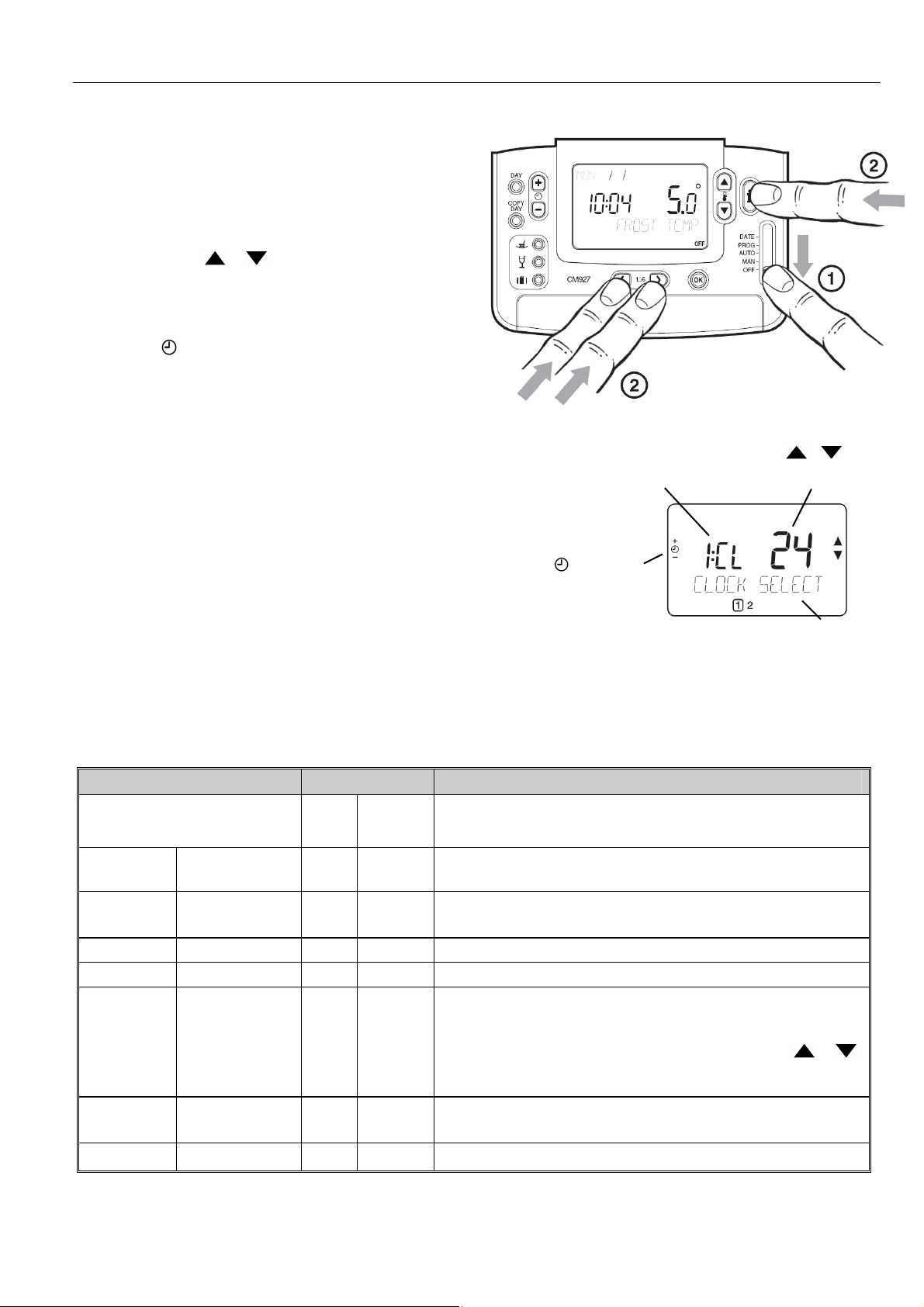

In Install

INSTALLER SET-UP

To enter the installer set-up mode:

a) Move the slider switch to the OFF position.

b) Press and hold the INFO

buttons ‘< >’ together.

c) The unit will display the first parameter of installer

parameter group category 1 (from n.1 to n.19).

d) Press the TEMP

setting. The display will flash indicating that a change has

been made.

e) Press the green OK button to confirm this change and the

display will stop flashing.

f) Press the

+ button to go to the next parameter.

g) Press the program button

Installer mode (from n.1 to n.14).

h) To exit the installer mode, move the slider switch to the

AUTO or MAN positions.

i button and the two program

or buttons to change the factory

> to go to category 2 in the

Abbreviated Set-Up Description

e.g. Cl = Clock Format

CM921 CHRONOTHERM

Factory Setting or New Choice

Press TEMP or to change

e.g. 12 = AM/PM Format

24 = 24hr Format

Installer Set-up Number

(Press + or - to change)

e.g. 1 = Clock Format

er set-up we can:

❑ Set-up specific applications parameters

❑ Enable special features

❑ Configure system timing master for the zoning system

Specific Applications Setting What do you need to change?

Heating Gas Boilers

(<30KW)

Air

Oil Boiler 3 4 1. Set Minimum ON Time to 4 minutes.

Thermal Actuator 12 1 Set Cycle/Hour to 12.

Zone valve 6 1 No changes required.

conditioning

Heat Pump/

Air conditioner

Fan coil 6 1 No changes required.

Cycle/

Hour

Minimum

ON time

(in minutes)

6 1 No changes required

3 4 1. Set Minimum ON Time to 4 minutes.

Note : All parameters listed below belong to category 2 – System

Parameters (see Installer Parameters Table)

2. Set Cycle/Hour to 3.

1. Configure the thermostat to allow switching between heating

and cooling modes (set parameter n.4:HC to 1)

2. Set the thermostat accordingly to the required mode of

operation (heating or cooling) by pressing the TEMP

buttons together for 5 seconds.

as required.

2. Set Cycle/Hour to 3.

Brief Description of the

Parameter Function.

or

Modify the cooling program

3

EN0H 8557 UK07 R0 09/06

Page 4

CM921 CHRONOTHERM

Special Features Description Setting

Optimisation

(Variable Start

Time)

Heating or Cooling

Operation

Summer/Winter

Auto time change

Temperature Offset If the thermostat is located in a particularly hot/cold location for

Upper/Lower

Temperature Limit

The thermostat will adjust the start time in the morning/afternoon

so the desired temperature is reached by the start of the program

period. The system will restrict the start time to a max of 2 hours.

This product can be used for heating or cooling applications. If

you select cooling mode the control algorithm and factory default

program will be modified. You can independently modify the

heating and cooling profile.

This feature moves time automatically on the last Sunday of

March and the last Sunday of October. The feature is factory

enabled.

reliable signal transmission reasons then the measured/displayed

temperature can be adjusted by +/- 3°C. This is useful if the

homeowner wants the reading to match another appliance

temperature display.

The normal upper temperature limit of 35°C can be reduced to

21°C to save the homeowner energy. The normal lower limit of

5°C can be increased up to 21°C to protect inhabitants from cold.

To enable: Set parameter 8:OP

(category 1) to 1.

To enable: Set parameter 4:HC

(category 2) to 1.

To enable: Set parameter 3:tC

(category 1) to 1.

Set parameter 12:tO (category

1) to the required

offset value.

Set parameter 6:uL (category 1)

to the desired upper limit.

Set parameter 7:LL (category 1)

INSTALLER PARAMETER TABLES

Parameter Installer Set-

Up Number /

Abbreviation

(Press + or keys to

select)

Category 1 Parameters – Room Thermostat Settings

Display Description Display Description

AM-PM / 24hr Display 1:Cl 24 24 hr clock display 12 12 hr AM / PM clock display

RESET Time /

Temperature Program

Automatic

Summer/Winter Time

Change

LCD Backlighting 5:bL 1 Backlighting Enabled 0 Backlighting Disabled

Upper Temperature

Limit

Lower Temperature

Limit

2:rP 1 Time / Temperature profile set

3:tC 1 Automatic Summer/Winter

6:uL 35 35°C Upper Temp. Limit 21 to 34 21°C to 34°C adjustment in 1°C steps

7:LL 5 5°C Lower Temp. Limit 6 to 21 6°C to 21°C adjustment in 1°C steps

Factory Setting

to factory default

Changes to 0 when one of the

time/temp profiles are changed

Time Change Enabled

Optional Setting

0

1

0 Automatic Summer/Winter Time Change

Time / Temperature are as programmed

To restore the factory profile set to 1

Disabled

Optimisation 8:0P 0 Optimisation disabled 1 Optimisation enabled

Temperature Offset 12:tO 0 No offset -3 to +3 -3°C to +3°C adjustment in 0.1°C steps

Proportional Band

Width

Reset Parameters to

Factory Defaults

4

EN0H 8557 UK07 R0 09/06

13:Pb 1.5 1.5°C Proportional Band 1.6 to 3.0 1.6°C to 3.0°C adjustment in 0.1°C steps

19:FS 1 All settings held are the factory

defaults.

Changes to 0 when one of the

0

1

Settings are as modified above

To restore the factory profile set to 1

Page 5

CM921 CHRONOTHERM

Parameter Installer Set-

Up Number /

Abbreviation

(Press + or keys to

select)

Factory Setting

Optional Setting

Category 2 Parameters – System Settings (press the > button to access this category)

Display Description Display Description

Minimum boiler ON

Time

Cycle Rate 2:Cr 6 6 cycles per hour (cph) 3, 9 or12

Heat / Cool Change 4:HC 0 Disabled 1 Enabled

Pump Exercise 5:PE 0 Pump Exercise Disabled 1 Pump Exercise Enabled

System

Synchronisation

Loss of Communication

Instruction

The following parameters are for the control of other Honeywell Wireless products such as Wireless Underfloor Heating controls and

Wireless Radiator controls. For more information please contact Honeywell sales.

Room Temperature

Sensor Use

1:Ot 1 1 minute minimum ON time 2 to 5

6:Sn 0 Standard operation of the

Room Unit

7:LC 0 Relay Off 1 Relay 20% on / 80% off

8:Su 0 HC60 Control 1,2,3 or 4

1 Room unit configured as Synchroniser

Selection of 2,3,4 or 5 minutes minimum

ON time

Selection of 3,9 or 12 cph

1 - HR80/HM80 control with own/remote

sensor (no temperature displayed)

2 - Hr80/HM80/HCE80 control with CM

Sensor

3 - HC60 control and HR80/HM80/

HCE80 control with own/remote sensor

4 – Hr80/HM80/HCE80 control with own/

remote sensor (temperature displayed)

HR80 Window-Open

Function

9:HO 0 Disabled 1 Enabled

HR80 Local Override 10:HL 1 Enabled 0 Disabled

Maximum Flow

Setpoint

Minimum Flow Setpoint 12:LF 15 15°C Minimum Flow Temp. 0 to 50 0°C to 50°C adjustments in 1°C steps

Mixing Value Run Time 13:Ar 150 150 seconds 0 to 240 0 to 240 sec. adjustments in 1sec steps

11:uF 55 55°C Maximum Flow Temp. 0 to 99 0°C to 99°C adjustments in 1°C steps

DIMENSIONS

5

EN0H 8557 UK07 R0 09/06

Page 6

CM921 CHRONOTHERM

b

INSTALLATION

• The CM921 is a radio frequency device and for the best performance should be installed in an open space.

• Leave at least 30cm distance from any metal objects including wall boxes and at least 1 metre from any other electrical equipment

e.g. radio, TV, PC etc.

• Do not mount onto metal wall boxes.

• NOTE: It is recommended that the R6660D relay box is installed before commencing with the room unit installation (refer to the

Installation Guide).

R6660D Relay box CMT921A Room Unit

a

WIRING

The R6660D relay box is designed for fixed wiring only and must be installed in accordance with latest l.E.E. regulations.

Ensure the wiring connection to the supply is via a fuse rated at no more than 10 amps and a Class "A" switch (having

contact separation of at least 3 mm in all poles).

IMPORTANT

1. The installer must be a trained service engineer

2. Disconnect the power supply before beginning installation

EN0H 8557 UK07 R0 09/06

6

Page 7

WIRING

CM921 CHRONOTHERM

NOTE: All wiring must be in accordance

with IEE regulations

Caution: Observe ambient temperature

and current limits (see the receiver box

wiring label)

ORDERING SPECIFICATION

Description Model Logo Literature Availability Spec Sheet

1-day RF system pack (includes HC60)

1-day RF system pack (includes HC60)

1-day RF system pack (includes HC60)

1-day room unit spare

1-day room unit spare

1-day room unit spare

HC60 Spare

HC60 Spare

HC60 Spare

CMT921A1018

CMT921A1026

CMT921A1042

CMS921B1018

CMS921B1026

CMS921B1042

R6660D1017

R6660D1025

R6660D1041

Honeywell

Honeywell

Honeywell

Honeywell

Honeywell

Honeywell

Honeywell

Honeywell

Honeywell

French & Dutch.

French

English (UK)

French & Dutch.

French

Spanish

French & Dutch.

French

English (UK)

Sep 06

Oct 06

Oct 06

Sep 06

Oct 06

Oct 06

Sep 06

Sep 06

Sep 06

ENOH8557

ENOH8557

ENOH8557

ENOH8557

ENOH8557

ENOH8557

ENOH8557

ENOH8557

ENOH8557

Honeywell Control Systems Limited http://europe.hbc.honeywell.com

Newhouse Industrial Estate

Motherwell ML1 5SB

United Kingdom

EN0H 8557 UK07 R0 09/06

7

Loading...

Loading...