Page 1

SmartLine Wireless Temperature and Universal IO Transmitters

34-SW-25-02, Revision 1, December 2019

INSTALLATION

Evaluate the site selected for the Transmitter installation with respect to the

process system design specifications and Honeywell’s published

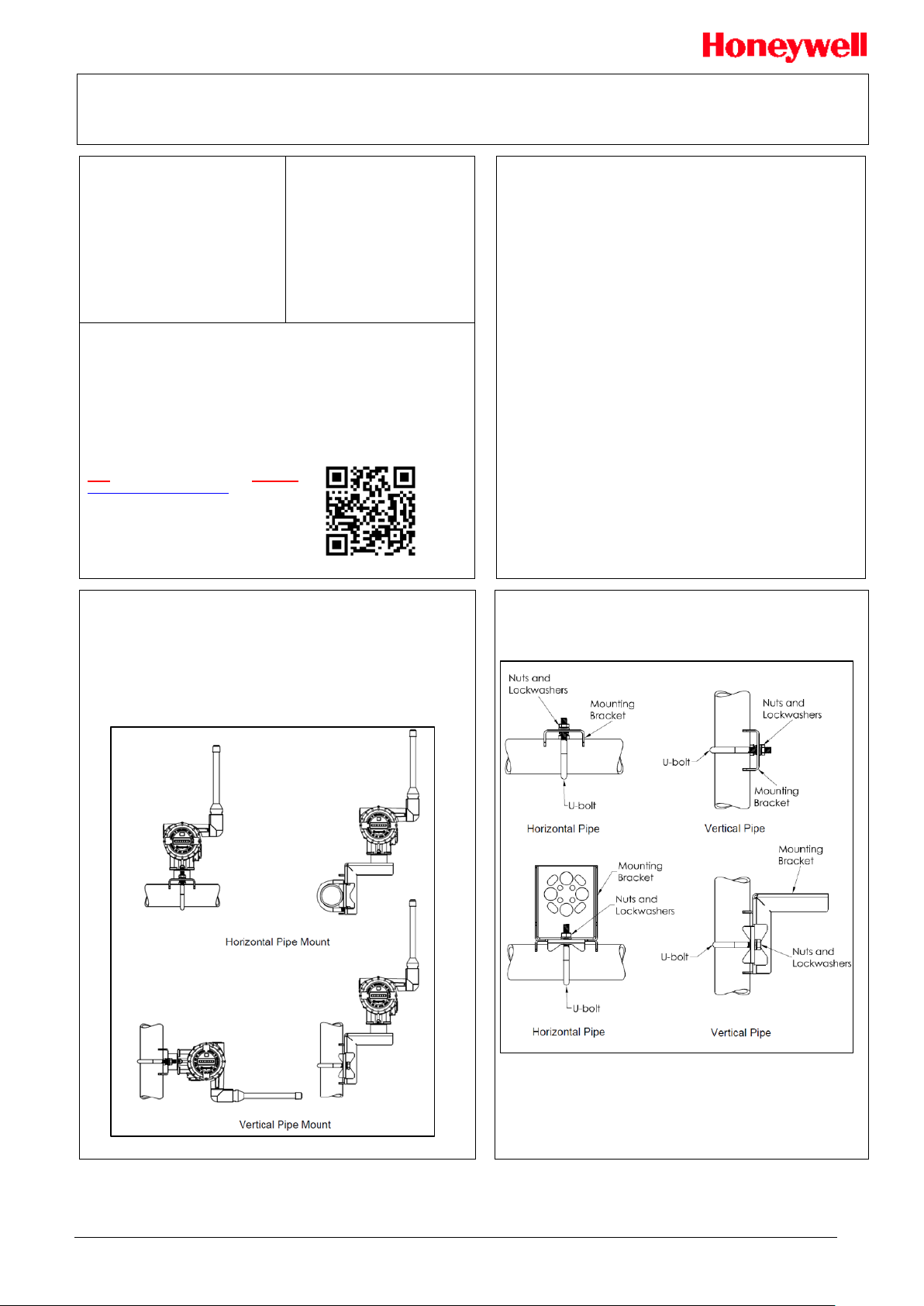

Figure 2: Mounting Brackets

Quick Start Installation Guide

For full details refer to the Wireless

Pressure User’s manual 34-SW-25-01

or the Wireless Temperature User’s

manual 34-SW-25-04, scan QR code

or use URL link below.

Including: Network, Security, Licensing,

Installation, Start Up, Operation,

Maintenance/Repair, Protocols and

Approvals/Certifications etc. including

options.

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

performance characteristics for your particular model.

Mounting the Transmitter

Temperature/UIO models can be attached to a two-inch (50 millimeter)

vertical or hori zo ntal pipe using Hon e yw ell ’s o pt io nal angle or fl at m o unti ng

bracket; alternately you can use your own bracket.

Copyright

Copyright 2019 by Honeywell

Revision 1 – December 2019

Trademarks

SmartLine, is a U.S. registered

trademark of Honeywell Inc.

Table of Contents

Documentation ............................................................................................................. 1

URL ............................................................................................................................. 1

INSTALLATION ........................................................................................................... 1

Bracket Mounting .................................................................................................. 1

Mounting the Transmitter ...................................................................................... 1

Rotating Transmitter Housing ............................................................................... 2

Conduit Entry Plugs and Adapters ............................................................................... 2

Procedures ........................................................................................................... 2

Battery Power Option ................................................................................................... 2

Install/Replace batteries ....................................................................................... 2

24V Power Supply Option ............................................................................................ 3

ELECTRICAL CONNECTION SPECIFICATIONS ................................................ 3

STIW400 TEMPERATURE TRANSMITTER CONNECTIONS .................................... 3

STUW750 UNIVERSAL IO TRANSMITTER CONNECTIONS .................................... 3

STUW751 UNIVERSAL IO TRANSMITTER CONNECTIONS .................................... 3

Environmental Conditions ............................................................................................ 4

Maintenance ................................................................................................................ 4

General Operation ....................................................................................................... 4

EU Declaration of Conformity ...................................................................................... 4

EMC Conformity .......................................................................................................... 4

Hazardous Locations Certifications ............................................................................. 4

Conditions of Certification ............................................................................................ 5

FM Approval Specific Conditions of Use............................................................... 5

CSA, IECEx and ATEX Conditions of Certification ............................................... 5

Apparatus Marked with Multiple Types of Protection ............................................ 5

Radio Compliance Information..................................................................................... 5

Radio Frequency (RF) statement ......................................................................... 5

European Union restriction ................................................................................... 6

FCC compliance statements ................................................................................. 6

IC compliance statements .................................................................................... 6

Bracket Mounting

• Optional mounting bracket, see

• Rotating the transimitter housing, see Figure 3.

Figure 1: Flat and Angle Mounting Brackets

SmartLine Wireless Transmitter Quick Start Installation Guide 1

Page 2

Step

Action

1

Remove the protective plastic cap from the threaded

conduit entry.

2

To ensure the environment ingress protection rating on

may be used.

3

Thread the appropriate size conduit plug (M20 or ½’’

reducers will be used.

4

Tighten adapters according to the following table.

Description

Tool

Torque

M20 Conduit Entry

10mm Hex Wrench

32Nm

24Lb-ft

½’’ NPT Conduit Entry

10mm Hex Wrench

32Nm

24Lb-ft

Step

Action

1

Remove the protective plastic cap from the threaded conduit entry.

2

To ensure the environment ingress protection rating on tapered

threads (NPT), a non-hardening thread sealant may be used.

3

Thread the appropriate size adapter (M20 or ½’’ NPT) into the

conduit entry opening.

4

Tighten adapters according to the following table.

Description

Tool

Torque

½’’ to ¾’’ NPT Conduit Entry

¼’’ Wrench

32Nm

24Lb-ft

CONDUIT ENTRY PRECAUTIONARY NOTICE

THE CONDUIT/CABLE GLAND ENTRIES OF THIS PRODUCT ARE SUPPLIED

NVIRONMENT INTO WHICH THIS PRODUCT WILL BE

INSTALLED. THIS INCLUDES ENSURING COMPLIANCE WITH HAZARDOUS

GOVERNING AUTHORITIES AS APPLICABLE.

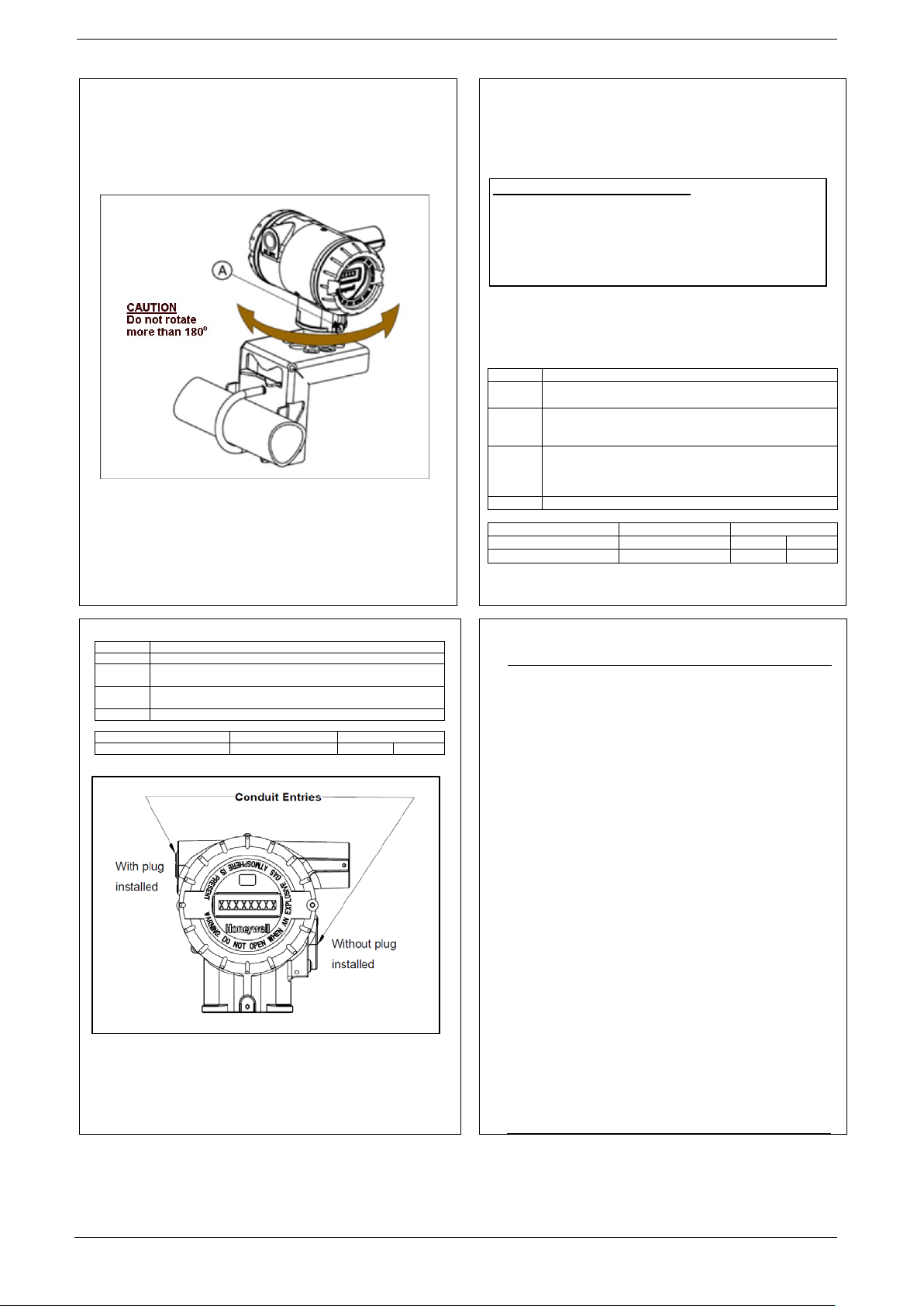

Rotating Transmitter Housing

You can rotate the transmitter for better viewing, access, or antenna

position. Loosen set screw (see A in Figure 3) on outside neck of

transmitter one full turn. Rotate transmitter housing up to 180 degrees in

either direction to desired position. Tighten set screw.

Figure 3: Rotating Transmitter Housing

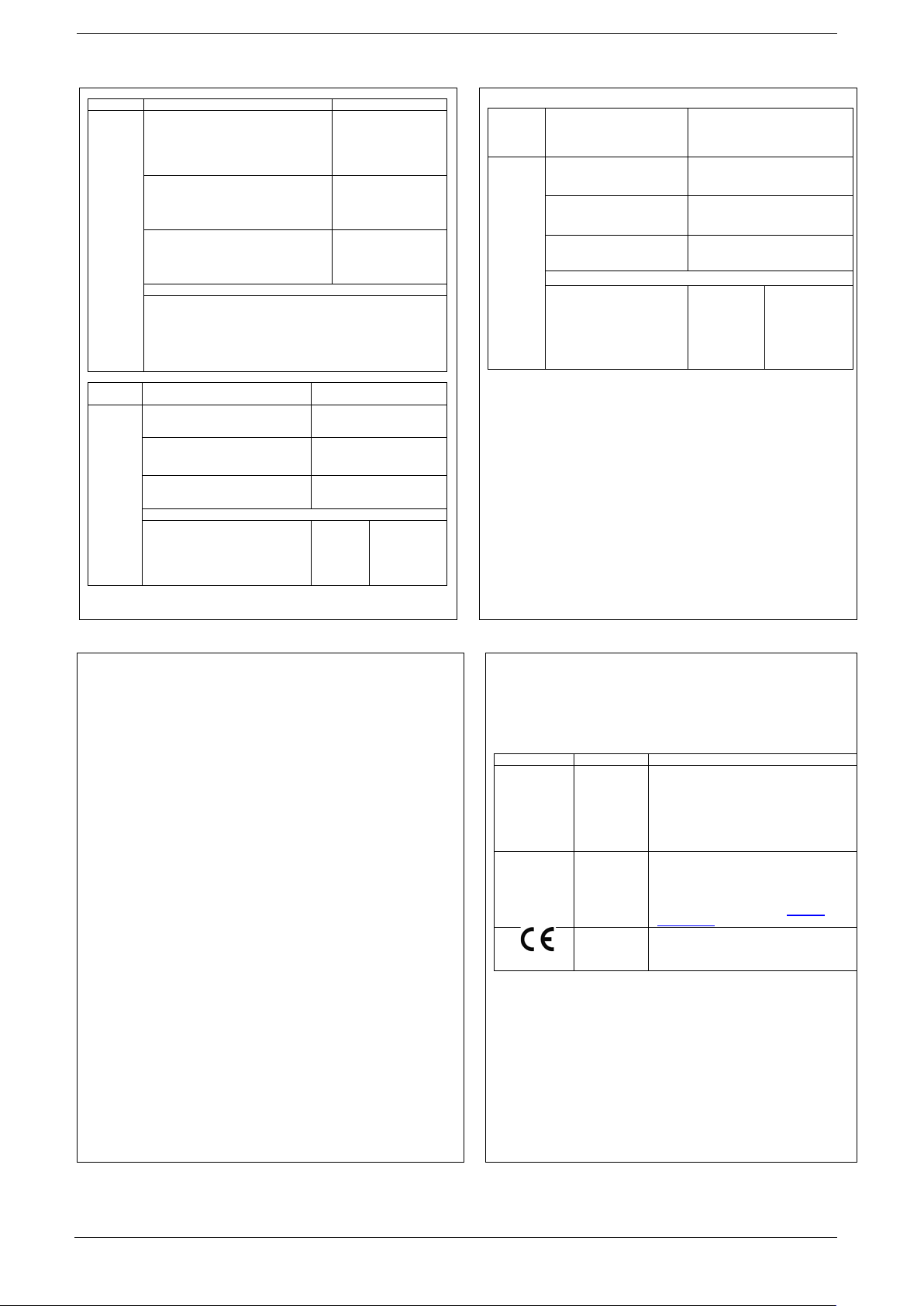

Conduit Entry Plugs and Adapters

Procedures

It is the User/Installer’s responsibility to install the Transmitters in

accordance with national and local code requirements. Conduit entry

plugs and adapters shall be suitable for the environment, shall be

WITH PLASTIC DUST CAPS WHICH ARE NOT TO BE USED IN SERVICE. IT

IS THE USER’S RESPONSI BILITY TO REPLACE THE DUST CAPS WITH

CABLE GLANDS, ADAPTORS AND/OR BLANKING PLUGS WHICH ARE

SUITABLE FOR THE E

LOCATION REQUIREMENTS AND REQUIREMENTS OF OTHER

certified for the hazardous location when required and acceptable to the

authority having jurisdiction for the plant.

Use the following procedures for installation:

Table 1 – Conduit Entry Plugs

tapered threads (NPT), a non-hardening thread sealant

NPT) into the conduit entry opening. Do not install conduit

entry plugs in conduit entry openings if adapters or

Table 1 – Conduit Adapters

Battery Power Option

Install/Replace batteries

WARNING

Risk of death or serious injury from explosion or fire.

• When not in use the Battery Pack must be stored in a non

Note. NO plugs come installed in the housing. All housings come with

temporary plastic dus t pr otecto rs (red ) install ed and a re not c ertifi ed fo r use

in any installation.

Figure 4: Electronic Housing Conduit Entries

Hazardous Area

• Do not change batteries in an explosive gas atmosphere.

• The batteries used in this device may present a risk of fire or

chemical burn if mistreated. Do not recharge, disassemble, heat

above 100°C (212°F), or incinerate.

• When installing batteries, do not snag the battery terminal on

the clip or the battery may be damaged. Do not apply excessive

force.

• Do not drop. Dropping the battery may cause damage. If a

battery is dropped, do not install the dropped battery into the

transmitter. Dispose of dropped battery promptly per local

regulations or per the battery manufacturer’s recommendations.

ATTENTION

Both batteries must be the same model from the same

manufacturer. Mixing old and new batteries or different

manufacturers is not permitted.

Use only the following 3.6V lithium thionyl chloride (Li-SOCl2)

batteries (non-rechargeable), size D. No other batteries are

approved for use in SmartLine Wireless Transmitters.

• Xeno Energy XL-205F

• Eagle Picher PT-2300H

• Tadiran TL-5930/s

• Tadiran GmbH, SL-2780 (Not approved by FM or CSA)

• Honeywell p/n 50026010-501 (Two 3.6V lithium thionyl

chloride batteries)

• Honeywell p/n 50026010-502 (Four 3.6V lithium thionyl

chloride batteries)

• Honeywell p/n 50026010-503 (Ten 3.6V lithium thionyl

chloride batteries)

SmartLine Wireless Transmitter Quick Start Installation Guide 2

Page 3

+

-

STW TRANSMITTER WITH 24VDC POWER SUPPLY OPTION

(Antenna and Meterbody Omitted for Clarity)

GROUND SHIELD AT THIS END ONLY

+

-

THE POWER SUPPLY OUTPUT SHALL

ONLY BE CONNECTED TO THE

INTERNAL TRANSMITTER CABLE

24Vdc Supply

16.0 Vmin

28.0 Vmax

100 mA max

T/C or mV or DI or 2 Wire Resistance

1

2

3

4

5

6

TB1

TB2

PV1

PV2

PV3

PV4

+

+

+

+

-

-

-

-

3 Wire RTD or Resistance

1

2

3

4

5

6

TB1

TB2

PV1

PV3

3 Wire RTD or Resistance

1

2

3

4

5

6

TB1 TB2

PV1

PV3

PV4

+

+

-

-

T/C or mV or DI or 2 Wire Resistance

HLAI (0/4-20mA) or T/C or mV or DI or 2 Wire Resistance

1

2

3

4

5

6

TB1 TB2

PV1 PV2

+

+

-

-

+

-

+

-

+

-

+

-

PV3

HLAI (0/4-20mA) or T/C or mV o r DI or 2 Wir e Resistance

AND Dig ital Output

1

2

3

4

5

6

TB1

TB2

PV1

PV2

+

+

-

-

+

-

+

-

+

-

PV3 Dig ital

Outpu t

24V Power Supply Option

ELECTRICAL CONNECTION SPECIFICATIONS

The 24V power supply requires 16 Vdc to 28 Vdc, 100 mA max supply connection

to the 24V wirin g connector te rminals. Fo r hazardous location instal lation, and

intrinsic safety entity parameters, refer to the control drawing.

1. The 24V wiring terminals will accept 26 to 12-gauge wiring. The

terminals shall be torqued from 0.4 Nm to 0.5 Nm (3.5 to 4.4 lb-in).

(Ordinary Non-Ha zar do us Locations)

STIW400 TEMPERATURE TRANSMI TTER CONNE CTI ONS

Figure 5: Power Supply 24Vdc Option (DC) System Diagram

STUW750 UNIVERSAL IO TRANSMITTER CONNECTIONS

NOTES:

Figure 7: STUW750 Universal Io Transmitter Connections

1. The terminals accept 14-26AWG wire, and the screws shall be torqued to

0.4-0.5Nm (3.5 – 4.4 in-lb)

2. Any combination of sensor type inputs is allowed

3. Shielded cable is required for EMC conformity and is recommended for

all remote sensor installations. The shield shall be grounded at the

transmitter end only. If the shiel d is gro unded at the remote end, the

shield shall not be connected at the transmitter end.

4. When remote mounted probe sensors are used, and the shield is

grounded at the probe, the shield shall not be connected at the

transmitter end.

5. Duplex (redundant) sensors that are bonded to the probe are not

permitted. All thermocouple/mV and RTD/ohms inputs must be insulated

from ground (the probe) and from each other.

6. Digital Input switches, DI, must be dry contact type, simple apparatus

and properly segregat ed from all oth er sour ces of po wer.

SmartLine Wireless Transmitter Quick Start Installation Guide 3

Figure 6: STIW400 Temperature Transmitter Connections

NOTES:

1. The terminals accept 14-26AWG wire, and the screws shal l be

torqued to 0.4-0.5Nm (3.5 – 4.4 in-lb)

2. Any combination of sensor type inputs is allowed

3. Shielded cable is required for EMC conformity and is

recommended for all remote sensor installations. The shield shall

be grounded at the transmitter end only.

4. When remote mounted probe sensors are used and the shield is

grounded at the probe, the shield shall not be connected at the

transmitter end.

5. Duplex (redundant) sensors that are bonded to the probe are not

permitted. All thermocouple/mV and RTD/ohms inputs must be

insulated from ground (the probe) and from each other.

6. Digital Input switches, DI, must be dry contact type, simple

apparatus and properly segregated from all other sources of

power.

STUW751 UNIVERSAL IO TRANSMITTER CONNECTIONS

Figure 8: STUW751 Universal Io Transmitter Connections

NOTES:

1. The terminals accept 14-26AWG wire, and the screws shal l be

torqued to 0.4-0.5Nm (3.5 – 4.4 in-lb)

2. Any combination of sensor type inputs is allowed

3. Shielded cable is required for EMC conformity and is

recommended for all remote sensor installations. The shield shall

be grounded at the transmitter end only. If the shield is grounded at

the remote end, the shield shall not be connected at the transmitter

end.

4. When remote mounted probe sensors are used and the shield is

grounded at the probe, the shield shall not be connected at the

transmitter end.

5. Duplex (redundant) sensors that are bonded to the probe are not

permitted. All thermocouple/mV and RTD/ohms inputs must be

insulated from ground (the probe) and from each other.

6. Digital Input switches, DI, must be dry contact type, simple

apparatus and properly segregated from all other sources of

power.

Page 4

DIRECTIVE

DESCRIPTION

2014/53/EU

Radio Equipment Directive

2014/34/EU

ATEX Directive

2014/68/EU

Pressure Equipment Directive (for

pressure models)

STANDARD

DESCRIPTION

EN 300 328 V2.1.1

Wideband transmission systems;

2,4GHz ISM band

EN 61326-1: 2013

Electrical equipment for

use - EMC requirements

EN 301 489-1 V2.1.1

ElectroMagnetic Compatibility (EMC)

services

AGENCY

TYPE OF PROTECT ION

Ambient Temperature

Intrinsically Safe:

Ex ic IIC T4 Gc

Non Incendive:

Gc

Explosion-Proof/ Flam e pr oo f/D u st Pr oof :

Class II, Zn 21, AEx tb [ia Da] IIIC T95 Db

Enclosure: Type 4X/ IP66/ IP67

Standards Used:

CSA C22.2 No. 0

CAN/CS

ANSI/UL 60079

FM 3616

CAN/CSA C22.2 No.60529:16

ANSI/ISA 12.12.01

FM 3600

ANSI/UL 61010

CAN/CSA C22.2 No.60079

ANSI/UL 60079

FM 3615 – Aug 2006, ANSI/UL 913-2015

Environmental Conditions

Refer to the specification sheet for performance considerations.

The transmitter operates with an ambient temperature of -40

o

C to +85 oC. If

installed in a hazardous environment, the maximum ambient temperature may

be limited. Refer to the control drawing and the markings on the transmitter

nameplate.

Ambient humidity limits are 0 to 100% relative humidity.

The transmitter may be installed indoors or outdoors, with pollution degree 4.

The enclosure is rated Type 4X, IP66 / IP 67.

The transmitter operates up to an altitude of 2,000 m.

Entry plugs/glands rated for the installation environment are required to be

installed on the transmitter.

Maintenance

The SmartLine Wireless Transmitter itself does not require any specific

maintenance routine at regularly scheduled intervals, other than changing the

batteries as required.

If the transmitter requires repair or replacement parts, please contact your local

Honeywell TAC. TAC contact information can be found on the last sheet of this

quick start guide.

General Operation

1. INSTALL.

2. ANTENNA. The transmitter can be supplied with an integral 4dBi

antenna. If the transmitter is equipped with a remote mount

antenna connection, connect the antenna with a RF cable. The

transmitter remote mount and antennas utilize N-type connectors.

3. POWER up the transmitter.

Remove the end cap, opposite the LCD display, to connect

power. Ensure the internal power cable is connected to the

battery pack or 24V supply module as applicable.

Once powered, verify that the transmitter LCD is functioning. If

the LCD is blank , check the power connections, and batteries as

applicable.

4. PROVISION the transmitter to the network

a. Over The Air (OTA) provisioning can be done using the

Wireless Device Manager (WDM) interface.

b. Handheld provisioning can be done through the IR port with a

Handheld Provisioning Device such as MCT404

5. VERIFY that the transmitter connects in the wireless network, and

can transmit PVs. This step may take several minutes,

depending on your network.

a. Load the DD file (if not done previously)

b. Configure the transmitter as desired using the property panel

c. Configure the channel(s) as desired using the pr op ert y p anel .

d. Activate the channel(s)

6. CALIBRATE. If required, calibration should only be done after the

transmitter is installed in its final location.

EU Declaration of Conformity

A copy of the Smartline Wireless Transmitters EU Declaration of Conformity can be

downloaded here:

https://www.honeywellprocess.com/library/support/Public/Documents/50136122.pdf

The Smartline Wireless Transmitters complies with the following directives

EMC Conformity

The Smartline Wireless Transmitters complied with the following EMC standards

SmartLine Wireless Transmitter Quick Start Installation Guide 4

Hazardous Locations Certifications

Hazardous location certifications

Refer to product label for applicable approvals and control drawing.

Table B-2 Certifications and Approvals

Class I; Division 1; Groups A, B, C, D;

Class II, Division 1, Groups E, F, G;

Class III, Division 1; T4

Class I, Zone 0 AEx ia IIC T4 Ga

Class I Zone 2 AEx ic IIC T4 Gc

Ex ia IIC T4 Ga

Class I; Division 2; Groups A, B, C, D;

Class II, Division 2, Groups E, F, G;

Class III, Division 2, T6...T5

Ex nA [ia Ga] IIC T6...T5 Gc

Class I, Zn 2, AEx nA [ia Ga] IIC T6...T5

Class I, Division 1; Groups A, B, C, D;

Class II, Division 1, Groups E, F, G;

Class III, Division 1; T6...T5

Ex db [ia Ga] IIC T6...T5 Gb

Ex tb [ia Da] IIIC T95 Db

Class I, Zn 1 AEx db [ia Ga] IIC T6...T5 Gb

-10, CSA C22.2 No.94.2-15, CSA C22.2 No.213-16,

A C22.2 No.60079-1:16, CAN/CSA C22.2 No.60079-31:15

-1-2015, ANSI/UL 60079-31-2015

– Dec 2011, ANSI/UL 50E-2015

CSA C22.2 No.25-17, CAN/CSA C22.2 No.61010-1-12

-2015, ANSI/UL 60079-11-2014

– Dec 2011, ANSI/IEC 60529 – 2004

CSA C22.2 No.30-M1986, CAN/CSA C22.2 No.157-92

-1-2016

-0-2013, ANSI/UL 60079-15-2013

, CAN/CSA C22.2 No.60079-11:14

-0:15, CAN/CSA C22.2 No.60079-15:16

-40 to +80°C: ia

-40 to +85°C: ic

-40°C to +85°C : T5

-40°C to +75°C : T6

-40°C to +85°C : T5

-40°C to +75°C : T6

-40°C to +85°C : T95

Data transmission equipment

operating in the

measurement, control and laboratory

standard for radio equipment and

CSA

(USA and

Canada)

Page 5

AGENCY

TYPE OF PROTECT ION

Ambient Temperature

Approvals

Intrinsically Safe:

T4

Non Incendive:

T5...T6

Dust Proof:

Db

C : T5, T95

Enclosure: Type 4X/ IP66/ IP67

Standards Used:

ANSI/ ISA 60079-11: 2014, ANSI/ ISA 60529: 2004

AGENCY

TYPE OF PROTECT ION

Ambient Temperature

Intrinsically Safe:

II 3 G Ex ic IIC T4 Gc

-40 to +80°C: ia

Flameproof / Dust Proof:

-40°C to +85°C : T5

Non Incendive:

-40°C to +85°C : T5

Enclosure: IP66/ IP67

Standards Used:

EN 60079

2014

EN 60079

2015

AGENCY

TYPE OF PROTECT ION

Ambient Temperature

Intrinsically Safe:

-40 to +80°C: ia

Flameproof / Dust Proof:

Ex tb [ia Da] IIIC Db T95C

-40°C to +85°C : T5

Enclosure: IP66 /IP67

Standards Used:

Agency

Certification

Description

Communications

The SmartLine Wireless Transmitters comply

cause undesired operation.

Industry Canada

The installer of this radio equipment must

sc.gc.ca/rpb.

The SmarLine wireless transmitter has been

2014/53/EU.

IS Class I, II, III; Division 1; Groups

ABCDEFG; T4

Class I, Zone 0 AEx ia IIC Ga T4

Class I, Zone 2[0] AEx ic [ia Ga] IIC Gc

NI-AIS Class I; DIV 2; Groups ABCD;

T5...T6

Class I, Zone 2[0] AEx nA [ia Ga] IIC Gc;

FM

TM

(USA)

DIP-AIS Class II, III DIV 1; Groups EFG;

T5...T6

Zone 21[20] AEx tb [ia Da] IIIC T95°C

FM 3600:2018, ANSI/ISA 60079-0: 2013

ANSI/ ISA 60079-15: 2013, ANSI/ NEMA 250: 2008

FM 3610: 2018, FM 3810: 2018

ANSI/ ISA 60079-31: 2015

FM 3611: 2018, FM 3616: 2011

II 1 G Ex ia IIC T4 Ga

II 2[1] G Ex d [ia Ga] IIC T6...T5 Gb

II 2[1] D Ex tb [ia Da] IIIC 95C Db

II 3[1] G Ex ec [ia Ga] IIC T6...T5 Gc

ATEX

EN 60079-0 : 2012 + A1:2013

-40 oC to +85 °C

-40 °C to +85 °C : T5

-40 °C to +70 °C : T6

-40 °C to +85 °

-40 °C to +70 °C : T6

-40 to +85°C: ic

-40°C to +75°C : T6

-40°C to +75°C : T6

-1 :

EN 60079-11 :

2012

-7 :

IEC 60079-31

2013

Conditions of Certification

FM Approval Spe ci f ic C o nd itions of Use

1) For Zone 2 installation with the 24V Power Supply, the installer shall

provide transient over-voltage protection external to the equipment

such that the voltage at the supply terminal of the equipment does not

exceed 140% of the voltage rating of the equipment.

2) The enclosure contains aluminum and is considered to present a

potential risk of ignition by impact or friction. Care must be considered

during installation and use to prevent impact or friction.

3) Painted surface of the enclosure may store electrostatic charge and

become a source of ignition in applications with a low relative humidity

less than approximately 30% relative humidity where the painted

surface is relatively free of surface contamination such as dirt, dust or

oil. Cleaning of the painted surface should only be done with a damp

cloth.

CSA, IECEx and ATE X Conditions of Certification

1) Under certain extreme circumstances, the non-metallic parts

incorporated in the enclosure of this equipment may generate an

ignition-capable level of electrostatic charge. Therefore, the

equipment shall not be installed in a location where the external

conditions are conducive to the build-up of electrostatic charge on

such surfaces. In addition, the equipment shall only be cleaned with

a damp cloth.

2) The enclosure is manufactured from low copper aluminum alloy. In

rare cases, ignition sources due to impact and friction sparks could

occur. This shall be considered during installation, particularly if the

equipment is installed in a zone 0 location.

Apparatus Marked with Multiple Types of Protection

The user must determine the type of protection required for installation of the equipment.

The user shall then check the box [�] adjacent to the type of protection used on the

equipment certification nameplate. Once a type of protection has been checked on the

nameplate, the equipment will not be reinstalled using any of the other certification types.

Ex ia IIC T4 Ga

Ex ic IIC T4 Gc

Ex db [ia Ga] IIC T6...T5 Gb

Non Incendive:

IECEx

Radio Compliance Information

The SmartLine Wireless pressure transmitter uses a low powered ISA100 2.4GHz

radio to communicate with the Radio Infrastructure and Gateway devices that are

connected to a wired DCS network. The wireless transmit power is set at the factory

depending on the destination country. The combination of allowed transmit power and

antenna gains result in a maximum EIRP of 26 dBm = 398 mW transmitted power.

This power is limited depending on destination country.

Federal

Commission

(FCC)

(IC)

Ex ec [ia] IIC T6..T5

IEC 60079-0 : 2017

Table B4: Radio Certifications

FCC ID:

S5751454941

IC:

573WI51454941

-40 to +85°C: ic

-40°C to +85°C : T5

-40°C to +75°C : T6

-40°C to +75°C : T6

IEC 60079-1

: 2014

IEC 60079-7

: 2015

with part 15 of the FCC rules. Operation is

subject to the following two conditions.

(1) this device may not cause harmful

interference, and

(2) this device must accept any interference

received, including interference that may

ensure that the antenna is located or pointed

such that it does not emit RF fields in excess

of Health Canada limits for the general

population; consult Safety Code 6, obtainable

from Health Canada’s web site www.hc-

assessed and is in compliance with the

Radio Equipment Directive (RED)

IEC 60079-11 :

2011

IEC 60079-31 :

2013

Radio Frequency (RF) st at em ent

To comply with FCC’s and Industry Canada’s RF exposure requirements, the

following antenna installation and device operating configurations must be satisfied.

• Remote Point-to-Multi-Point antenna(s) for this unit must be fixed and mounted

on outdoor permanent structures with a separation distance between the

antenna(s) of greater than 20cm and a separation distance of at least 20cm

from all persons.

• Remote Fixed Point–to-Point antenna(s) for this unit must be fixed and

mounted on outdoor permanent structures with a separation distance between

the antenna(s) of greater than 20cm and a separation distance of at least

100cm from all persons.

• Furthermore, when using integral antenna(s) the SmartLine Wireless

Transmitter unit must not be co-located with any other antenna or transmitter

device and have a separation distance of at least 20cm from all persons.

SmartLine Wireless Transmitter Quick Start Installation Guide 5

Page 6

34-SW-25-02, Rev.1

2019 Honeywell International Inc.

ATTENTION

ASIA PACIFIC (TAC) hfs-tac-support@honeywell.com

EMEA, Phone: + 80012026455 or +44 (0)1202645583. FAX: +44 (0) 1344 655554

AMERICAS, Honeywell Process Solutions,

European Union restriction

The SmartLine Wireless Transmitters are in conformity with the applicable standards

as required by the Radio Equipment Directive (RED) 2014/53/EU.

SmartLine Wireless units must be professionally installed

FCC compliance statem en ts

• This device complies with Part 15 of FCC Rules and Regulations. Operation is

subject to the following two conditions: (1) This device may not cause harmful

interference and (2) this device must accept any interference received,

including interference that may cause undesired operation.

• This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate

radiofrequency energy and, if not installed and used in accordance with these

instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference

at own expense.

• Intentional or unintentional changes or modifications must not be made to the

SmartLine Wireless Transmitters unless under the express consent of the

party responsible for compliance. Any such modifications could void the user’s

authority to operate the equipment and will void the manufacturer’s warranty.

IC compliance statements

• To reduce potential radio interference to other users, the antenna type and its

gain should be so chosen that the equivalent isotropic radiated power (EIRP)

is not more than that permitted for successful communication.

• Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

• This Class A digital apparatus complies with Canadian ICES-003.

French: Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective

materials and faulty workmanship. Contact your local sales office for

warranty information.

If warranted goods are retu rn ed to Hon e ywell du ring the period of

coverage, Honeywel l will rep air or re pla c e wit hou t char ge th os e item s it

finds defective. The foregoing is Buyer's sole remedy and is in lieu of all

other warranties, expr ess e d or implied, including those of

merchantability and fitness for a particular purpose. Specifications may

change without notice. The information we supply is believed to be

accurate and reliable as of this printing. However, we assume no

responsibility for its use .

While we provide application assistance personally, through our

literature and the Honeywell web site, it is up to the customer to

determine the suitability of the product in the application.

Sales and Service

For application assistance, current specifications, pricing, or

nearest Authorized Distributor, contact one of the offices below.

Australia Honeywell Limited, Phone: +(61) 7-3846 1255, FAX: +(61) 7-3840 6481

Toll Free 1300-36-39-36, Toll Free Fax: 1300-36-04-70

China – PRC – Shanghai, Honeywell China Inc. Phone: (86-21) 5257-4568,

Fax: (86-21) 6237-2826

Singapore, Honeywell Pte Ltd. Phone: +(65) 6580 3278. Fax: +(65) 6445-3033

South Korea, Honeywell Korea Co Ltd. Phone:+(822)799 6114. Fax:+(822) 792

9015

Email: (Sales) sc-cp-apps-salespa62@honeywell.com

or (TAC) hfs-tac-support@honeywell.com

Phone: (TAC) 1-800-423-9883 or 215/641-3610. (Sales) 1-800-343-0228.

Email: (Sales) FP-Sales-Apps@Honeywell.com

or (TAC) hfs-tac-support@honeywell.com

name of the

For more information

To learn more about SmartLine Transmitters,

visit www.honeywellprocess.com

Or contact your Honeywell Account Manager

Process Solutions

Honeywell

1250 W Sam Houston Pkwy S

Houston, TX 77042

Honeywell Control Systems Ltd

Honeywell House, Skimped Hill Lane

Bracknell, England, RG12 1EB

Shanghai City Centre, 100 Jungi Road

Shanghai, China 20061

www.honeywellprocess.com

December 2019

Loading...

Loading...