Page 1

TILLER

F720

OWNER'S MANUAL

MANUEL DE L'UTILISATEUR

BEDIENUNGSANLEITUNG

MANUAL DE EXPLICACIONES

Page 2

Thank you for purchasing a Honda tiller.

This manual covers operation and maintenance of the F720 tiller.

All information in this publication is based on the latest product

information available at the time of printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written

permission.

This manual is considered a permanent part of the tiller and it must

stay with the tiller if resold.

Pay special attention to statements preceded by the following words:

Indicates a strong possibility of severe personal injuly or

death if instructions are not followed.

Indicates a possibility of personal injury or equipment

damage if instructions are not followed.

Gives helpful information.

If a problem should arise, or if you have any questions about your tiller,

consult an authorized Honda tiller dealer.

The Honda tiller is designed to give safe and dependable service if

operated according to instructions. Read and understand the Owner’s

Manual before operating the tiller. Failure to do so could result in

personal injuly or equipment damage.

The illustration may vary according to the type.

1

Page 3

CONTENTS

High altitude operation

...................................................................1. SAFETY INSTRUCTIONS . 3

.............................................................2. SAFETY LABEL LOCATIONS . 8

..............................................................................CE mark location . 9

.....................................................3. COMPONENT IDENTIFICATION . 10

................................................................4. PRE-OPERATION CHECK . 12

.................................................................5. STARTING THE ENGINE . 16

.........................................................................6. TILLER OPERATION . 22

.................................................................7. STOPPING THE ENGINE . 29

................................................................................8. MAINTENANCE . 31

...........................................................9. TRANSPORTING/STORAGE . 43

......................................................................10. TROUBLESHOOTING . 44

.............................................................................11. SPECIFICATIONS . 45

............12. MAJOR Honda DISTRIBUTOR ADDRESSES IN EUROPE . 46

2

Page 4

SAFETY INSTRUCTIONS1.

To ensure safe operation

−

For your safety and the safety of others, pay special attention to these

precautions:

Honda tiller is designed to give safe and dependable

service if operated according to instructions.

Read and understand the Owner’s Manual before operating the tiller. Failure to do so could result in personal injury

or equipment damage.

Exhaust gas contains poisonous carbon monoxide.

Never run the tiller in an enclosed area.

Be sure to provide adequate ventilation.

When installed in ventilated protection are to be observed.

The rotating tines are sharp and they turn at high speed.

Accidental contact can cause serious injury.

Keep your hands and feet away from the tines while

engine is running.

Stop the engine and disengage the tines clutch before

inspection or maintenance of tines.

Disconnect the spark plug cap to prevent any possibility

of accidental starting. Wear heavy gloves to protect your

hands from the tines when cleaning the tines or when

inspecting or replacing the tines.

Operator responsibility

Keep the tiller in good operating condition. Operating a tiller in poor

or questionable condition could result in serious injury.

Be sure all safety devices are in working order and warning labels

are in place. These items are installed for your safety.

Be sure the safety covers (fan cover, recoil starter cover) are in place.

Know how to stop the engine and tines quickly in case of

emergency. Understand the use of all controls.

Keep a firm hold on the handlebars. They may tend to lift during

clutch engagement.

3

Page 5

To ensure safe operation

Operator responsibility

Read the owner’s manual carefully. Be familiar with the controls

and their proper use of the tiller.

Use the tiller for the purpose it is intended that is, cultivating the soil.

Any other use could be dangerous or damage the equipment,

especially never use it to cultivate soil containing rocks, stones,

wires and any other hard materials.

Never allow children or people unfamiliar with this owner’s manual

to use the tiller. Local regulations may restrict the age of the

operator.

Before each use, visually inspect the tiller including parts for any

wear, damage and looseness. If necessary, replace the damaged

partsasanassembly.

Keep in mind that the owner or user is responsible for accidents or

damage, occurring to other people or their property.

In the event of hire use, be sure that operational explanations are

given in the presence of the user.

Keep your hands and feet away from the tines while the engine is

running.

Allowing anyone to operate this tiller without proper instruction

may result in injury.

Wear sturdy, full-coverage footwear. Operating this tiller barefoot or

with open toe shoes or sandals increases your risk of injury.

Dress sensibly. Loose clothing may get caught in moving parts,

increasing your risk of injury.

Be alert. Operating this tiller when you are tired, ill or under the

influence of alcohol or drugs may result in serious injury.

Keep all persons and pets away from the tilling area.

Be sure drag bar is in place and properly adjusted.

Do not change the engine governor settings or overspeed the

engine.

Start the engine carefully according to the instructions in this

manual, keeping your feet away from the tines.

When starting the engine, keep your feet away from the tines.

Avoid operating the tiller at night or in a bad weather of poor

visibility, because there is much possibility of accident.

Walk, never run during operation.

When taking backward steps during operation, pay special attention

to people and obstacles behind the operator.

Before transporting or hoisting the tiller, make sure that the engine

is stopped.

−

4

Page 6

To ensure safe operation

Operator responsibility

Stop the engine in the following cases:

−

Whenever you leave the tiller unattended.

−

Before refueling

When stopping the engine, move the throttle lever to the LOW

position, then turn the engine switch OFF. If the fuel valve is

equipped on the tiller, be sure to turn the fuel valve OFF.

Keep all nuts, bolts and screws tight to be sure the tiller is in safe

working condition. Regular maintenance is an essential aid to user’s

safety and retaining a high level of performance.

Never store the tiller with gasoline in the tank inside a building

where fumes may reach an open flame, spark or high temperature

source.

Allow the engine to cool before storing in any enclosure.

To reduce the fire hazard, keep the tiller especially the engine,

muffler, the gasoline storage area as well, free of grass, leaves, or

excessive grease.

Do not leave containers of vegetable matters in or near a building.

If the fuel tank has to be drained, this should be done outdoors, with

a cold engine.

Replace the worn or damaged parts for safety.

Child safety

Keep children indoors and supervised at all times when any outdoor

power equipment is being used nearby. Young children move

quickly and are attracted especially to the tiller and the tilling

activity.

Never assume children will remain where you last saw them. Be

alert and turn the tiller off if children enter the area.

Children should never be allowed to operate the tiller, even under

adult supervision.

−

Thrown object hazard

Objects hit by the rotating tines can be thrown from the tiller with

great force, and may cause serious injury.

Before tilling, clear the tilling area of sticks, large stones, wire, glass,

etc. Till only in daylight.

Always inspect the tiller for damage after striking a foreign object.

Repair or replace any damaged parts before continuous use.

Pieces thrown from worn or damaged tines can cause serious injury.

Always inspect the tines before using the tiller.

5

Page 7

To ensure safe operation

Fire and burn hazard

Gasoline is extremely flammable, and gasoline vapor can explode.

Use extreme care when handling gasoline. Keep gasoline out of reach

of children.

Add fuel before starting the engine. Never remove the cap of the

fuel tank or add gasoline while the engine is running or when the

engine is hot.

Refuel in a well-ventilated area with the engine stopped.

Refuel outdoors only and do not smoke while refueling or handling

fuel.

Allow the engine to cool before refueling. Fuel vapor or spilled fuel

may ignite.

The engine and exhaust system become very hot during operation

and remain hot for a while after stopping. Contact with hot engine

components can cause burn injuries and can ignite some materials.

Avoid touching a hot engine or exhaust system.

Allow the engine to cool before performing maintenance or storing

the tiller indoors.

Tighten all fuel tanks and container caps securely.

Store fuel in containers specifically designed for this purpose.

If gasoline is spilled, do not attempt to start the engine but move the

tiller away from the area of spillage and avoid creating any source

of ignition until gasoline vapors have dissipated.

−

6

Page 8

To ensure safe operation

Carbon monoxide poisoning hazard

Exhaust contains poisonous carbon monoxide, a colorless and

odorless gas. Breathing exhaust can cause loss of consciousness and

may lead to death.

If you run the engine in an area that is confined or even partially

enclosed, the air you breathe could contain a dangerous amount of

exhaust gas. To keep exhaust gas from building up, provide

adequate ventilation.

Replace faulty muffler.

Do not operate the engine in a confined space where dangerous

carbon monoxide fumes can collect.

Operation on slope

When tilling on slopes, keep the fuel tank less than half full to

minimize fuel spillage.

Till across the slope (at equally spaced intervals) rather than up and

down it.

Be very careful when changing the direction of the tiller on a slope.

Do not use the tiller on a slope of more than 10°.

The maximum safe grade angle shown is for reference purpose only

and should be determined according to the type of the tool. Before

starting the engine, check that the tiller is not damaged and in good

condition. For your safety and safety of others, exercise extreme care

when using the tiller on up or down hill.

−

7

Page 9

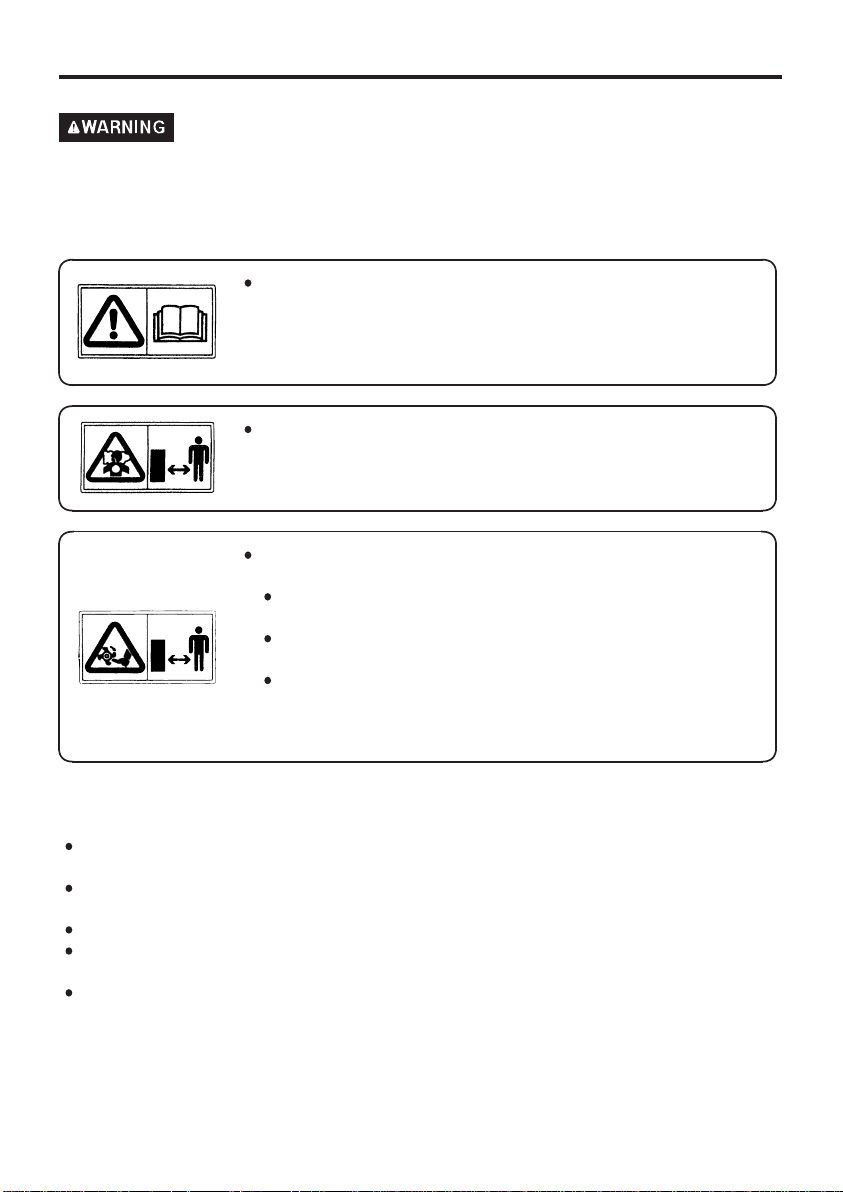

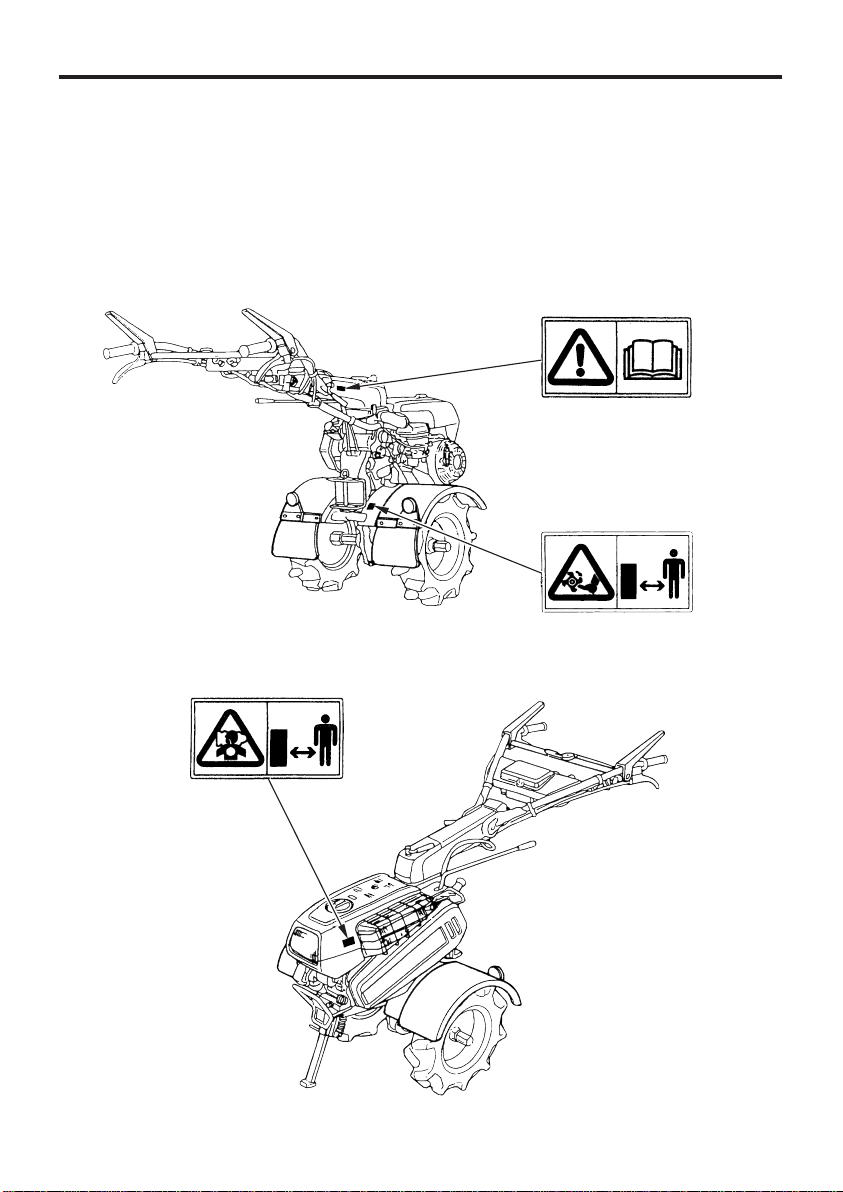

SAFETY LABEL LOCATIONS2.

These labels warn you of potential hazards that can cause serious

injury. Read the labels and safety notes and precautions described in

this manual carefully.

If a label comes off or becomes hard to read, contact your Honda

dealer for a replacement.

READ OWNER’S MANUAL

CUTTING DANGER

8

EXHAUST CAUTION

Page 10

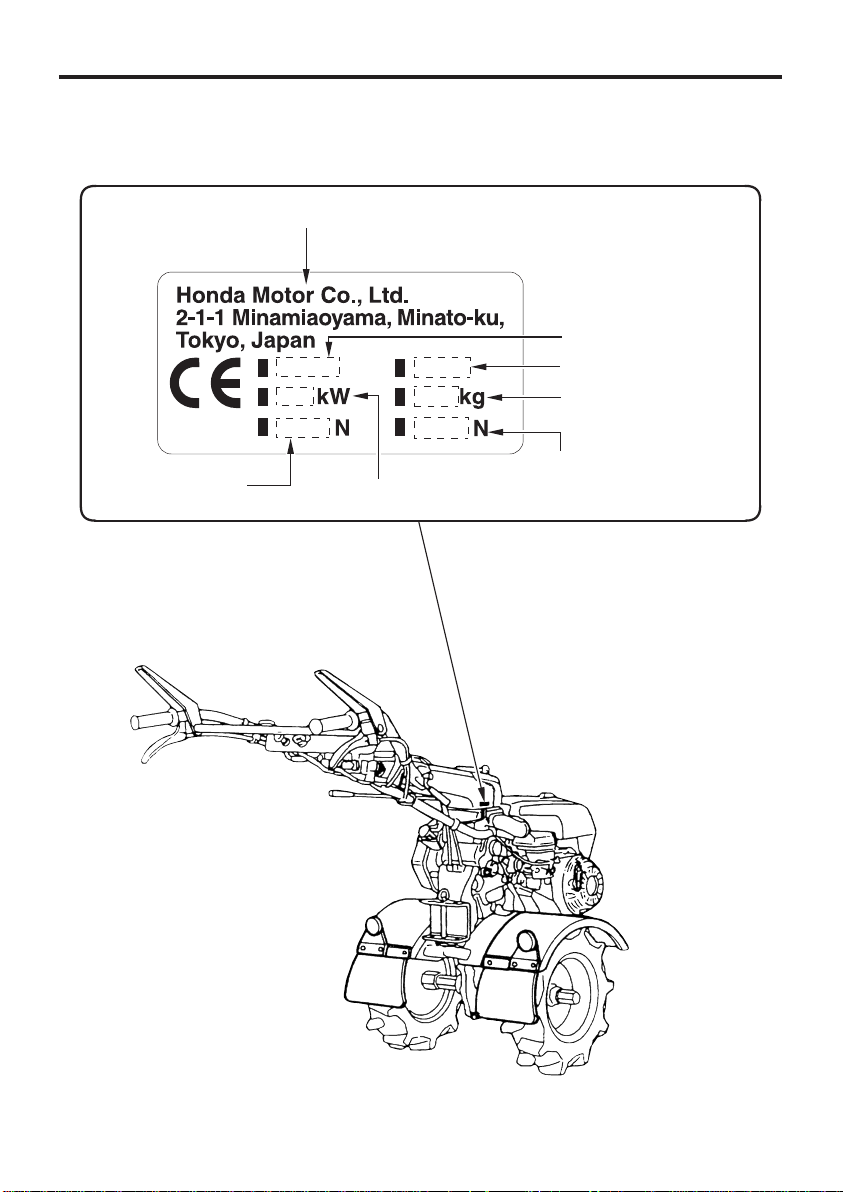

CE mark location

CE MARK

Maximum trailing

force of hitch

Manufacturer and address

Net power

Description code

Year of manufacture

Machine mass

(standard specification)

Maximum trailing

load of hitch

9

Page 11

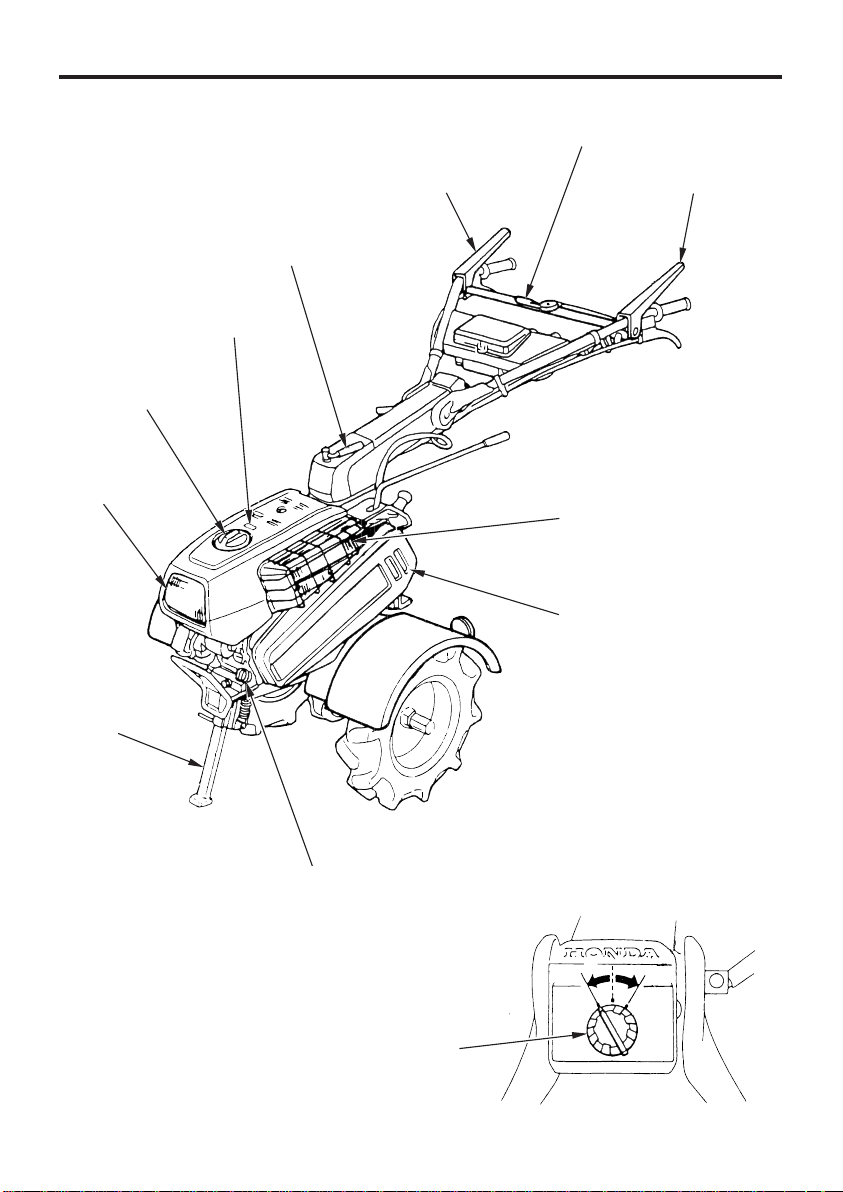

COMPONENT IDENTIFICATION3.

THROTTLE LEVER

FUEL LEVEL METER

FUEL TANK CAP

HEADLIGHT

STAND

MAIN CLUTCH LEVER

HANDLE ANGLE ADJUSTER

MAIN CLUTCH LEVER

MUFFLER

BELT COVER

10

ENGINE OIL FILLER CAP

ENGINE SWITCH

(Except for EE Type)

(EE Type)

Page 12

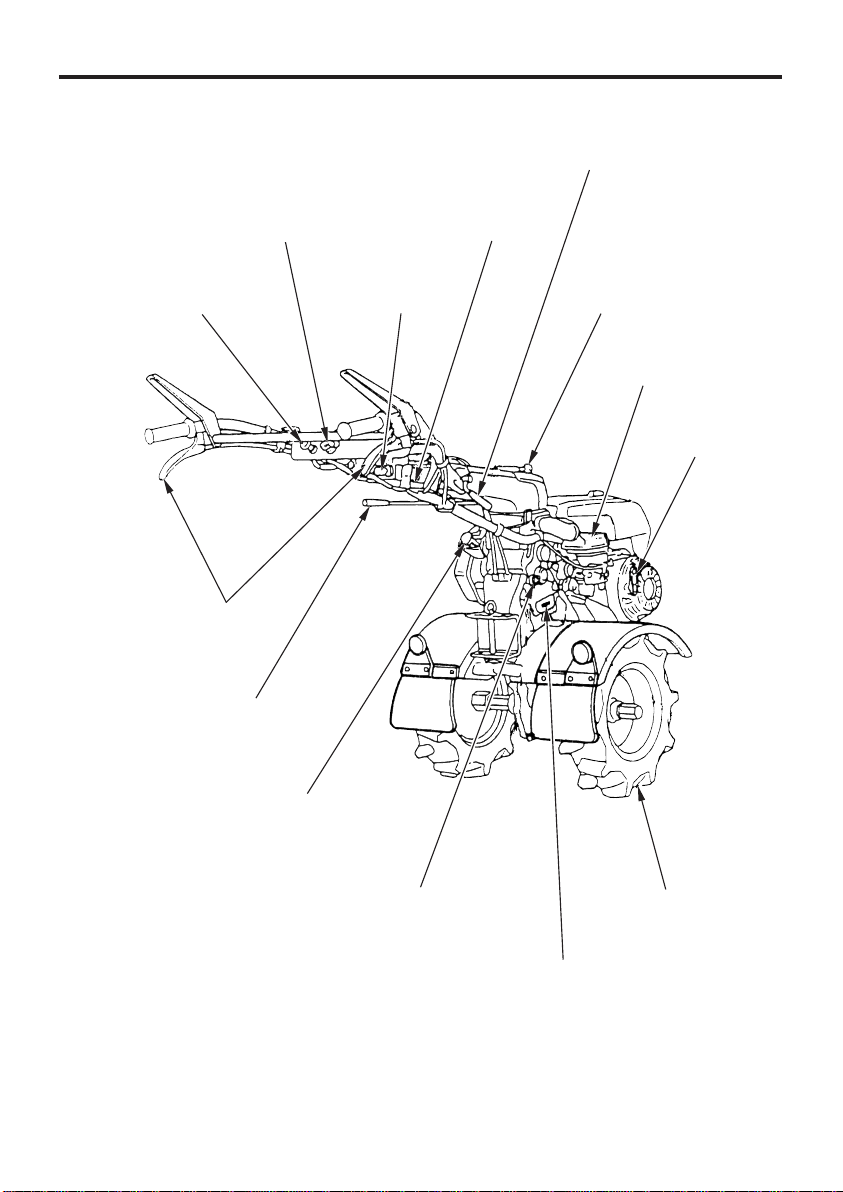

HANDLE HEIGHT ADJUSTER

ENGINE SWITCH

CHOKE KNOB

SIDE CLUTCH LEVERS

MAIN SHIFT LEVER

SUB SHIFT LEVER

BATTERY

LIGHT SWITCH

HANDLE ANGLE ADJUSTER

AIR CLEANER

STARTER GRIP

TRANSMISSION OIL FILLER CAP

FRAME SERIAL NUMBER

TIRE

11

Page 13

PRE-OPERATION CHECK4.

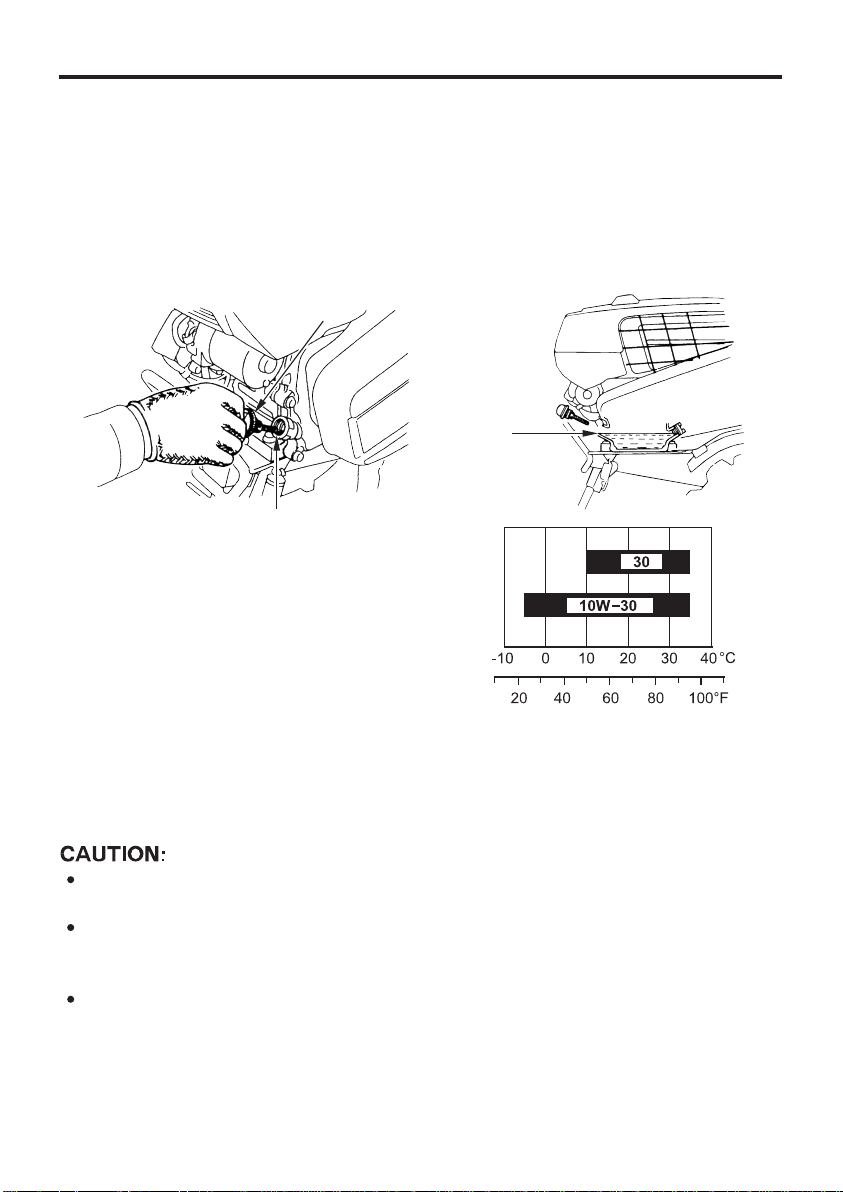

Engine oil

1.

Be sure to check the tiller on a level surface with the engine stopped.

Remove the oil filler cap and wipe the dipstick clean.

1.

Insert the dipstick into the oil filler neck, but do not screw it in.

2.

If the level is low, fill to the top of the oil filler neck with the recom-

3.

mended oil.

OOIILL FFIILLLLEERR CCAAPP

UPPER

LIMIT

OIL FILLER NECK

Use 4-stroke motor oil that meets

or exceeds the requirements for

API service classification SE or

later (or equivalent). Always check

theAPIservicelabelontheoil

container to be sure it includes

the letters SE or later (or

equivalent).

AMBIENT TEMPERATURE

SAE 10W-30 is recommended for general use. Other viscosities shown

in the chart may be used when the average temperature in your area is

within the indicated range.

Using nondetergent oil or 2-stroke engine oil will shorten the

engine’s service life.

Engine oil is a major factor affecting engine performance and

service life.

Non-detergent or vegetable oils are not recommended.

Running the engine with insufficient oil can cause serious engine

damage.

12

Page 14

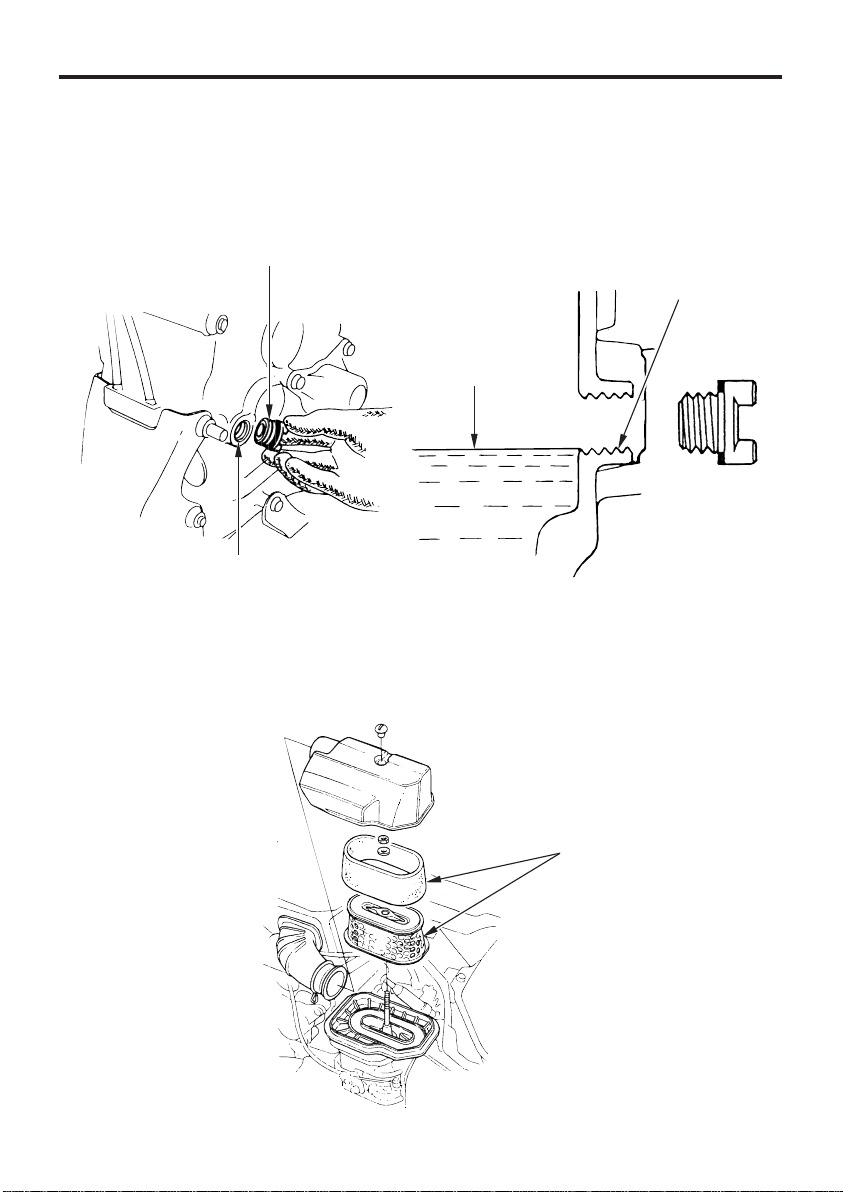

Transmission oil2.

Place the tiller on a level surface and remove the oil filler cap.

The oil should be level with the lower edge of the oil filler hole.

Add oil same as the engine oil (see page ) if the level is low.

12

TRANSMISSION OIL FILLER CAP

UPPER LIMIT

OIL FILLER HOLE

Air cleaner

3.

Check cleaner for dirt or obstruction of elements. (See page )

LOWER

EDGE OF THE OIL

FILLER HOLE

34

ELEMENTS

13

Page 15

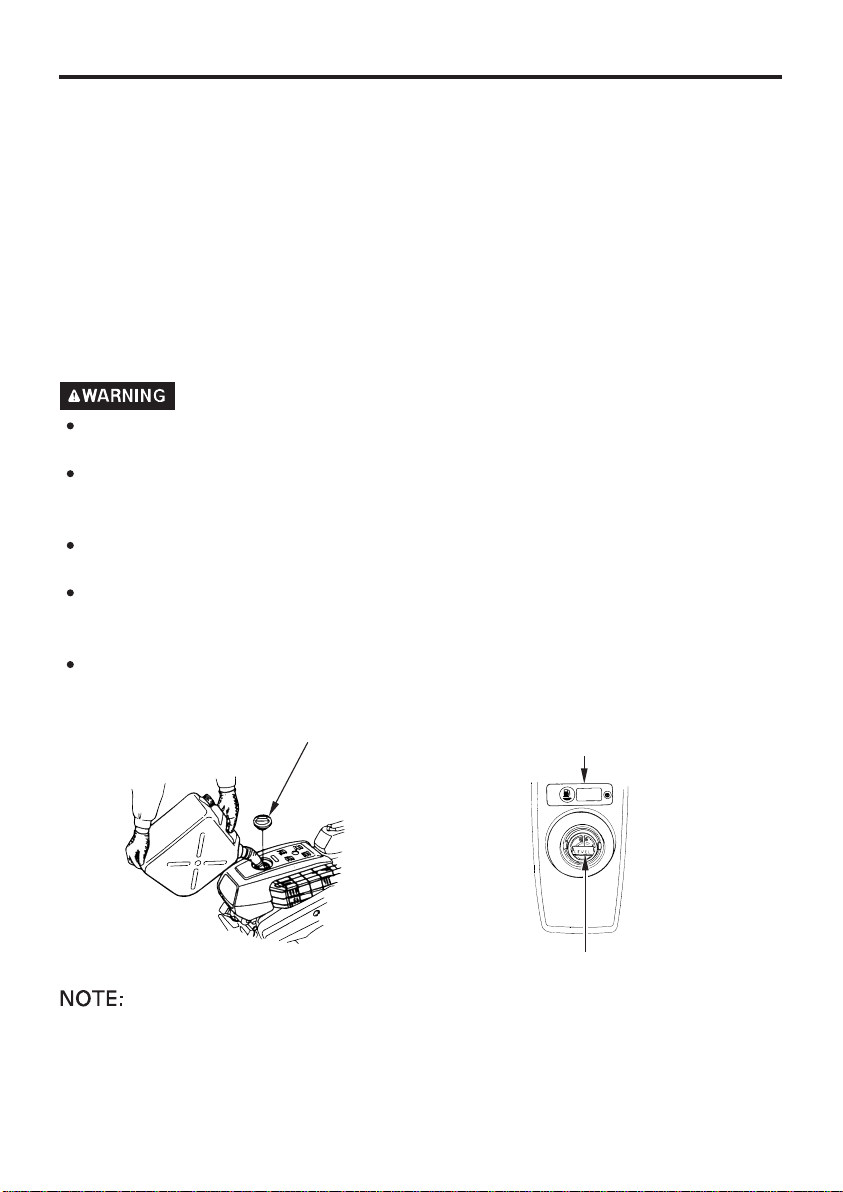

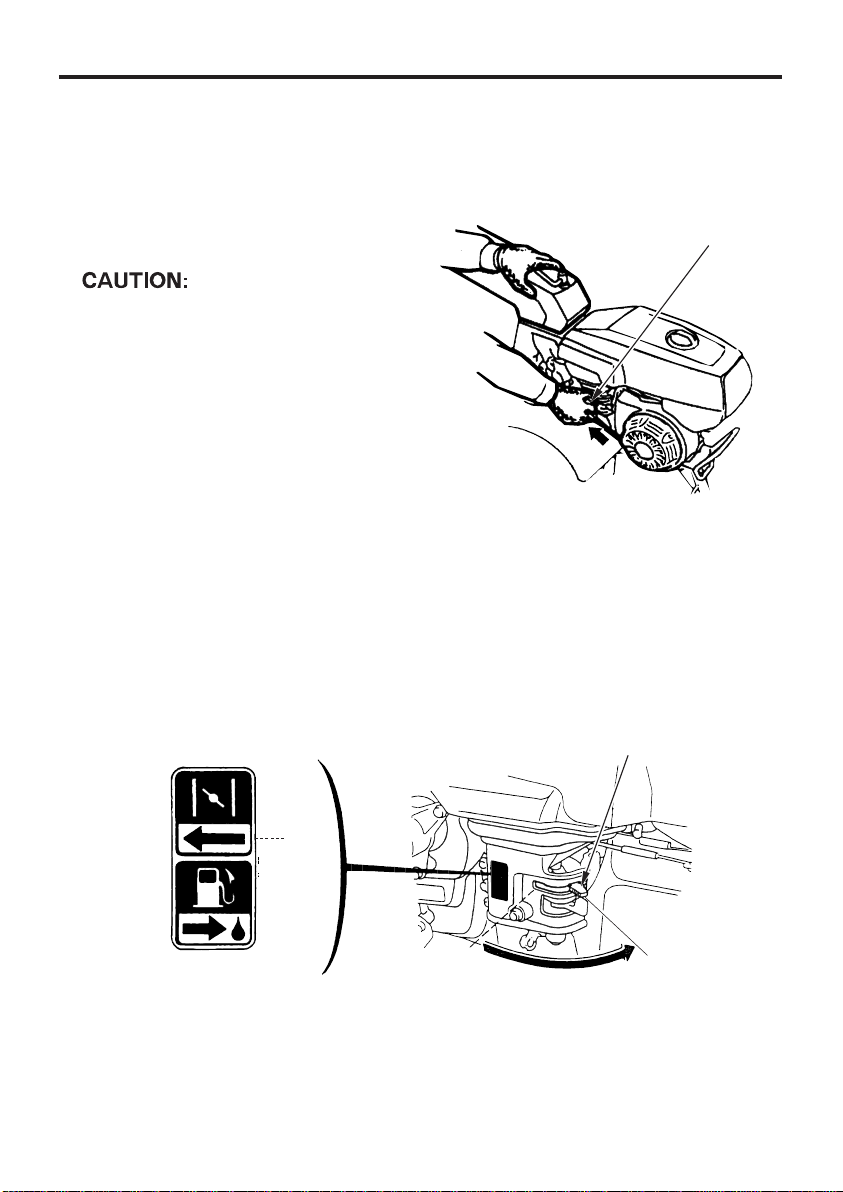

4.

Fuel

Remove the fuel tank cap and check the fuel level. Refill the tank if the

fuel level is low.

Use automotive unleaded gasoline with a Research Octane Number of

91 or higher (a Pump Octane Number of 86 or higher).

Never use stale or contaminated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

After refueling, tighten the fuel tank cap securely.

Gasoline is extremely flammable and is explosive under certain

conditions.

Refuel in a well-ventilated area with the engine stopped. Do not

smoke or allow flames or sparks in the area where the engine is

refueled or where gasoline is stored.

Do not overfill the fuel tank. After refueling, make sure the tank cap

is closed properly and securely.

Be careful not to spill fuel when refueling. Spilled fuel or fuel vapor

may ignite. If any fuel is spilled, make sure the area is dry before

starting the engine.

Avoid repeated or prolonged contact with skin or breathing of

vapor. KEEP OUT OF REACH OF CHILDREN.

FUEL TANK CAP

FUEL METER

FUEL LEVEL GAUGE

Gasoline spoils very quickly depending on factors such as light

exposure, temperature and time.

In worst cases, gasoline can be contaminated within 30 days.

Using contaminated gasoline can seriously damage the engine

(carburetor clogged, valve stuck).

14

Page 16

Such damage due to spoiled fuel is disallowed from coverage by the

warranty.

To avoid this please strictly follow these recommendations:

Only use specified gasoline (see page ).

14

Use fresh and clean gasoline.

To slow deterioration, keep gasoline in a certified fuel container.

If long storage (more than 30 days) is foreseen, drain fuel tank and

carburetor (see page ).

35

Gasolines containing alcohol

If you decide to use a gasoline containing alcohol (gasohol), be sure it’s

octane rating is at least as high as that recommended by Honda. There

are two types of ‘‘gasohol’’: one containing ethanol, and the other

containing methanol.

Do not use gasohol that contains more than 10% ethanol. Do not use

gasoline containing methanol (methyl or wood alcohol) that does not

also contain cosolvents and corrosion inhibitors for methanol.

Never use gasoline containing more than 5% methanol, even if it has

cosolvents and corrosion inhibitors.

Fuel system damage or engine performance problems resulting

from the use of gasoline that contains alcohol is not covered under

the warranty.

Honda cannot endorse the use of gasoline containing methanol

since evidence of its suitability is as yet incomplete.

Before buying gasoline from an unfamiliar station, first determine if

the gasoline contains alcohol; if it does, find out the type and

percentage of alcohol used.

If you notice any undesirable operating symptoms while using a

gasoline that contains alcohol, or one that you think contains

alcohol, switch to a gasoline that you know does not contain alcohol.

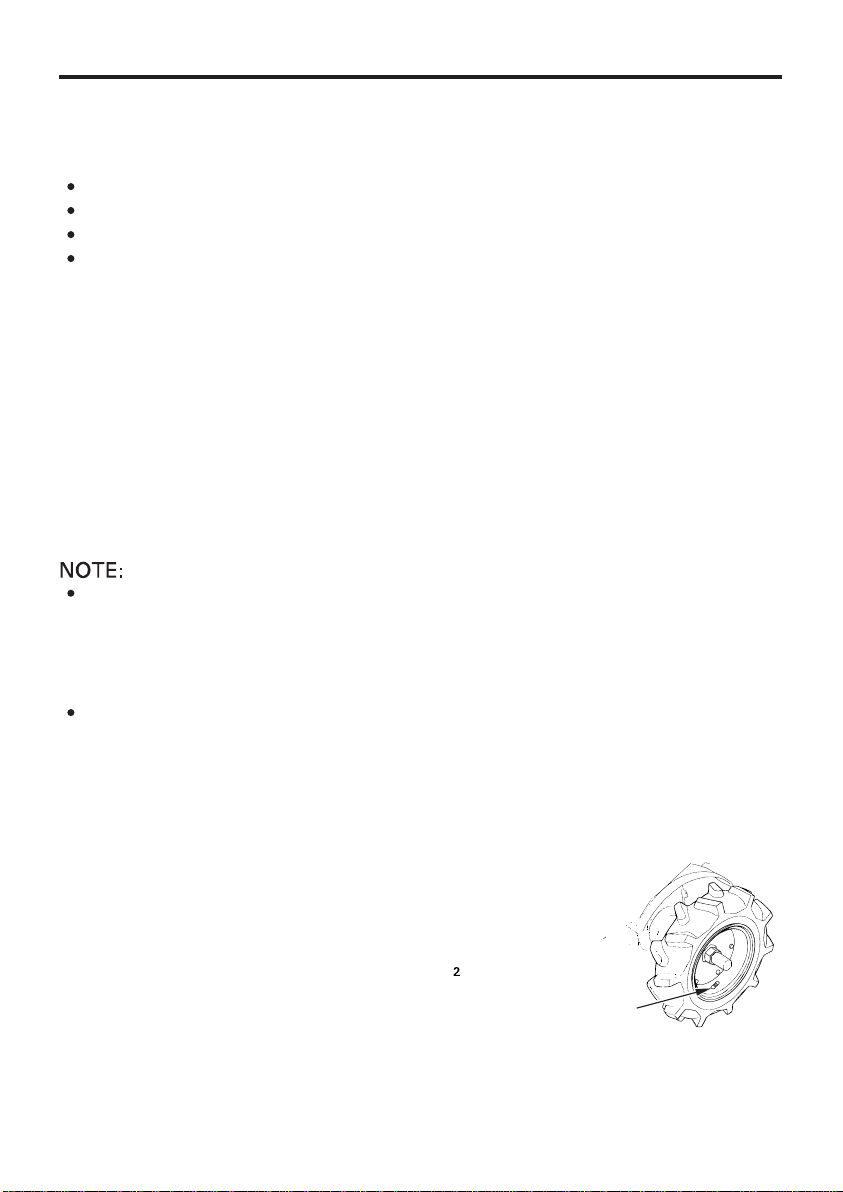

Tire pressure5.

Check tire pressures. lmproper inflation can

reduce both tire life and load carrying capacity.

TIRE SIZE: 4.00-8

TIRE PRESSURES: 118 kPa (1.2 kgf/cm

Tools and Attachments

6.

for DE and GE types

, 17 psi)

TIRE

VALVE

To install a tool or attachment on the tiller, follow the instructions

furnished with the tool or attachment. Ask your Honda dealer for

advice if you encouter any problem or difficulty in installing a tool or

attachment.

15

Page 17

STARTING THE ENGINE5.

With recoil starter

Be sure the clutch is disengaged and the shift lever is in the neutral

position to prevent sudden uncontrolled movement when the engine

starts.

The clutch is engaged by holding in the clutch lever and disengaged

by releasing the lever.

Turn the fuel valve ON. Check for tighteness of drain knob.

1.

FUEL VALVE

ON

DRAIN KNOB

In cold weather and when the engine is cold, move the choke lever

2.

ON

to the CLOSE position.

Do not use the choke if the engine is warm or the air temperature is

high.

CHOKE LEVER

CLOSE

CLOSE

16

Page 18

Turn the engine switch ON.

3.

ON

ON

OFF OFF

ENGINE SWITCH

ENGINE SWITCH

ON

OFF

(EE Type)

Align the mark ‘‘ ’’ on the throttle lever with the mark ‘‘ ’’ as

4.

△○

(Except for EE Type)

shown. (START position)

HIGH

START

THROTTLE LEVER

LOW

17

Page 19

Hold the handle post with your

5.

left hand and pull the starter

grip lightly until you feel

resistance, then pull the starter

grip briskly in the direction of

the arrow as shown.

STARTER GRIP

Do not allow the starter grip to

snap back against the engine.

Return it gently to prevent

damage to the starter.

DDiirreeccttiioonn

ttoo ppuullll

Let the engine warm up for several minutes. If the choke has been

6.

pulled out to the CLOSE position, return it gradually to the OPEN

position as the engine warms up.

18

CHOKE LEVER

OPEN

OPEN

Page 20

With electric starter (EE Type)

Turn the fuel valve to the ON position.

1.

Check for tighteness of drain knob.

FUEL VALVE

DRAIN KNOB

In cold weather and when the engine is cold, pull the choke knob to

2.

the CLOSE position.

CHOKE KNOB

CLOSE

19

Page 21

Align the mark ‘‘ ’’ on the throttle lever with the mark ‘‘ ’’ as

3.

△○

shown. (START position)

HIGH

START

LOW

Turn the engine switch to START and hold it there until the engine

4.

THROTTLE LEVER

starts.

Do not use the starter motor for more than 5 seconds. If the engine

fails to start, release the key, and wait at least 10 seconds before

operating the starter motor again.

The battery will automatically recharge while the tiller is operated. If

the tiller is not operated frequently enough to keep the battery

charged, there will be a decrease in starter motor speed. If the

battery is too discharged to run the starter motor, use the recoil

starter.

ENGINE SWITCH

START

OONN

OOFFFF

After the engine starts, let the engine switch return to ON.

5.

ST

ART

OONN

20

Page 22

Let the engine warm up for several minutes. If the choke has been

6.

pulled out to the CLOSE position, return it gradually to the OPEN

position as the engine warms up.

CHOKE KNOB

OPEN

High altitude operation

At high altitude, the standard carburetor air-fuel mixture will be

excessively rich. Performance will decrease, and fuel consumption will

increase.

High altitude performance can be improved by specifications to the

carburetor. If you always operate the tiller at altitude higher than

1,500 m (5,000 feet) above sea level, have your authorized Honda

dealer perform these carburetor modifications.

Even with suitable carburetor jetting, engine horsepower will decrease

approximately 3.5 % for each 300 m (1,000 feet) increase in altitude.

The effect of altitude on horsepower will be greater than this if no

carburetor modification is made.

Operation of the tiller at an altitude lower than the carburetor is jetted

for may result in reduced performance, overheating, and serious engine damage caused by an excessively lean air-fuel mixture.

21

Page 23

TILLER OPERATION6.

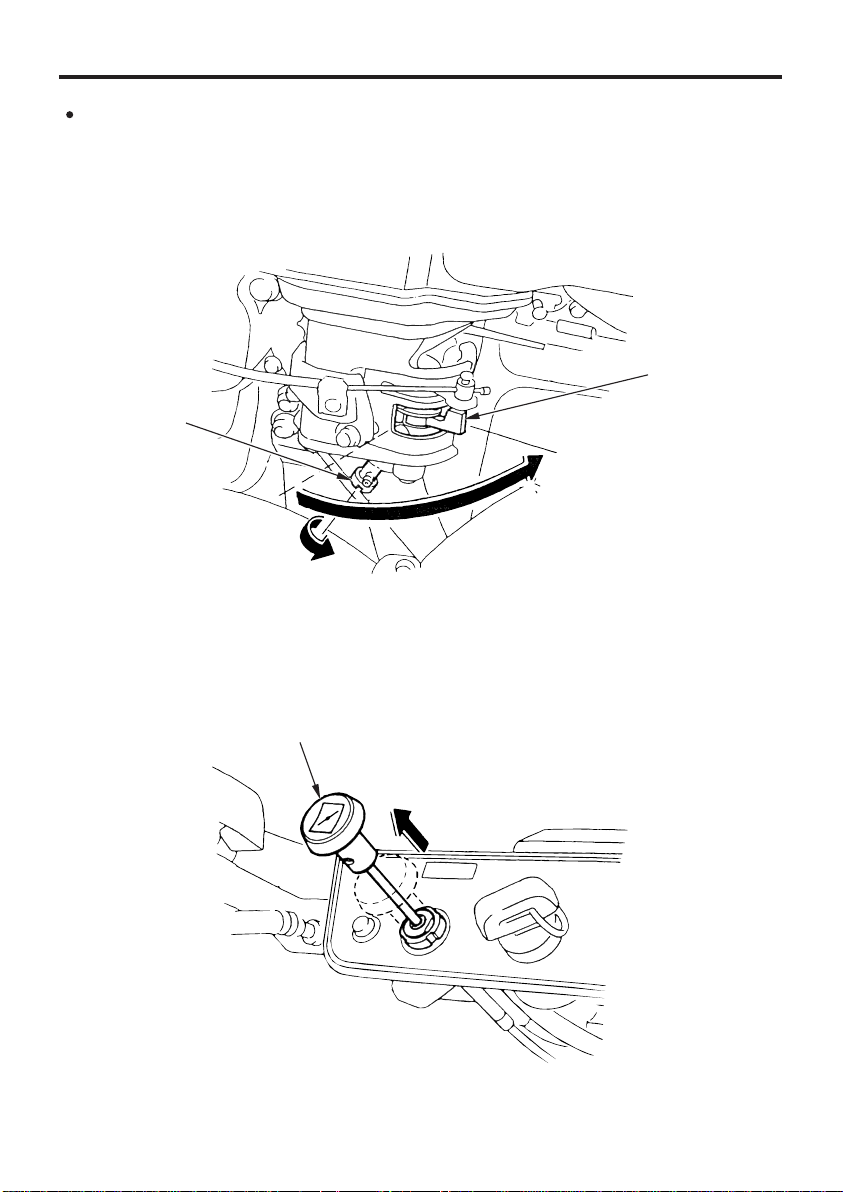

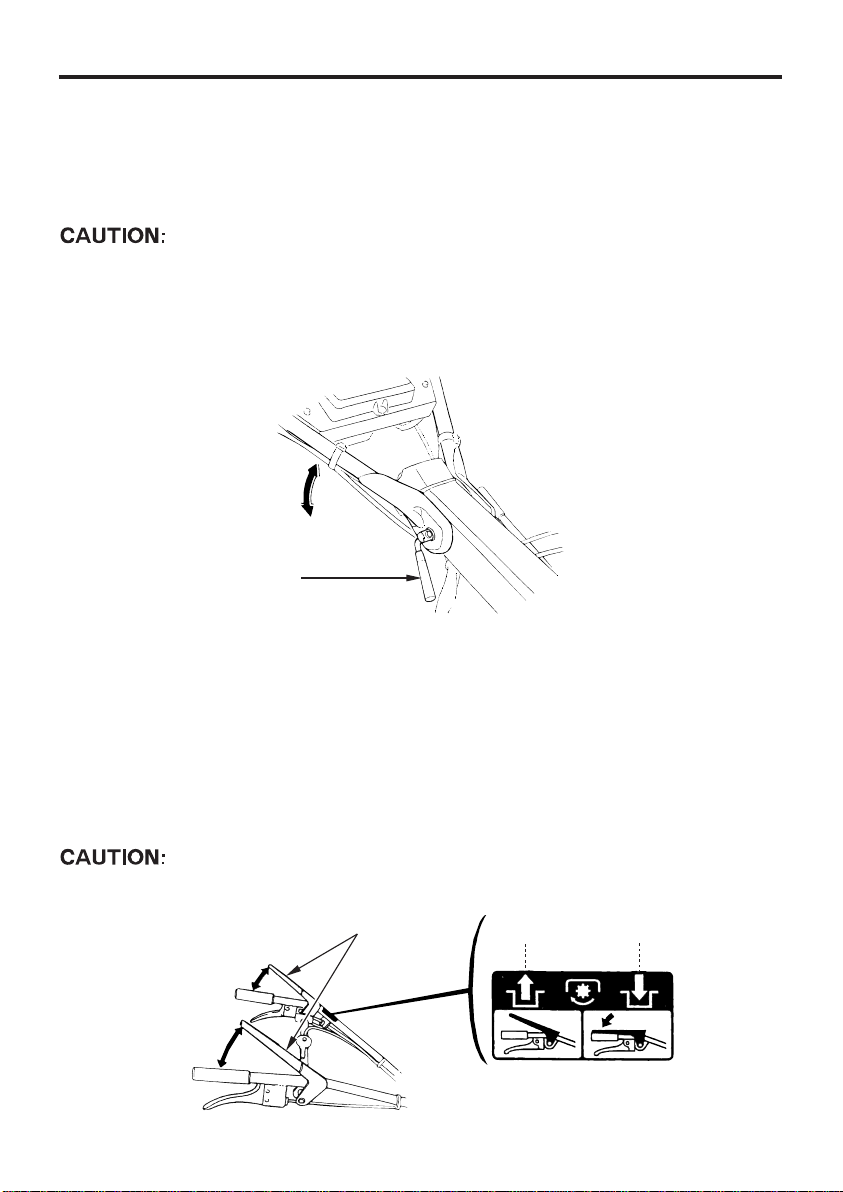

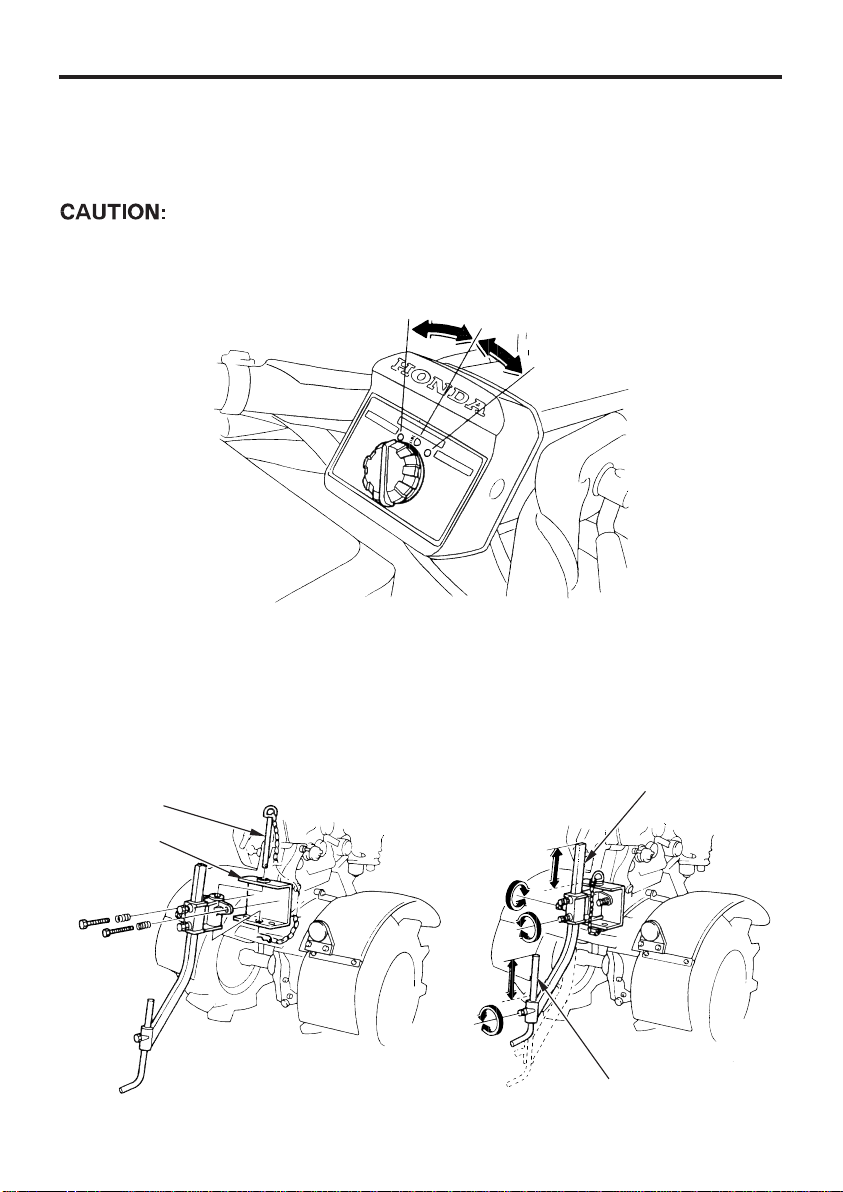

Handle angle adjustment1.

The handle can be adjusted at four different angles in either

1.

direction.

To adjust, loosen the handle angle adjuster and turn the handle

column to the required position. After adjustment, tighten the

adjuster securely.

LOOSEN

TIGHTEN

HANDLE ANGLE ADJUSTER

When the handle column is swung to the left, also turn the shift

2.

lever not to interfere with the handle column. Pull the main shift

lever up to release it from the change cover and turn clockwise.

HANDLE COLUMN

CHANGE COVER

MAIN SHIFT LEVER

22

Page 24

Handlebar height adjustment

2.

The handle position should be adjusted to suit the stature of the

operator and work condition.

Before adjusting the handlebar, place the tiller on the firm level

ground to prevent the handle from collapsing accidentally.

To adjust the handlebar height, loosen the adjuster, select the

appropriate position and tighten the adjuster.

LOOSEN

TIGHTEN

ADJUSTER

Main clutch operation

3.

The clutch engages and disengages the power from the engine to the

transmission.

When the clutch lever is squeezed, the clutch is engaged and power is

transmitted. Squeeze the lever. The tool will be rotated.

When the lever is released, the clutch is disengaged and power is not

transmitted. Release the clutch lever. The tool will be stopped.

Reduce engine rpm before operating main clutch operation.

MAIN CLUTCH LEVERS

Disengaged

Engaged

Disengaged

Engaged

DISENGAGED

ENGAGED

23

Page 25

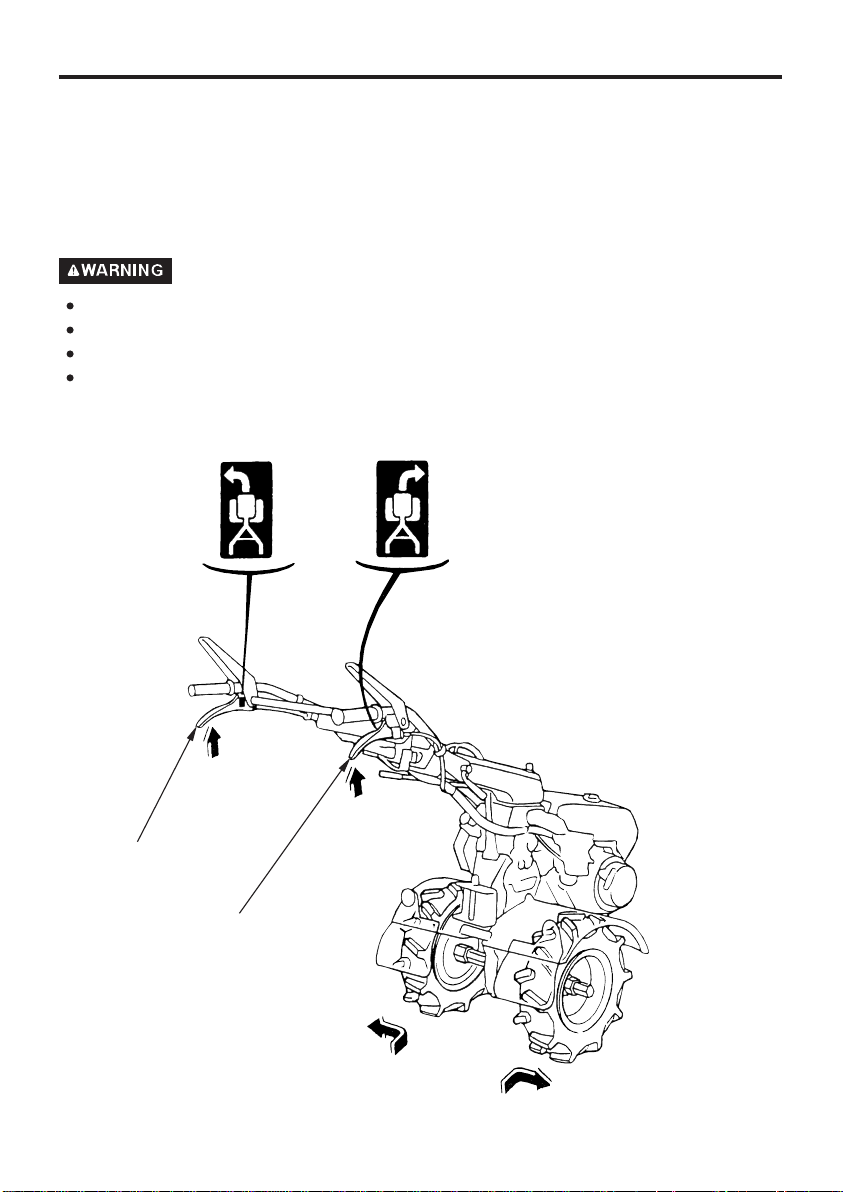

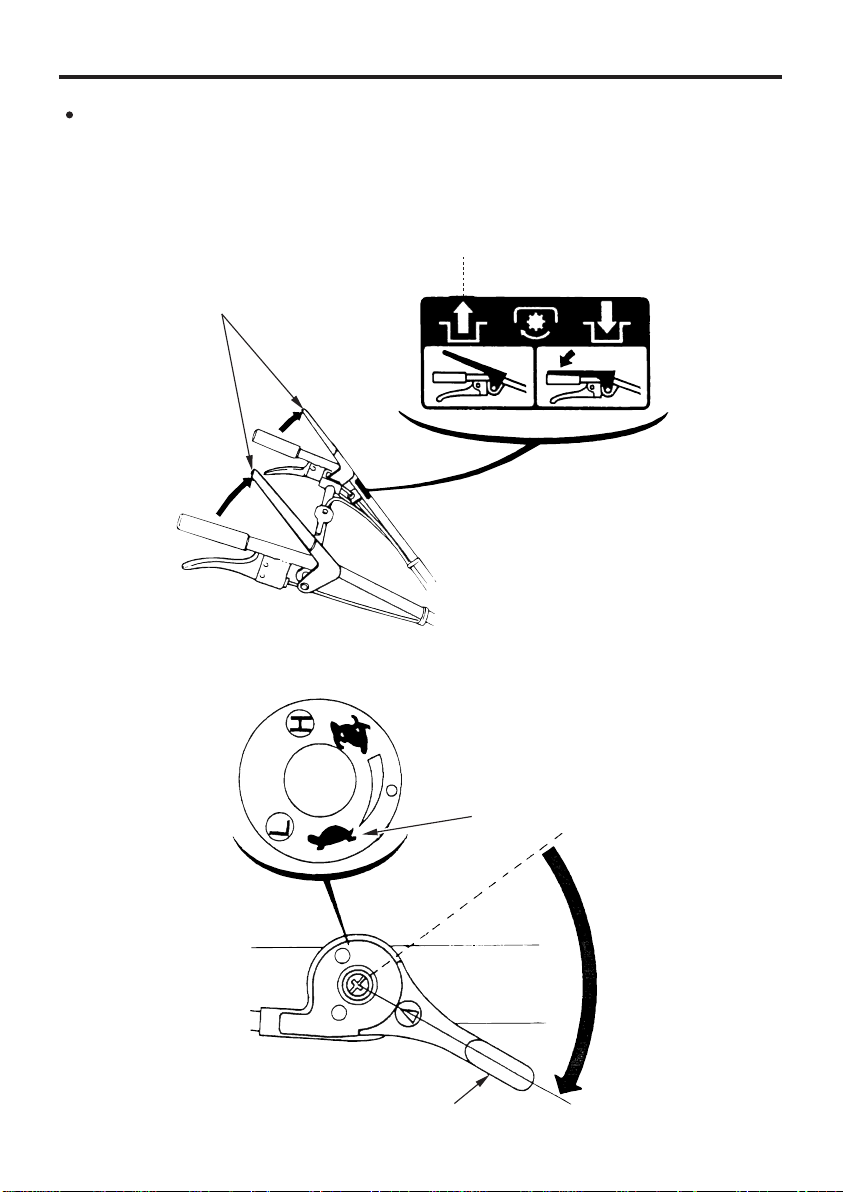

Side clutch operation

4.

The side clutches are used for turning the tiller to the right or to the left.

Turn the tiller to the RIGHT; Grasp the RIGHT side clutch.

Turn the tiller to the LEFT; Grasp the LEFT side clutch.

Reduce engine rpm before operating the side clutches.

Do not ever use the side clutches when pulling a trailer.

Avoid using the side clutches when going up or downhill.

In the case of heavy load trailing, side clutch operation should be

done carefully because it might be dangerous.

LEFT SIDE CLUTCH

24

RIGHT SIDE CLUTCH

Page 26

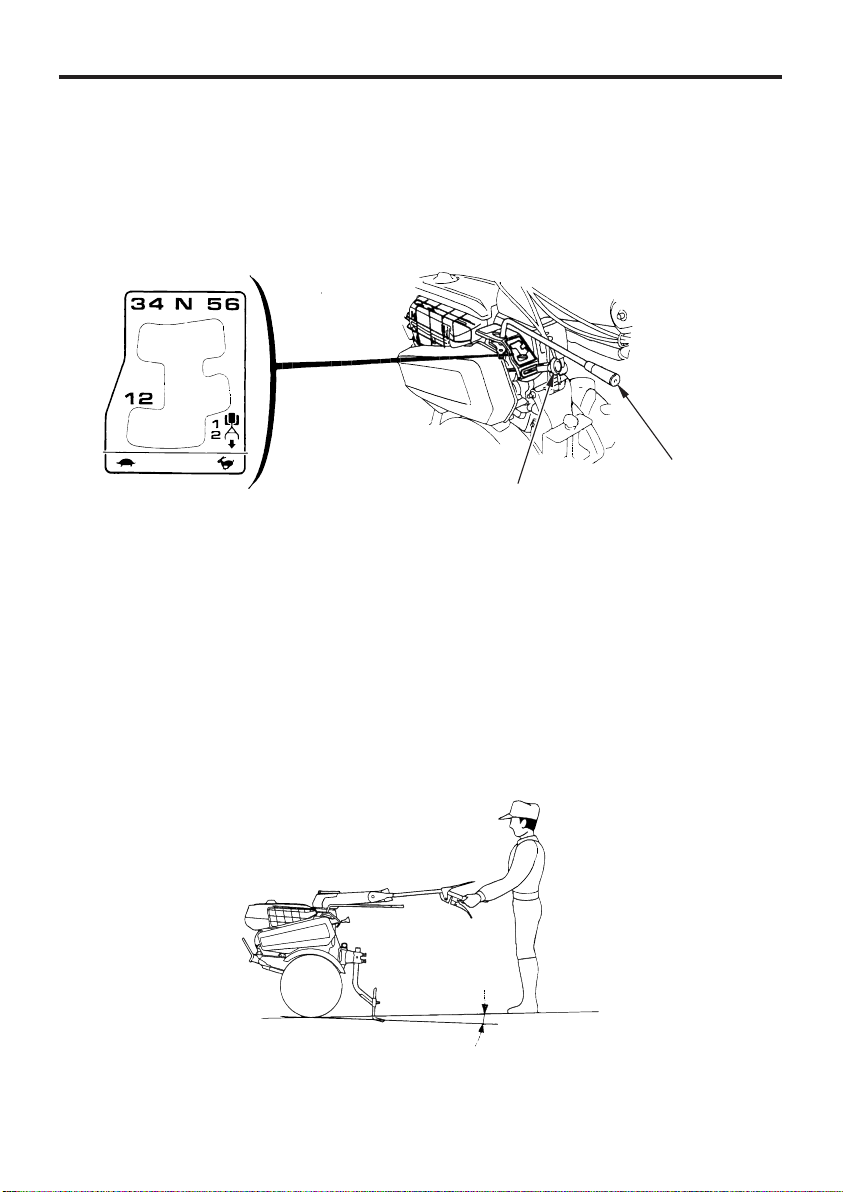

5.

Gear shift operation

The transmission is of a three forward speeds and one reverse speed

transmission (six forward speeds and two reverse speeds by

multipling the two speeds of the sub transmission). When shifting the

shift lever, make use of the shift lever indicator.

MAIN SHIFT LEVER

SUB SHIFT LEVER

Gear shifting

Move the throttle lever to the right fully to bring the engine speed to

1.

idle.

Disengage the main clutch.

2.

Shift into required position.

3.

Normal operating angle

6.

Lower the handle slightly so the front of the machine is raised about

〜

68°.

68°

〜

To get the maximum advantage from the tiller, try to hold the machine

at the angle shown while you are tilling the ground:

25

Page 27

Do not use the tiller with a rotor whose diameter is in excess of

360 mm.

Operating the tiller on grades could cause the tiller to tip over.

Allowing any one to operate this tiller without proper instruction

may result in injury.

Wear sturdy, full coverage footgear. Operating this tiller with bare

feet, or with open toe shoes or sandals increases your risk of injury.

Do not use the tiller in the night.

Be sure to use two people to transport the tiller from one place to

another without using a carrier.

When the rotor is clogged with mud, pebbles etc., immediately stop

the engine and clean the rotor in a safe place. Be sure to wear heavy

gloves when cleaning the rotor.

To prevent damage, check the tiller for any signs of damage or

other faults each time the tiller is used after it has been operated

last.

26

Page 28

P.T.O. (Power Take Off) operation

7.

The P.T.O. shaft is used for stationary work, hulling, spraying and

moving, etc.

To use, remove the three 6 mm bolts and P.T.O. cover.

To use, remove the P.T.O. cover.

When using for stationary work, the gear shift lever should be

shifed into Neutral position.

Do not operate the tiller without the P.T.O. cover when the P.T.O. is

not used.

P.T.O. SHAFT

6mmBOLT

P.T.O. COVER

A.C. output

8.

An alternating current (12V 50W) can be taken out of these terminals.

(GE Type)

−

27

Page 29

Headlight switch operation

9.

(EE Type)

The switch turns the headlights ON and OFF.

Shift the transmission to a lower speed range to maintain a safe

speed when visibility is poor.

OFF

Tilling depth adjustment

10.

Install the hitch attachment in the hitch box with a hitch pin.

1.

The tilling depth adjustment can be made by loosening the bolts

2.

(Equipped type only)

ON

OFF

securing the drag bars A and B and sliding the drag bars up down as

necessary.

DRAG BAR A

HITCH PIN

HITCH BOX

28

DRAG BAR B

Page 30

STOPPING THE ENGINE

7.

In normal use:

Release the clutch lever to the DISENGAGED position and shift lever

1.

is in neutral position.

Release the clutch lever. The tool will be stopped.

DISENGAGED

MAIN CLUTCH LEVERS

Disengaged

Disengaged

Move the throttle lever towards you (LOW position).

2.

LOW

THROTTLE LEVER

29

Page 31

Turn the engine switch OFF.

3.

(Except for EE Type) (EE Type)

OFFOFF

OFF

OFF

OFF

ENGINE SWITCH

Turn the fuel valve to the OFF position.4.

FUEL VALVE

30

OFF

OFF

Page 32

MAINTENANCE8.

The purpose of the maintenance schedule is to keep the tiller in the

best operating condition. Inspect or service as scheduled in the table

below.

Shut off the engine before performing any maintenance. Exhaust

contains poisonous carbon monoxide gas; Exposures cause loss of

consciousness and may lead to death. If the engine must be run,

make sure the area is well ventilated.

Use only genuine Honda parts or their equivalent for maintenance or

repair. Replacement parts which are not of equivalent quality may

damage the tiller.

Maintenance schedule

REGULAR SERVICE PERIOD (3)

Perform at every indicated month or

operating hour interval, whichever

comes first.

Item

Engine oil

Transmission oil

Air cleaner

Sediment cup

Spark plug

Belt tension

Throttle cable

Main clutch cable

Side clutch cable

Idle speed

Valve clearance

Combustion

chamber

Fuel tank and filter

Fuel tube

Replace paper element type only.

()

*

Service more frequently when used in dusty areas.

(1)

(2)

These items should be serviced by your Honda servicing dealer, unless you have the

proper tools and are mechanically proficient. Refer to Honda shop manual for service

procedures.

(3)

For commercial use, log hours of operation to determine proper maintenance

intervals.

Check level

Change

Check level

Check

Clean

Replace

Clean

Check-adjust

Replace

Adjust

Adjust

Adjust

Adjust

Check-adjust

Check-adjust

Clean

Clean

Check

Each use

First

month

or

20 hrs.

After every 500 hrs. (2)

Every 2 years (Replace if necessary) (2)

Every

3 months

or

50 hrs.

(1)

Every

6 months

or

100 hrs.

(2)

300 hrs.

Every

year

or

()

*

(2)

(2)

(2)

(2)

31

Page 33

Engine oil change

1.

Change the oil when the engine is warm to assure rapid and complete

draining.

1.

Remove the oil filler cap and the drain plug to drain.

2.

Tilt the tiller back to drain the crankcase completely.

3.

Reinstall the drain plug, refill with the recommended oil (p. 12 ), and

reinstall the oil filler cap.

Oil capacity:

DRAIN PLUG

(0.6 US qt , 0.5 Imp qt)

0.6

OIL FILLER CAP

LEVEL

Wash your hands with soap and water after handling used oil.

Transmission oil change

2.

1.

Place the tiller on a level surface.

2.

Remove the oil filler cap and drain plug to drain.

Install the drain plug. Fill the transmission with same oil as the

3.

engine oil (see page ) up to the level. Install the oil filler cap.

Oil capacity:

3.5

12

(3.7 US qt , 3.1 Imp qt)

32

OIL FILLER CAP

DRAIN PLUG

Page 34

Please dispose of used motor oil in a manner that is compatible with

the environment. We suggest you take it in a sealed container to your

local service station for reclamation. Do not throw it in the trash or

pour it on the ground.

33

Page 35

Air cleaner service

3.

A dirty air cleaner will restrict air flow to the carburetor. To prevent

carburetor malfunction, service the air cleaner regularly. Service more

frequently when operating the engine in extremely dusty areas.

Never use gasoline or low flash point solvents for cleaning the air

cleaner element. A fire or explosion could result.

Never run the engine without the air cleaner. Rapid engine wear will

result.

Remove the cover nut and the

1.

air cleaner cover. Remove the

elements and separate them.

AIR CLEANER COVER

COVER NUT

Carefully check both elements

for holes or tears and replace if

FOAM ELEMENT

damaged.

Foam element: Clean in warm

2.

soapy water, rinse and allow to

dry thoroughly. Or clean in high

flash-point solvent and allow to

dry. Dip the element in clean

engine oil and squeeze out all

the excess. The engine will

smoke during initial start-up if

too much oil is left in the foam.

Paper element: Tap the element

3.

lightly several times on a hard

surface to remove excess dirt,

or blow compressed air

through the filter from the

inside out. Never try to brush

the dirt off; brushing will force

dirt into the fibers. Replace the

paper element if it is excessively dirty.

PAPER ELEMENT

34

Page 36

Fuel strainer cup cleaning

4.

Gasoline is extremely flammable and is explosive under certain

conditions. Do not smoke or allow flames or sparks in the area.

Turn the fuel valve to the OFF position and remove the fuel strainer

cup and the O-ring.

Wash the removed parts in solvent, dry them thoroughly and reinstall

them securely.

Turn the fuel valve ON and check for leaks.

OOFFFF

O-RING

L

STRAINER CUP

FUE

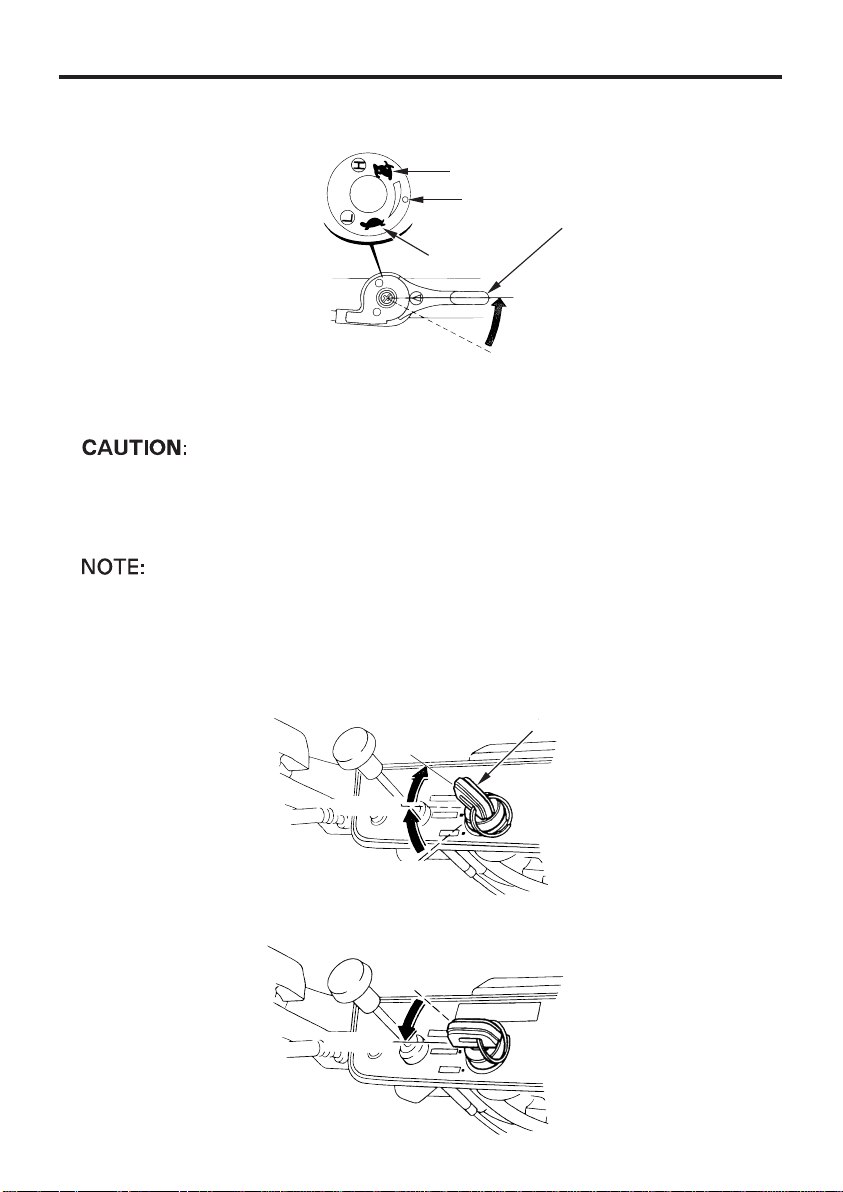

Spark plug service

5.

LOCK NUT

Recommended spark plug:

BPR5ES (NGK)

W16EPR-U (DENSO)

To ensure proper engine operation, the spark plug must be properly

gapped and free of deposits.

Remove the spark plug cap and use a spark plug wrench to remove

1.

the plug.

If the engine has been running, the muffler will be very hot. Be careful

not to touch the muffler.

PLUG WRENCH

35

Page 37

Visually inspect the spark plug. Discard it if the insulator is cracked

2.

or chipped. Clean the spark plug with a wire brush if it is to be

reused.

Measure the plug gap with a feeler gauge.

3.

Correct as necessary by bending the side electrode.

The gap should be:

Check that the spark plug washer is in good condition and thread the

4.

−−

0.70 0.80 mm (0.028 0.031 in)

−−

0.70 0.80 mm (0.028 0.031 in)

spark plug in by hand to prevent cross-threading.

Afterthesparkplugisseated,tightenwithasparkplugwrenchto

5.

compress the washer.

After seating it by hand, tighten a new spark plug 1/2 turn with the

wrench to compress the washer. If you are reusing a plug, it should

only take 1/8 1/4 turn.

−

The spark plug must be securely tightened. An improperly

tightened plug can become very hot and possibly damage the

engine.

Never use a spark plug with an improper heat range.

36

Page 38

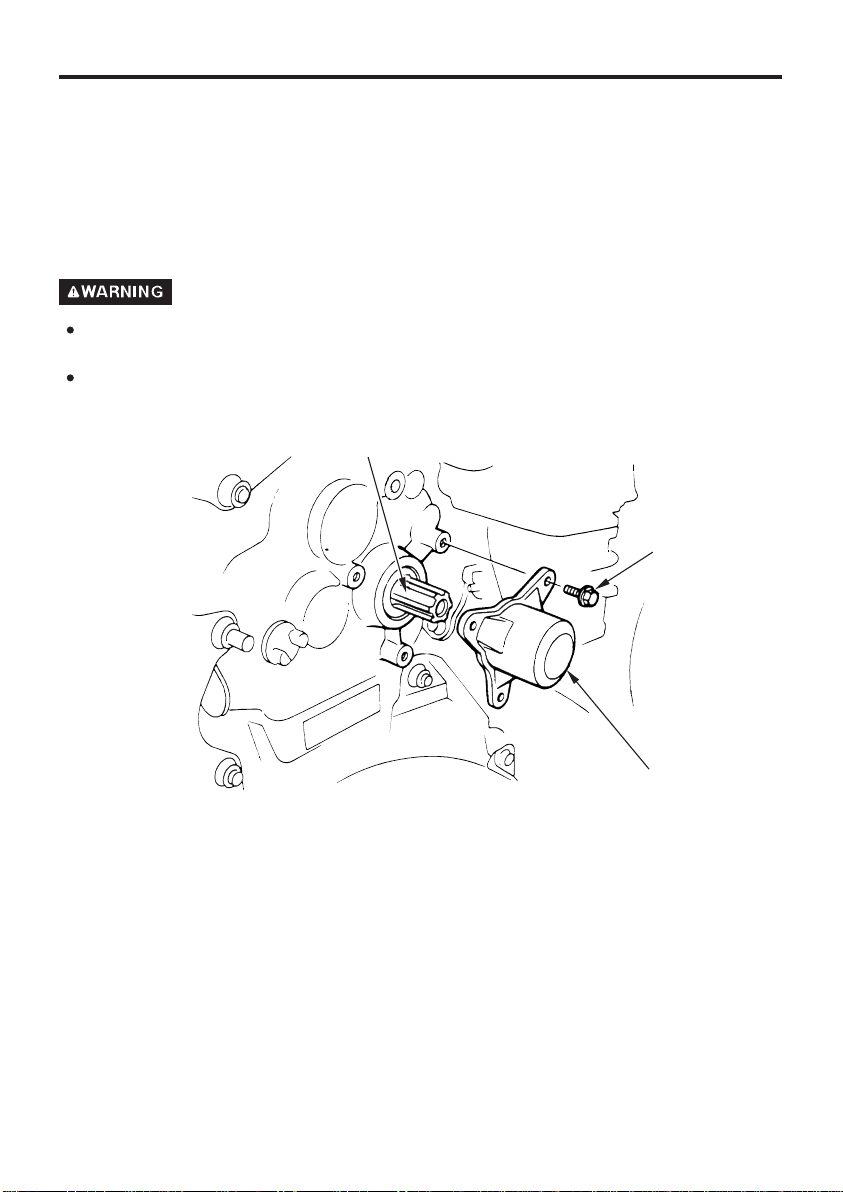

Belt tension adjustment6.

Adjust the clutch lever free play

(Pages ).

39, 40

The standard belt tension at the

tension roller with the clutch

engaged (clutch lever is

squeezed) is:

−−

63 69 mm (2.5 2.7 in)

To adjust, loosen the four engine

mounting bolts, nuts and the

engine stay tightening bolt and

move the engine forward or

reverse to get proper tension of

the belt.

After adjusting the tension, make

sure that the outside face of the

drive pulley is flush with the

outside face of the driven pulley

by using a straight gauge.

Loosen the belt stopper attaching

bolts.

Adjust the clearance between the

belt stopper and the belt as

illustrated with the clutch lever

squeezed.

23mm

(0.08 0.12 in)

ENGINE STAY TIGHTNING BOLT

ENGINE

MOUNTING BOLTS

BELT STOPPERS

−

23mm

−

(0.08 0.12 in)

−

−

BELT STOPPERS

−

46mm

−

(0.16 0.24 in)

37

Page 39

Throttle cable adjustment7.

Measure the free play at the lever tip.

Free play:

−−

510mm(0.20.4in)

If the free play is incorrect, loosen the lock nut and turn the adjusting

nut in or out as required.

−

510mm

−

(0.2 0.4 in)

THROTTLE LEVER

ADJUSTING NUT

38

LOCK NUT

Page 40

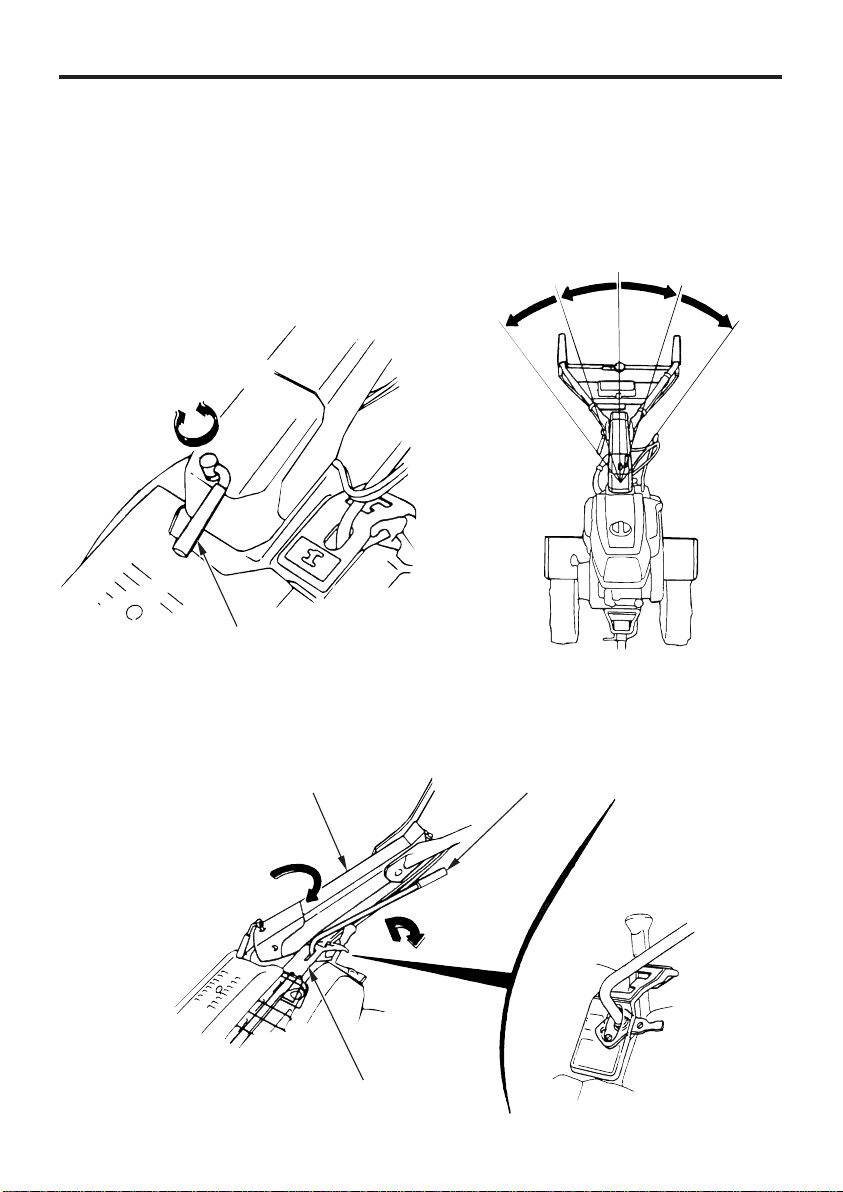

Main clutch cable adjustment8.

With the clutch disengaged, measure the free play at the lever end.

Free play:

−−

510mm(0.20.4in)

If the free play is incorrect, loosen the lock nut and turn the adjusting

bolt in or out as required.

Remove the belt cover, and perform the adjustment while pressing the

tension roller down with your hand.

After adjusting the cable free play, tighten the lock nut securely.

FREE PLAY

FREE PLAY

ADJUSTING BOLT

LOCK NUT

39

Page 41

Side clutch cable adjustment

9.

Measure the free play at the lever tip.

Free play:

−−

710mm(0.30.4in)

If the free play is incorrect, turn the adjusting nut in or out as required.

ADJUSTING NUT

Fuse replacement

10. (EE Type only)

If the fuse has blown, replace it with a specified fuse after checking the

cause. If the fuse is changed without finding the cause, the new fuse

may blow again.

Specified fuse: 1A

Do not substitute a higher capacity fuse, and do not use a wire or

other material in place of the fuse; using a fuse that is rated higher

than recommended can damage the electrical system.

40

SPARE FUSE

Page 42

Battery

11. (EE Type only)

Charge the battery in every 6 months whenever the tiller is stored for a

prolonged period.

Use the Honda recommended charger (FW3040: Friemann & Wolf) to

charge the battery or consult with your authorized Honda tiller dealer.

Battery service

The battery gives off explosive gases; keep sparks, flames and

cigarettes away. Provide adequate ventilation when charging or

using the batteries in an enclosed space.

The battery contains sulfuric acid (electrolyte). Contact with skin or

eyes may cause severe burns. Wear protective clothing and a face

shield.

KEEP OUT OF REACH OF CHILDREN.

To disconnect the battery cables, be sure to disconnect at the

negative ( ) terminal first.

To connect, connect the battery cable to the positive ( ) terminal

first, then to the negative ( ) terminal. Never connect/disconnect

−

+

−

the other way around as it might cause the shorted wire when a

tool touches the battery terminal. Tighten the bolts and nuts

securely so that the terminals are not loose.

Use the maintenance free battery whenever replacing the battery.

NEGATIVE ( ) TERMINAL

−

Cleaning

Remove the battery and clean it

whenever the battery terminals

are contaminated or corroded.

POSITIVE ( ) TERMINAL

+

If the battery terminals are

excessively corroded,

disconnect the battery cables

and clean them with a wire

brush or sand paper.

After cleaning, reconnect the

battery cables and coat the

battery terminals with grease.

41

Page 43

Headlight bulb replacement12. (EE Type only)

Turn the screw countorclockwise and open the top cover.

1.

Pull off the rubber boot, then remove the bulb by pushing and

2.

turning it counterclockwise.

Install a new bulb by aligning the boss of the bulb with the groove of

3.

the bulb socket.

Reinstall the removed parts in the reverse order of disassembly.

4.

Replacement bulb: 12V 25W

−

SCREW

TOP COVER

RUBBER BOOT

42

BULB SOCKET

HEADLIGHT BULB

Page 44

TRANSPORTING/STORAGE9.

When transporting the tiller, turn the fuel valve OFF and keep the tiller

level to prevent fuel spillage. Fuel vapor or spilled fuel may ignite.

Before storing the unit for an extended period:

Be sure the storage area is free of excessive humidity and dust.

1.

Drain the fuel:

2.

Gasoline is flammable and explosive under certain conditions. Do

not smoke or allow flames or sparks near the equipment while

draining fuel.

With the fuel valve turned OFF, remove and empty the fuel

a.

strainer cup.

Turn the fuel valve ON and drain the gasoline from the fuel tank

b.

into a suitable container.

Reinstall the fuel strainer cup and tighten securely.

c.

Drain the carburetor by loosening the drain knob. Drain the

d.

gasoline into a suitable container.

FUEL VALVE

DRAIN KNOB

FUEL STRAINER CUP

Pull the starter grip until resistance is felt. Continue pulling until

3.

the notch on the starter pulley aligns with the hole on the recoil

starter.

At this point, the intake and exhaust valves are closed, and this

will help to protect the engine from internal corrosion.

Change engine oil and transmission gear oil.

4.

Cover the tiller with plastic sheet.

5.

Do not place the tiller with the handlebars on the ground. It will cause

the oil entering the cylinder or fuel will spill over.

43

Page 45

TROUBLESHOOTING

10.

When the engine will not start:

Is there enough fuel?

1.

Is the fuel valve on?

2.

Is gasoline reaching the carburetor?

3.

To check, loosen the drain knob with the fuel valve on. Fuel should

flow out freely. Retighten drain knob.

If any fuel is spilled, make sure the area is dry before testing the

spark plug or starting the engine. Spilled fuel or fuel vapor may

ignite.

DRAIN KNOB

Is the engine switch on?

4.

Is the spark plug in good condition?

5.

Remove and inspect the spark plug. Clean, readjust gap and dry the

spark plug. Replace it if necessary.

If the engine still does not start, take the tiller to an authorized Honda

6.

dealer.

44

Page 46

description code

Type

Length

Width

Height

Dry mass [weight]

Engine

Model

Type

Displacement

×

Bore Stroke

Ignition system

Spark plug

Oil capacity

Fuel tank capacity

Clutch

Transmission oil capacity

SPECIFICATIONS11.

F720Model

FAEJPower products

TEFE EE GE DE

1,630 mm (64.2 in) 1,655 mm (65.2 in)

655 mm (25.8 in)

1,040 mm (40.9 in)

73 kg

(161 lbs)

4-stroke, 1-cylinder, OHV, forced air cooled

73 kg

(161 lbs)

196 cm

××

68.0 54.0 mm (2.7 2.1 in)

Transistor magneto

BPR5ES (NGK) W16EPR-U (DENSO)

0.6

(0.55 US gal , 0.46 Imp gal)

2.1

3.5

77 kg

(170 lbs)

GX200

(12.0 cu-in)

,

(0.6 US qt , 0.5 Imp qt)

Belt tension

(3.7 US qt , 3.1 Imp qt)

121 kg

(267 lbs)

87 kg

(192 lbs)

Noise and Vibration

Sound pressure level

A

(Lp

) Tested by EN709

Guaranteed sound

power level (L )

WA

86 dB

N.A.

Tested by 2000/14/EC

Vibration

18 m/s

Tested by EN709

Specifications are subject to change without notice due to

improvements.

45

Page 47

MAJOR Honda DISTRIBUTOR ADDRESSES IN EUROPE

12.

NAME OF FIRM (COMPANY) ADDRESS TEL: FAX:

Honda (U.K.) Limited 470 London Road, Slough,

Berkshire, SL38QY,

United Kingdom

Honda Europe Power Equipment S.A. Pole 45 Rue des Chataigniers

45140 Ormes

France

Honda Deutschland GmbH.

Honda Belgium H.V. Wijngaardveld 1, 9300 Aalst

Honda Italia Industriale S.P.A. Via della Cecchignola, 5/7

Honda (Suisse) S.A.

Honda Nederland B.V.

Honda Austria G.M.B.H.

Sprendlinger, Landstraße 166

D-63069 Offenbach/Maín

Germany

Belgium

00143 ROMA

Route des Mouliéres 10

Case Postale Ch 1214

Vernier-Geneve, Switzerland

Nikkelstraat 17

2984 Ridderkerk

Netherlands

Honda Strasse 1 A-2351

Wiener Neudorf

Austria

Tel: 01753-590-590

Fax: 01753-590-000

Tel: 1-38-65-06-00

Fax: 1-38-65-06-05

Tel: 069-83-09-0

Fax: 069-83-09-519

Tel: 053-725-111

Fax: 053-725-100

Tel: 06-54928-1

Fax: 06-54928-400

Tel: 022-341-22-00

Fax: 022-341-09-72

Tel: 018-04-57-333

Fax: 018-04-91-888

Tel: 223-66-900

Fax: 223-66-4130

Honda Power Equipment Sweden A.B.

Honda Produtos De Força, Portugal, S.A.

Berema A/S

46

Ostmästargränd 8

Stockholm-Årsta

Sweden

Lugar da Abrunheira

S. Pedro de Penaferrim

2710 Sintra, Portugal

Berghagan 5, Langhus

Box 454, 1401 Ski

Norway

Tel: 08-602-24-60

Fax: 08-722-36-27

Tel:351-9150374

Fax:351-9111021

Tel: 64-86-05-00

Fax: 64-86-05-49

Page 48

NAME OF FIRM (COMPANY) ADDRESS TEL: FAX:

OY Brandt AB Tuupakantie 4

SF-01740, Vantaa

Finland

TIMA PRODUCTS A/S Tel: 31-49-17-00

Greens

Automocion Canarias S.A.

(AUCASA)

The Associated Motors Company Ltd.

Two Wheels Ltd.

General Automotive Co., S.A.

BG technik s.r.o Radlická 117/520

Tårnfalkevej 16, Postboks 511

DK 2650 Hvidovre

Denmark

Polig. Industrial Congost

08530, La Garriga

(Barcelona), Spain

Apartado de Correos, num 206

SantaCruzdeTenerife

Canary Island

148, Rue D’Argens, Msida

Malta

Crosslands Business Park,

Ballymount Road, Dublin 12,

Ireland

P.O. Box 1200, 101 73 Athens

Greece

158 01 Praha 5

Czech Republic

Tel: 90-895-501

Fax: 90-878-5276

Fax: 36-77-16-30

Tel: 93-871-84-50

Fax: 93-871-81-80

Tel: 922-61-13-50

Fax: 922-61-13-44

Tel: 356-333001

Fax: 356-340473

Tel: 4602111

Fax: 4566539

Tel: 346-5321

Fax: 346-7329

Tel: 2-5694 573

Fax: 2-5694 571

Aries Power Equipment Ltd. 01-493 Warszawa, ul Wroclawska

25a

Poland

MO.TOR.PEDO Ltd. 1134 Budapest, Dózsa Gy.út 61-63

Hungary

Tel: 22-685 17 06

Fax: 22-685 16 03

Tel: 1-4652080

Fax: 1-4652081

47

Page 49

Nous vous remercions d’avoir porté votre choix sur une motobineuse Honda.

Ce manuel couvre les opèrations d’utilisation et d’entretien du motoculteur F720.

Toutes les informations contenues dans ce document sont basées sur les plus récentes

données conformes et disponibles au moment de l’impression.

La Honda Motor Co., Ltd. se réserve le droit d’effectuer des modifications à tout moment,

sans préavis et sans aucune obligation de sa part.

Aucune partie de cette publication ne peut être reproduite sans une autorisation écrite.

Ce manuel est considéré comme partie intégrale de la motobineuse et il doit

accompagner la motobineuse en cas de revente.

Prêter une attention particulière aux avertissements précédés par les termes suivants:

Indique un risque important de blessure grave ou mortelle si les

instructions ne sont pas respectées.

Indique des risques hautement probables de blessures sévères,

voire mortelles, si l’on ne suit pas les instructions.

Fournit des informations utiles.

Si l’on a un problème à résoudre ou des questions concernant la motobineuse, consulter

un concessionnaire agréé Honda.

La motobineuse Honda est connu pour assurer un service sûr et fiable dans des

conditions d’utilisation conformes aux instructions. Avant d’utiliser cette

motobineuse, veuillez lire et assimiler le contenu de ce manuel. A défaut, vous vous

exposeriez à des blessures et l’équipement pourrait être endommagé.

Les illustrations peuvent varier selon les modèles.

1

Page 50

SOMMAIRE

Utilisation à haute altitude

.....................................................................................................1. REGLES DESECURITE . 3

........................................2. EMPLACEMENT DES AUTOCOLLANTS DE SECURITE . 8

.......................................................................................Emplacement de la marque CE . 9

...............................................3. IDENTIFICATIONSDES PIECES CONSTITUTIVES . 10

.......................................................................4. CONTROLES AVANT L’UTILISATION . 12

................................................................................5. MISE EN MARCHE DU MOTEUR . 16

.......................................................6. UTILISATION DE LA MACHINE À LABOURER . 22

.......................................................................................................7. ARRÊT DU MOTEUR . 29

.......................................................................................................................8. ENTRETIEN . 31

..............................................................................................9. TRANSPORT/REMISAGE . 43

.............................................................................................10. DEPISTAGE DES PANNES . 44

......................................................................................................11. CARACTÉRISTIQUES . 45

.......12. ADRESSES DES PRINCIPAUX CONCESSIONNAIRES Honda EN EUROPE . 46

2

Page 51

REGLES DE SECURITE

1.

Pour assurer un fonctionnement sûr

−

Pour votre sécurité et celle des tiers, prêter une attention particulière à ces

avertissements:

Le motoculteur Honda a été conçu pour fonctionner de manière fiable et en

toute sécurité à condition qu’il soit utilisé conformément aux instructions

données.

Lire très attentivement le manuel d’utilisateur avant d’utiliser la

motobineuse. A défaut, vous vous exposeriez à des blessures et

l’équipement pourrait être endommagé.

Les gaz d’échappement contiennent du monoxyde de carbone. Ne jamais

faire fonctionner le motoculteur dans un espace clos. Toujours veiller à ce

que l’aération soit suf fisante. Lorsqu’il est nécessaire de f aire fonctionner

lamotobineusedansunespaceclos,veilleràcequel’aérationsoit

suffisante.

Lesoutilsrotatifssonttranchantsettournentàtrèsgrandevitesse.Elles

peuvent provoquer des accidents extrêmement graves.

N’approcher ni les mains ni les pieds des dents pendant que le moteur

tourne.

Arrêter le moteur et débrayer les outils rotatifs avant de procéder au

contrôle ou à l’entretien des dents.

Déconnecter le capuchon de la bougie d’allumage pour empêcher le

démarrage accidentel du moteur. Porter des gants épais pour seprotéger

lesmainspendantlenettoyage,lecontrôleouleremplacementdesdents.

Obligations de l’utilisateur

Maintenir le motoculteur en bon état de fonctionnement. L’utilisation d’un

motoculteur en mauvais état peut entraîner de graves blessures.

S’assurer que tous les dispositifs de sécurité sont en bon état de fonctionnement et

que les étiquettes d’avertissement sont en place. Ces pièces sont destinées à la

sécurité de l’utilisateur.

Vérifier que les caches de sécurité (cache de ventilateur, cache de démarreur à

réenroulement) sont en place.

Apprendre à arrêter rapidement le moteur et les outils rotatifs en cas d’urgence. Bien

assimiler l’utilisation de toutes les commandes.

Garder les deux mains fermement sur les mancherons. Les mancherons pourront

avoir tendance à se lever pendant l’embrayage des outils.

3

Page 52

Pour assurer un fonctionnement sûr

Obligations de l’utilisateur

Lisez attentivement le manual d’utilisateur. Familiarisez-vous avec les commandes de la

motobineuse et de leur utilisation appropriée.

−

Utiliser la motobineuse uniquement dans le but proposé, c.-à-d., le travail du sol. Tout

autre usage pourrait s’avérer dangereux ou endommager l’équipement. En particulier,

ne jamais l’utiliser pour cultiver un sol contenant des roches, cailloux, câblages et autres matériaux durs.

Ne jamais laisser des enfants ou des personnes non familières avec ce manuel de

l’utilisateur utiliser la motobineuse. Les règlements locaux peuvent restreindre l’âge de

l’opérateur.

Avant chaque utilisation, vérifier l’état de la motobineuse, y compris l’usure,

l’endommagement et le desserrement des pièces. Si nécessaire, remplacer les pièces

endommagées.

Bien s’aviser que le propriétaire ou l’utilisateur est responsable en cas d’accident ou de

dommage survenant aux autres personnes ou à leurs biens.

Dans le cas d’utilisation en location, ne pas manquer de fournir toutes les explications de

fonctionnement requises en présence de l’utilisateur.

Garder les mains et les pieds éloignés des outils rotatifs avec le moteur en marche.

Ne laisser personne utiliser ce motoculteur sans instructions d’utilisation appropriées

car ceci pourrait entraîner des blessures.

Se protéger les pieds avec de robustes souliers appropriés. L’utilisation du

motoculteur pieds nus ou avec des chaussures ouvertes ou des sandales augmente les

risques de blessures.

Porter des vêtements appropriés. Des vêtements trop lâches risquent d’être happés

dans les pièces mobiles et entraîner des blessures.

Etre vigilant. L’utilisation de ce motoculteur lorsqu’on est fatigué, malade ou sous

l’influence de l’alcool ou de médicaments peut entraîner de graves blessures.

Ne pas laisser de personnes ou des animaux approcher de la zone où l’on travaille.

S’assurer que l’éperon de terrage est en place et correctement réglée.

Ne pas modifier les réglages du régulateur de moteur.

Mettre soigneusement le moteur en marche en suivant les instruction de ce manual, en

gardant les pieds éloignés des outils rotatifs.

Lors de la mise en marche du moteur, garder les pieds éloignés des pointes.

Eviter d’utiliser le motoculteur la nuit ou par mauvais temps et mauvaise visibilité, car il y

un grand risque d’accident.

Marcher, ne jamais courir pendant l’utilisation.

En cas de marche arrière pendant l’utilisation, faire particulièrement attention aux

personnes et obstacles situés derrière l’opérateur.

Avant de transporter ou de soulever le motoculteur, vérifier que le moteur est arrêté.

4

Page 53

Pour assurer un fonctionnement sûr

Obligations de l’utilisateur

Arrêter le moteur dans les cas suivants:

−

Chaque fois que vous quittez le motoculteur sans surveillance.

−

Avant de faire le plein

En cas d’arrêt du moteur, déplacer le levier de commande des gaz vers la position ‘‘LOW’’,

puis désenclencher le commutateur de moteur. Si le motoculteur est équipé de robinet

d’essence, toujours fermer le robinet d’essence.

Garder tous les écrous, boulons et vis serrés pour être sûr que le motoculteur est en bon

état de travail. Un entretien régulier est une aide essentielle à la sécurité de l’utilisateur et

au maintien d’un bon niveau de performances.

Ne jamais remiser le motoculteur avec de l’essence dans le réservoir à l’intérieur d’un

bâtiment où des vapeurs d’essence peuvent atteindre une flamme ouverte, une étincelle ou

une source de haute température.

Laisser refroidir le moteur avant de le remiser dans un endroit clos.

Pour réduire les risques d’incendie, garder le motoculteur, et surtout le moteur, le

silencieux, ainsi que la zone de stockage d’essence libres d’herbes, de feuilles ou de

graisse excessive.

Ne pas laisser de récipients de matière végétales dans ou à proximité d’un bâtiment.

Si le réservoir d’essence doit être vidangé, procéder à l’extérieur, avec un moteur froid.

Remplacer les pièces usées ou endommagées par mesure de sécurité.

Sécurité des enfants

−

Garder les enfants à l’intérieur et les surveiller constamment lorsque la motobineuse

est utilisé à proximité. Les jeunes enfants se déplacent rapidement et sont tout

particulièrement attirés par la motobineuse et la motoculture.

Ne jamais supposer que les enfants resteront où ils ont été vus la dernière fois. Etre

vigilant et arrêter la motobineuse dès qu’un enfant s’en approche.

Ne jamais laisser un enfant manoeuvrer la motobineuse, même sous la surveillance

d’un adulte.

Danger de projection d’objets

Les objets heurtés par les outils rotatifs peuvent être projetés avec force et infliger de

graves blessures.

Avant d’utiliser la motobineuse, débarrasser la partie à travailler des bâtons, gros

cailloux, fils de fer, morceaux de verre, etc. Toujours travailler en plein jour.

Verifier toujours si la motobineuse n’est pas endommagé après avoir heurté un objet

étranger. Réparer ou remplacer toute pièce endommagée avant de continuer à

l’utiliser.

Des pièces projetées par des lames usées ou endommagées peuvent provoquer de

graves blessures. Toujours contrôler les outils rotatifs avant d’utiliser la motobineuse.

5

Page 54

Pour assurer un fonctionnement sûr

Danger d’incendie et de brûlure

L’essence est extrêmement inflammable et les vapeurs d’essence peuvent exploser.

Prendre toutes les précautions nécessaires lorsqu’on manipule de l’essence. Tenir

l’essence hors de portée des enfants.

Faire l’appoint de carburant avant de démarrer le moteur. Ne jamais retirer le bouchon du réservoir de carburant, ou faire l’appoint d’essence lorsque le moteur tourne

ou quand le moteur est chaud.

Refaire le plein dans un endroit bien aéré avec le moteur arrêté.

Faire l’appoint de carburant dehors exclusivement, et ne pas fumer à cette occasion ni

en manipulant du carburant.

Avant de refaire le plein, laisser le moteur se refroidir. Les vapeurs d’essence ou

l’essence renversée peuvent s’enflammer.

Le moteur et le système d’échappement deviennent très chauds pendant l’utilisation

et le restent pendant un certain temps après l’arrêt. Un contact avec des pièces

chaudes du moteur peut provoquer des brûlures et enflammer certaines matières.

Eviter de toucher un moteur ou un système d’échappement chaud.

Laisser le moteur se refroidir avant d’effectuer une intervention ou de ranger le

motoculteur à l’intérieur.

Bien remettre en place tous les bouchons de récipient et de réservoir d’essence.

Ranger l’essence dans des récipients spécialement conçus dans ce but.

Si de l’essence se trouve répandue, ne pas tenter de démarrer le moteur, mais

éloigner plutôt le cultivateur de l’endroit du déversement, puis éliminer toute source

de feu jusqu’à ce que les vapeurs d’essence soient dissipées.

−

6

Page 55

Pour assurer un fonctionnement sûr

Danger toxique d’oxyde de carbone

−

Les gaz d’échappement contiennent du monoxyde de carbone, un gaz toxique incolore

et inodore. Les gaz d’échappement peuvent provoquer des évanouissements et être

mortels.

Si l’on fait tourner le moteur dans un endroit fermé ou partiellement clos, l’air respiré

peut contenir une quantité dangereuse de gaz d’échappement. Pour empêcher une

accumulation de gaz d’échappement, prévoir une aération appropriée.

Remplacer le silencieux défectueux.

Ne pas faire fonctionner le moteur dans un endroit clos ou risquent de s’accumuler des

émanations dangereuses d’oxyde de carbone.

Utilisation sur terrain en pente

Lors d’un travail sur une pente, veiller à ce que le niveau dans le réservoir de

carburant ne dépasse pas la moitié pour empêcher le carburant de se renverser.

Travailler en travers de la pente (à des intervalles régulièrement espacés) plutôt que

dans le sens de la pente.

Etre très prudent lors d’un changement de direction sur une pente.

Ne pas utiliser le motoculteur ci dessus une pente de plus de 10°.

L’angle maximum de pente sur indiqué n’a qu’un but de référence et doit etre déterminé en

fonction du type de l’outil. Avant de mettre le moteur en marche, vérifier que la motobineuse

n’est pas endommagé et en bon état. Pour votre sécurité et celle des autres, faire très

attention lors de l’utilisation de la motobineuse en pente ou en descente.

7

Page 56

EMPLACEMENT DES AUTOCOLLANTS DE SECURITE2.

Ces étiquettes d’avertissement servent à prévenir des dangers éventuels risquant de causer des blessures sérieuses. Lire attentivement les étiquettes ainsi que les notes de sécurité et de précautions décrites dans ce manuel.

Si un autocollant se détache ou devient difficile à lire, s’adresser à un concessionnaire

Honda pour le faire remplacer.

LIRELE MANUEL DU

PROPRIETAIRE

RISQUE DE COUPE

8

ATTENTION GAZ D’ECHAPPEMENT

Page 57

Emplacement de marque CE

MARQUE CE

Nom et adresse du fabricant

Force de remorquage

maximale de l’attelage

Puissance nette

Code descriptif

Année de fabricant

Poids de la machine

(spécification standard)

Charge maximale de

traction de l’attelage

9

Page 58

IDENTIFICATIONS DES PIÈCES CONSTITUTIVES3.

LEVIER DES GAZ

LEVIER D’EMBRAYAGEPRINCIPAL

DISPOSITIF DE REGLAGE D’ANGLE DE POIGNEE

INDICATEUR DE

NIVEAU D’ESSENCE

BOUCHON DE

REMPLISSAGE

D’ESSENCE

PHARE

BEQUILLE

LEVIER

D’EMBRAYAGE

PRINCIPAL

SILENCIEUX

CARTER DE COURROIE

10

BOUCHON DE REMPLISSAGE

D’HUILE MOTEUR

CONTACTEUR MOTEUR

(Sauf type EE)

(Type EE)

Page 59

REGLAGEDEHAUTEURDUGUIDON

CONTACTEUR DUMOTEUR

BOUTON DE STARTER

LEVIERSD’EMBRAYAGE

LATERAL

LEVIER DESELECTIONPRINCIPAL

LEVIER DE SELECTION AUXILIAIRE

CONTACTEUR D’ECLAIRAGE

BATTERIE

DISPOSITIF DE

REGLAGE

D’ANGLEDEPOIGNEE

FILTRE A AIR

POIGNEE DE

DEMARREUR

BOUCHON DE REMPLISSAGE

D’HUILEDEBOITEDEVBITESSES

NUMERO DE SERIE DU CHASSIS

PNEU

11

Page 60

CONTRÔLES AVANT L’UTILISATION4.

1.

Huile moteur

S’assurer de vérifier le motoculteur placé sur une surface horizontale, le moteur étant

arrêté.

1.

Enlever le bouchon de remplissage d’huile et essuyer proprement la tige de jauge.

2.

Introduire la jauge dans le col de remplissage mais ne pas la visser.

3.

Si le niveau est trop bas, faire l’appoint avec de l’huile recommandée jusqu’au haut du

col de remplissage.

ENCOLURE DE REMPLISSAGE D’HUILE

Utiliser une huile moteur 4 temps

répondant ou dépassant les prescriptions

pour la classification service API SE ou

ultérieure (ou équivalente). Toujours

vérifier l’étiquette de service API sur le

bidon d’huile pour s’assurer qu’elle porte

bien la mention SE ou ultérieure (ou

équivalente).

BOUCHON DE REMPLISSAGE D’HUILE

LIMITE

SUPERIEUR

TEMPÉRATURE AMBIANTE

Une huile SAE 10W-30 est recommandée pour l’utilisation générale. Les autres viscosités

indiquées dans le tableau peuvent être utilisées lorsque la température moyenne du lieu

d’utilisation se trouve dans la plage indiquée.

L’emploi d’huile non détergente ou d’huile moteur à 2 temps abrégera la vie utile

du moteur.

Motoröl ist ein Hauptfaktor, der Leistung und Lebensdauer des Motors beeinflußt.

Nichtlösliche oder Pflanzenöle sind nicht zu empf ehlen.

L’utilisation du moteur avec une quantité d’huile insuffisante entraînera des dommages sérieux au moteur.

12

Page 61

Huiledetransmission2.

Placer le motoculteur sur une surface horizontale et retirer le bouchon de remplissage

d’huile.

L’huile doit atteindre le bord inférieur de l’orifice de remplissage d’huile.

Si le niveau est bas, ajouter la même huile que l’huile moteur (voir page ).3412

BORD INFERIEUR

BOUCHONDEREMPLISSAGED’HUILEDEBOITEDEVBITESSES

LIMITE SUPERIEUR

ORIFICE DE REMPLISSAGE D’HUILE

Filtreà air

3.

DE L’ORIFICE DE

DISPOSITIF DE

REMPLISSAGE

D’HUILE

Vérifier l’état de propreté du filtre ou s’ily a une obstruction des éléments. (voir page )

ELEMENTS

13

Page 62

4.

Carburant

Retirer le bouchon du réservoir de carburant et vérifier le niveau de carburant. Si le

niveau de carburant est bas, remplir le réservoir.

Utiliser de l’essence automobile sans plomb ayant un indice d’octane recherche d’au

moins 91 (ou un indice d’octane pompe d’au moins 86).

Ne jamais utiliser d’essence éventée ou polluée ou un mélange d’huile/essence. Eviter

que les salissures ou l’eau ne pénètrent dans le réservoir de carburant.

Après avoir fait le plein, resserrer le bouchon du réservoir de carburant à fond.

L’essence est un produit hautement inflammable et qui explose sous certaines

conditions.

Fairelepleindansunendroitbienaéréetaveclemoteurarrêté.Nepasfumerou

autoriser de f lammes ou d’étincelles à proximité du moteur lorsque l’on f ait le

plein ou près de l’endroit de stockage d’essence.

Ne pas trop remplir le réservoir. Après avoir fait le plein, vérfier que le bouchon du

réservoir est correctement fermé.

Faire attention à ne pas renverser d’essence pendant le remplissage du réservoir.

Leséclaboussuresoulesvapeursd’essencerisqueraientdeprendrefeu.Avantde

mettre le moteur en marche, s’assurer que l’essence renversée a séché et que les

vapeurs sont dissipées.

Eviter le contact prolongé et répété avec la peau ou la respiration des vapeurs.

GARDER HORS DEPORTEE DESENFANTS.

INDICATEUR DE

BOUCHON DE

REMPLISSAGE D’ESSENCE

NIVEAU D’ESSENCE

INDICATEUR DE

NIVEAU D’ESSENCE

L’essence se dégrade très rapidement sous l’effet de facteurs tels qu’exposition à la

lumière, la température et le temps.

Au pire des cas, elle peut être contaminée en moins de 30 jours.

L’utilisation d’essence contaminée peut endommager sérieusement le moteur

(obstruction du carburateur, grippage des soupapes).

14

Page 63

Les dommages dus au carburant dégradé ne sont pas couverts par la garantie.

Pour éviter ceci, observer rigoureusement ces recommandations:

N’utiliser que l’essence spécifiée (voir page ).

14

Utiliser de l’essence fraîche et propre.

Pour ralentir la dégradation, conserver l’essence dans un récipient de carburant

certifié.

Avant un long remisage (plus de 30 jours), vidanger le réservoir de carburant et le

carburateur (voir page ).

Essences contenant de l’alcool

35

Si l’on décide d’employer de l’essence contenant de l’alcool (carburol), s’assurer qu’elle

présente un indice d’octane au moins aussi élevé que la valeur recommandée par Honda.

Il existe deux types de ‘‘carburol’’: l’un contenant de l’éthanol, et l’autre contenant du

méthanol.

Ne pas employer de carburol contenant plus de 10 % d’éthanol. Ne pas employer d’essence contenant du méthanol (méthyle ou alcool de bois) sans également contenir des cosolvants et des inhibiteurs de corrosion pour le méthanol.

Ne jamais employer d’essence contenant plus de 5 % de méthanol, même si elle contient

des co-solvants et inhibiteurs de corrosion.

La détérioration du système de carburant ou la baisse de rendement du moteur

consécutifs à l’emploi d’essence contenant de l’alcool n’est pas couverte par la garantie.

Honda ne peut pas approuver l’emploi d’essence contenant du méthanol.

Avant de faire le plein d’essence dans une station service inhabituelle, s’enquérir

d’abord si l’essence contient de l’alcool; dans le cas positif, déterminer le type et le

pourcentage d’alcool utilisé.

Si l’on découvre toute anomalie de fonctionnement en utilisant de l’essence contenant

de l’alcool, ou que l’on soupçonne contenir de l’alcool, utiliser de l’essence qui est garantie ne pas contenir d’alcool.

Pression de gonflage des pneus

5.

Vérifier la pression des pneus. Un mauvais gonflage peut

réduree la durée de vie des pneus et la capacité de transport

de charge.

4,00-8

TAILLE DE PNEU:

PRESSION DE PNEU:

Outils et accessoires

6.

pour types DE et GE

118 kPa (1,2 kgf/cm

)

VALVE DE

PNEU

Pour installer un outil ou accessoire sur le motoculteur, suivre les instructions fournies

avec l’outil ou l’accessoire. Demander conseil au revendeur Honda en cas de problème ou

de difficulté à installer un outil ou un accessoire.

15

Page 64

MISE EN MARCHE DU MOTEUR5.

Avec démarreur à recul

S’asurer que l’embrayage est désengagé et que le levier de sélection se trouve au

point-mort afin d’éviter un mouvement incontrôlé lors du démarrage du moteur.

Pour emrayer tenir le levier d’embrayage et le relâcher pour débrayer.

Mettre le robinet d’essence sur la position ON. Vérifier si le bouton de vidange est

1.

serré.

ROBINET D’ESSENCE

OONN

BOUTON DEVIDANGE

2.

Par temps froid et lorsque le moteur est froid, tirer le levier de starter sur la position

ON

CLOSE.

Ne pas utiliser le starter si le moteur est déjà chaud ou si la température d’air ambiante

est élevée.

LEVIER DESTARTER

CL

OSE

CLOSE

16

Page 65

3.

Mettre l’interrupteur du moteur sur ON.

ON

OFF

ON

OFF

CONTACTEUR DUMOTEUR

CONTACTEUR DUMOTEUR

ON (Marche)

OFF (Arrêt)

(Type Type)

4.

Aligner le repère ‘‘ ’’ de la manette des gaz avec le repère ‘‘ ’’ comme illustré

△○

(Sauf type EE)

(position START).

ELEVE

DEMARRAGE

LEVIER DES GAZ

BAS

17

Page 66

5.

Tenir le montant de guidon de la main

gauche et tirer légèrement la poignée de

lancement jusqu’à ce que l’on ressente

une résistance, puis la tirer d’un coup

secdanslesensdelaflèchecommesur

la figure.

POIGNEEDEDEMARREUR

Ne pas laisser la poignée de lancement

du démarreur revenir brutalement

contre le moteur. La ramener

lentement pour éviter d’endommager

le démarreur.

DDiirreeccttiioonn

ddee ttrraaccttiioonn

6.

Laisser le moteur chauffer pendant quelques minutes. Si le starter a été tiré sur la

position CLOSE, le ramener graduellement sur la position OPEN au fur et à mesure

que le moteur chauffe.

18

OOPPEENN

LEVIER DESTARTER

EN

OP

Page 67

Avec démarreur électrique

Placer le robinet d’essence sur la position ON.

1.

(Type EE)

Vérifier si le bouton de vidange est serré.

ROBINET

D’ESSENCE

BOUTON DE

VIDANGE

Par temps froid et lorsque le moteur est froid, tirer le bouton de starter sur la position

2.

CLOSE.

BOUTON DE STARTER

FERMER

19

Page 68

Aligner le repère ‘‘ ’’ de la manette des gaz avec le repère ‘‘ ’’ comme illustré

3.

△○

(position START).

ELEVE

START (Démarrage)

BAS

4.

Tourner le commutateur du moteur sur la position START et le maintenir jusqu’à ce

LEVIER DES GAZ

que le moteur démarre.

Nepasutiliserledémarreurpendantplusde5secondes.Silemoteurnedémarre

pas, relâcher la clé et attendre au moins 10 secondes avant d’actionner de nouveau

le démarreur.

La batterie se rechargera automatiquement pendant le fonctionnement du

motoculteur. Si le motoculteur n’est pas utilisé suffisamment fréquemment pour

maintenir la batterie chargée, il y aura une diminution de la vitesse du moteur de

démarrage. Si la batterie est trop déchargée pour faire tourner le moteur de

démarrage, utiliser le démarreur à recul.

START

(Démarrage)

OONN ((MMaarrcchhee))

CONTACTEUR DUMOTEUR

O

FF (Arrêt)

Lorsque le moteur a démarré, laisser le commutateur du moteur revenir sur la

5.

position ON.

OONN ((MMaarrcchhee))

START

(Démarrage)

20

Page 69

6.

Laisser le moteur chauffer pendant quelques minutes. Si le starter a été tiré sur la

position CLOSE, le ramener graduellement sur la position OPEN au fur et à mesure

que le moteur chauffe.

BOUTON DE STARTER

OPEN

Utilisation à haute altitude

A haute altitude, le mélange standard air-carburant du carburateur est trop riche. Les

performances du moteur diminuent et la consommation de carburant augmente.

Des performances à haute altitude peuvent être améliorées par spécifications au

carburateur. Si vous utilisez toujours le cultivateur à des altitudes supérieures à 1.500 m

au-dessus du niveau de la mer, demandez à un revendeur Honda agréé d’effectuer ces

modifications du carburateur.

Même avec un réglage de gicleur de carburateur convenable, la puissance du moteur

diminue d’approximativement 3,5 % pour chaque 300 m d’altitude. L’effet de l’altitude sur

la puissance est plus grand si aucune modification de carburateur n’est effectuée.

L’utilisation du cultivateur à une altitude inférieure à celle pour laquelle le gicleur de

carburateur est réglé peut être la cause de performances réduites, de surchauff e et

de sérieux dommages du moteur causés par un mélange air-essence trop pauvre.

21

Page 70

UTILISATION DE LA MOTOBINEUSE6.

Réglagedel’inclinaisondesmancherons1.

1.

Le guidon peut être réglé selon quatre angles différents dans les deux sens.

Pour le réglage, desserrer le dispositif de réglage d’angle de poignée et tourner la

colonne de la poignée à la position voulue. Après le réglage, serrer le dispositif de

réglage à fond.

DESSERRER

SERRER

DISPOSITIF DE REGLAGE D’ANGLE DE POIGNEE

2.

Quand on vire la colonne du guidon à gauche, mouvoir également le levier de vitesse

pour ne pas gêner la colonne du guidon. Tirer sur le levier principal de vitesse vers le

haut pour le dégager du couvercle de la boîte et le tourner en sens direct.

LEVIER DESELECTIONPRINCIPALCOLONNE

CACHE DE SELECTION

22

Page 71

2.

Réglage de la hauteur des mancherons

La position des mancherons doit être réglée en fonction de la taille du conducteur et des

conditions de travail.

Avant d’ajuster le guidon, placer le cultivateur sur un sol ferme et nivelé pour éviter

queleguidonnes’affaisseaccidentellement.

Pour régler la hauteur des mancherons, desserrer le levier de réglage de hauteur, choisir

la position la plus appropriée, puis resserrer le levier de réglage.

DESSERRER

SERRER

REGLAGE

3.

Fonctionnement de l’embrayage principal

L’embrayage embraie et débraie la puissance en provenance du moteur vers la

transmission.

Lorsqu’on serre le levier d’embrayage, l’embrayage est embrayé et la puissance

transmise. Serrer le levier d’embrayage. L’outil tourne.

Lorsqu’on relâche le levier, l’embrayage est débrayé et la puissance n’est pas transmise.

Relâcher le levier d’embrayage. L’outil est arrêté.

Réduirelerégimedumoteuravantd’actionnerl’embrayageprincipal.

LEVIER D’EMBRAYAGEPRINCIPAL

Débrayage

Embrayage

Débrayage

Embrayage

DEBRAYAGE EMBRAYAGE

23

Page 72

4.

Fonctionnement des embrayages latéraux

Les embrayages latéraux servent à faire tourner la machine à droite ou à gauche.

Pour tourner à DROITE: Serrer le levier d’embrayage DROIT.

Pour tourner à GAUCHE: Serrer le levier d’embrayage GAUCHE.

Avant de serrer les leviers des embrayages latéraux, réduire le régime moteur.

Ne pas avoir recours aux embrayages latéraux lorsqu’on tire une remorque.

Eviter d’utiliser les embrayages latéraux dans une montée ou dans une descente.

Lorsqu’on tire une lourde charge, la manoeuvre des embrayages latéraux devra

être effectuée avec précautions car elle peut être dangereuse.

EMBRAYAGE

LATERAL GAUCHE

EMBRAYAGE LATERAL DROIT