Page 1

HBL26BVB

Page 2

Important!

It is essential that you read the instructions in this manual before assembling,

operating, and maintaining the product.

Subject to technical modifications.

Page 3

Original instructions | English

Safety, performance, and dependability have

been given top priority in the design of your

blower/vacuum.

INTENDED USE

The blower/vacuum is only intended for

use outdoors in dry and well-illuminated

conditions.

The product is not intended to be used by

children or persons with reduced physical,

mental, or sensory capabilities.

The product is designed for blowing or

vacuuming light debris, such as leaves, grass,

and other garden refuse.

The product is not designed to suck in water

or other liquids.

Do not use the product for any other purpose.

GENERAL SAFETY WARNINGS

WARNING

Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock,

re, and/or serious injury. Save all warnings

and instructions for future reference.

WARNING

Never allow children or people unfamiliar

with these instructions to use the product.

Local regulations may restrict the age of the

operator.

■ Some regions have regulations that restrict

the use of the product. Check with your

local authority for advice.

■ Do not allow children or untrained

individuals to use the product.

■ Ensure before each use that all controls

and safety devices function correctly. Do

not use the product if the off switch does

not stop the engine.

■ Never start or run the engine in a closed or

poorly ventilated area; breathing exhaust

fumes can kill.

■ Clear the work area before each use.

Remove all objects such as rocks, broken

glass, nails, wire, or string that can be

blown a considerable distance by high

velocity air.

■ Wear hearing protection at all times while

operating the product. The product is noisy,

and permanent hearing injury may result if

precautions to limit your exposure, reduce

noise, and wear hearing protection are not

strictly adhered to.

■ Wear full eye protection at all times while

operating the product. The manufacturer

strongly suggests a full face mask or fully

enclosed goggles. Normal spectacles or

sunglasses are not adequate protection.

Objects can be thrown at high speed by

the powerful air jet at any time and may

rebound from hard surfaces toward the

operator.

■ While operating the product, always wear

substantial footwear and long trousers.

Do not operate the product when barefoot

or wearing open sandals. Avoid wearing

clothing with loose fitting or that has

hanging cords or ties.

■ Do not wear loose clothing or jewellery that

can be drawn into the air inlet. Secure long

hair so it is above shoulder level to prevent

entanglement in moving parts.

■ Beware of thrown objects; keep all

bystanders, children, and pets at least 15

m away from the work area.

■ Operate the product only at reasonable

hours – not early in the morning or late at

night when people might be disturbed.

■ Use rakes or brooms to loosen debris

before operating the product.

■ Never operate the product in an explosive

1

Page 4

Original instructions | English

atmosphere.

■ Never use the product when you are tired,

ill, or under the influence of alcohol, drugs,

or medicine.

■ Before each use, ensure that all controls

and safety devices function correctly.

■ Operate the product in a recommended

position and only on a firm and level

surface.

■ Do not operate the product on a paved

or gravel surface where ejected material

could cause injury.

■ Before each use, always inspect the

housing for damage. Ensure that guards

and handles are in place and properly

secured. Replace worn or damaged

components in sets to preserve balance.

Replace damaged or unreadable labels.

■ Keep all cooling air inlets clear of debris.

■ Never operate the product while people,

especially children, or pets are nearby.

■ Avoid using the product in bad weather

conditions especially when there is a risk

of lightning.

■ Do not operate in poor lighting. The

operator requires a clear view of the work

area to identify potential hazards.

■ Operating similar tools nearby increases

both the risk of hearing injury and the

potential for other persons to enter your

working area.

■ Always be sure of your footing on slopes.

Walk, never run.

■ Keep proper footing and balance. Do not

overreach. Overreaching can result in loss

of balance.

■ Do not use on a ladder, rooftop, tree, or

other unstable support. Stable footing on a

solid surface enables better control of the

blower in unexpected situations.

■ Never use the product with defective

guards or shields, or without safety devices

in place.

■ Do not modify the product in any way or

use parts and accessories that are not

recommended by the manufacturer.

WARNING

Before using the product in vacuum mode,

you must assemble the upper and lower

vacuum tubes together. This is a one-time

operation only. Never operate the vacuum

with only the upper vacuum tube tted.

The risk of personal injury is signicantly

increased if you fail to follow this warning.

WARNING

If the product is dropped, suffers heavy

impact or begins to vibrate abnormally,

immediately stop the product and inspect

for damage or identify the cause of the

vibration. Any damage should be properly

repaired or replaced by an authorised

service centre.

■ Do not touch the area around the silencer

or engine of the product. These parts get

hot during operation.

■ Stop the engine and allow the product to

cool down before refuelling.

■ For refuelling and fuel mixing, chose an

area that is well-ventilated, and is away

from ignition sources, such as sparks or

flames, and flammable materials.

■ Remember to securely refit the fuel tank

filler cap. Do not smoke when mixing fuel

or filling the fuel tank.

■ Mix and store fuel in a container approved

for fuel. Keep an appropriate type of fire

extinguisher nearby for dealing with fuel

fires.

■ Remember to securely refit the fuel tank

2

Page 5

Original instructions | English

cap before starting the engine.

■ Wipe away any fuel spillage. Move 9 m

away from refuelling site before starting

engine.

■ To reduce the risk of injury associated with

contacting rotating parts, always stop the

engine, and make sure all moving parts

have come to a complete stop before:

– leaving the product unattended

– clearing blockages or unclogging

chute

– checking, cleaning, or working on the

product

– inspecting the product after striking a

foreign object

■ Immediately stop the engine in an event

of accident or breakdown. Do not operate

the product again until it has been fully

checked by an authorised service centre.

■ The product is not intended for frequent

use. It is for occasional use for general

applications, such as blowing leaves,

lawn clippings, etc. It is not intended for

prolonged use. Prolonged periods of

operation can cause circulatory problems

to your hands due to vibration. For use in

prolonged period, it is appropriate to use

the product with an anti-vibration feature.

BLOWER SAFETY WARNINGS

■ Wear a face filter mask in dusty conditions

to reduce the risk of injury associated with

the inhalation of dust.

■ Slightly dampen surfaces in dusty

conditions.

■ Do not use the product near open windows.

■ Use the full blower nozzle extension so that

the air stream can work close to the ground

and perform effectively.

■ Do not point the blower nozzle in the

direction of people or pets.

■ Never place objects inside the blower

tubes.

■ Do not place the product on top of or near

loose debris. Debris can be sucked into the

intake vent, resulting in possible damage

to the product.

VACUUM SAFETY WARNINGS

WARNING

Never operate the vacuum with only the

upper vacuum tube tted. Failure to follow

this warning increases the risk of personal

injury.

NOTE: Without the lower vacuum tube tted,

it is much easier to reach up inside the tube.

■ Do not operate the vacuum without the

debris collector bag assembly installed.

Flying debris could cause serious injury.

Make sure that the debris collector bag is

in good condition and completely closed

before operating the product.

■ Move the vacuum from side to side along

the outer edge of the debris. To avoid

clogging, do not place the vacuum tube

directly into the debris pile.

■ Hold the engine higher than the inlet end of

the vacuum tube.

■ To avoid serious injury to the operator

or damage to the product, do not try to

vacuum up rocks, broken glass, bottles, or

similar objects.

■ Avoid situations that could cause fire in

the debris collector bag. Do not operate

the product near an open flame. Do not

vacuum up warm ash from fireplaces and

barbecue pits. Do not vacuum up discarded

cigars or cigarettes unless the cinders are

completely cool.

■ Keep all parts of your body away from any

moving part. Rotating fan blades can cause

3

Page 6

Original instructions | English

severe injury. Stop the engine and ensure

that fan blades have stopped rotating

before opening the vacuum door, installing

or changing tubes, or opening or removing

debris bag.

■ When feeding material into the product,

make sure that the pieces of metal, rocks,

bottles, cans, or other foreign objects are

not included.

■ Do not allow processed material to build

up in the discharge zone. This may prevent

proper discharge and can result in kickback

of material through the intake opening.

■ If the product becomes clogged, stop the

engine before cleaning the debris.

TRANSPORTATION AND STORAGE

■ Stop the engine and allow the product to

cool down before storing or transporting.

■ Clean all foreign material from the product.

■ Drain all fuel from the tank into a container

approved for petrol. Remember to properly

replace and tighten the fuel cap.

■ Run the engine until it stops. This will

remove all fuel that could become stale and

leave varnish and gum in the fuel system.

■ Store the product in a cool, dry, and

well-ventilated place that is inaccessible

to children. Keep away from corrosive

agents, such as garden chemicals and deicing salts.

■ Do not store outdoors.

■ When transporting the product in a vehicle,

secure it against movement or falling to

prevent injury to persons or damage to the

product.

■ Abide by all government and local

regulations for the safe storage and

handling of petrol.

Short term (less than 1 month)

■ Stop the engine and allow the product to

cool down before storing or transporting.

■ Clean all foreign material from the product.

■ Store the product in a cool, dry, and well-

ventilated place that is inaccessible to

children.

■ Keep away from corrosive agents such as

garden chemicals and de-icing salts.

■ Do not store outdoors.

MAINTENANCE

WARNING

Use only original manufacturer’s

replacement parts, accessories, and

attachments. Failure to do so can cause

possible injury and poor performance, and

may void your warranty.

WARNING

Servicing requires extreme care and

knowledge and should be performed only

by a qualied service technician. Have the

product serviced by an authorised service

centre only. When servicing, use only

original replacement parts.

■ Stop the engine, allow the product to cool

down, and make sure all moving parts

have come to a complete stop.

■ You may make adjustments and repairs

described in this manual. For other repairs,

contact an authorised service centre.

■ After each use, clean the product with a

soft, dry cloth.

■ Check all nuts, bolts, and screws at

frequent intervals for proper tightness to

ensure that the product is in safe working

condition. Any part that is damaged should

be properly repaired or replaced by an

4

Page 7

Original instructions | English

authorised service centre.

■ Have the product serviced by an authorised

service centre to replace damaged or

unreadable labels.

CLEARING A BLOCKAGE

■ To reduce the risk of injury associated with

contacting rotating parts, always stop the

engine, and make sure all moving parts

have come to a complete stop.

■ Remove the blower/vacuum tubes to

inspect for blockage. Clear the tubes if

required.

■ Remove the vacuum bag. Check that the

bag adaptor is free from obstruction.

■ Inspect the opening to the fan enclosure

and the tube to the vacuum bag for

evidence of a blockage. Keep fingers away

from the fan at all times.

■ Do not attempt to remove the fan. If it is

necessary to remove the fan, have the

product serviced by an authorised service

centre.

■ Reinstall the tubes and the vacuum bag

before starting the product.

RESIDUAL RISKS

Even when the product is used as prescribed,

it is still impossible to completely eliminate

certain residual risk factors. The following

hazards may arise in use and the operator

should pay special attention to avoid the

following:

■ Injury caused by vibration.

– Always use the right tool for the job. Use

designated handles and restrict working

time and exposure.

■ Hearing damage caused by exposure to

noise.

– Wear ear protection and limit exposure.

■ Injury from flying objects from the blow tube

airflow

– Wear eye protection at all times.

RISK REDUCTION

It has been reported that vibrations

from handheld tools may contribute to a

condition called Raynaud’s Syndrome in

certain individuals. Symptoms may include

tingling, numbness, and blanching of the

ngers, usually apparent upon exposure to

cold. Hereditary factors, exposure to cold

and dampness, diet, smoking and work

practices are all thought to contribute to the

development of these symptoms. There are

measures that can be taken by the operator to

possibly reduce the effects of vibration:

■ Keep your body warm in cold weather.

When operating the product wear gloves

to keep the hands and wrists warm. It is

reported that cold weather is a major factor

contributing to Raynaud’s Syndrome.

■ After each period of operation, exercise to

increase blood circulation.

■ Take frequent work breaks. Limit the

amount of exposure per day.

If you experience any of the symptoms of this

condition, immediately discontinue use and

see your physician.

WARNING

Injuries may be caused, or aggravated, by

prolonged use of a tool. When using any

tool for prolonged periods, ensure you take

regular breaks.

FEATURES

KNOW YOUR BLOWER/VACUUM

See page 14.

The safe use of the product requires an

understanding of the information on the

product and in this operator’s manual as

well as knowledge of the project you are

attempting to do. Before use of the product,

familiarise yourself with all operating features

and safety rules.

5

Page 8

Original instructions | English

BLOWER TUBE AND NOZZLES

The blower tube can be installed on the blower

without using any tools.

POSITIVE SWITCHES

The product has positive switches at the

blowing and vacuuming opening sides. The

unit will only run if both the metal contacts

are inserted into the positive switches. When

running the unit in blower mode, the metal

contact on the blow tube and the door must be

inserted into their respective positive switches.

When running the unit in vacuuming mode,

the metal contact on the adaptor tube and

the vacuum tube must be inserted into their

respective positive switches. This reduces the

risk of accidental contact with rotating parts.

TWO ENGINE KILL SWITCHES

There are two ON/OFF switches, blower and

vacuum mode switches, in the top handle,

so that the engine can be stopped easily by

pressing either switch. Both switches should

be set to “I“ (ON) to run the engine.

ENGINE

The blower has a powerful 26 cc engine with

sufcient power to handle tough blowing and

vacuuming jobs.

THROTTLE TRIGGER

The blower can be operated at any speed

between idle and full throttle.

VACUUM

Converting the blower to a vacuum is

simple and can be done using a cross head

screwdriver.

VACUUM BAG

The vacuum bag attaches to the blower easily

by using the vacuum bag adaptor.

VACUUM HANDLE

This feature allows the user to perform

vacuuming duties comfortably.

VACUUM TUBES

The vacuum tubes can be installed on the

blower using a cross head screw driver.

ASSEMBLY

UNPACKING

The product requires assembly.

■ Carefully remove the product and any

accessories from the box. Make sure that

all items listed in the “What’s in the box”

section are included.

WHAT’S IN THE BOX

See page 14.

■ Blower/Vacuum x 1

■ Blower tube/nozzle x 1

■ Upper vacuum tube x 1

■ Lower vacuum tube x 1

■ Adaptor installed in vacuum bag x 1

■ Lubricating oil x 1

■ Operator’s manual x 1

TOOLS NEEDED

The following tools are not included in the

package but are needed for the assembly:

■ Socket wrench

■ Phillips head screwdriver

■ Flat head screwdriver

WARNING

Do not use the product if any parts in the

“What’s in the box” section are already

assembled when you rst open the box.

The parts on the list are not assembled

by the manufacturer and require customer

installation. Use of a product that may have

been improperly assembled could result in

serious personal injury.

6

Page 9

Original instructions | English

■ Carefully inspect the product to make sure

no breakage or damage occurred during

shipping.

■ Do not discard the packing material

until you have carefully inspected and

satisfactorily operated the product.

■ If any parts are damaged or missing,

please call your HOMELITE service centre

for assistance.

WARNING

If any parts are damaged or missing, do

not operate the product until the parts are

replaced. Use of the product with damaged

or missing parts could result in serious

personal injury.

WARNING

Do not attempt to modify the product or

create accessories not recommended for

use with the product. Any such alteration

or modication is misuse and could result

in a hazardous condition leading to possible

serious personal injury.

WARNING

Rotating impeller blades can cause severe

injury. Always stop the engine and ensure

impeller blades have stopped rotating

before opening the vacuum door or

installing/changing tubes. Do not put hands

or any other object into the vacuum tubes

while they are installed on the unit.

OPERATION

WARNING

Do not allow familiarity with tools to make

you careless. Remember that a careless

fraction of a second is sufcient to inict

serious injury.

WARNING

Always wear eye protection with side

shields marked to comply with standards,

along with hearing protection. Failure to do

so could result in serious injuries such as

objects being thrown into your eyes.

MIXING THE FUEL

The product is powered by a 2-stroke engine

and requires premixing petrol and 2-stroke oil.

The mixture should be at a 50:1 ratio.

NOTE: We recommend you use RYOBI

synthetic 2-stroke lubricant. Only use a quality

synthetic 2-stroke lubricant in the product to

ensure top performance and engine longevity.

NOTE: If using similar containers for different

fuels, label the container with its contents and

the date it was added.

To mix the fuel:

■ Pre-mix unleaded petrol and 2-stroke

engine lubricant in a clean container

approved for petrol.

■ The engine of the product is certified to

operate on unleaded petrol intended for

automotive use with an octane rating of 91

or higher.

■ Do not use any type of pre-mixed petrol/

lubricant from fuel service stations; this

includes the pre-mixed petrol/lubricant

intended for use in mopeds, motorcycles,

etc.

■ Avoid using ethanol fuels or fuels containing

ethanol. The use of ethanol fuels may result

in damage to the engine of the product.

■ Use only synthetic 2-stroke lubricant. Do

not use automotive lubricant or 2-stroke

outboard lubricant.

■ Mix 2% synthetic 2-stroke lubricant into the

petrol. This is a 50:1 ratio.

■ Mix the fuel thoroughly and also each time

7

Page 10

Original instructions | English

before fuelling.

■ Mix in small quantities. Do not mix quantities

larger than usable in a 30-day period. A

synthetic 2-stroke lubricant containing a

fuel stabiliser is recommended.

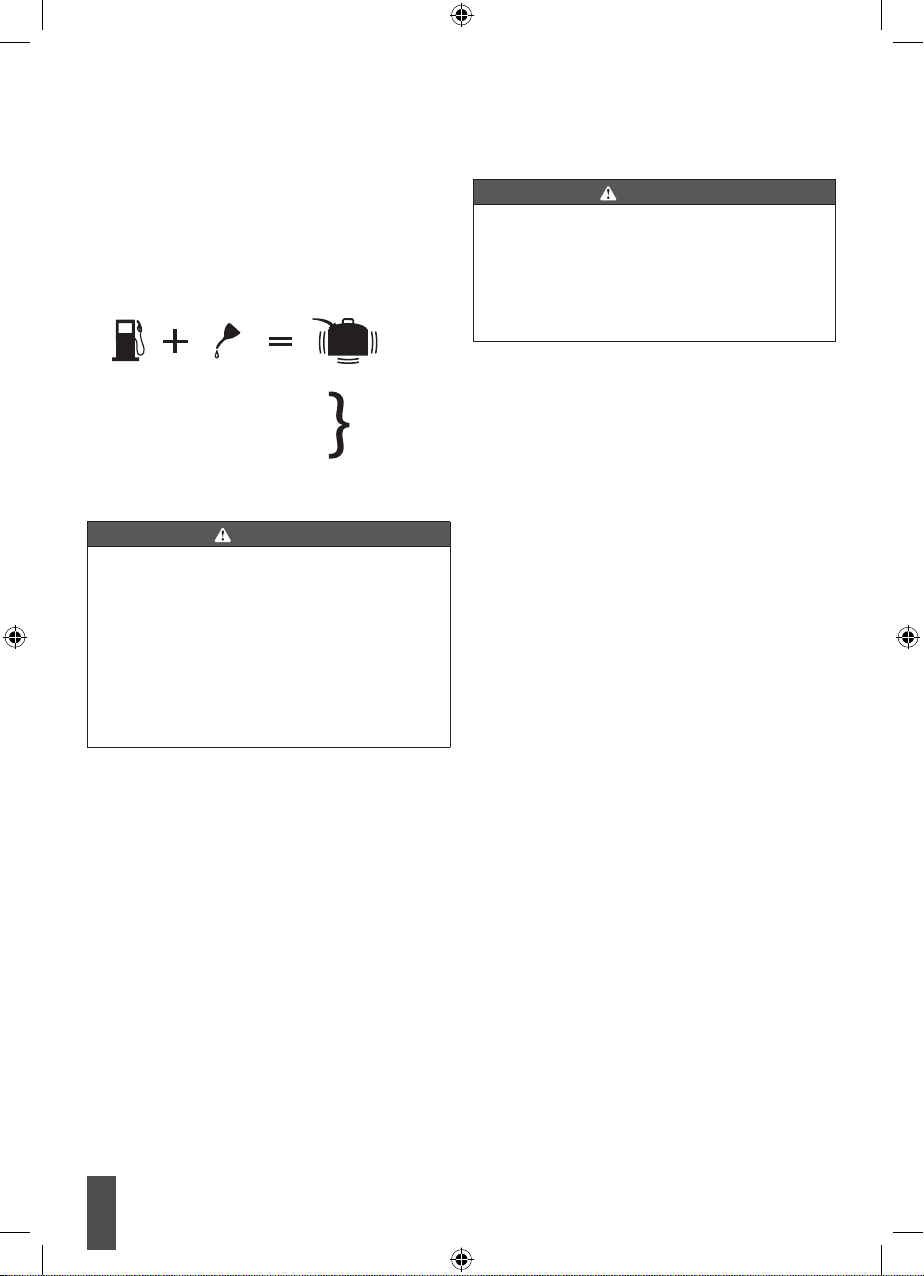

1 L + 20 mL =

2 L + 40 mL =

3 L + 60 mL = 50:1 (2%)

4 L + 80 mL =

5 L + 100 mL =

FILLING THE TANK

WARNING

Petrol is extremely ammable and explosive.

A re or explosion from petrol will burn you

and others. Always shut off engine before

fuelling. Never add fuel to a machine with

a running or hot engine. Move at least 9 m

from refuelling site before starting engine.

Do not smoke and stay away from open

ames and sparks. Failure to safely handle

fuel could result in serious personal injury.

1. Clean the surface around the fuel cap to

prevent contamination.

2. Loosen the fuel cap slowly.

3. Pour the fuel mixture carefully into the tank.

4. Clean and inspect the fuel cap gasket

before replacing the fuel cap.

5. Replace the fuel cap and tighten it. Do not

cross thread the fuel cap.

6. Wipe spilled fuel from the product.

7. Move at least 9m away from refuelling area

before starting the product.

NOTE: It is normal for smoke to be emitted

from a new engine during rst use.

WARNING

Check for fuel leaks. A leaking fuel cap

is a re hazard and must be replaced

immediately. If you nd any leaks, correct

the problem before using the product.

Failure to do so could result in a re that

could cause serious personal injury.

OXYGENATED FUELS

Do not use E85 fuel. It will void your warranty.

NOTE: Fuel system damage or performance

problems resulting from the use of an

oxygenated fuel containing more than the

percentages of oxygenates stated previously

are not covered under warranty.

Petrol containing up to 10% ethanol by volume

(commonly referred to as E10) or 15% ethanol

by volume (commonly referred to as E15) are

acceptable. Do not use E85 fuel.

USING THE BLOWER

See page 25.

■ To keep from scattering debris, blow

around the outer edges of a debris pile.

Never blow directly into the center of a pile.

■ Operate power equipment at reasonable

hours only - not early in the morning or late

at night when people might be disturbed.

Comply with the times listed in local

ordinances.

■ To reduce sound levels, limit the number of

pieces of equipment used at any one time

and operate blower at the lowest possible

throttle speed to do the job. This may also

reduce vibration levels.

■ Conserve water by using power blowers

instead of hoses for many lawn and

garden applications, including areas such

as screens, patios, grills, porches, and

gardens.

■ Check your equipment before operation,

especially the silencer, air intakes, and air

8

Page 11

Original instructions | English

filters.

■ Use rakes and brooms to loosen debris

before blowing.

■ In dusty conditions, slightly dampen

surfaces when water is available.

■ After using blowers or other equipment,

clean up. Dispose of debris properly.

WARNING

Never run the product without the blower/

vacuum tube installed. Failure to follow

these steps could result in possible serious

injuries.

WARNING

Always hold the blower/vacuum away

from your body with the handle in your

right hand when operating as a blower,

keeping clearance between your body and

the product. The mufer side of the blower

should be away from your body. Any

contact with the housing can result in burns

and/or other serious personal injury.

WARNING

Do not place blower on top of or near loose

debris or gravel. Debris may be sucked

into blower intake vent resulting in possible

damage to the product and could result in

serious personal injury.

WARNING

Watch out for children, pets, open windows,

or freshly washed cars, and blow debris

safely away.

USING THE VACUUM

See page 26.

WARNING

Keep the silencer and all hot surfaces of

the blower/ vacuum away from your body.

Failure to do so could result in possible

serious personal injury.

■ Place the vacuum bag strap over your right

shoulder. Hold the upper handle in your left

hand and the vacuum handle in your right

hand.

■ Move the blower/vacuum from side to side

along outer edge of the debris. To avoid

clogging, do not place the vacuum tube

directly into the debris pile.

■ Hold the engine higher than the inlet end of

the vacuum tube.

■ Always point vacuum tube downhill when

working on a hillside.

■ To avoid serious injury to the operator or

damage to the unit, do not pick up rocks,

broken glass, bottles, or other similar

objects.

■ If the vacuum tubes should clog, stop

the engine, ensure impeller blades have

stopped spinning, and disconnect the

spark plug wire before cleaning out the

obstruction.

■ Remove the vacuum tubes and clear

the debris from the blower fan housing.

Remove the bag and clear the tube. A

small rod or stick may be required to clear

the entire tube length. Ensure that all debris

has been cleared before reassembling the

vacuum tubes.

9

Page 12

Original instructions | English

GENERAL MAINTENACE

CLEANING THE AIR FILTER

See page 29.

A wet or dirty air lter causes starting difculty,

loss of performance, and shorten the life span

of the engine. The air lter should be checked

and cleaned after 5 hours of operation.

Inspect and clean more frequently if used in

dusty dirty conditions.

For best performance, the air lter should be

replaced every 25 hours or yearly.

CLEANING THE EXHAUST PORT, MUFFLER, AND SPARK ARRESTOR

NOTE: Depending on the type of fuel used,

the type and amount of lubricant used, and/

or your operating conditions, the exhaust

port, mufer, and/or spark arrestor screen

may become blocked with carbon deposits.

If you notice a power loss with your petrolpowered product, you may need to remove

these deposits to restore performance. We

highly recommend that only qualied service

technicians perform this service.

The mufer must be replaced every 50 hours

or yearly to ensure proper performance of

your product.

CLEANING THE VACUUM BAG

See page 30.

A dirt bag will reduce performance. To clean

the bag, turn it inside out and shake. Wash the

bag in soapy water at least once a year.

REPLACING THE SPARK PLUG

See page 28.

The engine uses a HOMELITE AC00160,

Champion RCJ-6Y or NGK BPMR7A spark

plug with .025 in. electrode gap. Use an exact

replacement and replace annually.

SYMBOLS ON THE PRODUCT

Read and understand

all instructions before

operating the product, follow

all warnings and safety

instructions.

Risk of loose clothing being

drawn into air intake.

Risk of long hair being drawn

into air inlet.

Warning! Hot surface.

FUEL CAP

WARNING

A leaking fuel cap is a re hazard and must

be replaced immediately.

The fuel cap contains a non-serviceable

lter and a check valve. A clogged fuel

lter will cause poor engine performance. If

performance improves when the fuel cap is

loosened, check valve may be faulty or lter

clogged. Replace fuel cap if required.

10

Wear eye protection.

Wear ear protection.

Do not run unit without tubes

in place.

Beware of rotating fans.

Keep hands and feet out of

openings while the product is

running.

Page 13

Original instructions | English

Beware of thrown or ying

objects. Keep all bystanders,

especially children and pets,

at least 15 m away from the

operating area.

To reduce the risk of injury or

damage, avoid contact with

any hot surface.

The measured sound power

level is 112 dB(A).

Use unleaded petrol intended

for motor vehicle use with an

octane rating of 91 or higher.

Use 2-stroke oil for air cooled

engines.

Mix the fuel mix thoroughly

and also each time before

refuelling.

Run position

Set the choke lever to “HALF”

choke position.

Waste electrical products

should not be disposed of

with household waste. Please

recycle where facilities exist.

Check with your local authority

or retailer for recycling advice.

The following signal words and meanings

are intended to explain the levels of risk

associated with this product.

DANGER

Indicates an imminently hazardous

situation, which, if not avoided, will result in

death or serious injury.

WARNING

Indicates a potentially hazardous situation,

which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation,

which, if not avoided, may result in minor or

moderate injury.

CAUTION

Without safety alert symbol

Indicates a situation that may result in

property damage.

SYMBOLS IN THIS MANUAL

Set the choke lever to “FULL”

choke position.

Starting a cold engine

Starting a warm engine

Regulatory Compliance

Mark (RCM). The product

meets applicable regulatory

requirements.

Note

Warning

Parts or accessories are sold

separately

11

Page 14

Original instructions | English

TROUBLESHOOTING

Problem Possible causes Solution

Engine fails to

start.

Engine hard to

start.

Engine lacks

power.

Engine

overheats.

No fuel in tank. Fill tank.

Spark plug shorted or

fouled.

Spark plug is broken

(cracked porcelain or

electrodes broken).

Ignition lead wire shorted,

broken, or disconnected

from spark plug.

Ignition inoperative.

Check and make sure

the switches engaged

ready to work and the on/

off switches are in the run

(I) position.

Water in petrol or stale

fuel mixture.

Water in petrol or stale

fuel mixture.

Engine is under or over

choked.

Weak spark at spark

plug.

Air lter clogged. Clean air lter. Refer to the “Cleaning the Air

Insufcient lubricant in

fuel mixture.

Replace spark plug.

Replace spark plug.

Contact authorised service centre.

Contact authorised service centre.

Drain entire system and rell with fresh fuel.

Drain and rell with correct mixture.

Adjust choke as necessary.

Contact authorised service centre.

Filter” section in this manual.

Mix fuel as described in starting instructions.

12

Page 15

Original instructions | English

13

Page 16

x 1x 1

x 1

14

x 1

x 1

x 1

x 1

Page 17

1. ON/OFF switch

for blower mode

2. Top handle

3. ON/OFF switch

for vacuum mode

4. Starter grip

5. Fuel cap

6. Vacuum grip handle

18

7. Choke lever

8. Primer bulb

9. Positive switch at

vacuuming side

10. Vacuum inlet door

11. Vacuum bag adaptor

12. Vacuum bag

13. Lower vacuum tube

2 3

1

14. Upper vacuum tube

15. Blower tube

16. Positive switch at

blowing side

17. Spark plug

18. Throttle trigger

4

17

16

15

12 111314

5

6

7

8

9

10

15

Page 18

1 2

(50 : 1)

Wear full eye and ear protection, substantial footwear, and

long trousers at all times while operating the product. Do

not operate the product when barefoot or wearing open

sandals.

Pre-mix 2-stroke engine lubricant and unleaded petrol in a

clean container approved for petrol at a 50:1 ratio.

B3 B4

Open the vacuum inlet door. Align the raised locking tabs of the lower vacuum tube with

the matching orice on the upper vacuum tube to secure

the vacuum tubes together.

16

Page 19

A B

3 A1

1

3

3

2

2

A2

B1

B2

A. Attach the blower tube. B. Attach the vacuum tubes.

B5

2

1

1. Align raised tabs on upper blower tube with the slots on

blower housing outlet. 2. Attach and tighten securely by

turning clockwise until it clicks into place.

Press slider plate into positive switch’s slot.

NOTE: Ensure to attach the blower tube securely to the

blower/vacuum housing.

3

2

1

1. Align the raised slots on the vacuum bag adaptor with

the raised locking tabs on the blower housing outlet; push

the bag adaptor onto the housing. 2. Twist to lock into

place. 3. Press the slider plate into the positive switch slot

to make sure the switch is engaged and ready to operate.

4

1

2

1. Depress door tab using a at head screwdriver.

2. Loosen the screw on the door to open vacuum inlet door.

1. Align tabs on housing with the vacuum tube assembly. 2. Tighten screws on upper vacuum tube to secure to blower

housing.

NOTE: Ensure to attach the vacuum tubes securely to the

blower/vacuum housing.

A. Hold the blower with the upper handle in your right hand.

Place the vacuum bag strap over your right shoulder. Hold

the upper handle in your left hand and the vacuum handle

in your right hand.

To stop the engine, toggle either the blower or vacuum

switch to the “STOP” position.

17

Page 20

18

Page 21

Cold start engine Warm start engine

p.21

p.23

Using the blower Using the vacuum

p.25

p.26

19

Page 22

Replacing the spark plug

Cleaning the air filter

Cleaning the vacuum bag

p.28 p.29

p.30

Cleaning the blower/vacuum

20

p.31

Storing the blower/vacuum

p.32

Page 23

1

STARTING A COLD ENGINE

1. Loosen the fuel cap slowly by turning it

counterclockwise. Remove the fuel cap.

Pour the fuel mixture carefully into the

tank. Replace and tighten the fuel cap.

2. Set the 2 switches to “I“ (ON) position.

3. Press the primer bulb 10 times. Set the

choke lever to “FULL“ position.

4. Squeeze the throttle trigger. Pull the

starter grip until the engine attempts to

start. Do not pull the starter grip more

than 8 times.

2

1

3

2

3

1010

1

2

4

2

1

8

21

Page 24

5. Set the choke lever to the “HALF“ choke

position.

6. Squeeze the throttle trigger. Pull the

starter grip until the engine attempts to

start. Do not pull the starter grip more

than 6 times.

7. When engine starts, wait for 10 seconds.

8. Set the choke lever to the “RUN”

position.

5

6

2

1

6

7

8

22

Page 25

NOTE: Hold blower as shown, so the

air stream can work close to the ground.

9. To stop the engine, toggle either the

blower or vacuum switch to the

“STOP" position.

9

23

Page 26

STARTING A WARM ENGINE

1. Toggle the 2 switches to the “I“ (ON)

position.

2. Press the primer bulb 10 times. Set the

choke lever to “RUN“ position.

3. Squeeze the throttle trigger. Pull the

starter grip until the engine starts. Do not

pull the starter grip more than 6 times.

4. To stop the engine, toggle either the

blower or vacuum switch to the “STOP“

position.

1

2

1010

1

2

3

24

2

1

6

4

Page 27

USING THE BLOWER

1. Attach the blower tube to the blower.

Refer to the “Getting Started” section for

the procedure.

2. Start the blower. Refer to the “Starting a

cold engine” or “Starting a warm engine”

section for the procedure.

3. Squeeze the throttle trigger to start the

blower. Hold the blower with the handle

in your right hand.

NOTE: Hold blower as shown, so the air

stream can work close to the ground.

1

2

1

2

3

25

Page 28

USING THE VACUUM

1. Align the raised slots on the vacuum bag

adaptor with the raised locking tabs on

the blower housing outlet; push the bag

adaptor onto the housing.

2. Twist to lock into place.

3. Press the metal contact into the positive

switch slot to make sure the switch is

engaged and ready to operate.

4. Loosen the screw on the door to open

vacuum inlet door.

1

2

3

26

4

1

2

Page 29

5. Open the vacuum inlet door.

6. Align the raised locking tabs with the

matching orice on the upper vacuum

tube to secure the upper and lower

vacuum tubes together. An audible click

can be heard to indicate that the blower

tubes are secured.

7. Align tabs on housing with vacuum

tube assembly. Tighten screws on

upper vacuum tube to secure to blower

housing.

8. Start the blower. Refer to the “Starting a

cold engine” or “Starting a warm engine”

section for the procedure. Squeeze the

throttle trigger to start the vacuum.

NOTE: Place the vacuum bag strap

over your right shoulder. Hold the upper

handle in your left hand and the vacuum

handle in your right hand.

5

6

7

3

2

1

3

2

8

1

2

27

Page 30

REPLACING THE SPARK PLUG

1. To stop the engine, toggle either the

blower or vacuum switch to the “STOP”

position.

2. Disconnect the lead wire from the

spark plug. Using a socket wrench with

an extension and spark plug socket,

loosen the spark plug by turning it

counterclockwise.

3. Remove the old spark plug and dispose

properly.

4. Using the socket wrench, install the

new spark plug and tighten by turning it

clockwise. Connect the lead wire to the

spark plug.

1

2

2

1

3

28

4

4

3

1

2

Page 31

CLEANING THE AIR FILTER

1. To stop the engine, toggle either the

blower or vacuum switch to the “STOP”

position.

2. Press the air filter cover tab to open the

air filter cover. Open the air filter cover.

3. Lift the edge of the air filter carefully

and peel it out. Clean the air filter with

a brush.

4. To reinstall the air filter cover, insert the

tabs into the notches and lock into place.

NOTE: Make sure the filter is seated

properly inside the cover. Installing the

filter incorrectly will allow dirt to enter the

engine, causing rapid engine wear.

1

2

1

2

3

4

2

1

29

Page 32

1

CLEANING THE VACUUM BAG

1. To stop the engine, toggle either the

blower or vacuum switch to the “STOP”

position.

2. To remove the vacuum bag and adaptor,

pull off the metal contact, twist the

adaptor counterclockwise, and then

remove the vacuum bag and adaptor

from the blower housing outlet.

3. Unzip the vacuum bag and dispose

debris properly.

2

3

1

2

3

30

Page 33

CLEANING THE BLOWER/VACUUM

1. To stop the engine, toggle either the

blower or vacuum switch to the “STOP”

position.

2. Clean the blower/vacuum using a brush.

WARNING: Avoid using solvents when

cleaning plastic parts. Most plastics are

susceptible to damage from various

types of commercial solvents and may

be damaged by their use. Use clean

cloths or brush to remove dirt, dust,

lubricant, grease, etc.

1

2

3

31

Page 34

1

CLEANING THE BLOWER/VACUUM

1. To stop the engine, toggle either the

blower or vacuum switch to the “STOP”

position.

A1.To remove the blower tube, twist and

remove the tube from the blower

housing outlet.

B1.To remove the vacuum tube assembly,

loosen the screws that secure the tube

assembly to the inlet cover.

B2.Press on the raised locking tab, and then

detach the upper vacuum tube from the

lower vacuum tube.

A1

B1

B2

1

2

3

1

2

3

1

1

32

2

Page 35

B3. Close the vacuum inlet door and secure

with the securing screw.

B4. To remove the vacuum bag and adaptor,

pull off the metal contact, twist the

adaptor counterclockwise, and then

remove the vacuum bag and adaptor

from the blower housing outlet.

2. Loosen the fuel cap slowly by turning

counterclockwise, and then drain all fuel

from the tank into a container approved

for fuel. After draining all the fuel, replace

the fuel cap and tighten by turning it

clockwise.

3. Store blower/vacuum and its parts in a

cool dry and well-ventilated place that is

inaccessible to children.

B3

B4

2

2

3

1

1

3

2

4

20180328v1d8

2

3

1

3

33

Page 36

PRODUCT SPECIFICATIONS

Blower/Vacuum

Model HBL26BVB

Rated power 0.65 kW

Engine displacement 26 cc

Engine speed (max) 8500/min

Engine speed (idle) 2800 - 3400/min

Air velocity 320 km/h

Air volume 11 m3/hr

Weight (without fuel) 5.2 kg

Vibration

Blower mode

Idling 6.2 m/s

Racing 31.3 m/s

Equivalent vibration total value 29.1 m/s

Sound

Blower mode

Idling 89.4 dB

Racing 109.4 dB

2

2

2

ACCESSORY

Vacuum bag HAC302

WARNING

The declared vibration value has been

measured with a standard test method

and may be used to compare one tool with

another.

The declared vibration value may be used in

a preliminary assessment of exposure.

The vibration emission during actual use of

power tool can differ from the declared total

value depending on the ways in which the

tool is used.

Identify safety measures to protect yourself

based on an estimation of exposure in the

actual conditions of use, taking account

of all parts of the operating cycle such as

the times when the tool is switched off and

when it is running idle in addition to the

trigger time.

Page 37

Page 38

Page 39

Page 40

Imported by:

Techtronic Industries Australia Pty. Ltd.

31 Gilby Road, Mount Waverly, VIC 3149,

Melbourne, Australia

Techtronic Industries NZ Limited

2 Landing Drive, Mangere,

Auckland, 2022 , New Zealand

960704016-01

Loading...

Loading...