Page 1

0

INSTALLATION AND OPERATION MANUAL.

MANUEL D’INSTALLATION ET D’UTILISATION.

INSTALLATIONS UND BEDIENUNGSANLEITUNG.

Page 2

1

English / CONTENTS.

Page

Safety information 2

Safety guidelines 2

Warning symbols 3

Liability 3

Foreword 3

General information 3

Mixer dimensions. Figure 1 3

Technical information. Table 1 4

Installation 4

Unpacking and handling 4

Location 5

Electrical installation 5

Electrical connection 6

Commissioning and operating instructions 6

Operation 6

Using for the first time 6

Mixer component identification. Figure 2 6

Using the bowl scraper 7

General bowl scraper use 7

Operating with the bowl scraper 8

Cleaning the bowl scraper 8

When mixing has finished 8

Using the attachment facility 9

Attachment safety instructions 9

Fitting an attachment 9

Safety instructions 9

Never 10

Always 10

Mixing capacity chart 11

Mixing chart-kitchen capacities HSM30 / NCM300. Table 2 11

Mixing chart-bakery capacities HSM30 / NCM300. Table 3. 11

Mixing chart-kitchen capacities HSM40 / NCM400. Table 4. 12

Mixing chart-bakery capacities HSM40 / NCM400. Table 5 12

Mixing chart-kitchen capacities 20 litre bowl. Table 6. 12

Mixing chart-bakery capacities 20 litre bowl. Table 7. 12

Mixer agitators 13

Cleaning 14

Cleaning before initial use 14

Cleaning after use 14

Guard removal and cleaning 14

Mixer maintenance 15

Fault finding 16

Recommended spares 17

Notes 18

Service information and addresses 19

Page 3

2

1.0 SAFETY INFORMATION.

The procedures and precautions contained in this manual are understood to apply to the

machinery only when it is used in the prescribed manner.

If the machinery is used other than in the recommended manner, the operator will be

responsible for his/her own safety and for the safety of the other persons who may be

involved.

The information in this manual has been prepared to assist the operator to understand,

maintain, and operate the mixer. In order to prevent accidents, read, understand and

follow all the precautions and warnings contained in this manual before installation or

operating for the first time. This manual must be studied to obtain a clear understanding of

the mixer and its capabilities.

1.1 SAFETY GUIDELINES.

Ensure sufficient precautions are observed during manually handling of the mixer

particularly when moving into position on installation. Reference must be made to manual

handling regulations. The mixer weights are given in table 1.

· Do not hose or pressure clean this appliance. It is vital to adhere to the cleaning

instructions detailed in section 9 of this manual.

· Do not remove any covers or loosen any fittings whilst the machine is operating.

· Ensure this manual is kept in an easily accessible place for future reference near the

mixer.

· All operators must be trained in the safe operation of the mixer and attachments.

· Ensure the electrical supply has been isolated before attempting to service or move

the mixer.

· Rotating machinery and electricity are potentially hazardous and may cause injury if

sufficient precautions are not taken prior to operating or servicing the machine.

· Always have your mixer and attachments regularly serviced; at least twice a year,

depending on frequency of use.

· Important! When using reduced size equipment only the following bowls detailed in

section 12 must be used. Do not operate a mixer with any other reduced size bowl

combinations. Reduced sizes are 30 or 20 litre bowls on an HSM40 / NCM400 or 20

litre bowl on an HSM30 / NCM300. The recommended spares table in section 12

details the respective bowl and agitator part numbers.

Page 4

3

1.2 WARNING SYMBOLS.

To identify the safety messages in this manual, the following symbols have been used

The " Warning" symbol is found primarily where the corresponding information is

important for the safe use of the machinery.

The electrical hazard symbol is used when there are risks of an electrical nature.

Prior to servicing the machinery, always disconnect the power cable from the

mains supply.

1.3 LIABILITY.

Installations and repairs which are not carried out by Authorised technicians or the use

of other than original spare parts, and any technical alterations to the machine, may

affect the warranty set out in the standard conditions of sale.

2.0 FOREWORD.

Hobart reserves the right to alter the design of their products without prior notice. Whilst

every effort is made to ensure this publication reflects the latest design, the Company

cannot guarantee full compliance.

Take pride in your HSM/NCM mixer - keep it clean and in good mechanical and electrical

condition.

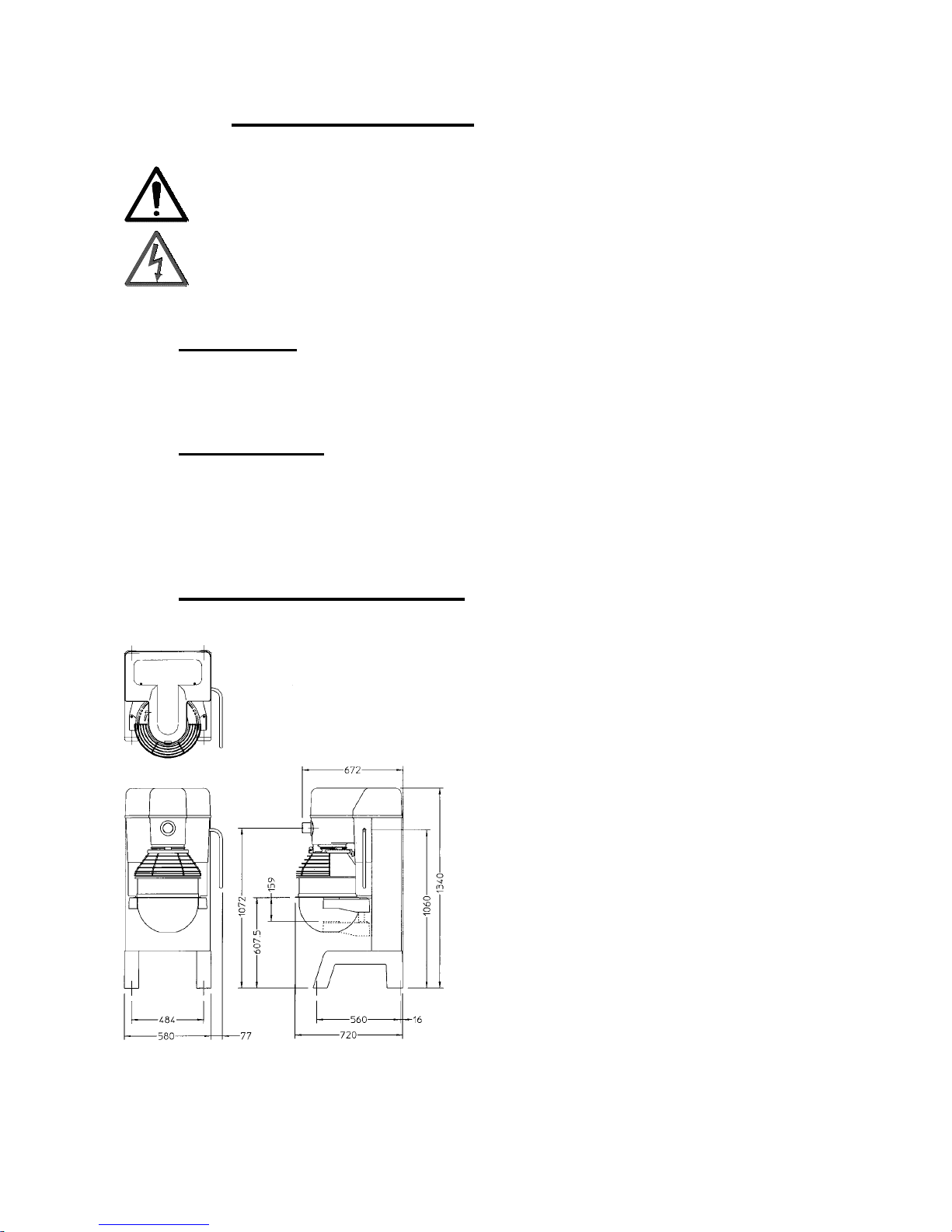

3.0 GENERAL INFORMATION

The information and instructions contained in this manual may not cover all details or

variations in the equipment, nor provide for

every eventuality to arise with installation,

operation, or maintenance. If additional

information is required please contact your

local Hobart office.

The HSM30, HSM40, NCM300 and NCM400

mixer range are designed to mix food

products as detailed on the specification

charts (tables 2, 3, 4 and 5).

The HSM mixers are manufactured from 2

mettalic painted castings, fabricated stainless

steel pedestal, back panel & feet, with a lastic

moulded top cover

The NCM mixers are manufactured from 2

iron castings, fabricated steel pedestal,

aluminium cast feet, with a plastic moulded

top cover all with a Hobart grey paint finish.

The machine is rated to operate on the

electrical supplies shown in table 1. The

mixer is fitted with a ‘no volt release’ safety

feature to prevent automatic restarting after a

supply failure or disconnection from the

mains.

FIGURE 1. OVERALL DIMENSIONS.

Page 5

4

The bowl support and the guard are interlocked so that when either are not in their correct

operating positions, the mixer will not work. The standard mixer is delivered with guard,

bowl and agitators.

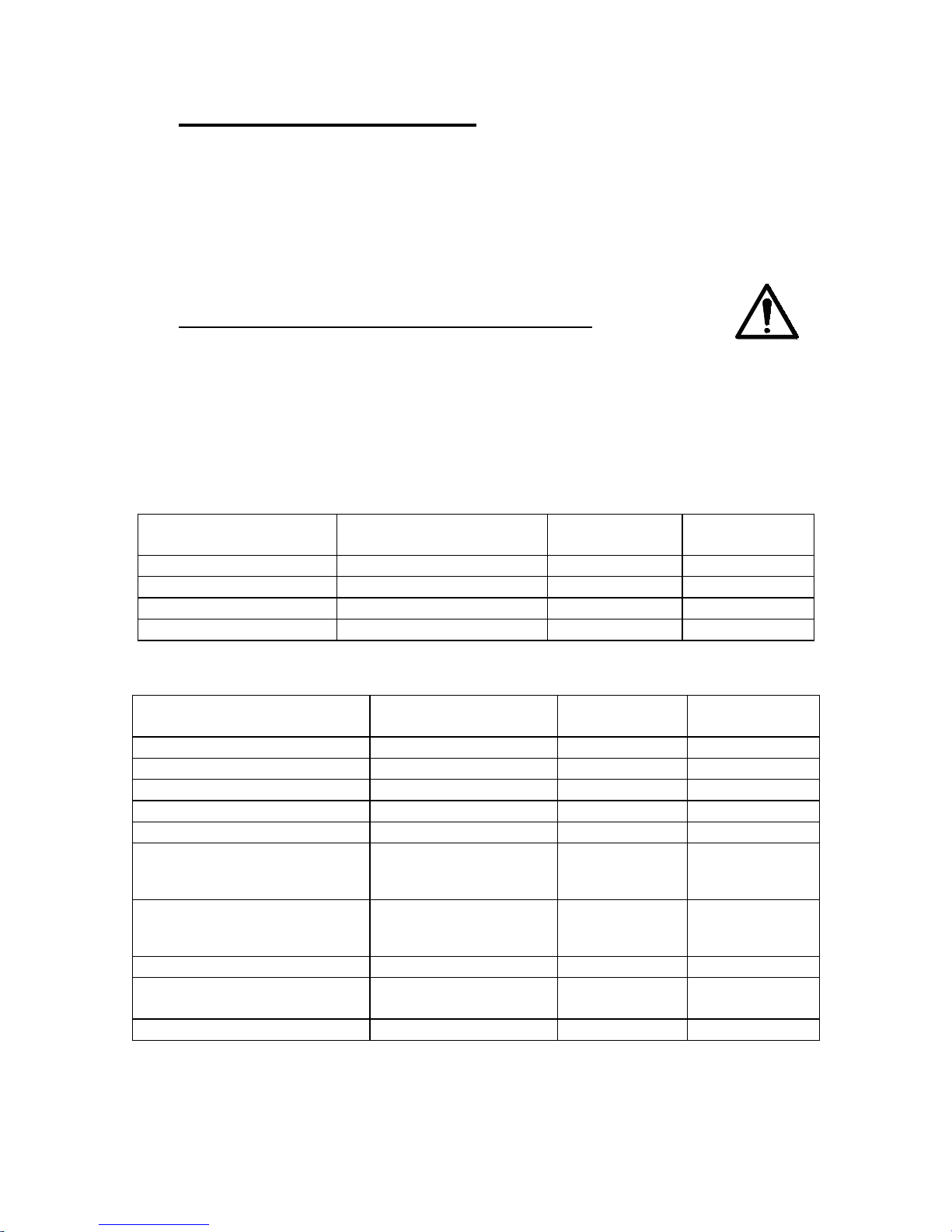

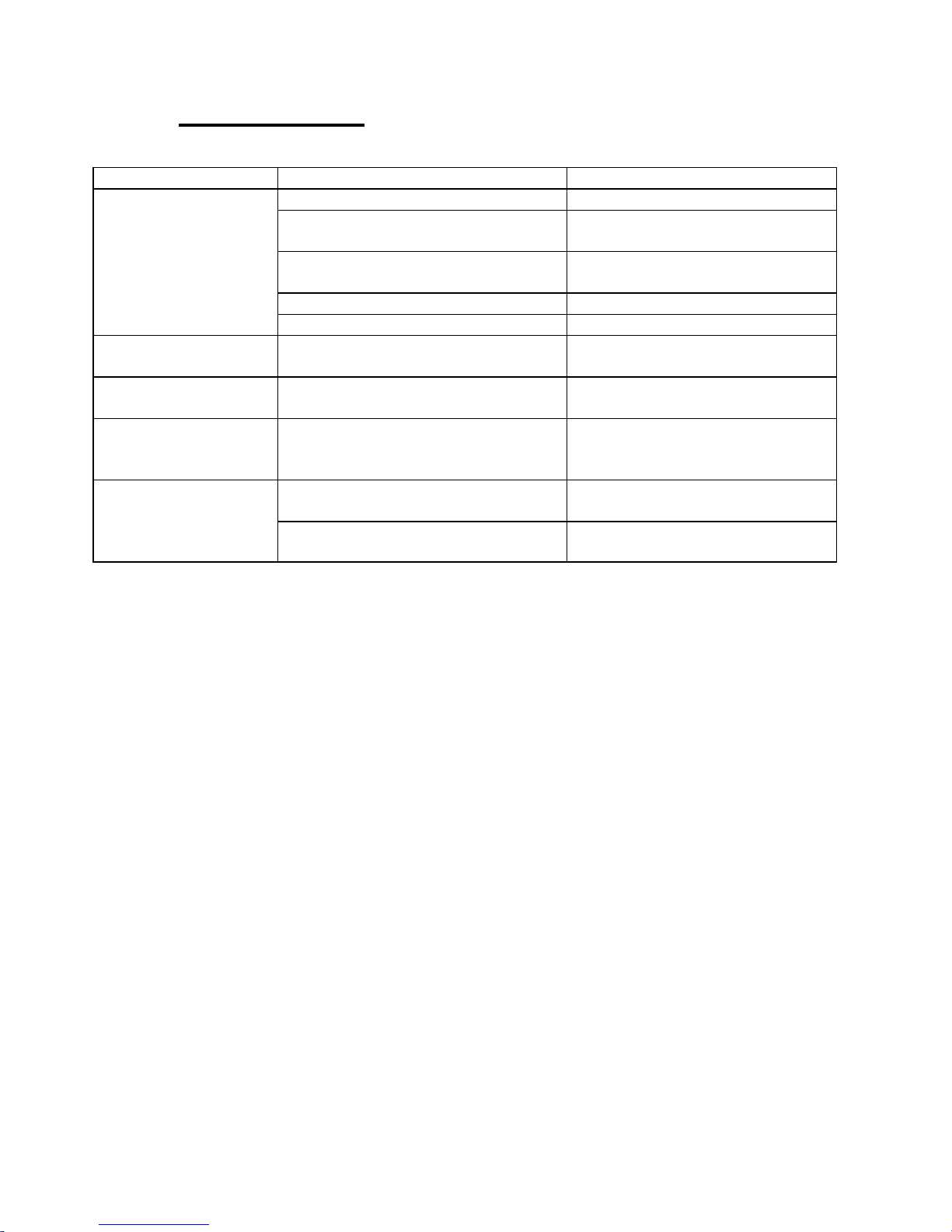

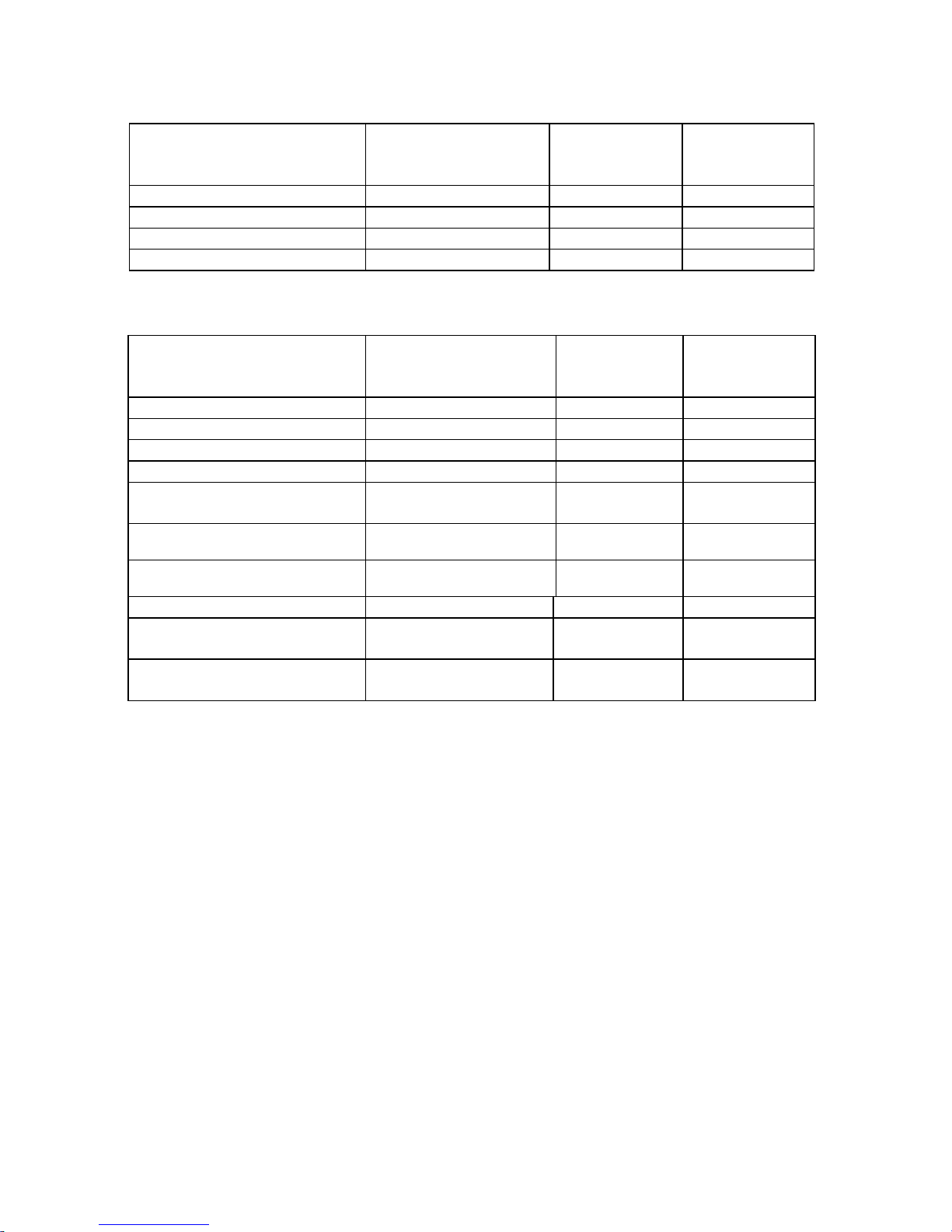

Table 1. Technical information.

Description Units HSM30

NCM300

HSM40

NCM400

Motor power kW (hp) 1.1 (1.5) 1.1 (1.5)

Maximum speed of rotating part (50Hz) rpm 1425 1425

Nominal electrical supply 1 ph Volts/Hz 230/50 230/50

3 ph 400/50 400/50

Full load current at above voltage 1 ph Amps 7.4 7.4

3 ph Amps 2.8 2.8

Locked rotor current at above voltage 1ph Amps 44 16

3 ph Amps 16 16

Recommended fuse size 230v/1 ph/50hz amps 20 20

Recommended fuse size 230v/3 ph/50hz amps 16 16

Recommended fuse size 400v/3 ph/50hz amps 10 10

Maximum ambient temperature

o

C40 40

Attachment hub drive size -- Number 12 Number 12

Mixer weight including agitator and bowl

(empty)

Kg (Lbs) 241 (531) 246 (542)

Noise level dB (A)

##

less than

70

##

less than

70

Shipping weight kg (Lbs) 255 (562) 260 (573)

Shipping dimensions (carton) LxWxHcm99x81x155 99x81x155

Storage conditions. Temperature and humidity.

o

C,

% RH

+5 to +38,

85

+5 to +38,

85

Class of appliance

#

Class I

#

Class I

Enclosure IP rating IP44 IP44

Wiring terminal size; single phase/3 phase mm

2

1.5/1.0 1.5/1.0

#

Refer to section 4.3.

##

In accordance with EN-ISO 12001:1996.

4.0 INSTALLATION.

4.1 UNPACKING AND HANDLING.

Where ever possible the food mixer should be transported to the installation position in

the packaging provided to avoid damage. Do not use a sharp knife to cut into the box as

damage to the machine may occur. Check for possible shipping damage. If the unit is

found to be damaged, save the packaging material and contact your nearest Hobart sales

office.

Caution: The mixer is a heavy object and must be correctly handled and lifted

to avoid personal injury.

Page 6

5

With the machine in the vicinity of its final position remove from the transportation pallet

following the instructions provided with the packaging. The machine is affixed to the pallet

by four retaining bolts through the pallet into the threaded feet.

Care must be taken during this operation to ensure: -

a) All required safety measures are taken to ensure correct lifting and handling to avoid

risk of injury through dropping, falling and tilting.

b) No damage occurs to the machine, which could impair the normal operation.

The top cover is packed separately within the main carton. Only fit the top cover once the

mixer is in position. Do not lift or manoeuvre the mixer by using the top cover.

4.2 LOCATION.

The mixer is not suitable for outdoor installation and must not be installed where a water

jet could be used for cleaning. The mixer must only be operated by trained staff and must

be installed in an area where the use and maintenance is restricted to trained personnel.

Select a suitable flat level surface that can support the weight of the mixer and bowl

contents when full (refer to table 1 for weights and dimensions). In areas where stability

may be an issue, the machine should be secured in position.

Ensure there is sufficient space around the mixer to enable safe operation of the bowl lift

handle, attachment hub (if fitted) and removal/replacement of the mixing bowl. Servicing

may be more difficult because of reduced clearances and you should always check that

equipment specifications permit the close proximity of other equipment. Refer to figure 1

for the overall dimensions of the mixer. Service access is required to the rear and top of

the mixer.

4.3 ELECTRICAL INSTALLATION.

The electrical installation of the mixer must conform to the local electricity board

regulations. When installed in the United Kingdom the installation must be in accordance

with the current edition of the IEE Regulations for electrical equipment in buildings and the

Electricity at work act.

A competent person must carry out the electrical installation.

The technical data shown in table 1 details the electrical requirements for the various

mixer options.

The HSM30, HSM40, NCM300 and NCM400 mixers are ‘class I’ appliances where the

protection against electric shock does not rely solely on basic insulation. An external

electrical isolator and MCB/fuses (both items supplied by others) must be fitted to the

incoming electrical supply to the mixer. In addition a 30mA residual current device is

strongly recommended to provide extra protection.

Note: The single-phase model must not be installed via a 13 amp fused plug.

Page 7

6

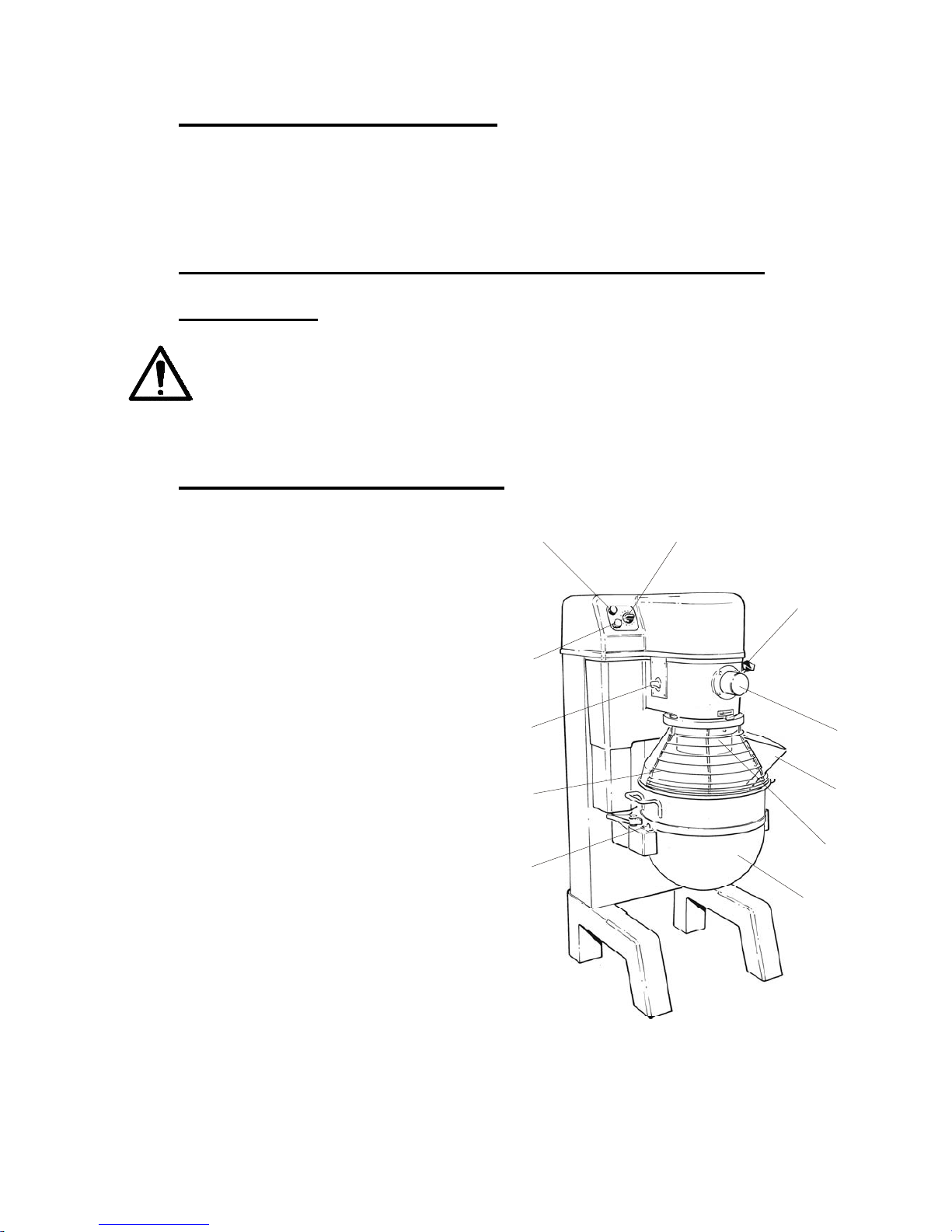

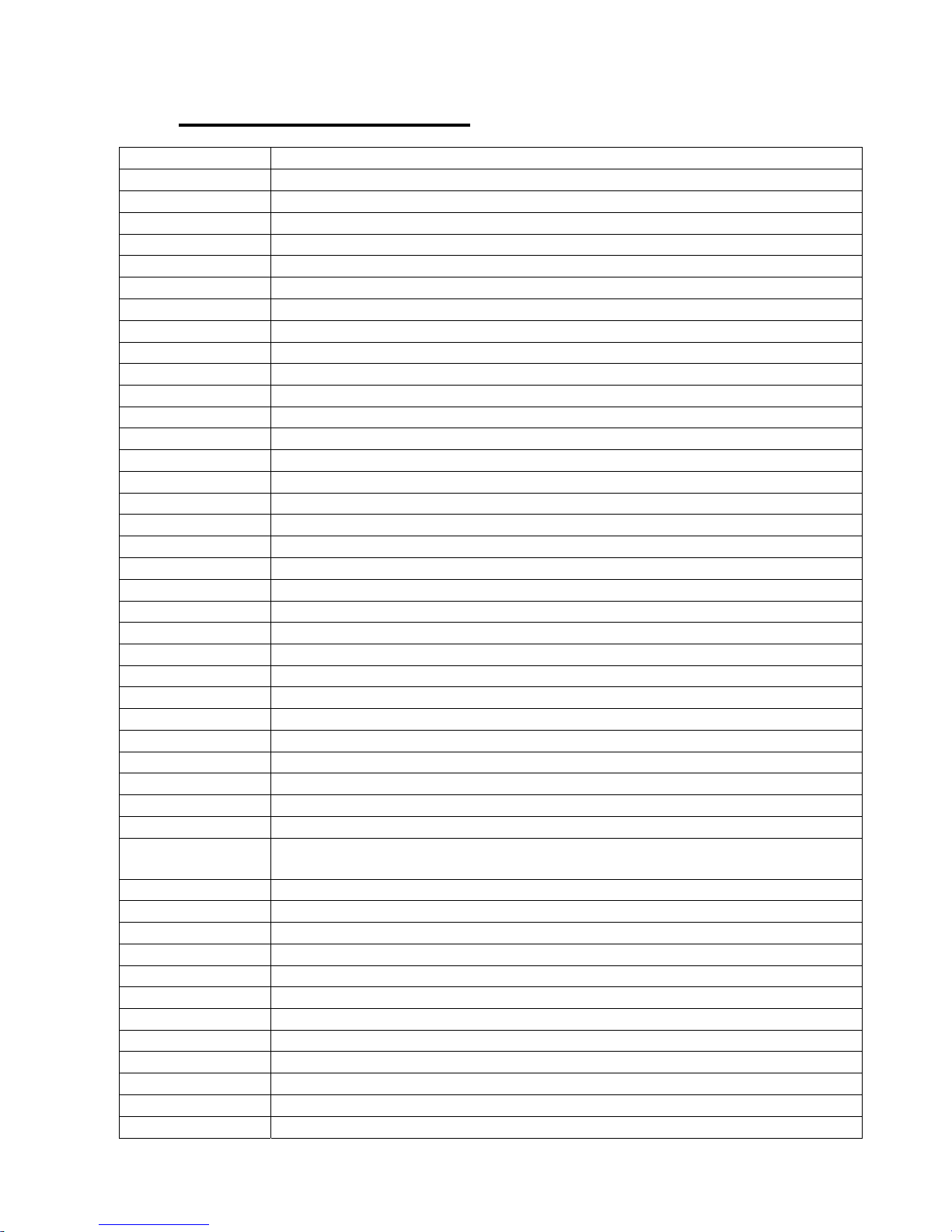

2

1

3

4

5

6

11

7

8

9

10

4.4 ELECTRICAL CONNECTION.

Refer to the wiring diagram supplied with the mixer and enclosed in the document

envelope.

Check direction of rotation.

5.0 COMMISSIONING AND OPERATING INSTRUCTIONS.

5.1 OPERATION

This food mixer is only for professional use by suitably trained persons.

Ensure operators have read and understood this manual and have

received adequate training.

Refer to figure 2 for the mixer component identification.

5.2 USING FOR THE FIRST TIME.

Before use for the first time thoroughly clean the

bowl and agitator as described in the cleaning

section 9.

Ensure the mixer is switched off.

Ensure the cover (10) is fitted to the hub (where

applicable) if an attachment is not in use.

· Always remove any attachment before

using the agitator.

· Lower the bowl support by using the hand

lever.

· Rotate the front of the guard (5) to allow

access to the bowl.

· Place the required agitator in the bowl

(7), and fit the bowl onto the bowl support in

the lowered position.

Position the bowl by aligning the back of the

bowl with the stop situated on the bowl support.

Engage the alignment pins (6) on the bowl

support into the bowl ‘ears’,and secure in place

with the bowl clamps.

FIGURE 2. MIXER COMPONENT

IDENTIFICATION.

Page 8

7

· Important! When using reduced size equipment only the following bowls detailed in

section 12 must be used. Do not operate a mixer with any other reduced size bowl

combinations. Reduced sizes are 30 or 20 litre bowls on an HSM40 / NCM400 or 20

litre bowl on an HSM30 / NCM300. The recommended spares table in section 12

details the respective bowl and agitator part numbers.

Slide the agitators on the shaft turning to engage the drive pin in the "L" slot.

· Add ingredients to the bowl and raise the bowl by hand lever.

· Rotate the front of the guard (5) to the operating (closed) position.

(NOTE. An electrical interlock is fitted to the bowl support to prevent accidental starting

when bowl is in the down position and an electrical interlock is also fitted to the guard to

prevent accidental starting when in the open position).

Select the desired speed (4) and set timer setting (1) if fitted.

· Setting the Timer .

a) Non-timed operation - Adjust the timer to the “HOLD” position.

b) Timed Operation – Turn timer past the desired position and then rotate back to

the desired time

· Start the machine by pressing start button (2). Note the mixer speed must not be

changed while the machine is operating. Stop (3) the mixer before changing speed.

If machine fails to operate, please check that the bowl support is in the up position and the

guard is in the operating position.

5.3 USING THE BOWL SCRAPER.

5.3.1 GENERAL BOWL SCRAPER USE.

The mixer bowl scraper attachment continually scrapes the sides of the bowl as the

agitator turns causing material around the sides and bottom of the bowl to be constantly

re-introduced into the mixture. Manual scraping is not required when using the bowl

scraper. The bowl scraper should only be used with stainless steel bowls.

Always use the correct size sleeve with the scraper arm. Be careful not to mix sleeves and

arms if you have multiple sizes of scrapers. Always ensure the correct scraper is used with

the right sized bowl.

Page 9

1

4th July 2006

HSM30/40 bowl height adjustment.

Fit the beater and raise the

bowl to the ‘up’ position.

Isolate the electricity supply to

the mixer. Rotate the beater to

an accessible position.

Using a gauge of the

correct thickness (1.5 mm)

check the clearance

between the beater and

bowl.

Rotate the lock nut anti-clockwise to

reduce the clearance and clockwise

to increase the clearance.

The height of the bowl support on

the guide rods determines the bowl

to beater clearance. If the

clearance is incorrect adjust the

lock nut to alter the height.

Lock nut

Bowl

support

19mm

socket.

1.

2.

3.

4.

5.

Page 10

8

5.3.2 OPERATING WITH THE BOWL SCRAPER.

1. Place the bowl scraper in the bowl before lifting into position as described in section

5.1.

2. Lubricate the surface of the bowl with vegetable oil or shortening, especially in the

area above the product where the sleeve may rub against the bare surface of the

bowl.

3. The bowl scraper rotates clockwise as you look into the bowl. Insert the scraper

shaft into the bayonet housing and rotate 90o anti-clockwise.

4. Raise the bowl to its operating position. Add the ingredients and mix normally.

5. After mixing lower the bowl and rotate the bowl scraper clockwise and lower to

remove.

Note:

¨ Only use speeds 1 and 2.

¨ Products, which can be mixed, whilst using the bowl scraper are: mashed potato,

waffle batter, cake batter, icing, creaming shortening/sugar, creaming eggs/sugar, and

mayonnaise.

¨ The bowl scraper should only be used with a wire whip or flat beater only. Do not use

when mixing dough products.

¨ Never raise a bowl of stiff product (i.e. cream cheese, shortening, unmashed potatoes)

with the scraper arm located in the housing. The scraper arm can be permanently bent

and become damaged by rotating agitators. Load the bowl with ingredient after it is

raised.

5.3.3 CLEANING THE BOWL SCRAPER.

Remove the plastic sleeve from the stainless steel arm. Tapping the sleeve against the

edge of a table will aid its removal. Clean both parts in a sink with hot water and detergent

solution. Rinse with clean water and dry.

Slide the sleeve onto the arm so the bevelled edge is the leading edge. Use water as a

lubricant. The end of the sleeve must be flush with the end of the arm.

Note: Do not use aggressive chemicals to clean the sleeve since they may degrade the

plastic material.

5.4 WHEN MIXING HAS FINISHED.

· When mixing is complete stop the machine using the stop button (3).

· Rotate the front of the guard (5) to the open position.

· Lower the bowl support and remove agitator from shaft (8).

· If fitted remove the bowl scraper from the bayonet housing by rotating anti-

clockwise.

· Remove bowl (7) and agitator from mixer to empty .

Page 11

9

USING THE ATTACHMENT FACILITY.

5.5.1 ATTACHMENT SAFETY INSTRUCTIONS.

The following instructions must be observed when using the mixer with

attachments. Please also refer to the safety instructions detailed in section 6.0

and the instructions provided with the attachment.

THE ATTACHMENT AND/OR MIXER SHOULD ONLY BE USED BY A FULLY

TRAINED AND COMPETENT PERSON.

· Do not fit an attachment while the mixer is operating.

· Do not wear loose clothing.

· Do not use the mixer or attachment if a fault develops or the machine is unsafe.

· Do not access rotating parts.

· Do not use excessive force when operating the attachment, which could affect the

stability of the mixer.

· Do not operate the mixer if parts are disassembled.

· Always use the attachment and/or mixer in a well-lit area.

· Always ensure the attachment is operating at the correct speed.

· Always clean the attachments after use and refer to the attachment manufacturer’s

cleaning instructions.

· Always service your mixer and attachments regularly; at least twice a year depending

on the frequency of use.

5.5.2 FITTING AN ATTACHMENT.

When installing the attachment ensure the electricity supply is isolated.

Loosen the thumb screw (item 12 shown on figure 2) situated on the attachment hub and

remove the plastic cover and put in a safe place to be refitted after use.

Offer the shaft of the attachment to the hub and ensure the square shank of the

attachment locates in the square drive of the mixer

Secure the attachment by tightening the thumbscrew.

Select the correct mixer speed for the type of attachment fitted.

6.0 SAFETY INSTRUCTIONS.

A FULLY TRAINED AND COMPETENT PERSON MUST ONLY USE THE

ATTACHMENT AND/OR MIXER.

The following instructions must be observed when using the mixer.

Note: The mixer must only be used for the purpose it was design and inline with the

supplied operating instructions.

When mixing ingredients care must be taken to avoid the inhalation of dust particles

e.g. flour. Reference should be made to product supplier’s data sheets to ensure

adequate precautions/protections are taken.

Page 12

10

Items such as flour must be added in such a manner to avoid dust particles being

dispersed into the local atmosphere.

When manoeuvring or lifting a bowl and contents with a total weight in excess of

25kg a bowl truck must be used (Hobart part number M-L108865).

6.1 NEVER

· Operate the mixer or attachment if a fault develops or the mixer is unsafe.

· Wear loose clothing.

· Attempt to reach into the bowl when mixing.

· Access rotating parts.

· Fit the agitator to the mixer without a bowl in place.

· Leave the agitator on machine without the bowl being fitted.

· Operate the mixer with both attachments and agitator fitted.

· Leave the gear lever in mid position.

· Use the gear lever to stop the machine.

· Change speed whilst the mixer is operating.

· Use excessive force when operating which could affect the stability of the mixer.

· Operate the mixer if parts are disassembled.

· Over ride the safety switches fitted to the mixer.

· Open the guard to stop machine.

· Use the bowl lift handle to stop machine.

· Use the mixer in an unsafe condition.

· Clean the mixer with scouring powder or a scouring pad.

· Clean aluminium agitators in a dishwasher.

· Inhale mixing ingredient dust particles.

6.2 ALWAYS

· Use the mixer in a well-lit area.

· Ensure the bowl, bowl clamps, agitator, attachment and guard are correctly fitted to

the mixer.

· Disconnect the mains electricity supply before cleaning the mixer.

· Clean the mixer daily.

· Remove Agitator before using any attachments.

· Stop mixer before adding more ingredients.

· Use the stop button to stop machine.

· Clean the bowl, agitators and attachments after use.

· Clean the mixer using mild soap and water.

· Service the mixer and attachments at least twice a year depending on the frequency of

use.

· Use the mixer as intended and inline with the operating instructions.

· Use the correct reduced size equipment (bowl and agitators specified in section 12).

Page 13

11

7.0 MIXING CAPACITY CHART

The following charts (Tables 2, 3, 4, 5, 6 and 7) show the maximum recommended

capacities for the mixer. With high gluten flour reduce the dough batch size by 10%.

Always ensure the correct agitator is selected for the mix.

Dough capacities are based on water at a temperature of 21oC and a 12% flour moisture

content. If colder water is used, the mixing capacity will need to be reduced. Colder water

temperatures result in a product which is harder to mix. Ensure the correct speed is

selected.

DO NOT EXCEED THE SPECIFIED MIX QUANTITY

Overloading the mix can be detrimental to the quality of the finished product and affect the

life expectancy of the machine. Always refer to the mixing chart

The maximum capacity for the mixers: -

HSM30 / NCM300 = 28.75 litres

HSM40 / NCM400 = 38.5 litres

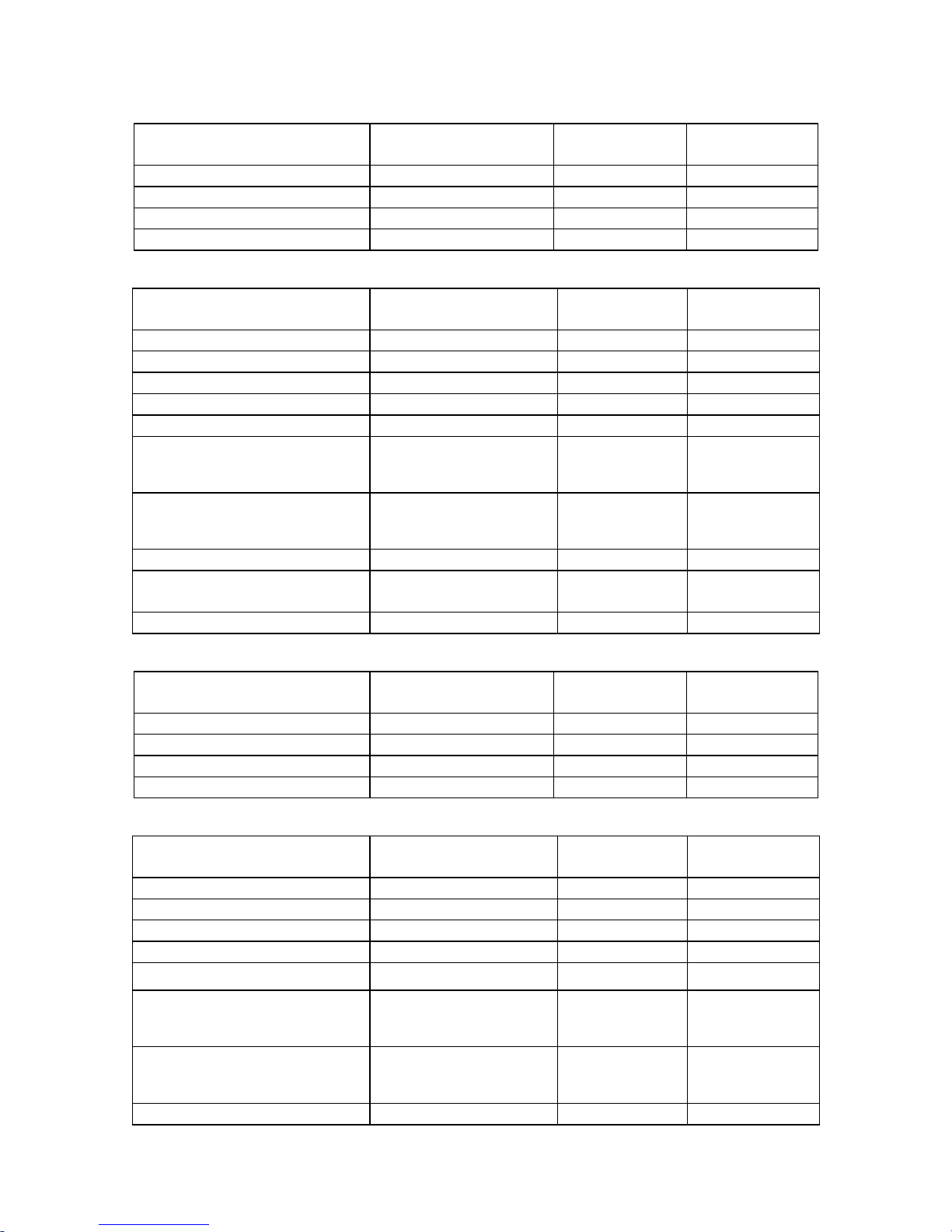

Table 2 HSM30 / NCM300 Kitchen Capacities - Single Batch

Type of Product Quantity

Recommended

Agitator

Recommended

speeds

Egg Whites 1.7 litres (3 pints) Whip 1/2/3

Mashed Potatoes 10.4 kg (23 Lbs) B Beater 1

Mayonnaise (Oil) 13.6 litres (24 pints) Whip 2 / 3

Whipped Cream 17.0 litres (30 pints) Whip 1/2/3

Table 3 HSM30 / NCM300 Bakery Capacity - Single Batch

Type of Product Quantity Recommended

Agitator

Recommended

Speeds

Cake, Madeira 13.5 kg (30 Lbs) B Beater 1/2/3

Cake , Pound 12.7 kg (28 Lbs) B Beater 1/2/3

Light Batter (Sponge Cake) 9.1 kg (20 Lbs) B Beater 1/2/3

Steamed pudding 13.5 kg (30 Lbs) E or EB 1/2/3

Yorkshire batter 13.6 litres (24 pints) B or C whip 2 or 3

Dough (light -medium) 13.5 kg (30 Lbs)

(65% A/R)

(8.8kg flour 4.7 litre water)

ED Hook 1 only

Dough (heavy) 10.9 kg (24 Lbs)

(50% A/R)

(7.3 kg flour 3.6 litre water)

ED Hook 1 only

Pizza dough 6.8 kg (15Lbs) E or ED only 1 only

Pie Pastry 10.9 kg (24 Lbs) Pastry Knife

ED Hook

1 only

Fat & Sugar for Sponge Cake 10.9 kg (24 Lbs) Whip 1/2/3

Page 14

12

Table 4 HSM40 / NCM400 Kitchen Capacities - Single Batch

Type of Product Quantity

Recommended

Agitator

Recommended

speeds

Egg Whites 2 litres (3.5 pints) Whip 1/2/3

Mashed Potatoes 12.7 kg (28 Lbs) B Beater 1

Mayonnaise (Oil) 17 litres (30 pints) Whip 2 / 3

Whipped Cream 22.6 litres (40 pints) Whip 1/2/3

Table 5 HSM40 / NCM400 Bakery Capacity - Single Batch

Type of Product Quantity Recommended

Agitator

Recommended

Speeds

Cake, Madeira 18 kg (40 Lbs) B Beater 1/2/3

Cake , Pound 16 kg (35 Lbs) B Beater 1/2/3

Light Batter (Sponge Cake) 12.7 kg (28 Lbs) B Beater 1/2/3

Steamed pudding 18 kg (40 Lbs) E or EB 1/2/3

Yorkshire batter 17 litres (30 pints) B or C whip 2 or 3

Dough (light-medium) 18 kg (40 Lbs)

(65% A/R

(11 kg flour 7 litre water)

ED Hook 1 only

Dough (heavy) 13.5 kg (30 Lbs)

(50% A/R)

(9 kg flour 4.5 litre water)

ED Hook 1 only

Pizza dough 9.1 kg (20 Lbs) E or ED only 1 only

Pie Pastry 13.5 kg (30 Lbs) Pastry Knife

ED Hook

1 only

Fat & Sugar for Sponge Cake 13.5 kg (30 Lbs) Whip 1/2/3

Table 6. 20 Litre bowl Kitchen Capacities - Single Batch

Type of Product Quantity

Recommended

Agitator

Recommended

speeds

Egg Whites 1.1 litres (2 pints) Whip 1/2/3

Mashed Potatoes 6.8 kg (15 Lbs) B Beater 1

Mayonnaise (Oil) 11.4 litres (20 pints) Whip 2 / 3

Whipped Cream 11.4 litres (20 pints) Whip 1/2/3

Table 7. 20 Litre bowl Bakery Capacity - Single Batch

Type of Product Quantity Recommended

Agitator

Recommended

Speeds

Cake, Madeira 9 kg (20 Lbs) B Beater 1/2/3

Cake , Pound 9 kg (20 Lbs) B Beater 1/2/3

Light Batter (Sponge Cake) 6.4 kg (14 Lbs) B Beater 1/2/3

Steamed pudding 9 kg (20 Lbs) E or EB 1/2/3

Yorkshire batter 9.1 litres (16 pints) B or C whip 2 or 3

Dough (light-medium) 9.1 kg (20 Lbs)

(65% A/R)

(5.6 kg flour 3.5 litre water)

ED Hook 1 only

Dough (heavy) 5.8 kg (13 Lbs)

(50% A/R)

(3.9 kg flour 1.9 litre water)

ED Hook 1 only

Pizza dough 5.0 kg (10 Lbs) E or ED only 1 only

Page 15

13

Pie Pastry 7.3 kg (16 Lbs) Pastry Knife

ED Hook

1 only

Fat & Sugar for

Sponge Cake

6.8 kg (15 Lbs) Whip 1/2/3

* A/R absorption ratio.

Speed “1” (LOW) is for Heavy mixtures such as dough, heavy batters and mashed potatoes

Speed “2” (MEDIUM) is for mixing cake batters

Speed “3” (HIGH) is for mixing the maximum amount of air into light batches. The “D”

whip is generally used for whipping cream, beating egg whites, mixing light icings,

meringues and whipping.

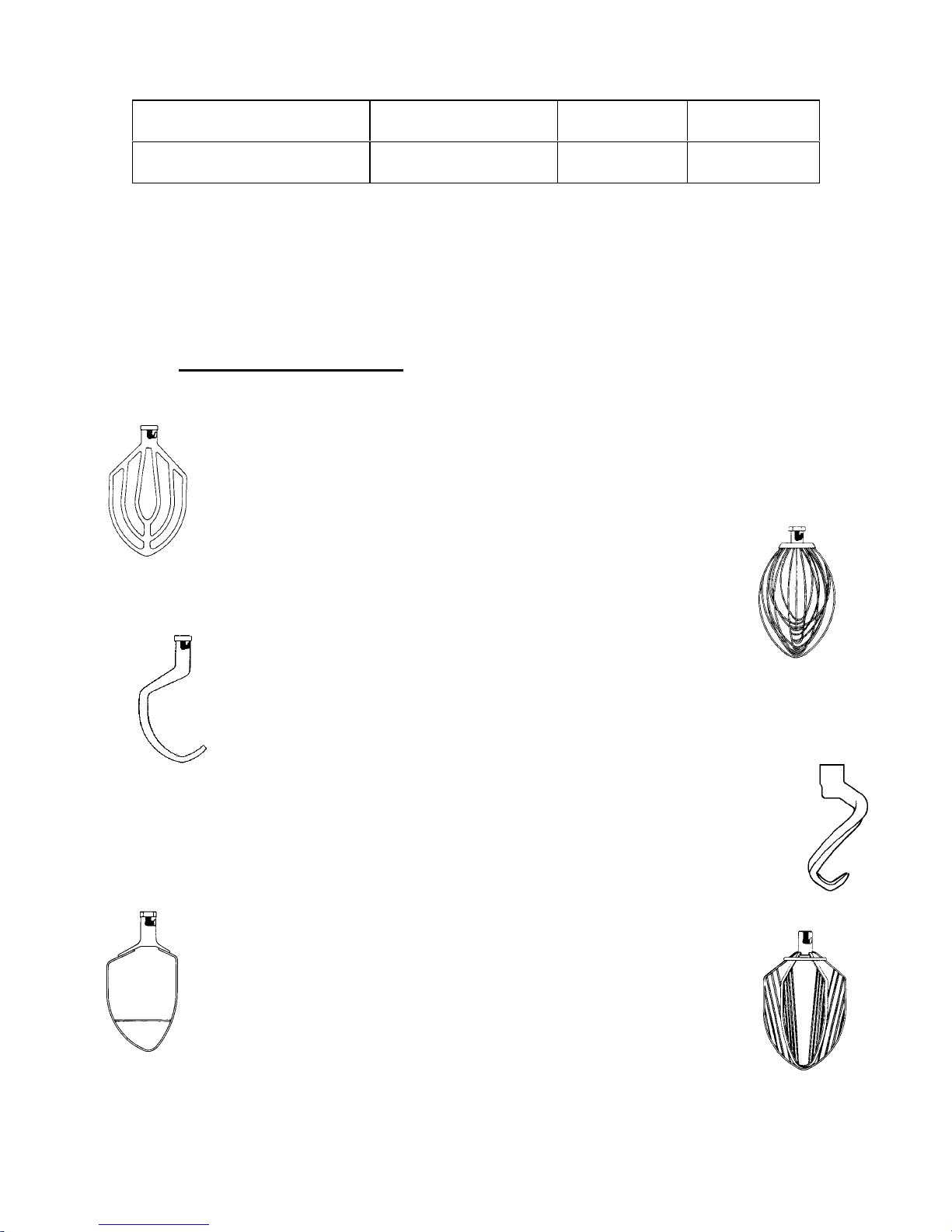

8.0 MIXER AGITATORS.

The agitators available for the mixer are designed for the specific duties as follows:

The ‘B Beater’ is a multi-purpose agitator for mashing potatoes and other

cooked vegetables, mixing cakes, batters, and icings. Use first speed for

starting most operations, increasing to speed 2 for finishing where applicable.

The ‘D Whip’ is designed for maximum blending of air into light products. It can

be used for whipping cream, beating egg whites, and mixing very light egg

whites. The whip is commonly used on speeds two and three.

The ‘E Dough Hook’ is used for mixing bread, roll and pizza dough which

require folding and stretching action for optimum development. The dough

hook should be used predominantly on speed 1.

The ‘ED Dough Hook’ is used for mixing bread, roll and pizza dough which require

folding and stretching action for optimum development. The dough hook should be

used predominantly on speed 1.

The ‘PK Pastry Knife’ is used for mixing pastry. The Pastry knife should be

used in speed 1 only.

The ‘C Winged Whip’ is used for light batters, mayonnaise oil and mashed

potatoes. The whip can be used in speeds 1, 2 or 3.

Page 16

14

9.0 CLEANING.

DO NOT HOSE OR PRESSURE CLEAN THIS MIXER

DO NOT USE ANY ABRASIVE CLEANERS

Ensure that the machine is disconnected from the main electrical power supply prior to

cleaning

9.1 CLEANING BEFORE INITIAL USE.

Before using for the first time, thoroughly wash new mixer bowls, agitators and attachments.

Wash in hot water and a mild detergent solution. This procedure should also be followed for

bowls and agitators before whipping egg whites or whole eggs.

9.2 CLEANING AFTER USE.

After use, clean the mixing bowl, agitators and attachments with hot water, using a

suitable non-abrasive detergent and soft bristle brush. (Flushing the bowl with hot water

immediately after use will ease the cleaning).

Note: Do not clean the aluminium agitators in a dishwasher

Clean the mixer with a hot damp cloth; thoroughly wipe the bowl support arms and all

exterior surfaces. The guard should be cleaned as follows.

9.3 GUARD REMOVAL & CLEANING.

The guard assembly has been designed to be removed easily for machine washing.

To remove the guard assembly.

· Ensure that the bowl support is in the lowered position.

· Remove the agitator and bowl.

· Withdraw the interlock plunger and rotate the guard deflector assembly in an anti-

clockwise direction until the unit disengages from the sprung retainers. At this point

care should be taken, as the guard will now be able to drop freely from the machine.

· Carefully lower the guard assembly and remove.

Cleaning the guard.

The guard should be cleaned at the end of each day.

Once the guard is removed it can be cleaned with hot water, using a suitable nonabrasive detergent and soft bristle brush. Alternatively the guard can be cleaned in a

commercial dishwasher.

To refit guard assembly to the machine.

· Orientate the guard with the deflector to the back of the mixer and push on to the

mixer.

· Rotate the guard deflector clockwise so it is fully engaged onto the sprung retainers.

When in position the guard will come to a dead stop.

Page 17

15

10.0 MIXER MAINTENANCE.

A HOBART TRAINED AND COMPETENT PERSON SHOULD CARRY OUT

SERVICING.

Do not remove any covers or loosen any fittings while the mixer is operating.

Ensure the electrical supply has been isolated before attempting to service or

move the mixer. The motor and transmission are packed with special grease,

which will last for several years. When replacement is needed, contact your

local service centre.

The bowl support guide rods should be lubricated occasionally with a small amount of

food grade grease applied with the fingertip, to prevent corrosion and ensure smooth

operation

It is recommended that the mixer is serviced regularly (recommended twice yearly)

A spare parts Manual (ple200459) is available on request from Hobart National Parts

Distribution Centre. For continued safe and reliable operation of this mixer, it is

recommended that servicing is only carried out by Hobart trained service personnel.

Page 18

16

11.0 FAULT FINDING.

Fault Possible cause Remedy

Blown control circuit fuse Check and replace faulty fuse

Bowl guard is not in the correct

operating position

Check that guard is in the closed

position

Speed selection lever not in correct

operating position

Set to required speed position

Electrical supply isolated Plug in and switch on.

Machine fails to start.

Machine still fails to operate Call local Hobart service centre.

Scraper (option) binds

on bowl.

Scraper rubbing dry Lubricate bowl surface with

vegetable oil or shortening

Scraper (option) bevel

edge not leading.

Plastic sleeve incorrectly fitted Remove the arm and correctly

install the plastic sleeve.

Excessive

bowl/scraper

clearance

Bent scraper arm or incorrect bowl

clearance

Call local Hobart service centre

Gear selection lever incorrectly

positioned.

Move to correct speed position.Motor starts but

agitator fails to rotate.

Machine still fails to operate Call local Hobart service centre

Page 19

17

12.0 RECOMMENDED SPARES

Part Number Description

PLE200459 Catalogue of replacement parts

144452-1 Motor 1 phase. 230/50/1 (as appropriate for model)

138725 Capacitor, start (160-200 µF) (as appropriate for model)

138724 Capacitor, run (15 µF) (as appropriate for model)

144453-1 Motor 3 phase. 400/50/3(as appropriate for model)

00-737986 Drive belt

00-737991-4 Top cover, timer NCM300, NCM400

00-737991-3 Top cover, no timer NCM300, NCM400

00-737991-9 Top cover, timer HSM30, HSM40

141932 Switch, gear change

EPM-E-16-14 Switch Start,

EPM-E-16-15 Switch Stop,

SS-E-18-11 Timer, 30 min

140807 Reed switch, guard.

144358 Switch, bowl support

00-738163 Guard. HSM30 / NCM 300

00-738164 Guard. HSM40 / NCM400

142403-10 Thermal overload, 230/50/1(as appropriate for model)

142403-8 Thermal overload, 400/50/3 (as appropriate for model)

141440-1 Contactor

140869-10 Fuse, control 315mA

140869-19 Fuse, control 2A

140908-3 Transformer 400/50/3

OSM-E-1-12 Oil seal

R-9440-E Beater, HSM30 / NCM300

R-9443-E Whip, HSM30 / NCM300

141721 ED hook, HSM30 / NCM300

53572 Beater, HSM40 / NCM400

53577 Whip, HSM40 / NCM400

140688 ED hook, HSM40 / NCM400

SU-E-3-4 Light food grade oil

00-738662 20 litre bowl to suit HSM30, HSM40, NCM300 and NCM400. Adaptor

required for HSM40 / NCM400

00-738664 30 litre bowl to suit HSM40 / NCM400

53600 Adaptor to suit 30 litre bowl for HSM40 / NCM400

10470-E D Whip, 20 litre (half size)

10469-E Beater, 20 litre (half size)

51831 E flat hook 20 litre (half size)

ML-109241 Bowl scraper assembly 20 litre including blade and housing

737458-2 Blade-scraper 20 litre

ML-109242 Bowl scraper assembly 30 litre including blade and housing

737458-3 Blade-scraper 30 litre

ML-109243 Bowl scraper assembly 40 litre including blade and housing

737458-4 Blade-scraper 40 litre

00-738071 Housing-bowl scraper (all capacities)

Page 20

18

NOTES:

Page 21

19

13.0 SERVICE CONTACT NUMBERS.

Hobart trained service technicians strategically located at national Hobart service

branches are prepared to give you fast, efficient and reliable service. Protect your

investment by having a Hobart inspection contract, which assures the continued, efficient

operation of your Hobart machines, spares and accessories.

For further details please contact: -

Department Telephone Facsimile

SALES: 07002 101 101 020 88364396

SERVICE 07002 202 202 01733 371709

SPARES 07002 303 303 01733 371332

Continued product improvement is a Hobart Still policy, specifications may change without notice.

The Hobart Manufacturing Company Limited

Hobart House, 51 The Bourne,

Southgate, London N14 6RT

Tel: 07002 101101 Fax 020 883604

Page 22

20

Français / SOMMAIRE.

Page

Notes concernant la sécurité 21

Consignes de sécurité 21

Symboles de mise en garde 22

Responsabilité 22

Avant-propos 22

Généralités 22

Figure 1. Dimensions. 22

Tableau 1. Données techniques. 23

Installation 23

Déballage et manutention 23

Emplacement 24

Installation électrique 24

Raccordements électriques 25

Consignes de mise en marche et d’utilisation 25

Utilisation 25

Première utilisation 25

Composants du batteur-mélangeur. Figure 2 25

Utilisation du racloir de cuve 26

Généralités concernant l’utilisation du racloir de cuve 26

Fonctionnement avec le racloir de cuve 27

Nettoyage du racloir de cuve 27

Lorsque la préparation est terminée 27

Utilisation des accessoires 28

Consignes de sécurité concernant les accessoires 28

Montage des accessoires 28

Consignes de sécurité 29

Ne jamais 29

Toujours 30

Tableaux de capacités de préparation 30

Tableau 2 HSM30 / NCM300 Capacités cuisine – par charge 30

Tableau 3 HSM30 / NCM300 Capacités pâtisserie – par charge 31

Tableau 4 HSM40 / NCM400 Capacités cuisine - par charge 31

Tableau 5 HSM40 / NCM400 Capacités pâtisserie - par charge 31

Tableau 6 20 liters cuve. Capacités cuisine - par charge 32

Tableau 7 20 liters cuve. Capacités pâtisserie - par charge 32

Outils 33

Nettoyage 33

Nettoyage avant la première utilisation 33

Nettoyage après usage 34

Démontage et nettoyage de la grille 34

Maintenance de l’appareil 35

Recherche des pannes 35

Pièces de rechange recommandées 36

Notes 37

Service après-vente et adresses 38

Page 23

21

1.0 NOTES CONCERNANT LA SÉCURITÉ.

Il est entendu que les procédures et précautions décrites dans le présent manuel ne

valent que lorsque le batteur-mélangeur est utilisé suivant les instructions. Dès lors où

l’appareil est utilisé autrement, l’opérateur est responsable de sa propre sécurité ainsi que

celle des autres personnes impliquées.

Ce manuel a été rédigé dans le but d’aider l’opérateur à comprendre et à utiliser le

batteur-mélangeur ainsi qu’à en prendre soin. Afin de prévenir tout accident, il est

important de lire, de comprendre et de respecter les précautions et mises en gardes ciaprès avant d’installer ou de manipuler l’appareil pour la première fois. Ce manuel est à

étudier pour bien cerner l’appareil et ses fonctions.

1.1 CONSIGNES DE SÉCURITÉ.

Les précautions adéquates doivent être prises pendant la manutention manuelle du

batteur-mélangeur, surtout lors de son installation. Pour ce faire, il convient de consulter

la réglementation concernant la manutention manuelle. Les masses des appareils sont

données dans le tableau 1.

· Ne pas nettoyer l’appareil au jet d’eau ou à la pression. Les consignes de nettoyage indiquées

dans la section 9 de ce manuel sont à respecter de manière impérative.

· Ne pas enlever de couvercle et ne desserrer aucun accessoire lorsque l’appareil est en plein

travail.

· Conserver ce manuel dans un endroit facilement accessible, non loin de l’appareil, pour

pouvoir le consulter.

· Tous les opérateurs doivent être formés à l’utilisation de l’appareil et des accessoires.

· Vérifier que l’appareil est coupé de l’alimentation secteur avant de procéder à sa

révision ou avant de le déplacer.

· Les appareils à parties tournantes et l’électricité peuvent être dangereux et provoquer

des accidents, si les précautions suffisantes ne sont pas prises préalablement à la

manipulation ou à la révision de l’appareil.

· Faire réviser le batteur-mélangeur et les accessoires de manière régulière, au moins

deux fois par an, selon la fréquence d’utilisation.

· Important ! En ce qui concerne les équipements de taille réduite, seules les cuves

suivantes (détails à la section 12) doivent être employées. Ne pas utiliser le batteurmélangeur avec d’autres combinaisons de cuves de taille réduite. Dans la gamme des

tailles réduites, il existe des cuves de 30 et 20 litres, adaptées au modèle HSM40 /

NCM400, et de 20 litres pour l’appareil HSM30 / NCM300. Les références respectives

des cuves et des agitateurs sont indiquées dans le tableau des pièces de rechange

recommandées, à la section 12.

Page 24

22

1.2 SYMBOLES DE MISE EN GARDE.

Les messages de sécurité contenus dans ce manuel sont identifiés par les

symboles suivants.

Le symbole "Attention" accompagne essentiellement les mises en garde

importantes au bon usage de l’appareil.

La présence de ce symbole indique un risque de nature électrique. Avant de

réviser le batteur-mélangeur, il est impératif de débrancher le câble

d’alimentation de la prise secteur.

1.3 RESPONSABILITÉ.

Les installations et réparations non effectuées par un technicien agréé, ainsi que l’usage

de pièces de rechange autres que d’origine, ou toute altération technique réalisée sur

l’appareil peuvent affecter la garantie stipulée dans les conditions générales de

vente.

2.0 AVANT-PROPOS.

Hobart se réserve le droit d’apporter des modifications à la conception de ses produits

sans préavis. Bien que tout soit mis en œuvre pour que les informations présentées dans

cette publication soient en accord avec le dernier modèle, la société ne peut garantir une

conformité absolue.

Il est important de prendre soin du batteur-mélangeur HSM / NCM, de le maintenir propre

et en bon état mécanique et électrique.

Les informations et consignes données dans ce manuel ne couvrent pas obligatoirement

tous les détails et variantes de l’appareil, ni ne prévoient toutes les situations qui peuvent

se présenter durant l’installation, l’utilisation ou la maintenance. Des compléments

d’information peuvent être obtenus auprès de votre vendeur Hobart.

3.0 GÉNÉRALITÉS

La gamme de batteurs-mélangeurs HSM30,

NCM300, HSM40 et NCM400 est conçue pour

réaliser des préparations alimentaires suivant

les tableaux de spécifications (tableaux 2, 3, 4

et 5). Le mélangeur HSM30/40 est manufacturé

de deux bâtis peints metalic, le piédestal

fabriqué d'acier inoxydable, une base, de

panneau arrière, avec la couverture supérieure

en plastique moulé. Le mélangeur NCM300/400

est manufacturé de deux moulages en fer, avec

une base en acier manufacturé, des pieds en

aluminium, un couvercle en plastique moulé et

une plaque arrière en acier. L’ensemble est fini

en couleur gris Hobart. L’appareil est réglé

pour fonctionner sur les alimentations décrites

dans le tableau 1, et est équipé d’une sécurité à

minimum de tension qui interdit le redémarrage

automatique de l’appareil après une panne ou

une coupure d’alimentation.

FIGURE 1. DIMENSIONS

Page 25

23

Le porte-cuve et la grille de protection sont tous les deux munis d’un système de

verrouillage qui empêche l’appareil de fonctionner tant que ces éléments ne sont pas

prêts. L’appareil standard est livré avec grille, cuve et outils.

TABLEAU 1. DONNÉES TECHNIQUES.

Description Unité HSM30 /

NCM300

HSM40 /

NCM400

Puissance du moteur kW 1,1 1,1

Vitesse max. de la partie tournante (50 Hz) rpm 1425 1425

Alimentation nominale monophasé Volts/Hz 230/50 230/50

triphasé 400/50 400/50

Courant de pleine charge pour tension cidessus monophasé

A7,4 7,4

triphasé A 2,8 2,8

Courant à rotor bloqué pour tension cidessus monophasé

A44 16

triphasé A 16 16

Fusible recommandé 230 V/1 ph/50 Hz A 20 20

Fusible recommandé 230 V/3 ph/50 Hz A 16 16

Fusible recommandé 400 V/3 ph/50 Hz A 10 10

Température ambiante maximum

o

C40 40

Prise d’accessoires -- type 12 type 12

Masse du batteur-mélangeur avec

agitateur et cuve (vide)

kg 241 246

Niveau sonore dB (A)

##

Inférier à 70

##

Inférier à 70

Masse d’expédition kg 255 260

Dimensions d’expédition (carton) LxlxH cm 99x81x155 99x81x155

Conditions de stockage. Température et

humidité.

o

C, %

hum. rel.

+5 à +38,

85

+5 à +38,

85

Classe de l’appareil

#

Classe I

#

Classe I

Indice IP d’armoire IP44 IP44

Taille du terminal de câblage monophasé mm

2

1,5 1,5

triphasé mm

2

1,0 1,0

#

Voir section 4.3.

##

En accord avec la norme EN-ISO 12001:1996

4.0 INSTALLATION.

4.1 DÉBALLAGE ET MANUTENTION.

Dans la mesure du possible et par mesure de protection du batteurmélangeur, conserver celui-ci dans son emballage pour le transporter

jusqu’à son emplacement d’installation. Ne pas utiliser de couteau

pointu pour découper l’emballage sous peine d’endommager l’appareil.

Vérifier que l’appareil n’a pas été abîmé durant le transport. Dans le

cas coutraire, conserver l’emballage et contacter l’agence Hobart la

plus proche.

Page 26

24

Attention : Le batteur-mélangeur est un objet lourd qui nécessite d’être

manipulé et levé correctement pour éviter tout accident.

Suivre les consignes fournies avec l'emballage et placer l’appareil à proximité de son

emplacement final avant de le libérer de sa palette de transport. L’appareil est fixé à la

palette par quatre boulons de retenue enfoncés au travers de la palette dans les pieds

taraudés.

Durant cette opération, veiller à ce que :-

a) Toutes les mesures de sécurité nécessaires soient prises pour assurer un levage et

une manutention corrects, de manière à éviter tout risque d’accident par lâchage,

chute ou basculement.

b) L’appareil ne subisse aucune détérioration qui pourrait affecter son fonctionnement

normal.

Le couvercle supérieur est emballé séparément dans le carton principal. Ne fixer ce

couvercle que lorsque le batteur-mélangeur est en place. Ne pas lever ou manipuler

l’appareil par le couvercle supérieur.

4.2 EMPLACEMENT.

Le batteur-mélangeur n’est pas adapté à un usage en extérieur, et ne doit pas être

installé là où un jet d’eau pourrait être utilisé pour le nettoyer. L’appareil ne doit être

utilisé que par des personnes formées, et se trouver dans une zone où son usage et sa

maintenance sont restreints à un personnel formé.

Choisir une surface plane adéquate, capable de supporter la masse du batteurmélangeur et celle de la cuve pleine (consulter le tableau 1 pour connaître les masses et

les dimensions). Dans les zones où la stabilité peut être un problème, il importe que

l’appareil soit fermement immobilisé.

Prévoir suffisamment d’espace autour de l’appareil pour pouvoir, sans danger, manipuler

la poignée de montée de cuve, la prise d’accessoires (si montée), et retirer/remplacer la

cuve. La révision de l’appareil peut être plus difficile s’il n’y a pas beaucoup d’espace

libre, et il est important de toujours vérifier que les caractéristiques de l’appareil

permettent d’avoir d’autres appareils juste à côté. Voir figure 1 pour connaître les

dimensions du batteur-mélangeur. Un accès pour l'entretien est nécessaire à l'arrière et

au-dessus du batteur-mélangeur.

4.3 INSTALLATION ÉLECTRIQUE.

L’installation électrique du batteur-mélangeur doit être conforme aux normes de

l’entreprise d’électricité locale.

L’installation électrique doit être effectuée par une personne habilitée.

Les données techniques du tableau 1 donnent les caracteristiques électriques pour les

diverses options de l’appareil.

Page 27

25

2

1

3

4

5

6

11

7

8

9

10

Les batteurs-mélangeurs HSM30 / NCM300 et HSM40 / NCM400 sont des appareils de

‘classe I’ : la protection contre les chocs électriques ne dépend pas exclusivement de

l’isolation de base. L’installations electrique doit être conformes à la legislation en vigeur

au jour de l’installation.

4.4 RACCORDEMENTS ÉLECTRIQUES.

Consulter le schéma de câblage électrique fourni avec l’appareil et se trouvant dans

l’enveloppe.

Vérifier le sens de rotation.

5.0 CONSIGNES DE MISE EN MARCHE ET

D’UTILISATION.

5.1 UTILISATION

Cet appareil est exclusivement destiné à un usage professionnel par des

personnes suffisamment formées. Les opérateurs doivent avoir lu et

compris ce manuel, et avoir reçu une formation adéquate.

La figure 2 énumère le nom de chaque composant du batteur-mélangeur.

5.2 PREMIÈRE UTILISATION.

Avant la toute première utilisation, il est important

de bien nettoyer la cuve et l’outil selon les

instructions de la section 9.

Vérifier que l’appareil est éteint.

Vérifier que le couvercle (11) est fixé sur la prise

d’accessoires (le cas échéant), si aucun

accessoire n’est utilisé.

· Retirer impérativement tout accessoire

avant d’utiliser l’agitateur.

· Abaisser le porte-cuve à l’aide du levier

manuel.

· Tourner le devant de la grille de protection

(5) pour permettre l’accès à la cuve.

· Placer l’outil adéquat dans la cuve (7), puis

soulever celle-ci sur le porte-cuve abaissé.

FIGURE 2. COMPOSANTS DU BATTEUR-

MELANGEUR.

Page 28

26

Positionner la cuve en alignant l’arrière de celle-ci avec le dispositif d’arrêt qui se trouve

sur le porte-cuve. Enclencher les goujons d’assemblage du porte-cuve (6) dans les

« oreilles » de la cuve, puis immobiliser le tout à l’aide des vis à poignée.

Important ! En ce qui concerne les équipements de taille réduite, seules les cuves

suivantes (détails à la section 12) doivent être employées. Ne pas utiliser le batteurmélangeur avec d’autres combinaisons de cuves de taille réduite. Dans la gamme des

tailles réduites, il existe des cuves de 30 et 20 litres, adaptées au modèle HSM40 /

NCM400, et de 20 litres pour l’appareil HSM30 / NCM300. Les références respectives

des cuves et des agitateurs sont indiquées dans le tableau des pièces de rechange

recommandées, à la section 12.

Glisser les outils sur l’arbre en faisant tourner pour enclencher l’axe d’entraînement dans

l’encoche en L.

· Ajouter les ingrédients dans la cuve puis lever celle-ci à l’aide du levier manuel.

· Tourner le devant de la grille de protection (5) en position de travail (fermée).

(N.B. : Le porte-cuve est équipé d’un système de verrouillage électrique qui interdit les

démarrages intempestifs lorsque la cuve est abaissée. La grille de protection est

également dotée d’un système de verrouillage électrique qui interdit les démarrages

intempestifs lorsqu’elle est ouverte).

Sélectionner la vitesse (4) et régler la minuterie (1) s’il y en a une.

· Réglage de la minuterie.

a) Fonctionnement sans minuterie - Régler la minuterie sur « HOLD ».

b) Fonctionnement avec minuterie – Tourner la minuterie juste après la position

désirée puis la faire revenir à l’heure voulue.

· Mettre l’appareil en route en appuyant sur le bouton de démarrage (2). N.B. : la vitesse

ne doit pas être changée pendant que l’appareil travaille. Il convient de toujours arrêter

(3) le batteur-mélangeur avant de changer de vitesse.

5.3 UTILISATION DU RACLOIR DE CUVE

5.3.1 GÉNÉRALITÉS CONCERNANT L’UTILISATION DU

RACLOIR DE CUVE (OPTION).

Le racloir de cuve est un accessoire de l’appareil qui racle en permanence les parois de

la cuve, pendant que l’agitateur tourne, pour ramener le produit qui se trouve sur les

côtés et dans le fond de la cuve dans la préparation. Un raclage manuel n’est pas

nécessaire avec le racloir de cuve. Cet accessoire ne doit être utilisé qu’avec des cuves

en inox.

Veiller à utiliser la taille de manchon qui correspond avec le bras de racloir. Faire

attention à ne pas mélanger les manchons et les bras en cas d’utilisation de différentes

tailles de racloirs.

Page 29

27

5.3.2 FONCTIONNEMENT AVEC LE RACLOIR DE CUVE

1 Placer le racloir dans la cuve avant de lever celle-ci en position de travail (voir

section 5.1.)

2 Lubrifier la surface de la cuve avec de l’huile végétale ou de la matière grasse, en

insistant sur la zone au-dessus du produit, là où le manchon a des chances de

frotter contre la paroi nue de la cuve.

3 Si on regarde dans la cuve, le racloir tourne dans le sens des aiguilles d’une

montre. Insérer l’arbre du racloir dans le logement à baïonnette puis le faire pivoter

à 90° dans le sens contraire des aiguilles d’une montre.

4 Lever la cuve en position de travail. Ajouter les ingrédients et mélanger

normalement.

5 Lorsque la préparation est terminée, descendre la cuve puis faire pivoter le racloir

dans le sens des aiguilles d’une montre avant de le baisser pour le retirer.

N.B. :

¨ N’utiliser que les vitesses 1 et 2.

¨ Les produits pouvant être préparés lorsque le racloir est installé sont les suivants :

purée de pommes de terre, pâte à gaufre, pâte à gâteau, glaçages, travail matière

grasse/sucre, travail œufs/sucre, et mayonnaise.

¨ Utiliser le racloir de cuve uniquement avec un fouet métallique ou un batteur plat. À

éviter pour les préparations de pâtes dures.

¨ Ne jamais lever une cuve contenant un produit ferme (ex. fromage blanc, matière

grasse, purée non écrasée) lorsque le bras du racloir se trouve dans le logement. Le

bras du racloir peut se plier de manière irréversible et se retrouver abîmé par les

outils en rotation. Attendre que la cuve soit levée pour la remplir d’ingrédients.

5.3.3 NETTOYAGE DU RACLOIR DE CUVE

Ôter le manchon en plastique du bras en inox. Pour faciliter son retrait, on peut tapoter le

manchon contre le rebord d’une table. Nettoyer les deux éléments dans un évier, avec de

l’eau chaude et un détergent. Rincer à l’eau propre et sécher.

Glisser le manchon par-dessus le bras de sorte que le bord biseauté soit le bord

d’attaque. Utiliser de l’eau comme lubrifiant. Le bout du manchon doit être aligné avec

l’extrémité du bras.

N.B. :

Ne pas utiliser de produit chimique agressif pour nettoyer le manchon car ils risquent

d’endommager le plastique.

5.4 LORSQUE LA PRÉPARATION EST TERMINÉE.

· Lorsque la préparation est terminée, arrêter l’appareil à l’aide du bouton d’arrêt (3).

· Tourner le devant de la grille (5) en position ouverte.

· Abaisser le porte-cuve et retirer l’agitateur de l’arbre (8).

· Démonter le racloir de cuve (s’il était monté) de sa fixation à baïonnette, en le faisant

tourner dans le sens contraire des aiguilles d’une montre.

· Retirer la cuve (7) et l’agitateur de l’appareil pour la vider.

Page 30

28

5.5 UTILISATION DES ACCESSOIRES

5.5.1 CONSIGNES DE SÉCURITÉ CONCERNANT LES

ACCESSOIRES

Les consignes suivantes doivent impérativement être respectées lors de

l’utilisation du batteur-mélangeur avec les accessoires. Lire également

les consignes de sécurité de la section 6.0 et les consignes fournies avec

les accessoires.

LES ACCESSOIRES ET/OU LE BATTEUR-MÉLANGEUR NE DOIVENT ÊTRE

UTILISÉS QUE PAR DES PERSONNES SUFFISAMMENT FORMÉES ET

COMPÉTENTES.

· Ne pas fixer d’accessoire lorsque le batteur-mélangeur est en plein travail.

· Ne pas porter de vêtements lâches.

· Ne pas utiliser le batteur-mélangeur ou un accessoire si une panne survient et que la

machine devient dangereuse à utiliser.

· Ne pas essayer d’atteindre les parties tournantes.

· Ne pas exercer, au moment de l’utilisation de l’accessoire, une force excessive qui

pourrait rendre le batteur-mélangeur instable.

· Ne pas faire fonctionner le batteur-mélangeur lorsque des pièces sont démontées.

· Toujours utiliser les accessoires et/ou le batteur-mélangeur dans un endroit bien

éclairé.

· Toujours vérifier que les accessoires sont utilisés avec la bonne vitesse.

· Toujours nettoyer les accessoires après le travail, et se référer aux procédures de

nettoyage préconisées par le fabricant d’accessoires.

· Toujours faire réviser le batteur-mélangeur et les accessoires à intervalles réguliers,

au moins deux fois par an selon la fréquence d’utilisation.

5.5.2 MONTAGE DES ACCESSOIRES SUR LA PRISE

D’ACCESSORES.

Vérifier, avant de monter les accessoires, que l’appareil est coupé de l’alimentation

secteur.

Desserrer la vis à oreilles (pièce 12 sur la figure 2) située sur le moyeu pour accessoires,

puis ôter le couvercle en plastique et le garder dans un endroit sûr pour le remettre

après l’utilisation.

Présenter l’arbre de l’accessoire devant le moyeu, et vérifier que la tige carrée de

l’accessoire entre dans le conducteur carré de l’appareil.

Fixer l’accessoire en place en serrant la vis à oreilles.

Régler le levier de vitesse sur la vitesse adaptée au type d’accessoire.

Page 31

29

6.0 CONSIGNES DE SÉCURITÉ.

LA MANIPULATION DE L’ACCESSOIRE ET/OU DU BATTEURMÉLANGEUR DOIT ÊTRE EXCLUSIVEMENT RÉSERVÉE À UNE

PERSONNE FORMÉE ET COMPÉTENTE.

Les consignes suivantes, relatives à l’utilisation du batteur-mélangeur, sont à respecter

de manière impérative.

N.B. : L’appareil ne doit être utilisé que pour effectuer les tâches entrant dans ses

attributions, et conformément aux consignes d’utilisation fournies.

Lors du mélange des ingrédients, il convient d’éviter l’inhalation de particules

de poussière, comme la farine. Les fiches techniques du fournisseur du produit

précisent les précautions à prendre et les protections à prévoir.

Des produits comme la farine doivent être ajoutés d’une manière précise, de

façon à éviter la dispersion de particules de poussière dans l’atmosphère

environnante.

Si la cuve avec son contenu pèse plus de 25 kg, utiliser un chariot (Référence

Hobart M-L108865) pour la manœuvrer ou la soulever.

6.1 NE JAMAIS. ATTENTION

· Ne jamais faire fonctionner le batteur-mélangeur ou l’accessoire lorsqu’une panne

survient ou lorsque l’appareil est dangereux.

· Ne jamais porter des vêtements lâches.

· Ne jamais essayer de mettre la main à l’intérieur de la cuve lorsque l’appareil

mélange.

· Ne jamais essayer d’atteindre les parties tournantes.

· Ne jamais fixer l’outil sur le batteur-mélangeur sans cuve.

· Ne jamais laisser l’outil sur l’appareil sans cuve.

· Ne jamais faire fonctionner le batteur-mélangeur avec les accessoires sur la prise

d’accessoire et l’outil installés en même temps.

· Ne jamais laisser le levier de changement de vitesse en position intermédiaire.

· Utiliser le levier de changement de vitesse pour arrêter l’appareil.

· Ne jamais changer de vitesse lorsque l’appareil mélange.

· Ne jamais exercer, lorsque l’appareil travaille, une force excessive susceptible de

rendre le batteur-mélangeur instable.

· Ne jamais faire fonctionner le batteur-mélangeur lorsque des pièces sont démontées.

· Ne jamais ignorer les commutateurs de sécurité installés sur l’appareil.

· Ne jamais ouvrir la grille de protection pour arrêter l’appareil.

· Ne jamais utiliser la poignée de montée de cuve pour arrêter l’appareil.

· Ne jamais utiliser l’appareil s'il ne fonctionne pas en toute sécurité.

· Ne jamais nettoyer l’appareil avec de la poudre à récurer ou un tampon de récurage.

· Ne jamais inhaler les particules de poussière des ingrédients de mélange.

Page 32

30

6.2 TOUJOURS

· Utiliser le batteur-mélangeur dans un endroit bien éclairé.

· Vérifier que la cuve, les vis à poignée, l’outil, l’accessoire et la grille sont

correctement fixés sur l’appareil.

· Couper l’alimentation secteur avant de nettoyer l’appareil.

· Nettoyer l’appareil quotidiennement.

· Retirer l’outil avant d’utiliser tout accessoire.

· Arrêter le batteur-mélangeur avant d’ajouter des ingrédients.

· Utiliser le bouton d’arrêt pour arrêter l’appareil.

· Nettoyer la cuve, les outils et les accessoires après le travail.

· Nettoyer l’appareil au savon doux et à l’eau.

· Faire réviser le batteur-mélangeur et ses accessoires au moins deux fois par an,

selon la fréquence d’utilisation.

· Utiliser les équipements de taille réduite adaptés (cuve et agitateurs spécifiés à la

section 12).

7.0 TABLEAUX DE CAPACITÉS DE PRÉPARATION

Les tableaux suivants (Tableaux 2, 3, 4, 5, 6 et 7) indiquent quelles sont les capacités

maximales recommandées du batteur-mélangeur. Avec une farine à haute teneur en

gluten, réduire la quantité de préparation de 10 %.

Vérifier que l’agitateur utilisé convient au type de préparation.

Les capacités indiquées se basent sur une eau à 21°C et une farine à 12 % de teneur en

eau. Ces capacités doivent être réduites si l’eau est plus froide, car des températures

d’eau plus froides rendent le mélange d’un produit plus difficile. Vérifier le bon réglage de

la vitesse.

NE PAS DÉPASSER LA QUANTITÉ DE PRÉPARATION SPÉCIFIÉE

Une trop grosse quantité de préparation peut nuire à la qualité du produit fini et altérer la

durée de vie de l’appareil. Il convient de toujours consulter les tableaux de préparation.

Capacité maximale des batteurs-mélangeurs :-

HSM30 / NCM300 = 28,75 litres

HSM40 / NCM400 = 38,5 litres

Tableau 2 HSM30 / NCM300 Capacités cuisine - par charge

Type de produit Quantité Outil

recommandé

Vitesses

recommandées

Blancs en neige 1,7 litre Fouet 1 / 2 / 3

Purée de pommes de terre 10,4 kg Batteur B 1

Mayonnaise (huile) 13,6 litres Fouet 2 / 3

Crème fouettée 17,0 litres Fouet 1 / 2 / 3

Page 33

31

Tableau 3 HSM30 / NCM300 Capacités pâtisserie - par charge

Type de produit Quantité Outil

Recommandé

Vitesses

recommandées

Gâteau de Madère 13,5 kg Batteur B 1 / 2 / 3

Quatre-quarts 12,7 kg Batteur B 1 / 2 / 3

Préparation légère (biscuit

de Savoie)

9,1 kg Batteur B 1 / 2 / 3

Pudding cuit à la vapeur 13,5 kg E ou EB 1 / 2 / 3

Yorkshire pudding 13,6 litres Fouet B ou C 2 ou 3

Pâte (légère - moyenne) 13,5 kg

(TA 65 %)

(8.8 kg de farine 4,7 litres

d’eau)

Crochet ED 1 exclusivement

Pâte (lourde) 10,9 kg

(TA 50 %)

(7,3 kg de farine 3,6 litres

d’eau)

Crochet ED 1 exclusivement

Pâte à pizza 6,8 kg E ou ED

exclusivement

1 exclusivement

Tourtes, tartes 10,9 kg Couteau à

pâtisserie

Crochet ED

1 exclusivement

Matière grasse & sucre

pour biscuit de Savoie

10,9 kg Fouet 1 / 2 / 3

Tableau 4 HSM40 / NCM400 Capacités cuisine - par charge

Type de produit Quantité Outil

recommandé

Vitesses

recommandées

Blancs en neige 2 litres Fouet 1 / 2 / 3

Purée de pommes de terre 12,7 kg Batteur B 1

Mayonnaise (huile) 17 litres Fouet 2 / 3

Crème fouettée 22,6 litres Fouet 1 / 2 / 3

Tableau 5 HSM40 / NCM400 Capacités pâtisserie - par charge

Type de produit Quantité Outil

recommandé

Vitesses

recommandées

Gâteau de Madère 18 kg Batteur B 1 / 2 / 3

Quatre-quarts 16 kg Batteur B 1 / 2 / 3

Préparation légère (biscuit de

Savoie)

12,7 kg Batteur B 1 / 2 / 3

Pudding cuit à la vapeur 18 kg E ou EB 1 / 2 / 3

Yorkshire pudding 17 litres Fouet B ou C 2 ou 3

Pâte (légère - moyenne) 18 kg (TA 65 %)

(11 kg de farine 7 litres d’eau)

Crochet ED 1 exclusivement

Pâte (lourde) 13,5 kg (TA 50 %)

(9 kg de farine 4,5 litres d’eau)

Crochet ED 1 exclusivement

Pâte à pizza 9,1 kg E ou ED

exclusivement

1 exclusivement

Tourtes, tartes 13,5 kg Couteau à

pâtisserie

Crochet ED

1 exclusivement

Matière grasse & sucre pour

biscuit de Savoie

13,5 kg Fouet 1 / 2 / 3

Page 34

32

Tableau 6. 20 litres cuve. Capacités cuisine - par charge

Type de produit Quantité Outil

recommandé

Vitesses

recommandées

Blancs en neige 1.1 litres Fouet 1 / 2 / 3

Purée de pommes de terre 6.8 kg Batteur B 1

Mayonnaise (huile) 11.4 litres Fouet 2 / 3

Crème fouettée 11.4 litres Fouet 1 / 2 / 3

Tableau 7. 20 litres cuve. Capacités pâtisserie -par charge

Type de produit Quantité Outil

recommandé

Vitesses

recommandées

Gâteau de Madère 9 kg Batteur B 1 / 2 / 3

Quatre-quarts 9 kg Batteur B 1 / 2 / 3

Préparation légère (biscuit de

Savoie)

6.4 kg Batteur B 1 / 2 / 3

Pudding cuit à la vapeur 9 kg E ou EB 1 / 2 / 3

Yorkshire pudding 9.1 litres Fouet B ou C 2 ou 3

Pâte (légère - moyenne) 9.1 kg (65% A/R)

(5.6 kg de farine 3.5 litre

d’eau)

Crochet ED 1 exclusivement

Pâte (lourde) 5.8 kg (50% A/R)

kg de farine 1.9 litre d’eau)

Crochet ED 1 exclusivement

Pâte à pizza 5.0 kg E ou ED

exclusivement

1 exclusivement

Tourtes, tartes 7.3 kg Couteau à

pâtisserie

Crochet ED

1 exclusivement

Matière grasse & sucre pour

biscuit de Savoie

6.8 kg Fouet 1 / 2 / 3

* TA taux absorbant.

La vitesse “1” (BAS) est destinée aux mélanges lourds telles que les pâtes dures, les pâtes

molles lourdes et les purées de pommes de terre.

La vitesse “2” (MOYEN) est destinée au mélange des pâtes à gâteau.

La vitesse “3” (ÉLEVÉ) sert à mélanger le maximum d’air dans les préparations légères.

Le fouet « D » s’utilise pour fouetter la crème fraîche, battre les blancs en neige,

préparer des glaçages légers, des meringues et fouetter.

Page 35

33

8.0 LES OUTILS.

Les outils destinés au batteur-mélangeur sont conçus pour les opérations décrites cidessous :

Le ‘batteur B’ est un agitateur polyvalent servant à réaliser des purées de

pommes de terre et d’autres légumes cuits, des pâtes à gâteau et à crêpe et

des glaçages. Sélectionner la vitesse 1 pour démarrer la plupart des

opérations, puis passer à la vitesse 2 pour finir le travail, au besoin.

Le ‘fouet D’ est conçu pour mélanger le maximum d’air dans les produits légers. Il

sert à fouetter la crème fraîche, battre les blancs en neige et mélanger des blancs

en neige très légers. Ce fouet s’utilise sur les vitesses 2 et 3.

Le ‘crochet ED’ sert à pétrir les pâtes à pain et la pâte à pizza, qui nécessitent

d’être pliées et étirées pour un développement optimal. Ce crochet s’utilise

principalement sur la vitesse 1.

Le ‘couteau à pâtisserie’ sert à mélanger les pâtes à tarte et à tourte. Le

couteau à pâtisserie s’utilise seulement sur la vitesse 1.

9.0 NETTOYAGE

NE PAS NETTOYER L’APPAREIL AU JET D’EAU OU À LA PRESSION

NE PAS UTILISER DE NETTOYANTS ABRASIFS

Couper l’appareil de l’alimentation secteur avant de procéder au nettoyage

9.1 NETTOYAGE AVANT LA PREMIÈRE UTILISATION.

Avant d’utiliser l’appareil pour la première fois, il convient de nettoyer soigneusement la cuve,

les outils et les accessoires du nouveau batteur-mélangeur. Utiliser pour cela de l’eau chaude

et un détergent doux. Nettoyer de la même manière la cuve et les outils avant de battre des

blancs en neige ou des œufs entiers.

Page 36

34

9.2 NETTOYAGE APRÈS USAGE.

Après usage, il convient de nettoyer la cuve, les outils et les accessoires à l’eau chaude,

en utilisant un détergent non-abrasif adéquat et une brosse à poils doux. (Un rinçage à

l’eau chaude juste après le travail facilite le nettoyage de la cuve).

Nettoyer le batteur-mélangeur avec un chiffon chaud et humide, et bien essuyer les bras

de la cuve ainsi que toutes les surfaces extérieures. Nettoyer également la grille de la

manière suivante.

9.3 DÉMONTAGE ET NETTOYAGE DE LA GRILLE.

La grille a été conçue pour être démontée facilement afin de nettoyer l’appareil.

Démontage de la grille :

· Vérifier que le porte-cuve est abaissé.

· Retirer la cuve et l’agitateur.

· Retirer le piston de verrouillage et faire tourner le déflecteur de la grille dans le sens

oppose des aiguilles d’une montre jusqu’à ce que l’ensemble se libère des dispositifs

de retenue à ressorts. Il convient alors d’être vigilant car la grille n’est plus retenue et

peut tomber de l’appareil.

· Abaisser la grille avec précaution et la retirer.

Nettoyer la grille.

Il est important de nettoyer la grille de protection tous les jours après le travail.

Une fois la grille retirée, celle-ci peut être lavée à l’eau chaude, en utilisant un détergent

non-abrasif adéquat et une brosse à poils doux. La grille peut également être lavée dans

un lave-vaisselle ménager.

Remontage de la grille sur l’appareil.

· Orienter la grille en positionnant le déflecteur à l’arrière de l’appareil, puis emboîter la

grille sur l’appareil en poussant.

· Tourner le déflecteur de la grille dans le sens des aiguilles d’une montre pour

l’enclencher complètement dans les dispositifs de retenue à ressorts. Une fois en

place, la grille ne bouge plus.

Il convient de nettoyer la grille chaque jour après le travail.

Page 37

35

10.0 MAINTENANCE DE L’APPAREIL.

LA MAINTENANCE DE L’APPAREIL DOIT ÊTRE EFFECTUÉE PAR UNE

PERSONNE COMPÉTENTE, FORMÉE PAR HOBART.

Ne pas enlever de couvercle et ne desserrer aucun accessoire lorsque l’appareil est en

plein travail. Couper l’appareil de l’alimentation secteur avant de le réviser ou de le

déplacer.

Le moteur et la transmission sont lubrifiés avec une graisse spéciale qui durera plusieurs

années. En cas de besoin de remplacement, contacter le service après-vente local.

Pour prévenir la corrosion et assurer un bon fonctionnement, il convient de lubrifier les

tiges du porte-cuve de temps en temps, avec une petite quantité d’huile propre à la

consommation appliquée avec le bout du doigt.

Il est conseillé de faire réviser régulièrement (deux fois par an) l’appareil.

Un catalogue de pieces de recharge (ple200459) est disponible sur demande auprès du

service SAV Hobart le plus proche. Afin que cet appareil continue à fonctionner en toute

sécurité et fiabilité, il est conseillé de confier son entretien à des techniciens qualifiés de

Hobart.

11.0 RECHERCHE DES PANNES

Défaut Cause possible Solution

L’appareil ne démarre pas Fusible de circuit de

commande a sauté

Vérifier et remplacer le fusible

défaillant

La grille n’est pas en position

de travail

Vérifier que la grille de

protection est fermée

Le levier de changement de

vitesse n’est pas

correctement positionné

Régler sur la bonne vitesse

L’appareil est coupé de

l’alimentation secteur

Brancher et allumer l’appareil

L’appareil ne fonctionne

toujours pas

Contacter le centre local de

service après-vente Hobart

Le racloir (option) se coince

contre les parois de la cuve

Le racloir frotte sur une

surface sèche

Lubrifier les parois de la cuve

avec de l’huile végétale ou de

la matière grasse

Le bord biseauté du racloir

(option) n’est pas le bord

d’attaque

Le manchon en plastique

n’est pas mis correctement

Ôter le racloir et insérer

correctement le manchon en

plastique.

Trop d’espace entre la cuve

et le racloir

Le bras du racloir est plié ou

dégagement cuve incorrect

Contacter le centre local de

service après-vente Hobart

Le moteur démarre mais

l’agitateur ne tourne pas

Levier de changement de

vitesse mal positionné

Régler sur la bonne vitesse

L’appareil ne fonctionne

toujours pas

Contacter le centre local de

service après-vente Hobart

Page 38

36

12.0 PIÈCES DE RECHANGE RECOMMANDÉES

Référence Description

PLE200459 Catalogue de pieces de recharge

144452-1 Moteur monophasé 230/50/1 (selon modèle)

138725 Condensateur, démarrage (160-200 µF) (selon modèle)

138724 Condensateur, fonctionnement (15 µF) (selon modèle)

144453-1 Moteur triphasé 400/50/3 (selon modèle)

00-738242 Courroie d’entraînement

00-737991-4 Couvercle supérieur, minuterie NCM300, NCM400

00-737991-3 Couvercle supérieur, pas de minuterie NCM300, NCM400

00-737991-9 Couvercle supérieur, minuterie HSM30, HSM40

141932 Commutateur, changement de vitesse

EPM-E-16-14 Commutateur démarrage

EPM-E-16-15 Commutateur arrêt

SS-E-18-11 Minuterie 30 min.

140807 Interrupteur à lames, grille de protection

144358 Commutateur, porte-cuve

00-738163 Grille. HSM30 / NCM300

00-738164 Grille. HSM40 / NCM400

142403-10 Surcharge thermique, 230/50/1 (selon modèle)

142403-8 Surcharge thermique, 400/50/3 (selon modèle)

141440-1 Contacteur

140869-10 Fusible, commande 315 mA

140869-19 Fusible, commande 2 A

140908-3 Transfo. 400/50/3

OSM-E-1-12 Joint étanche à l’huile

R-9440-E Batteur, HSM30 / NCM300

R-9443-E Fouet, HSM30 / NCM300

141721 Crochet ED, HSM30 / NCM300

53572 Batteur, HSM40 / NCM400

53577 Fouet, HSM40 / NCM400

140688 Crochet ED, HSM40 / NCM400

00-738662 Cuve 20 litres pour HSM30 / NCM300 et HSM40 / NCM400. Adaptateur

requis pour HSM40 / NCM400

00-738664 Cuve 30 litres pour HSM40 / NCM400

53600 Adaptateur pour installer la cuve de 30 litres sur un HSM40 / NCM400

50181 20 liters adaptateur de cuve

10470-E Fouet 20 liters

10469-E Batteur 20 liters

51831 Crochet 20 liters

ML-109241 Ensemble racloir de cuve 20 litres comprenant lame et logement

737458-2 Lame-racloir 20 litres

ML-109242 Ensemble racloir de cuve 30 litres comprenant lame et logement

737458-3 Lame-racloir 30 litres

ML-109243 Ensemble racloir de cuve 40 litres comprenant lame et logement

737458-4 Lame-racloir 40 litres

00-738071 Logement-racloir (toutes capacités)

Page 39

37

NOTES :

Page 40

38

13.0 SERVICE APRÈS-VENTE ET ADRESSES

Nos techniciens qualifiés S.A.V, stratégiquement répartis dans les établissements

Hobart, sont prêts à vous offrir un service rapide, efficace et fiable. Protégez votre

investissement en optant pour un contrat d’inspection Hobart afin d’assurer la continuité

et la qualité de fonctionnement de vos appareils, pièces de rechange et accessoires

Hobart.

Renseignements :-

Téléphone Fax

DIRECTION COMMERCIAL 01 64 11 60 00 01 64 11 60 05

DIRECTION SERVICE 01 64 11 60 77 01 64 11 60 03

Hobart ayant une politique d’amélioration constante de ses produits, les spécifications peuvent changer

sans préavis.

Compagnie Hobart

ZI Paris-Est,

1, Allee du 1er Mai,

Croissy-Beaubourg

BP68-77312

Marne-la-Vallee

France

Tél. : +33 (0)1 64 11 60 00 Fax : +33 (0)1 64 11 60 01

Page 41

39

Deutsch / INHALT

Seite

Information zur Sicherheit 40

Sicherheitsrichtlinien 40

Warnsymbole 41

Haftung 41

Vorwort 41

Allgemeines 41

Ausmaße des Mixers. Abbildung 1 42

Technische Information. Tabelle 1 42

Installation 43

Auspacken und Handhabung 43

Standort 43

Elektrische Installation 44

Stromanschluß 44

Inbetriebnahme- und Betriebsanweisung 44

Betrieb 44

Erste Inbetriebnahme 45

Identifikation der Mixerbauteile. Abbildung 2 45

Verwendung des Schüsselschabers 46

Allgemeines zur Verwendung des Schüsselschabers 46

Betrieb mit dem Schüsselschaber 46

Reinigung des Schüsselschabers 47

Nach dem Rühren 47

Verwendung des möglichen Zubehörs 48

Sicherheitsanweisung für das Zubehör 48

Einsetzen eines Zubehörteils 48

Sicherheitsanweisungen 49

Niemals 49

Immer 50

Tabelle der Mischmengen 50

Küchenübliche Mengen HSM30 / NCM300. Tabelle 2 50

Bäckereiübliche Mengen HSM30 / NCM300. Tabelle 3. 51

Küchenübliche Mengen HSM40 / NCM400. Tabelle 4. 51

Bäckereiübliche Mengen HSM40 / NCM400. Tabelle 5 51

Küchenübliche Mengen 20 litre schüssel. Tabelle 6. 52

Bäckereiübliche Mengen 20 litre schüssel. Tabelle 7. 52

Mixerrührwerke 53

Reinigen 54

Reinigung vor der ersten Inbetriebnahme 54

Reinigung nach dem Gebrauch 54

Entfernen und Reinigen des Schutzgitters 54

Wartung des Geräts 55

Fehlersuche 56

Empfohlene Ersatzteile 57

Notizen 58

Kundendienstinformation und Adressen 59

Page 42

40

1.0 INFORMATION ZUR SICHERHEIT

Die Verfahren und Vorsichtsmaßnahmen in diesem Handbuch beziehen sich

ausschließlich auf den sachgerechten Einsatz des Geräts.

Wenn das Gerät nicht sachgemäß eingesetzt wird, dann ist der Bediener für seine

eigene Sicherheit sowie die Sicherheit anderer Personen verantwortlich.

Die Information in diesem Handbuch wurde zusammengestellt, um den Bediener beim

Verständnis, der Wartung und des Betriebs des Mixers zu unterstützen. Zur Verhütung