Page 1

INSTALLATION OPERATION

INSTALLATION MODE D’EMPLOI

AUFSTELLUNG BEDIENUNG

Page 2

English

Français

Contents

Safety Information 2

General Information 3

Installation 3

Safety Instructions 4

Mixing Chart 5

Operation 6

Cleaning 7

Fault Finding 8

Recommended Spares 9

Notes 10

Service information 11

Sommaire

Renseignements relatifs à la sécurité 12

Généralités 13

Installation 13

Consignes de sécurité 14

Tableau de malaxage 15

Mode d’emploi 16

Nettoyage 17

Diagnostic des pannes 18

Pièces de rechange recommandées 19

Remarques 20

Service après-vente 21

Deutsch

Sicherheitsinformation 22

Allgemeine Information 23

Aufstellung 23

Sicherheitsvorschriften 24

Mischtabellen 25

Bedienung 27

Störungsbehebung 28

Empfohlene Ersatzteile 29

Notizen 30

Kundendienstinformation 31

Inhalt

- 1 -

Page 3

ENGLISH

SAFETY INFORMATION

The procedures and precautions contained in this manual are understood to apply to

the machinery only when it is used in the authorised manner

If the machinery is used other than in the authorised manner, the operator will be

responsible for his/her own safety and for the safety of the other persons who may

be involved.

Many accidents are caused by insufficient knowledge and failure to apply the safety

regulations which should be implemented during the operation, cleaning and

maintenance of the machinery.

To prevent accidents, read , understand and follow all the precautions and warnings

contained in this manual before starting work and carrying out any of the

cleaning/maintenance operations.

To identify the safety messages in this manual, the following symbols have been

used

WARNING!

The " Warning" symbol is found primarily where

the corresponding warnings are important for

the safe use of the machinery

This symbol is used when there are risks of an

electrical nature (Prior to servicing the

machinery , always disconnect the power cable

from the mains supply)

This equipment should only be transported and stored in an environment with an

ambient temperature and should not be subject to freezing conditions or

temperatures less than 5OC or exceeding 55OC

Liability

Installations and repairs which are not carried out by Authorised technicians or the

use of other then original spare parts , and any technical alterations to the

machine, may affect the warranty set out in the standard conditions of sale.

- 2 -

Page 4

GENERAL INFORMATION

The HSM20 & NCM20 mixers are designed to mix food products as per specification

chart, standing on a standard height worktop. The HSM20 mixer is manufactured

from 2 metallic painted castings, Fabricated stainless steel pedestal , back panel &

feet, with a plastic moulded top cover. The NCM20 is manufactured from 2 iron

castings, a fabricated steel pedestal, aluminium cast feet with a plastic moulded top

cover and steel back panel. All with a Hobart grey paint finish. The machine will

operate on either a 230v/50/1 or 400v/50/3 supply, and is fitted with an NVR safety

feature to prevent automatic restarting after a supply failure/disconnection. The bowl

support and guard are electrically interlocked so that when the bowl is in the down

position, or the guard is in the open position, the machine will not work.

MACHINE NOISE LEVEL: In accordance with EN-ISO 12001:1996 the recorded

noise level is less then 70db (A) (55db Recorded)

WEIGHTS: Gross 86Kg Net 78Kg

INSTALLATION

Electrical rating :

400/50/3 FLC 1.1 Amps fused at 4A

230/50/3 FLC 1.9 Amps fused at 6A

230/50/1 FLC 4.6Amps fused at 16A

This machine must be installed in accordance with current regulations by a qualified

person.

Carefully unpack the machine. Do not use a sharp knife to cut into the box as

damage to the machine may occur.

With the machine in the vacinity of its final position remove from the transportation

pallet. The machine is affixed to the pallet by four retaining bolts through the pallet

into the threaded feet.

Care must be taken during this operation to ensure :-

a) All required safety measures are taken to ensure correct lifting and handling to

avoid risk of injury through dropping, falling & tilting.

b) No damage to the machine which could impair the normal operation

Place the mixer in its correct operating position, which should be firm and level

Ensure that the electrical supply agrees with the machine specification, prior to

connection

Note: The single phase model should not be installed via a 13A fused plug

If machine fails to operate, please check that the bowl support is in the up position

and the guard is in the operating position

Notes :-

1. For installation to a dedicated stand, static or mobile, the transportation bolts

should be used to secure machine into position

2. In areas where stability may be an issue, again the machine should be secure in

position

- 3 -

Page 5

SAFETY INSTRUCTIONS

The following instructions must be observed when using the mixer.

NEVER

· attempt to reach into the bowl when mixing

· fit agitator to mixer without bowl

· leave agitator on machine without bowl being fitted

· run mixer with both attachments or agitator fitted

· Leave gear lever in mid position

· Use gear to stop machine

· Use guard to stop machine

· Use bowl lift handle to stop machine

· Use machine in an unsafe condition

ALWAYS

· Always Disconnect the mains supply and clean mixer daily

· Remove Agitator before using any attachments

· Stop mixer before adding more ingredients

· Use stop button to stop machine

· Clean the bowl and agitators after use

· After daily use disconnect mains power supply or switch off isolating switch.

Clean mixer using mild soap and water, never scouring powder

· Ensure mixer is subject to regular servicing ( Recommended twice yearly)

The machine should only be used for the design purposes and

inline with the supplied operating instructions

- 4 -

Page 6

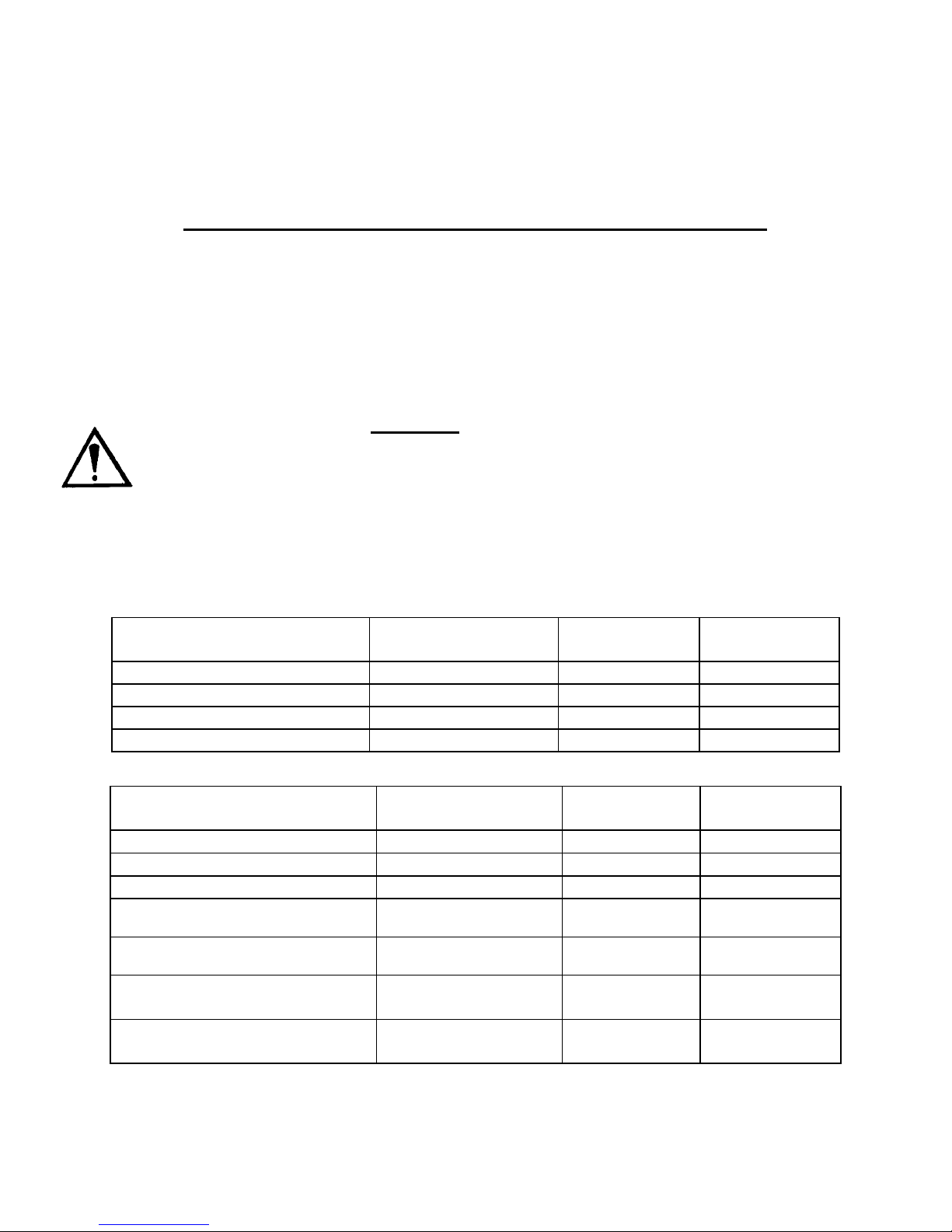

MIXING CHART

· The following chart shows the maximum recommended capacities

· With high gluten flour reduce dough batch by 25%

· Ensure the correct tool is selected

· Ensure the correct speed is selected

DO NOT EXCEED THE SPECIFIED MIX QUANTITY

HSM20 = 20 Litres

NCM20 = 20 Litres

Overloading the mix can be detrimental to the quality of the finished product and

affect the life expectancy of the machine. Always refer to the mixing chart

When mixing ingredients care must be taken to avoid the inhalation of dust

particles e.g. Flour. Reference should be made to the product suppliers data

sheets to ensure that adequate precautions/protection are taken.

Items such as flour should be added in such a manner to avoid dust particles

being dispersed into the local atmosphere.

HSM20 / NCM20 Kitchen Capacities - Single Batch

Type of Product Quantity

Egg Whites 1.14 litres Whip 1 / 2 / 3

Mashed Potatoes 6.8 kg B Beater 1

Mayonnaise (Oil) 11.36 litres Whip 2 / 3

Whipped Cream 11.36 litres Whip 1 / 2 / 3

Recommended

Agitator

Recommended

speeds

HSM20 / NCM20 Bakery Capacity - Single Batch

Type of Product Quantity Recommended

Agitator

Cake, Madera 9.1 kg B Beater 1 / 2 / 3

Cake , Pound 9.1 kg B Beater 1 / 2 / 3

Light Batter (Sponge Cake) 6.4 kg B Beater 1 / 2 / 3

Dough (light -medium) 9.0 kg (65% A/R)

(5.5 kg flour 3.5 litre water)

Dough (heavy) 5.7kg (50% A/R)

(3.8 kg flour 1.9 litre water)

Pie Pastry 7.3 kg Pastry Knife

Fat & Sugar for

Sponge Cake

6.8 kg Whip 1 / 2 / 3

ED Hook 1 only

ED Hook 1 only

ED Hook

Recommended

speeds

1 only

- 5 -

Page 7

OPERATION

This machine is only for professional use by suitably qualified persons.

· Ensure that the machine is switched

off (1)

· Lower bowl support (2) by using the

hand lever (3)

· Rotate front guard (6) to allow access

1 9

· Place the required agitator in the

bowl (7),and lift bowl onto the bowl

support (2).

5

· Ensure that the bowl is correctly

positioned and engaged on the

location pins of thebowl support.

4

· Slide the agitators on the shaft (8)

turning to engage the drive pin in

the "L" slot

6 3

· Add ingredients to the bowl and

raise the bowl by hand lever (3)

(NOTE. An electrical interlock is

fitted to the bowl support to prevent

accidental starting when bowl is in

the down position)

7

· Rotate front guard (6) to operating

position

2

· Select speed (4) and set timer (5) if

fitted

· Start machine by pressing start

button (9)

· When mixing is complete: -

· Stop machine using Stop button (1)

· Lower bowl support.

· Open front guard (6)

· Remove agitator from shaft

· Remove bowl and agitator from mixer to empty

The Number “1” (LOW) is for Heavy mixtures such as dough, heavy batters and mashed potatoes

The number “2” (MEDIUM) is for mixing cake batters

The number “3” (HIGH) is for mixing maximum amount of air into light batches. The “D” whip is used for

whipping cream, beating egg whites, mixing light icings, meringues and whipping

REFERENCE IS TO BE MADE TO THE MIXING CHART SHOWN ON PAGE 5

- 6 -

Page 8

CLEANING DO NOT HOSE OR PRESSURE CLEAN THIS MIXER

DO NOT USE ANY ABRASIVE CLEANERS

Ensure that the machine is disconnected from the main electrical power supply prior to cleaning

Clean the mixing bowl and agitators with hot water, a suitable non-abrasive

detergent and soft bristle brush. (Flushing the bowl with hot water immediately after

use will ease the cleaning of the bowl)

Note: Do not clean the aluminium agitators in a dishwasher

Clean the mixer with a hot damp cloth, thoroughly wipe the bowl support arms and

all exterior surfaces.

GUARD CLEANING & REMOVAL – HSM20 & NCM20

The cage assembly of the guard has been designed to be removed easily for

machine washing.

To remove the cage assembly,

· Ensure that the bowl support is in the lowered position.

· Remove the bowl and agitator

· Rotate the cage assembly in a clockwise direction until the front block is aligned

with cut out in the drip cup runner. At this point care should be taken, as the cage

will now be able to drop freely from the machine.

· Lower front to clear the runner and carefully push to the rear to allow blocks to

clear runner. Lower and remove

To refit cage assembly to the machine.

· Align the front single slide block with the cut out in the drip cup.

· Engage the two rear slide blocks to the drip cup

· Raise the front of the cage assembly until the front slider block can be engaged

onto the drip cup.

· Rotate the cage anti-clockwise so that it is fully engaged onto the drip cup

The cage should be cleaned at the end of each day.

To remove the rear splash shield.

The rear splash shield should be inspected regularly and when necessary removed

for machine washing. This should be performed by suitably trained supervisor or

maintenance department on minimum 3 monthly period, or if signs of cleaning

required.

· Ensure that the bowl support is in the lowered position, with bowl & agitator

removed, and the cage assy has been removed (see above).

· Using a suitable tool (bladed screwdriver) or by hand if thumbscrews fitted,

remove the 3 retaining screws and place in a safe place for refitting.

· The drip cup can now be removed from the machine by carefully rotating and

lowering.

· The Drip cup should be cleaned to ensure no risk of elements dropping into

product.

· Refit the rear splash shield in reverse ensuring the screws are adequately

tightened

Note: The rear splash shield can be adequately cleaned in situ for normal applications

- 7 -

Page 9

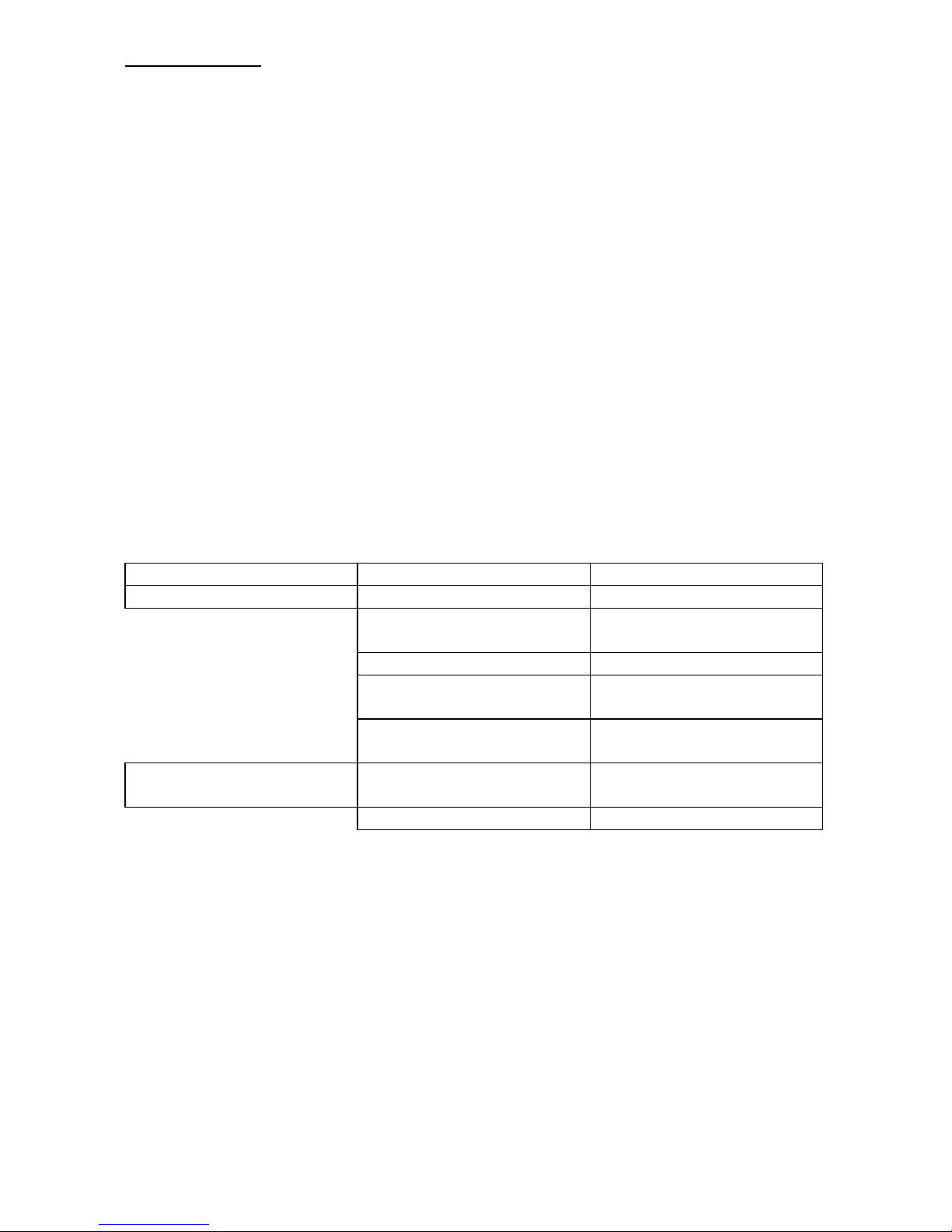

MAINTENANCE

The motor and transmission are packed with special grease, which will last for

several years. When replacement is needed, contact your local service centre.

The bowl support slideways should be lubricated occasionally with a small amount of

light oil applied with the finger tip, to prevent corrosion and ensure smooth operation

It is recommended that the mixer is serviced regularly (recommended twice yearly)

Electrical rating : 400/50/3 F.L.C 1.1 Amps

230/50/3 F.L.C 1.9 Amps

230/50/1 F.L.C 4.6Amps

A Service Maintenance Manual (PLE200467) is available upon request at the

designated SERVICE CENTRE. However, for the continued safe and reliable

operation of this machine, it is recommended that servicing is to be carried out by

HOBART trained service personnel only

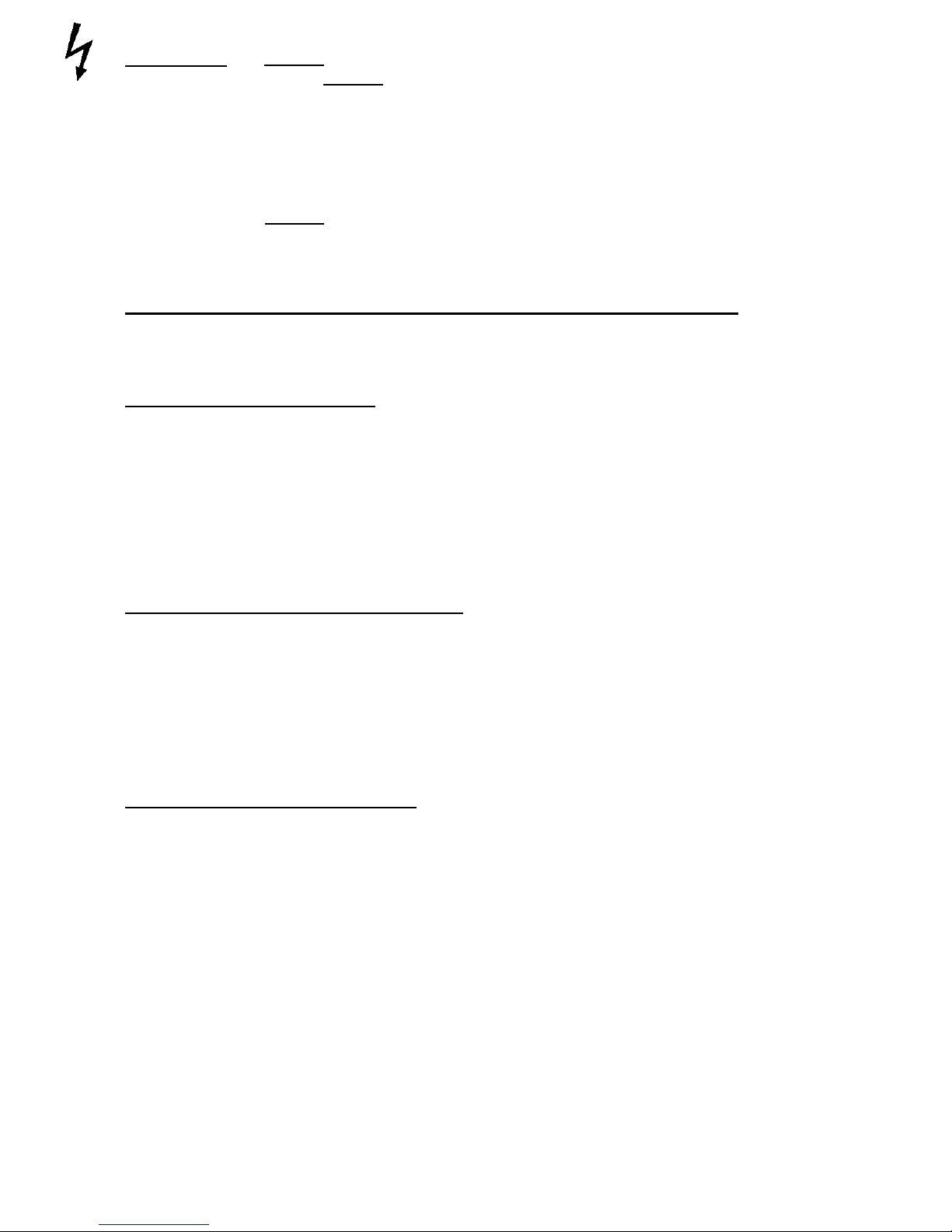

FAULT FINDING

Fault

Machine fails to start Check fuses If faulty replace fuses

Check bowl support is in

Place bowl in up position

operating position

Check speed control Set to required speed

check guard is in operating

position

machine still fails to

Rotate guard to closed

position

Call local service centre

operate

Motor starts but shaft fails

to turn

check drive belt for wear or

damage

If damaged , replace with

new belt

if shaft still fails to turn Call local service centre

- 8 -

Page 10

RECOMMENDED SPARES

Part Number Description

143192-1 Motor 1 phase. 230/50/1

00-738026-50 Capacitor

143193-1 Motor 3 phase. 400/50/3

EPM-E-16-14 Switch Start,

EPM-E-16-15 Switch Stop,

00-738177 Switch, guard.

140462-6 Switch, bowl support

00-438490 Guard.

00-738090 Internal gear

141440-1 Contactor

EP-E-10-10 Fuse, control

140908-3 Transformer

145149-1 Freewheel

OS-E-2-6 Oil seal

00-738102 Shaft, transmission

40679 Worm Wheel (50Hz)

40847 Worm Wheel (60Hz)

145150 Slow Speed Gear

GUIDANCE NOTES:

· The ‘HSM’ & ‘NCM’ Series mixers are designed to operate with the Guard closed

and the Bowl support raised. If the machine operates outside of these

parameters, your local Hobart service should be contacted

· A bowl scraper is only available for the HSM20 & NCM20, Part Number 00-

315281. The bowl should be lubricated with vegetable oil especially in the area

above the mix product where the sleeve might rub against the bare surface of the

bowl.

· The scraper should only be used with the whip or flat beater agitators, and

operated in speeds 1 & 2 only

- 9 -

Page 11

NOTES:-

- 10 -

Page 12

SERVICE

Hobart trained service technicians strategically located at the listed Hobart branches

are prepared to give you fast, efficient and reliable service. Protect your investment

by having a Hobart inspection contract which assures the continued, efficient

operation of your Hobart machines, spares and accessories.

For further details contact:-

SALES: 07002 101 101

SERVICE: 07002 202 202

SPARES: 07002 303 303

Continued product improvement is a Hobart Still policy, specifications may change without notice.

The Hobart Manufacturing Company Limited

Tel: 020 8920 2800 Fax 020 8886 0450

Hobart House, 51 The Bourne,

Southgate, London N14 6RT

- 11 -

Page 13

FRANÇAIS

RENSEIGNEMENTS RELATIFS A LA SECURITE

Il est considéré que les procédures et précautions contenues dans la présente

notice ne s’appliquent à l’appareil que si celui-ci est utilisé dans le respect des

consignes agréées.

Si la procédure d’application diffère des consignes agréées, l’utilisateur sera

responsable de sa sécurité personnelle et de la sécurité des tiers pouvant être

impliqués.

De nombreux accidents sont dus à des connaissances insuffisantes et au nonrespect des consignes de sécurité qu’il faut appliquer pendant l’emploi, le nettoyage

et l’entretien de cet appareil.

Afin d’éviter les accidents, lisez, comprenez et suivez toutes les précautions et tous

les avertissements contenus dans la présente notice avant de commencer à utiliser

l’appareil et d’entamer des travaux de nettoyage et d’entretien.

Afin d’identifier les messages de sécurité donnés dans la présente notice, on a

utilisé les symboles suivants :

AVERTISSEMENT !

On trouve le symbole " Avertissement”

principalement lorsque les avertissements

correspondants sont importants pour

garantir un emploi de l’appareil en toute

sécurité

Ce symbole sert s’il existe des risques

de nature électrique (avant l’entretien de

l’appareil, il faut toujours débrancher le

cordon d’alimentation du secteur).

Cet appareil doit impérativement être transporté et stocké à température ambiante

et ne doit en aucun cas être soumis à des conditions de gel ou à des températures

inférieures à 5OC ou supérieures à 55OC

Responsabilité

Les installations et les réparations qui ne sont pas entreprises par des Techniciens

agréés ou l’utilisation de pièces de rechange autres que celles qui sont des pièces

d’origine, ainsi que toutes les modifications techniques de l’appareil, peuvent

avoir un effet sur la garantie donnée dans les conditions ordinaires de vente.

- 12 -

Page 14

GENERALITES

La gamme de batteurs-mélangeurs HSM20 et NCM20 est conçu pour mixer des

produits alimentaires selon le tableau de spécification, posé sur une surface de

travail de hauteur standard. Le mélangeur HSM20 est manufacturé de deux bâtis

peints metalic, le piédestal fabriqué d'acier inoxydable, une base, de panneau

arrière, avec la couverture supérieure en plastique moulé Le mélangeur NCM20 est

manufacturé de deux moulages en fer, avec une base en acier manufacturé, des

pieds en aluminium, un couvercle en plastique moulé et une plaque arrière en acier.

L’ensemble est fini en couleur gris Hobart. L’appareil fonctionne soit en 230v/50/1

ou 400v/50/3 et comprend une fonction de sécurité NVR pour empêcher un

redémarrage automatique après une panne de secteur ou un débranchement. Le

support et la protection du bol sont équipés d’un asservissement électrique afin que

lorsque le bol est abaissé ou lorsque la protection est ouverte, l’appareil ne puisse

pas fonctionner.

LE NIVEAU SONORE DE L’APPAREIL Conformément à la norme EN-ISO

12001:1996, l'intensité sonore de l'appareil est inférieure à 70 dB (A) (55 dB

enregistrés)

POIDS : Brut 86 Kg Net 78 Kg

INSTALLATION

Renseignements électriques :

400/50/3 FLC 1,1 A fusible de 4 A

230/50/3 FLC 1,9 A fusible de 6 A

230/50/1 FLC 4,6 A fusible de 16 A

Cet appareil doit être installé conformément aux réglementations en vigueur, par un

technicien qualifié.

Déballez soigneusement l’appareil. N’utilisez pas de couteau pointu pour découper

la boîte car vous risqueriez d’endommager l’appareil.

Avec l’appareil à proximité de sa position définitive, retirez-le de la palette de

transport. L’appareil est fixé à la palette par quatre boulons de fixation, qui passent

au travers de la palette et se vissent dans les pieds filetés.

Il faut prendre soin, au cours de cette opération, de s’assurer que :

a) Toutes les mesures de sécurité requises sont prises pour garantir la levée et la

manutention correctes afin d’éviter tout risque de blessure suite à une chute ou

un basculement.

b) L’appareil n’est pas endommagé, pouvant empêcher son fonctionnement normal.

Placez le mixeur dans sa position d’emploi, qui doit être solide et horizontale.

Assurez-vous que l’alimentation électrique convient à la spécification de l’appareil,

avant son branchement.

Si l’appareil ne fonctionne pas, vérifiez que le support du bol est soulevé et que la

protection est en position de marche.

Remarques :

1. Pour une installation sur un bâti spécial, statique ou mobile, les boulons de

transport doivent être utilisés pour fixer l’appareil en place.

2. Dans les lieux où la stabilité peut poser un problème, il faudra aussi fixer

l’appareil en place.

- 13 -

Page 15

CONSIGNES DE SECURITE

Il est impératif de respecter les consignes suivantes lors de l’emploi du mixeur.

IL EST INTERDIT DE

· Essayer de toucher au contenu du bol pendant le malaxage

· Monter l’agitateur sur le mixeur sans le bol

· Laisser l’agitateur dans l’appareil sans que le bol soit à sa place

· Faire tourner le mixeur avec les deux accessoires ou l’agitateur en place

· Laisser le levier de vitesse en position intermédiaire

· Utiliser l’engrenage pour arrêter l’appareil

· Utiliser la protection pour arrêter l’appareil

· Utiliser la poignée de levage du bol pour arrêter l’appareil

· Utiliser l’appareil dans des conditions qui ne respectent pas la sécurité

IL IMPERATIF DE

· Toujours débrancher du secteur et nettoyer le mixeur tous les jours

· Retirer l’agitateur avant d’utiliser les accessoires

· Arrêter le mixeur avant d’ajouter des ingrédients.

· Utiliser le bouton d’arrêt pour arrêter l’appareil

· Nettoyer le bol et les agitateurs après emploi

· Après un usage quotidien, débrancher du secteur ou mettre l’isolateur en

position arrêt. Nettoyer le mixeur avec de l’eau et du savon doux, sans jamais

utiliser de poudre à récurer.

· S’assurer que le mixeur est entretenu régulièrement (révision recommandée

deux fois par an)

Il ne faut utiliser l’appareil qu’aux fins prévues par la conception et

en respectant les consignes d’emploi prescrites

- 14 -

Page 16

TABLEAU DE MALAXAGE

· Le tableau suivant donne les capacités maximales recommandées.

· Avec une farine à haute teneur en gluten, réduisez la pâte de 25 %

· Assurez-vous de choisir le bon accessoire

· Assurez-vous de choisir la bonne vitesse

NE DEPASSEZ PAS LA QUANTITE SPECIFIEE POUR LE MELANGE

HSM20 = 20 litres

NCM20 = 20 litres

Il peut être préjudiciable à la qualité du produit fini de surcharger le mélange et cela

peut avoir un impact sur la durée de vie de l’appareil. Reportez-vous toujours au

tableau de malaxage.

Lorsqu’on mélange des ingrédients, il est impératif de prendre des

précautions pour éviter de respirer des particules de poussière, par ex. la

farine. Il faut se reporter aux fiches techniques des fournisseurs de produits

pour garantir le respect des précautions et protections adéquates.

Les ingrédients comme la farine doivent être ajoutés de manière à éviter que les

particules de poussière se dispersent dans l’atmosphère ambiante.

Capacités du HSM20 / NCM20 en cuisine – Mélange unique

Type de produit Quantité

Blancs d’œuf 1,14 litre Fouet 1 / 2 / 3

Purée 6,8 kg Batteur B 1

Mayonnaise (huile) 11,36 litres Fouet 2 / 3

Crème fouettée 11,36 litres Fouet 1 / 2 / 3

Agitateur

recommandé

Vitesses

recommandées

Capacité du HSM20 / NCM20 en boulangerie-pâtisserie –

Mélange unique

Type de produit Quantité Agitateur

recommandé

Gâteau de Savoie 9,1 kg Batteur B 1 / 2 / 3

Quatre quarts 9.1 kg Batteur B 1 / 2 / 3

Pâte légère (gâteau

mousseline)

Pâte (légère-moyenne) 9,0 kg (65 % A/R)

(5,5 kg de farine, 3,5 litres

Pâte (lourde) 5,7kg (50 % A/R)

(3,8 kg de farine, 1,9 litre

Pâte à tarte 7,3 kg Couteau à

Graisse et sucre pour gâteau

mousseline

6,4 kg Batteur B 1 / 2 / 3

Crochet ED 1 seulement

d’eau)

Crochet ED 1 seulement

d’eau)

pâtisserie

Crochet ED

6,8 kg Fouet 1 / 2 / 3

Vitesses

recommandées

1 seulement

- 15 -

Page 17

MODE D’EMPLOI

Cet appareil est destiné à un usage professionnel par des personnes

possédant les qualifications appropriées.

· Assurez-vous que l’appareil est sur arrêt (1)

· Abaissez le support du bol (2) au moyen du levier à main (3)

· Faites tourner la protection avant (6) pour permettre l’accès

1 9

· Placez l’agitateur requis dans le

bol (7)et placez le bol sur le

support de bol (2).

5

· Assurez-vous que le bol est

correctement positionné et

enclenché sur les broches de

positionnement du support du bol.

4

· Placez les agitateurs sur l’arbre (8)

en tournant pour enclencher la

broche d’entraînement dans la fente

"L"

6 3

· Ajoutez les ingrédients au bol et

soulevez le bol au moyen du levier à

main (3)

(REMARQUE. Le support du bol

est équipé d’un asservissement

électrique pour empêcher un

démarrage accidentel lorsque le bol

est en position abaissée)

7

· Faites tourner la protection avant (6)

jusqu’à la position de marche

2

· Choisissez la vitesse (4) et réglez le

minuteur (5) si l’appareil est équipé

· Démarrez l’appareil en appuyant sur le bouton de démarrage (9)

· Une fois le malaxage terminé :

· Arrêtez l’appareil au moyen du bouton d’arrêt (1)

· Abaissez le support du bol

· Ouvrez la protection avant (6)

· Retirez l’agitateur de l’arbre

· Retirez le bol et l’agitateur du mixeur pour le vider

Le numéro “1” (BASSE) est pour les mélanges lourds comme les pâtes à gâteau, les pâtes liquides épaisses et

la purée

Le numéro “2” (MOYENNE) est pour le mélange des pâtes à gâteau

Le numéro “3” (HAUTE) est pour ajouter un maximum d’air dans les mélanges légers. Le fouet “D” sert

pour la crème fouettée, pour battre les blancs d’œuf, mélanger les glaçages

légers, les meringues et pour fouetter.

Il FAUT SE REPORTER AU TABLEAU DE MALAXAGE DE LA PAGE 15

- 16 -

Page 18

NETTOYAGE

IL EST INTERDIT DE NETTOYER CE MIXEUR AU JET OU SOUS PRESSION

IL EST INTERDIT D’UTILISER DES NETTOYANTS ABRASIFS

Assurez-vous que l’appareil est débranché du secteur avant de le nettoyer

Nettoyez le bol et les agitateurs dans de l’eau chaude, avec un détergent non

abrasif adapté et une brosse douce. Si vous rincez le bol tout de suite après son

emploi avec de l’eau chaude, le nettoyage en sera facilité.

Remarque : Il est interdit de nettoyer les agitateurs en aluminium dans un lave-

vaisselle

Nettoyez l’appareil avec un chiffon humide et chaud, essuyez soigneusement les

bras de support du bol et toutes les surfaces extérieures.

NETTOYAGE DE LA PROTECTION ET RETRAIT – HSM20/NCM20

La grille de protection a été conçue pour un retrait facile pour le nettoyage de

l’appareil.

Pour retirer la grille,

· Assurez-vous que le support du bol est en position abaissée.

· Retirez le bol et l’agitateur

· Faites tourner la grille vers la droite jusqu’à ce que le bloc frontal soit aligné avec

la fente dans la glissière de la coupe d’égouttement. Il faudra alors prendre des

précautions, car la grille peut se détacher de l’appareil.

· Abaissez la partie avant pour dégager la glissière et poussez doucement vers

l’arrière pour que les blocs sortent de la glissière. Abaissez et retirez.

Pour remonter la grille sur l’appareil.

· Alignez le bloc avant à glissière unique avec la fente dans la coupe

d’égouttement.

· Enclenchez les deux blocs arrières à glissière sur la coupe d’égouttement

· Soulevez l’avant de la grille jusqu’à ce que le bloc avant à glissière puisse

s’enclencher sur la coupe d’égouttement.

· Faites tourner la grille vers la gauche afin qu’elle s’enclenche entièrement dans

la coupe d’égouttement

Il faut nettoyer la grille à la fin de chaque journée.

Pour retirer l’écran arrière anti-éclaboussures

Il faut vérifier régulièrement l’écran arrière anti-éclaboussures et le cas échéant, le

retirer de l’appareil pour le nettoyer. Cette opération doit être entreprise par un

surveillant qualifié ou par du personnel de maintenance au minimum tous les 3 mois

ou s’il a besoin d’être nettoyé.

· Assurez-vous que le support du bol est en position abaissée, que le bol et

l’agitateur sont retirés et que la grille a été retirée (voir ci-dessus).

· A l'aide d'un outil adapté (tournevis à lame plate) ou à la main si l'appareil est

muni de molettes, retirer les trois vis de retenue et les placer en lieu sûr pour le

remontage.

- 17 -

Page 19

· On peut alors retirer la coupe d’égouttement de l’appareil en la faisant tourner et

en l’abaissant avec précaution.

· Il faut nettoyer la coupe d’égouttement pour s’assurer qu’aucune substance ne

peut tomber dans le produit.

· Remontez l’écran arrière anti-éclaboussures dans l’ordre inverse en vous

assurant que les vis sont suffisamment serrées.

Remarque : L’écran arrière anti-éclaboussures doit être correctement nettoyé en le

laissant à sa place pour les applications normales

MAINTENANCE

Le moteur et la transmission sont recouverts de graisse spéciale, qui durera

plusieurs années. Lorsqu’il faut la remplacer, contactez votre centre local de service

après-vente.

Les glissières du support du bol doivent être lubrifiées occasionnellement avec une

petite quantité d’huile légère, appliquée du bout du doigt, pour empêcher la

corrosion et assurer un bon fonctionnement.

Il est recommandé de faire réviser le mixeur régulièrement (périodicité

recommandée de deux fois par an)

Renseignements électriques : 400/50/3 F.L.C 1,1 A

230/50/3 F.L.C 1,9 A

230/50/1 F.L.C 4,6 A

Vous pouvez vous procurer un Manuel de révision et d’entretien (PLE200467) au

CENTRE APRES-VENTE désigné. Cependant, pour garantir le maintien du

fonctionnement sûr et fiable de l’appareil, il est recommandé que l’entretien soit

réalisé seulement par du personnel qualifié du service après-vente de chez

HOBART

DIAGNOSTIC DES PANNES

Panne

L’appareil ne démarre pas Vérifiez les fusibles S’ils sont défectueux,

remplacez les fusibles

Vérifiez que le support du

bol est en position de

Placez le bol en position

haute

marche

Vérifiez la commande de

vitesse

Vérifiez que la protection

est en position de marche

Réglez à la vitesse

correcte

Faites tourner la protection

pour la placer en position

fermée

Le moteur démarre mais

l’arbre ne tourne pas

L’appareil ne fonctionne

toujours pas

Vérifiez que la courroie

d’entraînement n’est pas

usée ou abîmée

Si l’arbre ne tourne

toujours pas

Appelez le centre après-

vente local

Si elle est abîmée,

remplacez-la par une

courroie neuve

Appelez le centre après-

vente local

- 18 -

Page 20

PIECES DE RECHANGE RECOMMANDEES

Nomenclature Description

143192-1 Moteur monophasé. 230/50/1

00-738026-50 Condensateur

143193-1 Moteur triphasé. 400/50/3

EPM-E-16-14 Commutateur de démarrage,

EPM-E-16-15 Commutateur d’arrêt,

00-738177 Commutateur, protection.

140462-6 Commutateur, support de bol

00-438490 Protection

00-738090 Engrenage interne

141440-1 Contacteur

EP-E-10-10 Fusible, commande

140908-3 Transformateur

145149-1 Roue libre

OS-E-2-6 Joint d’huile

00-738102 Arbre, transmission

40679 Roue à vis sans fin (50 Hz)

40847 Roue à vis sans fin (60 Hz)

145150 Engrenage vitesse lente

CONSEILS D'UTILISATION :

· Les batteurs-mélangeurs de la Série ‘HSM’ et ‘NCM’ ont été conçus pour

fonctionner une fois la grille de protection fermée et le porte-cuve levé. Contacter

le service Hobart le plus proche si l'appareil fonctionne lorsque ces conditions ne

sont pas respectées

· Une raclette n'est disponible que pour le modèle HSM20/NCM20 (Référence pièce

00-315281-1).La cuve doit être lubrifiée à l'huile végétale, surtout à l'endroit du

dessus de la cuve où le manchon pourrait frotter contre la surface à vif de la cuve.

· La raclette ne doit être utilisée qu'avec les agitateurs fouet et batteur plat, à une

vitesse de 1 ou 2 uniquement.

- 19 -

Page 21

REMARQUES :

- 20 -

Page 22

SERVICE APRES-VENTE

Les techniciens qualifiés du service après-vente de Hobart, situés de manière

stratégique dans les succursales Hobart répertoriées, sont prêts à vous apporter un

service rapide, efficace et fiable. Protégez vos investissements en prenant un

contrat d’inspection Hobart qui garantit le maintien du fonctionnement performant de

vos appareils, pièces et accessoires Hobart.

Hobart Still a pour politique d’améliorer continuellement ses produits et les spécifications peuvent

changer sans préavis.

Compagnie Hobart SA

ZI Pariest

1 Allée du ler Mai BP68

Croissy Beaubourg

77312 Marne-la-Vallée

Cedex 2

- 21 -

Page 23

DEUTSCH

SICHERHEITSINFORMATION

Die Beschreibungen in dieser Anleitung beziehen sich auf den bestimmungsgemäßen Gebrauch des Geräts.

Wenn Sie die Maschine für einen anderen als den vorgesehenen Zweck einsetzen,

tragen Sie selbst die Verantwortung für Ihre Sicherheit und die Sicherheit anderer.

Viele Unfälle sind auf Unwissenheit und Nichtbeachtung der für den Einsatz, die

Reinigung und Wartung eines Geräts geltenden Sicherheitsbestimmungen zurückzuführen.

Verhüten Sie Unfälle, indem Sie alle Hinweise, auch die Warnhinweise, in dieser

Anleitung sorgfältig lesen und beim Gebrauch sowie bei der Wartung und Reinigung

Ihres Geräts gewissenhaft beachten.

Diese beiden Symbole weisen Sie darauf hin, dass Sie in dem betreffenden Zusammenhang besonders auf Sicherheit achten müssen:

WARNUNG!

Dieses Warnsymbol kennzeichnet einen

Hinweis, der für den sicheren Gebrauch

des Geräts wichtig ist.

Dieses Symbol kennzeichnet eine elektrische

Gefahr (Ziehen Sie vor Wartungsarbeiten an

dem Gerät immer den Netzstecker.)

Dieses Gerät sollte in einem Umfeld mit Raumtemperatur transportiert und gelagert

werden. Es sollte nicht in kalten Witterungsverhältnissen oder bei Temperaturen

benutzt werden, die 5OC unterschreiten bzw. 55OC überschreiten.

Haftung

Arbeiten und Reparaturen, die nicht von autorisierten Technikern durchgeführt

werden, die Verwendung anderer als Orginal-Ersatzteile sowie alle technischen

Änderungen an dem Gerät können zum Erlöschen der in den Verkaufs- und

Lieferbedingungen vorgesehenen Gewährleistung führen.

- 22 -

Page 24

ALLGEMEINE INFORMATION

Die Mixer der Serien HSM20 und NCM20 dienen zum Mischen und Rühren von

Lebensmitteln entsprechend der bedrienungs anleibung. Als Aufstellungsort ist eine

Arbeitsfläche normaler Höhe vorgesehen. Der Mixer HSM20 besteht aus einem

Getriebekasten aus Graugluss, Edelstahl unterbau, Verkleidung und Füßen, sowie

einer Kunststoffabdeckung . Die Endlackierung ist in Hobart-Grau ausgeführt. Das

Gerät arbeitet mit einer Netzspannung von entweder 230V/50/1 oder 400V/50/3.

Eine Schutzeinrichtung verhindert, dass der Betrieb nach einem Fehler oder einer

Unterbrechung der Stromversorgung automatisch wieder aufgenommen wird.

Schüsselhalter und Schutzgitter sind elektrisch verriegelt, so dass die Maschine

nicht eingeschaltet werden kann, wenn die Schüssel abgesenkt ist oder das

Shutzgitter geöffnet ist.

GERÄUSCHENTWICKLUNG Im Einklang mit EN-ISO 12001:1996 liegt der

aufgezeichnete Geräuschpegel unter 70 dB (A) (55 dB aufgezeichnet)

GEWICHT: Brutto 86 kg Netto 78 kg

AUFSTELLUNG

Elektrische Nennwerte: 400/50/3 FLC 1,1 Ampere, Sicherung 4 A

230/50/3 FLC 1,9 Ampere, Sicherung 6 A

230/50/1 FLC 4,6 Ampere, Sicherung 16 A

Die Aufstellung des Geräts soll durch einen Fachmann unter Beachtung der einschlägigen Vorschriften erfolgen.

Packen Sie das Gerät vorsichtig aus. Stechen Sie nicht mit einem scharfen Messer

in den Karton, damit der Inhalt nicht beschädigt wird.

Bringen Sie das Gerät an seinen vorgesehenen Standort, und nehmen Sie es dann

von der Transportpalette. Das Gerät ist mit vier durch die Palette in die Schraubfüße

eingedrehten Schrauben an der Palette fixiert.

Verhindern Sie

a) dass Personen von dem fallenden oder kippenden Gerät verletzt werden, indem

Sie Vorkehrungen für das sichere Heben und Bewegen des Geräts treffen,

b) Schäden an dem Gerät, die seine Funktion oder die Betriebssicherheit beein-

trächtigen

Setzen Sie den Mixer in seiner endgültigen Position zurecht. Die Stellfläche soll

stabil und gerade sein.

Kontrollieren Sie vor dem Anschluss, dass die Netzversorgung mit den Betriebsdaten des Geräts übereinstimmt.

ACHTUNG Nach Anschluss an der maschine an die strom-versorgung. Muss das

schutz-gitter betaetiegt werden um den sicherheits-schalter zu initialisieren.

Wenn das Gerät nicht arbeitet, kontrollieren Sie, ob der Schüsselständer oben und

die Drehhaube geschlossen ist.

Hinweise:

1. Das Gerät mit den Transportschrauben an der Stellfläche sichern, wenn es auf

einem eigenen feststehenden oder mobilen Gestell aufgestellt wird.

2. Sichern Sie das Gerät auch auf diese Art, wenn sein fester Stand in irgendeiner

Weise gefährdet ist.

SICHERHEITSVORSCHRIFTEN

- 23 -

Page 25

Beachten Sie beim Gebrauch des Mixers bitte die untenstehenden Anweisungen.

NIE

· Bei laufendem Mixer in die Schüssel greifen

· Das Rührgerät ohne Schüssel anbringen

· Das Rührgerät ohne Schüssel eingesetzt lassen

· Den Mixer mit sowohl Aufsätzen als auch Rührgerät laufen lassen

· Den Geschwindigkeitshebel auf eine Zwischenstellung einstellen

· Das Gerät mit dem Geschwindigkeitshebel anhalten

· Das Gerät mit der Drehhaube anhalten

· Das Gerät mit dem Schüsselhebel anhalten

· Das Gerät unter nicht sicheren Bedingungen einschalten

IMMER

· Den Netzstecker ziehen und den Mixer täglich reinigen

· Das Rührgerät von der Verwendung von Aufsätzen abnehmen

· Den Mixer vor der Zugabe von Zutaten anhalten

· Das Gerät mit der Stopptaste anhalten

· Rührgerät und Schüssel nach dem Gebrauch reinigen

· Am Ende eines Arbeitstags die Netzversorgung unterbrechen oder den

Trennschutzschalter ausschalten und den Mixer mit milder Seifenlösung, nie mit

Scheuerpulver, reinigen

· Regelmäßigen Kundendienst durchführen lassen (2 x jährlich empfohlen)

Das Gerät nur für den vorgesehenen Zweck

und laut Anleitung einsetzen.

- 24 -

Page 26

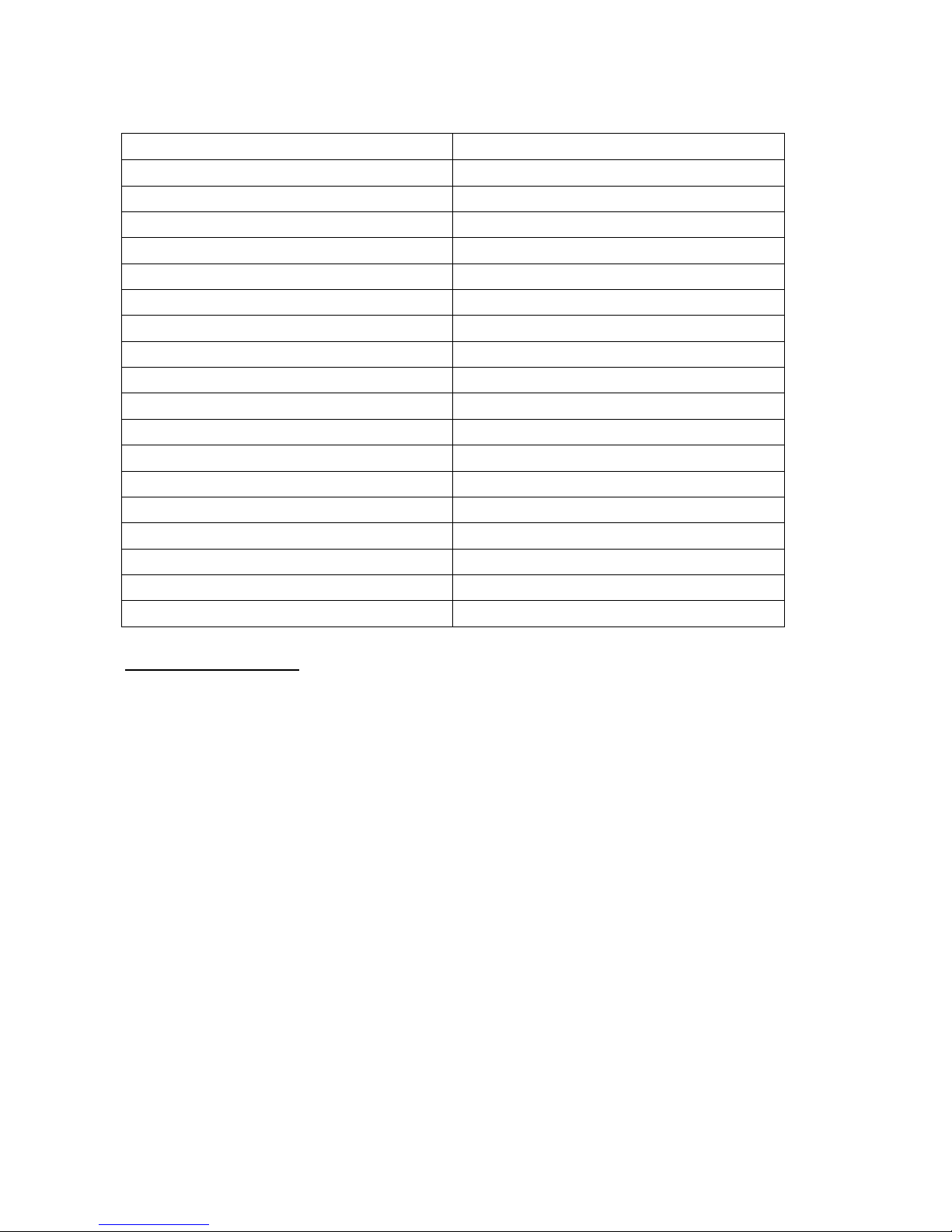

MISCHTABELLEN

· Die Tabelle unten nennt die empfohlenen Höchstmengen.

· Bei Mehl mit einem hohen Glutenanteil reduziert sich die Teigmenge um 25 %.

· Kontrollieren Sie stets, ob das richtige Werkzeug ausgewählt wurde.

· Kontrollieren Sie stets, ob die richtige Geschwindigkeit eingestellt ist.

ANGEGEBENE MENGEN NICHT ÜBERSCHREITEN.

HSM20 = 20 Liter

NCM20 = 20 Liter

Zu große Mengen schaden der Qualität des fertigen Produkts und verkürzen die

Lebensdauer des Geräts. Richten Sie sich immer nach der Mischtabelle.

Vermeiden Sie das Einatmen von Partikeln, z.B. von Mehlstaub. Hinweise zu

angemessenen Vorkehrungen und Schutzmaßnahmen enthalten die Datenblätter der Produktlieferanten.

Füllen Sie Zutaten wie Mehl so ein, dass sie nach Möglichkeit nicht in die

Umgebung stauben.

HSM20/NCM20 Haushaltsmengen – Eine Füllung

Produkt Menge

Eiweiß 1,14 Liter Schneeschläger 1 / 2 / 3

Kartoffelbrei 6,8 kg Rührbesen B 1

Mayonnaise (Öl) 11,36 Liter Schneeschläger 2 / 3

Schlagsahne 11,36 Liter Schneeschläger 1 / 2 / 3

Empfohlenes

Rührgerät

Empfohlene

Geschwindigkeit

HSM20/NCM20 Bäckereimengen – Eine Füllung

Produkt Menge Empfohlenes

Rührgerät

Kuchen, Rührteig 9,1 kg Rührbesen B 1 / 2 / 3

Kuchen, fester Rührteig 9,1 kg Rührbesen B 1 / 2 / 3

Geschlagener Rührteig

(Biskuit)

Teig (leicht – mittel) 9,0 kg (65 % A/R)

(5,5 kg Mehl 3,5 l Wasser)

Teig (schwer) 5,7kg (50 % A/R)

(3,8 kg Mehl 1,9 l Wasser)

Torten-/Pastetenteig 7,3 kg Tortenblatt

Fett und Zucker für Biskuit 6,8 kg Schneeschläger 1 / 2 / 3

6,4 kg Rührbesen B 1 / 2 / 3

Haken ED nur 1

Haken ED nur 1

Haken ED

Empfohlene

Geschwindigkeit

nur 1

- 25 -

Page 27

BEDIENUNG Dieses Gerät ist ausschließlich für den professionellen Gebrauch durch

ausgebildetes Personal bestimmt.

ACHTUNG Nach Anschluss an der maschine an die strom-versorgung. Muss das schutz-

gitter betaetiegt werden um den sicherheits-schalter zu initialisieren.

· Sicherstellen, dass die Maschine

ausgeschaltet ist (1).

· Schüsselständer (2) mit dem Hebel

(3) herunterlassen.

· Drehhaube (6) zum Öffnen zur Seite schieben.

1 9

· Benötigtes Rührgerät in die

Schüssel (7) setzen und die

Schüssel in den Schüsselständer

(2) setzen.

5

· Prüfen, ob die Schüssel richtig sitzt

und mit den Führungsstiften im

Ständer verbunden ist.

4

· Das Rührgerät auf der Welle (8)

drehen, so dass der Antriebsstift in

den Schlitz "L" greift.

6 3

· Zutaten in die Schüssel füllen und

die Schüssel mit dem Hebel (3)

anheben.

(HINWEIS: Eine elektrische Verriegelung verhindert, dass das

Gerät bei gesenkter Schüssel

gestartet werden kann.)

7

· Drehhaube (6) schließen.

2

· Geschwindigkeitsstufe (4) und ggf.

Zeituhr (5) einstellen.

· Gerät mit der Starttaste (9)

einschalten.

· Nach dem Arbeitsvorgang:

· Maschine mit der Stopptaste (1) anhalten.

· Schüsselständer absenken.

· Drehhaube (6) öffnen.

· Rührgerät von der Welle abnehmen.

· Schüssel und Rührgerät zum Entleeren aus dem Mixer nehmen.

Stufe “1” (NIEDRIG) für schwerere Teige und Kartoffelbrei

Stufe “2” (MITTEL) für leichtere Kuchenteige

Stufe “3” (HOCH) zum Aufschlagen leichter Massen. Der Besen “D” wird zum Aufschlagen von

Schlagsahne, Eischnee, leichten Cremes, Schaumgebäck usw. eingesetzt.

BITTE BEACHTEN SIE DIE MISCHTABELLE AUF SEITE 25.

- 26 -

Page 28

REINIGUNG

MIXER NICHT ABSPRITZEN ODER DAMPFREINIGEN.

KEINE SCHEUERMITTEL VERWENDEN.

Vor der Gerätereinigung die Netzstromversorgung trennen.

Reinigen Sie Mixschüssel und Rührgeräte mit heißem Wasser, einem milden

Reinigungsmittel und einer weichen Bürste (Schüssel zur leichteren Reinigung am

besten nach dem Gebrauch sofort mit heißem Wasser ausspülen).

Hinweis: Die Rührgeräte aus Aluminium nicht in den Spülmaschine geben.

Mixer, Schüsselständer und alle Außenflächen mit einem warm angefeuchteten

Tuch abreiben.

AUSBAU UND REINIGUNG DER DREHHAUBE – HSM20/NCM20

Der Käfig der Drehhaube kann zur Reinigung des Geräts abgenommen werden.

Haubenkäfig abnehmen

· Den Schüsselständer absenken.

· Schüssel und Rührgerät herausnehmen.

· Den Haubenkäfig in Uhrzeigerrichtung drehen, bis der vordere Schlitten mit der

Aussparung in der Tropfschalenschiene übereinstimmt. Achtung – der Käfig ist

nun frei und kann herunterfallen.

· Käfig zum Aushaken vorn absenken und vorsichtig nach hinten schieben, dann

ganz herunterlassen und wegnehmen.

Haubenkäfig einsetzen

· Den vorderen einzelnen Schlitten auf die Aussparung in der Tropfschale

ausrichten.

· Die beiden hinteren Schlitten in die Tropfschale einsetzen.

· Haubenkäfig vorn anheben, so dass der vordere Schlitten in die Tropfschale

eingehängt werden kann.

· Den Käfig entgegen dem Uhrzeigersinn vollständig in die Tropfschale eindrehen.

Den Käfig täglich nach Arbeitsende reinigen.

Hinteres Spritzblech abbauen

Inspizieren Sie das Rückblech regelmäßig, und nehmen Sie es bei Bedarf zur Reinigung ab. Diese Arbeit soll von einem Fachmann oder Kundendienst spätestens alle

3 Monate bzw. nach Bedarf vorgenommen werden.

· Schüsselständer absenken, Schüssel und Rührgerät entfernen und den Haubenkäfig abnehmen (siehe oben).

· Mit einem Schlitzschraubendreher die 3 Halteschrauben entfernen und gut verwahren.

· Die Tropfschale vorsichtig aus der Maschine drehen und herunterlassen.

· Die Tropfschale reinigen, damit kein Material in das Produkt fällt.

· Das hintere Spritzblech in umgekehrter Reihenfolge wieder anbringen und die

Schrauben gut festziehen.

Hinweis: Bei normaler Verschmutzung braucht das Blech zur Reinigung nicht ausgebaut werden.

- 27 -

Page 29

WARTUNG

Motor und Getriebe sind mit Spezialfett gepackt. Diese Schmierung hält mehrere

Jahre an. Bitte wenden Sie sich an Ihr Kundendienstzentrum, wenn die Schmierung

wiederholt werden muss.

Auf die Gleitführungen des Schüsselständers sollten Sie zum Schutz vor Rost und

zur Schmierung ab und zu mit den Fingerspitzen etwas dünnes Öl auftragen.

Es wird ein regelmäßiger Kundendienst empfohlen (zweimal jährlich).

Elektrische Nennwerte: 400/50/3 F.L.C 1,1 Ampere

230/50/3 F.L.C 1,9 Ampere

230/50/1 F.L.C 4,6 Ampere

Eine Kundendienstanleitung ist auf Anfrage (PLE200467) von Ihrem zuständigen

KUNDENDIENSTZENTRUM erhältlich. Im Sinne des sicheren und zuverlässigen

Gerätebetriebs wird jedoch empfohlen, den Kundendienst nur von geschultem

HOBART-Kundendienstpersonal durchführen zu lassen.

STÖRUNGSBEHEBUNG

Problem

Gerät startet nicht Sicherungen prüfen. Defekte Sicherung ersetzen.

Stellung des Schüsselständers

Schüssel nach oben bringen.

prüfen.

Geschwindigkeitseinstellung

prüfen.

Stellung der Drehhaube

Richtige Geschwindigkeit

einstellen.

Drehhaube schließen.

prüfen.

Gerät lässt sich trotzdem nicht

einschalten.

Nach Anschluss an der

Kundendienstzentrum

anrufen.

Rufen Sie den Kundendienst.

maschine an die stromversorgung. Muss das schutzgitter betaetiegt werden um

den sicherheits-schalter zu

initialisieren.

dreht nicht

Antriebsriemen auf

Verschleiss/Beschädigung

Riemen ersetzen.Motor startet, aber Welle

prüfen.

Welle dreht trotzdem nicht. Kundendienstzentrum

anrufen.

- 28 -

Page 30

EMPFOHLENE ERSATZTEILE

Teilenummer Beschreibung

143192-1 Motor, einphasig 230/50/1

00-738026-50 Kondensator

143193-1 Motor, dreiphasig 400/50/3

EPM-E-16-14 Schalter "Start"

EPM-E-16-15 Schalter "Stopp"

00-738401 Schalter "Haube"

140462-6 Schalter "Schüsselständer"

00-738451 Haube

00-738090 Innenzahnrad

141440-1 Schütz

00-738402 Schaltschütz

EP-E-10-10 Sicherung, Steuerung

140908-3 Trafo

145149-1 Freilauf

OS-E-2-6 Öldichtung

00-738102 Getriebewelle

40679 Schneckenrad (50Hz)

40847 Schneckenrad (60Hz)

145150 Zahnrad f. langsame Stufe

RICHTLINIEN:

· Die Mixer de ‘HSM‘ und 'NCM'-Serien sind für Betrieb mit geschlossenem

Schutzgitter und angehobenen Schüsselträger ausgelegt. Wenn die Maschine nicht

innerhalb dieser Kennwerte eingesetzt werden kann, fragen Sie bitte Ihre HobartService vor Ort um Rat.

· Ein Schüsselschaber ist nur die HSM20 und NCM20, Teilenummer 00-315281

erhältlich. Die Schüssel sollte besonders im Bereich über den vermischten

Produkten mit Pflanzenöl geölt werden, wo die Muffe die blanke Schüsselfläche

reiben könnte.

· Der Schaber sollte nur mit den Rührbesen oder flachen Knethaken und nur bei der 1.

und 2. Geschwindigkeit benutzt werden.

- 29 -

Page 31

PLATZ FÜR NOTIZEN:

- 30 -

Page 32

KUNDENDIENST

Ausgebildete Hobart-Kundendiensttechniker in den Hobart-Niederlassungen bieten

Ihnen einen schnellen und zuverlässigen Service. Im Sinne einer langen Lebensdauer und des rundum zufriedenstellenden Einsatzes von Geräten, Ersatzteilen und

Zubehör empfehlen wird einen Hobart-Wartungsvertrag.

Laufende Produktverbesserungen können dazu führen, dass sich technische Merkmale ohne Ankündigung ändern.

Hobart GmbH

Am Holderstock 4, Postfach 1620

D-77652 Offenburg

PLE200470-D-10-01

- 31 -

Loading...

Loading...