Hobart HSM10, NCM10 Installation & Operation Manual

INSTALLATION OPERATION

INSTALLATION FONCTIONNEMENT

INSTALLATION BETRIEB

English

Français

Contents

Safety Information 2

General Information 3

Installation 3

Safety Instructions 4

Mixing Chart 5

Operation 6

Cleaning 7

Fault Finding 7

Recommended Spares 8

Service information 9

_____________________________________________

Sommaire

Deutsch

Informations sur la sécurité 10

Généralités 11

Installation 11

Consignes de Sécurité 12

Tableau des capacités de mixage 13

Fonctionnement 15

Nettoyage 16

Détection des pannes 16

Pièces détachées recommandées 17

Entretien et maintenance 18

_____________________________________________

Inhalt

Informationen zur Sicherheit 19

Allgemeine Informationen 20

Installation 20

Sicherheitshinweise 21

Mischtabelle 22

Betrieb 24

Reinigung 25

Fehlersuche 25

Empfohlene Ersatzteile 26

Informationen zum Kundendienst 27

-1-

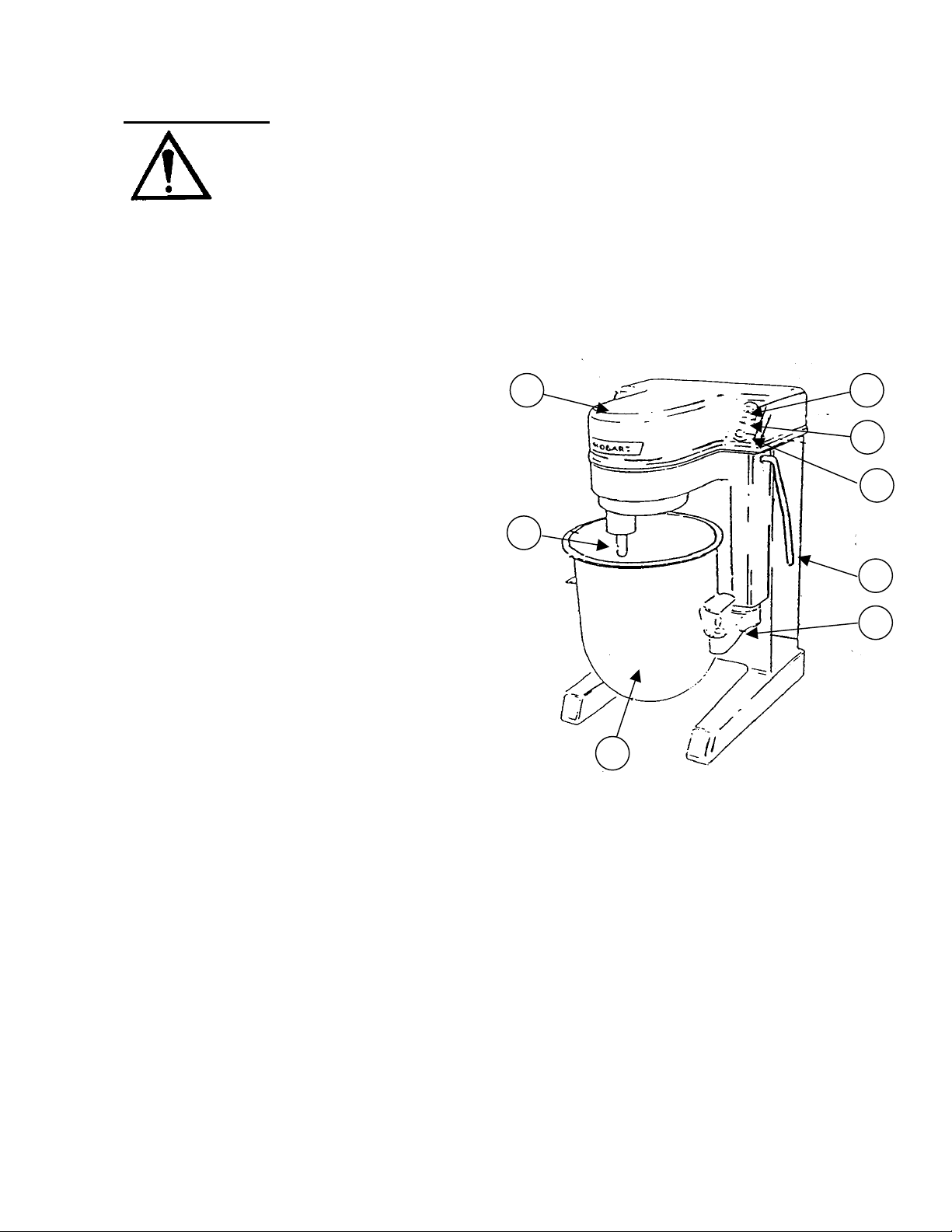

SAFETY INFORMATION

The procedures and precautions contained in this manual are understood to apply to

the machinery only when it is used in the authorised manner

If the machinery is used other than in the authorised manner, the operator will be

responsible for his/her own safety and for the safety of the other persons who may

be involved.

Many accidents are caused by insufficient knowledge and failure to apply the safety

regulations which should be implemented during the operation, cleaning and

maintenance of the machinery.

To prevent accidents, read , understand and follow all the precautions and warnings

contained in this manual before starting work and carrying out any of the

cleaning/maintenance operations.

To identify the safety messages in this manual, the following symbols have been

used

WARNING!

The " Warning" symbol is found primarily where

the corresponding warnings are important for the

safe use of the machinery

This symbol is used when there are risks of an

electrical nature (Prior to servicing the machinery ,

always disconnect the power cable from the mains

supply)

Liability

Installations and repairs which are not carried out by Authorised technicians or the

use of other then original spare parts , and any technical alterations to the

machine, may affect the warranty set out in the standard conditions of sale.

-2-

GENERAL INFORMATION

The NCM10 mixer is designed to mix food products as per specification chart ,

standing on a standard height worktop. The HSM10 is manufactured from an

aluminium alloy casting with a plastic moulded top cover and stainless steel back

panel . All with a metallic paint finish. The NCM10 is manufactured from an

aluminium alloy casting with a plastic moulded top cover and steel back panel . All

with a Hobart grey paint finish.

The standard machine is set to operate on a 230v/50/1 supply, and is fitted with an

NVR safety feature to prevent automatic restarting after a supply

failure/disconnection. The bowl support has an electrical interlocked so that when

the bowl is in the down position the machine will not work.

The mixer is supplied with a plug (which conforms to BS1363) and a 13A fuse,( UK

only).

MACHINE NOISE LEVEL is less then 70db (A)

WEIGHTS: Gross 32Kg Net 26Kg

INSTALLATION

This machine must be installed in accordance with current

regulations by a qualified persons.

Carefully unpack the machine. Do not use a sharp knife to cut into

the box as damage to the machine may occur.

Place the mixer in it's correct operating position, which should be

firm and level

Ensure that the electrical supply agrees with the machine

specification, prior to connection

If machine fails to operate, please check the following points:-

That the bowl support is in the up position

Check the mains fuse (13A)

-3-

SAFETY INSTRUCTIONS

The following instructions must be observed when using the mixer.

NEVER

· attempt to reach into the bowl when mixing

· fit agitator to mixer without bowl

· leave agitator on machine without bowl being fitted

· run mixer with both attachments or agitator fitted

· Leave gear lever in mid position

· Use gear to stop machine

· Use guard to stop machine

· Use bowl lift handle to stop machine

· Use machine in an unsafe condition

ALWAYS

· Always Disconnect the mains supply and clean mixer daily

· Remove Agitator before using any attachments

· Stop mixer before adding more ingredients

· Use stop button to stop machine

· Clean the bowl and agitators after use

· After daily use disconnect mains power supply or switch off isolating switch.

Clean mixer using mild soap and water, never scouring powder

· Ensure mixer is subject to regular servicing ( Recommended twice yearly)

The machine should only be used for the design purposes and

inline with the supplied operating instructions

-4-

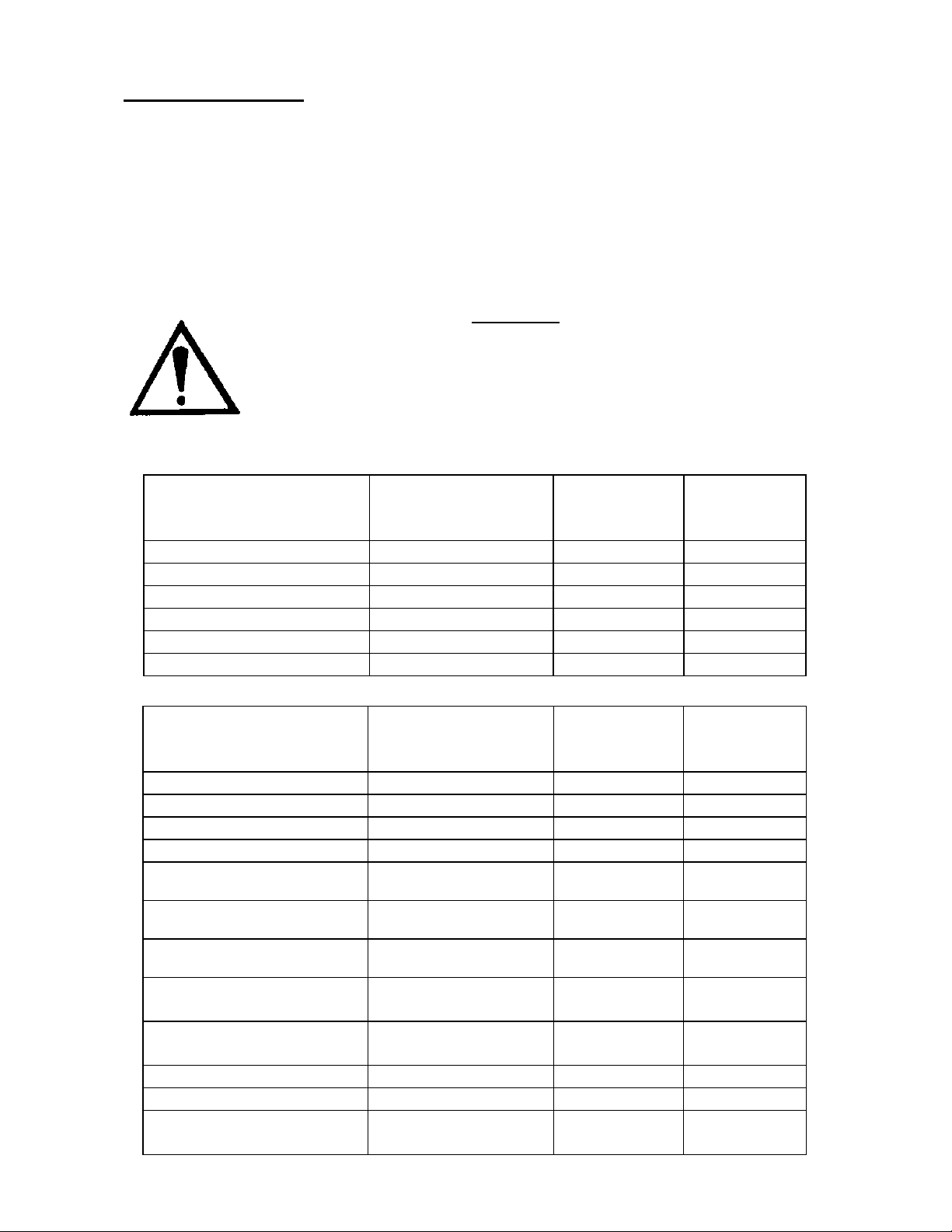

MIXING CHART

· The following chart shows the maximum recommended capacities

· With high gluten flour reduce dough batch by 25%

· Ensure the correct tool is selected

· Ensure the correct speed is selected

DO NOT EXCEED THE SPECIFIED MIX QUANTITY

Overloading the mix can be detrimental to the quality of the finished product and

affect the life expectancy of the machine. Always refer to the mixing chart

When mixing ingredients care must be taken to avoid the inhalation

of dust particles e.g. Flour. Reference should be made to the

product suppliers data sheets to ensure that adequate

precautions/protection are taken.

Items such as flour should be added in such a manner to avoid dust

particles being dispersed into the local atmosphere.

Kitchen Capacities - Single Batch

Type of Product Quantity Recommende

d

Agitator

Egg Whites 0.5 litres Whip 1 to 6

Mashed Potatoes 5.0 kg B Beater 1 to 5

Mayonnaise (Oil) 3.5 litres Whip 1 to 6

Meringue (Water) 0.25 litres Whip 1 to 6

Waffle on Hot Cake Batter 4.5 litres Whip 1 to 5

Whipped Cream 2.25 litres Whip 1 to 6

Recommend

ed

speeds

Bakery Capacity - Single Batch

Type of Product Quantity Recommende

d

Agitator

Cake , Box or Slab 4.5 kg B Beater 1 to 5

Cake, Layer 4.0 kg B Beater 1 to 5

Cake , Pound 4.5 kg B Beater 1 to 5

Cake , Short (Sponge) 3.0 kg B Beater 1 to 6

Dough (light -medium) 4.5 kg (65% A/R)

(2.7 kg flour 1.8 litre water)

Dough (heavy) 3.0 kg (50% A/R)

(2 kg flour 1 litre water)

Dough (pizza) 2.25 kg (40% A/R)

(1.6 kg flour 0.65 litre water)

Pie Pastry 4.0 kg Pastry Knife

Egg & Sugar for

Sponge Cake

Icing , Fondant 3.0 kg Whip 1 to 6

Icing , Marshmallow 0.5 kg Whip 1 to 6

Shortening & Sugar

(creamed)

2.0 kg Whip 1 to 6

3.5 kg Whip 1 to 6

ED Hook 1

ED Hook 1

ED Hook 1

ED Hook

Recommend

ed

speeds

1

-5-

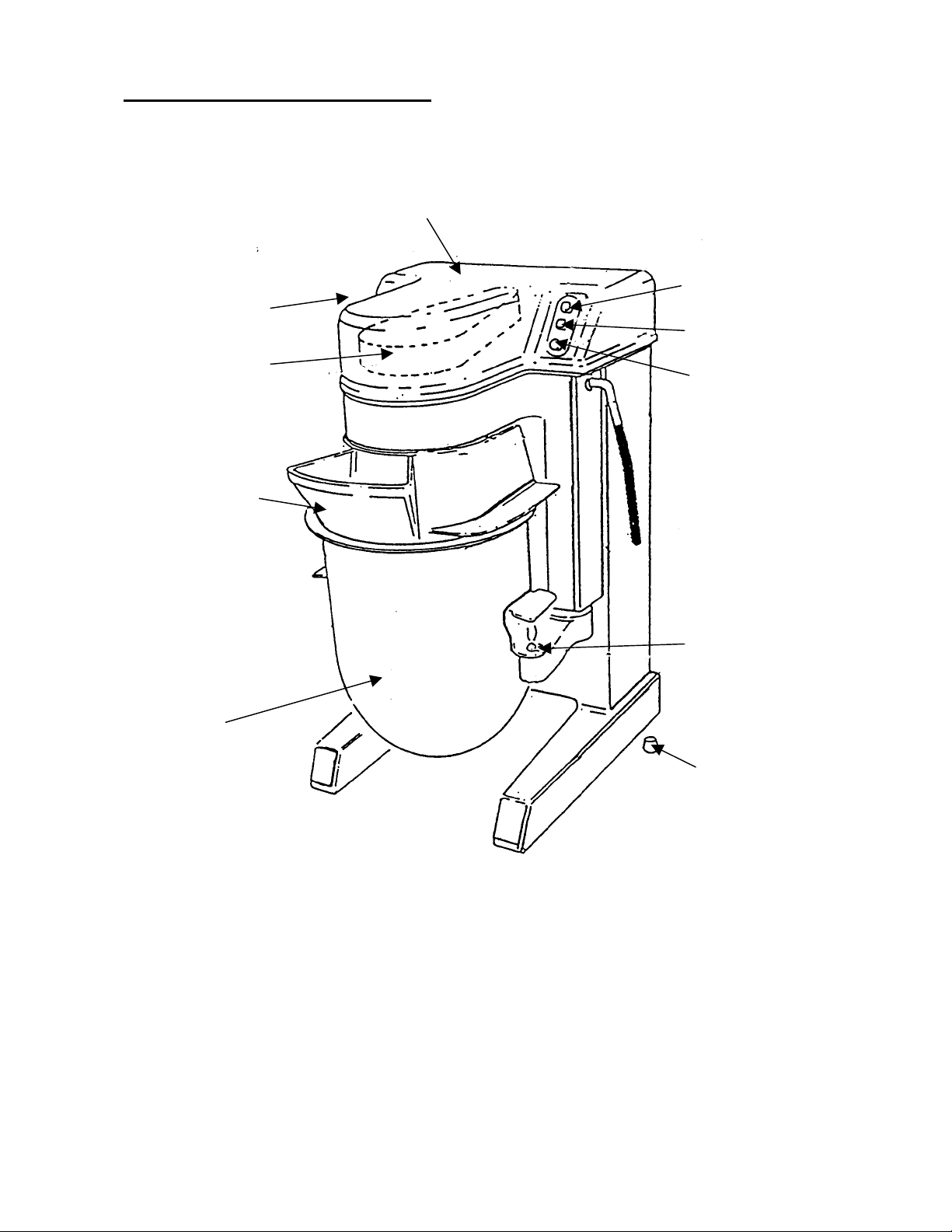

OPERATION

This machine is only for professional use by suitably trained

persons.

Ensure that the machine is switched off (1)

Lower bowl support (2) by using the

hand lever (3)

Place the required agitator in the bowl (7) 5 6

and lift bowl onto the bowl support (2).

1

Place the splash shield in position on the

bowl. The shield is designed not to be 4

removed with the bowl in the raised position.

DO NOT ATTEMPT TO REMOVE THE 8

SHIELD DURING MACHINE OPERATION

Ensure that the bowl is correctly positioned

and engaged on the location pins of the 2

bowl support.

If the splash shield is used , place the shield

in position on the bowl

3

Slide the agitators on the shaft (8 ) turning

to engage the drive pin in the "L" slot 7

Add ingredients to the bowl and raise the

bowl by hand lever (3)

(NOTE. An electrical interlock is fitted to the bowl support to prevent accidental starting

when bowl is in the down position)

Select speed (4) and set timer (5) if fitted.

Setting Timer a) Non-timed operation- Set Timer to the “HOLD” position

b) Timed Operation - Turn timer past position “3” and then set

to desired time

Start machine by pressing start button (6)

When mixing is complete:-

Stop machine using Stop button (1)

Lower bowl support. Remove agitator from shaft

Remove bowl and agitator from mixer to empty

-6-

CLEANING

DO NOT HOSE OR PRESSURE CLEAN THIS MIXER

DO NOT USE ANY ABRASIVE CLEANERS

Ensure that the machine is disconnected from the main electrical

power supply prior to cleaning

Note: Do not clean aluminium agitators in a dishwasher

Clean the mixing bowl and agitators with hot water, a suitable non

abrasive detergent and soft bristle brush. (Flushing the bowl with hot

water immediately after use will ease the cleaning of the bowl)

Clean the mixer with a hot damp cloth, thoroughly wipe the bowl arms

and all exterior surfaces.

MAINTENANCE

The motor and transmission are packed with special grease, which will last for

several years. When replacement is needed, contact your local service centre.

The bowl support rods should be lubricated occasionally with a small amount of

light oil applied with the fingertip, to prevent corrosion and ensure smooth operation

It is recommended that the mixer is serviced regularly (recommended

twice yearly)

FAULT FINDING

Fault

Machine fails to start Check fuses If faulty replace fuses

Motor starts but shaft fails

to turn

Check bowl support is in

operating position

Check speed control Set to required speed

machine still fails to

operate

check drive belt for wear or

damage

if shaft still fails to turn Call local service centre

Place bowl in up position

Call local service centre

If damaged , replace with

new belt

-7-

RECOMMENDED SPARES

Cover

Timer ) Start Switch

Knob ) Optional

Label ) Stop Switch

Belt Speed Control

Knob Label

Splash Shield

Bowl and

Equipment

Bowl Pin Kit

Footpad

-8-

Loading...

Loading...