Page 1

I

N

S

T

HR5 & HR7 ROTISSERIE OVENS

&

HW5 & HW7 WARMERS

MODELS

HR5

auto. controls ML-126454

ML-126727

prog. controls ML-126456

ML-126728

R

HR5 Oven/

HW5 Warmer

U

C

T

I

O

N

S

HR7

auto. controls ML-126455

ML-126725

prog. controls ML-126457

ML-126726

HW5 ML-126207

HW7 ML-126208

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

– 1 –

FORM 34046 Rev. B (7-99)

Page 2

TABLE OF CONTENTS

MODELS............................................................................................................................................... 4

GENERAL ............................................................................................................................................. 5

Features and Options .................................................................................................................... 5

Ovens.............................................................................................................................................. 6

Warmers ......................................................................................................................................... 6

INSTALLATION.................................................................................................................................... 7

Location .......................................................................................................................................... 7

Legs / Casters ................................................................................................................................7

Assembly ........................................................................................................................................ 7

Assembling the Drip Plate ....................................................................................................... 7

Assembling the Rotor (HR7 only) ............................................................................................ 8

Electrical Connections ................................................................................................................. 10

Stacked Oven or Oven and Warmer..................................................................................... 10

Single Oven or Warmer ......................................................................................................... 10

Electrical Data ........................................................................................................................ 11

Before First Use ........................................................................................................................... 12

OPERATION ...................................................................................................................................... 12

Programmable Oven Control Panel With Manual Controls ....................................................... 13

Manual Controls........................................................................................................................... 14

Using Manual Controls .......................................................................................................... 14

Programmable Controls............................................................................................................... 15

Setting the Time of Day ......................................................................................................... 15

Programming Menu Buttons.................................................................................................. 16

Verifying Programmed Temperatures and Times ................................................................ 16

Starting a Processing Cycle .................................................................................................. 17

Displaying Time/Temperature During a Process Cycle....................................................... 17

Interrupting a Process Cycle ................................................................................................. 17

End of Processing Cycle ........................................................................................................ 17

Changing a Programmed Setting.......................................................................................... 17

Turning the Buzzer Off........................................................................................................... 18

Setting the End Time (Delayed Start)................................................................................... 18

Setting an Early Warning Buzzer .......................................................................................... 18

Stopping the Rotisserie .......................................................................................................... 18

Automatic Oven Control Panel With Manual Controls............................................................... 19

Manual Controls........................................................................................................................... 20

Using Manual Controls .......................................................................................................... 20

© HOBART CORPORATION, 1999

– 2 –

Page 3

Automatic Controls....................................................................................................................... 21

Setting the Temperature........................................................................................................ 21

Setting the Roasting Time ..................................................................................................... 21

Setting an Early Warning Buzzer .......................................................................................... 22

Setting End Time (Delayed Start) ......................................................................................... 22

Interrupting an Automatic Cooking Operation...................................................................... 22

Stopping an Automatic Cooking Operation .......................................................................... 23

Changing a Setting ................................................................................................................ 23

Stopping the Rotisserie .......................................................................................................... 23

Setting the Time of Day ......................................................................................................... 23

Turning the Buzzer Off........................................................................................................... 23

Resetting the Automatic Controls ......................................................................................... 23

Preparing the Product.................................................................................................................. 24

Loading Products Onto Accessories........................................................................................... 24

Loading Products onto Spits ................................................................................................. 24

Loading Products onto Chicken Racks.................................................................................25

Loading Products in a Basket ................................................................................................ 26

Loading Accessories Into Oven .................................................................................................. 27

Loading Spits Into Oven ........................................................................................................ 28

Loading Fork Spits Into Oven................................................................................................ 28

Loading Racks, Baskets, or Backing Plates Into Oven ....................................................... 29

Unloading Accessories From Oven ............................................................................................ 29

Suggestive Roasting Guidelines ................................................................................................. 30

Emptying Grease Drawer ............................................................................................................ 31

Warmer Controls .......................................................................................................................... 32

Using Warmers (Models HW5 and HW7)................................................................................... 32

CLEANING ......................................................................................................................................... 33

Cleaning Stainless Steel Surfaces.............................................................................................. 33

Cleaning Nonstick Coated Surface............................................................................................. 33

How To Clean Nonstick Coated Surfaces (Routine Cleaning)............................................ 34

How to Clean Severe Buildup on Nonstick Coated Surfaces.............................................. 34

Cleaning Probe ............................................................................................................................ 34

Cleaning Grease Drawer ............................................................................................................. 35

Cleaning Warmers ....................................................................................................................... 35

Cleaning Quartz Lamps............................................................................................................... 35

Monthly Cleaning ......................................................................................................................... 35

MAINTENANCE ................................................................................................................................. 36

Model HR5 Only........................................................................................................................... 36

Service..........................................................................................................................................36

– 3 –

Page 4

Model HR5 Oven

Model HR7 Oven

Model HW5 Warmer

Model HR5 Oven/HW5 Warmer

Model HW7 Warmer

Model HR7 Oven/HW7 Warmer

• Rotisserie Ovens with Programmable Controls shown; Meat probe not shown.

– 4 –

Page 5

Installation, Operation and Care of

HR SERIES ROTISSERIE OVENS AND

HW SERIES ROTISSERIE WARMERS

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

GENERAL

The Hobart HR Series Rotisserie Ovens and HW Series Rotisserie Warmers feature full view tempered

glass doors, both front and back, and quartz lighting that promotes visual appeal and stimulates

customer interest. They also feature a stainless steel interior and exterior for ease of cleaning.

Ovens and Warmers are available in two sizes:

HR5 — Oven with five spits (15-20 chickens)

HW5— Warming cabinet

HR7 — Large oven with seven spits (28-35 chickens)

HW7— Warming cabinet

Features and Options

Quantity Required per Oven

Spit Basket Turkey Spit Baking Plate Chicken Rack Meat Forks Warmer Shelves

3 rack 4 rack 5 rack

HR5 5 std. 5 opt. 1 opt. 5 opt. 5 opt. NA NA 5 opt. NA

HR7 7 std. 7 opt. 1 opt. NA NA 7 opt. 7 opt. 7 opt. NA.

HW5 NA NA NA NA NA NA NA NA 3 std.

HW7 NA NA NA NA NA NA NA NA 3 std.

DO NOT mix accessories on the rotor.

Stacking kits are available to stack ovens or stack an oven and warmer. You must stack the same size

oven and warmer. Refer to the Stacking Kit Installation Instructions (F-24860) for further information.

– 5 –

Page 6

OVENS

There are two types of oven control operations:

• Programmable with Manual control operation

• Automatic with Manual control operation

When you purchase your rotisserie oven you have the option of ordering the rotor, drip plates, and

some accessories with either a nonstick coated surface or stainless steel surface. Refer to the next

page to assemble the drip plate and rotor.

The HR ovens use self-basting spits with optional flat baking racks, meat forks, or baskets. The rotation

of the spits, racks, or baskets with the combination convection and radiant heat provide thorough

cooking and even browning in the oven. The oven's grease drawer has a drain valve for elimination

of excess fat and can be completely removed for cleaning.

WARMERS

The HW warmers feature low velocity, high humidity air circulation which keeps foods moist. The HW

warming cabinets have three shelves.

– 6 –

Page 7

INSTALLATION

Immediately after unpacking the oven, check for possible shipping damage. If oven is found to be

damaged after unpacking, save the packaging material and contact the carrier within 15 days of

delivery.

Prior to installation, test the electrical service to assure that it agrees with the specifications on the

machine data plate located on the right side panel near the controls.

LOCATION

The oven may be placed where cooking may be observed to enhance customer awareness, but must

be installed on a level surface if the oven or warmer is not on casters.

The installation location must allow adequate clearances for servicing and for proper operation of the

front and rear doors.

• A minimum wall clearance of 10" (254 mm) from any glass, and 4" (101.6 mm) from each side panel

must be maintained.

LEGS / CASTERS

Each oven and warmer is furnished on 1

9

⁄16" (39.7 mm) legs. Casters are included with the stacking kit.

ASSEMBLY

The drip plate and rotor come in a separate boxed kit with either a nonstick coated surface or stainless

steel surface. They must be assembled at installation.

CAUTION: Special care must be taken when assembling coated parts. Any abrasion reduces

the life of the coated parts.

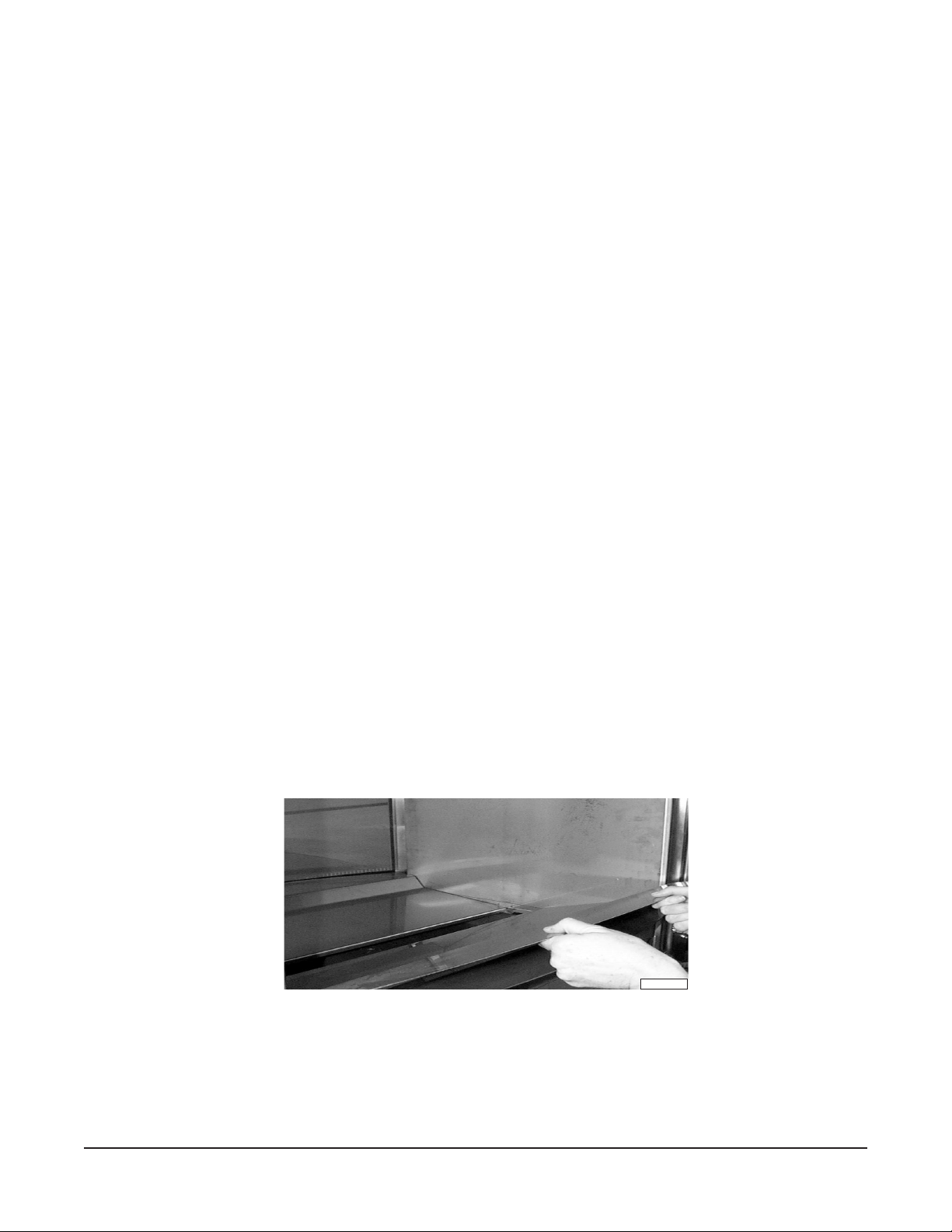

Assembling the Drip Plate

Place the two bottom drip plates in oven. The two plates slant to the middle to allow fat to drip into the

grease drawer (Fig.1).

Fig. 1

– 7 –

PL-41161

Page 8

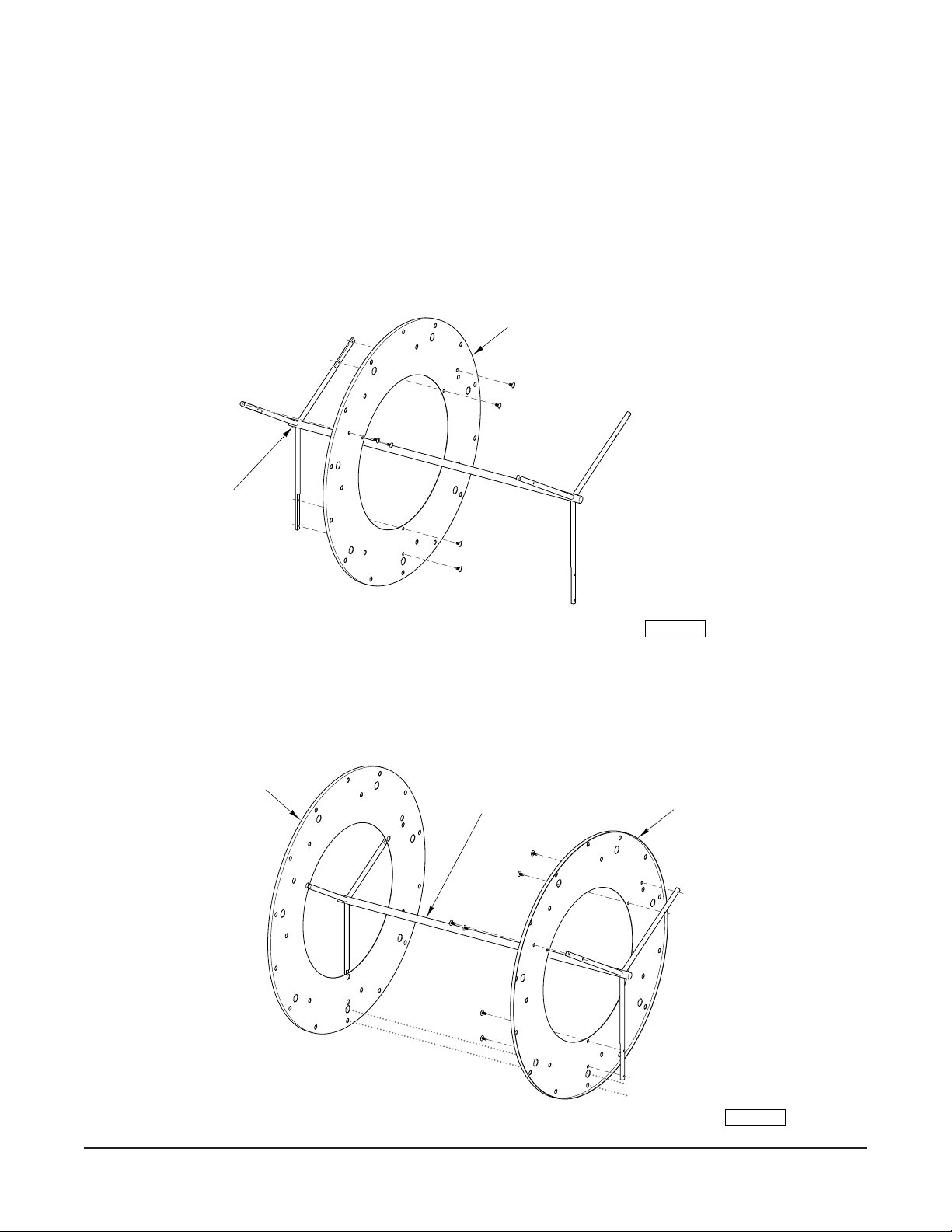

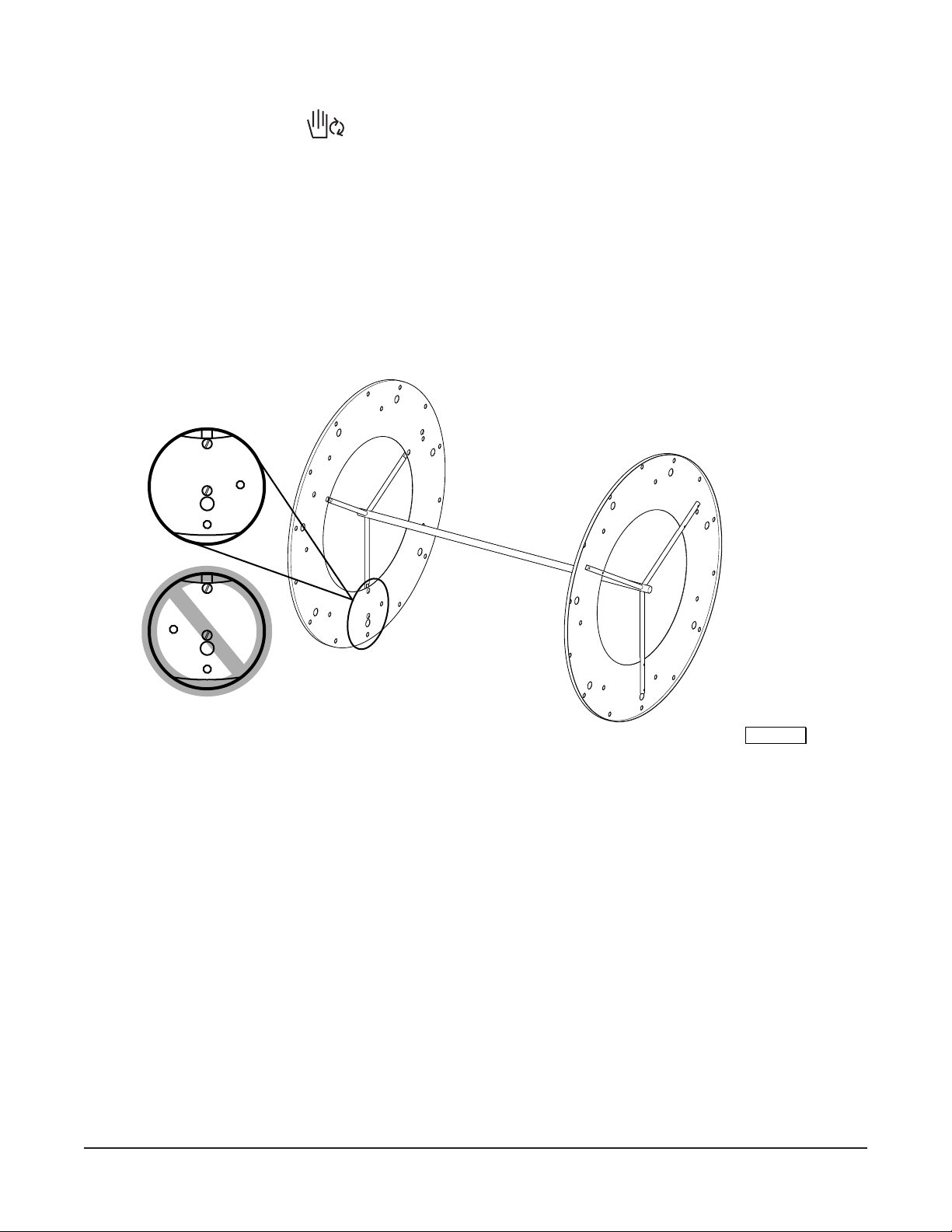

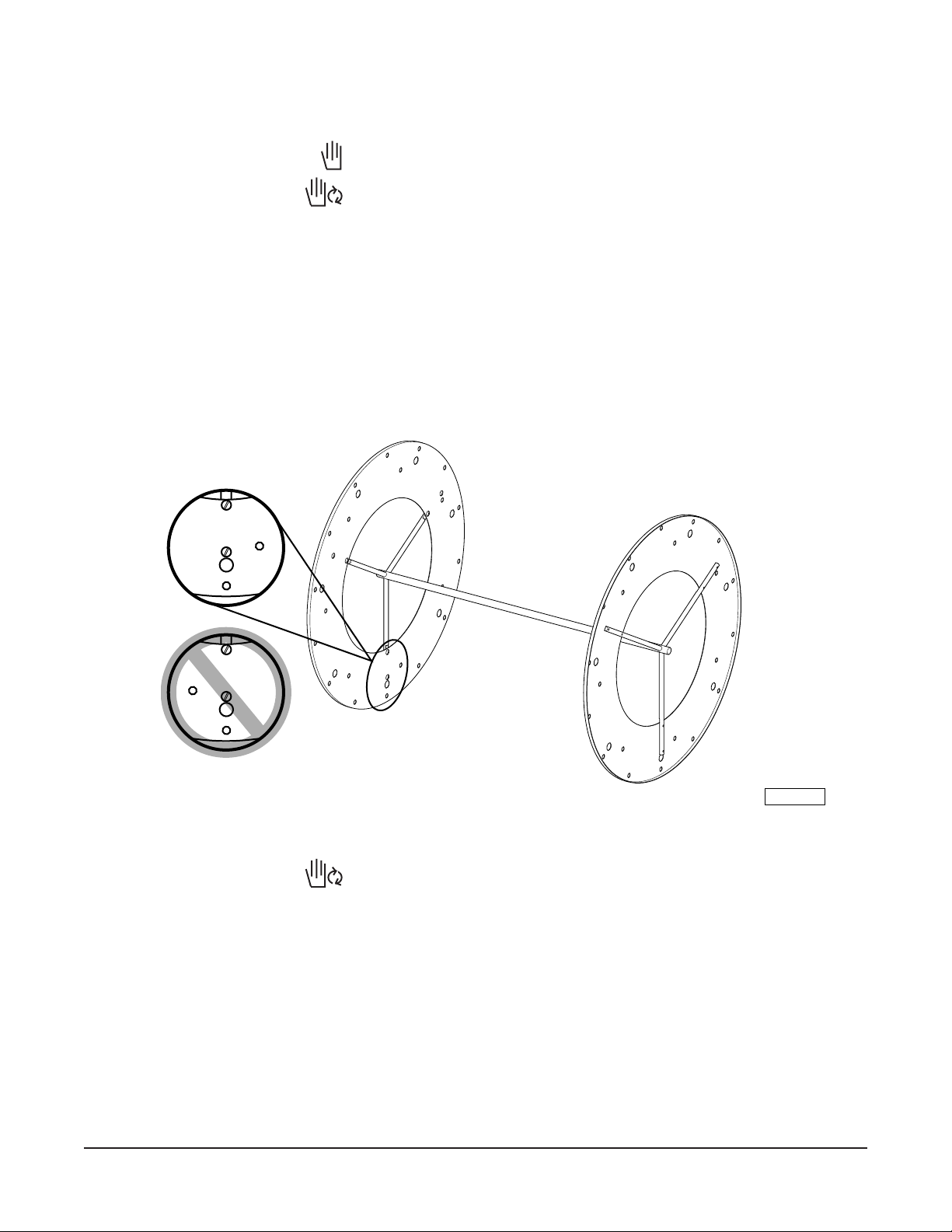

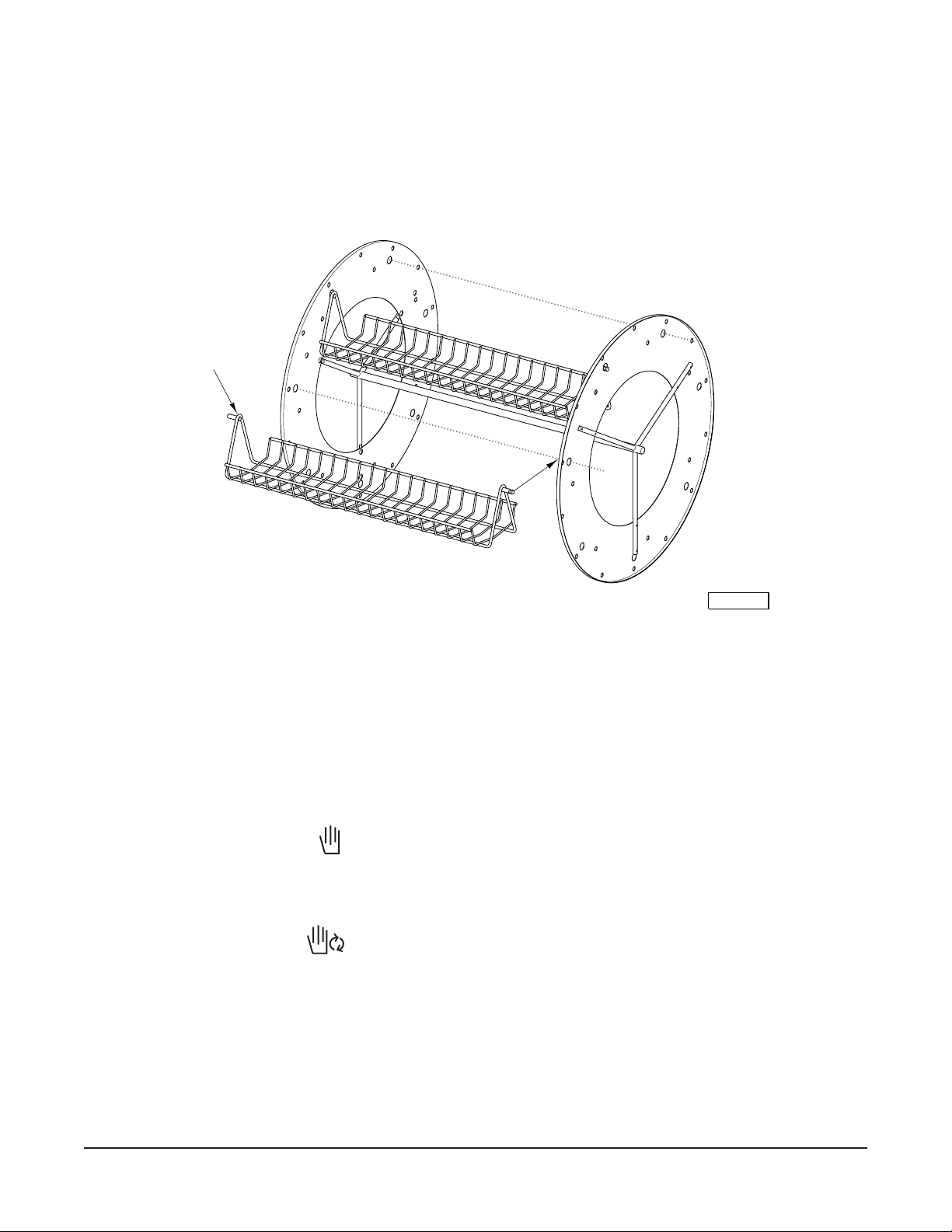

Assembling the Rotor (HR7 only)

You should have: (2) rotor end plates; (1) rotor shaft; (12) screws

1. Face the two rotor end plates against each other to make sure the holes match. This is done to

ensure you have a matched set of rotor end plates. If holes do not match, the accessories will

not align properly.

2. Align the holes on the left rotor end plate (as you face the rotor) with the holes on one side of the

rotor shaft.

3. Secure the rotor end plate to the rotor shaft with the screws available (Fig. 2).

LEFT HAND

ROTOR END PLATE

ROTOR SHAFT

HR7

Fig. 2

PL-53376

4. Assemble the right rotor end plate (as you face the rotor).

5. Align the hole pattern with the assembled left rotor end plate as indicated by the dotted lines

shown below (Fig. 3). This is done to ensure the rotor end plate is in the correct position.

6. Repeat steps 2 and 3 to secure the right rotor end plate.

LEFT HAND

ROTOR END PLATE

ROTOR SHAFT

RIGHT HAND

ROTOR END PLATE

HR7

Fig. 3

– 8 –

PL-53377

Page 9

7. Place the assembled rotor in the oven.

8. Turn Rotisserie dial to to rotate rotor.

9. Turn Rotisserie dial to "0/P" to stop rotation when the hole pattern (Fig. 4) is located at the bottom

of the oven.

10. Verify that the hole pattern is identical to the top illustrated hole pattern shown in Fig. 4.

11. If hole pattern does not match the top illustrated hole pattern, but does match the bottom

illustrated hole pattern in Fig. 4:

a. Take rotor assembly out of oven.

b. Flip rotor assembly.

c. Place rotor assembly back in oven.

d. Repeat steps 8-10 above.

HR7

Fig. 4

– 9 –

PL-53381

Page 10

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THIS PLUG MUST BE CONNECTED

INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE RECEPTACLE IS NOT

THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO NOT REMOVE THE

GROUNDING PRONG FROM THIS PLUG.

Access the electrical connection point by removing the side panel(s) where the controls are located.

Ensure that the electrical power supply agrees with the specifications on the oven's data plate and

complies with the wiring diagram, located behind the oven side panel and under the drive motor.

Stacked Ovens or Oven and Warmer

Refer to the Stacking Kit Installation Instruction (F-24860) included with your stacking kit.

Single Oven or Warmer

1. Remove the side panels.

2. At the same time attach power leads to oven or warmer terminal block as shown on the wiring

diagram, located behind the side panel and under the drive motor, and attach the power supply

conduit to the bottom of the oven or warmer.

3. Attach power supply leads to line side of the terminal block.

4. Inspect and check all wiring and terminal connections for tightness and proper routing away from

any moving parts or pinch points.

5. Carefully replace the side panels.

Refer to the Electrical Data chart on the next page.

– 10 –

Page 11

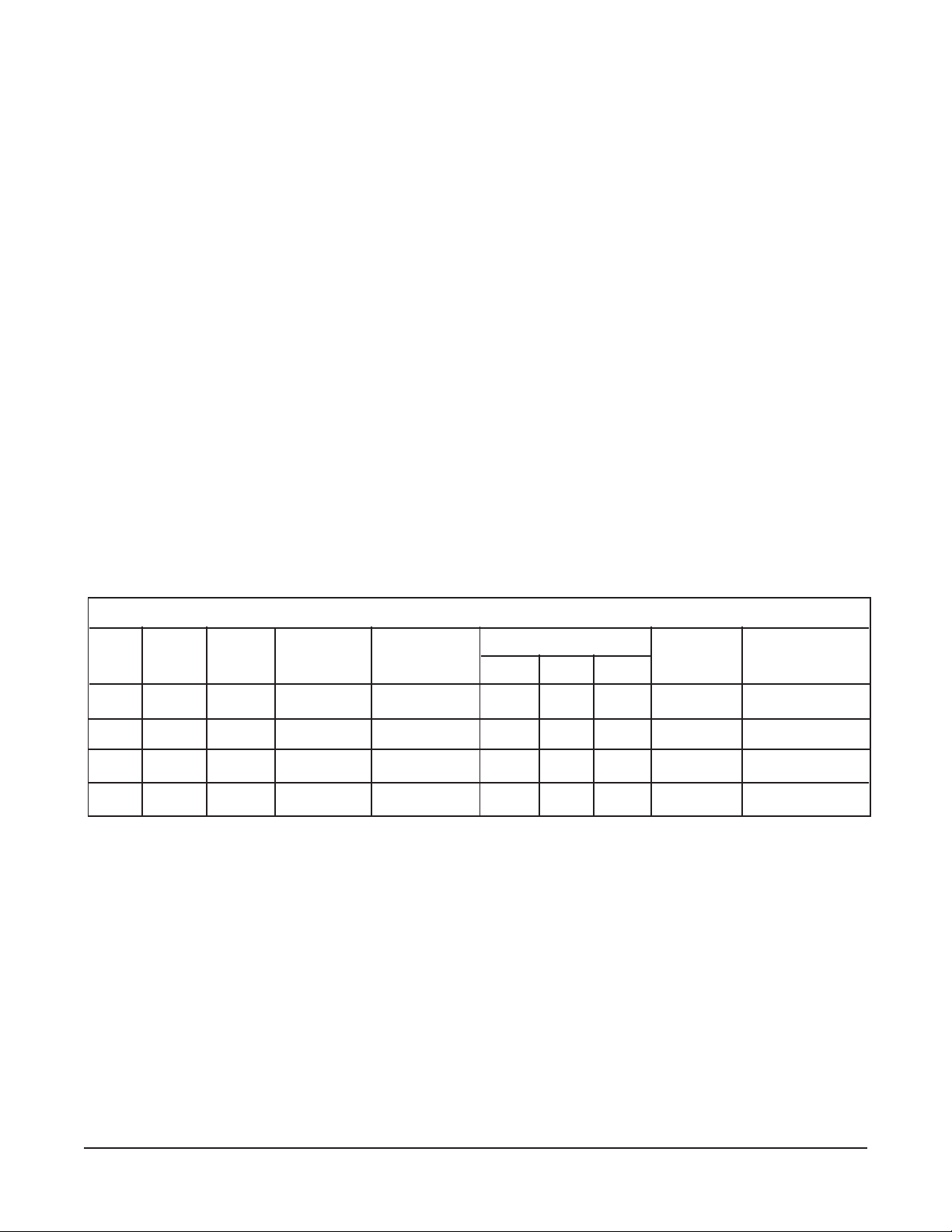

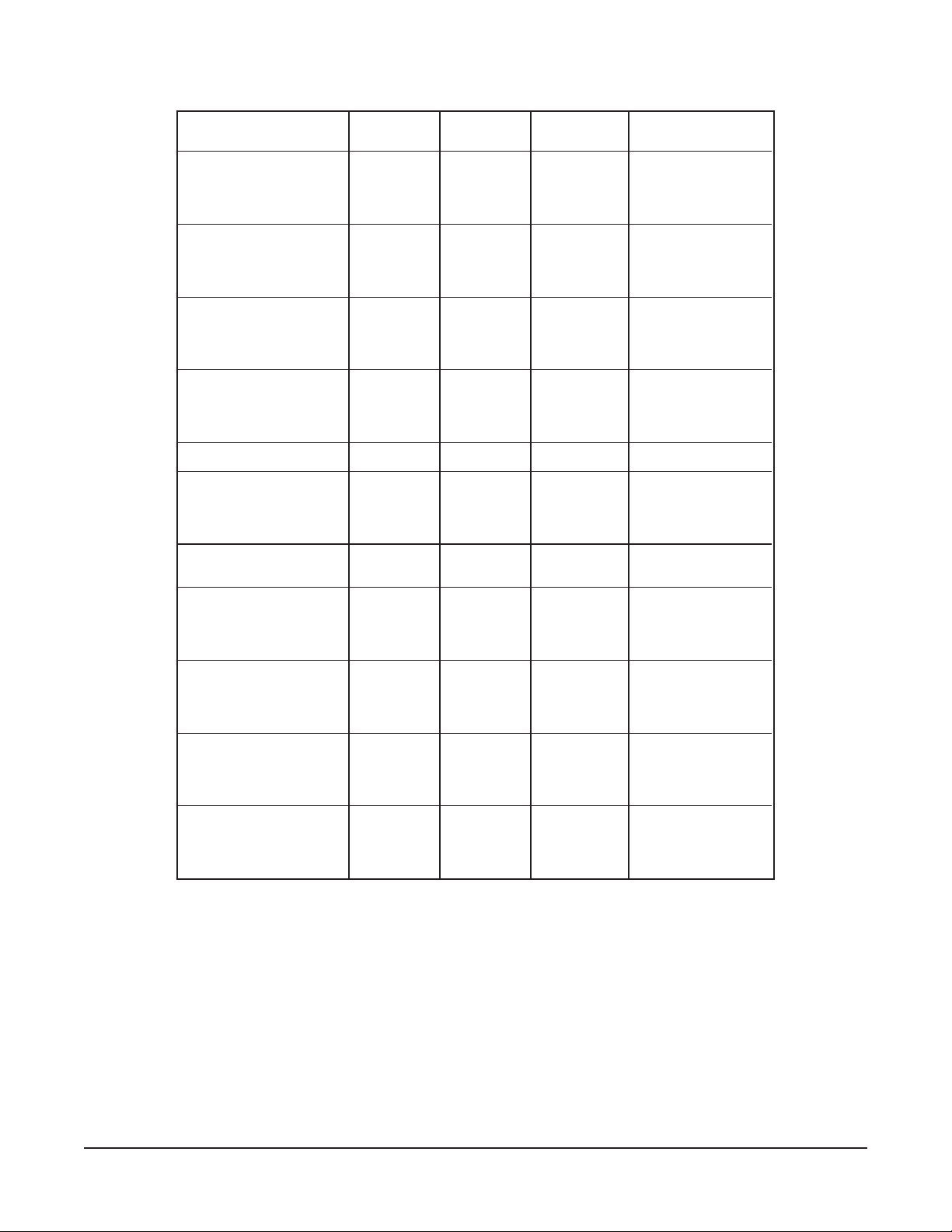

ELECTRICAL DATA

MODEL VOLTS HERTZ PHASE CIRCUIT SIZE*

HR5 208 60 1 35

208 60 3 20

240 60 1 35

240 60 3 20

HR7 208 60 1 60

208 60 3 35

240 60 1 60

240 60 3 35

HW5 208 60 1 15

208 60 3 10

240 60 1 15

240 60 3 10

HW7 208 60 1 15

208 60 3 15

240 60 1 20

240 60 3 15

STACKED MODELS

(2) HR5 208 60 1 70

208 60 3 40

240 60 1 70

240 60 3 45

(2) HR7 208 60 3 70

240 60 3 70

(AMPS)

(2) HW5 208 60 1 30

(2) HW7 208 60 1 30

HR5 & HW5 208 60 1 50

HR7 & HW7 208 60 1 80

* Maximum Circuit Breaker Size / Minimum Circuit Amperage compiled in accordance with the

National Electrical Code, 1990 edition.

208 60 3 240 60 1 35

240 60 3 -

208 60 3 25

240 60 1 40

240 60 3 30

208 60 3 40

240 60 1 50

240 60 3 40

208 60 3 50

240 60 3 80

240 60 1 50

– 11 –

Page 12

BEFORE FIRST USE

WARNING: DISCONNECT ELECTRICAL POWER BEFORE CLEANING.

Oven must be "burned in" to release any odors that might result from heating the new oven surfaces.

1. Clean oven, accessories, and warmer (if present), both inside and outside, with warm soapy

water. Refer to "Cleaning" in this manual for further instructions.

2. Rinse thoroughly and wipe dry with a soft clean cloth. Avoid water contact with quartz lamps.

3. Operate oven at maximum temperature setting of 480°F (249°C) for 45 minutes. Smoke with an

unpleasant odor will normally be given off during this burn-in period.

OPERATION

WARNING: HOT GLASS, GREASE, AND PARTS CAN CAUSE BURNS. USE CARE WHEN

OPERATING AND SERVICING THE OVEN.

There are two types of oven controls:

• Programmable with Manual Controls

• Automatic with Manual Controls

– 12 –

Page 13

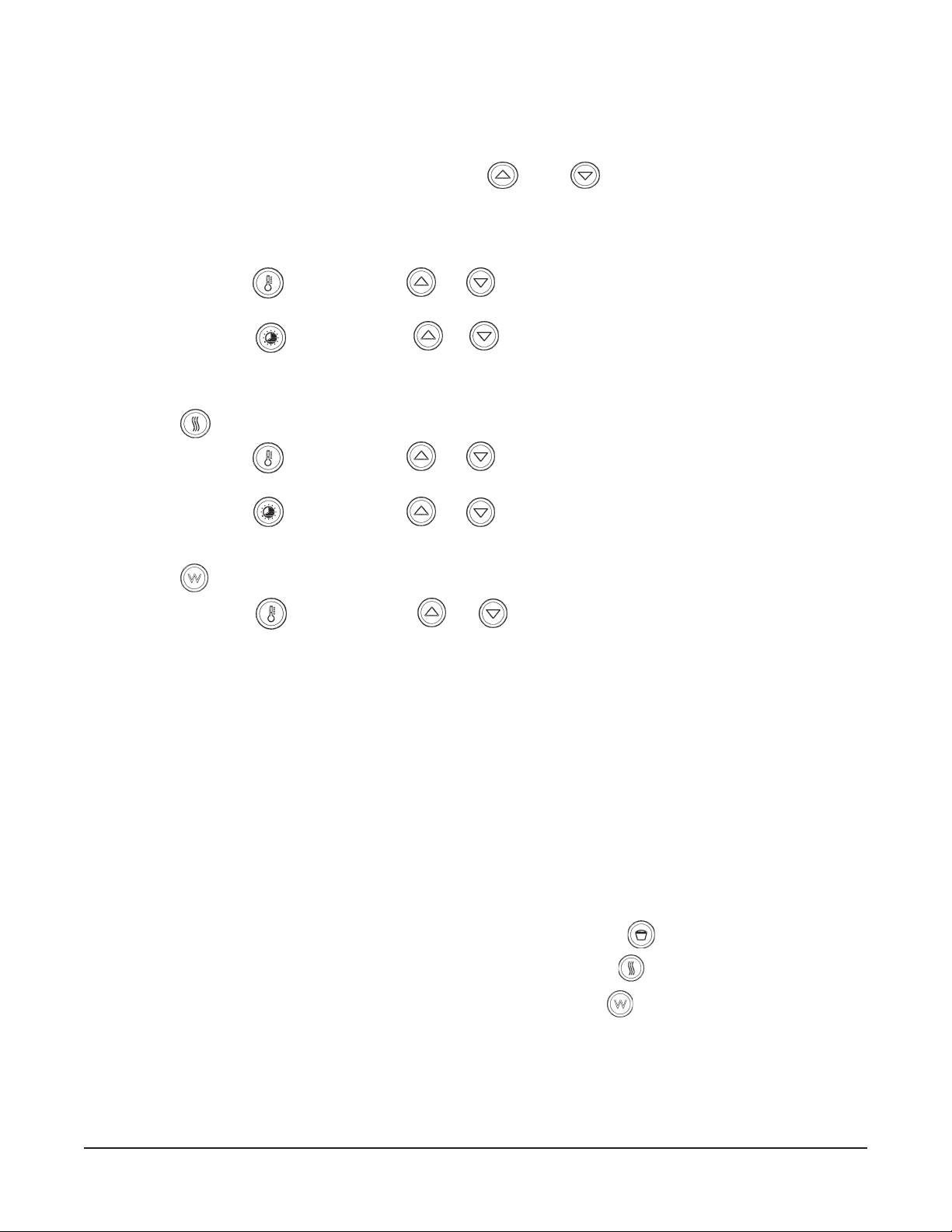

PROGRAMMABLE OVEN CONTROL PANEL WITH MANUAL CONTROLS (Fig. 5)

Display

Shows temperature (°F) and time (HH:MM) when first turned on.

Colon flashes, remaining cooking time shows.

Programmable Controls

Set all control dials to "P". See pages 15-18.

Manual Controls

Use control dials. See page 14.

DISPLAY

PROGRAMMABLE

CONTROLS

Manual

Controls

THERMOSTAT

DIAL

ROTISSERIE

DIAL

MAIN POWER

DIAL

– 13 –

PL-53362

Fig. 5

Page 14

MANUAL CONTROLS (Fig. 5)

Use control dials on the Programmable Control Panel.

Thermostat Dial

0°F – Heat is OFF.

Temperature settings – 150°F - 480°F (66°C - 249°C).

Rotisserie Dial

"0/P" – Rotisserie is OFF or in Programming Mode.

– Oven operates without restrictions.

– Customer heating lamp remains on, operator heating lamp cycles on and off to maintain the

desired temperature.

– Oven OFF, only rotor moves.

– Use to load and unload accessories.

– Oven operating.

– Customer heating lamp remains off, operator heating lamp cycles on and off for longer

cooking.

– Oven operating to keep food warm.

– Both heating lamps remain off.

Main Power Dial

"0" – Power is OFF

– Manual Mode

"P" – Programming Mode

Using Manual Controls

1. Set Main Power Dial to .

2. Set Thermostat Dial to your desired temperature setting. The operator heating lamp remains on

until the desired temperature is reached in the oven.

3. Set Rotisserie Dial to your desired manual setting.

– 14 –

Page 15

PROGRAMMABLE CONTROLS (Fig. 6)

All programming must be done with all dials in the "P" position (Thermostat , Rotisseries, and Main

Power dials). If all dials are not set to "P", the manual controls override the programmable controls.

The programmable control allows you to program three different functions for each of the 5 menu

buttons. The three functions are Cook, Grill, and Warm/Hold.

• Cook cycle is for roasting. Cook time range is 1 hour to 1 hour and 30 minutes.

• Grill cycle is for searing and browning.

• Warm/Hold cycle is a holding cycle.

- Recommended holding temperature is 160°F (71°C) or 180°F (82°C).

- Rotisserie will continue to turn during the hold cycle.

PROGRAM

INDICATORS

PROGRAM

KEYS

BUZZER

TEMPERATURE

Setting the Time of Day

1. Turn Main Power dial to "P".

UP

TIME

DOWN

PROGRAM

PROBE

END

ROTOR

COOKING

PROCESS

Fig. 6

PROCESS

INDICATORS

POWER

INDICATOR

START/ STOP

BUTTON

TIME OF

DAY

WARM / HOLD

PROCESS

GRILL

PROCESS

PL-41185-1

2. Press and hold and adjust to current time by using or . This is a 12-hour clock.

The actual time of day may be viewed on the display at any time, except during a running process, by

pressing .

– 15 –

Page 16

Programming Menu Buttons

1. Before entering the program mode, you must first press a Menu Button. Press Menu Button #1.

Its LED will light.

2. To enter Program mode, press and hold both and simultaneously until time display

shows "PROG" (approximately 2 seconds). The LED on Menu Button #1 and Cooking Process

Indicator will start blinking.

3. Cook function time and temperature must be programmed first.

Press and hold while pressing or to adjust to temperature desired.

• Maximum allowable temperature setting is 480°F (249°C); minimum is 32°F (0°).

Press and hold while pressing or to adjust to time desired.

• Maximum time setting is 5 hours, 59 minutes.

4. Program the Grill function for Menu Button #1.

Press . The Grilling Process Indicator and LED on Menu Button #1 will start blinking.

Press and hold while pressing or to adjust to temperature desired.

• Maximum allowable temperature setting is 480°F (249°C); minimum is 32°F (0°C).

Press and hold while pressing or to adjust to time desired.

5. Program the Warm/Hold function for Menu Button #1.

Press . The Warm/Hold Process Indicator and LED on Menu Button #1 will start blinking.

Press and hold while pressing or to set temperature for the hold cycle.

You cannot program a time for the warm/hold function. If you try to program a time, the buzzer

will sound for 3 seconds, then shut off. After programming of Menu Button #1 is completed, the

time display will show the current time of day.

6. Press flashing Menu Button #1 to lock in the programmed settings.

After programming, the display will show the time and temperature programmed for the Cook

function. If you have programmed "0" time and minimum temperature (32°F [0°C]) for the Cook

function, the displays will show the actual cavity temperature and actual time of day.

7. Continue programming Menu Buttons 2-5 in the same manner. All functions must have a value

entered to allow the program to work properly.

Verifying Programmed Temperatures and Times

Cook function: Press and hold the desired Menu Button, then press

Grill function: Press and hold the desired Menu Button, then press

.

.

Warm/Hold: Press and hold the desired Menu Button, then press

• Only the temperature will be displayed in the Warm/Hold function.

• Time display will show "00:00".

– 16 –

.

Page 17

Starting a Processing Cycle

1. Press desired Menu Button (its LED will light).

2. Press (its LED will light).

• Time display will show total processing time and will count down to the end of the

processing cycle.

• Temperature display will show pht (preheat) until oven cavity temperature reaches 125°F

(52°C). Then it will show the actual cavity temperature while maintaining the programmed

temperature.

Displaying Time/Temperature During a Processing Cycle

— If pressed during a processing cycle, probe icon under temperature display will light

and probe temperature will be displayed for 20 seconds. You may press it again if

you like.

— Press and hold to display both Cook temperature and time programmed for the Menu Button

you're using.

— Press and hold to display both Grill temperature and time programmed for the Menu Button

you're using.

— Press and hold to display programmed temperature only.

— Press and hold to display programmed time only.

Interrupting a Processing Cycle

1. Press if you want to check the food before the end of the processing cycle.

• This will turn off the heaters, front lamp (customer side), and rotor will flash.

2. Press again to start cycle from where it left off.

3. Press to start all over at the beginning of programmed cycle.

End of Processing Cycle

At the end of a Cook or Grill cycle, a buzzer will sound. Press to silence the buzzer.

When oven goes into Warm/Hold cycle, the buzzer will sound and operator side lamp will cycle on and

off with heaters.

• Press and hold to silence buzzer.

• The temperature and time displays will show actual oven cavity temperature and time of day until

reaching holding temperature.

• Press to end holding process.

Changing a Programmed Setting

You may modify temperature or time of a Cook or Grill function only on any Menu Button prior to

starting processing, or during processing.

• Press (for temperature) or (for time) while pressing or .

• This will not change the temperature or time programmed in the memory for that Menu Button.

– 17 –

Page 18

Turning the Buzzer Off

Press .

Setting the End Time (Delayed Start)

Assume roasting time is one hour and fifteen minutes and it is currently 2 o'clock. If you want to finish

roasting at 4:00, program as follows:

1. Press and hold while pressing or to adjust the time to 4:00.

• Colon in display will flash.

• Time display will show cooking time.

2. Press .

• Cooking will begin at 2:45. Colon starts flashing.

• Roasting stops at 4:00; buzzer sounds. Press to silence.

If after pressing the end time comes earlier than the current time + the program time, a beep will

sound (for three minutes) and program will not start.

• Programmed end time is now cancelled.

• When is pressed again, program starts in the normal way.

Setting an Early Warning Buzzer

You can program an early warning buzzer for basting or whatever reason.

• This function is completely independent of any program, whether it is running or not.

• Buzzer always sounds for three minutes.

1. Press when buzzer is not engaged, the current time or the already programmed time will

be shown in the display.

2. Press or and at the same time to program the moment when the beep tone will

sound.

• Minimum is the current time.

• Maximum is the current time minus 1.

• Buzzer delay time can always be changed as long as the beep tone has not sounded.

• As soon as a beep tone sounds as a result of the elapsed buzzer delay time, the programming

is cancelled.

Stopping the Rotisserie

Press .

• Heaters, operator side lamp, and rotisserie will turn off.

• To start rotisserie again, see procedures described under "Interrupting a Processing Cycle".

– 18 –

Page 19

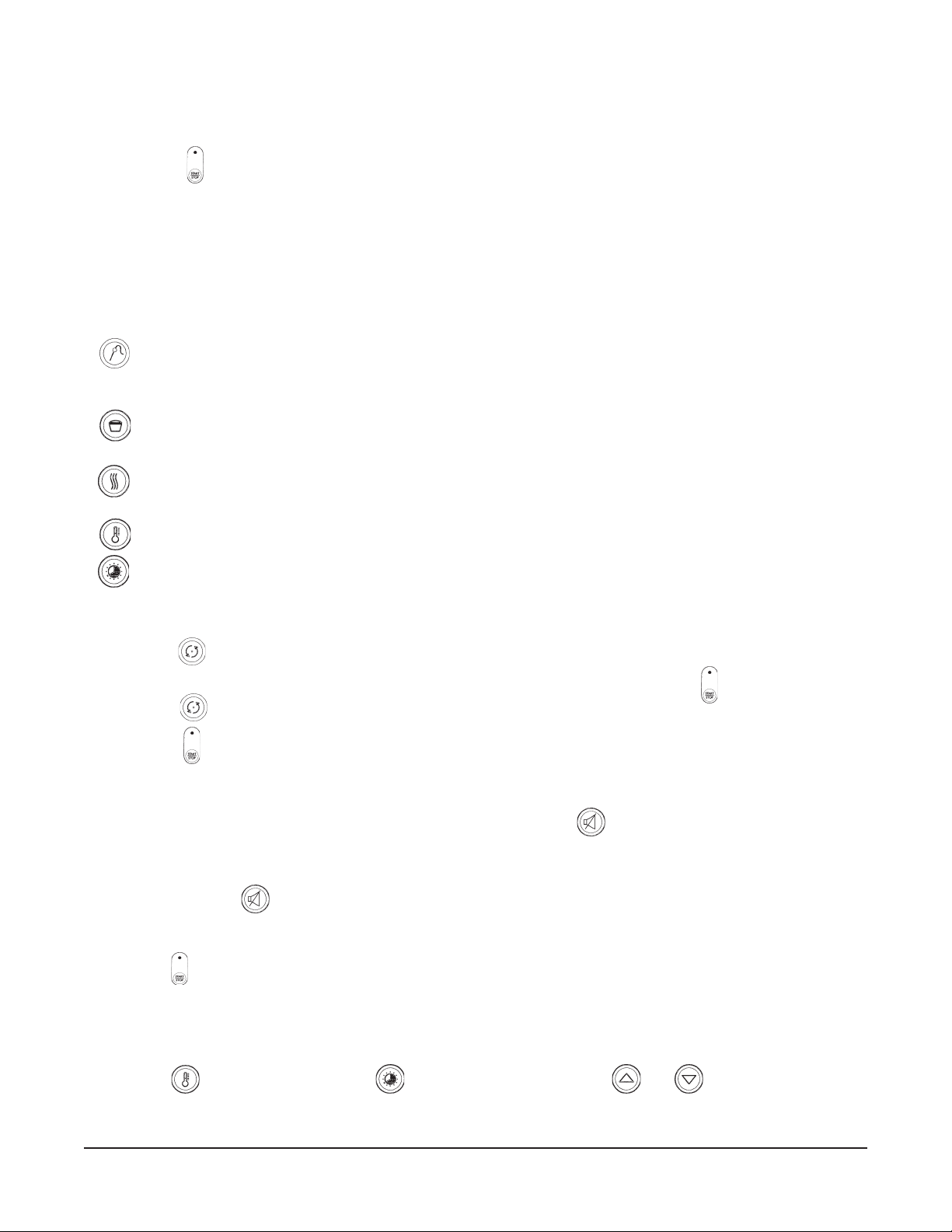

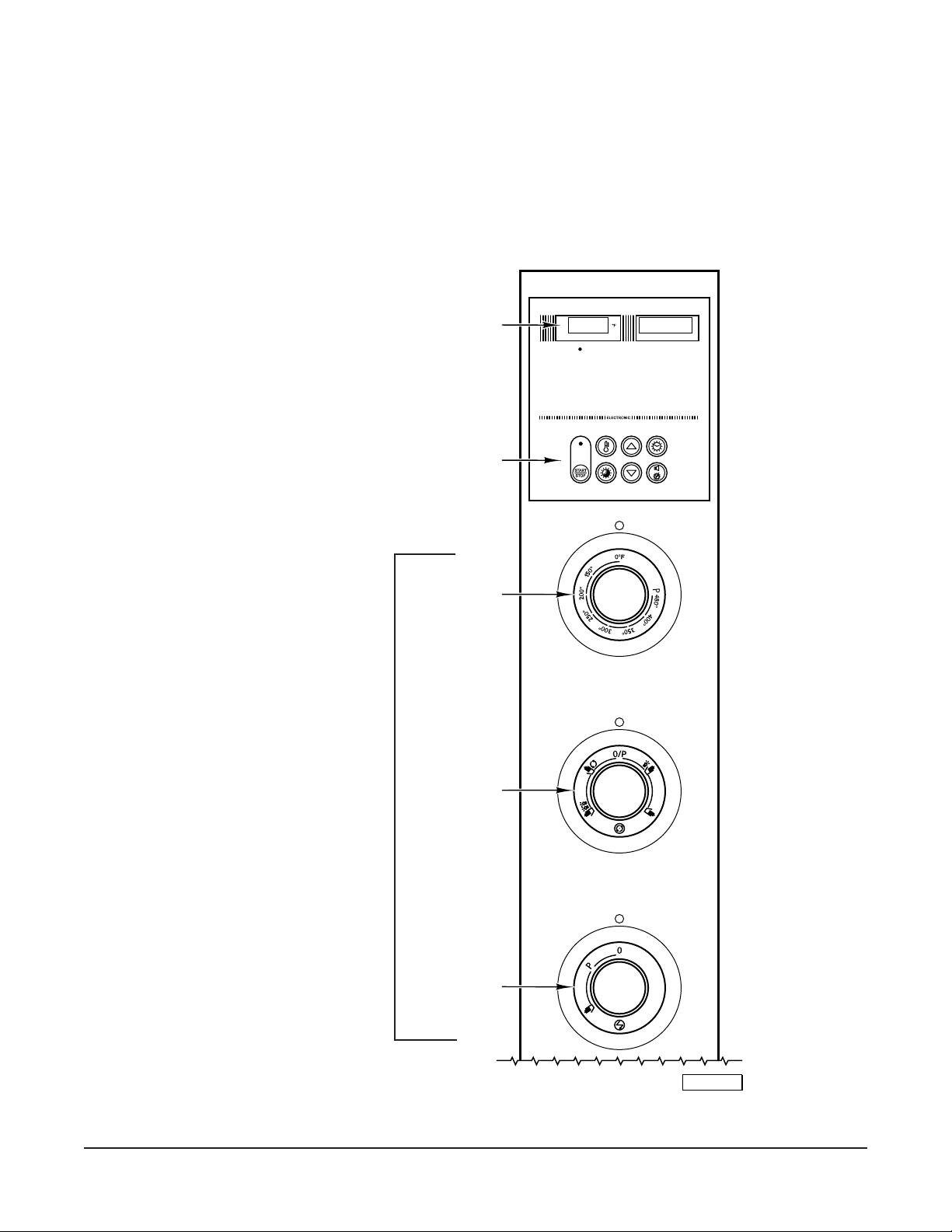

AUTOMATIC OVEN CONTROL PANEL WITH MANUAL CONTROLS (Fig. 7)

Display

Shows temperature (°F) and time (HH:MM) when first turned on.

Colon flashes, remaining cooking time shows.

Automatic Controls

Set all control dials to "P". See pages 21-23.

Manual Controls

Use control dials. See page 20.

DISPLAY

AUTOMATIC

CONTROLS

Manual

Controls

THERMOSTAT

DIAL

ROTISSERIE

DIAL

MAIN POWER

DIAL

– 19 –

PL-53361

Fig. 7

Page 20

MANUAL CONTROLS (Fig. 7)

Use control dials on the Automatic Control Panel.

Thermostat Dial

0°F – Heat is OFF.

Temperature settings – 150°F - 480°F (66°C - 249°C).

Rotisserie Dial

"0/P" – Rotisserie is OFF or in Automatic Mode.

– Oven operates without restrictions.

– Customer heating lamp remains on, operator heating lamp cycles on and off to maintain the

desired temperature.

– Oven OFF, only rotor moves.

– Use to load and unload accessories.

– Oven operating.

– Customer heating lamp remains off, operator heating lamp cycles on and off for longer

cooking.

– Oven operating to keep food warm.

– Both heating lamps remain off.

Main Power Dial

"0" – Power is OFF

– Manual Mode

"P" – Automatic Mode

Using Manual Controls

1. Set Main Power Dial to .

2. Set Thermostat Dial to your desired temperature setting. The operator heating lamp remains on

until the desired temperature is reached in the oven.

3. Set Rotisserie Dial to your desired manual setting.

– 20 –

Page 21

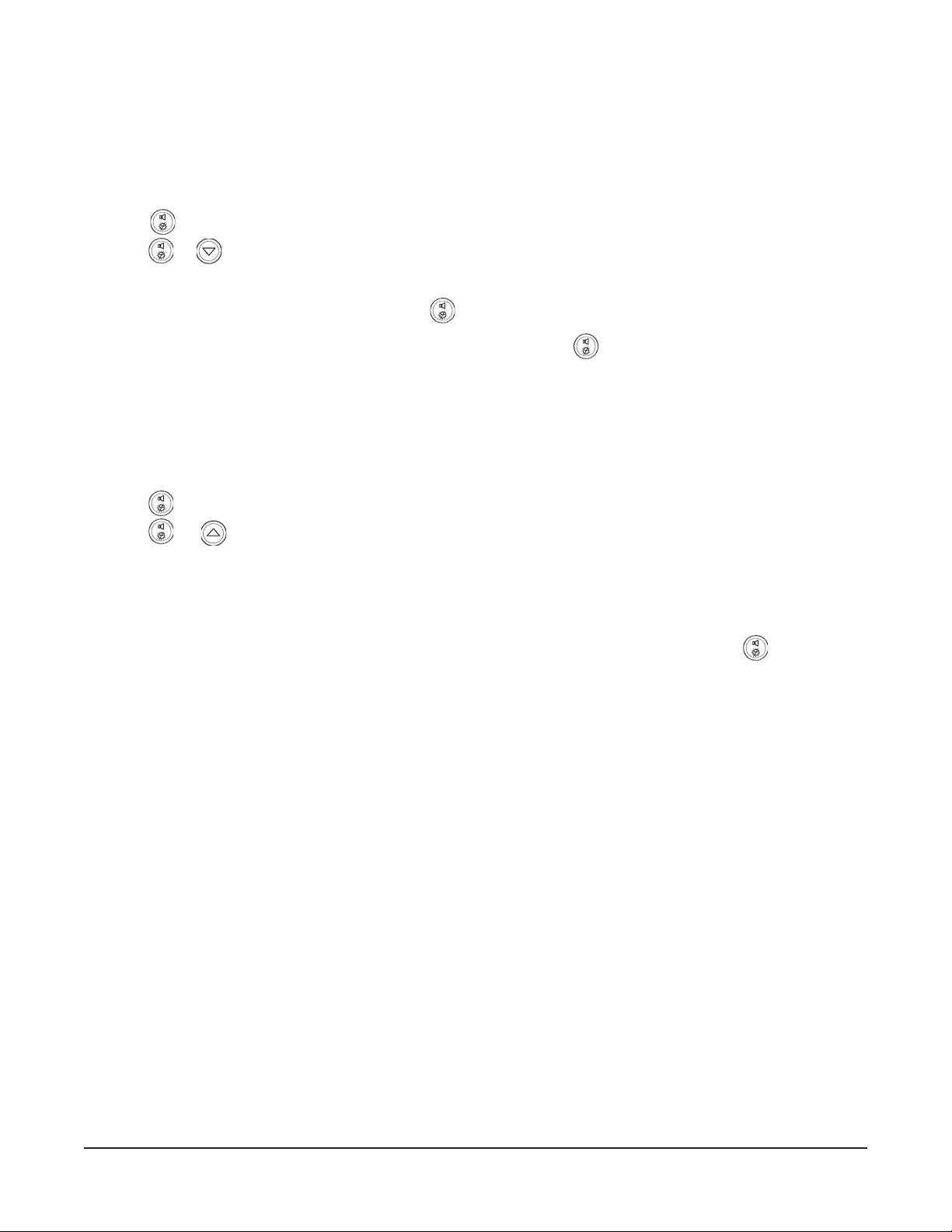

AUTOMATIC CONTROLS (Fig. 8)

TEMPERATURE

POWER INDICATOR

START/ STOP

BUTTON

ROASTING TIME

Fig. 8

UP

DOWN

TIME OF DAY

BUZZER

PL-41184-1

Automatic Controls can regulate roasting temperature, stop cooking at a preset time, or allow buzzer

to be timed.

If no temperature or roasting time has been programmed, the Automatic Control recalls the values for

the previous Automatic Cooking Operation. The last entered temperature and roasting time is always

retained in memory by the Automatic Controls. These values can be displayed by pressing the

appropriate symbol.

1. Turn all dials to the "P" position. If all dials are not set to "P", the manual controls override the

automatic controls.

2. Set the temperature and roasting time.

3. Press START to begin. The red light on the START/STOP button is lit.

Setting the Temperature

DISPLAY TEMP

Press 325 — Displays the thermostat setting (150 - 480°F [66 - 249°C]).

Press + 326 — Increases the temperature setting.

Press + 324 — Decreases the temperature setting.

Setting the Roasting Time

DISPLAY TIME

Press 1:15 — Displays the automatic roasting time.

Press + 1:16 — Increases the automatic roasting time.

Press + 1:14 — Decreases the automatic roasting time.

– 21 –

Page 22

Setting an Early Warning Buzzer

Assume roasting time is one hour and fifteen minutes and it is currently 2 o’clock. The cycle completes

and the buzzer will sound at 3:15. If you want an early warning buzzer for basting or whatever reason,

program as follows:

DISPLAY TIME

Press 3:15 — Displays the sum of the current time plus the roasting time.

Press + 3:00 — Buzzer will sound at 3:00.

Press START. — Roasting begins.

• At 3:00, interim buzzer sounds. Press to silence.

• At 3:15, roasting stops and buzzer sounds again. Press to silence.

Setting End Time (Delayed Start)

Assume roasting time is one hour and fifteen minutes and it is currently 2 o’clock. If you want to finish

roasting at 4:00, program the Automatic Control as follows:

DISPLAY TIME

Press 3:15 — Displays sum of current time plus roasting time.

Press + 4:00 — Roasting will stop at 4:00.

Press START. — Red light on the START/STOP button is lit.

Rotisserie stays off until:

• Roasting begins at 2:45. Colon flashes.

• Roasting stops at 4:00; buzzer sounds. Press to silence.

Interrupting an Automatic Cooking Operation

If you want to temporarily interrupt an Automatic Cooking Operation, press START/STOP.

• Red light on the START/STOP button flashes.

• Colon stops flashing.

• Rotisserie stops.

• Heat lamps and elements go off.

• Automatic Control retains the set temperature and the remaining roasting time.

• Current temperature and remaining roasting time are displayed.

• Temperature decreases because heating is off. The control does not compensate.

To restart, press START/STOP again. The Automatic Cooking Operation will resume.

– 22 –

Page 23

Stopping an Automatic Cooking Operation

When an Automatic Cooking Operation is completed, a buzzer sounds.

If you want to temporarily interrupt an Automatic Cooking Operation, see above.

If you want to abort an Automatic Cooking Operation, turn Main Power dial to "0".

• Temperature and Roasting Time remains in memory, not the remaining cooking time.

Changing A Setting

All settings, except Time of Day, can be changed before, during, or after the cooking process. Time

of Day cannot be changed during an Automatic Cooking Operation. After a change, operation

continues according to new values.

Stopping the Rotisserie

Turn Main Power dial to "0" or press START/STOP.

• Everything will switch off.

Setting the Time of Day

Time of Day cannot be reset during an Automatic Cooking Operation.

• Red light on the Start/Stop button must be off.

• Colon is not flashing.

Set the Time of Day as follows:

DISPLAY TIME

9:23 — Current time of day is displayed.

Press + 9:24 — Increases the time of day.

Press + 9:22 — Decreases the time of day.

Turning the Buzzer OFF

Press .

Resetting the Automatic Control

Press STOP/START.

• Automatic Control retains Time and Temperature for the last Automatic Cooking Operation.

• Remaining cooking time and early warning buzzer are lost.

– 23 –

Page 24

PREPARING THE PRODUCT

• Oven is not designed to roast frozen foods.

• Use only fresh or previously thawed product.

• Clean all work areas before and after preparing poultry.

• Maintain proper sanitation at all times.

LOADING PRODUCTS ONTO ACCESSORIES

Make sure the product weight is evenly balanced on the accessory.

To load a chicken or garnish hen you must do the following:

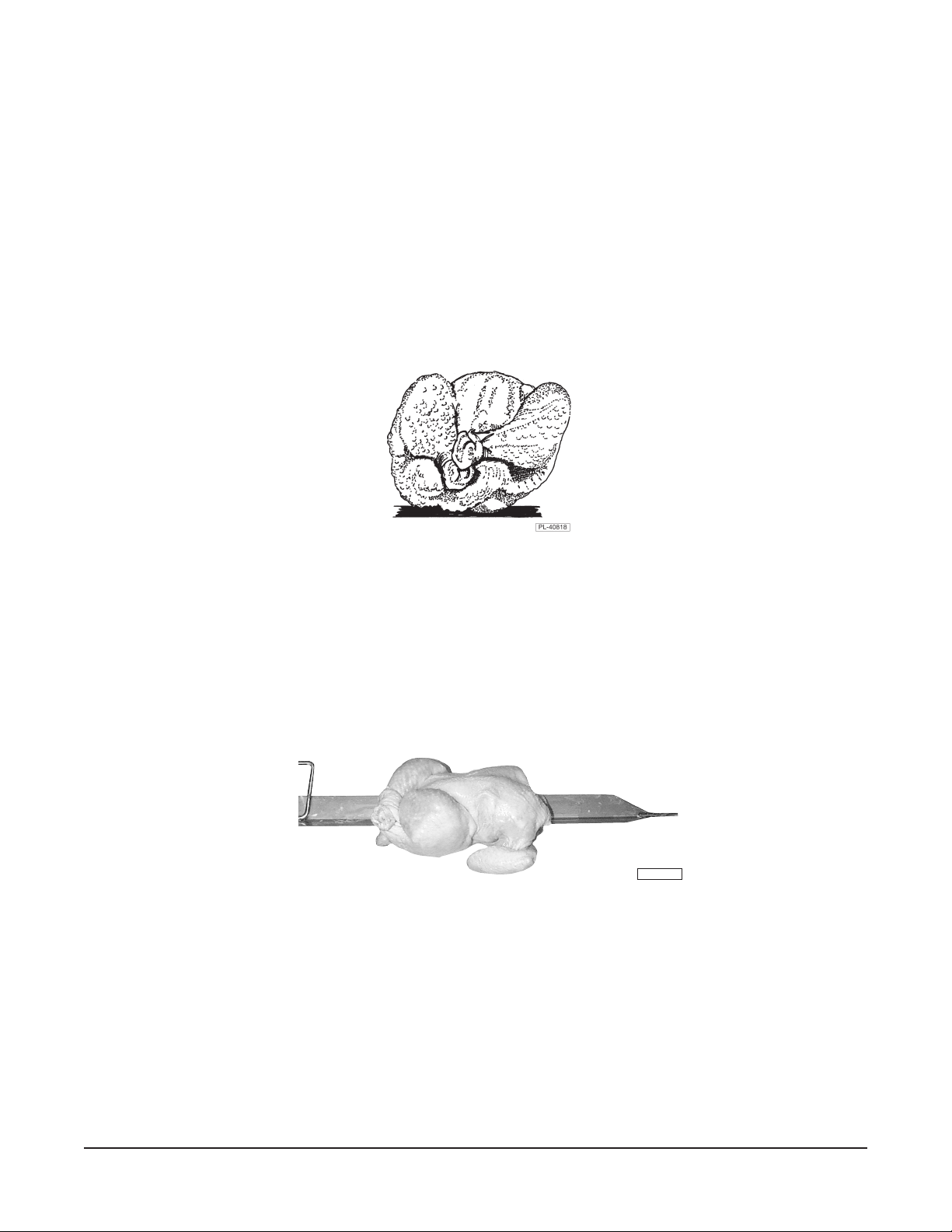

• Tuck the wings to the back (see Fig. 10)

• Tie the legs (Fig. 9)

Fig. 9

Loading Products onto Spits

WARNING: SKEWERS ARE SHARP. BE VERY CAREFUL WHEN LOADING PRODUCT.

V Spit (Standard)

Skewer spit into the whole poultry so the point goes through the rear then the head (Fig. 9).

• Leave approximately

1

⁄2" (1.2 cm) between each chicken to permit proper browning.

SPIT

V SPIT

Fig. 10

PL-41367-1

– 24 –

Page 25

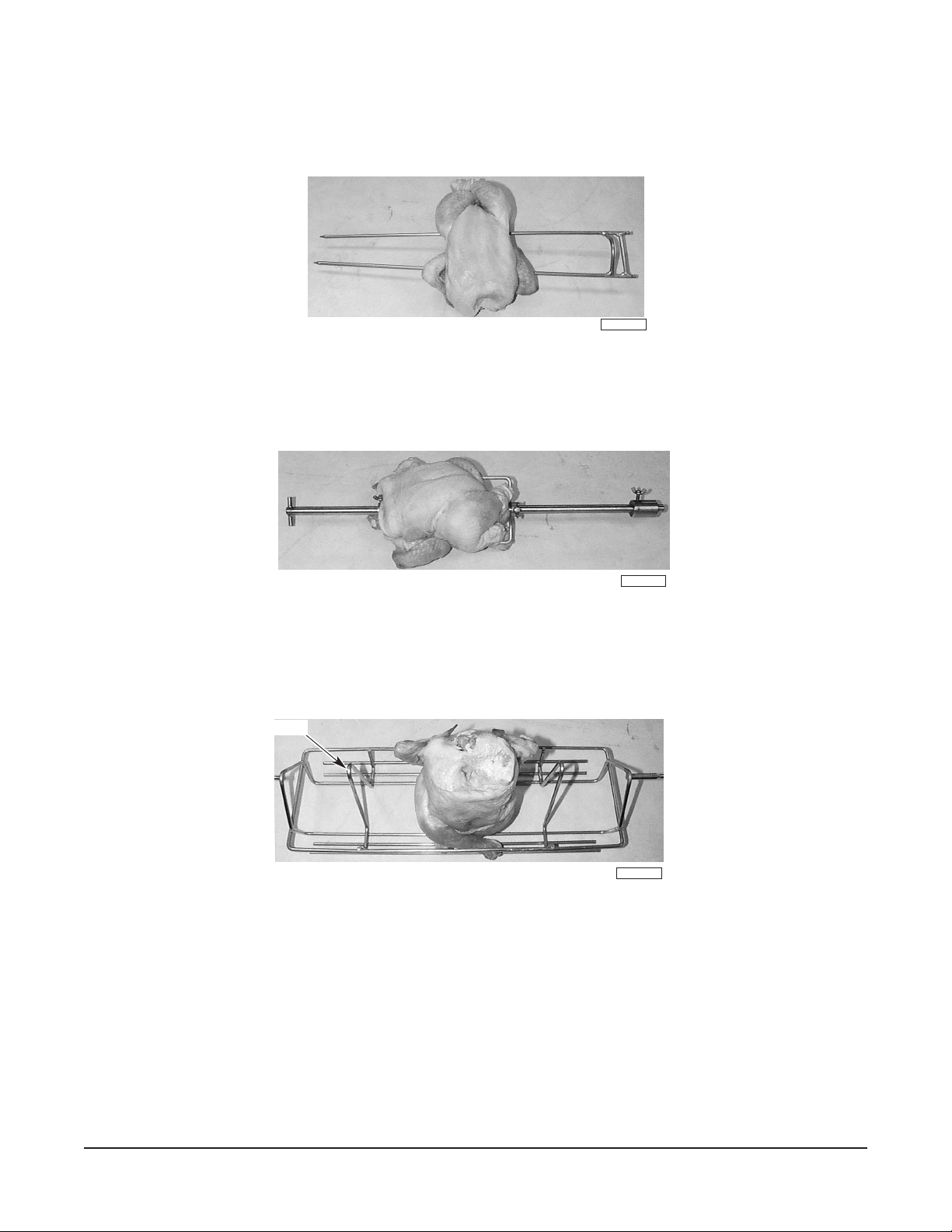

Fork Spit (Optional)

Skewer spits into whole poultry so that point goes through the chest and thighs (Fig. 11).

• Leave approximately

1

⁄2" (1.2 cm) between each chicken to permit proper browning.

FORK SPIT

PL-41373-1

Fig. 11

Turkey Spit (Optional)

You must remove the rotor assembly from the oven and replace it with the turkey spit to roast one whole

turkey (Fig. 12).

TURKEY SPIT

PL-41372-1

Fig. 12

Loading Products onto Chicken Racks (Optional)

Place the chicken on a rack, breast forward, with legs down and wings up as shown (Fig. 13).

RACK

3 RACK CHICKEN RACK

Fig. 13

PL-41368-1

– 25 –

Page 26

2. Make sure the product is not sticking out of the rack rods. Shown below is a 3 rack chicken rack

(Fig. 14). Four rack and 5 rack chicken racks are also available as an option.

3 RACK CHICKEN RACK LOADED

Fig. 14

Loading Products in a Basket (Optional)

Load the chickens, breast up, in the basket (Fig. 15 & 16).

HR5 BASKET

Fig. 15

HR7 BASKET

PL-41369-1

PL-41370-1

PL-41371-1

Fig. 16

– 26 –

Page 27

LOADING ACCESSORIES INTO THE OVEN

If you are loading an HR5, skip steps 2-7.

1. Turn Main Power dial to .

2. Turn Rotisserie dial to to rotate rotor.

3. Turn Rotisserie dial to "0/P" to stop rotation when the hole pattern (Fig. 17) is located at the

bottom of the oven.

4. Verify that the hole pattern is identical to the top illustrated hole pattern shown in Fig. 17.

5. If hole pattern does not match the top illustrated hole pattern, but does match the bottom

illustrated hole pattern in Fig. 17:

a. Take rotor assembly out of oven.

b. Flip rotor assembly.

c. Place rotor assembly back in oven.

d. Repeat steps 2-4 above.

HR7

Fig. 17

PL-53381

6. Load accessory with product into oven. Make sure the product is distributed evenly. (See the next

page for further instructions on loading specific accessories into the oven.)

7. Turn Rotisserie dial to to rotate rotor.

8. Turn Rotisserie dial to "0/P" to stop rotation.

9. Load accessory with product into the oven.

10. Repeat steps 7-9 until all loading is complete.

11. Close oven door.

When you load any accessories with a product into the oven, make sure the product clears the top of

the oven and no part of the product is sticking out.

Do not mix accessories on the rotor.

– 27 –

Page 28

Loading Spits Into Oven

1. Place the skewer into the small outside hole on the rotor end plate on your left (as you face the

oven). The back of the V-shape spit should be pointing towards you (Fig.18).

V-SPIT

HR7

Fig. 18

PL-53379

2. Fit the other end on the spit into the small corresponding holes on the rotor end plate on your right

(as you face the oven) (Fig.18).

3. Make sure the spit is level. If spit is not level make, sure you are using the correct holes on the

rotor end plates.

Loading Fork Spits Into Oven

1. Place sharp end of spit into holes on the rotor end plate on your left (as you face the oven).

2. Fit the opposite end of spit into corresponding holes in the rotor end plate on your right (Fig. 19).

FORK SPIT

HR7

Fig. 19

– 28 –

PL-53378

Page 29

Loading Racks, Baskets, or Baking Plate Into Oven

A Chicken Rack, Basket, and Baking Plate all load the same. Loading a basket is shown (Fig. 20).

1. Place one end of the accessory into the a rotor end plate.

2. Place the other end of the accessory into the corresponding hole on the other rotor end plate.

Make sure the accessory is level.

BASKET

HR7

Fig. 20

UNLOADING ACCESSORIES FROM OVEN

Opening the door does not stop the rotisserie or cooking process.

1. Press STOP/START. Red light on button will go off.

2. Turn Thermostat dial to 0°F.

3. Turn Main Power dial to .

4. Turn Rotisserie to "0/P" to stop rotation.

5. Remove an accessory with insulated gloves or safety mitts.

6. Turn Rotisserie dial to to rotate.

7. Turn Rotisserie to "0/P" to stop rotation.

8. Repeat steps 5 thru 7 until unloading is complete.

PL-53380

– 29 –

Page 30

SUGGESTED ROASTING GUIDELINES

The chart indicates suggested cooking times and temperatures. Initial product temperature, size,

shape, and other factors may require adjustment to suit your operation.

Internal Capacity

Thermostat Time Temperature

Product (°F) (°C) (HH:MM) (°F) (°C) HR5 HR7

Chicken, Whole, 350-275 177-135 1:10 - 1:30 180-185 82-85 15-20 28-35

3 lb. (1.4 kg)

Cornish Hens, 350-275 177-135 0:50 - 1:20 180-185 82-85 20-24 28-42

1 lb. (.45 kg)

Duck, Whole, 350-275 177-135 1:50 - 2:15 180-185 82-85 10 14

4-41⁄2 lb. (1.8-2 kg)

Turkey, Whole, 350-275 177-135 1:50 - 2:15 180-185 82-85 1 1

11-13 lb. (5-5.9 kg)

Roast Beef, 350-275 177-135 0:45 - 0:55 140 Rare 60 10 14

4 lb. (1.8 kg) 160 Medium 71

180 Well Done 82

Pork Ribs, 350 177 0:50 - 1:20 170 77 5 7

3 lb. (1.4 kg)

* These are approximate cooking times. They will fluctuate based upon the weight and size of the

product.

– 30 –

Page 31

EMPTYING GREASE DRAWER

Empty the grease drawer when necessary.

• Be careful if grease is warm.

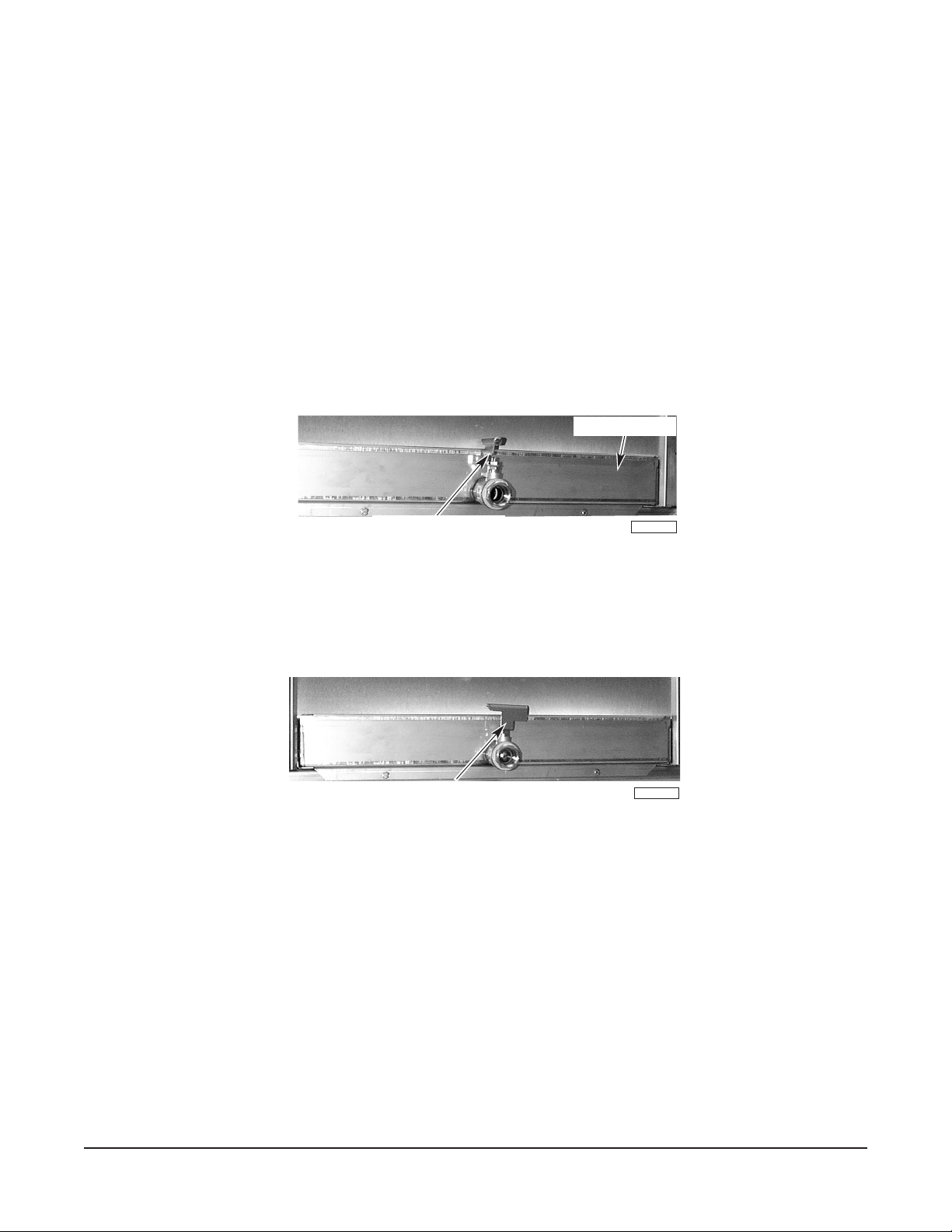

1. Open door and slide grease drawer out about 5" (13 cm) (Fig. 21).

2. Provide a suitably large bucket or vessel under drain valve and open valve handle (Fig. 21).

3. Close drain valve when empty (Fig. 22).

4. Slide grease drawer shut.

5. Close oven door.

GREASE DRAWER

OPENED DRAIN VALVE

Fig. 21

CLOSED DRAIN VALVE

Fig. 22

PL-41366-1

PL-41365-1

– 31 –

Page 32

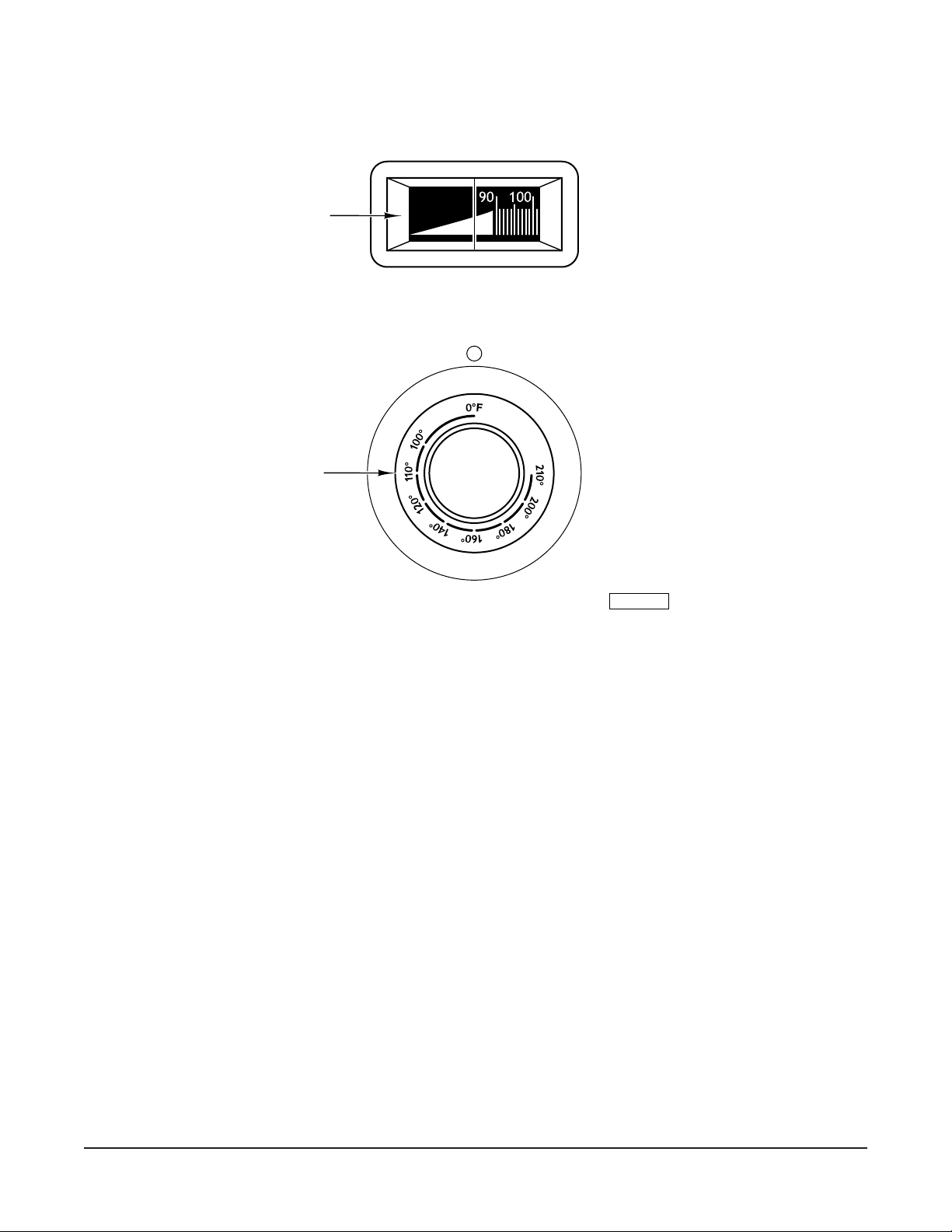

WARMER CONTROLS (Fig. 23)

THERMOMETER

THERMOSTAT

DIAL

PL-53364

Fig. 23

Thermometer — Displays temperature in degrees Fahrenheit.

Thermostat — 0°F is OFF. Turn dial to desired temperature.

USING WARMERS (Models HW5 and HW7)

Fill warmer drawer with cold water about three-quarters full to minimize steaming.

• Use softened water, if available, to reduce lime build-up in drawer.

Cooked product other than poultry may be held in the warmer for 3 to 4 hours; then it must be

refrigerated.

When holding poultry, it is recommended that the temperature of the warmer be at least 160°F – 180°F

(71°C - 82°C) and that poultry be held no longer than 2 hours. The minimum temperature of the product

must be 140°F (60°C)

Every 4 to 5 hours, add lukewarm water to drawer as needed.

• If water evaporates completely, product will dry out.

– 32 –

Page 33

CLEANING

WARNING: DISCONNECT ELECTRICAL POWER BEFORE CLEANING.

Proper cleaning prolongs the life and productivity of the oven. The oven should be routinely cleaned

throughout the day and thoroughly cleaned at the end of the day.

Allow oven to cool before cleaning.

CAUTION: Do not use oven cleaners. Do not clean with a high pressure hose.

1. Wash both doors and inside glass with warm soapy water, rinse and dry or use a commercial

glass cleaner.

2. With door open, pull inside glass away from door to clean.

• Take extra care when cleaning outside surface of inner glass door because of its special

reflective coating.

• Do not remove glass from door.

3. Clean control panel with a damp cloth only.

4. Remove oven rotisserie, accessories, bottom plates, and other removable parts for cleaning.

Refer to specific instructions below for cleaning stainless steel or nonstick coated surfaces.

5. Clean oven interior and exterior with warm soapy water.

6. Rinse interior and exterior thoroughly and dry with a soft clean cloth.

CLEANING STAINLESS STEEL SURFACES

1. Wash stainless steel parts with warm soapy water.

2. Rinse parts thoroughly.

3. Dry with a soft clean cloth.

CLEANING NONSTICK COATED SURFACES

Several parts of your rotisserie may have a nonstick coating surface. Abrasion reduces the life of the

coating. With proper care, the nonstick coating surface should provide a long life of easy-to-clean

service.

DO NOT do the following:

• Do Not use scouring pads, steel wool, Scotch-Brite pads, or other abrasive cleaning hardware.

• Do Not use sharp instruments such as knives, forks, scrapers, or metal objects of any kind.

• Do Not use chemicals intended for uses other than dish washing or pot and pan washing.

• Do Not attempt to burn-off or bake-off and surface contamination.

• Do Not go longer than eight hours without cleaning.

– 33 –

Page 34

How To Clean Nonstick Coated Surfaces (Routine Cleaning)

This should be done at the end of each cook cycle.

CAUTION: Cleaning should not be delayed beyond 8 hours of service.

1. Use a mild dish washing soap in warm water to remove grease and food residue immediately after

the coated component has cooled.

2. Rinse with clean water and let dry.

3. Wipe a light vegetable oil into the surface to condition the surface. Do not use “Pam”.

How To Clean Severe Buildup on Nonstick Coated Surfaces

After continuous cook cycles without cleaning, some food residues may become more difficult to

remove. If severe buildup is a regular problem, cleaning schedules should be reevaluated.

1. Soak parts in the following solution:

• 3 tablespoons of bleach

• 1 tablespoon liquid dish washing detergent

• 1 cup of water

2. Use a sponge or a cloth to apply solution to affected areas. "

Plastic

" wash pads designed for use

on nonstick cookware may be necessary, but steel pads must be avoided.

3. Thoroughly rinse with clean water and let dry.

4. Condition with vegetable oil.

CLEANING PROBE

Clean after every use.

1. Remove the probe from the probe holder located on the side of the oven.

2. Unplug probe cord from the bottom of the probe holder, if needed. Do not submerge cord in water.

3. Wipe probe with an antibacterial soap or cleaner.

4. Carefully plug probe cord back into the bottom of the probe holder. (The plug pins are different

sizes to ensure proper orientation.)

5. Place probe back in probe holder.

– 34 –

Page 35

CLEANING GREASE DRAWER

1. Empty grease drawer (see page 31).

2. Remove drawer when machine is idle.

3. Wash in a sink with warm soapy water.

• Any hard soil can be scrubbed with a soft, non-scratching pad.

4. Rinse and wipe dry with a soft clean cloth.

5. Return clean drawer.

CLEANING WARMERS

1. Remove water drawer and shelves.

2. Wash with warm soapy water, rinse and dry.

3. If scale builds up on water drawer or warmer interior, soak with vinegar.

4. Rinse thoroughly and dry with a soft clean cloth.

CLEANING QUARTZ LAMPS

CAUTION: Do not clean the quartz lamps in the top of the oven with soap and water.

Be very careful when cleaning lamps. Lamps can be broken by mishandling.

Clean lamps with a cloth soaked in alcohol.

Do not touch lamps with your bare hands. Touching the quartz lamp could shorten the life of the bulb.

MONTHLY CLEANING

Clean ventilation grate and fan blades located in the top of the oven.

1. Remove ventilation grate by unscrewing nuts (clockwise) on both sides of vents.

2. Unscrew nut in center of fan blade.

3. Wash in a sink with warm soapy water.

4. Rinse thoroughly and dry with a soft dry cloth.

5. Wipe fan blades with a clean damp cloth.

6. Dry with a soft dry cloth.

7. After cleaning, reinstall in reverse order.

– 35 –

Page 36

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE PERFORMING ANY

MAINTENANCE.

WARNING: HOT GLASS, GREASE, AND PARTS CAN CAUSE BURNS. USE CARE WHEN

OPERATING AND SERVICING THE OVEN.

MODEL HR5 OVEN ONLY

Should the rotisserie become out of alignment, use the allen key to unscrew and retighten the drum

on the rotor shaft until properly aligned.

SERVICE

Contact your local Hobart office.

FORM 34046 Rev. B (7-99) PRINTED IN U.S.A.

– 36 –

Loading...

Loading...