Page 1

HQC45 & HQC90 QUICKCHILLERS &

HQCF45 QUICKCHILLER-FREEZER

MODEL

HQC45 ML-124066

HQCF45 ML-124067

HQC90 ML-124068

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34639 Rev. A (Sept. 2001)

Page 2

Model HQC45 Model HQCF45 Model HQC90

QuickChiller QuickChiller-Freezer QuickChiller

With Legs With Casters With Casters

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

UNCRATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LEGS OR CASTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended Pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fan Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION OF REMOTE ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION CHECKOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

HOBART CORPORATION, 2001

– 2 –

Page 3

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OVER-TEMPERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PRINTER SUPPLIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LOADING ROLL STOCK ONTO THE PRINTERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Plain Thermal Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adhesive-Backed Label Stock for Optional Label Printer . . . . . . . . . . . . . . . . . . . . . 9

WHEN POWER IS RESTORED AFTER A POWER INTERRUPTION. . . . . . . . . . . . . . . 9

MAIN MENU — Chill: BY TEMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MAIN MENU — Chill: BY TIME. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

MAIN MENU — Chill: BY PROD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PRODUCT LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HOLD PROD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DEFROST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PRINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SETUP — PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SETUP — USERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SYS PAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PROBES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TEMPS IN °F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LOGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

REMOTE ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MODE Parameters — CHILL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MODE Parameters — SOFT CHILL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

MODE Parameters — FREEZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

BUZZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

FACTORY PRESETS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

COMMUNICATION WITH SmartChill™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

CONDENSER COIL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

EVAPORATOR COIL, CONDENSATE LOOP AND CONDENSATE REMOVAL PAN . 32

ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MAINTENANCE PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

– 3 –

Page 4

Installation, Operation, Use and Care of

HQC45 & HQC90 QuickChillers &

HQCF45 QuickChiller-Freezer

SAVE THESE INSTRUCTIONS

GENERAL

The HQC45 QuickChiller is designed for rapid chilling of 45 pounds of food (9 pounds of food per pan

in five 12" x 20" x 21⁄2" pans or five 18" x 26" sheet pans) from 150°F to 37°F in approximately 90 minutes.

The rapid chilling process preserves food quality, texture and nutritional value for up to 5 days. As

many as 5 chill cycles can be handled per 8 hour shift. At the end of a chill cycle, the chiller

automatically goes into Hold mode at normal refrigerator temperatures, enabling overnight chilling.

The HQCF45 QuickChiller-Freezer is designed to chill exactly like the HQC45 and it can also freeze

product down to – 20°F. Freezing time varies according to the initial and final product temperatures

as well as product type and quantity. Coated wire shelves can accommodate five full-size 12" x 20"

1

⁄2" pans or five 18" x 26" sheet pans.

x 2

The HQC90 QuickChiller is designed for rapid chilling of 90 pounds of food (9 pounds of food per pan

in ten 12" x 20" x 2

shelves can accommodate ten full-size 12" x 20" x 2

1

⁄2" pans) from 150°F to 37°F in approximately 90 minutes. Optional coated wire

1

⁄2" pans or five 18" x 26" x 21⁄2" pans.

Chill and Freeze times are dependent upon product type, thickness, density, thermal conductivity, and

type of covering. For best results, approximately 9 pounds of product per 12" x 20" x 2

1

⁄2" pan or

18" x 26" sheet pan is recommended. If more product per pan is being chilled, the time required to

chill will be increased.

Cabinets are provided with a junction box in the lower section which allows for permanent, hard-wire

connection. Stainless steel legs or casters are available accessories.

The durable stainless steel interior has coved corners for ease of cleaning. The exterior sides, front,

and back are stainless steel. Left or right door swing is available on order and cannot be changed in

1

1

the field. Compressors supplied by Hobart are rated

3

1

are rated

⁄4 HP on HQC90. Refrigerant is R404A. Remote refrigeration system or water cooled

⁄4 HP on HQC45 and HQCF45. Compressors

refrigeration system are optional. Location of RS232 port for SmartChill is standard in front behind the

printer door and optional at the rear.

The SmartChill™ controller provides the ability to:

• Select the chill mode: By Product, By Time or By Temperature (Chill or Freeze, model HQCF45).

• Display the current air and product temperatures and time.

• Monitor product temperature with three smart probes to reduce chances of freezing.

• Select Soft Chill to reduce the chances of freezing in the final phase of chilling.

• Provide service diagnostics to quickly check machine functions and control circuitry.

• Send Chill Cycle data via RS232 port to SmartChill™ computer software, state-of-the-art

HACCP data management.

The standard printer provides the ability to:

• Print data from the last or any chill cycle with time, date, and temperature information.

• Charts chill temperatures vs. time at intervals that can be set by the supervisor.

An optional second printer can print a condensed ‘Label’ type of report with Product and User info.

• Printers provide HACCP reporting of chill data.

– 4 –

Page 5

INSTALLATION

Before installing, check the electrical service to make sure it agrees with the electrical specifications

on the rating plate located inside the cabinet.

UNCRATING

Immediately after unpacking, check for possible shipping damage. If the chiller is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

DO NOT LAY THE CHILLER ON ITS FRONT, BACK OR SIDES. EXERCISE EXTREME CARE WHEN

REMOVING THE CRATE BOTTOM ESPECIALLY WHEN THE LAST SHIPPING BOLT IS REMOVED.

CABINET MUST BE PROPERLY BLOCKED AND STABLE.

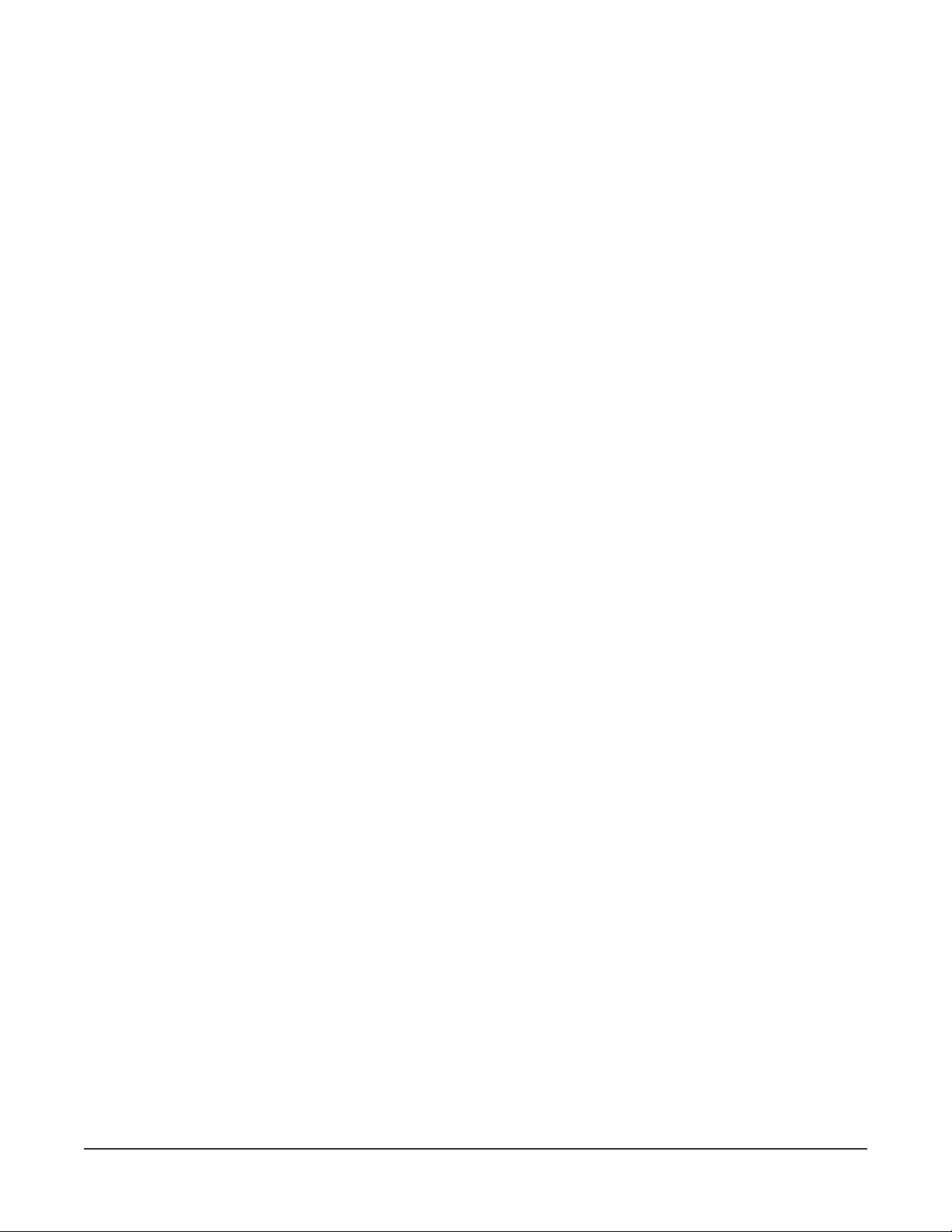

Cabinet is bolted onto a wood shipping base from underneath using the Threaded Hole (Fig.1).

Remove shipping bolts.

LEGS OR CASTERS

The HQC45, HQCF45 and HQC90 must be installed with legs or casters.

WARNING: THE CABINET MUST BE BLOCKED AND STABLE BEFORE INSTALLING THE LEGS OR

CASTERS.

Legs (Optional)

To install the legs, raise up and block the cabinet a minimum of 7" from the floor and thread the legs

into the threaded holes on the bottom of the cabinet.

The chiller must be level to operate properly. Turn the adjustable feet in or out as required to level the

chiller front-to-back and side-to-side (Fig. 1).

Casters (Optional)

Casters may be supplied for use on self-contained units. The swivel casters with brake should be

installed in front; casters without brake, in rear (Fig. 2). Caster equipped chillers should be located on

a level floor.

Fig. 1 Fig. 2

– 5 –

PL-50909

Page 6

LOCATION

Good air circulation at the condenser coil in the lower section is necessary to provide proper operation.

The cabinet may be located in any one of the following three ways to assure satisfactory performance.

• The unit can be situated so the lower back section is open to room air, allowing free air discharge.

No side clearance and no top clearance is required. This is the preferred situation and provides

the most effective cooling.

• The unit can be provided with no side clearance, two inches of clearance at the rear, and six inches

of clearance above.

• If the unit is situated with no back clearance and no top clearance, it is necessary to provide either

five inches of clearance on each side or ten inches of clearance on one side of the cabinet.

NOTE: Performance is enhanced when the air going into the condenser coil through the lower front

section is cool. For example, locating the chiller adjacent to an oven would not be recommended.

FEATURES

Shelves (Set of Five)

A set of five shelves is optional on HQC90. A set of five shelves is standard with HQC45 and HQCF45.

Shelf clips are packed with the shelves. For each shelf, insert two front shelf clips and two rear shelf

clips into the pilaster slots at the same height. After installing shelf clips on pilasters, place shelves

on clips.

Optional single shelves are available; up to eight shelves can be installed in the cabinet at one time.

Recommended Pans

1

Full size 12" x 20" x 2

⁄2" pans or 18" x 26" sheet pans are recommended. Pans are not included.

Probes

During a chill cycle, insert probes in pans of food to

monitor temperatures. Probes should not touch

bottom of pan. Place probe in the middle of the food

for best temperature indication.

The Top Probe in the cabinet corresponds to Probe 1

(Fig. 3); the Center Probe is Probe 2; the Bottom

CHILLING AIR: 14°F

1 159

2 154°F

0:00:03 ADD/REMOVE

°F 156°F 3

Fig. 3

Probe is Probe 3.

Door Switch

When the door is opened, the door switch shuts off fans and DOOR OPEN displays. If the door is open

D

for 30 seconds, the refrigerant valve closes. If the door is open for 120 seconds (or the

OOR OPEN

time setting on page 25), a buzzer sounds. After the door closes, timer and chiller operations resume.

Fan Door Switch

A fan door switch also shuts the fans and refrigerant valve off if the metal fan grill is not properly

fastened in place. A notice displays: WARNING !!! FAN DOOR IS OPEN. CALL HOBART SERVICE

FOR REPAIR. If the operator and supervisor cannot shut the interior fan door, contact Hobart Service.

The chiller will not operate with the fan door open.

– 6 –

Page 7

ELECTRICAL CONNECTIONS

Line voltage supplied to the cabinet junction box must not be affected by the operation of other

electrical equipment. Junction box is located at the rear of the lower section. The rear compressor

cover is maintained in place with Velcro. Pull to remove it.

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

The circuit should be protected with a Dual Element Time-Delay Fuse or Inverse Time Circuit Breaker.

INSTALLATION OF REMOTE ALARM (Optional)

The chiller provides a connection for a remote alarm that operates when the buzzer sounds on

completion of a chill cycle. Connect to terminals on terminal block (# 5 and # 6 in the upper section

of the chiller) per the wiring diagram and these restrictions:

–

1. Maximum remote alarm rating: 120

240 Volts at 2 amps resistive or 100 watt incandescent lamp.

2. Connection must be made of 600 volt insulated wire suitable for supply voltage. Do not use bell

wire, lamp cord or similar type wire.

INSTALLATION CHECKOUT

The self-contained refrigeration system (when equipped) is shipped fully charged with refrigerant and

requires only proper electrical connections. Remote refrigeration systems must be installed, connected

and charged by others.

After proper electrical connections are made, place the switch next to the control in the On position.

– 7 –

Page 8

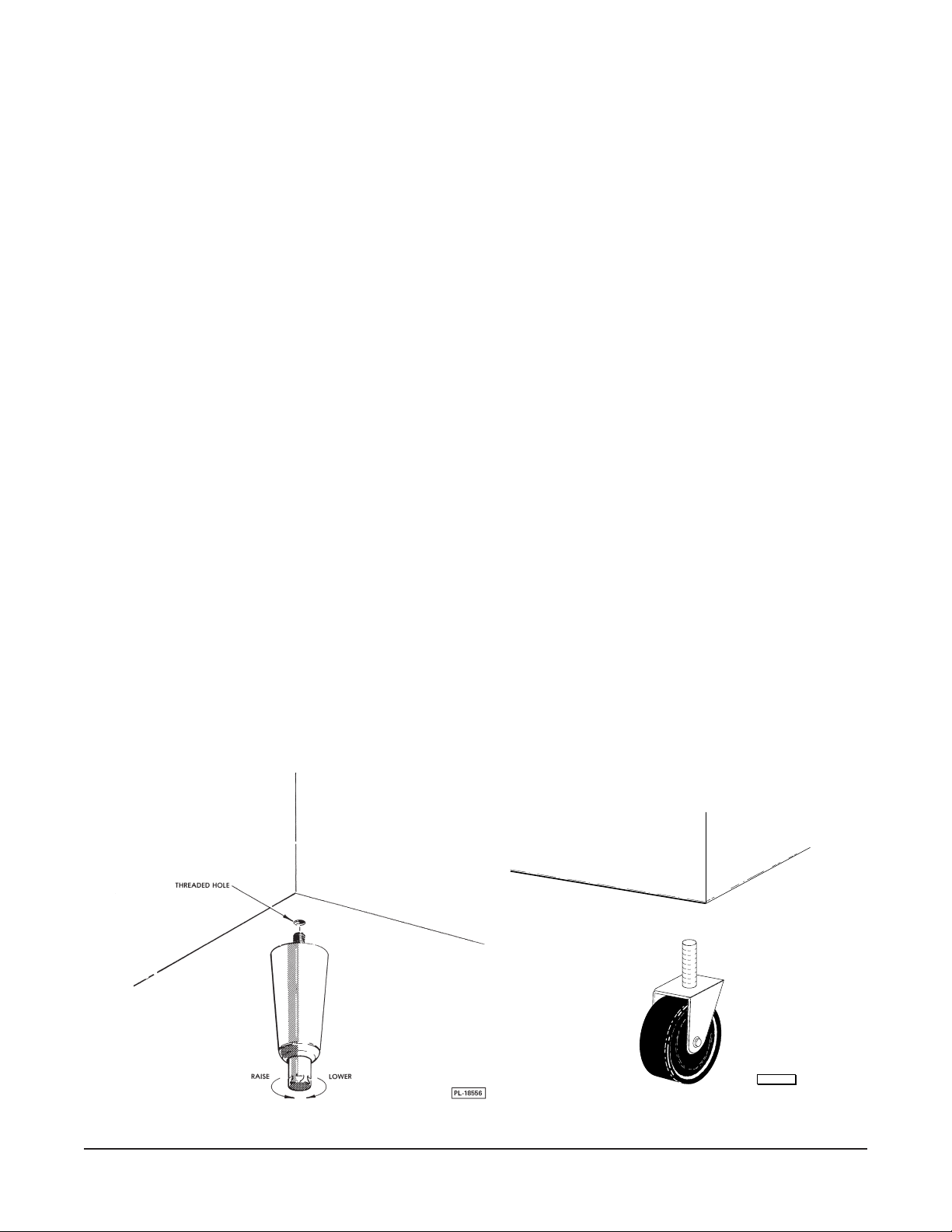

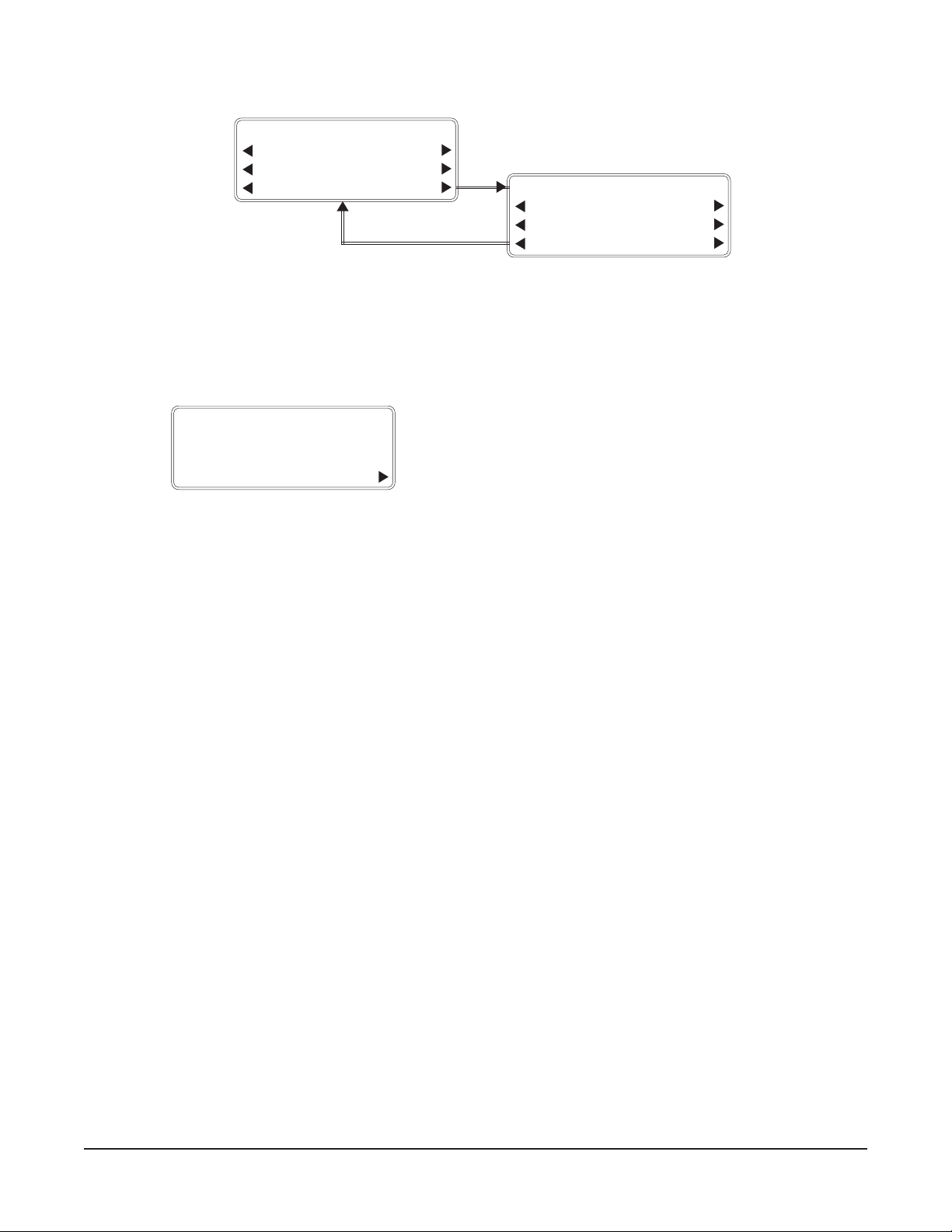

CONTROLS (Fig. 4)

OPERATION

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

Fig. 4

Choose a selection from the menu that appears on the control’s display by pressing the button

graphically connected to the display prompt. Four buttons are arranged on the left and four on the right.

For example, to select By Temp, press the second button on the left.

START-UP

SmartChill

HQC90

INITIALIZING

VERSION 1.00

OVER TEMPERATURE

If CAUTION HI AIR 150°F displays, turn the chiller off, open the door and allow the excessively high

temperature and humidity to evacuate the chamber. Then restart the chiller and resume the chill cycle.

If air temperature increases to 160°F, the unit will shut down and service must be called.

The screen at left is displayed when the chiller is first

turned on.

– 8 –

Page 9

PRINTER SUPPLIES

Printer supplies are available from your local Hobart sales and service office.

1

The standard printer uses 2

/4" thermal printer paper, Hobart Part Number 434409, per roll. Minimum

order quantity: 50 rolls per 1 case. Roll length is 80 feet.

The optional label printer uses peel-off label stock, Hobart Part Number 434408, per roll. Minimum

order quantity: 50 rolls per 1 case. Each roll contains 225 labels.

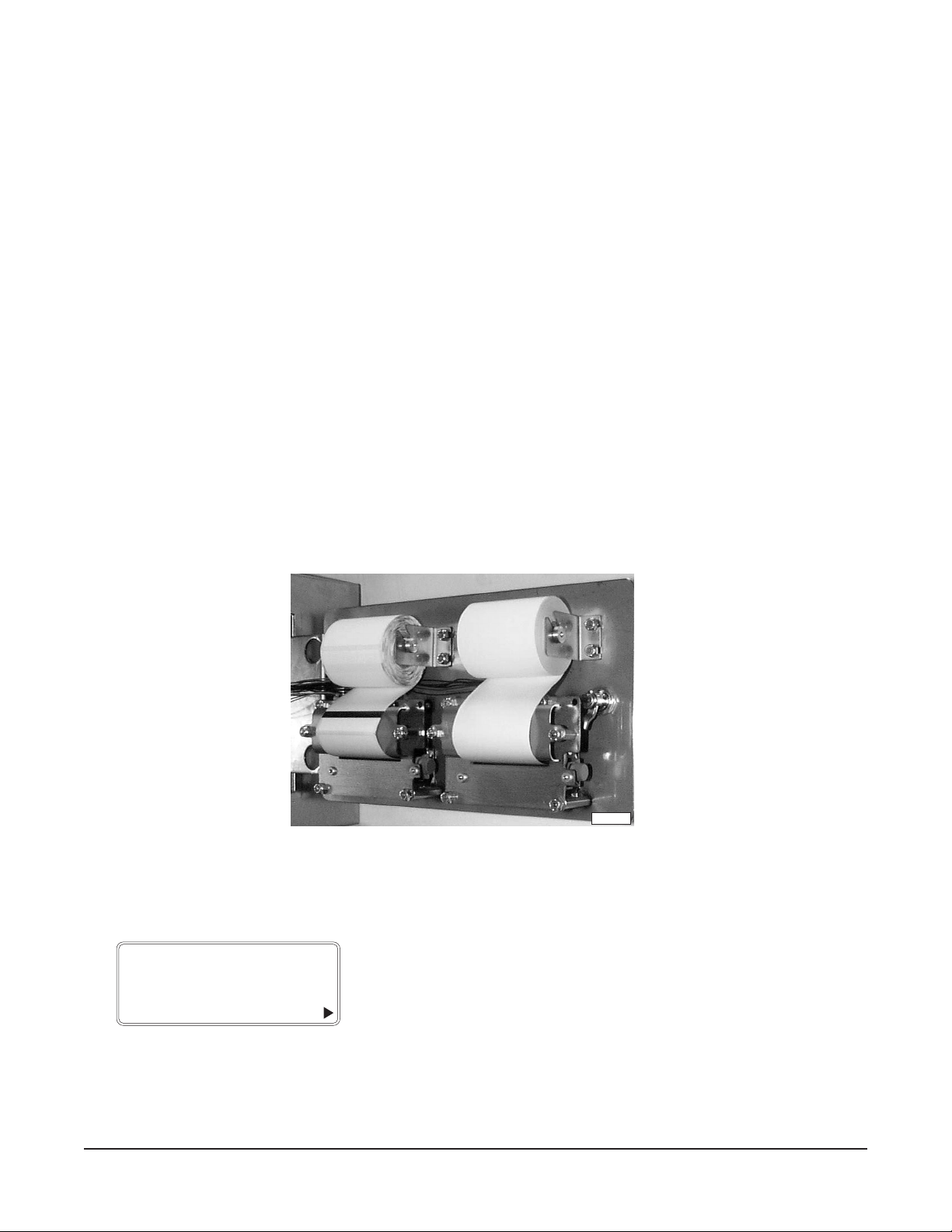

LOADING ROLL STOCK ONTO THE PRINTERS (Fig. 5)

Plain Thermal Paper

A roll is placed on the printer shaft. The ends of the printer shaft are installed in the two roll holders.

Follow the diagram on the back of the printer so the paper is correctly fed through the printer. The

bottom of the roll feeds down over the feeder bar and into the printer. The printer mechanism will

automatically advance the paper through the slot. If this is done properly, the correct side of the thermal

paper can be activated by the thermal printer head.

Adhesive-Backed Label Stock for Optional Label Printer

A roll of label stock is placed on the printer shaft. The ends of the printer shaft are installed in the two

roll holders. Follow the diagram on the back of the printer so the paper is correctly fed through the

printer. The bottom of the roll feeds down over the feeder bar and into the printer. The printer

mechanism will automatically advance the label paper through the slot.

PL-41530

Fig. 5

WHEN POWER IS RESTORED AFTER A POWER INTERRUPTION

The display indicates the time and duration of any power

interruption that occurs during a Chill cycle. The operator can

CYCLE INTERRUPTED:

FROM 3/15/01 10:17

UNTIL 3/15/01 13:22

CONT. CHILLING OK

make appropriate decisions about food stored in the chiller.

Press OK to continue. A

CYCLE INTERRUPT

Then, the system resumes at the previous activity. Return to the

Main Menu for any other action.

NOTE: The display indicates

CYCLE INTERRUPTED

the power switch is turned off and on during any chilling, holding,

or freezing mode. Always stop chilling by returning to the Main

Menu before turning the power switch off.

– 9 –

report is printed.

any time

Page 10

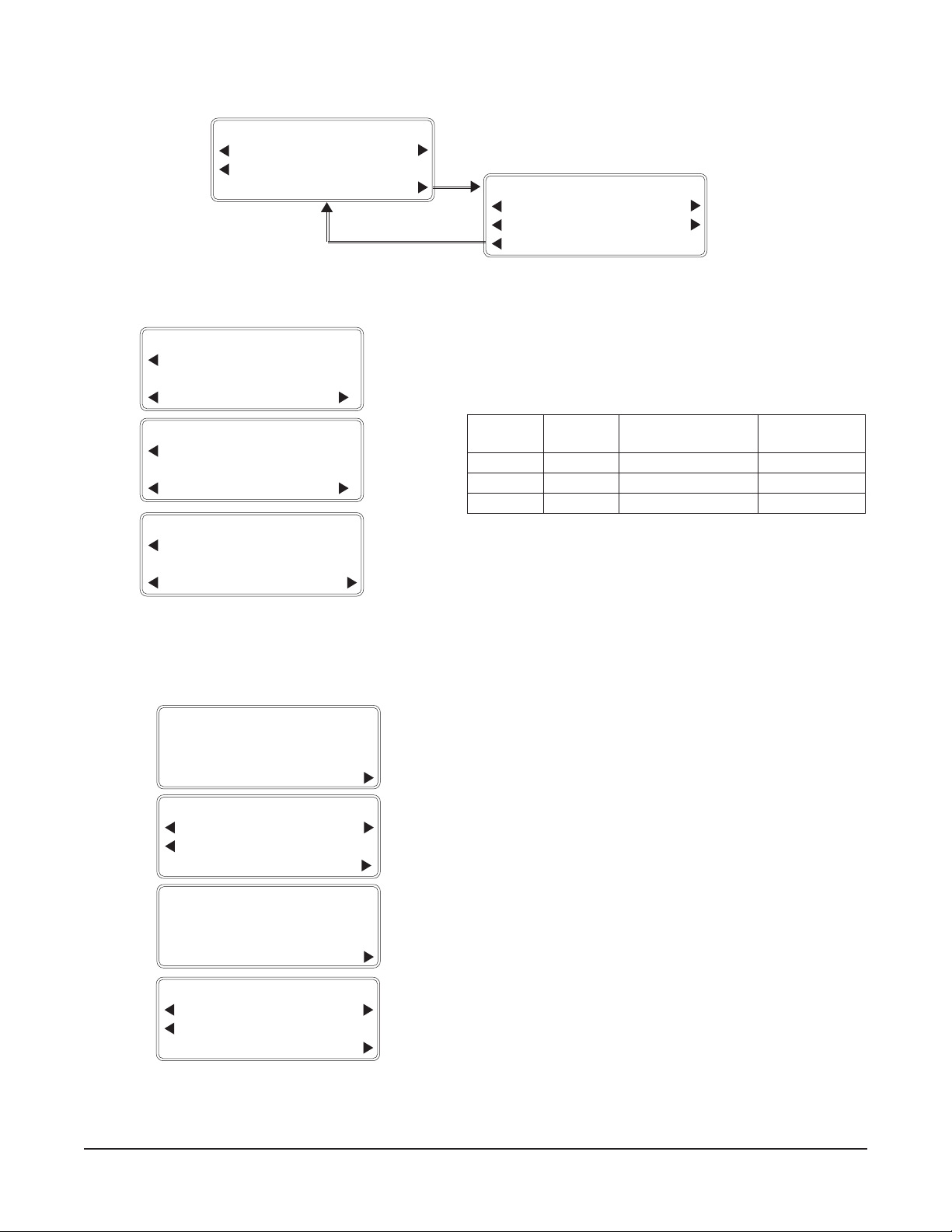

MAIN MENU

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

BY TEMP —

BY TEMPERATURE

TYPE: CHILL

↓TARGET TEMP: 37

MAIN START

BY TEMPERATURE

TYPE: SOFT CHILL

↓TARGET TEMP: 37

MAIN START

BY TEMPERATURE

TYPE: FREEZE

↓TARGET TEMP: 0

MAIN START

❄

CHILLING AIR: 14°F

1 159

2 154°F

0:00:03 ADD/REMOVE

Chill Cycle is complete when any (or all) product probe(s) reaches the Target Temp.

From the Main Menu, select BY TEMP.

°F↑

°F↑

°F↑

• Select the Type: CHILL, SOFT CHILL or FREEZE*.

SEIRESPMETYB

FCQH,CQHLLIHC73°F 04OT33°**F

FCQH,CQHLLIHCTFOS73°F 04OT33°**F

FCQHEZEERF0°F 82ot22–°F

55otdednetxeebnacegnaR**°F .62egapees—derisedfirosivrepusyb

TESERPYROTCAF

PMETTEGRAT

EGNAR

• To adjust the TARGET TEMP: Press ↓ or ↑.

• Insert probes in product — smart probes sense

temperature of product and are automatically selected.

• Close the door.

• To begin Chilling, select START.

(MAIN returns to the Main Menu.)

°F 3

• To add more product while chilling: Open door; insert

probe in product; close door; press ADD/REMOVE.

SELECT PROBE:

1 159°F 3

2 154°F

0:00:07 CONTINUE

CHILLING AIR: 14°F

1 159

2 154°F

0:00:19 ADD/REMOVE

CHILLING AIR: 14°F

1 41°F DONE 3

2 44°F

1:16:01 MUTE

°F 156°F 3

* Some chill types are not available

on all models.

• If any probes are

O

FF

, select the desired probe(s).

• Press CONTINUE.

• The chill time displays in the lower left corner —

Hr: Min: Sec.

☛ A probe has reached the target temperature.

• Press MUTE or select the ‘done’ probe’s number to

silence the buzzer.

(This step is repeated as each probe reaches the

target temperature; see next page.)

– 10 –

Page 11

CHILLING AIR: 14°F

1 41°F DONE 3

2 44°F

1:16:01 ADD/REMOVE

SELECT PROBE:

1 41°F DONE 3

2 44°F

1:16:08 CONTINUE

SELECT PROBE:

1 39°F REMOVE 3

2 44°F

1:16:28 CONTINUE

PRINT PROBE #3

NONE RECORD

• Press ADD/REMOVE.

• If all probes are ‘done

the display goes to

HOLDING.

HOLDING AIR: 37°F

,’

1 DONE DONE 3

2 DONE

1:16:01 ADD/REMOVE

• Select the ‘done’ probe’s number to remove it.

• Remove all product associated with the ‘done’ probe.

• Select any other probe’s

number to stop cycle

and remove it. Answer

YES or NO.

STOP CYCLE ON #2

REMOVE PRODUCT?

NO YES

• Press CONTINUE.

• Select NONE to continue chilling with no report.

• Or, select RECORD to print a Chill Report on Probe

#3. Refer to the alternate Print Probe menu at the

bottom of this page.

CHILLING AIR: 13°F

1 39

2 44°F

1:17:42 ADD/REMOVE

CHILLING AIR: 14°F

1 DONE 3

2 40°F

1:19:02 MUTE

PRINT PROBE #3

LABEL

°F 3

PRINTING

PLEASE WAIT...

RECORD

NONE BOTH

• Repeat from ☛ as each probe reaches the target

temperature.

• When all probes are done, return to the Main Menu.

• If equipped with the optional label printer, an alternate

Print Probe menu, shown at left, permits the choice of

printing . . . RECORD, LABEL or BOTH . . . types

of reports.

– 11 –

Page 12

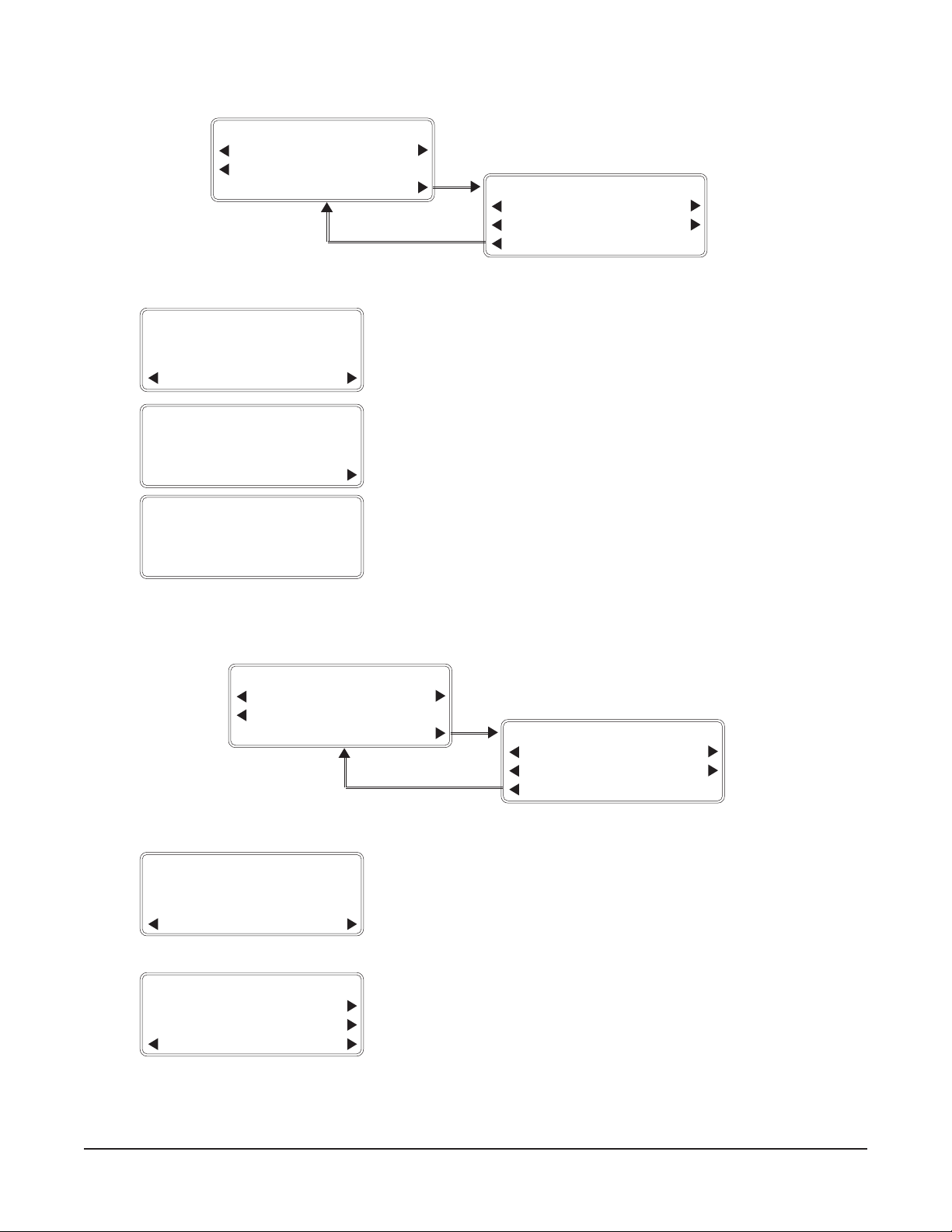

MAIN MENU

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

BY TIME —

BY TIME

TYPE: CHILL

↓CYCLE TIME: 01:30↑

MAIN START

BY TIME

TYPE: SOFT CHILL

↓CYCLE TIME: 01:30↑

MAIN START

BY TIME

TYPE: FREEZE

↓CYCLE TIME: 01:30↑

MAIN START

❆

Timer counts down until cycle is done.

From the Main Menu, select BY TIME.

• Select the Type: CHILL, SOFT CHILL or FREEZE*.

• To adjust the CYCLE TIME: Press ↓ or ↑.

• To begin Chilling, select START.

DOOR OPEN AIR: 14°F

1 159

2 154°F

1:30:00 STOP/RESET

°F 156°F 3

• Close the door.

• Probes display temperatures but have no effect on the

• Select STOP / RESET to obtain these menu items:

BY TIME

ADD 30 MINUTES

RESET TIMER

STOP CONTINUE

SEIRESPMETYBGNITTESEMITLAITINIEGNAREMIT

FCQH,CQHLLIHC03:1000:42OT10:00

FCQH,CQHLLIHCTFOS03:1000:42OT10:00

FCQHEZEERF03:1000:42OT10:00

(MAIN returns to the Main Menu.)

chilling process.

ADD 30 MINUTES adds 30 minutes to the timer.

°

RESET TIMER re-starts at the original time setting.

°

CONTINUE resumes the cycle at the time remaining.

°

STOP allows a report to be printed and then returns

°

to Main Menu.

CHILLING AIR: 14°F

1 159

2 154°F

1:29:57 STOP/RESET

HOLDING AIR: 14°F

1 39°F 4 2°F 3

2 44°F

0:00:00 MUTE

°F 156°F 3

• Time Remaining displays in the lower left corner —

Hr: Min: Sec.

☛ The timer has counted down to 0:00:00. The chiller

changes to HOLDING Mode.

• Press MUTE to silence buzzer.

* Some chill types are not available on all models.

– 12 –

Page 13

HOLDING AIR: 14°F

1 39°F 42°F 3

2 44°F

0:00:11 STOP/RESET

PRINT

• The total time since the cycle was finished is displayed

— Hr: Min: Sec.

• Remove all chilled product.

• Press STOP/ RESET.

• Select NONE to continue without printing.

NONE RECORD

PRINTING

PLEASE WAIT...

MAIN MENU

PRINT

RECORD

LABEL

NONE BOTH

• Select RECORD to print a Chill Report. If equipped

with the optional label printer, refer to the alternate

Print menu below. NOTE: Chilling BY TIME does not

retain Product Probe temperature data in memory and

will not print

TEMP vs. TIME information.

• After printing or selecting NONE, return to Main Menu.

• If equipped with the optional label printer, an alternate

Print menu, shown at left, permits the choice of printing

. . . RECORD, LABEL or BOTH . . . types of reports.

– 13 –

Page 14

MAIN MENU

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

BY PROD —

SELECT USER:

↓TIM SMITH ↑

BACK SELECT

SELECT PRODUCT:

↑CHICKEN PARTS

↓SOUP VEGETABLE

Recalls programmed chill parameters for the product, either BY TEMP or BY TIME.

From the Main Menu, select BY PROD.

• If two or more users have been entered, use the ↓ or

↑ keys until the users name is displayed. Then press

SELECT.

• The two products displayed are the most recently

chilled products. The ↓ key will access the next

MAIN MENU

enabled product from the product list, etc.

• Press the

key beside the product name to recall that

product’s chill parameters and begin chilling.

(MAIN returns to the Main Menu.

NOTE: If the product you wish to select is

on the Product List on page 16 but is not

available from the Select Product screen,

it needs to be enabled. The Supervisor

should refer to Setup Products, page 19.

– 14 –

Page 15

If the selected product was set to chill BY TEMP:

CHILLING AIR: 14°F

1 159

2 154

0:00:03 ADD/REMOVE

°F 3

°F

If the selected product was set to chill BY TIME:

• Follow the cycle run information on pages 10 – 11

beginning at

❄.

CHILLING AIR: 14°F

1 159

2 154

1:29:57 STOP/RESET

NOTE: If the chill parameters for the product

you selected do not chill the way you want,

the product’s chill settings need to be edited.

The Supervisor should refer to Setup

Products, page 19.

°F 156°F 3

°F

• Follow the cycle run information on pages 12 – 13

beginning at

❆.

– 15 –

Page 16

PRODUCT LIST

Any product from the PRODUCT LIST can be chilled using the BY PROD mode, once it has been

enabled in Setup Products (page 19). Only CHICKEN PARTS and SOUP VEGETABLE are initially

enabled as preset at the factory.

NOTE: All products are initially set in the BY TEMP – CHILL mode with a Target Temp of 37°F and

Hold Temp of 37°F.

ASPARAGUS LAMB SALAD POTATO

BEANS LASAGNA SANDWICHES

BEANS BAKED LIVER SAUCE

BEEF MACARONI & CHEESE SAUCE CHEESE

BEEF CREAMED MACARONI & GROUND BEEF SAUCE MEAT

BEEF ROAST MEAT SAUCE TOMATO

BEEF TIPS MEAT GROUND SAUSAGE

BROCCOLI MEAT LOAF SOUP BEAN

CABBAGE STUFFED MEAT SLICED SOUP CREAM OF CELERY

CARROTS MEAT WITH SAUCE SOUP POTATO

CASSEROLE OATMEAL SOUP TOMATO

CEREAL COOKED PASTA SOUP VEGETABLE

CHICKEN & DUMPLINGS PEAS SPAGHETTI

CHICKEN PARTS PEPPERS STUFFED STARCH DISH

CHICKEN POT PIE PORK STEAK

CHOWDER CORN PORK CHOPS STEAK CHOPPED

COLE SLAW POTATO MASHED STEAK SALISBURY

COMBINATION DISHES POTATO SLICED STEAK SWISS

CORN POTATOES STEW

DRESSING CORNBREAD POTATOES SCALLOPED STEW BEEF

FISH BAKED POULTRY TACO MEAT

FISH BREADED POULTRY SLICED TUNA SALAD

GRAVY POULTRY WITH SAUCE TURKEY BREAST

GRITS PRE PLATES TURKEY ROAST

HAM RICE VEAL CHOPS

JELLO ROAST WHOLE VEGETABLES

– 16 –

Page 17

HOLD PROD —

After Chilling or when selected, runs the chiller like a regular refrigerator.

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

From the Main Menu, select MORE and HOLD PROD.

SELECT HOLD MODE:

REFRIGERATOR

FREEZER

BACK

HOLDING AIR: 34°F

1 37

2 37

0:00:04 EXIT

NOTE: Freezer Hold mode is only

available on Model HQCF45.

°F 37°F 3

°F

• Select REFRIGERATOR or FREEZER mode, if

available.

(BACK returns to the Main Menu.)

(Temperatures are indicated for air and probes.)

(Timer indicates the run time.)

(EXIT returns to the Main Menu; however, Hold mode

continues until another selection is made.)

NOTE: HOLD mode does not retain temperature vs. time

data in memory; printed reports are not available.

– 17 –

Page 18

DEFROST

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

READY TO DEFROST

REMOVE FOOD

CANCEL START

DEFROSTING

COIL 12

TIME REMAINING 19:52

EXIT

DEFROST

NOT REQUIRED

°F

NOTE: DEFROST starts automatically after 6 hours of

chilling but only if operating in Holding mode.

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

From the Main Menu, select MORE and DEFROST.

• To begin Defrosting, remove food and select START.

(CANCEL returns to the Main Menu.)

• The DEFROST cycle runs 20 minutes or until the Coil

Temperature reaches 50°F.

(EXIT returns to the Main Menu.)

• If DEFROST NOT REQUIRED is displayed, return to

Main Menu is automatic.

PRINT —

PRINT CYCLE #____

PROBE #_ MM/DD HH:mm→

←BACK SELECT NEXT→

PRINT PROBE #_

Once a chill cycle is done, data can be printed.

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

MAIN MENU 08:06:01

From the Main Menu, select MORE and PRINT.

• The last chill cycle displays Probe # (if BY TEMP),

MM/DD (= month/day), and HH:mm (= hour:minute).

MAIN MENU PRINT

Probe # will not display if the chill cycle was BY TIME.

• Select the Cycle you want to print by pressing ← (for

previous) and → (for next).

RECORD

LABEL

NONE BOTH

• Press PRINT.

(MAIN returns to the Main Menu.)

• To print, select RECORD, LABEL or BOTH. After

printing, the display returns to the Main Menu.

HOLD PROD PRINT

DEFROST SETUP

BACK

(NONE returns to the Main Menu.)

– 18 –

Page 19

SETUP

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

From the Main Menu, select MORE and SETUP.

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

SELECT SUPERVISOR:

↓PRESET SUPERVISOR↑

↓PASSWORD (PIN): 00↑

CANCEL ENTER

SELECT SUPERVISOR:

↓TIM SMITH ↑

↓PASSWORD (PIN): 07↑

CANCEL ENTER

PRODUCTS

SETUP 09:04:11

PRODUCTS SYS PAR

USERS

MAIN MENU

SETUP PRODUCTS:

ENABLE/DISABLE

EDIT SETTINGS

BACK

PRODUCT SELECTION:

↓ASPARAGUS ↑

ENABLED: NO

BACK

• When you first enter SETUP, only Preset Supervisor is

available. On the PASSWORD (PIN) line, use the ↓ or

↑ keys until 57 is displayed as the Preset Supervisor’s

Personal Identification Number. Press ENTER.

• If users have already been setup, select the supervisor’s

name using the ↓ or ↑ keys. On the next line, use the

↓ or ↑ keys to enter their Password (or Personal

Identification Number). Press ENTER.

• From Setup, select PRODUCTS.

• Select ENABLE / DISABLE to choose what products

are enabled from the Product List. Only an enabled

product is available to chill BY PROD. Go to ☞.

• Select EDIT SETTINGS to adjust chill parameters for

any product that has already been enabled. Go to ➢.

(BACK returns to SETUP.)

☞ After selecting ENABLE / DISABLE, use the ↓ or ↑

keys to select a product from the list. Press

to

change ENABLED: NO to YES to enable the product

or to change YES to NO to disable it. The two most

recently chilled products cannot be disabled.

• BACK saves the ‘enabled’ and returns to SETUP

PRODUCTS.

↓ASPARAGUS ↑

TYPE: CHILL

↓TARGET TEMP: 37

BY TEMP MORE

↓ASPARAGUS ↑

↓HOLD TEMP: 37

BACK SAVE

°F↑

CANCEL

°F↑

➢ After selecting EDIT SETTINGS, use the ↓ or ↑ keys

to select a product. Finish all ⊗ steps to change any

setting(s).

⊗ Select the Type: CHILL, SOFT CHILL or FREEZE.

⊗ Select BY TEMP or BY TIME. Use the ↓ or ↑ keys to

adjust the TARGET TEMP if BY TEMP is displayed, or

to adjust the CYCLE TIME if BY TIME is displayed.

⊗ Select MORE and use the ↓ or ↑ keys to adjust the

HOLD TEMP.

⊗ Press SAVE to keep the changes and return to SETUP

PRODUCTS. (CANCEL returns to SETUP

PRODUCTS without saving the changes. BACK

returns to the previous screen).

– 19 –

Page 20

SETUP

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

From the Main Menu, select MORE and SETUP.

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

USERS

SELECT SUPERVISOR:

↓PRESET SUPERVISOR↑

↓PASSWORD (PIN): 00↑

CANCEL ENTER

SELECT SUPERVISOR:

↓TIM SMITH ↑

↓PASSWORD (PIN): 07↑

CANCEL ENTER

SETUP 09:04:11

PRODUCTS SYS PAR

USERS

MAIN MENU

SETUP USERS:

ADD DELETE ALL

EDIT/DELETE

BACK

SELECT USER #1:

↓TIM SMITH ↑

EDIT DELETE

BACK

ENTER NAME:

↓_ ↑

BACK NEXT

CANCEL ENTER

• When you first enter SETUP, only Preset Supervisor is

available. On the PASSWORD (PIN) line, use the ↓ or

↑ keys until 57 is displayed as the Preset Supervisor’s

Personal Identification Number. Press ENTER.

• If users have already been setup, select the supervisor’s

name using the ↓ or ↑ keys. On the next line, use the

↓ or ↑ keys to enter their Password (or Personal

Identification Number). Press ENTER.

• From Setup, select USERS.

(MAIN MENU returns to the Main Menu.)

• Press ADD to add a user to the roster. The first user

entered will automatically be given Supervisor status.

(DELETE ALL removes all users from the roster.)

(EDIT / DELETE allows a user’s security level or PIN

to be revised or the user removed from the roster.)

• To ENTER NAME: Press the ↓ or ↑ keys until the first

letter of the user’s name is entered; then, press NEXT

to move the cursor one space to the right. Repeat this

step until all letters of the user’s name are entered.

BACK moves the cursor one space to the left to edit.

• Press ENTER to save the user’s name, as displayed.

(CANCEL aborts the process.)

SETUP USER:

SECURITY LEVEL:0PER

↓PASSWORD (PIN): 00↑

ENTER

• Press

to change the security level from OPER to

SUPV or from SUPV to OPER. See above, operator

level security is only available after the first user is

entered.

• Use the ↓ or ↑ keys to select the user’s PASSWORD

(PIN).

• Press ENTER to save the user’s security level and

PIN. Return to SETUP USERS.

– 20 –

Page 21

SYS PAR

• From the Main Menu, select MORE and SETUP.

MAIN MENU 08:05:01

BY TEMP BY PROD

BY TIME

MORE

MAIN MENU 08:06:01

HOLD PROD PRINT

DEFROST SETUP

BACK

SELECT SUPERVISOR:

↓PRESET SUPERVISOR↑

↓PASSWORD (PIN): 00↑

CANCEL ENTER

SELECT SUPERVISOR:

↓TIM SMITH ↑

↓PASSWORD (PIN): 07↑

CANCEL ENTER

SETUP 09:04:11

PRODUCTS SYS PAR

USERS

MAIN MENU

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

• When you first enter SETUP, only Preset Supervisor is

available. On the PASSWORD (PIN) line, use the ↓ or

↑ keys until 57 is displayed as the Preset Supervisor’s

Personal Identification Number. Press ENTER.

• If users have already been setup, select the supervisor’s

name using the ↓ or ↑ keys. On the next line, use the

↓ or ↑ keys to enter their Password (or Personal

Identification Number). Press ENTER.

• From Setup, select SYS PAR.

• Refer to the diagram below to access Sys Par settings

(pages 22 – 29).

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

• From Sys Par 1, select MORE to access Sys Par 2.

– 21 –

Page 22

CLOCK

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

SET CLOCK: Month

00/00/00 00:00↑

↓

←BACK NEXT→

CANCEL ENTER

SET CLOCK: Day

00/00 00:00↑

↓00/

←BACK NEXT→

CANCEL ENTER

• Access the Sys Par 1 menu as shown on page 21.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

• From Sys Par 1, select CLOCK.

• Set the Month using the ↓ or ↑ keys.

• Select NEXT to move to the Day field.

• Set the Day using the ↓ or ↑ keys.

• Select NEXT to move to the Year field.

SET CLOCK: Year

↓00/00/

←BACK NEXT→

CANCEL ENTER

SET CLOCK: Hour

↓00/00/00

←BACK NEXT→

CANCEL ENTER

SET CLOCK: Minute

↓00/00/00 00:

←BACK NEXT→

CANCEL ENTER

00 00:00↑

00:00↑

00↑

(BACK returns to the previous screen.)

• Set the Year using the ↓ or ↑ keys.

• Select NEXT to move to the Hour field.

• Set the Hour using the ↓ or ↑ keys.

• Select NEXT to move to the Minute field.

• Set the Minutes using the ↓ or ↑ keys.

(NEXT returns to the Month field.)

(CANCEL returns to Main Menu without saving.)

• Press ENTER to save the clock settings.

– 22 –

Page 23

PROBES

• Access the Sys Par 1 menu as shown on page 21.

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

• From Sys Par 1, select PROBES.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

(Probe #’s 1 – 3 should be ON.)

SELECT PROBE:

1 ON ON 3

2 ON N/A 4

CANCEL ENTER

TEMPS IN

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

LOGGING

(Probe 4 is marked N/A; Not Available.)

• Select any probes marked OFF to turn them ON.

• Select ENTER to save any changes.

(CANCEL returns to SYS PAR 1 without saving any

changes.)

°F

• From Sys PAR 1:

(TEMPS IN °F indicates the control uses Fahrenheit

temperatures.)

• If TEMPS IN °C is displayed, select it to change the

control from Celsius to Fahrenheit temperatures.

• From Sys Par 1, select LOGGING.

SELECT DATA LOGGING

INTERVAL:

↓ 5 MINUTE(S) ↑

CANCEL ENTER

• Use the ↓ or ↑ keys to set the Data Logging Interval.

This determines how often the data will be logged in

memory. Range = 5, 10, 15, or 30 Minutes.

• ENTER accepts the change and returns to SYS PAR 1.

• CANCEL reverts back to the previously entered Data

Logging Interval and returns to SYS PAR 1.

– 23 –

Page 24

REMOTE ALARM

• Access the Sys Par 2 menu as shown on page 21.

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

• From Sys Par 2, select REMOTE ALARM.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

ACTIVATE REMOTE

ALARM WHEN:

PRINTER ERROR =NO

ENTER

ACTIVATE REMOTE

ALARM WHEN:

CYCLE ENDS =NO

ENTER

ACTIVATE REMOTE

ALARM WHEN:

DOOR OPEN =NO

ENTER

ACTIVATE REMOTE

ALARM WHEN:

HIGH/LOW TEMPS=YES

ENTER

• Yes closes the Remote Alarm circuit in the event of a

printer error. (Use

• Press

to move to the next field.

to change No to Yes, etc.)

• Yes closes the Remote Alarm circuit when the cycle

ends. (Use

• Press

to move to the next field.

to change No to Yes, etc.)

• Yes closes the Remote Alarm circuit whenever the

door is open for longer than the ‘Door Open’ alarm time

setting on page 25. (Use

• Press

to move to the next field.

to change No to Yes, etc.)

• Yes closes the Remote Alarm circuit if temperature is

sensed above the High Alarm Temperature limit or

below the Low Alarm Temperature limit. (Use

to

change Yes to No, etc.) Refer to pages 26 and 28 to

set the High Alarm and Low Alarm temperatures.

• Press

to move to the next field.

ACTIVATE REMOTE

ALARM WHEN:

POWER FAILURE =YES

ENTER

ACTIVATE REMOTE

ALARM WHEN:

CYCLE RUNNING =NO

ENTER

• Yes closes the Remote Alarm circuit when power is

restored after a power interruption. (Use

to change

Yes to No, etc.)

• Press

to move to the next field.

• Yes closes the Remote Alarm circuit when a cycle is

running. The Cycle Running option has a higher

precedence and overrides all other remote alarm

options, resetting them to NO. (Use

to change Yes

to No, etc.)

(Pressing

returns to . . . Printer Error.)

• Select ENTER to keep any changes and return to SYS

PAR 2.

– 24 –

Page 25

ALARMS

• Access the Sys Par 2 menu as shown on page 21.

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

• From Sys Par 2, select ALARMS.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

ALARM TIME SETTINGS:

↓DOOR OPEN=120 SECS↑

↓CLEAN COIL=30 DAYS↑

ENTER

• Use the ↓ or ↑ keys to adjust the DOOR OPEN setting.

Range = 0, 30, 60, 90, 120, 150, 180, 210, 240 seconds.

Refer to page 24.

• Use the ↓ or ↑ keys to adjust the

Range =

30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90

CLEAN COIL setting.

days. The CLEAN COIL setting determines how many

days the compressor will run before a display appears

to remind you to clean the condenser coil.

• Select ENTER to accept the displayed values and

return to SYS PAR 2.

– 25 –

Page 26

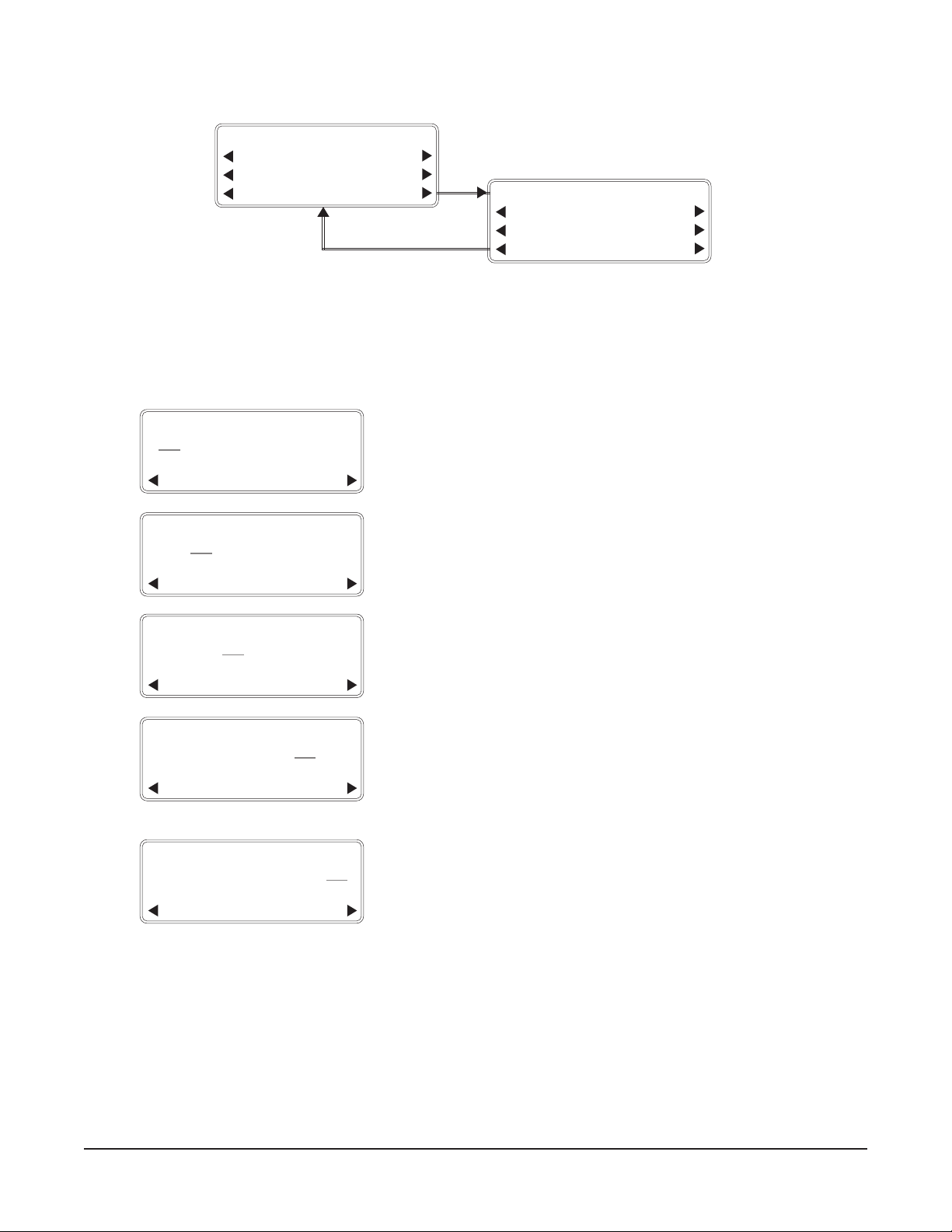

MODE

CHILL

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

MODE PARAMETERS

CHILL FREEZE

SOFT CHILL

BACK

• Access the Sys Par 2 menu as shown on page 21.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

• From Sys Par 2, select MODE.

• From Mode Parameters, select CHILL.

(BACK returns to SYS PAR 2.)

CHILL MODE EDITOR

↓TARGET 37

←BACK NEXT→

CANCEL ENTER

CHILL MODE EDITOR

↓AIR 10

←BACK NEXT→

CANCEL ENTER

CHILL MODE EDITOR

↓HOLD 37

←BACK NEXT→

CANCEL ENTER

CHILL MODE EDITOR

↓HIGH ALARM 45

←BACK NEXT→

CANCEL ENTER

CHILL MODE EDITOR

↓LOW ALARM 32

←BACK NEXT→

CANCEL ENTER

CHILL MODE EDITOR

↓CHILL MAX 40

←BACK NEXT→

CANCEL ENTER

°F ↑

°F↑

°F↑

°F↑

°F↑

°F↑

• Set the TARGET Temp using the ↓ or ↑ keys.

Range: [33°F to 40°F].

• Select NEXT to move to the next field.

(BACK returns to the previous field.)

• Set the AIR Temp using the ↓ or ↑ keys.

Range: [10°F to 40°F].

• Select NEXT to move to the next field.

• Set the HOLD Temp using the ↓ or ↑ keys.

Range: [10°F to 40°F].

• Select NEXT to move to the next field.

• Set the HIGH ALARM Temp using the ↓ or ↑ keys.

Range: [35°F to 60°F].

• Select NEXT to move to the next field.

• Set the LOW ALARM Temp using the ↓ or ↑ keys.

Range: [–30°F to 34°F].

• Select NEXT to move to the next field.

• Set the CHILL MAX Temp using the ↓ or ↑ keys.

Range: [40°F to 55°F].

(NEXT returns to the TARGET TEMP screen.)

NOTE: To extend the Target Temp range for Chill

and Soft Chill modes, first change the CHILL MAX

value. Then change the Target Temp. The Target

Temp range can be extended to as high as 55°F.

• Select ENTER to keep any changes and return to

Mode Parameters.

(CANCEL retains the previous settings and returns to

Mode Parameters.)

– 26 –

Page 27

MODE

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

MODE PARAMETERS

CHILL FREEZE

SOFT CHILL

BACK

• Access the Sys Par 2 menu as shown on page 21.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

• From Sys Par 2, select MODE.

• From Mode Parameters, select SOFT CHILL.

(BACK returns to SYS PAR 2.)

SOFT CHILL —

SOFT CHILL EDITOR

↓BY TIME 70%↑

←BACK NEXT→

CANCEL ENTER

SOFT CHILL EDITOR

↓BY TEMP 5

←BACK NEXT→

CANCEL ENTER

SOFT CHILL EDITOR

↓2ND TEMP 28

←BACK NEXT→

CANCEL ENTER

Assures against freezing by reducing air flow at end of cycle or by increasing air temp.

[ % ] x Chill Time = Time when reduced air flow occurs.

Range: [10% to 90% ].

• Set the By Time % using the ↓ or ↑ keys.

• Select NEXT to move to the next field.

[_°F ] + Target Temp = Temp when reduced air flow occurs.

Range: [ 5 to 20 °F].

°F↑

• Set the By Temp degrees using the ↓ or ↑ keys.

• Select NEXT to move to the next field.

(BACK returns to the previous field.)

[ 2nd Temp ] = Sets an alternate Air Temp during the Soft Chill cycle.

Range: [ 10°F to 40°F ]. Normal Air Temp (regular chill cycle) = 10 °F.

°F↑

• Set the 2nd Temp degrees using the ↓ or ↑ keys.

(NEXT returns to the By Time field.)

• Select ENTER to keep any changes and return to

Mode Parameters.

(CANCEL retains the previous settings and returns to

Mode Parameters.)

– 27 –

Page 28

MODE

FREEZE

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

MODE PARAMETERS

CHILL FREEZE

SOFT CHILL

BACK

• Access the Sys Par 2 menu as shown on page 21.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

• From Sys Par 2, select MODE.

• From Mode Parameters, select FREEZE.

(BACK returns to SYS PAR 2.)

FREEZE MODE EDITOR

↓TARGET 0

←BACK NEXT→

CANCEL ENTER

FREEZE MODE EDITOR

↓AIR -25

←BACK NEXT→

CANCEL ENTER

FREEZE MODE EDITOR

↓HOLD -6

←BACK NEXT→

CANCEL ENTER

FREEZE MODE EDITOR

↓HIGH ALARM 32

←BACK NEXT→

CANCEL ENTER

FREEZE MODE EDITOR

↓LOW ALARM -20

←BACK NEXT→

CANCEL ENTER

°F ↑

°F↑

°F↑

°F↑

°F↑

• Set the TARGET Temp using the ↓ or ↑ keys.

Range: [–22°F to 28°F].

• Select NEXT to move to the next field.

• Set the AIR Temp using the ↓ or ↑ keys.

Range: [–32°F to 20°F].

• Select NEXT to move to the next field.

(BACK returns to the previous field.)

• Set the HOLD Temp using the ↓ or ↑ keys.

Range: [–32°F to 20°F].

• Select NEXT to move to the next field.

• Set the HIGH ALARM Temp using the ↓ or ↑ keys.

Range: [1°F to 35°F].

• Select NEXT to move to the next field.

• Set the LOW ALARM Temp using the ↓ or ↑ keys.

Range: [–30°F to 0°F].

(NEXT returns to the TARGET TEMP field.)

NOTE: Freeze Mode is only available on

model HQCF45.

• Select ENTER to accept the displayed values and

return to Mode Parameters.

(CANCEL retains the previous settings and returns to

Mode Parameters.)

– 28 –

Page 29

BUZZER

SYS PAR 1 09:07:31

CLOCK TEMPS IN °F

PROBES LOGGING

SETUP MENU MORE

BUZZER SETTINGS:

↓ VOLUME 9 ↑

↓ TONE 3 ↑

ENTER

• Access the Sys Par 2 menu as shown on page 21.

SYS PAR 2 09:08:41

REMOTE ALARM MODE

ALARMS BUZZER

BACK FAC PRESETS

• From Sys Par 2, select BUZZER.

• Set the Volume [0 – 9 ] using the ↓ or ↑ keys.

• Set the Tone [ 1 – 8 ] using the ↓ or ↑ keys.

• Select ENTER to accept the displayed values and

return to SYS PAR 2.

FAC PRESETS

RESET SYSTEM

PARAMETERS TO

FACTORY PRESETS?

NO YES

• From Sys Par 2, select FAC PRESETS.

• Select YES to restore system parameters to the factory

preset values and return to SYS PAR 2.

• Select NO to retain the present system parameters

and return to SYS PAR 2.

– 29 –

Page 30

GLOSSARY

Alarms — Sets the buzzer intervals after Door is Open or when to be notified that the

Compressor needs to be Cleaned.

Buzzer — The control’s buzzer can have its volume and tone adjusted in the System Parameters.

By Temp — Chill cycle that terminates when the probes reach the Target Temperature.

By Time — Chill cycle that terminates after a set amount of time has lapsed.

By Prod — Chill cycle that terminates after a particular product’s specified chill parameters are

met (the parameters can be set either By Temp or By Time with specific cut-offs for

a particular product.

Chill — Chilling Cycle that may end with either Time or Temperature controlled events. (Also

see Soft Chill or Freeze).

Clock — Allows the Date and Time to be entered so the system’s clock correctly records

chilling events.

Cycle # — The system assigns a consecutive number to each Chill Cycle.

Defrost — System Controlled Defrost occurs after six hours of chilling. The defrost will not

begin during a chill cycle. The system waits until it is in Holding mode before starting

the defrost cycle. The Defrost from the Main Menu is a manual defrost that will not

run if selected and unneeded. The Defrost cycle requires about 20 minutes.

Fac Presets — Factory Presets are system parameters that are set at the factory but can be

changed by the supervisor.

Freeze — This mode is only available on model HQCF45. It allows the product to be frozen

down to a target temperature of 0°F (–18°C). The target temperature range available

for freeze mode varies from –22°F to 28°F.

Hold Prod — After a chill mode has been done or when selected from the Main Menu, the chiller

will act like a regular refrigerator (or freezer on model HQCF45).

Label — A condensed Chill Cycle Report that can be printed on adhesive-backed label stock

by the optional second label printer.

Logging — The time interval at which Chill Cycle data (temperature vs. time) is logged into

memory for record purposes. This time interval can be modified in Sys Par (System

Parameters) by the supervisor. The range of settings available for this time interval

is: 5, 10, 15 or 30 minutes.

Main Menu — The two initial menus available from the controller after the chiller is turned on.

Mode — Basic chiller operating parameters are available from Sys Par in Setup mode.

Chill mode parameters allow adjustment of the target temperature, the air temperature

during chill mode, the hold mode temperature, the high alarm temperature, the low

alarm temperature and the maximum chill mode target temperature.

Soft Chill mode parameters apply a modification of some of the Chill settings during

the final portion of the chill cycle if Soft Chill is selected. Soft Chill provides additional

protection against freezing of surfaces.

Freeze mode parameters (only available on model HQCF45) provide separate

freeze settings that allow a direct hard freeze of product.

– 30 –

Page 31

Oper — An Operator is a user who is allowed to operate the chiller and make reports of chill

cycles performed.

Print — Allows a report of any Chill Cycle and probe to be printed. Chillers equipped with

the optional second printer can print the condensed ‘Label’ type of report. All

Chillers can print the ‘Record’ type of report.

Probe # — Each probe is numbered and its temperature vs. time is recorded for each probe

# during every chill cycle and the record can be printed, either at the end of the chill

cycle or subsequently.

Product List — A list of products in system memory which can have individual chill parameters

specifically set for each product (assuming that the product is already enabled).

Refer to Setup Products.

Record — Type of report that can be printed by all chillers. This report provides a record of

time vs. temperature for a specific Probe and Chill Cycle.

Remote Alarm — The chiller can be wired to a remote alarm which will close the remote alarm circuit

in the event of one or more of the following situations: Printer Error, Cycle End,

Door Open, High or Low Temperatures or Power Failure. If Cycle Running is

chosen, the remote alarm circuit will close when a chill cycle is running and all other

remote alarm settings are overridden (reset to NO). The supervisor can determine

which events the remote alarm will signal by adjusting the settings in the Sys Par

(System Parameters) section.

Setup — Specific control settings that can be set by the supervisor which determine how the

chiller will operate.

Soft Chill — Type of chill process that moderates the temperatures and fan speed near the end

of the chill cycle to provide less risk of freezing at the product’s surface.

Supv — A Supervisor is a user who is allowed to identify the users and limit their access to

system parameters, enable products to be selected, set specific product chill

parameters and change system parameters.

Sys Par — System Parameters are control settings that determine how the chiller will operate.

These settings can be adjusted by the supervisor in Setup mode.

Temps in °C — If so displayed on the Sys Par 1 screen, all temperatures will be recorded in °C

(Celsius).

Temps in °F — If so displayed on the Sys Par 1 screen, all temperatures will be recorded in °F

(Fahrenheit).

COMMUNICATION WITH SmartChill™

COMMUNICATING WITH

COMPUTER

During communication with the SmartChill™ program

on a PC, the screen at left displays.

PLEASE WAIT...

– 31 –

Page 32

MAINTENANCE

CLEANING

Wash, rinse and sanitize the product probes before and after use as you would any food-contact utensil

that measures temperature.

Chiller surfaces of stainless steel should be wiped clean with a damp cloth or mild cleaning solution.

DO NOT flush with running water. Avoid the use of solvents around plastic or painted areas; clean

these with a damp cloth moistened with a solution of mild detergent and warm water. Clean hinge

hardware with a chrome cleaner. Use a solution of warm water and baking soda to clean the gasket;

then wipe with a soft cloth. Hinges may require occasional lubrication of the plastic cam. Do not use

the top of the chiller for storage.

CONDENSER COIL

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY PARTS OF

THE UNIT.

The lower front compressor cover is attached with Velcro. Pull to remove.

Check the condenser coil weekly. Air must be able to freely circulate through the condenser. This

surface must be kept free of dirt and grease for proper system operation. Carefully clean dirt and lint

from the condenser coil using a vacuum cleaner, whisk broom or soft brush; do not use a wire brush.

CAUTION: Do not damage the condenser coil fins. Replace lower front compressor cover.

Reconnect electrical power supply.

EVAPORATOR COIL, CONDENSATE LOOP AND CONDENSATE REMOVAL PAN

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEANING ANY PARTS OF

THE UNIT.

When needed, these components can be flushed with fresh water by a qualified service technician.

This should be part of any routine maintenance program and can prolong the life of the equipment.

Condensate removal is provided at the lower right portion of the

equipment cabinet and does not need a drain. Periodic cleaning

CONDENSER COIL

of the condensate removal pan (Fig. 6) may be needed. To

access the condensate removal pan, remove the lower front

EVAPORATOR

compressor cover which is attached with Velcro. Pull to

remove. Clean the condensate removal pan by wiping with a

clean damp cloth or sponge, using care with the condensate

loop inside. Replace compressor cover. Reconnect electrical

power supply.

ERROR MESSAGES

Contact your Hobart service technician if either of the following error messages appears: [

FAILURE ], [ DEFROST NOT WORKING ].

CONDENSATE LOOP

PL-41383-1

Fig. 6

COMPRESSOR

MAINTENANCE PROGRAM

For additional information or to discuss a maintenance program, contact your local Hobart authorized

refrigeration service company.

FORM 34639 Rev. A (Sept. 2001) PRINTED IN U.S.A.

– 32 –

Loading...

Loading...