Page 1

OVEN

HKX9 + HKS90

ELECTRIC

INSTALLATION

AND OPERATING

INSTRUCTIONS

( ) KS-90 / 2000

( ) KS-94-A / 2000

( ) KS-95 / 2000

( ) BASIC / 2000

REVISION: 6/02/01

Page 2

MANUFACTURER'S DATA

..

. .

. .

. .

.

.

.

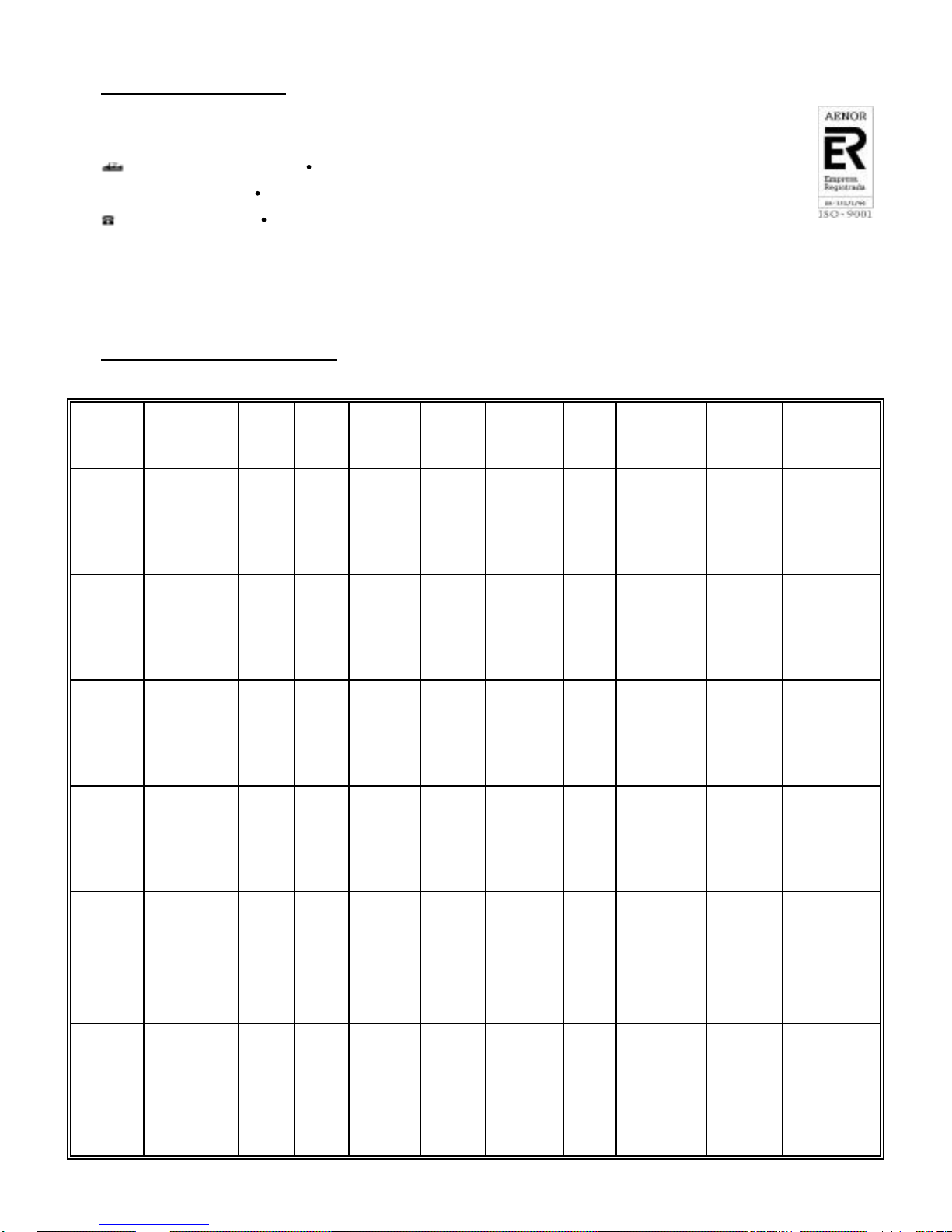

TECHNICAL CHARACTERISTICS

Type Model kW kcal/h Phases V A Hz Area

dm2/ sq. ft

96 / 10.33

230/40

KX-4+H 00 7.5 6300 3N~

18.5/10.5 50/60

0

121 / 13.2

96 / 10.33

KX-4+H 00 6 5200 I~ 230 26.5 50/60

121 / 13.2

120 / 11.6

230/40

KX-5+H 00 7.5 6300 3N~

18.5/10.5 50/60

0

152 / 16.35

120 / 11.6

KX-5+H 00 6 5200 I~ 230 26.5 50/60

152 / 16.35

Volume

dm3/ cu ft

94 / 3.3

118 /

4.15

94 / 3.3

118 /

4.15

94 / 3.3

149 /

5.24

94 / 3.3

149 /

5.24

Capacity

4 (60 x 40)

4 (66 x 46)

4 (60 x 40)

4 (66 x 46)

5 (60 x 40)

5 (66 x 46)

5 (60 x 40)

5 (66 x 46)

KX-9+H 00 14.5 12600 3N~

KX-9+H 00 12 10500 I~ 230 53 50/60

230/400

36,5/21 50/60

216 / 23.24

273 / 29.37

216 / 23.24

273 / 29.37

221 /

7.77

280 /

9.85

221 /

7.77

280 /

9.85

9 (60 x 40)

9 (66 x 46)

9 (60 x 40)

9 (66 x 46)

Page 3

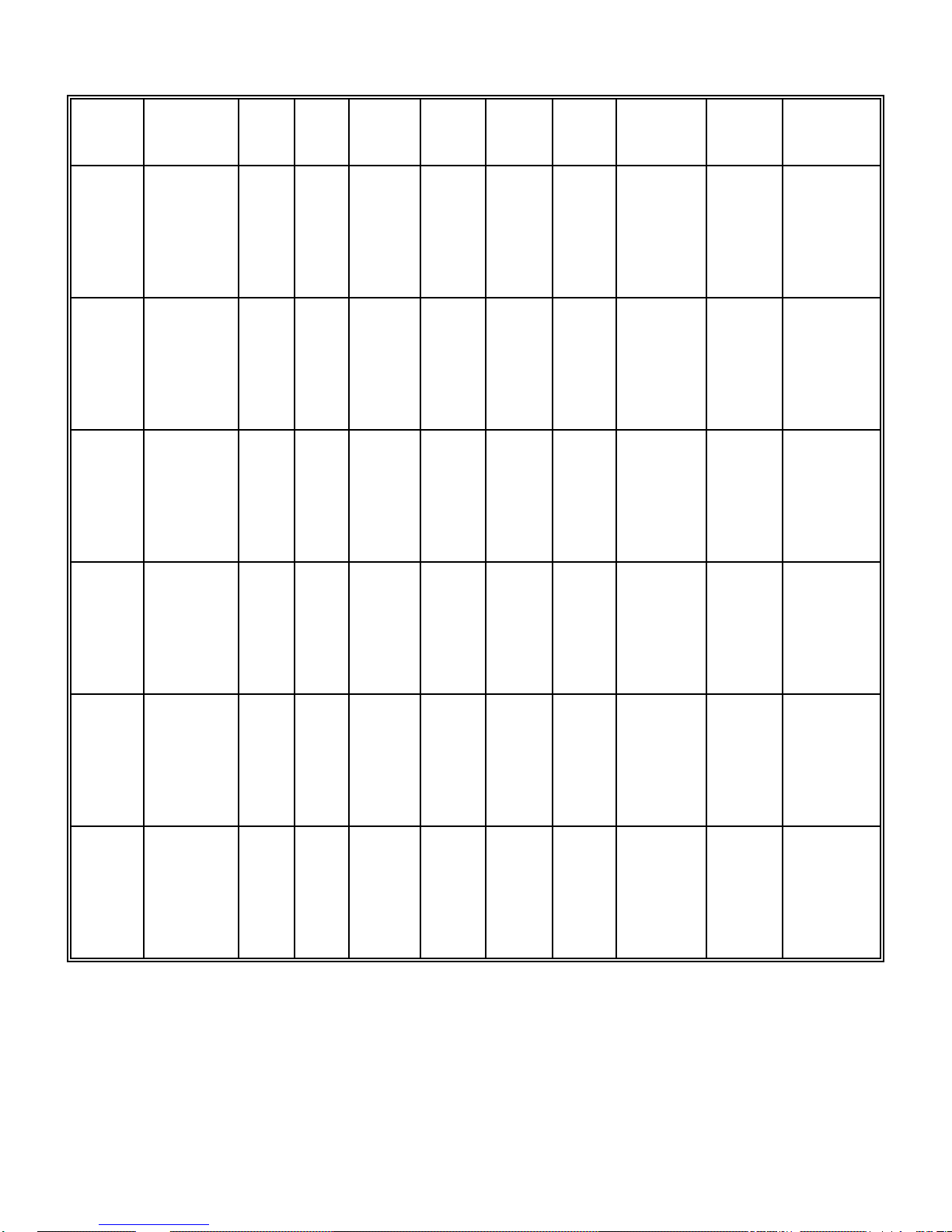

Type Model kW kcal/h Phases V A Hz Area

dm2/ sq. ft

Volume

dm3/ cu ft

Capacity

KX-10+H 00 14.5 12600 3N~

36,5/21 50/60

0

KX-10+H 00 12 10500 I~ 230 53 50/60

230/40

230/40

KL-9+H 00 14.5 12600 3N~

36,5/21 50/60

0

KL-9+H 00 12 10500 I~ 230 53 50/60

240 / 25.82

303 / 32.6

240 / 25.82

303 / 32.6

288 / 40

331 / 35.61

288 / 40

331 / 35.61

221 /

7.77

280 /

9.85

221 /

7.77

280 /

9.85

295 /

10.4

339 /

11.9

295 /

10.4

339 /

11.9

10 (60 x 40)

10 (66 x 46)

10 (60 x 40)

10 (66 x 46)

9 (80 x 40)

9 (80 x 46)

9 (80 x 40)

9 (80 x 46)

295 /

KL10+H 00 14.5 12600 3N~

230/40

0

320 / 34.43

36,5/21 50/60

368 / 39.59

10.4

339 /

11.9

320 / 34.43

295 /

10.4

KL10+H 00 12 10500 I~ 230 53 50/60

368 / 39.59

339 /

11.9

* The above indicated power figures are for standard ovens, for power other than indicated, whether

three-phase or single-phase, check chapter 1.4 ELECTRICAL CONNECTION.

10 (80 x 40)

10 (80 x 46)

10 (80 x 40)

10 (80 x 46)

Page 4

INDEX

0. WARNINGS................................................................................................................................0-1

1. PREASSEMBLY INSTRUCTIONS...........................................................................................1-1

1.1 STORAGE AND TRANSPORT..................................................................................................1-1

1.2 CONDITIONS FOR USE.............................................................................................................1-1

1.3 ACCESS TO PREMISES...........................................................................................................1-2

1.4 ELECTRICAL CONNECTION.....................................................................................................1-3

1.4.1 Three phase oven................................................................................................................1-3

1.4.2 Single phase oven...............................................................................................................1-4

1.4.3 Change of voltage of three-phase oven...............................................................................1-4

1.5 CHIMNEY...................................................................................................................................1-5

1.5.1 Outlet chimney for oven steam.............................................................................................1-6

1.5.2 Joining two ovens steam outles...........................................................................................1-7

1.6 STEAM CONDENSER................................................................................................................1-7

1.6.1 Joining two ovens steam outlets to a condenser..................................................................1-8

1.7 WATER INSTALLATION............................................................................................................1-9

1.8 DRAIN (OPTIONAL)...................................................................................................................1-9

1.9 WATER SYSTEM CONNECTION TO THE MAINS...................................................................1-10

2. DRAWINGS................................................................................................................................2-1

2.1 BACK OF THE KWIK-CO............................................................................................................2-1

2.2 GENERAL PLAN........................................................................................................................2-2

2.3 INTERIOR LAYOUT OF CHAMBER...........................................................................................2-3

3. BAKING STEAM OUTLET (OVENS FITTED WITH KS-95 PANEL ARE EXCLUDED)......3-1

3.1 DAMPER....................................................................................................................................3-1

4. MAINTENANCE INSTRUCTIONS............................................................................................4-1

Page 5

5. GUARANTEE..............................................................................................................................5-1

6. ELECTRICAL SCHEME............................................................................................................6-1

7. LIST OF SPARES......................................................................................................................7-1

7.1 ELECTRICAL BOX (6 kW – III OVENS)......................................................................................7-1

7.2 ELECTRICAL BOX (7.2 kW – III OVENS)...................................................................................7-2

7.3 ELECTRICAL BOX (8.5 kW – III OVENS)...................................................................................7-3

7.4 ELECTRICAL BOX (6 kW – I OVENS)........................................................................................7-4

7.5 ELECTRICAL BOX (7.2 kW – I OVENS).....................................................................................7-5

7.6 ELECTRICAL BOX (12 kW – III OVENS)....................................................................................7-6

7.7 ELECTRICAL BOX (14.5 kW – III OVENS).................................................................................7-7

7.8 ELECTRICAL BOX (17.5 kW – III OVENS).................................................................................7-8

7.9 ELECTRICAL BOX (12 kW – I OVENS)......................................................................................7-9

7.10 DOOR...................................................................................................................................7-10

7.11 REST OF THE OVEN...........................................................................................................7-12

7.12 CONTROL PANEL................................................................................................................7-15

8. ANNEX........................................................................................................................................8-1

8.1 ASSEMBLY OF HIGH OVEN WITH CONDENSER ON PROVER KXE-20+H OR KLE-10+H........8-1

8.2 ASSEMBLY OF SMALL OVEN WITH CONDENSER ON PROVER KXE-20+H OR KLE-10+H.....8-1

Page 6

0. WARNINGS

IMPORTANT

Read this instruction manual before switching the oven on.

FOR YOUR SAFETY

Do not use or store petrol, inflammable liquids, or gases near this equipment. Nothing should be baked

in this oven that contains alcohol or gives off inflammable gases during baking.

STARTING UP INSTRUCTIONS

This unit must be grounded for your protection in order to avoid the risk of electrical discharges. It

should be connected directly to the ground terminal of the control cabinet. The ground cable must not

be cut or disconnected from the oven.

CAUTION

During the baking process in order to avoid the possibility of burns produced by the steam, the door

shall be opened with care.

NOISE LEVEL

The acoustic power emitted by the oven is lower than 70 dB.

Keep this instruction manual in a safe and accessible place.

Page 7

1. PREASSEMBLY INSTRUCTIONS

1.1 STORAGE AND TRANSPORT

The oven is sent packed on a wooden platform, covered with plastic film, that protects the machine

against humidity and rain.

The oven should be transported in a completely closed vehicle and it should never be left outdoor.

1.2 CONDITIONS FOR USE

• The oven has been manufactured to be installed indoor. It is not made to work outdoor. Any possible

contact with water has to be avoided.

• The oven should not be installed in places with excessive heat, steam and/or humidity production.

• The oven is prepared to work under the following external conditions: -10 <t> 40 ºC (14 <t> 104 ºF),

and 0 <h> 90 % of humidity

• The room in which the oven has to be installed must have an adequate ventilation. If there is a

fumes extractor, then a window with at least the section of the fumes extractor should be kept open.

• The position of the oven regarding the side and back wall of the installation premises should have a

minimum distance of 2" (50 mm) between the oven sides and the walls of the room.

VERY IMPORTANT

The base on which the oven is fitted has to be of a nonflammable material and able to withstand a

constant temperature of 300º C (572 ºF) without deteriorating.

Page 8

1.3 ACCESS TO PREMISES

ka342ci1.dft

C

D

E

The KWIK-CO oven is shipped to the client fully assembled. Its dimensions are as follows: (Oven

dimensions with door open).

OVEN

KX-4+H

KX-5+H

KX-9+H

KX-10+H

KL-9+H

KL10+H

A

(mm / inc)B(mm / inc)C(mm / inc)D(mm / inc)E(mm / inc)

838 / 33 1682 / 66 657 / 26 915 / 36 110 / 4.33 535 / 21 120 / 264 4 100 / 3.9

838 / 33 1682 / 66 657 / 26 915 / 36 110 / 4.33 535 / 21 120 / 264 5 80 / 3.1

838 / 33 1682 / 66 657 / 26 915 / 36 110 / 4.33 1070 / 42 195 / 429 9 103 / 4

838 / 33 1682 / 66 657 / 26 915 / 36 110 / 4.33 1070 / 42 195 / 429 10 93 / 3.6

838 / 33 1842 / 73 657 / 26 1075 / 42 110 / 4.33 1070 / 42 200 / 440 9 103 / 4

838 / 33 1842 / 73 657 / 26 1075 / 42 110 / 4.33 1070 / 42 200 / 440 10 93 / 3.6

* The hood is not include. Hood + (160 mm / 6.3 inc)..

B

Height *

(mm / inc)

Weight

(kg / lbs)

Nº of trays Separation btw. trays

(mm / inc)

A

Page 9

1.4 ELECTRICAL CONNECTION

This should be carried out by authorized professionals according to regulations in the country in

question. The appropriate circuit breaker for total amperage should be installed at the same time as the

premises’ electrical installation. The appliance should also have a plug fitted. UNPLUG THE OVEN

before accessing any of its electrical parts.

1.4.1 Three phase oven

Three phases plus ground are required for 230 V connection, three phases plus neutral and ground

for 400V connection.

EN 60204-1 requires that sections for three-phase cables plus ground or four-pole plus ground be as

follows:

POWER

CONNECTION 230 V.

kW

3 phases + ground

6 2.5 mm

7.5 2.5 mm

9 4 mm

12 6 mm

14.5 10 mm

17.5 10 mm

CONNECTION 400 V.

3 phases + neutral + ground

2

2

2

2

2

2

1.5 mm

1.5 mm

1.5 mm

2.5 mm

4 mm

6 mm

2

2

2

2

2

2

Page 10

1.4.2 Single phase oven

These ovens require two phases + ground or one phase and neutral + ground for 230 V connection.

La EN 60204-1 requires that sections for two-phase cables plus ground be as follows:

POWER

CONNECTION A 230 V.

kW

2 phases + ground or 1 phase + neutral + ground

6 6 mm

7.5 10 mm

12 16 mm

14.5 25 mm

2

2

2

2

1.4.3 Change of voltage of three-phase oven

The oven is supplied totally assembled and set for 400 V.

If the current on the premises is 230 V then prior to connection it will be necessary to alter the following

components accordingly:

1- Voltage change in the terminal plates of the motor and of the heating elements.

It will be necessary to disassemble the bridges connected for 400 V and reassemble then with the

230 V connection, as shown in the figure.

IMPORTANT: Securely tighten the nuts and locknuts of all terminals.

2- Bridge the terminals "T" and "N" (See scheme).

Page 11

IMPORTANT: Before the oven is used, check that the air turbine is turning in the right direction, i.e.

from left to right as indicated by the arrow on the front separating plate of the baking

chamber. If the direction is wrong, then it will be necessary to change between two the

pin phases of the current intake on the oven cable

1.5 CHIMNEY

The steam outlet chimney should be installed by authorized professionals according to local

regulations.

Fundamental aspects:

• The chimney should preferable be insulated along its length and not in contact with combustible

materials (such as wooden beams or ceilings).

• Sections should not be horizontal, but should instead have a slope of at least 10º without bends or

elbows of radius less than twice the tube diameter.

• The chimney should incorporate a system for preventing backflow of condensates.

• It is recommended that the chimney used be insulated and of interior diameter 2 1/2".

• The steam outlet pipe from the oven should be coupled to this chimney.

Page 12

1.5.1 Outlet chimney for oven steam.

To the draft outlet it is advisable to fit a hood and conduits, of the standard type normally fitted in

the case of butane water heaters, and release into chimney or directly to the exterior.

A- Optional

Page 13

1.5.2 Joining two ovens steam outles.

When an oven is assembled on top of another oven, we recommend you to fit only one fumes outlet

for both, using a K5-K5 pipe coupling.

1 - Chimney.

2 - Outlet fumes pipe.

3 - Damp hood.

4 - Female T 90º 2 _ " x 2” x 2 _ ” G.

5 - Conical joint.

6 - Reduction nut 2 1/2" - 1".

7 - Reduction nut 1" - 3/4".

8 - Spigot 3/4" - 16 mm inside diameter pipe.

1.6 STEAM CONDENSER

When the premises are so situated that the steam outlet from the oven cannot be to the exterior, a

good solution is to fit a SALVA CV-K CONDENSER. Designed for such cases, this will condense oven

steam and facilitate its removal by drain or sink.

Page 14

1.6.1 Joining two ovens steam outlets to a condenser.

When an oven is assembled on top of another, it is advisable to join both steam chimneys toghether,

so that a single chimney is required, using a K5-K5 pipe coupling, that can then be joined to a

fumes condenser.

Page 15

1.7 WATER INSTALLATION

It is very important that feedwater to the oven be demineralized.

The place where the oven is to be installed must have a water intake on which a constant water

pressure of 1,5 kg/cm2 is assured during a steam injection by means of a pressure regulator device.

The connection between this connector and the oven will be by flexible hose-pipe of an inner

diameter of 10 mm (0.4 inc.)..

NOTE: For those cases in which water is calcareous, it is necessary to install a water softener between

the water supply and the oven intake. (Not supplied with the oven)

Fitting of the water softener decalcifier is shown in the following drawing.

A - Water intake from mains.

B - Water input to oven.

C - Drain-off from water softener.

1 - Water softener.

2 - Pressure regulator.

3 - 3/8" manual valve.

4 - Couple hose, 3/8".

5 - Coupling hose.

If a connection between point B (water softener outlet, Fig. ka0021c0.ei1) and point D (oven water

intake Fig. vistatra.dft, see point 2.1), is desired, this must be done with 3/8 “ diameter hose leaving at

both ends a 1/2 “ male pipe.

1.8 DRAIN (OPTIONAL)

It is necessary to construct a drain of diameter at least 1". This should preferably be made of metal and

should be temperature-resistant in any case. It will be coupled to the oven by a flexible hose of internal

diameter 18 mm, washing-machine type.

Page 16

1.9 WATER SYSTEM CONNECTION TO THE MAINS

5

A1-A2- Without fumes condenser

B1-B2- With fumes condenser

1- MIKALOR 8-16 Clip.

2- K-5 / 96 BASIC Solenoid valve support.

3- EV ref.: 255.208 A Solenoid valve.

4- CV-K Condenser.

5- Washing machine type water intake 10 atm.

6- ”T” 90º female _” Fig.130

7- K-5 / 96 BASIC Water inlet tube

8- ”T” 90º Plastic.

9- Water inlet restrictor.

10- Condenser solenoid valve support.

11- _” double male nipple.

12- Hose 10 ATM. 10 x 18.

3

9

ka090ci2.dft

Page 17

2. DRAWINGS

vistatra.dft

A

B

C

D

A

B

C

D

2.1 BACK OF THE KWIK-CO

OVEN

KX-4+H A B C (OPTIONAL) D

KX-5+H A B C (OPTIONAL) D

KX-9+H A B C (OPTIONAL) D

KX-10+H A B C (OPTIONAL) D

KL-9+H A B C (OPTIONAL) D

KL-10+H A B C (OPTIONAL) D

Steam

outlet

Electrical connection

(flexible hose)

Drain

(flexible hose)

Water inlet

(flexible hose)

Page 18

2.2 GENERAL PLAN

kj240ci1.dft

FIG 1

FIG 2

C

D

25

35

I

B

35

3

3

20

3

3

A

H

G

F

E

C

25

35

D

B

35

3

3

20

3

3

I

OVEN Fig.

KX-4+H 1

KX-5+H 1

KX-9+H 2

KX-10+H 2

KL-9+H 2

KL-10+H 2

A

A

(mm /

inc)

838 /

33

838 /

33

838 /331070 /42160 /

838 /331070 /42160 /

838 /331070 /42160 /

838 /331070 /42160 /

B

(mm /

inc)

535 /

21

535 /

21

(mm /

inc)

160 /

160 /

6.3

6.3

6.3

6.3

6.3

6.3

H

C

D

(mm /

inc)

695 /271160 /46105 /

695 /271160 /46105 /

1230 /481160 /46105 /

1230 /481160 /46105 /

1230 /481320 /52105 /

1230 /481320 /52105 /

E

(mm /

inc)

G

E

(mm /

F

inc)

4.1

4.1

4.1

4.1

4.1

4.1

F

G

(mm /

inc)

945 /

37

945 /

37

945 /

37

945 /

37

1105 /44110 /

1105 /44110 /

H

(mm /

inc)

110 /

4.3

110 /

4.3

110 /

4.3

110 /

4.3

4.3

4.3

I

(mm /

inc)

60 /

2.4

60 /

2.4

60 /

2.4

60 /

2.4

60 /

2.4

60 /

2.4

Page 19

2.3 INTERIOR LAYOUT OF CHAMBER

Maintenance and cleaning.

1.- To remove inner sides, first raise side, move towars inside and afterwards pull towards the

outside.

2.- Remove separator plate locknuts.

3.- Remove separator plate from chamber.

A.- Steam system.

• To reassemble, follow reverse procedure.

Page 20

3. BAKING STEAM OUTLET (OVENS FITTED WITH KS-95 PANEL ARE

EXCLUDED)

3.1 DAMPER

To open the cooking-steam outlet, pull the draft control "Z" at the top of the control panel (see drawing)

until it stops. To close, push in other direction as far as stop.

z- Damper control

1- Damper opened

2- Damper closed

Page 21

4. MAINTENANCE INSTRUCTIONS

IMPORTANT

Maintenance and reparation works should be made by the INDUSTRIAL SALVA, S.A. Official

Technical Service or by one of our distributors.

IMPORTANT: Before carrying out any repairing or servicing of the electrical oven parts, the

magnetothermical protection devices located behind the control panel must be switched off. As far

as possible, work with the current disconnected from the power supply..

Daily maintenance

The glass panes of the door are to be cleaned carefully and with soft, nonabrasive detergents, to avoid

damaging the silkscreen print. To access the inside of the panes, the mould on the opposite side of the

hinges must be slid upwards in order to let the pane down. Carry out the same procedure inversely to put

the pane back, making sure the rubber seal is well placed.

Monthly maintenance

The internal parts of the oven should be cleaned: floor, roof, and sliders (to clean the internal parts of

the oven it is necessary to withdraw the sliders from the chamber. (see point 2.3)..

The internal parts of the oven should be cleaned: floor, roof, and sliders (to clean the internal parts of

the oven it is necessary to withdraw the sliders from the chamber. (see point 2.3).

NOTE: If this oven is been used continuously without stop, the internal parts of the oven has to be

cleaned more than once a month.

6 month period maintenance (should be made by the Official Technical Service of INDUSTRIAL

SALVA, S.A.)

The motor cavity and sorroding areas must be cleaned.

NOTE: Lach of clean may causean early failure on the electrical motor.

The electrical parts of the oven should be cleaned. Special care should be taken in not wetting the

oven controls, since major faults could occur in the electrical system.

NOTE: Dust and flour could cause malfunctions of the electrical components of the electrical

control box.

Page 22

5. GUARANTEE

Our products are guaranteed against every failure or manufacturing defect, within a correct use of them.

The guarantee does NOT apply to the substitutions and mending appearing from:

• An abnormal use of the machine.

• The damage or accidents originated by negligence.

• Lack of maintenance.

• Defective installation or use of the devices.

The guarantee is limited to the replacement and repairing of damaged pieces as a consequence of

construction defects, being at your charge both manpower and travelling.

The normal guarantee time of the materials goes up to six months.

Guarantee conditions

The materials must be installed, used and kept in the conditions shown in this "Using guide".

The problems which require the help of an engineer, will only have to be solved by the After-Sales

Service Department of INDUSTRIAL SALVA S.A. or by one of our distributors.

If these watchwords are not respected, the guarantee may not apply.

INDUSTRIAL SALVA, in its constant research of improvement concerning its products, reserves the right

of making any modifications without previous notice.

Loading...

Loading...