Page 1

Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

FT900SBD

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Opti-RinSe™ system

■ Water usage 102 gph @ 20 psi

■ Microprocessor controls

■ Low temperature alert

■ Blower-Dryer

■ Single point vent connection

■ 42" access door on power wash chamber,

34" access doors on prewash chamber and

blower-dryer chamber

■ Variable speed conveyor 4-6.3 fpm

■ Start and stop switches at both ends

■ Door open indicator

■ Load end ush system

■ Door interlocks

■ 3 H.P. TEFC prewash, power wash pump

motors

■ Easy to remove wash arms

■ Easy to remove scrap trays and baskets

■ 301⁄2" wide conveyor

■ Insulated hinged access doors

■ Front and rear panels

DIRECTION OF OPERATION

❑ Right to Left

❑ Left to Right

FLIGHT-TYPE DISHWASHER

MODEL

❑ FT900SBD – Flight-Type Dishwasher

OPTIONS AT EXTRA COST

❑ Energy Recovery – (will require a back

draft preventer)

❑ Electric Tank Heat

❑ Steam Tank Heat

❑ Booster Heater

❑ Electric

❑ Steam

❑ 6" higher than standard

❑ Insulated counterbalanced split sliding doors

option

❑ Multiple conveyor choices

❑ Circuit breakers

❑ Other options available, consult factory

FT900SBD FLIGHT-TYPE DISHWASHER

ACCESSORIES

❑ Feet

❑ Extended

❑ Flanged

❑ Water hammer arrestor/PRV

Specications, Details and Dimensions on Inside and Back.

VOLTAGE

❑ 208/60/3

❑ 240/60/3

❑ 480/60/3

❑ Other options available, consult factory.

LA Research Report #M660004

F39804 – FT900SBD Flight-Type Dishwasher Page 1 of 12

Page 2

FT900SBD

FLIGHT-TYPE DISHWASHER

DESIGN: Fully automatic, ight-type dishwasher

machine consisting of a load section with power

recirculating prewash, a 4 foot power wash, nal

rinse section. Included with each machine will be

exible plastic strip curtains to control over spray.

CONSTRUCTION: Stainless steel tank and chambers with No. 3 polish on appearance surfaces.

Frame, legs and feet to be constructed of stainless

steel. Inspection doors to be chamber width.

PUMPS: Recirculating stainless steel pumps with

stainless steel impellers. Pump housing has easy to

remove coverplate for access to impeller. All pumps

are self-draining. 150 gpm prewash; 292 gpm power

wash.

MOTORS: Totally enclosed fan cooled design, with

inherent overload protection. Prewash and power

wash to be 3 H.P. each, conveyor 1⁄2 H.P. Available

in electrical specications of 208-240/60/3 and

480/60/3.

CONTROLS: A stainless steel control center with

electronic digital controls mounted at eye level.

Power “On/Off” and “Start/Stop” switches integrated

into keypad. Digital display indicates door(s) open,

low temperature alert, tanks/nal rinse temperatures

and other pertinent operating data. Additional “Start/

Stop” switches are located at each end of machine.

FLIGHT-TYPE CONVEYOR: Stainless steel side

links, tie rods and conveyor tracks. Injection molded,

resilient Duraex ight links.

VENT: Single built-in vent duct with dampers

mounted in cleanable cross duct.

RECIRCULATING PREWASH SECTION: Prewash

compartment is tted with upper and lower wash

arms. Prewash ush down for prewash tank bed.

Large removable one piece perforated stainless

steel screen sloped downward to deep stainless

steel scrap basket.

TANK HEAT: Power wash water temperature is

thermostatically controlled. Low water protection is

provided. Specify either electric or steam heat.

FINAL RINSE: Easily removed nal rinse arms.

CONVEYOR DRIVE UNIT: Powered by a 1⁄2 H.P.

motor. Trip mechanism provided on unload section.

Jam protection is provided by load sensing switch at

drive platform. Conveyor speed adjustment of 4 fpm

to 6.3 fpm is provided in the main control box.

DRAINS: Manual, hand operated, located in each

tank.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

BLOWER DRYER

To assist and promote drying of tableware and trays

by forced circulation of high velocity heated air

through the clean dishware section of the Hobart

Flight-type dishmachines.

Blower dryer is built on a minimum 7' unloading

section only. Hooded chamber/blower section covers

66" length of conveyor, to provide adequate drying

time.

• CONSTRUCTION: All sheet metal construction

is 16 gauge stainless steel. Large insulated

inspection door on front side of machine provides

access. Stainless steel wrap-around encloses

entire external component assembly, consisting

of steam or electric heaters, motor and blower.

• ELECTRIC HEATER: Nine Incoloy sheathed

electric heaters for a total of 9.6 KW heating

capacity. Thermostatic over temperature

protection is standard. Electric specications

are 208/60/3, 240/60/3 or 480/60/3.

• STEAM COIL: Heavy-duty, high-efciency nned

tube-type heat exchanger. Copper tubes and

aluminum ns with galvanized frame. 11⁄2" F.P.T.

steam connection 3⁄4" F.P.T. condensate return

connection. Steam requirements are 75 pounds

per hour at 20 P.S.I. or about 2.2 boiler H.P.

Maximum allowable steam pressure is 25 P.S.I.

Operating pressures above 25 P.S.I. may require

a pressure reducing valve.

• BLOWER: Industrial fan-type with squirrel-cage

type wheel. Housing of welded construction

throughout.

Blower is directly driven by a 2 H.P. motor with

sealed ball bearings. Motor construction is of

open drip proof design. The blower dryer is totally

enclosed by removable stainless steel panels

mounted on top of the dryer chamber. Exhaust

requirement is 1000 C.F.M. (at standard air conditions). Sound level at end of 7-foot unloading

section, with full machine operation is less than

85 DBA, dened by A.N.S.I. (American National

Standards Institute) Standard No. S1.1-1960 ...

below existing O.S.H.A. rules. At loading end of

dishwasher, sound level is 80 DBA or less.

The blower motor is provided with inherent over-

load protection and a manual reset. Furnished only

in three-phase electrical specications of the basic

Flight-Type Model in 208-240/60/3 and 480/60/3.

Operation interlocked with conveyor operation,

i.e., blower functions only during conveyor

operation.

Page 2 of 12 F39804 – FT900SBD Flight-Type Dishwasher

Page 3

FT900SBD

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

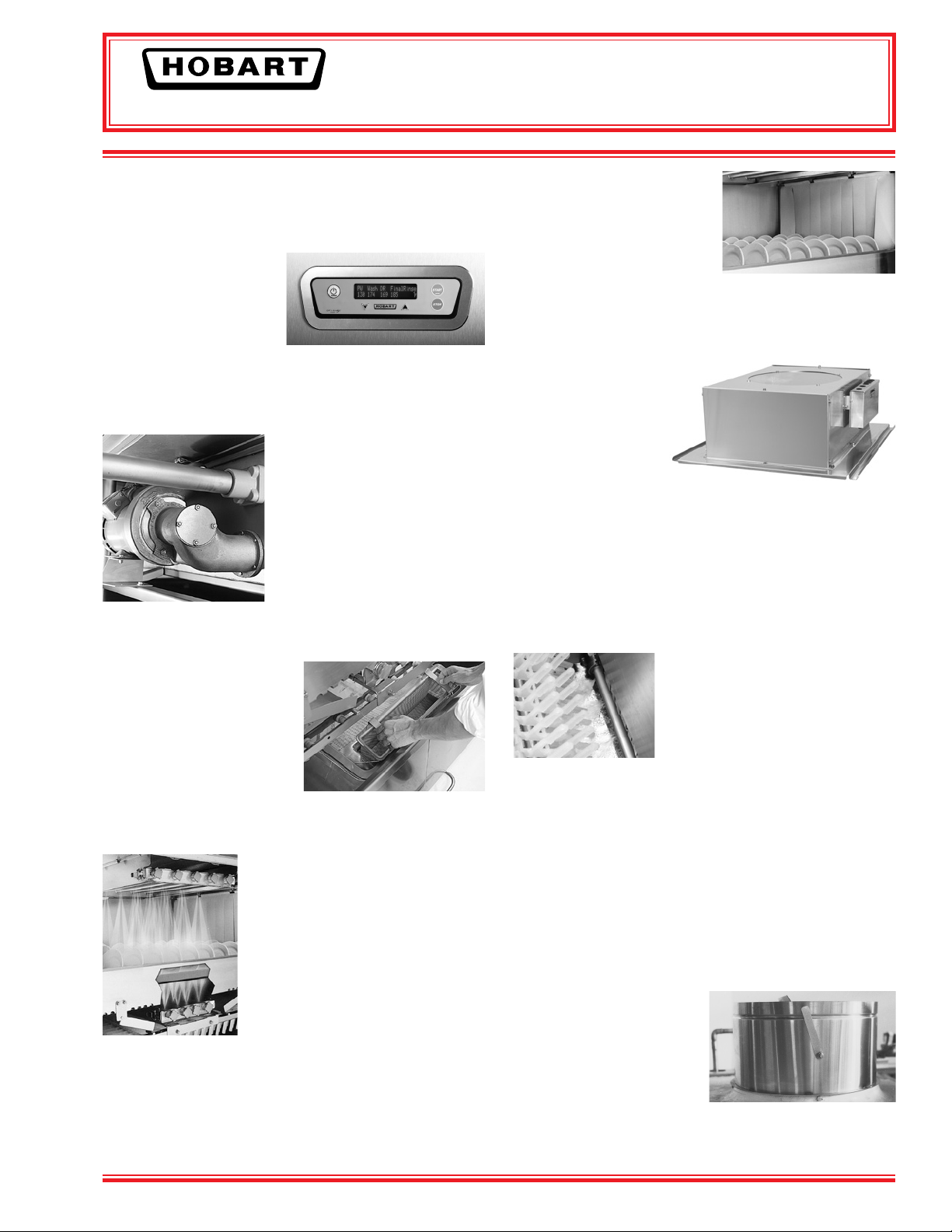

No other control system allows easier

monitoring.

The controls are placed in a convenient panel that

lets operators verify proper operation and temperatures at a glance. Digital

display indicates the

unit is on, and conrms

that the doors are

closed. Automatic door

interlocks prevent the

pump and conveyor from operating if the doors are

open. Easy-to-read digital display indicates accurate

temperatures of the 160°F wash and 180°F nal rinse

— critical for proper HACCP system record-keeping.

Stainless steel pump is

built for long life.

The stainless steel pump

housing and impeller offer

greater durability and long

life. The pump motor is

totally enclosed and fan

cooled (TEFC) to protect

it from water spray during

dishroom clean-up. The

pump is also externally mounted to the frame for

added rigidity and easy access to the clean-out port.

Scrap baskets capture

food particles and are

easy to clean.

The sloped screens that

carry scraps to the scrap

baskets are steeper, so

less soil gets into the

tanks. The basket opening

is larger for easy cleaning and basket handles have

been designed for easy lift-out access.

FLIGHT-TYPE DISHWASHER

Wider, variable speed

conveyor offers

increased throughput.

The conveyor on the

FT900SBD is wider so

it can handle more ware.

Result: more volume and versatility, quicker work.

Its speed is servicer adjustable for the type of ware,

soiled condition, or workforce requirements. It can be

adjusted from 4 to 6.3 feet per minute.

Optional Energy

Recovery system.

The optional Energy

Recovery system

captures escaping

heat and steam from

the exhaust air and

uses a heat exchanger to recycle it into energy.

This free energy is used to preheat the incoming

water supply before it enters the booster heater. The

cold ground temperature water passes through a

heat exchanger positioned directly in line with the

machine’s exhaust system to capture the energy

from the exhaust air to elevate the temperature of the

water to 128° before it enters the booster heater.

Flush arm keeps

load end clean.

The load end also has a readily removable ush arm to rinse

food scraps into the prewash

area scrap basket.

Self-draining pumps help keep water clean.

Pumps are self-draining when the machine is shut

down and drained, so there is no residual water left in

the pumps.

The FT900SBD Series

saves water and energy.

The unit is designed to cut water

and energy usage, yet provide

effective cleaning and sanitizing

that meet NSF International

requirements.

This is achieved through a care fully balanced ratio of water ow

to pressure. At 292 gallons per

minute (gpm), the machine offers excellent wetting

and ooding over ware. Insulated doors also reduce

heat loss. The unit’s 1.9 gpm/102 gallons per hour

rinse ow rate saves both water and the energy to

heat it.

F39804 – FT900SBD Flight-Type Dishwasher Page 3 of 12

Installation is quick and easy with modular

design, minimal wiring connections, and

single point vent.

Modular design means the FT900SBD Series installs

quickly, and reliably. Sections t through 42" doors.

The control panel is already in place, premounted to

the power wash/nal rinse section.

Wiring connections are

minimal, and there is only

a single vent connection,

saving time and expense.

The control box uses a

“single plane” circuitry

design for easy accessibility during installation and service. The FT900SBD

Series is ready to run quickly.

Page 4

FT900SBD

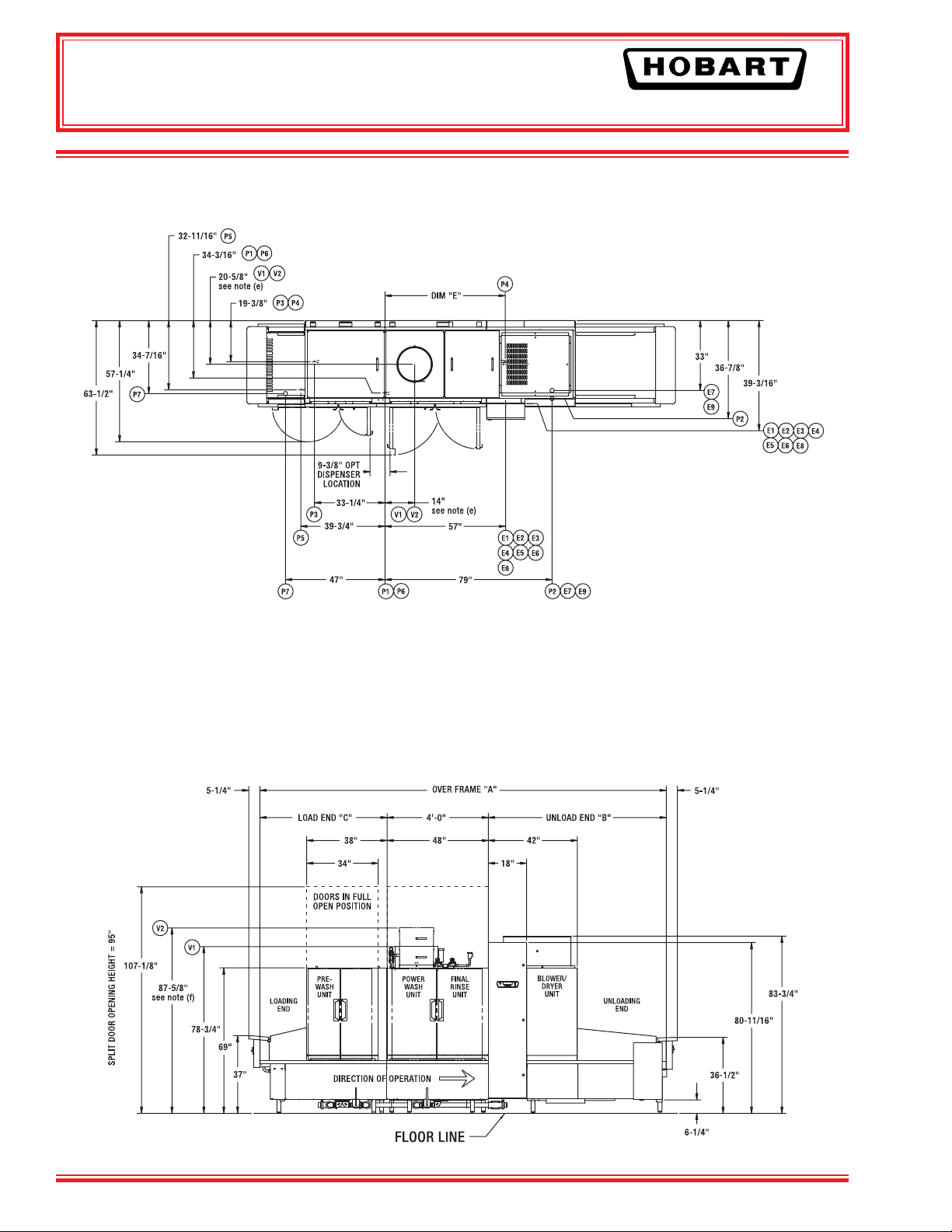

ELECTRIC L-R

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 4 of 12 F39804 – FT900SBD Flight-Type Dishwasher

Page 5

FT900SBD

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ELECTRIC L-R

F39804 – FT900SBD Flight-Type Dishwasher Page 5 of 12

Page 6

FT900SBD

ELECTRIC R-L

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 6 of 12 F39804 – FT900SBD Flight-Type Dishwasher

Page 7

FT900SBD

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

ELECTRIC R-L

F39804 – FT900SBD Flight-Type Dishwasher Page 7 of 12

Page 8

FT900SBD

STEAM L-R

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 8 of 12 F39804 – FT900SBD Flight-Type Dishwasher

Page 9

FT900SBD

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STEAM L-R

F39804 – FT900SBD Flight-Type Dishwasher Page 9 of 12

Page 10

FT900SBD

STEAM R-L

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 10 of 12 F39804 – FT900SBD Flight-Type Dishwasher

Page 11

FT900SBD

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STEAM R-L

F39804 – FT900SBD Flight-Type Dishwasher Page 11 of 12

Page 12

FT900SBD

FLIGHT-TYPE DISHWASHER

FT Dual Rinse (ight type) Models—many additional

variations of these model specications are available.

Engineering data furnished on request.

* Numbers in parentheses, after model number from left to

right, represent length in feet of the following respectively;

Load section, Wash and Unload section.

Flight-type dishwasher with BLOWER-DRYER OPTION

has the same specications as the Basic FT900S Series

EXCEPT for one additional Blower Motor (2 H.P. — 208240/60/3 and 480/60/3) and is available on any model having either a 9 or 11 foot Unloading section.

Entire FT900S Series is listed by UL and NSF and meets

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

requirements of ASSE Standard No. 1004.

FT900SBD Series (5, 7 Load / 4 Center / 7, 9, 11 Unload)*

Machine Ratings (Mechanical)

Conveyor Speed — Feet per minute 4 - 6.3

Dishes per Hour 10,611

Floor Space - Feet — Machine length plus 101⁄2"

total for load and unload platform overhangs

Overall Dimensions (H x W) 84 x 461⁄8 x *(B) *(C)

Motor — Hobart Designed — H.P. Pre-Wash - 3; Wash - 3; Conveyor - 1⁄2

Tank Capacity — Gallons Pre-Wash - 40; Wash - 40

Blower Dryer Motor 2 H.P.

Electric Blower Dryer — Heating Coil (if used) UL Listed 9.6 KW

Steam Blower Dryer — Based on 20 PSI & Flowing

Steam (if used) (25 PSIG max.) 62 lbs./hr.

Pump Capacity

Gallons per minute—Weir Test Pre-Wash - 150; Wash - 292

Final Rinse — Minutes of operation during one

hour of continuous operation 60 at continuous loading condition

Rate of Final Rinse — Gallons per minute

at 20 PSI ow pressure 1.7

Final Rinse Consumption — Gallons per hour

at 20 PSI ow pressure 102

Electric Heat Requirements —

and should be installed by the electrical contractor at the time of installation.

Wash Tank Heat - Kilowatt (Regulated)

Optional Electric Booster - Kilowatt

Steam Heat Requirements —

Steam Consumption

Wash Tank Heat - Pounds per hour - maximum

(Regulated) - based on 15 to 52 PSI steam at

the machine and on the customer supplying

nal rinse water at minimum (A) (20 PSIG)

Optional Steam Booster - Pounds per hour - maximum

- based on 20 PSI steam at 20 PSI water owing 120°F incoming water raised to 190°F (70°F rise)

(180°F minimum)

Exhaust Requirements — Cubic feet per minute

Single point connection with Blower Dryer

Peak Rate of Drain Flow — Gallons per minute

Initial rate with full tanks 38

Shipping Weight Crated Varies by individual model - consult your Hobart representative

30 KW - 105°F or above incoming water raised to 190°F (85°F rise) (180°F minimum)

(A) If only 10-12 PSIG Steam Pressure available at machine - specify Low Pressure Steam Option.

(B) With all rear panels and plumbing removed, machine width is 391⁄8".

*Example: FT918SBD = 5' Load + 4' Center + 7' Unload +

101⁄2" Platform Overhangs = 18'101⁄2" long

Disconnect switches are recommended for each power circuit connected

to dishwasher. These disconnect switches are NOT furnished by Hobart

Circuit breakers optional at extra cost.

Total tank heat - 40KW

15 KW - 140°F incoming water raised to 190°F (85°F rise) (180°F minimum)

Approximately 34.5 lbs. per hour = 1 boiler H.P. (BHP)

175 lbs./160°F minimum

85 lbs. - Std. Ht.; 90 lbs. - 6" HTS

1000

(at standard air conditions)

NOTE: Refer to specic specication sheet for standard machines (FT900) and low water machines (FT900D/FT900SD).

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

Page 12 of 12 F39804 – FT900SBD Flight-Type Dishwasher

F39804 (REV. 05/13) LITHO IN U.S.A. (H-01)

Loading...

Loading...