Item # _____________________________________

Quantity ___________________________________

C.S.I. Section 11400

FT1000SD ENERGY RECOVERY

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

STANDARD FEATURES

■ Pumped rinse system

■ Water usage 58 gph

■ Digital controls with machine diagnostics

■ Low temperature alert

■ Single point vent connection

■ 36" access doors on prewash and wash

chambers, 25" door access on dual rinse

chamber and ASR chamber

■ Start and stop switches at both ends

■ Doors open indicator

■ Drains open indicator

■ Door interlocks

■ 3 H.P. prewash, and 5 H.P. power wash pump

motors, all TEFC

■ Capless Auto Clean wash arms

■ Easy to remove scrap trays and baskets

■ Deep drawn tanks without welds

■ 30" wide conveyor belt

■ Dual Rinse

■ Automatic Soil Removal system (ASR)

■ Auto Clean feature

■ Auto Delime feature

■ Energy Recovery

■ Front and rear panels

■ Variable speed conveyor

FLIGHT-TYPE DISHWASHER

MODEL

❑ FT1000SD Energy Recovery Flight-Type

Dishwasher

OPTIONS AT EXTRA COST

❑ Electric Tank Heat

❑ Steam Tank Heat

❑ Booster Heater

❑ Electric

❑ Steam

❑ Blower Dryer

❑ Electric

❑ Steam

❑ 6" higher than standard chamber

❑ Multiple conveyor choices

❑ Circuit breakers

❑ Other options available, consult factory

ACCESSORIES

❑ Feet

❑ Extended

❑ Flanged

❑ Water hammer arrestor/PRV

Specications, Details and Dimensions on Inside and Back.

FT1000SD ENERGY RECOVERY FLIGHT-TYPE DISHWASHER

UL, NSF and LA approvals pending

DIRECTION OF OPERATION

❑ Right to Left

❑ Left to Right

VOLTAGE

❑ 208/60/3

❑ 240/60/3

❑ 480/60/3

❑ Other voltages available – consult factory

F40354 – FT1000SD Energy Recovery Flight-Type Dishwasher Page 1 of 20

FT1000SD ENERGY RECOVERY

FLIGHT-TYPE DISHWASHER

DESIGN: Fully automatic, ight-type dish machine

consisting of a load section with Automatic Soil

Removal system, power recirculating prewash, power

wash, dual rinse and nal rinse section. Included with

each machine will be exible plastic strip curtains to

control overspray.

CONSTRUCTION: Stainless steel tank and chambers

with No. 3 polish on appearance surfaces. Frame,

legs and feet to be constructed of stainless steel.

Inspection doors to be chamber width.

PUMPS: Recirculating stainless steel pumps with

stainless steel impellers. Pump housing has easy to

remove coverplate for access to impeller. All pumps

are self-draining.

MOTORS: Totally enclosed fan cooled (TEFC) design

with overload protection. Pump motors to be 3 H.P.

for prewash and 5 H.P. for power wash, with conveyor

motor to be 1⁄3 H.P. Available in electrical specications of 208/60/3, 240/60/3 and 480/60/3.

CONTROLS: A stainless steel control center with

electronic digital controls mounted at eye level.

Power “On/Off” and “Start/Stop” switches integrated

into keypad. Digital display indicates door(s) open,

low temperature alert, tanks/nal rinse temperatures,

Auto Clean and Auto Delime instructions and notications, and other pertinent operating data. Additional

“Start/Stop” switches are located at each end of

machine. Conveyor speed button to be included on

the control center to provide for the adjustable speed

conveyor.

FLIGHT-TYPE CONVEYOR: Stainless steel side

links, tie rods and conveyor tracks. Injection molded,

resilient Duraex ight links.

VENT: Single built-in vent duct with dampers

mounted in ventilation duct.

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

AUTOMATIC SOIL REMOVAL SYSTEM (ASR):

Two foot section with specialized soil removal wash

arms removes food soil from the machine before it

reaches the prewash tank. System will pump food soil

from the ASR tank into an external collector located

under the load section, minimizing the need to

pre-scrap dishes and reducing detergent consumption. Operator can easily remove and clean external

collector without interruption of machine operation.

RECIRCULATING PREWASH SECTION: Prewash

compartment is tted with upper and lower wash

arms. Prewash ush down for prewash tank bed.

Large removable one piece perforated stainless steel

screen sloped downward to deep stainless steel

scrap basket.

TANK HEAT: Power wash and dual rinse tank water

temperatures are thermostatically controlled. Low

water protection is provided. Specify either electric

or steam heat.

FINAL RINSE: Easily removed nal rinse arms.

ENERGY RECOVERY: Energy Recovery system

operates with a cold water line, capturing energy from

exhaust air, and using it to elevate the temperature

of the water entering the booster heater. The result is

savings – both in hot water and in energy.

CONVEYOR DRIVE UNIT: Powered by a 1⁄3 H.P.

motor. Trip mechanism provided on unload section.

Jam protection is provided by load sensing switch at

drive platform. Conveyor speed adjustment of 4 feet

per minute to 6.5 feet per minute is provided on the

digital display keypad.

DRAINS: Manual, hand-operated, located in each

tank.

One automatic master drain to be used for Auto

Clean and Auto Delime.

BLOWER DRYER (OPTIONAL): Includes (2) 1 H.P.

fan motors with sealed ball bearings and overload

protection. Blower functions only during conveyor

operation.

Page 2 of 20 F40354 – FT1000SD Energy Recovery Flight-Type Dishwasher

FT1000SD ENERGY RECOVERY

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

No other control

system allows

easier monitoring.

The digital controls are

placed in a convenient

panel that lets operators verify proper operation and

temperatures at a glance. Digital display indicates

the unit is on, and conrms that the doors are

closed. Automatic door interlocks prevent the pump

and conveyor from operating if the doors are open.

Easy-to-read digital display indicates accurate temperatures of the 160°F wash, 160°F dual rinse and

180°F nal rinse — critical for proper HACCP system

record-keeping.

Stainless steel pump is built for long life.

The stainless steel pump housing and impeller offer

greater durability and long life. The pump motor is

totally enclosed and fan cooled (TEFC) to protect it

from water spray during dishroom clean-up.

Scrap baskets

capture food particles

and are easy to clean.

The sloped screens that

carry scraps to the scrap

baskets are steeper, so less

soil gets into the tanks. The basket

opening is larger for easy cleaning and basket

handles have been designed for easy lift-out access.

The load section also features a removable scrap

basket which contains soil that is pumped from the

ASR section. All scrap baskets and strainers are

stainless steel for strength and durability.

The FT1000

Series saves

water and

energy.

The unit has the

lowest water

and energy

consumption in

the industry, yet

provides effective cleaning and sanitizing that meets

NSF International requirements.

This is achieved through

a carefully balanced ratio

of water ow to pressure.

Insulated doors and thermal

layered curtain at load also

reduce heat loss. The unit’s

58 gallons per hour rinse ow

rate saves both water and the

energy to heat it.

FLIGHT-TYPE DISHWASHER

Wider, variable

speed conveyor

offers increased

throughput.

The conveyor

on the FT1000

Series is wider

so it can handle

more ware.

Result: more volume and versatility, quicker work.

Its speed is servicer adjustable for the type of ware,

soiled condition, or workforce requirements. It runs at

4 - 6.5 feet per minute.

Energy Recovery system

reclaims heat for energy.

The Energy Recovery

system captures escaping

heat and steam from the

exhaust air and uses a heat

exchanger to recycle it into

energy. This free energy is

used to preheat the incoming water supply before it

enters the booster heater.

The cold ground temperature water passes through

a heat exchanger positioned directly in line with the

machine’s exhaust system to capture the energy

from the exhaust air to elevate the temperature of the

water to 128° before it enters the booster heater.

Self-draining pumps help keep water clean.

Pumps are self-draining when the machine is shut

down, so there is no residual water left in the pumps.

Installation is quick and easy with modular design,

minimal wiring connections, and single point vent.

Modular design means

the FT1000 installs quickly

and reliably. Sections t

through 42" doors. The

control panel is already in

place, premounted to the

power wash/power rinse/

nal rinse section.

Wiring connections are

minimal, and there is only

a single vent connection,

saving time and expense.

The control box uses a

“single plane” circuitry

design for easy accessibility during installation and

service. The FT1000 is

ready to run quickly.

F40354 – FT1000SD Energy Recovery Flight-Type Dishwasher Page 3 of 20

FT1000SD ENERGY RECOVERY

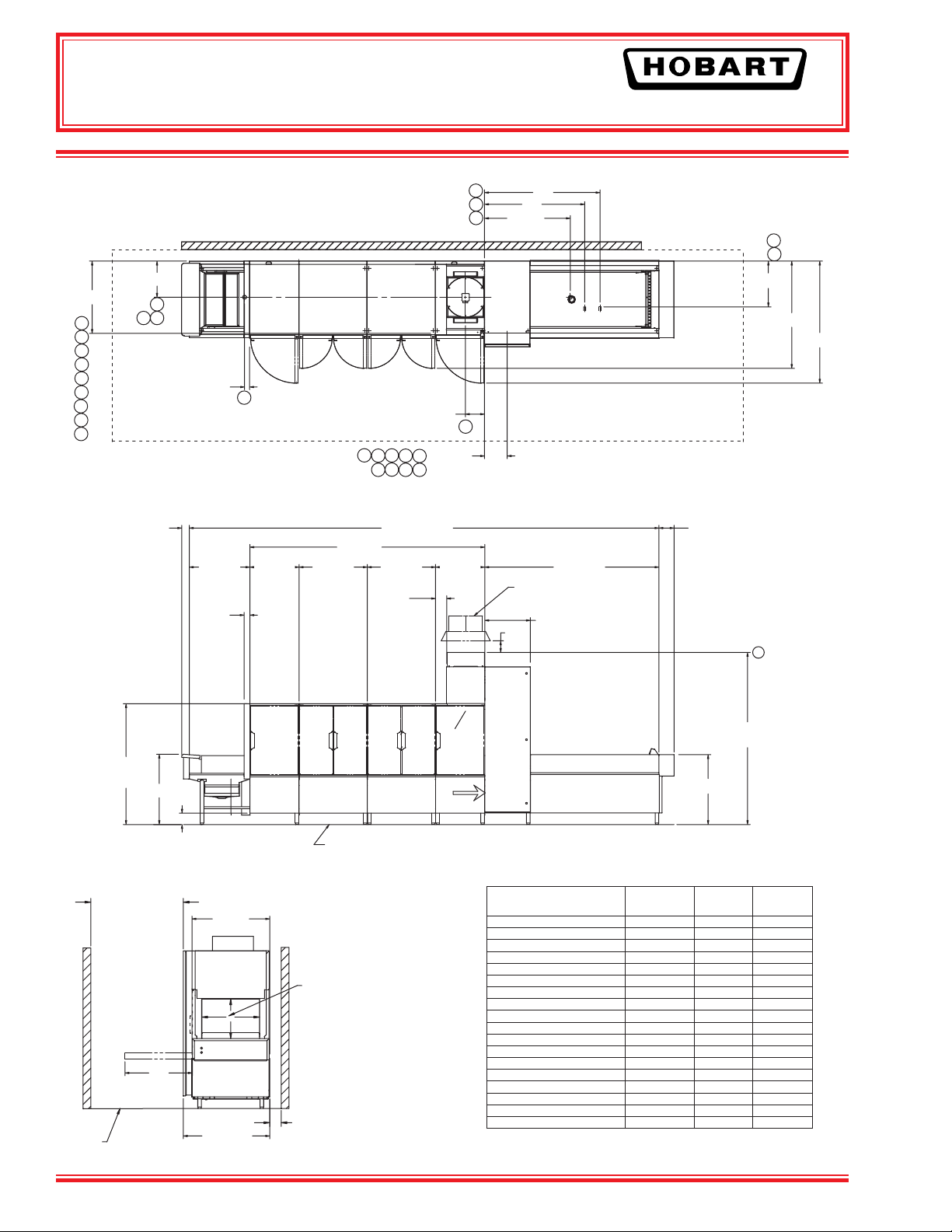

NOTE: OVERALL LENGTH OF MACHINE IS DIMENSION "A" + 11 3/4"

63 3/8"

SEE NO

)

FLOOR LINE

7 7/8"

3 15/16"

OVER FRAME "A"

6" MINIMUM

ON THE TOP

FLOOR LIN

NOTE: REFER TO LATEST

ELECTRIC L-R

18 3/4"

37 1/2"

E1

E2

E3

E4

E5

E6

E7

E8

E9

V1

P3P4

2 5/8"

P3

LOAD "B"

3"

25 9/16"

9 15/16"

V1

E3

E8

5 3/4"

11 13/16"

E2

E1

E6E7

E5

E4

E9

10' 2-1/8"

35 7/16" 35 7/16" 25 9/16"

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

P2

P1

P4

60"

52"

44 9/16"

EXHAUST HOOD

SUPPLIED BY

OTHERS

23 3/4"

6"

P2

P1

23 3/4"

55 11/16"

UNLOAD "C"

V1

EDITION OF NATIONAL

ELECTRICAL CODE AND

LOCAL BUILDING CODES

FOR PROPER CLEARANCE

NOTE: STRAINER PANS

REQUIRE 35" TO

BE REMOVED. EXTRA

CLEARANCE SHOULD BE

PROVIDED.

E

62 3/4"

(h)

TE

36 1/2"

35"

6"

LOAD

END

40 3/8"

44 13/16"

see note (a)

ASR

22" HIGH X 29-13/16"

WIDE OPENING WILL

HANDLE 18" X 26" BUN PANS

NOTE: CLEARANCE FROM WALL

24" RECOMMENDED,

WITH DETERGENT DISPENSER

PRE-

WASH

DIRECTION OF OPERATION

POWER

WASH

AUX

RNS

FNL

RNS

FT1018S (2-1/2'-10'-5-1/2')

FT1019S (3-1/2'-10'-5-1/2')

FT1020S (4-1/2'-10'-5-1/2')

FT1020S (2-1/2'-10'-7-1/2')

FT1021S (3-1/2'-10'-7-1/2')

FT1022S (4-1/2'-10'-7-1/2')

FT1022S (2-1/2'-10'-9')

FT1023S (3-1/2'-10'-9')

FT1024S (4-1/2'-10'-9')

FT1024S (2-1/2'-10'-11')

FT1025S (3-1/2'-10'-11')

FT1026S (4-1/2'-10'-11')

FT1027S (2-1/2'-10'-15')

FT1028S (3-1/2'-10'-15')

FT1029S (4-1/2'-10'-15')

FT1029S (2-1/2'-10'-17')

FT1030S (3-1/2'-10'-17')

FT1031S (4-1/2'-10'-17')

UNLOAD

END

MODEL NO. "A" "B" "C"

18' 4-9/16"

19' 4-5/16"

20' 4-5/32"

20' 4-1/16"

21' 3-13/16"

22' 3-21/32"

21' 11-13/16"

22' 11-9/16"

23' 11-13/32"

23' 11-7/16"

24' 11-3/16"

25' 11-1/32"

27' 6-3/4"

28' 6-1/2"

29' 6-11/32"

29' 6-5/16"

30' 6-1/16"

31' 5-29/32"

89 3/8"

SEE NOTE (g

36 1/4"

2' 7-1/2"

3' 7-1/4"

4' 7-3/32"

2' 7-1/2" 7' 6-1/2"

3' 7-1/4" 7' 6-1/2"

4' 7-3/32" 7' 6-1/2"

2' 7-1/2" 9' 2-1/4"

3' 7-1/4" 9' 2-1/4"

4' 7-3/32" 9' 2-1/4"

2' 7-1/2" 11' 1-7/8"

3' 7-1/4" 11' 1-7/8"

4' 7-3/32" 11' 1-7/8"

2' 7-1/2" 14' 9-3/16"

3' 7-1/4" 14' 9-3/16"

4' 7-3/32" 14' 9-3/16"

2' 7-1/2" 16' 8-3/4"

3' 7-1/4" 16' 8-3/4"

4' 7-3/32" 16' 8-3/4"

5' 7"

5' 7"

5' 7"

Page 4 of 20 F40354 – FT1000SD Energy Recovery Flight-Type Dishwasher

FT1000SD ENERGY RECOVERY

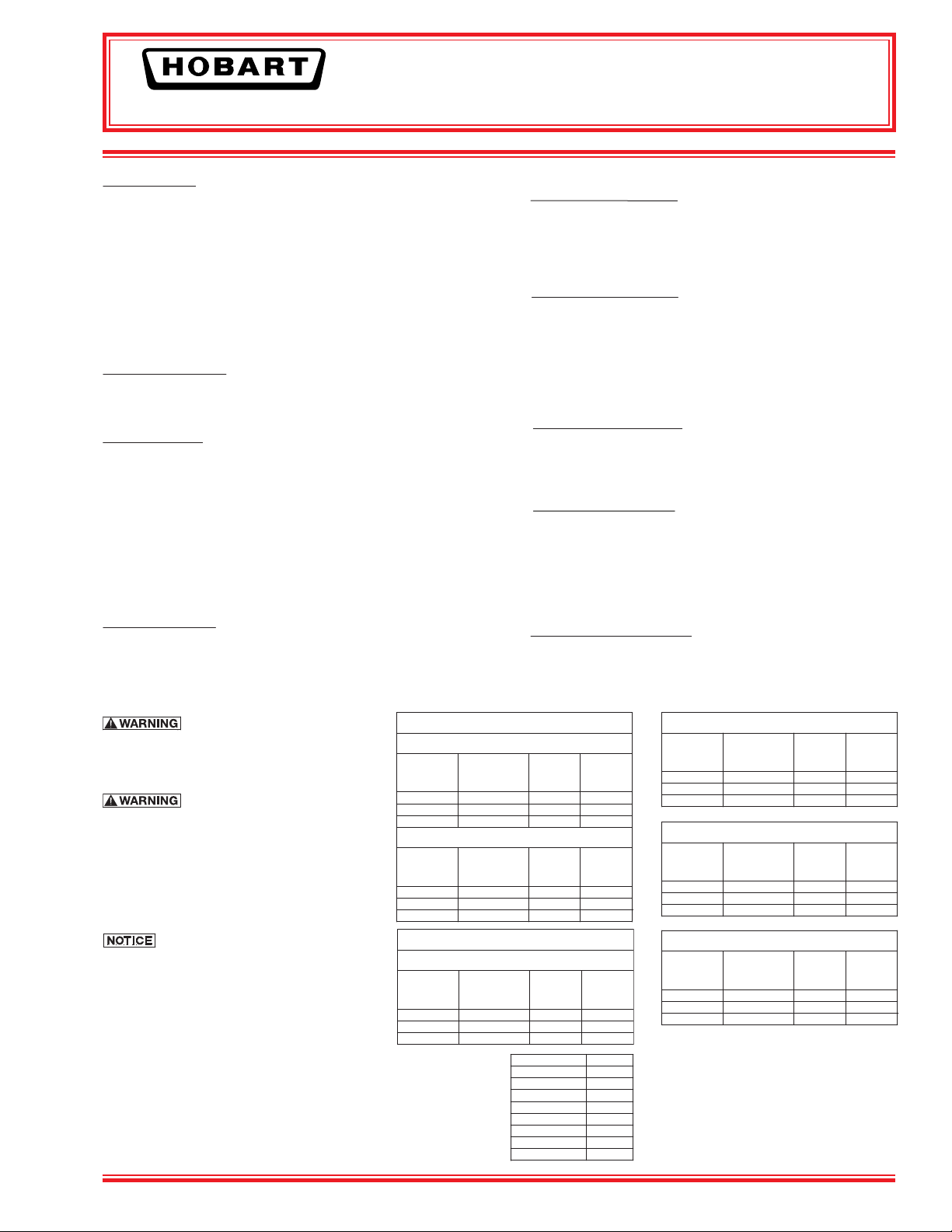

GENERAL NOTES:

(

THE CONTROL

TION

CLEARANCE FOR DOORWAYS.

ELECTRICAL WARNING:

E

ITH

SERVICE WIRE TEMPERATURE RATING: 90C.

PLUMBING NOTES:

Y,

(b)

(

(d)

(

T

SALES ENGINEERING.

VENTILATION NOTES:

SH,

Do not premix other chemicals and sodium

hypochlorite (liquid bleach).

Mixing may cause hazardous gas to form.

Electrical and grounding connection

must comply with the applicable portions

of the National Electrical Code and/or

other local electrical codes.

Plumbing connections must comply with

applicable sanitar

codes.

vary, some methods are shown on this drawing.

Pressure gauge not required on pumped rinse machines.

Important:

above floor

If chemical containers are to be placed in cabinet adjacent to machine,

a 1/2" dia. hole is required in the cabinet to run chemical supply line

Use only 6% or 8.4% sodium hypochlorite (liquid bleach) as sanitizing

chemical to insure proper operation of dishmachine

Certain materials including silver plat

attacked

manual.

MODEL:

FT1000S ENERGY RECOVERY

(ASR

ELECTRIC

L-R OPERA

00-949513

REV A

ELECTRICAL CONNECTIONS

COMMON ON

E1

ND RINSE FEEDERS

E2 ELECTRIC CONNECTIO

(SWITCH CONTACTS) 1/2" CONDUIT. 79-1/8" AFF

ELECTRICAL CONNECTIONS

W/O CIRCUIT BREAKERS:

E3

E5

E6

E7

1" CONDUIT. 79-1/8" AFF

ELECTRICAL CONNECTIONS

WITH CIRCUIT BREAKERS:

E8

.

(

E9

1-1/4" CONDUIT, 79-1/8" AFF

PLUMBING CONNECTIONS:

D END OPTION IS SPECIFIED).

2" FPT. 7" AFF

VENTILATION REQUIREMENTS:

V1

BLE OF

95-3/8" AFF see note (f).

SERVICE CONNECTION WITH CIRCUIT BREAKERS

CONVEYOR

1/3 HP

ELECTRIC TANK HEAT, WASH

ELECTRIC TANK HEAT, BOOSTER

07

07

480/60/3

53

MOTORS AND CONTROLS

04

53

02

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

a) THE CONTROL BOX IS ATTA CHED TO THE CENTER SECTION, AND

BOX IS ROTATED 90 DEGREES ALLOWING THE CENTER SECTION TO FIT

THROUGH A 42" WIDE, 7' DOOR OPENING.

WITH BACK PANEL AND END CAPS REMOVED, CONTROL PANEL HINGED BACK

AND ALL REAR PIPING REMOVED, OVERALL WIDTH OF MACHINE IS 40".

AFF = ABOVE FINISHED FLOOR

ALL DIMENSIONS TAKE FROM THE FLOOR LINE MAY INCREASE 3-1/4" WITH

LEG ADJUSTMENT.

FOR CONVENIENCE WHEN CLEANING, CUSTOMER SHOULD INSTALL WATER

TAP NEAR MACHINE WITH 30 FT. OF HEAVY DUTY HOSE WITH SQUEEZE VALVE.

THIS DRAWING IS SUPPLIED AS A REFERENCE FOR CONNECTION INFORMA

ONLY. IT WILL NOT BE UTILIZED FOR MANUFACTURING OF UNIT.

INSULATED TOP COVER TOP COVER PANELS CAN BE TEMPORARILY REMOVED

FROM THE PRE-WASH, WASH OR POWER RINSE SECTIONS TO YIELD 61-3/4"

LECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY W

THE APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE

AND/OR OTHER ELECTRICAL CODES.

PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITAR

SAFETY AND PLUMBING CODES.

RECOMMENDED WATER HARDNESS TO BE 3 GRAINS OR LESS PER

GALLON FOR BEST RESULTS.

RECOMMENDED BUILDING FLOWING HOT WATER PRESSURE TO THE

DISHWASHER IS 30-35 PSI.

c) RECOMMENDED BUILDING FLOWING COLD WATER PRESSURE TO THE

DISHWASHER IS 20 PSI (45-50 PSI WHEN EQUIPPED WITH AUTOCLEAN

OPTION IS SPECIFIED). IF COLD WATER IS LESS THAN 55°F CONTACT

SALES ENGINEERING.

WATER HAMMER ARRESTOR (MEETING ASSE-1010 STANDARD OR

EQUIVALENT) TO BE SUPPLIED (BY OTHERS) IN FINAL RINSE WATER

SUPPLY LINE AT SERVICE CONNECTION.

e) IF STEAM PRESSURE IS UNDER 15 PSI AT THE DISHWASHER, CONTAC

ELECTRIC L-R

ALL MODELS:

ELECTRIC CONNECTION, DETERGENT A

(MACHINE SERVICE VOLTAGE), 1/2" CONDUIT.

79-1/8" AFF

ELECTRIC CONNECTION, MOTORS & CONTROLS,

1" CONDUIT. 79-1/8" AFF

ELECTRIC TANK HEAT CONNECTION, WASH TA NK, 30 KW.

1-1/4" CONDUIT. 79-1/8" AFF

ELECTRIC TANK HEAT CONNECTION, D UAL RINSE TANK, 10KW.

1" CONDUIT. 79-1/8" AFF

ELECTRIC TANK HEAT CONNECTION, B OOSTER, 18KW.

ELECTRIC CONNECTION, MOTORS, CONTROLS, RINSE HEAT,

BOOSTER HEAT (WHEN CIRCUIT BREAKER OPTION IS SPECIFIED)

TB1) 2" CONDUIT, 79-1/8" AFF

ELECTRIC CONNECTION, WASH HEAT & DUAL RINSE HEAT (TB2)

P1 COMMON HOT WATER CONNECTION (AUTOMATIC FILL) 140°F WATER,

MINIMUM, 1" FPT, 5-1/2" AFF see notes (b) AND (d).

P2 COMMON COLD WATER CONNECTION (FINAL RINSE WITH OR W/O THE

AUTO CLEAN OPTION) 55°F WATER MINIMUM.

1" FPT, 1-1/2" AFF see notes (b) and (d).

P3 COMMON DRAIN CONNECTION, (WHEN DRAIN TO LOAD END IS SPECIFIED).

2" FPT. 7" AFF

P4 COMMON DRAIN CONNECTION, (WHEN DRAIN TO UNLOA

N, VENT FAN CONTROL.

(f) THIS DIMENSION IS SUBJECT TO NORMAL SHEET METAL TOLERANCES

(g) THE VENT STACK AND ITS ENCLOSURE CAN BE TEMPORARILY REMOVED FROM

THE ENERGY RECOVERY UNIT TO YIELD 81-78" CLEARANCE FOR DOORWAYS

(h) THE INSULATED TOP COVER PANELS CAN BE TEMPORARILY REMOVED FROM THE PREWA

WASH OR POWER RINSE SECTIONS TO YIELD 61-3/4" CLEARANCE FOR DOORWAYS.

(j) BACK DRAFT PREVENTER RECOMMENDED (REQUIRED ON MACHINES EQUIPPED WITH ER)

y, safety and plumbing

Drain and fill line configurations

Chemical containers should be placed no higher than 10"

.

by sodium hypochlorite (liquid bleach). See instructional

, ER)

TION

F40354 – FT1000SD Energy Recovery Flight-Type Dishwasher Page 5 of 20

e, aluminum and pewter are

s

.

MINIMUM OF 24" SQUARE VENT HOOD (SUPPLIED BY OTHERS) CAPA

PROVIDING 706 CFM EXHAUST (AT STANDARD AIR CONDITIONS).

(2) SERVICE CONNECTIONS AS SHOWN BELOW

MOTORS, CONTROLS & BOOSTER HEAT(TB1)

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

208/60/3

240/60/3

480/60/3

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

208/60/3

240/60/3

480/60/3

SERVICE CONNECTION W/O CIRCUIT BREAKERS

(5) SERVICE CONNECTIONS AS SHOWN BELOW

(1) 10KW CONNECTION AS SHOWN BELOW

ELEC.

.

SPECS.

208/60/3

240/60/3

480/60/3

RATED

AMPS

87.6

80.7

40.3

WASH, DUAL RINSE HEAT(TB2)

RATED

AMPS

120.1 150 150

114.5 150 150

57.3 70 70

ELECTRIC TANK HEAT, DUAL RINSE

RATED

AMPS

30.0

28.6

14.3

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

100 100

100 100

50 50

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

35 35

35 35

20 20

MOTORS

ASR PUMP

ASR SOIL

PREWASH

WASH

DUAL RINSE

PUMPED RINSE

EXHAUST

MAXIMUM

PROTECTIVE

DEVICES

MAXIMUM

PROTECTIVE

DEVICE

MAXIMUM

PROTECTIVE

DEVICES

SIZE

1/3 HP

1/4 HP

3 1/2 HP

5 HP

1/6 HP

1/2 HP

1/3 HP

(1) 30 KW CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

208/60/3

240/60/3

480/60/3

ELEC.

SPECS.

208/60/3

240/60/3

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

208/60/3

240/60/3

480/60/3

RATED

AMPS

96.1 125 125

91.6 125 125

45.8 60 60

(1) 18 KW CONNECTION AS SHOWN BELOW

RATED

AMPS

54.07

51.57

25.83

RATED

AMPS

33.64

29.23

14.62

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICES

MAXIMUM

PROTECTIVE

DEVICES

0

0

5

MAXIMUM

PROTECTIVE

DEVICE

0

5

0

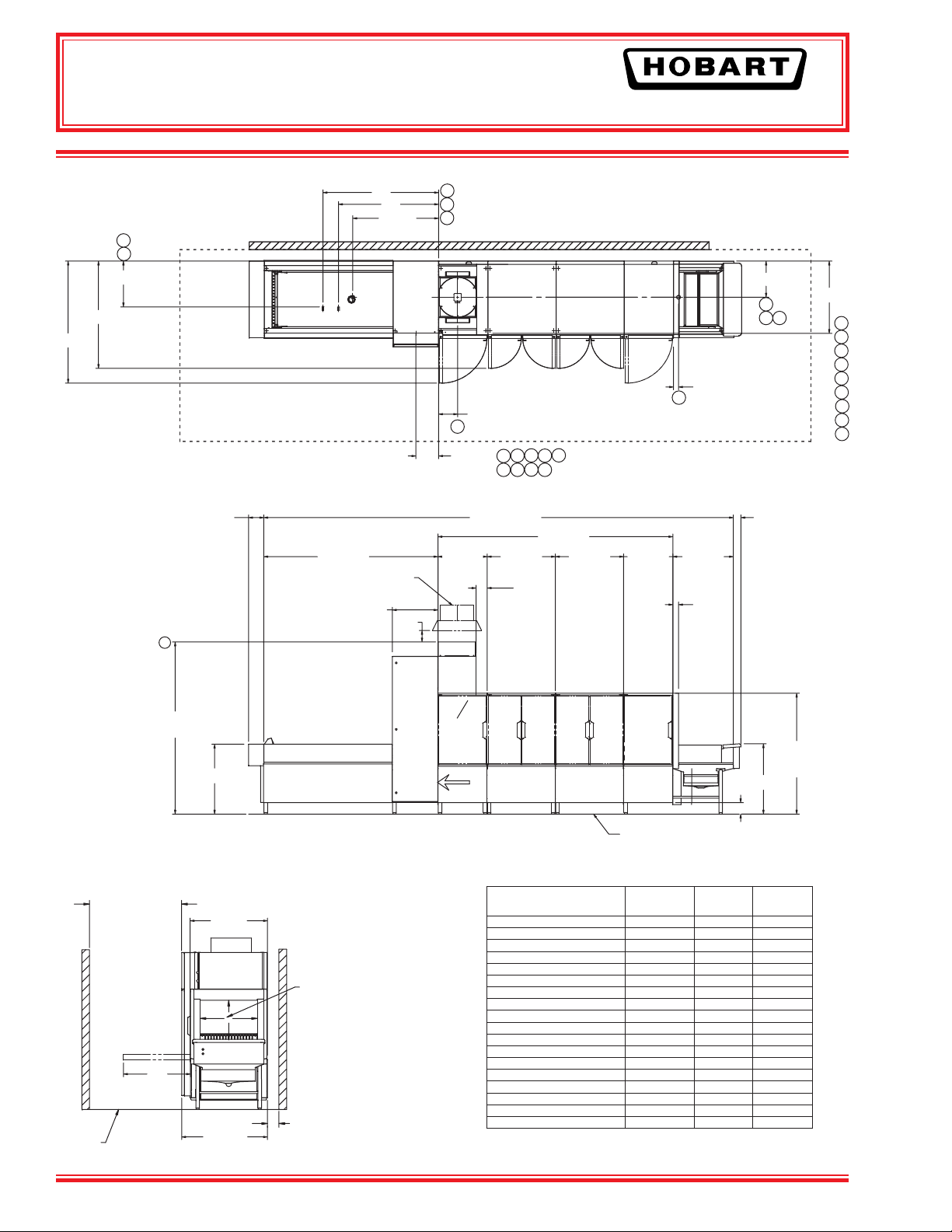

FT1000SD ENERGY RECOVERY

TE

SEE NO

FLOOR LINE

7 7/8" 3 15/16"

OVER FRAME "A"

63 3/8"

6" MINIMUM

ON THE TOP

FLOOR LIN

NOTE: REFER TO LATEST

NOTE: OVERALL LENGTH OF MACHINE IS DIMENSION "A" + 11 3/4"

ELECTRIC R-L

P2

P1

23 3/4"

55 11/16"

V1

UNLOAD "C"

EXHAUST HOOD

SUPPLIED BY

OTHERS

23 3/4"

60"

52"

44 9/16"

701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

P2

P1

P4

18 3/4"

V1

P3 P4

2 5/8"

P3

9 15/16"

V1

E5

E1

E6 E7

E2

E3

E8

5 3/4"

E4

E9

10' 2-1/8"

35 7/16"35 7/16"25 9/16"

25 9/16"

LOAD "B"

3"

11 13/16"

6"

37 1/2"

E1

E2

E3

E4

E5

E6

E7

E8

E9

FNL

89 3/8"

TE (g)

36 1/4"

EDITION OF NATIONAL

ELECTRICAL CODE AND

LOCAL BUILDING CODES

FOR PROPER CLEARANCE

NOTE: STRAINER PANS

REQUIRE 35" TO

BE REMOVED. EXTRA

CLEARANCE SHOULD BE

PROVIDED.

E

35"

40 3/8"

44 13/16"

see note (a)

UNLOAD

END

22" HIGH X 29-13/16"

WIDE OPENING WILL

HANDLE 18" X 26" BUN PANS

NOTE: CLEARANCE FROM WALL

24" RECOMMENDED,

WITH DETERGENT DISPENSER

RNS

WASH

RNS

DIRECTION OF OPERATION

FT1018S (2-1/2'-10'-5-1/2')

FT1019S (3-1/2'-10'-5-1/2')

FT1020S (4-1/2'-10'-5-1/2')

FT1020S (2-1/2'-10'-7-1/2')

FT1021S (3-1/2'-10'-7-1/2')

FT1022S (4-1/2'-10'-7-1/2')

FT1022S (2-1/2'-10'-9')

FT1023S (3-1/2'-10'-9')

FT1024S (4-1/2'-10'-9')

FT1024S (2-1/2'-10'-11')

FT1025S (3-1/2'-10'-11')

FT1026S (4-1/2'-10'-11')

FT1027S (2-1/2'-10'-15')

FT1028S (3-1/2'-10'-15')

FT1029S (4-1/2'-10'-15')

FT1029S (2-1/2'-10'-17')

FT1030S (3-1/2'-10'-17')

FT1031S (4-1/2'-10'-17')

PRE-

WASH

MODEL NO. "A" "B" "C"

POWER

AUX

ASR

18' 4-9/16"

19' 4-5/16"

20' 4-5/32"

20' 4-1/16"

21' 3-13/16"

22' 3-21/32"

21' 11-13/16"

22' 11-9/16"

23' 11-13/32"

23' 11-7/16"

24' 11-3/16"

25' 11-1/32"

27' 6-3/4"

28' 6-1/2"

29' 6-11/32"

29' 6-5/16"

30' 6-1/16"

31' 5-29/32"

LOAD

END

36 1/2"

6"

2' 7-1/2"

3' 7-1/4"

4' 7-3/32"

2' 7-1/2" 7' 6-1/2"

3' 7-1/4" 7' 6-1/2"

4' 7-3/32" 7' 6-1/2"

2' 7-1/2" 9' 2-1/4"

3' 7-1/4" 9' 2-1/4"

4' 7-3/32" 9' 2-1/4"

2' 7-1/2" 11' 1-7/8"

3' 7-1/4" 11' 1-7/8"

4' 7-3/32" 11' 1-7/8"

2' 7-1/2" 14' 9-3/16"

3' 7-1/4" 14' 9-3/16"

4' 7-3/32" 14' 9-3/16"

2' 7-1/2" 16' 8-3/4"

3' 7-1/4" 16' 8-3/4"

4' 7-3/32" 16' 8-3/4"

5' 7"

5' 7"

5' 7"

62 3/4"

SEE NO

(h)

Page 6 of 20 F40354 – FT1000SD Energy Recovery Flight-Type Dishwasher

Loading...

Loading...