Page 1

SERVICE MANUAL

KA SERIES ELECTRIC ROTARY

OVENS

Information in this manual superceedes TSB 1406.

KA7E ML-137701 SELF-CLEAN, GLASS BACK

ML-137709 SELF-CLEAN, SOLID BACK

KA7EM ML-137710 MANUAL-CLEAN, GLASS

BACK WITH GREASE ASSIST

ML-137711 MANUAL-CLEAN, GLASS

BACK WITHOUT GREASE

ASSIST

ML-137713 MANUAL-CLEAN, SOLID BACK

WITH GREASE ASSIST

ML-137714 MANUAL-CLEAN, SOLID BACK

WITHOUT GREASE ASSIST

KA7E WITH STAND ACCESSORY SHOWN

This Manual is prepared for the use of trained Hobart Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Hobart Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Hobart Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Hobart, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

- NOTICE -

A product of Hobart Service 701 S. Ridge Ave Troy, OH 45374

F25294 Rev. A (0412)

Page 2

KA SERIES ELECTRIC ROTARY OVENS

TABLE OF CONTENTS

GENERAL .................................................................................................. 4

REFERENCE INFORMATION .......................................................................... 4

TSB'S & TSI'S ...................................................................................... 4

INSTRUCTIONS & SPECIFICATIONS .............................................................. 4

INTRODUCTION ....................................................................................... 4

ELECTRICAL SPECIFICATIONS ....................................................................... 5

WATER SUPPLY REQUIREMENTS (KA7E ONLY) ...................................................... 5

TOOLS ................................................................................................. 5

ACCESSORY STAND INSTRUCTIONS ................................................................. 5

KA7E SELF-CLEAN (ML-137701, ML-137709) ...................................................... 5

KA7EM WITH GREASE ASSIST (ML-137710, ML-137713) .......................................... 7

KA7EM WITHOUT GREASE ASSIST (ML-137711, ML-137714) ..................................... 8

TETHER BRACKET AND OVEN MOUNTING TO STAND (KA7E, KA7EM) ........................... 9

REMOVAL AND REPLACEMENT OF PARTS .............................................................. 10

COVERS .............................................................................................. 10

PUMP COVER .................................................................................... 10

RIGHT SIDE COVER .............................................................................. 10

LEFT SIDE COVER ............................................................................... 10

TOP COVER (CONTROL PANEL) ................................................................. 10

TOP COVER ...................................................................................... 10

FAN COVER ...................................................................................... 11

DOOR ................................................................................................ 11

DOOR ADJUSTMENT ............................................................................. 12

DOOR SWITCH ADJUSTMENT (KA7E ONLY; IF REQUIRED) ..................................... 12

DOOR SWITCH MAGNET (KA7E ONLY) .............................................................. 13

OUTER DOOR GLASS ................................................................................ 13

WASH ARM, STRAINER PANS, STRAIN PAN SUPPORT, DRAIN SHROUD (KA7E ONLY) ............. 13

LAMP ................................................................................................. 14

FAN MOTORS ASSEMBLY ............................................................................ 15

HEATING ELEMENTS ................................................................................ 17

HIGH LIMIT THERMOSTAT ........................................................................... 18

TEMPERATURE SENSOR ............................................................................ 18

CONTACTORS ....................................................................................... 19

POWER SWITCH AND MOMENTARY SWITCHES .................................................... 19

DISPLAY BOARD AND KEYPAD ...................................................................... 20

ROTOR STOP/START SWITCH ....................................................................... 21

MEAT PROBE MINI JACK ............................................................................. 22

CAPACITORS ........................................................................................ 22

WATER LEVEL CONTROL BOARD (KA7E ONLY) ..................................................... 23

WATER LEVEL SENSOR (KA7E ONLY) ............................................................... 24

CHEMICAL SENSOR (KA7E ONLY) ................................................................... 24

WASH PUMP RELAY (KA7E ONLY) ................................................................... 24

TRANSFORMER ...................................................................................... 25

CPU BOARD .......................................................................................... 25

PERISTALTIC PUMPS ................................................................................ 26

PUMP REMOVAL ................................................................................. 26

PROCEDURE TO REPLACE PUMP HOSE ........................................................ 26

WATER FILL VALVE (KA7E ONLY) .................................................................... 28

WASH PUMP (KA7E ONLY) ........................................................................... 28

DRAIN PUMP (KA7E ONLY) ........................................................................... 29

DRIVE MOTOR ASSEMBLY ........................................................................... 29

DRIVE MOTOR ADJUSTMENT .................................................................... 31

DRIVE MOTOR, SPEED REDUCER AND GEARBOX .................................................. 33

SERVICE PROCEDURES AND ADJUSTMENTS ........................................................... 36

SERVICE MODE - PROGRAMMING AND DIAGNOSTICS ............................................. 36

F25294 Rev. A (0412) Page 2 of 72

Page 3

KA SERIES ELECTRIC ROTARY OVENS

PROCEDURE TO ENTER SERVICE MODE ....................................................... 36

PROCEDURE TO TOGGLE BETWEEN NO ID AND OPERATOR ID MODE ........................ 36

PROCEDURE TO TOGGLE BETWEEN 9 AND 99 PROGRAMS .................................... 36

SERVICE MODE PARAMETERS .................................................................. 36

DEMO MODE (KA7E ONLY) ........................................................................... 41

RETURN TO NORMAL MODE ..................................................................... 43

TEMPERATURE SENSOR TEST ...................................................................... 43

HEATING ELEMENT TEST ............................................................................ 44

PUMP, K3 RELAY COIL TESTS ....................................................................... 44

CONTROLS CALIBRATION ........................................................................... 44

CALIBRATION PROCEDURE ..................................................................... 44

ELECTRICAL OPERATION ................................................................................ 46

COMPONENT FUNCTION ............................................................................ 46

SEQUENCE OF OPERATION ......................................................................... 46

PROGRAMMED COOKING ....................................................................... 46

WASHING CYCLE SEQUENCE OF OPERATIONS ................................................ 47

USER PRESSES CLEAN BUTTON ................................................................ 47

CONTROLS EXPLANATION .......................................................................... 48

MODEL KA7E ..................................................................................... 48

MODEL KA7EM ................................................................................... 49

COMPONENT LOCATIONS ........................................................................... 50

MODEL KA7E ..................................................................................... 50

MODEL KA7EM ................................................................................... 52

WIRING DIAGRAMS .................................................................................. 54

KA7E - COMPONENT CONNECTIONS ............................................................ 54

KA7EM - COMPONENT CONNECTIONS .......................................................... 55

POWER CONNECTION ........................................................................... 56

SCHEMATIC DIAGRAMS ............................................................................. 57

MODEL KA7E ..................................................................................... 57

MODEL KA7EM ................................................................................... 59

PLUMBING DIAGRAMS (KA7E ONLY) ................................................................ 62

TROUBLESHOOTING ..................................................................................... 64

TROUBLESHOOTING ................................................................................. 64

TROUBLESHOOT ROTOR COMPONENTS ........................................................... 67

APPENDIX ................................................................................................ 69

REVERSING CONTROLS ............................................................................. 69

© HOBART SERVICE 2012

Page 3 of 72 F25294 Rev. A (0412)

Page 4

KA SERIES ELECTRIC ROTARY OVENS - GENERAL

GENERAL

Oven cleaners are corrosive and can cause chemical burns. Rubber gloves, goggles and protective

clothing are required. Read and follow the instructions for the oven cleaner.

Safety standards require that, when the rotary oven’s electric supply line is properly connected to the

electrical power supply, an adequate means must be provided to limit movement of the oven without applying stress

to the electrical conduit. This means that, as part of the installation, the oven must be secured to either the wall or

the floor to limit movement of the oven and, thus, preventing damage to the flexible electrical conduit during cleaning,

maintenance and service operations.

REFERENCE INFORMATION

TSB'S & TSI'S

NOTE: Links or references to the TSB's are provided

here and in the appropriate sections of service

manual.

TSB 1381 KA7E ROTARY OVEN SCRAMBLED VFD DISPLAY.

TSB 1383

TSB 1400 KA7E - LEAKS AT DRIVE ARM GASKET DURING WASH CYCLE.

TSB 1417 KA7E - CLOGGING AT INPUT AND OUTPUT OF PERISTALTIC PUMPS.

TSI

Instructions & Specifications

KA7E F-40182 F-35521

KA7EM F-40287 F-45111

ROTISSERIE OVENS HR5E, HR7E AND KA7E NEW DRIVE MOTOR

ASSEMBLIES.

HR7E AND KA7E ROTISSERIE OVEN ROTOR CRANK ARM DISENGAGING

FROM ROTOR.

Model Specifications Instructions Manual

INTRODUCTION

• Electronic control with message center, time,

temperature and program display features.

See Multimedia

section in TIS.

See Multimedia

section in TIS.

See Multimedia

section in TIS.

All pictures and illustrations shown are of a KA7E

unless otherwise specified. When specific model

number designations are needed for clarity, they are

added to the procedure or picture.

General

• Capacity of the KA series seven spit oven is 21

to 35 chickens.

• Stacking kit available to stack ovens.

• Refer to the Specifications sheet for oven

Installation details and Instructions manual for

operating and cleaning instructions.

KA7E - Model Description

• Rotisserie oven with automatic clean cycle.

F25294 Rev. A (0412) Page 4 of 72

• Pass through controls on the unload side to

• Equipped with grease assist and chemical

• Pump for automatic draining.

KA7EM - Model Description

• Rotisserie oven without automatic clean cycle

• Electronic control with time, temperature and

• Manual drain valve.

snooze cook cycle, silence beeper and stop cook

cycle.

cleaner peristaltic pumps.

features (manual cleaning).

program display features.

Page 5

KA SERIES ELECTRIC ROTARY OVENS - GENERAL

• Equipped with grease assist and chemical

cleaner peristaltic pumps.

• Available with a grease assist peristaltic pump to

remove grease during a cook cycle (optional).

ELECTRICAL SPECIFICATIONS

KA7E AND KA7EM

VOLTS PHASE WATTAGE AMPERAGE

208 1 9,300 42.8

208 3 9,300 24.7

240 1 9,300 37.7

240 3 9,300 21.8

NOTE: Separate power supplies must be used when

stacking two ovens.

INSTALLATION NOTE:

Before putting oven into service, check to ensure

incoming power terminal block TB6 wire retaining

screws are tight.

• VOM with AC current tester (Any VOM with a

sensitivity of at least 20,000 ohms per volt can be

used.)

• Temperature Tester

• Field Service Grounding Kit

• Torque wrench capable of measuring up to 45 inlbs.

• Jewelers screwdriver

• Power switch and momentary switch removal

tool (two required) made locally to dimensions in

graphic below

NOTE: Material for tool can be aluminum, hard plastic

or any other hard material which can be easily

fabricated to dimensions.

Ovens mounted on casters or installed on stands with

casters must be provided with an adequate restraining

means to guard against transmission of strain to the

electric supply line. Instructions for tethering are

included in stacking kit instructions and with optional

oven stand. Disconnect the flexible electrical

conduit(s) before disconnecting the restraint.

WATER SUPPLY REQUIREMENTS

(KA7E ONLY)

NOTE: For proper operation, use only HOT water

supply. For installations at the end of a long hot water

line, a second pre-rinse may be required to be

programmed to prime the line.

Hot water supply:

• 3/4" hose bib fitting.

• 0.5 GPM @ 25-50 PSI.

• 120°F - 140°F.

• Recommended hardness, 4 - 6 grains.

• Minimum conductivity required, 30

MICROMHOS/CM.

Fig. 1

ACCESSORY STAND

INSTRUCTIONS

NOTE: Separate units can be lifted by means of a

forklift. To do this, open both doors. Remove fan

cover. Slide forks all of the way thru top of oven. Make

sure forks rest on the frame member and are spread

as far apart as possible. Stacked units must not be

lifted in this manner.

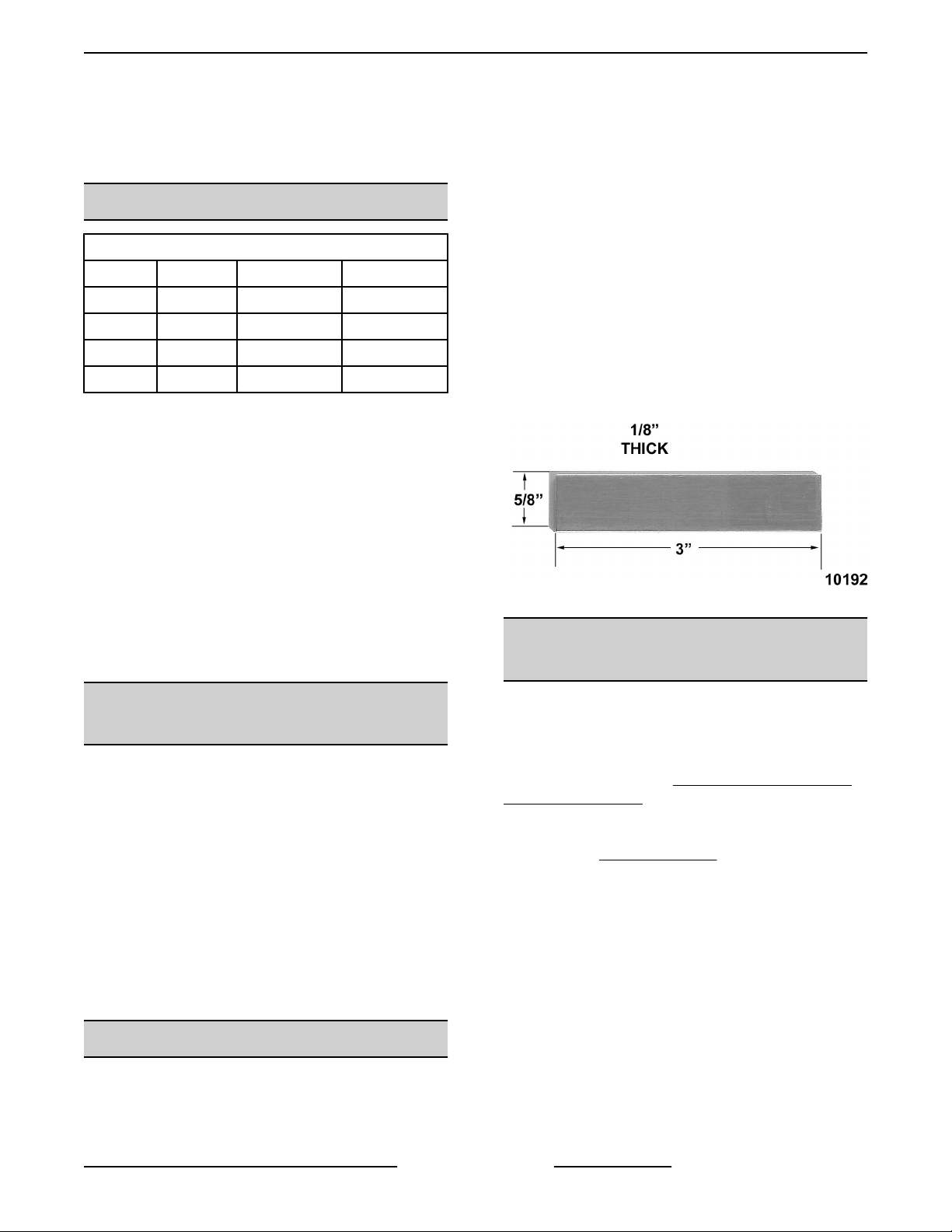

KA7E Self-Clean (ML-137701, ML-137709)

1. Remove Right Side Cover.

2. With oven lifted, remove drain plug and save it.

Drain hose is connected here and routed down

thru base.

3. Remove electric power cord blank and install

proper restraining fitting for power cord.

TOOLS

• Standard set of hand tools

Page 5 of 72 F25294 Rev. A (0412)

Page 6

KA SERIES ELECTRIC ROTARY OVENS - GENERAL

BOTTOM VIEW SHOWN

4. Remove screws securing water fill valve to utility

plate.

5. Remove screws securing drain manifold to utility

plate and utility plate to frame.

PREVIOUS CONSTRUCTION

6. Current construction - Remove strain relief nuts

securing chemical-in and grease-out hoses.

A. Remove hoses from strain relief fittings (pull

hoses through fittings but leave connected

to machine).

CURRENT CONSTRUCTION

7. Previous construction - Remove chemical-in and

grease-out hoses from 45 degree strain relief

fittings.

Fig. 5

8. Discard original utility plate, saving screws.

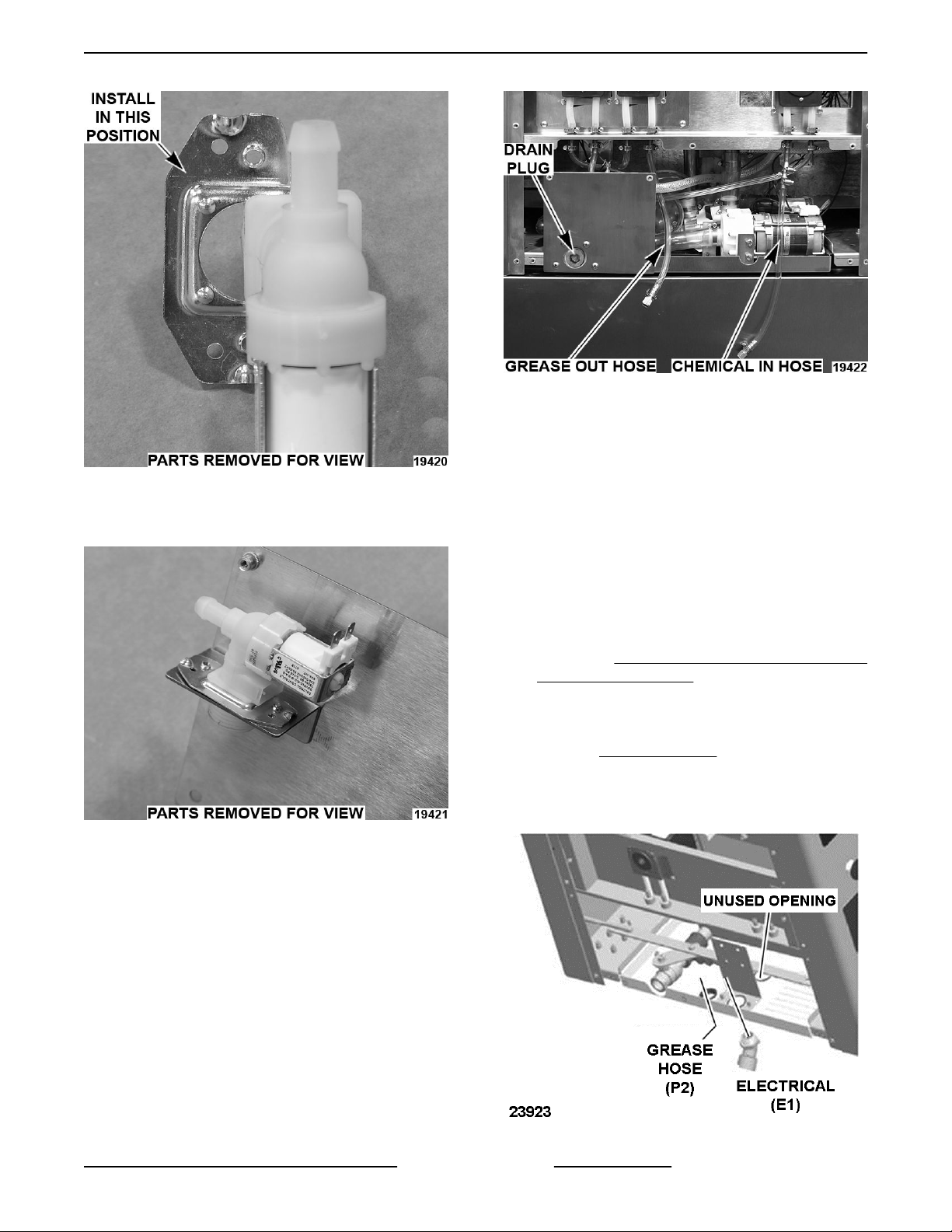

9. Slide mounting bracket off water fill valve.

10. Reinstall mounting bracket to water fill valve

F25294 Rev. A (0412) Page 6 of 72

Fig. 6

(rotated as shown).

Page 7

KA SERIES ELECTRIC ROTARY OVENS - GENERAL

15. Route water supply through the bottom of the

stand and connect. (Fittings mate to ¾ inch male

hose bib, not supplied.)

Fig. 9

Fig. 7

11. Install water valve onto bracket on new utility

plate (supplied with stand).

Fig. 8

12. Install new utility plate onto oven using screws

removed earlier.

13. Install drain plug removed earlier.

16. Route water drain through the bottom of the

stand and connect. (Fittings mate to 1 inch

female NPT, not supplied.)

17. Route chemical-in and grease-out hoses down

through bottom of machine into stand. Connect

hoses to grease vessel and chemical container.

18. Route power cord thru base into oven and

connect to terminal block.

19. Proceed to Tether Bracket and Oven Mounting to

Stand (KA7E, KA7EM).

KA7EM with Grease Assist (ML-137710,

ML-137713)

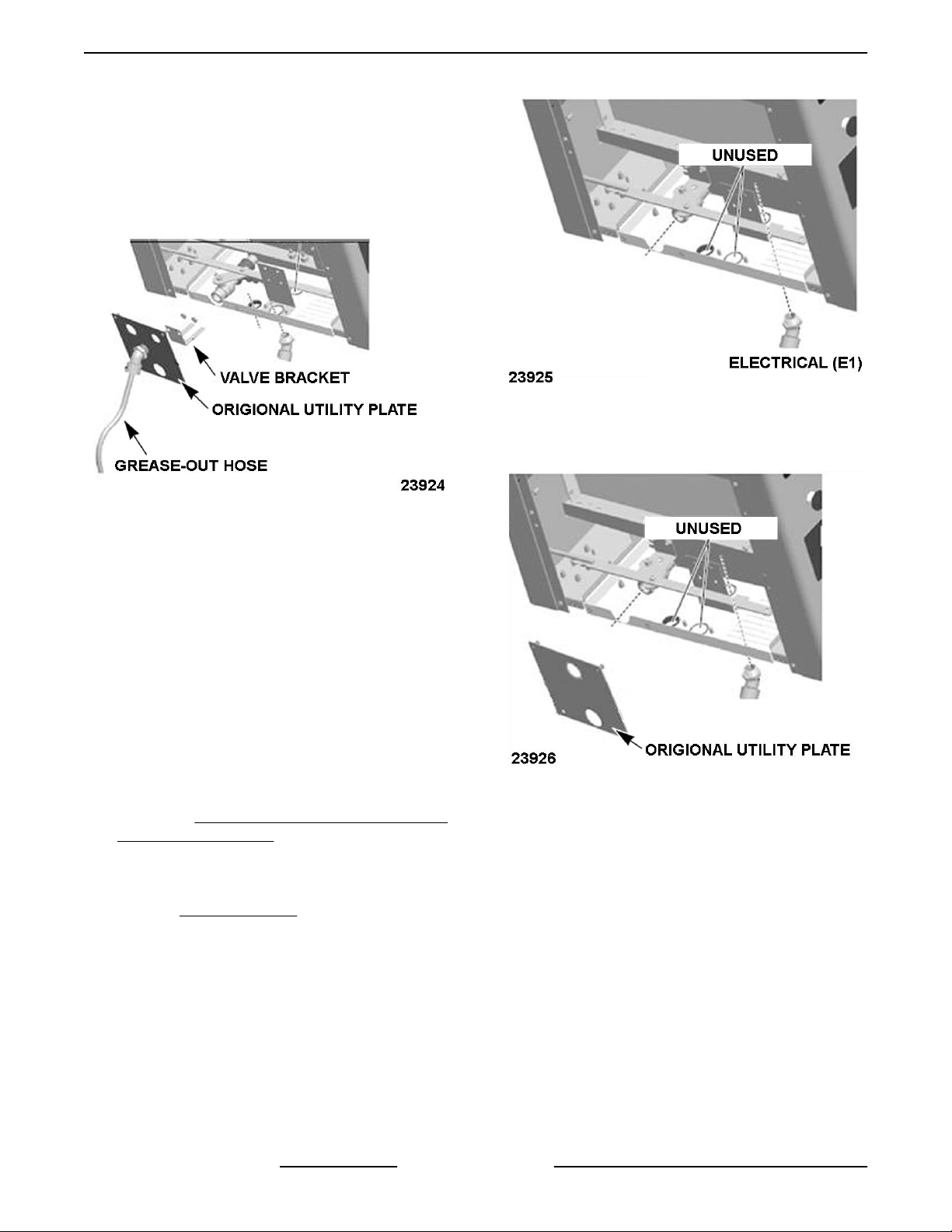

1. Remove Right Side Cover.

2. Remove electric power cord blank. Install power

cord restraining fitting (not supplied) in the proper

hole E1.

14. Install new hoses supplied with oven and route

down into base.

Fig. 10

Page 7 of 72 F25294 Rev. A (0412)

Page 8

KA SERIES ELECTRIC ROTARY OVENS - GENERAL

3. Remove screws and valve bracket from factory

standard utility plate.

4. Save screws and bracket. Discard original

factory standard utility plate.

5. Remove grease-out hose from 45 degree strain

relief fitting.

Fig. 12

3. Remove screws from factory standard utility

plate.

Fig. 11

6. Install valve bracket from old plate onto new utility

plate (supplied with stand).

7. Install new utility plate assembly onto oven using

screws removed earlier.

8. Install ¾" MNPT to ¾" ID, 90 deg, Barb Hose

Fitting (not supplied) into P1 drain connection.

NOTE: P1 drain connection cannot drop through into

stand and must exit out the right side of the oven.

9. Route grease-out hose down through bottom of

machine into stand.

10. Route power cord through stand up into oven and

connect to terminal block.

11. Proceed to Tether Bracket and Oven Mounting to

Stand (KA7E, KA7EM).

KA7EM without Grease Assist (ML-137711,

ML-137714)

1. Remove Right Side Cover.

2. Remove electric power cord blank. Install power

cord restraining fitting (not supplied) in the proper

hole E1.

Fig. 13

4. Install ¾" MNPT to ¾" ID, 90 deg, Barb Hose

Fitting (not supplied) into P1 drain connection.

5. Install new utility plate (supplied with stand)

assembly onto oven using screws removed

earlier.

6. Install Plug Button (supplied with stand

accessory) into new utility plate.

F25294 Rev. A (0412) Page 8 of 72

Page 9

KA SERIES ELECTRIC ROTARY OVENS - GENERAL

Fig. 14

7. Route power cord through stand up into oven and

connect to terminal block.

2. Using holes in oven's caster mounting plate,

secure oven to stand using 4 screws and 4

washers provided with stand accessory. Install

washers such that bolt does not slip through.

8. Proceed to Tether Bracket and Oven Mounting to

Stand (KA7E, KA7EM).

Tether Bracket and Oven Mounting to Stand

(KA7E, KA7EM)

1. Ensure that tether bracket is installed.

A. The bracket must be installed along with

one of the swivel casters to a corner as

shown using the caster hardware provided.

The remaining open hole in the center of the

tether bracket is to be used to secure one

end of the tether (locally supplied chain,

cable, etc.). The other end of the tether is to

be secured to an anchoring point in the wall

or floor when oven installation is complete.

Make sure that during oven movement, no

stress is applied to the flexible electrical

conduit(s).

Fig. 16

3. Install all removed covers.

4. Continue with installation per Instructions

Manual.

Fig. 15

Page 9 of 72 F25294 Rev. A (0412)

Page 10

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

REMOVAL AND REPLACEMENT OF PARTS

Due to use of chemical detergents, all interior replacement hardware must be stainless steel hardware

as listed in the parts catalog.

COVERS

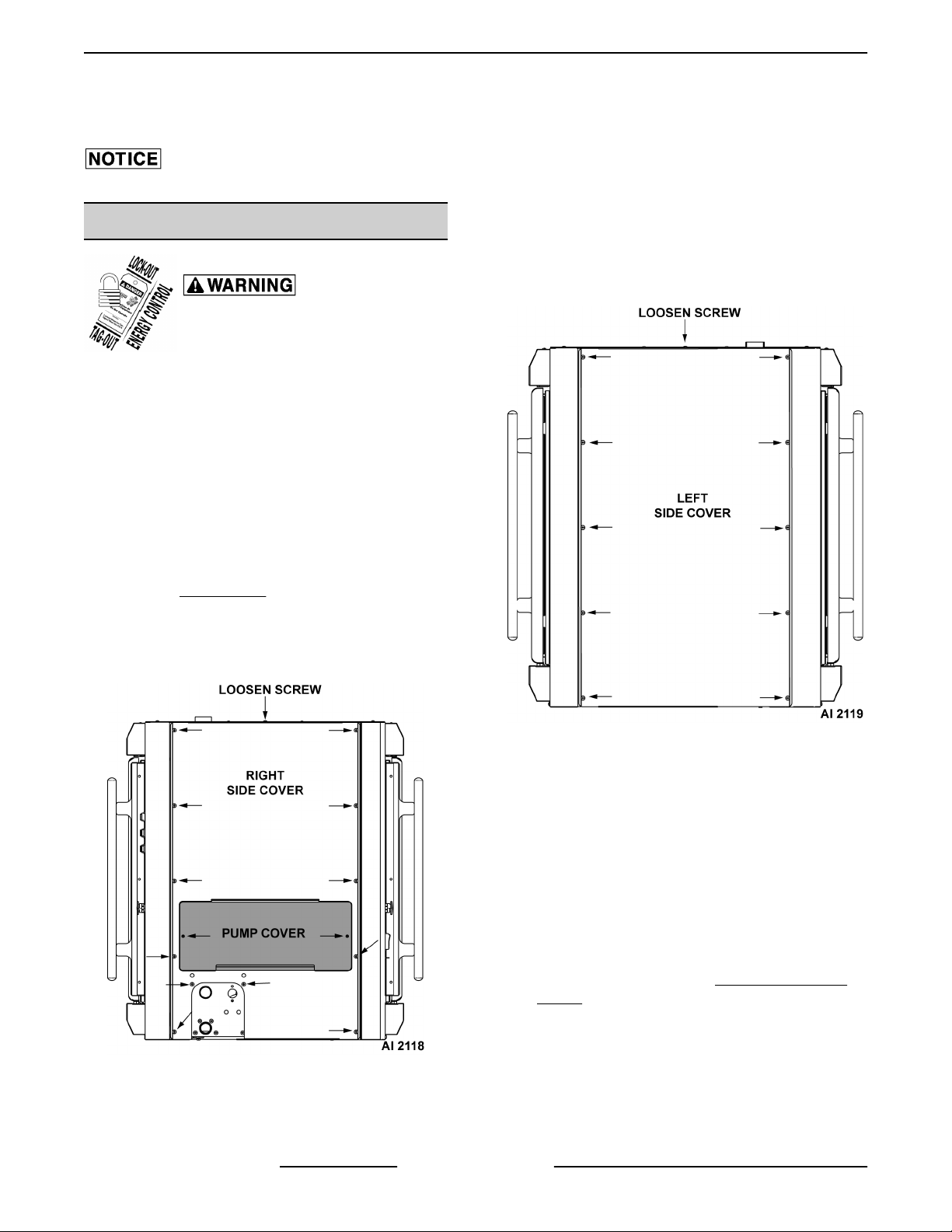

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Pump Cover

1. Remove two thumbscrews securing pump cover

and lift cover off.

2. Reverse procedure to install.

NOTE: Anytime service is performed requiring the

right side cover to be removed, check to ensure

incoming power terminal block wire retaining screws

are tight.

Right Side Cover

1. Remove Pump Cover.

2. Remove twelve screws securing right side cover

to frame.

Left Side Cover

1. Remove ten screws securing left side cover to

frame.

2. Loosen one screw securing top center of cover.

3. Loosen one screw securing top center of cover.

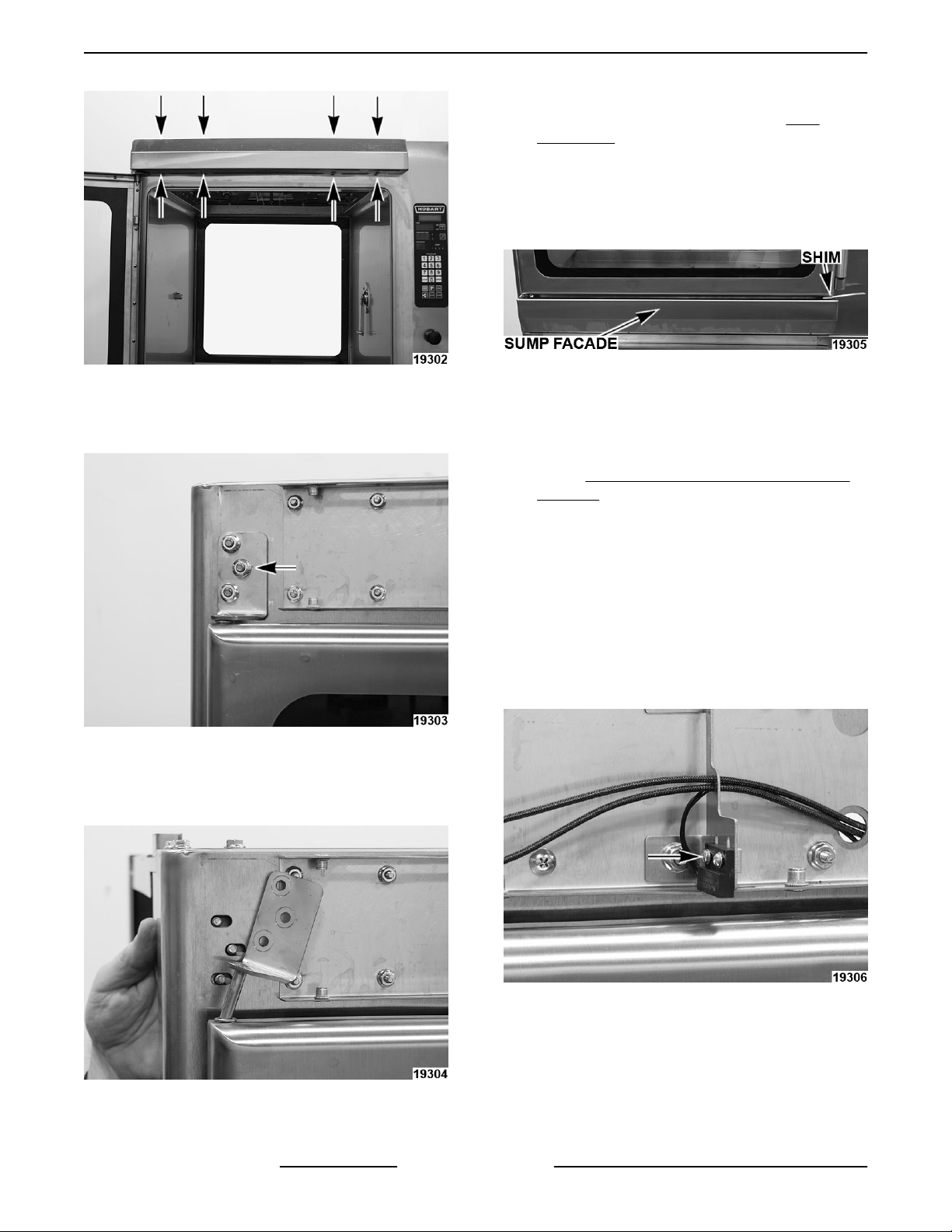

Fig. 17

4. Remove cover.

Fig. 18

3. Remove cover.

4. Reverse procedure to install.

Top Cover (Control Panel)

1. Remove screws securing top cover over controls

area.

2. Remove cover.

3. Reverse procedure to install.

Top Cover

1. Remove screws securing Top Cover (Control

Panel).

2. Remove cover.

3. Remove remaining screws securing top cover

and lift cover off.

5. Reverse procedure to install.

F25294 Rev. A (0412) Page 10 of 72

Page 11

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 19

4. Reverse procedure to install.

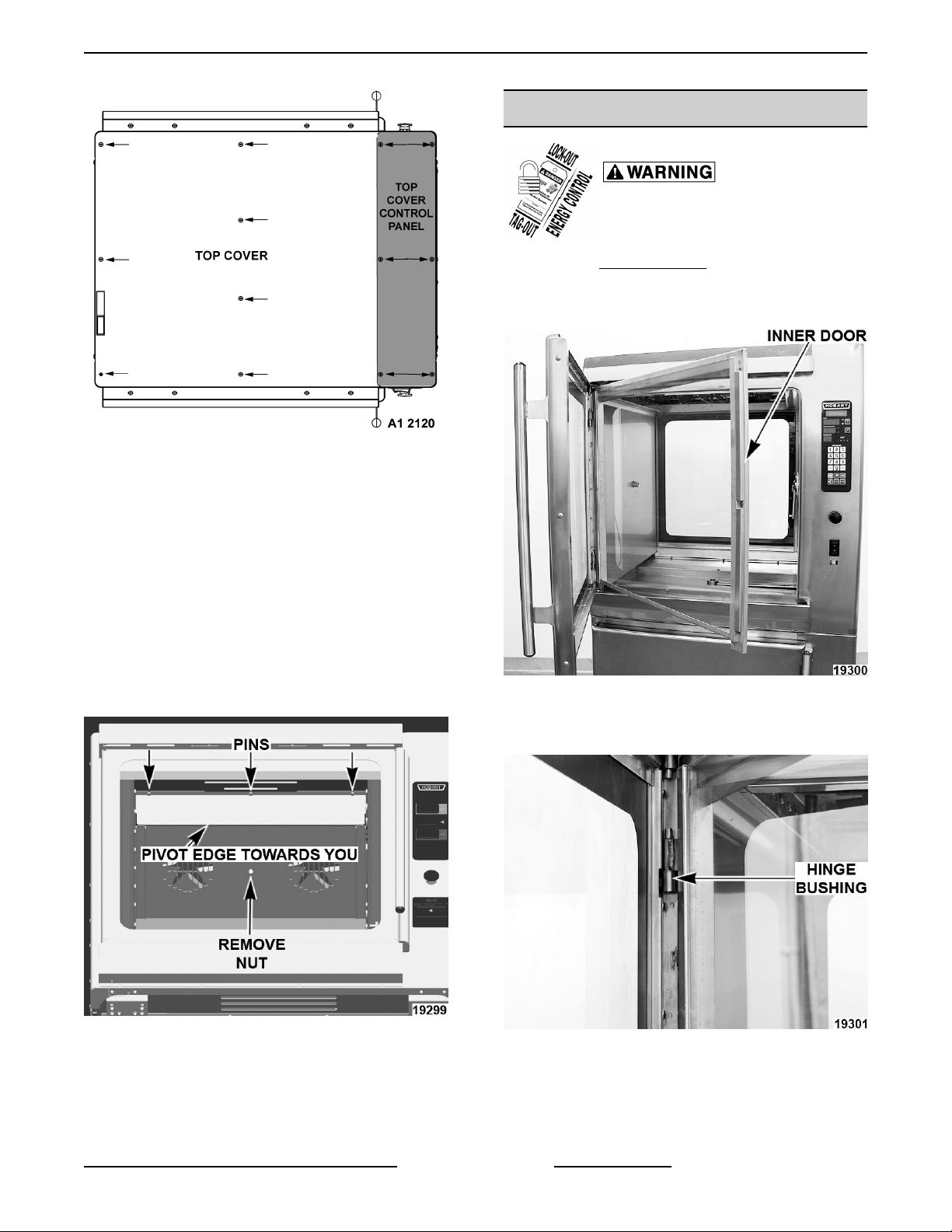

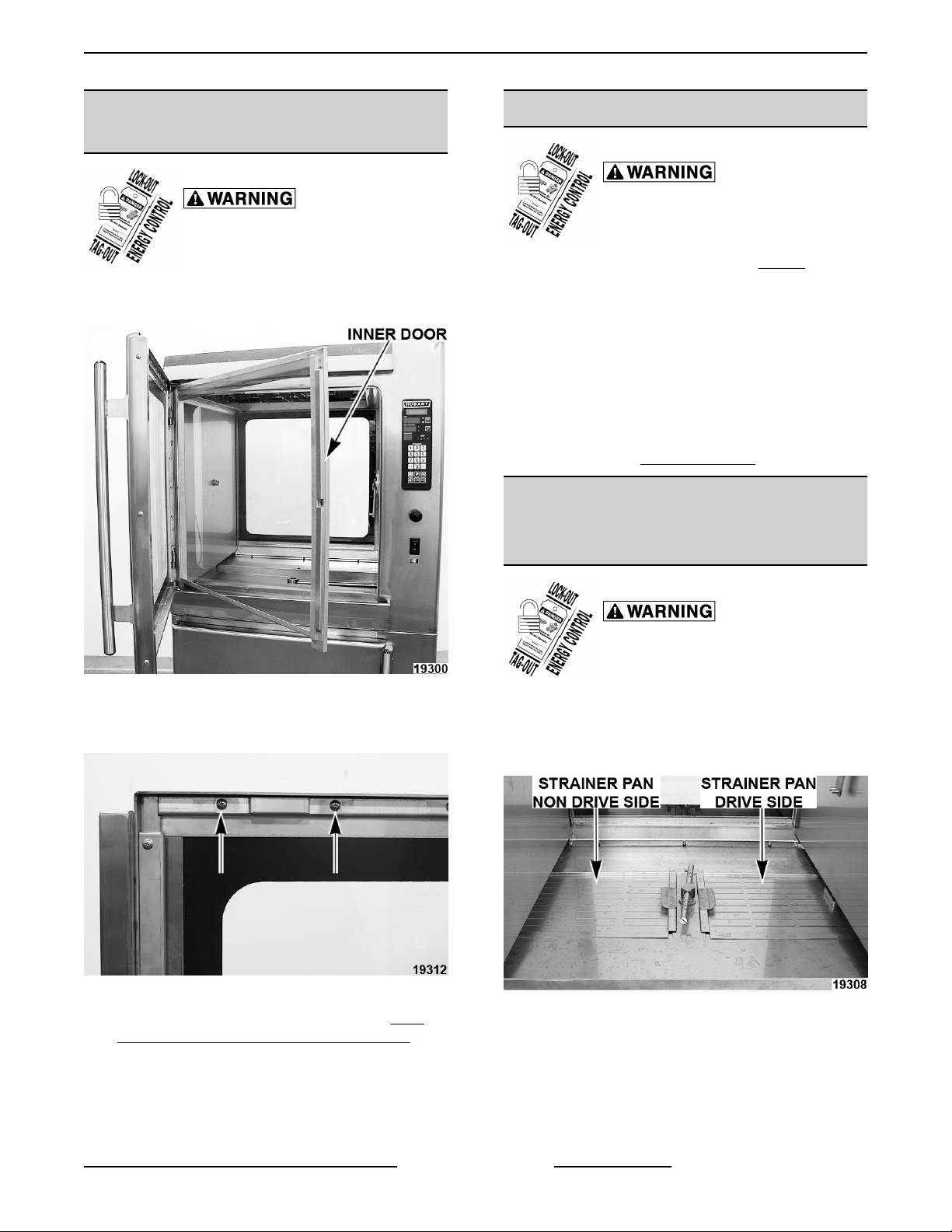

DOOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Left Side Cover.

2. Open oven door and pull inner oven door to

overcome magnet hold to main door.

Fan Cover

1. Open door.

2. Remove nut securing fan cover to top of cavity.

3. Grab deflector edge and pivot edge toward you

to disengage cover from studs.

4. Slide cover off studs at opposite side and remove

cover.

NOTE: Fan cover can be removed thru either door in

the same manner.

Fig. 21

3. Lift inner door hinge pins out of hinge bushings

and lay door on a flat padded surface.

VIEW - AS LOOKING THROUGH DOOR GLASS

5. Reverse procedure to install.

NOTE: Make sure all six studs are engaged properly

and that the cover does not hang down.

Page 11 of 72 F25294 Rev. A (0412)

Fig. 22

4. Remove screws securing facade to oven.

Page 12

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

8. Reverse procedure to install but leave nuts

securing hinge plate loose. Perform Door

Adjustment.

Door Adjustment

1. With top hinge plate mounting nuts loose, use an

object to shim handle end of door to make bottom

of door parallel to the sump facade.

Fig. 23

5. Close door.

6. Remove nuts securing top hinge to cabinet.

Fig. 24

7. Carefully remove hinge plate while supporting

hinge backing plate and lift door off lower hinge

pin.

Fig. 26

2. Tighten hinge plate nuts and check door

operation. Make sure there is no interference or

rubbing when door is operated. Door must not

contact sump facade when opening or closing.

3. Check Door Switch Adjustment (KA7E only; if

required). LED at CPU board input X22 should

be on when both doors are closed and both door

switches are closed.

Door Switch Adjustment (KA7E only; if required)

1. With oven top facade removed to access door

switch, loosen switch mounting screws and

adjust switch as required. LED at CPU board

input X22 should be on when both doors are

closed and both door switches are closed.

2. Install all covers and check for proper operation.

Fig. 25

F25294 Rev. A (0412) Page 12 of 72

Fig. 27

Page 13

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

DOOR SWITCH MAGNET (KA7E

ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Open oven door and pull inner oven door to

overcome magnet hold to main door.

OUTER DOOR GLASS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove door as outlined under DOOR.

2. Lay door on a flat padded surface.

3. Remove screws securing glass and remove

glass.

4. Install new glass in same orientation as old glass.

NOTE: Avoid contact such as bumping or hitting, or

abrasion of glass edges.

5. Install in reverse order and adjust door as

outlined under Door Adjustment.

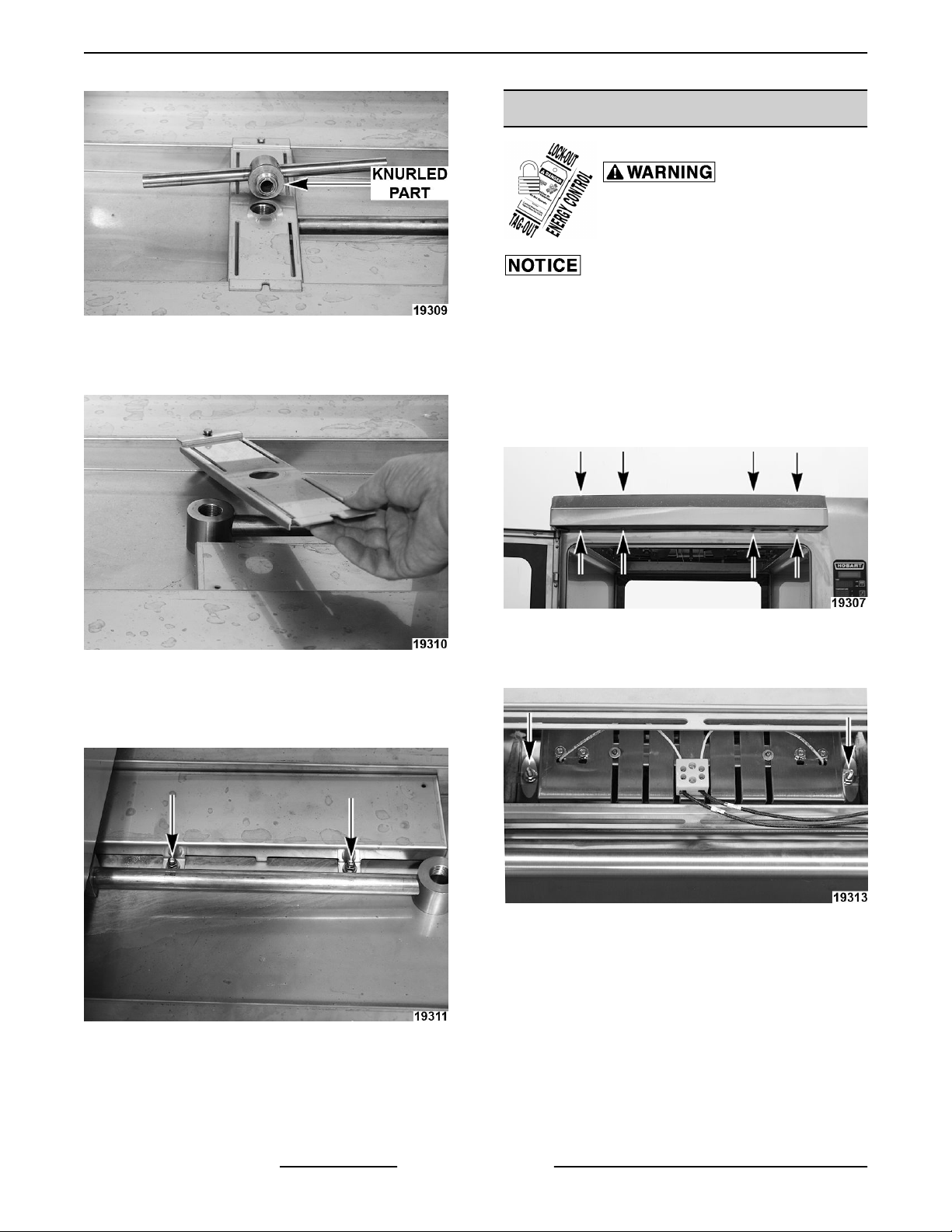

WASH ARM, STRAINER PANS,

STRAIN PAN SUPPORT, DRAIN

SHROUD (KA7E ONLY)

Fig. 28

2. Remove screws securing magnet housing and

remove magnet.

Fig. 29

3. Reverse procedure to install and check Door

Switch Adjustment (KA7E only; if required).

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Open oven door.

2. Use strainer pan handle and lift pan out of oven.

NOTE: Pan positions are not interchangeable.

Fig. 30

3. To remove wash arm, unscrew knurled part of

wash arm.

Page 13 of 72 F25294 Rev. A (0412)

Page 14

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 31

4. To remove strain pan support, lift end and

disengage other end from stud.

LAMP

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Do not touch the glass portion of the lamp

with your hands. The oil from your hands could affect

the operation of the lamp. Skin oil may be removed

with alcohol while the lamp is cold.

NOTE: Use a clean rag or paper towel to handle

replacement lamp.

1. Open door.

2. Remove screws securing facade to oven.

Fig. 32

5. To remove drain shroud, remove nuts and

washers securing shroud and lift shroud out of

oven.

Fig. 33

6. Reverse procedures to install.

Fig. 34

3. Remove two nuts securing lamp assembly to top

of oven.

Fig. 35

4. Lift lamp assembly out of oven and support it.

5. Loosen screws in terminal block securing lamp

wires and pull wires out of block.

F25294 Rev. A (0412) Page 14 of 72

Page 15

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 36

6. Work lamp with wires out of lamp brackets. Wires

can not be removed from lamp.

Fig. 37

7. Install and tighten insulators evenly to prevent

damage.

8. Reverse procedure to install.

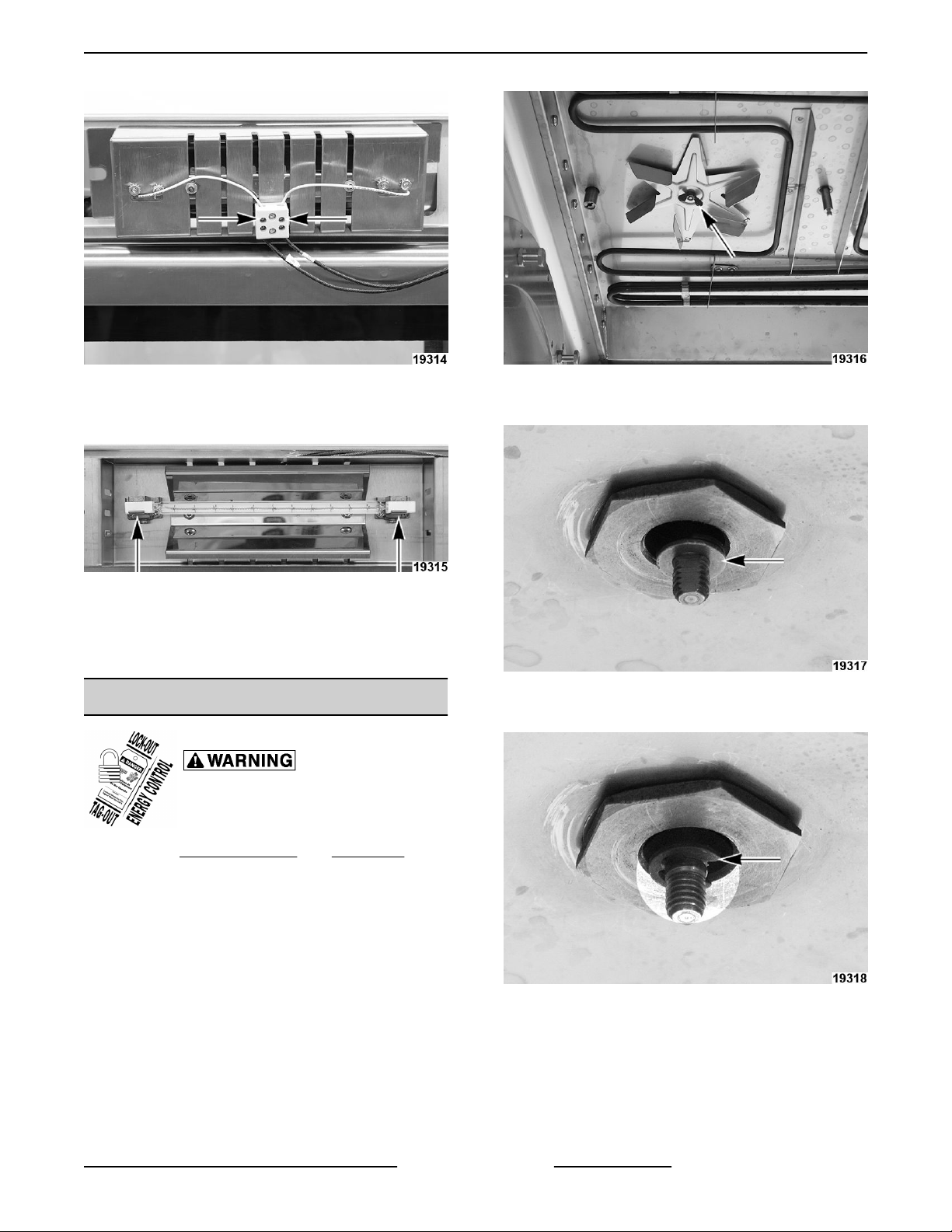

FAN MOTORS ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

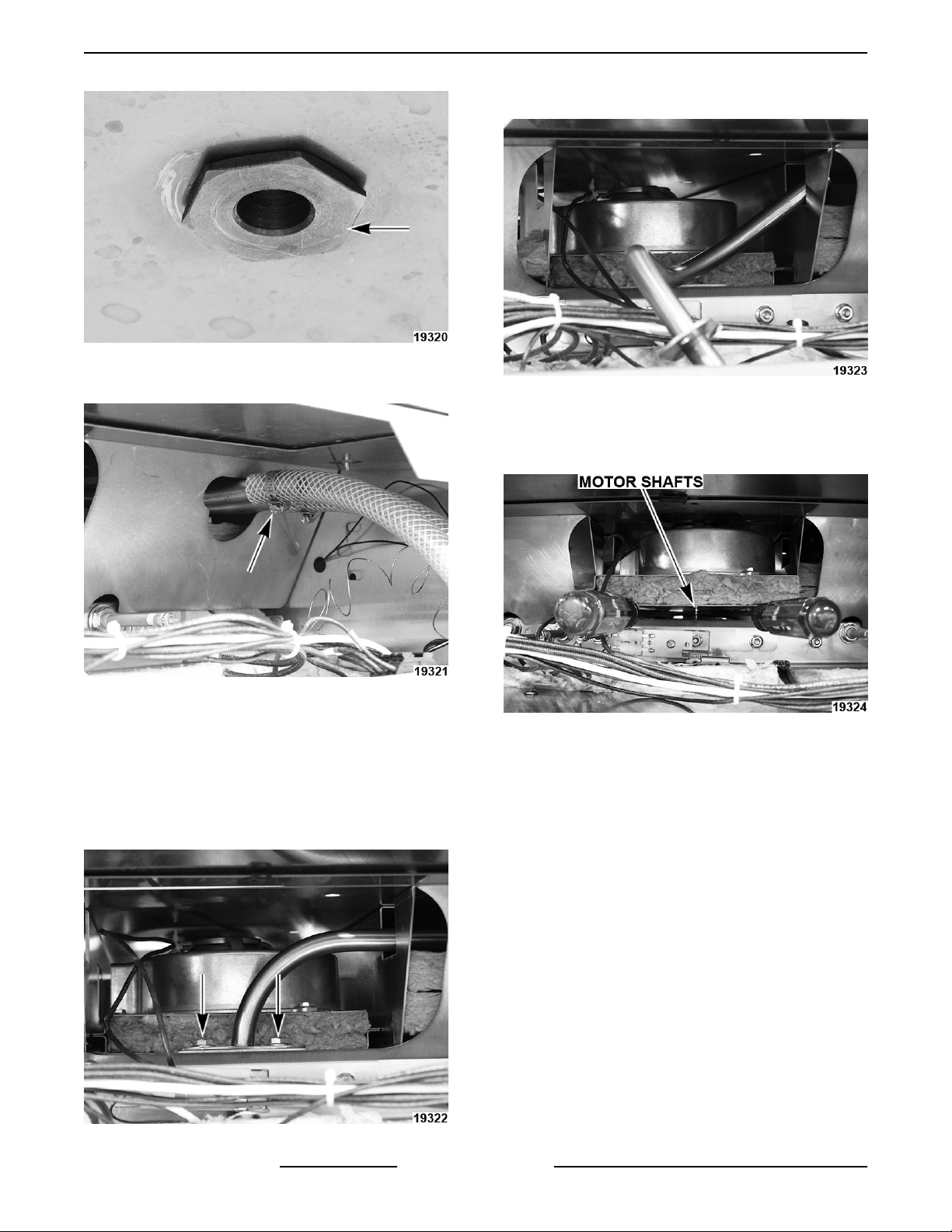

Fig. 38

4. Remove washer from both shafts.

Fig. 39

5. Remove C clip from both shafts.

1. Remove

2. Remove wing nut securing each fan blade. Nut is

left hand thread, turn clockwise to remove.

3. Remove both fan blades.

Right Side Cover and Fan Cover.

Page 15 of 72 F25294 Rev. A (0412)

Fig. 40

6. Unscrew both fan mounting nuts.

NOTE: Check condition of o-ring on fan mounting nut

and replace if necessary.

Page 16

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

C. Work pipe out of oven.

Fig. 41

7. KA7E only:

Fig. 42

A. Loosen hose clamp and remove hose from

control side nozzle and pipe assembly.

B. Remove screws and nuts securing control

side nozzle pipe assembly to top of oven.

NOTE: Check condition of o-rings on screw heads

and replace if necessary.

Fig. 44

8. Insert two large screwdrivers or similar objects

that can lift fan motor assembly enough for motor

shafts to clear inside ceiling.

Fig. 45

9. Identify and disconnect motor wires.

10. Carefully slide fan motor assembly out of cavity.

11. Remove screws securing fan motor assembly

and lift out.

Fig. 43

F25294 Rev. A (0412) Page 16 of 72

Page 17

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

2. Disconnect lead wires from element being

replaced.

Fig. 46

12. Remove o-ring from old fan motor shaft and

install on new fan motor. If not in good condition,

install new o-ring.

Fig. 47

13. Reverse procedure to install.

14. After installing the fan blade, verify that it does

not rub the top of the cavity. If required, remove

fan blade and tighten fan mounting nut (shown in

Step 6 above).

Fig. 48

3. Use a wrench on element inside oven while

removing and installing mounting nut.

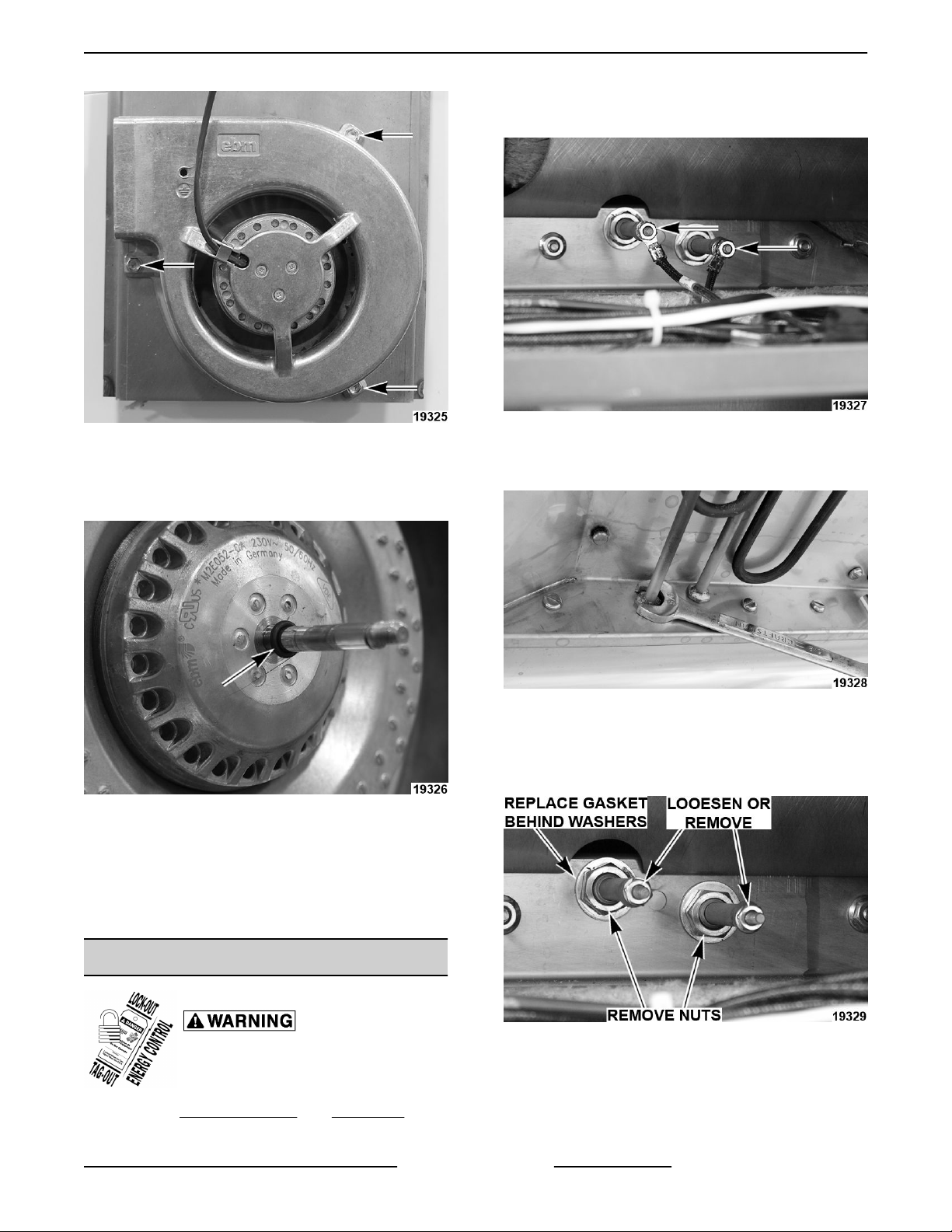

Fig. 49

4. Remove nuts securing element being replaced.

NOTE: If mounting nuts will not slide over wire lead

backup nuts, loosen them or remove them.

HEATING ELEMENTS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover and Fan Cover.

Fig. 50

5. Remove screws securing element support

bracket to ceiling and remove bracket.

Page 17 of 72 F25294 Rev. A (0412)

Page 18

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 51

6. Slide element out of wall.

7. Clean off old gasket that may stick to wall or

washer and replace with new gasket (not

included with element).

Fig. 53

3. Disconnect wires from high limit thermostat.

4. Remove screws securing high limit to frame.

Fig. 52

8. Reverse procedure to install.

9. Torque element mounting nuts to 45in-lbs. Use

backup wrench on element inside oven to

prevent twisting and damage to element.

10. Torque nuts securing wires onto element to 1420in-lbs. Use a backup wrench on back nut to

prevent twisting and damage to element.

HIGH LIMIT THERMOSTAT

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Pull high limit probe out of hole located in top right

hand corner.

Fig. 54

5. Reverse procedure to install.

NOTE: Set the high limit thermostat to its maximum

clockwise position.

TEMPERATURE SENSOR

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Remove screw and nut securing temperature

sensor to mounting bracket.

F25294 Rev. A (0412) Page 18 of 72

Page 19

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

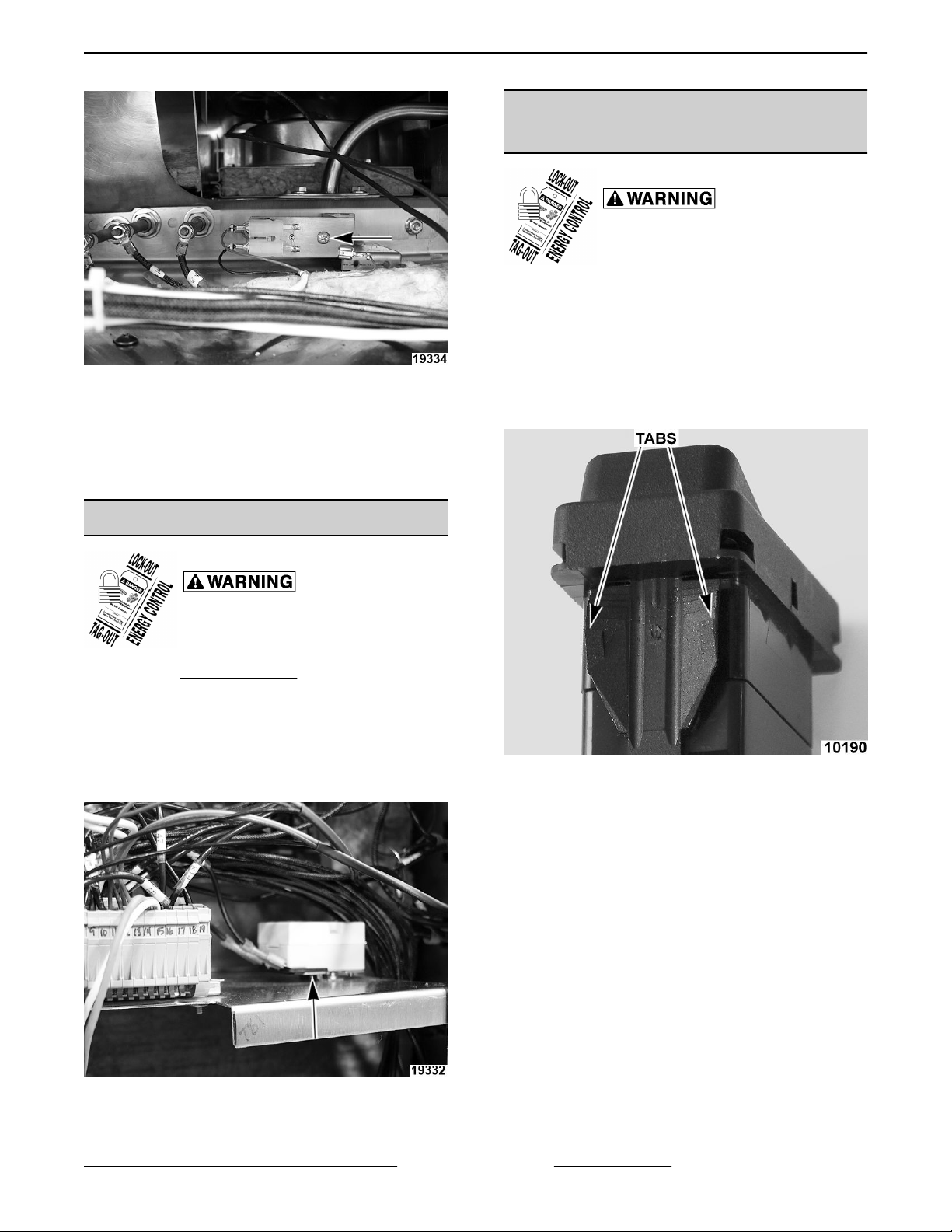

POWER SWITCH AND

MOMENTARY SWITCHES

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: Momentary switches on KA7E only.

Fig. 55

3. Disconnect wires from temperature sensor.

4. Pull temperature sensor out thru the opening in

oven wall.

5. Reverse procedure to install.

CONTACTORS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Disconnect lead wires from contactor being

replaced.

3. Push down on top of contactor and pull bottom of

contactor out then up to remove it from the din

rail.

Right Side Cover.

1. Remove

2. Disconnect wires from switch.

NOTE: There are four tabs (two at each end) that

must be depressed in order for switch to slide out of

bezel.

SWITCH DISASSEMBLED FOR VIEW

3. Use recommended tools to release locking tabs

at both top and bottom of switch body.

Right Side Cover.

PARTS REMOVED FOR VIEW

4. Reverse procedure to install.

NOTE: Picture below shows parts not installed in

oven for illustration purposes. It is recommended that

you fully insert tools and gently spread tool ends apart

as shown. Then gently pull switch out of bezel. Some

gentle prying may be necessary to start switch out of

bezel.

Page 19 of 72 F25294 Rev. A (0412)

Page 20

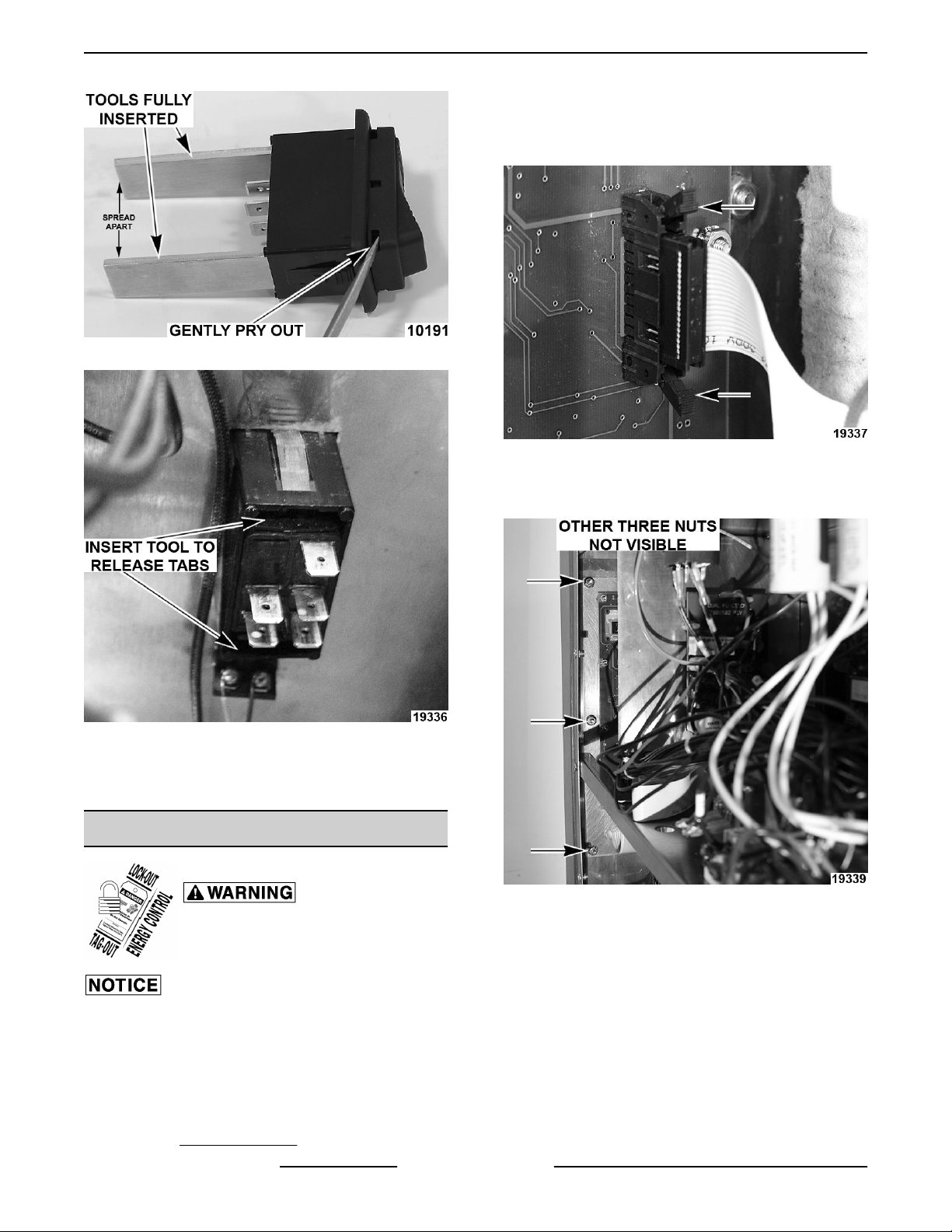

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

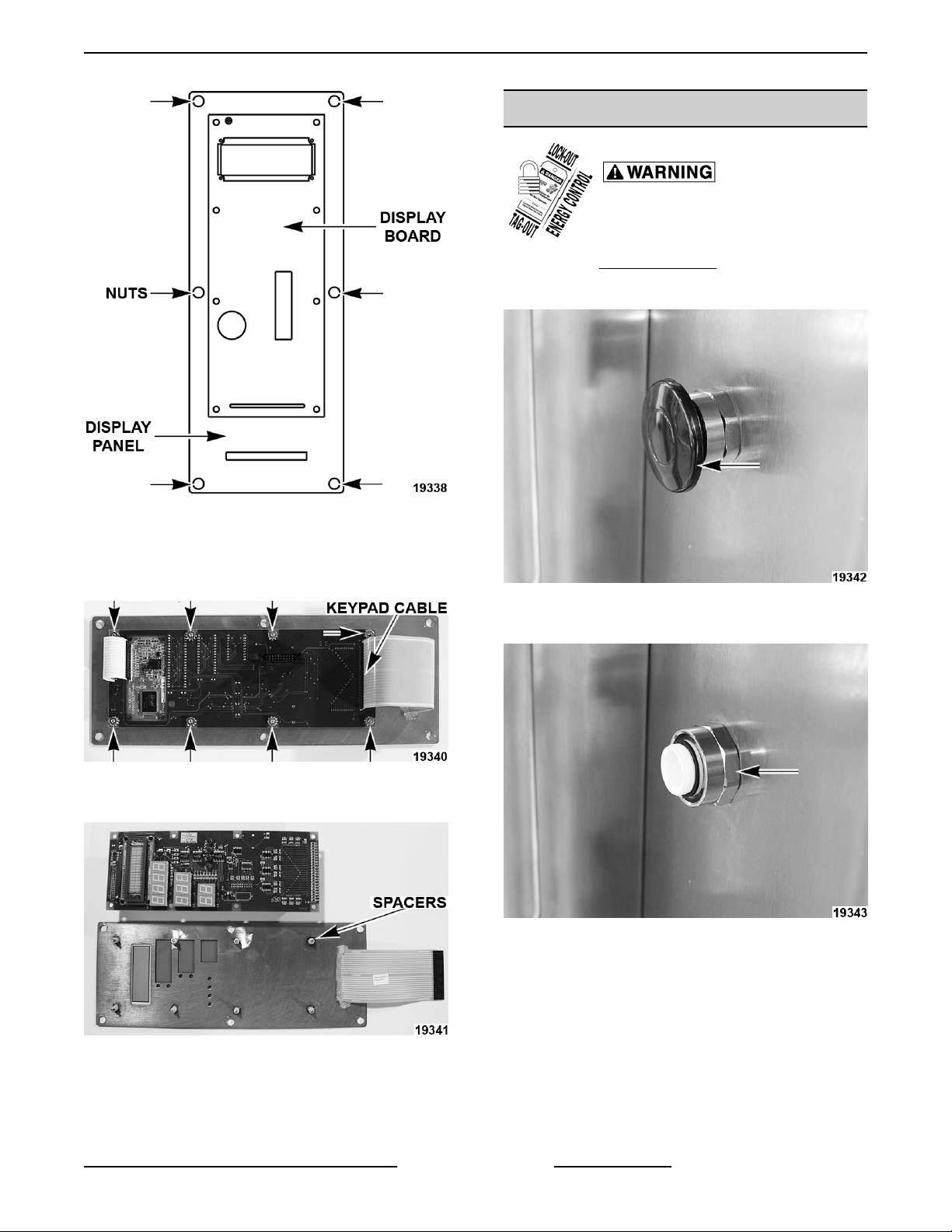

2. Unplug ribbon cable from display board.

A. Spread retaining clips to extract plug from

socket.

Fig. 58

Fig. 60

3. Remove six nuts securing display panel with

display board attached and lift out of oven.

Fig. 59

4. Push switch out of bezel.

5. Reverse procedure to install.

DISPLAY BOARD AND KEYPAD

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available

to prevent damage. The field service grounding kit

must be used anytime the control board is handled.

TSB 1381 KA7E ROTARY OVEN SCRAMBLED VFD

DISPLAY.

1. Remove

F25294 Rev. A (0412) Page 20 of 72

Right Side Cover.

Fig. 61

Page 21

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

ROTOR STOP/START SWITCH

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Unscrew black knob and remove from switch.

Fig. 62

4. Unplug keypad cable from display board.

5. Remove eight nuts and washers securing board

to panel and lift board off studs.

Fig. 63

6. Remove spacers from studs on display panel.

Fig. 65

3. Unscrew mounting nut.

Fig. 66

Fig. 64

7. Reverse procedure to install.

4. Pull switch out of hole.

5. Identify and disconnect wires.

6. Reverse procedure to install.

Page 21 of 72 F25294 Rev. A (0412)

Page 22

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

MEAT PROBE MINI JACK

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Mini jack is located under power switch.

Fig. 68

4. Identify and disconnect wires from mini jack

terminals.

Fig. 67

3. Use a small screwdriver or similar object to

carefully pry tabs out and work retainer clip off

jack.

NOTE: Jack shown removed from oven for view. Also

notice that wires are polarity sensitive and must be

connected properly for correct operation.

5. Reverse procedure to install.

CAPACITORS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Disconnect wires from capacitor being replaced.

3. Remove hardware securing capacitor being

replaced and remove capacitor.

Right Side Cover.

F25294 Rev. A (0412) Page 22 of 72

Fig. 69

Page 23

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

4. Identify and disconnect wires.

Fig. 70

4. Reverse procedure to install.

WATER LEVEL CONTROL BOARD

(KA7E ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available

to prevent damage. The field service kit must be used

anytime the control board is handled.

1. Remove Right Side Cover.

2. Remove four screws securing divider wall that

water level control board is fastened to.

Fig. 72

5. Use needle nose pliers to squeeze tabs on five

board supports. Work board off supports.

Fig. 71

3. Pivot divider wall to access water level control

board.

Fig. 73

6. Reverse procedure to install.

Page 23 of 72 F25294 Rev. A (0412)

Page 24

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

WATER LEVEL SENSOR (KA7E

ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove

2. Remove wire attached to sensor.

3. Unscrew sensor and remove from oven.

4. Reverse procedure to install.

Right Side Cover.

PARTS REMOVED FOR VIEW

CHEMICAL SENSOR (KA7E ONLY)

Fig. 75

4. Reverse procedure to install.

WASH PUMP RELAY (KA7E ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Use small screwdriver to pry out release tab, lift

front of relay and disengage rear of relay from din

rail.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Oven cleaners are corrosive and

can cause chemical burns. Rubber gloves, goggles

and protective clothing are required. Read and follow

the instructions for the oven cleaner.

1. Remove Right Side Cover.

2. Remove wire attached to sensor.

3. Loosen hose clamps and work hoses off sensor.

F25294 Rev. A (0412) Page 24 of 72

3. Identify and disconnect wires.

4. Reverse procedure to install.

Fig. 76

Page 25

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

TRANSFORMER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Remove two screws and nuts securing

transformer.

Fig. 77

CPU BOARD

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is available

to prevent damage. The field service kit must be used

anytime the control board is handled.

1. Remove

2. Carefully identify and disconnect all wires from

CPU board.

Right Side Cover.

3. Identify and disconnect wires to transformer.

4. Unscrew nut and remove mounting bracket.

Fig. 78

5. Reverse procedure to install.

Fig. 79

3. Squeeze tabs on one support at a time and pull

board off supports.

Fig. 80

4. Reverse procedure to install.

Page 25 of 72 F25294 Rev. A (0412)

Page 26

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

PERISTALTIC PUMPS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Oven cleaners are corrosive and

can cause chemical burns. Rubber gloves, goggles

and protective clothing are required. Read and follow

the instructions for the oven cleaner.

NOTE: Procedure applies to KA7E; and the KA7EM

with grease assist only.

NOTE: KA7E rotisserie ovens previously were

produced with 3 peristaltic pumps - a gray water/sump

pump, grease pump, and chemical pump. The gray

water/sump pump is no longer required in current

production beginning with Serial No. 46300096. The

pump system parameters have changed so that the

main drain pump (not pictured) removes any lingering

gray water from the sump. Refer to

- PROGRAMMING AND DIAGNOSTICS for

Programming parameters

SERVICE MODE

Pump Removal

1. Remove Right Side Cover.

2. Disconnect wires for pump to be removed.

3. Disconnect hoses for pump to be removed.

4. Remove screws securing pump to frame.

Fig. 82

5. Rotate pump slightly counterclockwise to line up

with cutout in frame and withdraw pump out of

frame.

6. Reverse procedure to install.

Procedure to Replace Pump Hose

NOTE: Only use recommended replacement hose

found in the parts catalog.

Fig. 81

TSB 1417 KA7E - CLOGGING AT INPUT AND

OUTPUT OF PERISTALTIC PUMPS. See Multimedia

section in TIS.

F25294 Rev. A (0412) Page 26 of 72

1. Remove three screws securing face plate and

Fig. 83

pull face plate off.

Page 27

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

KA7E PREVIOUS CONSTRUCTION WITH GREY

WATER/SUMP PERISTALTIC SHOWN ON LEFT

2. Disconnect hose ends and work hose out of

pump.

Fig. 87

5. Install new hose. Work hose around cavity and

manually turn rollers as hose is positioned. Make

sure hose clamp is in cutout to hold hose in

position.

Fig. 85

3. If rollers need to be removed, use a screwdriver

and release both sides of retaining clamp.

Fig. 86

4. Pull roller assembly off shaft.

Page 27 of 72 F25294 Rev. A (0412)

Fig. 88

6. Install face plate.

7. Install hose clamps and connect hoses. Trim

discharge hose length if needed for proper fit.

8. Complete reversing procedure to install.

9. Verify that pump is working properly as outlined

under SERVICE MODE - PROGRAMMING AND

DIAGNOSTICS.

Page 28

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

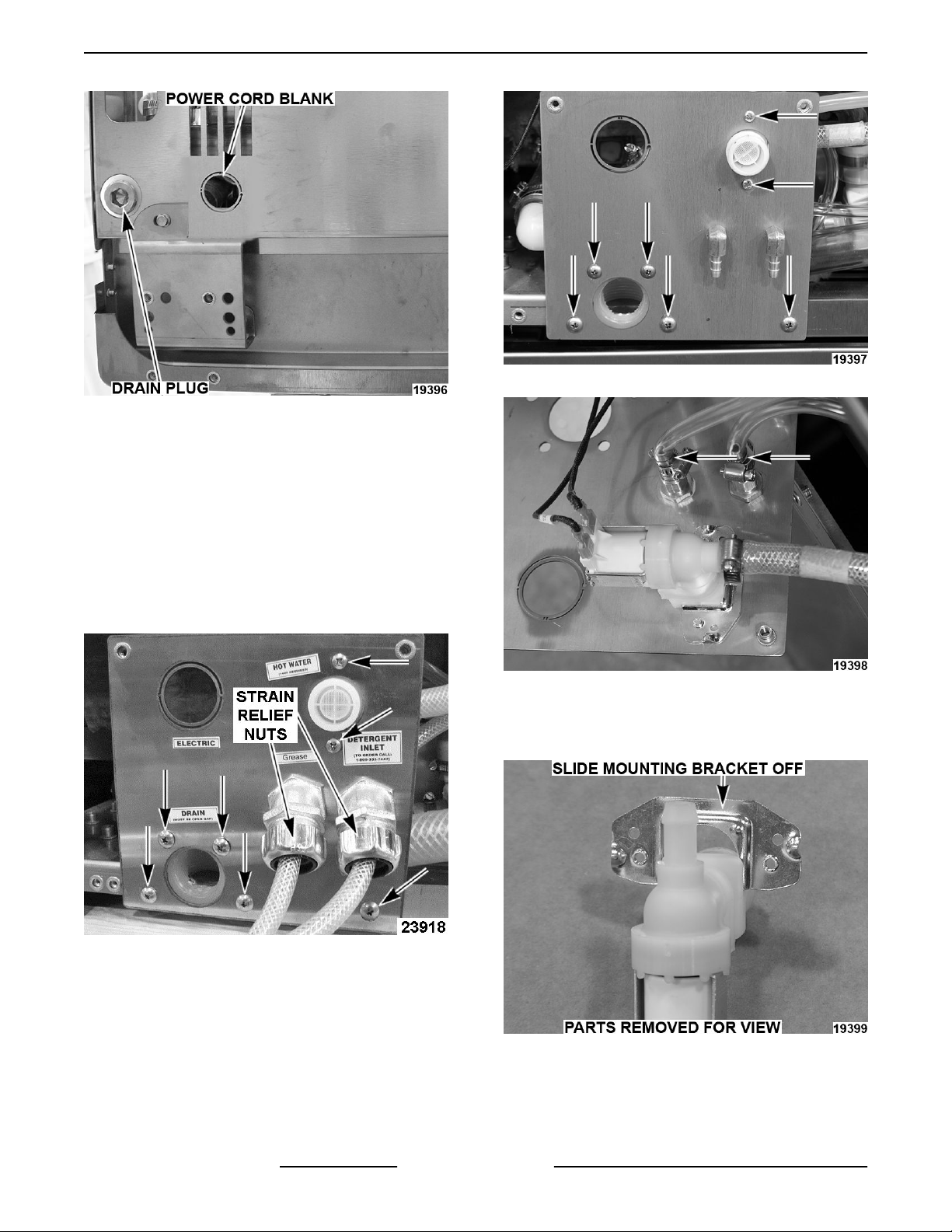

WATER FILL VALVE (KA7E ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Shut off water supply to oven.

3. Disconnect water hose into oven water fill valve.

4. Disconnect wires to water fill valve.

5. Remove screws securing water valve to utility

plate.

KA7E - CURRENT CONSTRUCTION

6. Disconnect hose connected to outlet of water

valve.

7. Reverse procedure to install.

WASH PUMP (KA7E ONLY)

KA7E - PREVIOUS CONSTRUCTION

3. Remove screws securing pump to bracket.

4. Loosen both hose clamps.

Fig. 91

5. Pivot pump and pull out of oven.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Disconnect wires from wash pump.

6. Reverse procedure to install.

F25294 Rev. A (0412) Page 28 of 72

Fig. 92

Page 29

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

DRAIN PUMP (KA7E ONLY)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove Right Side Cover.

2. Remove WASH PUMP (KA7E ONLY).

3. Disconnect wires from drain pump.

4. Remove screws securing pump to bracket.

5. Loosen both hose clamps.

DRIVE MOTOR ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

TSB1400 KA7E - LEAKS AT DRIVE ARM GASKET

DURING WASH CYCLE.

TSB 1383 ROTISSERIE OVENS HR5E, HR7E AND

KA7E NEW DRIVE MOTOR ASSEMBLIES. See

Multimedia section in TIS.

TSI HR7E AND KA7E ROTISSERIE OVEN ROTOR

CRANK ARM DISENGAGING FROM ROTOR. See

Multimedia section in TIS.

1. Check that crank arm is stopped pointing to the

side that has the interior light (or pointing away

from motor). If it is not, apply power to unit and

use the rotate switch to start and stop drive motor

when crank arm is in the proper position. Then

disconnect power.

NOTE: If there is a motor malfunction and you cannot

position the crank arm, you will be able to manually

put the crank arm in the proper position after you

remove the motor and speed reducer. Refer to DRIVE

MOTOR, SPEED REDUCER AND GEARBOX.

Fig. 93

6. Pivot pump and pull out of oven.

Fig. 94

7. Reverse procedure to install.

Fig. 95

2. Remove Right Side Cover.

3. Remove screws securing gasket bracket and

gasket.

NOTE: Replace washers and gasket with new ones

on reassembly.

Page 29 of 72 F25294 Rev. A (0412)

Page 30

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 96

NOTE: Gasket bracket may not be able to be

removed until gear box mounting screws are

removed.

4. Identify and remove motor wires from terminal

block.

A. Insert jeweler screwdriver or similar small

tool into holes to release spring tension and

pull wires out.

NOTE: The following picture shows the terminal block

disassembled to illustrate how the tool is inserted to

release the wire.

KA7E - PREVIOUS CONSTRUCTION SHOWN

6. Remove four screws, washers and nuts securing

assembly to motor support.

Fig. 99

7. Pivot motor away from oven and work crank arm

out of hole in side wall.

Fig. 97

5. Remove four screws securing pump mounting

box and allow box to slide down for access to

motor support screws.

F25294 Rev. A (0412) Page 30 of 72

8. Remove gasket bracket and gasket if not already

Fig. 100

removed.

Page 31

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 101

9. If replacing any individual piece, remove four

screws securing motor and speed reducer to

gearbox. Torque screws to 22 inch lbs. on

reassembly.

3. Place non-driven side of rotor shaft onto upper

notch of support bearing.

NOTE: Ensure rotor is slid as far as possible on

bearing support toward non-drive side.

Fig. 103

MOTOR ALREADY REMOVED

10. Install in reverse order.

11. Snug but do not tighten screws securing gasket

bracket at this time. Bracket and gasket must be

loose during the drive motor adjustment

procedure.

12. Continue to Drive Motor Adjustment.

Drive Motor Adjustment

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

4. Place drive end of rotor shaft on crank arm

support notch.

Fig. 104

5. Loosen screws securing rotor drive motor to

support bracket.

NOTE: Some pictures show different model oven

parts. They are used for view and adjustment is

identical.

1. Remove Right Side Cover.

2. Install rotor.

Fig. 105

6. Use a square or similar tool to make gearbox

square to motor support.

Page 31 of 72 F25294 Rev. A (0412)

Page 32

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

Fig. 106

Fig. 108

8. Rotate rotor to align crank arm pins with slots on

rotor.

Fig. 107

7. Slide gearbox in or out, while keeping it square

to motor support, until there is sufficient

clearance for rotor shaft to be lifted off and on the

support notch without the end of shaft contacting

crank arm.

Fig. 109

9. Slide rotor toward crank arm to engage pins.

F25294 Rev. A (0412) Page 32 of 72

Page 33

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

17. Check for proper removal and installation of

rotor.

18. Tighten gasket bracket screws.

19. Continue reassembly and check oven for proper

operation.

DRIVE MOTOR, SPEED REDUCER

AND GEARBOX

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Fig. 110

10. Apply power to oven and carefully jog motor to

place crank pointing toward side with interior

light. Ensure crank arm is parallel with oven wall.

Position motor as necessary while maintaining

adjustment in previous step.

11. Jog motor to point crank arm to opposite side of

oven. Ensure crank arm is parallel with oven wall.

Position motor as necessary while maintaining

adjustment in previous steps.

12. Repeat steps 6 thru 11 as necessary until

conditions are met.

13. Jog motor to put crank arm pointing down.

14. Disconnect power to oven.

15. Tighten gear case mounting screws.

NOTE: Non-drive end rotor shaft should seat itself in

lower notch of support bearing. This is normal

operating position.

1. Remove the rotor.

2. Remove

3. Identify and remove motor wires from terminal

block.

A. Insert jeweler screwdriver or similar small

NOTE: The following picture shows the terminal block

disassembled to illustrate how the tool is inserted to

release the wire.

Right Side Cover.

tool into holes to release spring tension and

pull wires out.

Fig. 111

16. Lift rotor out of oven.

Fig. 112

4. Remove four screws securing pump mounting

box and allow box to slide down for access to

motor screws.

Page 33 of 72 F25294 Rev. A (0412)

Page 34

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

KA7E - PREVIOUS CONSTRUCTION SHOWN

5. Remove four screws securing motor and speed

reducer to gearbox. Torque screws to 22 inch lbs.

on reassembly.

Fig. 114

6. Pull motor away from speed reducer and lay it

aside.

Fig. 116

8. To remove gearbox, manually rotate worm gear

to position crank arm to point toward the side with

the interior light (or away from the motor).

Fig. 117

9. Remove screws securing gasket bracket and

gasket.

NOTE: Replace washers and gasket with new ones

on reassembly.

Fig. 115

7. Pull speed reducer away from gearbox and lay it

aside.

F25294 Rev. A (0412) Page 34 of 72

NOTE: Gasket bracket may not be able to be

removed until gear box mounting screws are

removed.

Fig. 118

Page 35

KA SERIES ELECTRIC ROTARY OVENS - REMOVAL AND REPLACEMENT OF PARTS

10. Remove four screws, washers and nuts securing

gearbox to motor support.

11. Pivot gearbox away from oven and work crank

arm out of hole in side wall.

12. Remove gasket bracket and gasket if not already

removed.

Fig. 119

13. Install in reverse order.

14. Snug but do not tighten screws securing gasket

bracket at this time. It must be loose during the

drive motor adjustment procedure.

15. Continue to Drive Motor Adjustment.

Page 35 of 72 F25294 Rev. A (0412)

Page 36

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE PROCEDURES AND ADJUSTMENTS

SERVICE MODE - PROGRAMMING

AND DIAGNOSTICS

NOTE: Service Mode allows access to the

programming parameters and diagnostic tests to

check the oven settings and the electrical component

functionality. Additionally, on KA7E machines a

DEMO MODE can be utilized as a continuation of the

diagnostic tests that allow the technician to manually

step through and verify clean cycle operation without

having to run an actual clean cycle.

NOTE: The P key is used to toggle the minus sign on

and off. Use this key if a negative value must be

entered. Entering an invalid number results in the time

display being set to 0 and a beep-beep will sound

indicating you should key in a new value.

Procedure to Enter Service Mode

1. Turn power switch off.

2. Press and hold keys CLOCK, 7, and 8 at the

same time while turning power switch on.

3. Displays shows flashing P in temperature

window which indicates you are in service mode.

2. Press and hold keys 1, 2, and 3 at the same time

while turning power switch on.

3. Display shows ID in the temperature window and

ON or OFF in the time window.

4. Turn power switch off and then back on to return

to operator mode.

5. Repeat steps 1 thru 4 to toggle back.

Procedure to Toggle Between 9 and 99 Programs

1. Turn power switch off.

2. Press and hold keys PROBE, ENTER, and 2 at

the same time while turning power switch on.

3. Display shows 9 or 99 in temperature window

and PROG in the time window.

4. Turn power switch off and then back on to return

to operator mode.

5. Repeat steps 1 thru 4 to toggle back.

4. Press number key(s) to enter Parameter Number

according to the chart below, then press ENTER

key.

A. Time display will flash showing current value

of the parameter.

5. Either accept this value by pressing ENTER key

or key in new value and then press ENTER key

to accept it.

A. P will flash in temperature window indicating

a new parameter number can be entered.

6. To save parameter settings and exit service

mode, turn the power switch to off. The unit will

remember the changes. After the power is turned

off, power can be disconnected from unit if

necessary to complete repairs.

Procedure to Toggle Between No ID and Operator

ID Mode

1. Turn power switch off.

PROGRAMMING, ALL SOFTWARE VERSIONS

Parameter

Number

0 Time display will show software version (Read Only). X X

Description KA7E KA7EM

Service Mode Parameters

KA7E DISPLAY SHOWN

F25294 Rev. A (0412) Page 36 of 72

Page 37

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Parameter

Number

1

PROGRAMMING, ALL SOFTWARE VERSIONS

Description KA7E KA7EM

0 = Fahrenheit. F 0 will display in Time window. Default = 0

1 = Celsius. C 1 will display in Time window.

FC will display in Program window.

If the temperature display option is changed, you will see a slight pause as all

stored cook programs are converted to new units.

0 = AM/PM. AP 0 will display in Time window. Default = 0

X X

2

3

4

5

NOTE: In the table below, an asterisk (*) beside

Parameter Number indicates a Service Only

parameter that must be unlocked to verify or edit the

setting as outlined in the following procedure. After the

unlock code is entered, any of the Service Only

parameters are viewable.

1. Press 72 and select ENTER (parameter to unlock

service only parameters.

2. Press 1972 and select ENTER (code to unlock

service only parameters) (1 beep).

Parameter

Number

31 43

1 = 24 hour clock. 24 1 will display in Time window.

CL will display in Program window.

Future use - To be used when connected to remote computer.

0 = ASCII serial protocol. 0 will display in Time window. Default = 0

1 = Binary serial protocol. 1 will display in Time window.

SP will display in Program window.

Future use - To be used when connected to remote computer.

Oven ID number Range = 0 to 31. The number entered will display in Time window.

Default = 0

ID will display in Program window.

Temperature offset. Difference between sensor temperature and displayed

temperature value; used to correct for the difference between sensor and cooking

chamber temperature if any.

Range = +30 to -30. The number entered will display in Time window. Default = 0

C or F depends on unit selected.

OS will display in Program window.

PROGRAMMING CONTINUED, CURRENT SOFTWARE VERSION C027

Setting Description KA7E KA7EM

Chemical pump ON time in seconds (default = 43). Time required may

vary for type of chemical used.

CP will display in Program window.

X X

X X

X X

X X

3. Enter desired Parameter Number containing an

asterisk (*) and verify or edit the setting as

necessary.

4. After all desired Parameter Numbers are

checked, press 0 (zero) and select ENTER.

Normal programming can continue.

5. Verify the remaining Parameter numbers as

necessary.

X ---

Page 37 of 72 F25294 Rev. A (0412)

Page 38

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Parameter

Number

*32 10

*33 2

34 120

35 2

*36 2

PROGRAMMING CONTINUED, CURRENT SOFTWARE VERSION C027

Setting Description KA7E KA7EM

Preheat time in minutes (default = 10)

X X

PH will display in Program window.

Main Drain pump ON time in minutes (default = 2)

X ---

SP will display in Program window.

Chemical wash time in minutes (default = 120)

X ---

Ct will display in Program window.

Number of rinse cycles (default = 2)

X ---

nr will display in Program window.

Rinse time in minutes (default = 2)

X ---

Rt will display in Program window.

Number of pre-rinses (default = 1).

37 1

38 0

39 0

*40 5

*41 150

*42 150

*43 200

44 0

nP will displayed in Program window.

Increase pre-rinse number if initial fill is not hot enough.

Leave setting at 0 and advance to next program number.

Ft will display in Program window.

Leave setting at 0 and advance to next program number.

LC will display in Program window.

Water fill time limit in minutes (default = 5)

FL will display in Program window.

Add time as necessary if water pressure is low.

Cool down temperature in Fahrenheit (default = 150)

Ct will display in Program window.

Oven must cool to this temperature before next operation can start.

Preheat temperature in Fahrenheit (default = 150)

CP will display in Program window.

Drying temperature in Fahrenheit (default = 200)

Cd will display in Program window.

Demo Mode. Leave setting at 0 (zero) and continue to the next

Program Number. See DEMO MODE in the next section.

dE will display in Program window.

X ---

X ---

X ---

X ---

X X

X X

X ---

X ---

*45 15

Additional fill time in seconds (default = 10)

0F will display in Program window.

Wash pump ON time during cleaning (default = 4)

48 4

Pr is display in Program window.

Wash pump OFF time during cleaning (default = 4)

49 4

SO will display in Program window.

F25294 Rev. A (0412) Page 38 of 72

X ---

X ---

X ---

Page 39

Parameter

Number

93 ---

Parameter

Number

31 80

34 120

37 2

48 4

49 4

93 ---

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

PROGRAMMING CONTINUED, CURRENT SOFTWARE VERSION C027

Setting Description KA7E KA7EM

0 (zero) will display in time window as the initial value. Used to set

all parameters to default and clear all recipes.

Set value to 73 and press Enter. Machine is set to factory default

settings.

PROGRAMMING CONTINUED, PREVIOUS SOFTWARE VERSION dA09

Setting Description KA7E ---

Chemical pump ON time in seconds (default = 80). Time required may

vary for type of chemical used.

CP will displayed in Program window.

Chemical wash time in minutes (default = 120)

Ct will displayed in Program window.

Number of pre-rinses (default = 1). Increase if initial fill is not hot

enough.

nP will displayed in Program window.

Wash pump ON time during cleaning (default = 1)

Pr will displayed in Program window.

Wash pump OFF time during cleaning (default = 7)

SO will displayed in Program window.

0 (zero) will display in time window as the initial value. Used to set

all parameters to default and clear all recipes.

Set value to 73 and press Enter. Machine is set to factory default

settings.

X X

X ---

X ---

X ---

X ---

X ---

x x

DIAGNOSTICS, ALL SOFTWARE VERSIONS

Parameter

Number

Display Test

20

21

22 Relay Test, components should function KA7E KA7EM

All segments and LEDs are cycled to check operation.

When complete, oven will beep and be ready for the next Parameter Number

entry.

Keypad Test

When keys are pressed one at a time, the time display will indicate which one.

When no keys are pressed, the display should be blank. If not blank, indicates

a stuck key. Exit service mode by turning power switch off and then on again.

Enter service mode again if necessary.

Press 1 - Operates CR1 "Lights" at terminal X1 X X

Press 2 - Operates CR2 "Fans" at terminal X2 X X

Description KA7E KA7EM

X

X X

Page 39 of 72 F25294 Rev. A (0412)

X

Page 40

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Parameter

Number

DIAGNOSTICS, ALL SOFTWARE VERSIONS

Description KA7E KA7EM

Press 3 - Operates CR3 "Rotate Motor" at terminal X3 X X

Press 4 - Operates CR4 "Contactor K1" at terminal X4

X X

NOTE: Contactor K2 is already energized thru power switch & high limit.

Press 5 - Operates CR5 "Sump/ Main Drain Motor" at terminal X5 X ---

Press 6 - Operates CR6 "Wash Pump" at terminal X6 (door(s) must be closed) X ---

Press 7 - Operates CR7 "Chemical Pump" at terminal X7 X ---

Press 8 - Operates CR8 "Sump Fill Valve" at terminal X8 X ---

Press 9 - Operates CR9 "Grease drain" at terminal X9.

X X

NOTE: KA7EM with grease assist option only.

Press 0 - Operates CR10 "Gray water/sump peristaltic" at terminal X10.

23

Press ENTER to exit this test.

NOTE: Gray water/sump peristaltic removed from ovens with Serial No.

46300096 and higher.

CPU Board Input Test, display indicates function KA7E KA7E

This tests for 24VAC input on X16 thru X24 to the CPU board. Uses one of

the 9 digits on the front display for each of the inputs (digit 8 & 9 future use).

The digits are arranged on the display in the pattern shown in the picture at

the end of this section.

- If an input is OFF, the digit displays a dash ( - ).

- If the input is ON, the digit displays a 1.

Included in the picture are display examples for the KA7E input test "Fill Me"

(digit 2) and "Door Position" (digit 7). The tests show a "1" for both the inputs

indicating 24VAC is present (water fill valve energized and doors closed).

NOTE: KA7EM will always display one "1" in digit 2 position and a dash in all

the other digit positions.

Digit 1 - Press rotate switch to test input to CPU board (X16). X X

Digit 2 - Fill Me input to CPU board ( X17 ). Ground the probe to a metal surface

on machine to test (approximately 3 second time delay).

Digit 3 - Low Level Input (X18). Ground the chemical probe sensor to a metal

surface on machine to test (approximately 3 second time delay).

Digit 4 - Press stop switch at rear of machine to test input to CPU board(X19). X ---

Digit 5 - Press silence switch at rear of machine to test input (X20). X ---

X ---

X ---

X ---

X ---

Digit 6 - Press snooze switch at rear of machine to test input (X21). X ---

Digit 7 - Open door(s) to test. The input to CPU board is removed from (X22).

Close door(s) and input is back ON.

Digit 8 & 9 - Future Use. X ---

Press ENTER to exit this test. X ---

F25294 Rev. A (0412) Page 40 of 72

X ---

Page 41

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

A. Press 0 and select ENTER to verify software

version.

B. Press ENTER to return to parameter

selection screen.

2. If current software version C027, continue to step

4.

3. If previous software version, press 72 and select

ENTER (parameter to unlock service only

parameters.

A. Press 1972 and select ENTER (code to

unlock service only parameters) (1 beep).

DIAGNOSTIC DISPLAY EXAMPLES

DEMO MODE (KA7E ONLY)

NOTE: Diagnostic tests in SERVICE MODE -

PROGRAMMING AND DIAGNOSTICS should be

performed prior to entering DEMO MODE. The DEMO

MODE is a continuation of the diagnostic tests for

verifying clean cycle operation on KA7E machines.

After verifying clean cycle operation, the machine

must be returned to NORMAL MODE as outlined in

the procedure.

NOTE: Remove tube from chemical cleaner bottle

before starting procedure to keep excess chemical

from entering machine during test.

NOTE: The grey water/sump peristaltic pump was

removed from machines with Serial No. 46300096

and higher.

1. Enter SERVICE MODE - PROGRAMMING AND

DIAGNOSTICS. Use the keypad to enter

parameter numbers.

Operation

VFD Display - Current

Software Version (C027)

VFD Display - Previous

Software Version (dA09)

4. Press 44 and select ENTER (allows selection of

DEMO/NORMAL Mode parameter).

5. Press 1 and select ENTER (sets machine to

DEMO MODE).

6. Turn power switch OFF (save settings and exit

service mode).

7. Turn power switch ON. Oven is now operating in

demo mode and is idle. Door should remain

closed.

A. Press CLEAN key to enter clean mode.

Disregard error messages.

B. Cavity light should be ON to indicate the

oven is in demo mode. If light is not on,

repeat procedure to enter DEMO MODE.

NOTE: As you press ENTER to advance through the

clean cycle operation, there may be short delays

before the cycle begins. You can pause the cycle at

any time by pressing the rotate switch or opening the

door.

Verify Functionality

• Cavity light ON

8

9

10

NORMAL WASH MODE

PREHEATING

NORMAL WASH MODE

DRAINING GREASE

NORMAL WASH MODE

WATER FILL

CLEANING

PREHEATING

CLEANING

DRAINING GREASE

CLEANING

WATER FILL

Page 41 of 72 F25294 Rev. A (0412)

• Rotor turning

• Heaters ON

If correct, press ENTER.

• Grease pump ON

• Rotor stops

• Heaters OFF

If correct, press ENTER.

If correct, allow water to fill up to the

water level probe. When water level is

satisfied, it will automatically roll to the

next step.

Page 42

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Operation

11

12

13 ---

14

15

16

17

18 ---

19

20

21

22 ---

23

VFD Display - Current

Software Version (C027)

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

ADDING DETERGENT

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

NORMAL WASH MODE

VFD Display - Previous

Software Version (dA09)

CLEANING

DEGREASE #1

WATER DRAIN

WATER FILL

WASHING CLEANING

SOAKING

WATER DRAIN

WATER FILL

RINSE #1

WATER DRAIN

WATER FILL

DEGREASE #1

CLEANING

WATER DRAIN

CLEANING

WATER DRAIN

CLEANING

WATER FILL

CLEANING

ADDING DETERGENT

WASHING

CLEANING

WATER DRAIN

CLEANING

WATER DRAIN

CLEANING

WATER FILL

CLEANING

RINSE #1

CLEANING

WATER DRAIN

CLEANING

WATER DRAIN

CLEANING

WATER FILL

Verify Functionality

If the machine is washing (wash arm

spinning), press ENTER.

If the machine is draining water, press

ENTER.

If installed, the grey water/sump

peristaltic pump should be running.

If correct, press ENTER.

If correct, allow water to fill up to water

level probe. When satisfied it will

automatically roll to the next step.

• Chemical pump ON

• Verify pump is pulling chemical.

See Clean Cycle Troubleshooting

(KA7E Only) as necessary.

If correct, press ENTER.

If the machine is washing (wash arm

spinning), press ENTER.

NOTE: Total cycle time is 2 hrs (timer

counts down). Washing/ soaking

alternates every 4 min during the cycle.

• Drain pump ON

• Rotor stop

If correct, press ENTER.

If installed, the grey water/sump

peristaltic pump should be running.

If correct, press ENTER.

If correct, allow water to fill up to water

level probe. When satisfied it will

automatically roll to the next step.

• Wash arm spraying

• Rotor turning

If correct, press ENTER.

• Drain pump ON

• Rotor stop

If correct, press ENTER.

If installed, the grey water/sump

peristaltic pump should be running.

If correct, press ENTER.

If correct, allow water to fill up to water

level probe. When satisfied it will

automatically roll to the next step.

F25294 Rev. A (0412) Page 42 of 72

Page 43

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Operation

24

25

26 ---

27

28

Return to Normal Mode

1. Enter SERVICE MODE - PROGRAMMING AND

DIAGNOSTICS. Use the keypad to enter

parameter numbers.

2. If current software version C027, continue to step

4.

3. If previous software version dA09, press 72 and

select ENTER (parameter to unlock service only

parameters.

A. Press 1972 and select ENTER (code to

4. Press 44 and select ENTER (allows selection of

DEMO/NORMAL Mode parameter).

5. Press 0 and select ENTER (sets machine to

NORMAL MODE).

6. Turn power switch OFF (save settings and exit

service mode).

7. Turn power switch ON. Oven is now operating in

normal mode and is idle.

A. Cavity light should be OFF to indicate the

B. Install tube back into chemical cleaner

VFD Display - Current

Software Version (C027)

NORMAL WASH MODE

RINSE #2

NORMAL WASH MODE

WATER DRAIN

NORMAL WASH MODE

DRYING

PRESS START OR CLEAN

CLEAN CYCLE

COMPLETE

Select program 0-9

unlock service only parameters) (1 beep).

oven is in normal mode. If light is not off,

repeat procedure to enter NORMAL MODE.

bottle.

VFD Display - Previous

Software Version (dA09)

WATER DRAIN

WATER DRAIN

CLEAN CYCLE

CLEANING

RINSE #2

CLEANING

CLEANING

CLEANING

DRYING

COMPLETE

1. Remove Right Side Cover.

2. Remove the probe lead wires from the CPU

3. Test the probe with an ohmmeter.

60 530

70 541

80 552

90 563

100 573

125 600

150 627

200 680

250 732

300 785

Verify Functionality

• Wash arm spraying

• Rotor turning

If correct, press ENTER.

If correct, allow the water to drain

completely from the machine. It will

automatically roll to the next step.

If installed, the grey water/sump

peristaltic pump should be running.

Allow the pump to remove the water. It

will automatically roll to the next step

after 2 minutes.

• Heaters ON

• Rotor turning

If correct, press ENTER.

Done. The machine will automatically

exit CLEANING and go to IDLE.

TEMPERATURE SENSOR TEST

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

board.

TEMPERATURE in °F RESISTANCE ±5 OHMS

Page 43 of 72 F25294 Rev. A (0412)

Page 44

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

TEMPERATURE in °F RESISTANCE ±5 OHMS

350 836

400 887

450 938

HEATING ELEMENT TEST

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

MODEL

KA7E,

KA7EM

*Tolerance +5 / -10 %.

WATTAGE/

RESISTANCE*

VOLTAGE

2500/208 18

2500/240 24

3000/208 16

3000/240 21

PUMP, K3 RELAY COIL TESTS

3. Record the temperature tester readout for an

additional 3 cycles. It should cycle around a set

point.

4. Calculate the amplitude. Amplitude = (Turn Off Turn On). An amplitude of more than 40 degrees

may indicate a failed element. See heating

element test.

5. Calculate the average. Actual average = (Turn

On + Turn Off ) divided by 2. Variance (between

actual average and programmed set point) of

greater than 5 degrees indicates that adjustment

is needed.

6. To adjust:

A. Enter SERVICE MODE - PROGRAMMING

AND DIAGNOSTICS, enter parameter

number 5 Temperature Offset.

NOTE: The P key is used to toggle the minus sign on

and off. Use this key if a negative value must be

entered.

B. If the actual average temperature is higher

than the programmed set point, then enter

a positive offset value of the same amount.

(For example if the oven is cycling around

an actual average of 360 degrees, adjust by

entering an offset of +10.)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

MODEL PUMP RESISTANCE ±5 OHMS

KA7E Drain 87

KA7E Wash 32

KA7E,

KA7EM*

KA7E K3 190

*Models with grease assist option only.

Grease

Peristaltic

14

CONTROLS CALIBRATION

Calibration Procedure

NOTE: See Table 12 at the end of this procedure.

1. Place temperature tester probe in the geometric

center of oven cavity.

2. Program a set point of 350 degrees. Allow oven

temperature to cycle 3 times. Oven display

temperature reading should equal the set point of

350 degrees.

C. If the actual average temperature is lower

than the programmed set point, then enter

a negative offset value of the same amount.

(For example if the oven is cycling around

an actual average of 340 degrees, adjust by

entering an offset of -10.)

1) The offset can be adjusted + or - 30 deg

F, but is only functional within the

operating limits of the oven. Factory

setting is 0.

7. To save the setting, press the enter key.

8. Turn the power switch to off and then on again.

The oven will remember the changes.

9. To recall the offset value, enter SERVICE MODE

- PROGRAMMING AND DIAGNOSTICS, enter

parameter number 5 Temperature Offset. Verify

that the value you set is visible on the time

display.

F25294 Rev. A (0412) Page 44 of 72

Page 45

KA SERIES ELECTRIC ROTARY OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

Temperature Data Recording Table

Temperature Tester

Heater Turn on

________ ________ ________

________ ________ ________

________ ________ ________

Actual Average

Temperature Tester

(Turn On + Turn Off)

Heater Turn off

divide by 2

Page 45 of 72 F25294 Rev. A (0412)

Page 46

KA SERIES ELECTRIC ROTARY OVENS - ELECTRICAL OPERATION

ELECTRICAL OPERATION

COMPONENT FUNCTION

Power Switch ......... Controls power to control circuits.

High Limit Thermostat ...Prevents oven from exceeding 482°F ±12 °F if controls malfunction.

Wash Pump M1

(KA7E) ................

Drain Pump M2 ....... Empties water from oven when turned on.