Page 1

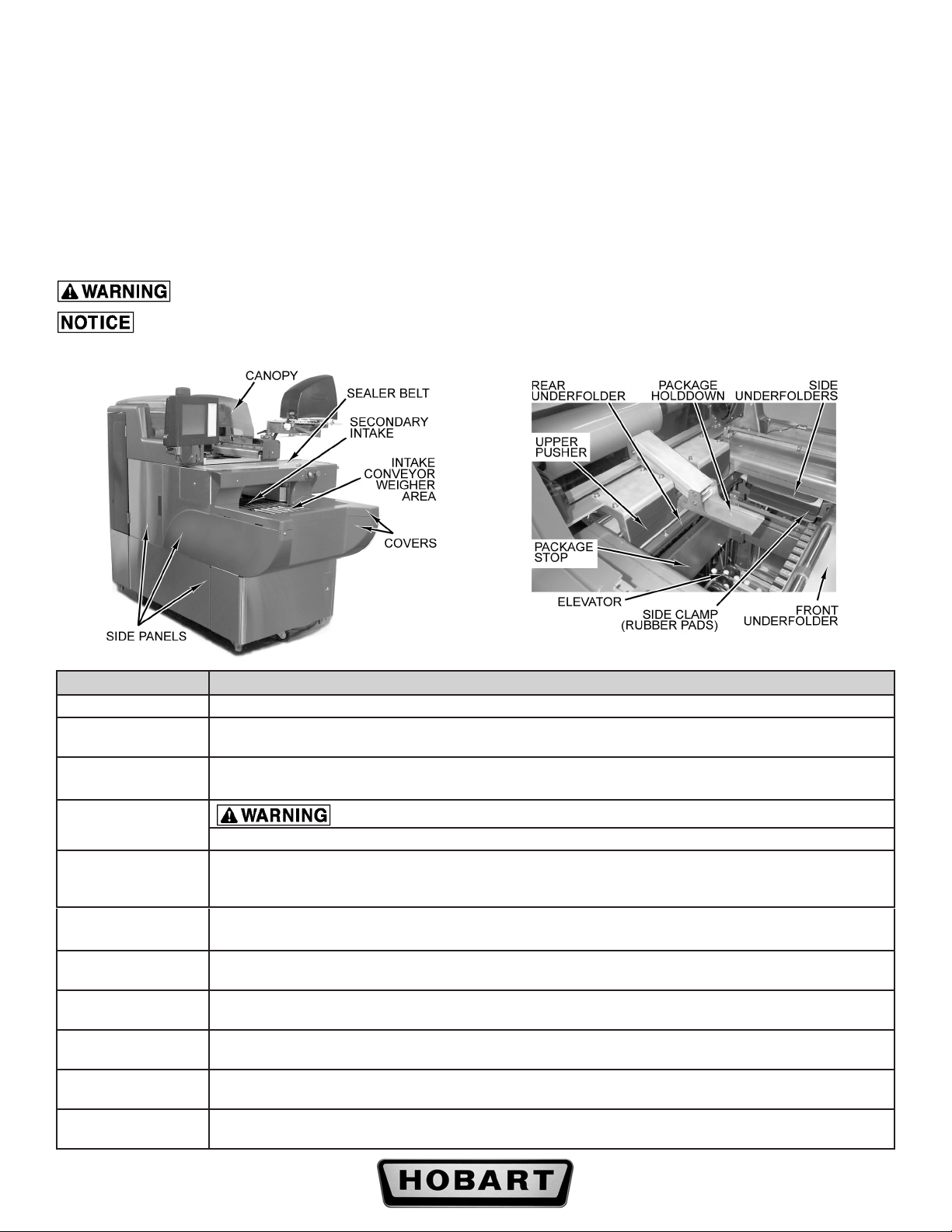

Essential (EWS) Wrapping System

Operating & Cleaning Tips

WRAPPING

1. Make sure all product is inside the tray.

2. Be sure to center the package on the intake.

3. If the wrapper shuts down automatically, an error condition has occured. Carefully read the message on the console

display and follow appropriate procedures to correct the problem(s).

CLEANING

Prior to cleaning, power down the touch screen, printer and wrapper. Unthread the lm from the lm selector.

Disconnect power source to wrapper before cleaning.

Use of high pressure washing system will cause damage to the wrapper.

To appropriately clean each component of the system, refer to the following component cleaning table.

Component Explanation

Rear Film Chamber Clean as needed with a soft cloth moistened with a mild detergent and water. Rinse and allow to air dry.

Canopy and Film

Chamber Doors

Covers (External Plastic)

Sealer Belt

Intake Conveyor Area

and Weigher Rods

Side Panels

(Stainless Steel)

Package Hold Down Lift upward and clean as needed with a soft cloth moistened with a mild detergent and water. Rinse and allow

Rubber Pads, Side

Clamp Gripper

Rubber Roller (in lm

selector)

Front, Rear and Side

Underfolders

Elevator Area Clean as needed by using a soft cloth. Open the canopy and the side doors to get access to the elevator area.

Clean as needed with a soft cloth moistened with a mild detergent and water. Rinse and allow to air dry.

Clean as needed by using a soft cloth moistened with a mild detergent and water. Rinse and allow to air dry.

Hot surface. Do not touch.

Clean as needed by using a soft cloth moistened with a mild detergent and water. Rinse and allow to air dry.

Clean as needed by using a long-handled brush or a moist cloth. Weigher rods can be removed and cleaned in

a sink with mild detergent and water. Use the long-handled brush for additional cleaning of the belts. Replace

weigher rods after cleaning. Rinse and allow to air dry.

Clean as needed by using a soft cloth moistened with a mild detergent and water. Rinse and allow to air dry.

to air dry.

Clean as needed with Hobart cleaning solvent or isopropyl alcohol.

Clean as needed with Hobart cleaning solvent or isopropyl alcohol.

Clean as needed by using a soft cloth moistened with a mild detergent and water. Rinse and allow to air dry.

Rinse and allow to air dry. A soft brush may be required to reach conned areas.

©HOBART, 2011 FORM 35539 (October 2011)

Page 2

Essential (EWS) Wrapping System

Operating & Cleaning Tips

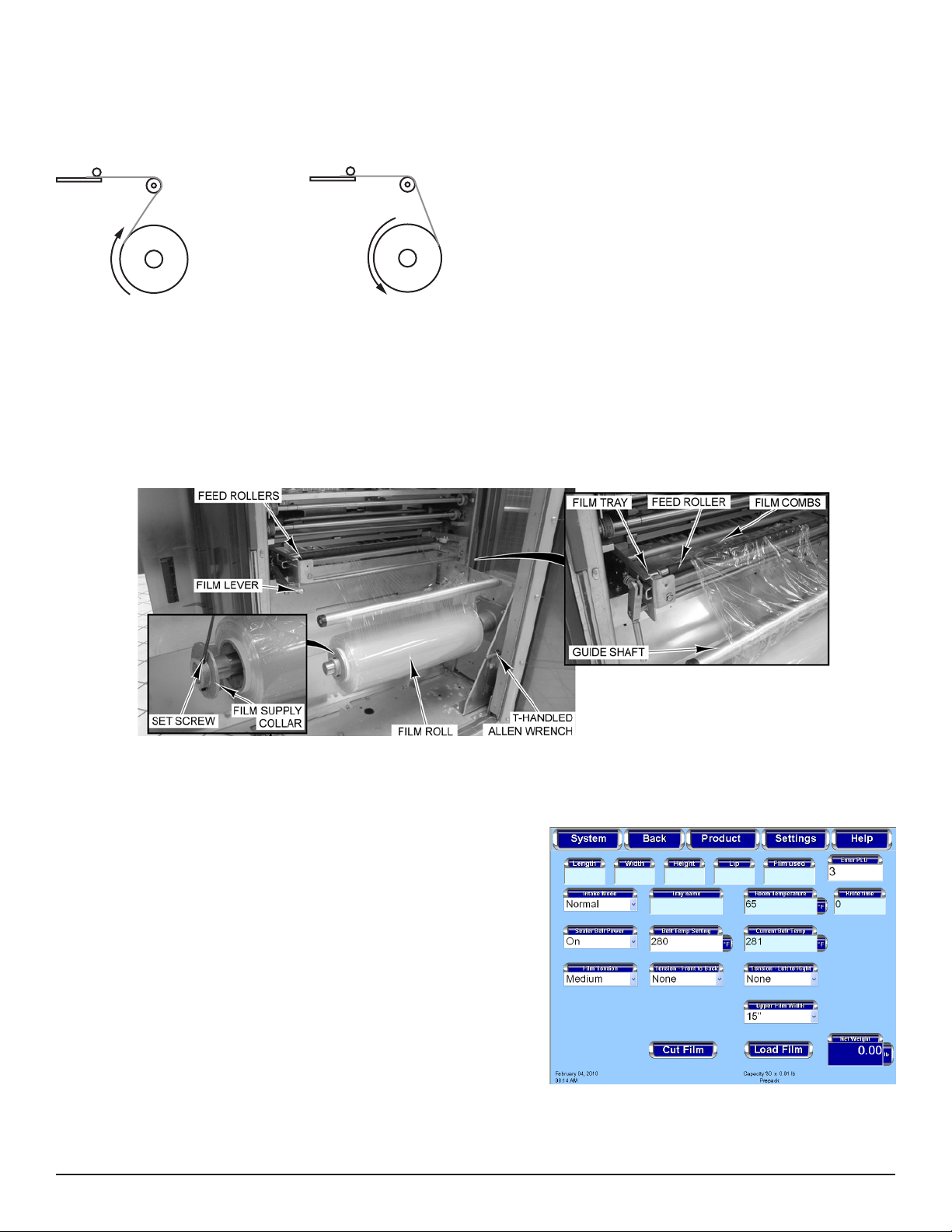

FILM LOADING

Keep the lm as straight as possible through the threading process. The following diagram shows the different

ways to load lm.

TO THREAD FILM:

1. PRESS the STOP (red) button and allow the machine

to stop.

2. Open the rear doors.

3. Release feed rollers by pulling the lm lever

down.

4. Loosen 2 set screws on the lm supply collar. (A T-Handled Allen wrench is located on the inside of the

machine for this purpose.

5. If applicable, remove the empty lm core.

6. Install the lm roll on the shaft.

7. Install the lm supply collar. Be sure both collars are ush with the lm roll. You may need to tap the lm

collar into place with the old lm core.

8. Verify that the lm is centered on the shaft. (You may have to loosen the other set screw to center.) Once

centered, tighten the set screws on both collars.

9. Slide the lm tray out, exposing the lm combs.

10. Pull the lm end upward to the front of the guide shaft continuing around the shaft toward the extended lm

tray.

11. Put the lm over the rubber feed roller and make sure the lm gets to the ends of the lm combs, securing

the lm end down over the combs.

12. Push the feed tray in and lift the lm lever up.

13. Close the rear doors.

14. PRESS the ON (green) button. Wait for a steady light,

no blink mode.

15. From the Operator Start Screen, TOUCH Settings. TOUCH

Wrapper. You should now be on the Wrapper Screen.

16. If the lm width installed is different than the displayed

width, TOUCH Upper Film Width eld to set lm width.

17. TOUCH Load Film and the wrapper will position lm, cut

any excess lm and set itself (home) for operation.

18. TOUCH Back to exit this screen.

19. PRESS the STOP (red) button and allow the machine to

stop.

20. Lift the canopy and remove excess lm.

21. Close canopy.

22. PRESS the ON (green) button. It will be a steady light, no blink mode. Ready for operation.

FORM 35539 (October 2011) PRINTED IN U.S.A.

Loading...

Loading...