Hobart AM15VL Service Manual

In this document:

1. Machine Operation

2. ICC Code Opinions

3. Customer Testing

4. Operational Test Report

5. Installation Basics

6. FAQ’s

Warewash Engineering

Troy, OH 45374-0001

Technical Report - AM15VL Series “Ventless” Dishmachines

This document explains the operation of the new Advansys Ventless dishmachines, AM15VL series, and

provides information to assist in the Code Plan Review process. Please Note: It is imperative that this

information, along with supporting documentation such as the specification sheet and independent test

report, be provided to the Authority Having Jurisdiction (AHJ) to ensure compliance with current local

requirements. Links to these documents can be found on page 5 of this report.

The Advansys Ventless dishmachine does not require a Type II vent hood because it does not produce

“excessive” amounts of steam or vapors. Even though it is a high temperature sanitizing dishmachine, it

produced almost the exact same amount of latent and sensible heat as a comparable chemical sanitizing

or low temperature dishmachine in an independent test.1

The Ventless Dishmachine has three primary advantages:

1. Bleach is not discharged into the sanitary sewer system

2. A ventilation hood is not required

3. Reduced energy consumption results in a savings of up to $1,568/year

1

See independent Commercial Kitchen Ventilation Lab (FSTC) Report dated November 2009.

F38361 (August 5, 2010) Page 1 of 6 Printed in U.S.A.

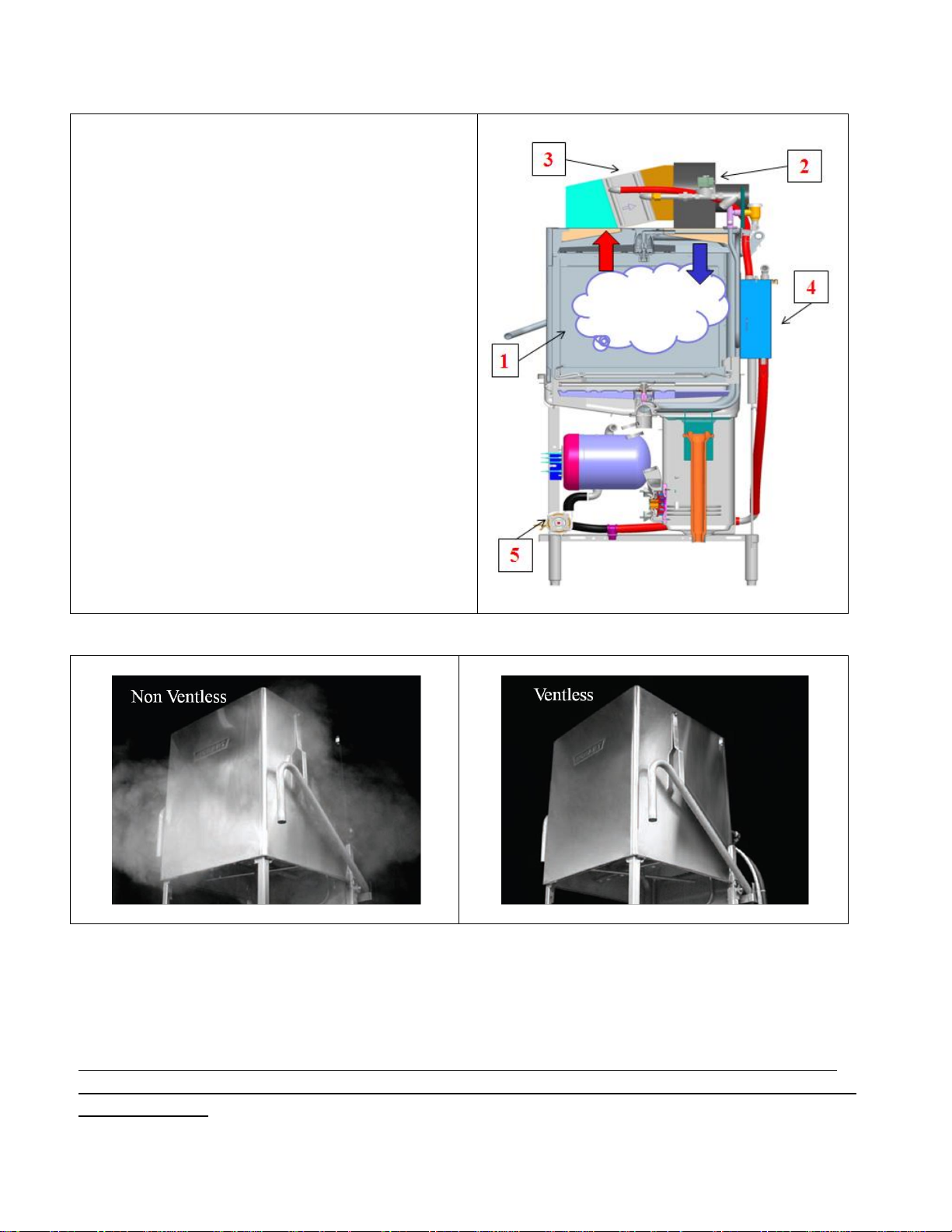

The Advansys Ventless AM15VL has a unique

energy recovery condensing cycle that captures

water vapor (1) (more commonly referred to as

steam) from the wash cycle and condenses it to

heat the incoming cold water. A fan (2) circulates

the air from the chamber — filled with water vapor

— across the fins of the heat exchanger coils (3)

filled with cold water at 50 to 80 degrees

Fahrenheit. The difference in temperatures causes

the water vapor to condense and preheats the

inlet water (4) used for final rinsing through the

rinse pump (5). The preheated water temperature

reaches up to 140 degrees Fahrenheit, which

reduces the amount of energy needed to reach the

required 180 degree Fahrenheit rinse-water

temperature. The energy recovery system allows

operation using a cold water supply and uses the

hot water line only for the initial fill. After the

completion of the 30-second condensing cycle, an

indicator light signals the machine is ready for

unloading, and then the process starts over.

Machine Operation

Results:

ICC Code Opinions

The International Code Council (ICC) has provided the following opinions to Hobart:

1) 2009 International Mechanical Code:

Where the heat and moisture loads from a dishmachine, such as a “commercial-type” with a built-in

condensing system, are incorporated into the HVAC system design, a Type II hood is not required to be

installed above it.

F38361 (August 5, 2010) Page 2 of 6 Printed in U.S.A.

Loading...

Loading...