Page 1

AM15 DISHWASHE R

TECHNICAL MANUAL

208-240V/60/3

SPECIFICATION SHEET

INSTALLATION INSTRUCTIONS

OPERATION INSTRUCTIONS

CLEANING INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

TROUBLE SHOOTING INSTRUCTIONS

WIRING DIAGRAMS

CATALOG OF REPLACEMENT PARTS

SMARTPARTS™ USER GUIDE

RECOMMENDED SPARE PARTS LIST

Page 2

AM15 Dishwasher Technical Manual Page 2 of 83

Need other Hobart Services?

• Warranty Registration

• Delivery and Installation

• Preventive Maintenance

• Hobart Service Contracts

• Extended Warranty Contracts

• Parts and Accessories

• Specialty Programs

• Water Treatment Programs

Page 3

Item # _____________________________________

AM15 Dishwasher Technical Manual Page 3 of 83

Quantity ___________________________________

C.S.I. Section 11400

AM SELECT

701 S Ridge Avenue, Troy, OH 45374

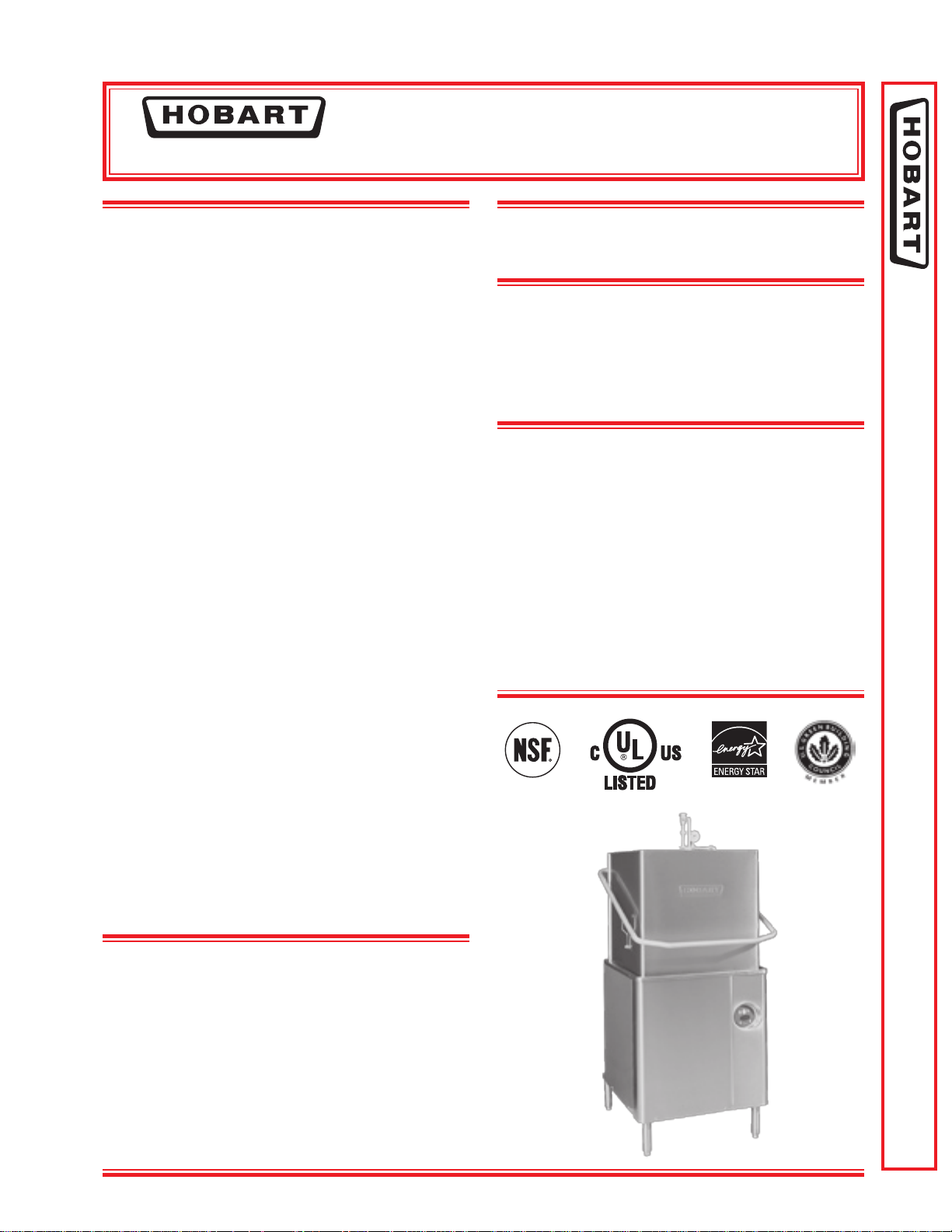

STANDARD FEATURES

■ .74 gallons per rack nal rinse water

■ 58 racks per hour – hot water sanitizing

■ 65 racks per hour – chemical sanitizing

■ NSF pot and pan listed for 2-, 4- & 6- minute

cycles

■ Timed wash cycles for 1, 2, 4 or 6 minutes

■ Solid state, integrated controls with digital status

indicators

■ Self-draining, high efciency stainless steel pump

and stainless steel impeller

■ Stainless steel drawn tank, tank shelf, chamber,

trim panels, frame and feet

■ Spring counterbalanced chamber with

polyethylene guides

■ Revolving, interchangeable upper and lower anticlogging wash arms

■ Revolving, interchangeable upper and lower rinse

arms

■ Slanted, self-locating, one-piece scrap screen

and basket system

■ Automatic ll

■ Door actuated start

■ Automatic drain closure

■ Vent fan control

■ External booster activation

■ Delime cycle

■ Service diagnostics

■ NAFEM Data Protocol capable

■ Straight-through or corner installation

■ Hot water or chemical sanitation

DISHWASHER

MODEL

❑ AM15

OPTIONS AT EXTRA COST

❑ Gas heat

❑ Sense-A-Temp™ 70°F rise electric booster heater

❑ Single point electrical connection for booster

equipped machines (3 phase only)

ACCESSORIES

❑ 3⁄4" pressure regulator valve

❑ Peg rack

❑ Combination rack

❑ Splash shield for corner installations

❑ Flanged and seismic feet

❑ End of cycle audible alarm (eld activated)

❑ Delime notication (eld activated)

❑ Drain water tempering kit

Specications, Details and Dimensions on Inside and Back.

AM SELECT DISHWASHER

VOLTAGE

❑ 208-240/60/1

❑ 208-240/60/3

❑ 480/60/3

❑ 200-240/50/3*

❑ 380-415/50/3*

*Not submitted for UL/CUL Listing

F-40078 – AM Select Dishwasher Page 1 of 8

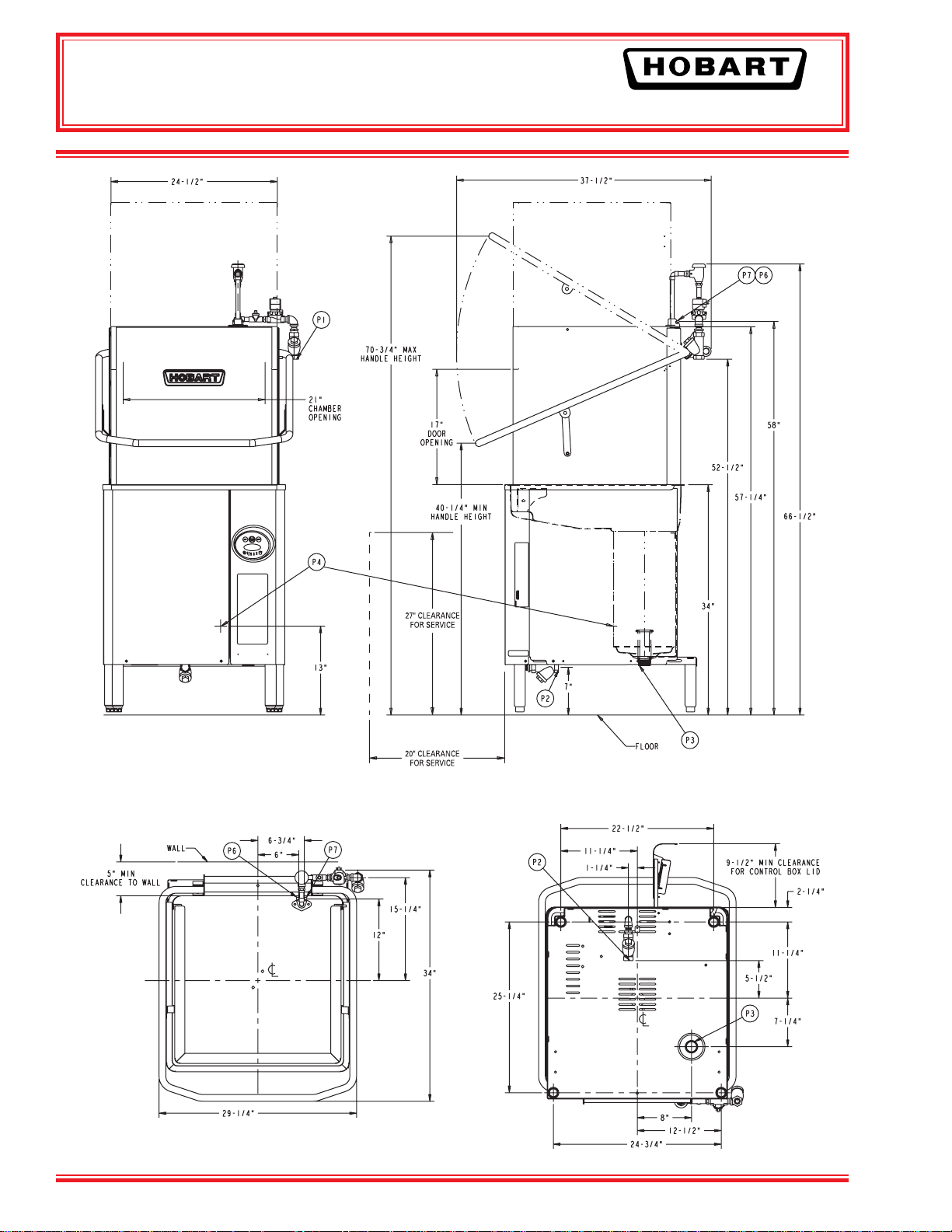

Page 4

AM SELECT

AM15 Dishwasher Technical Manual Page 4 of 83

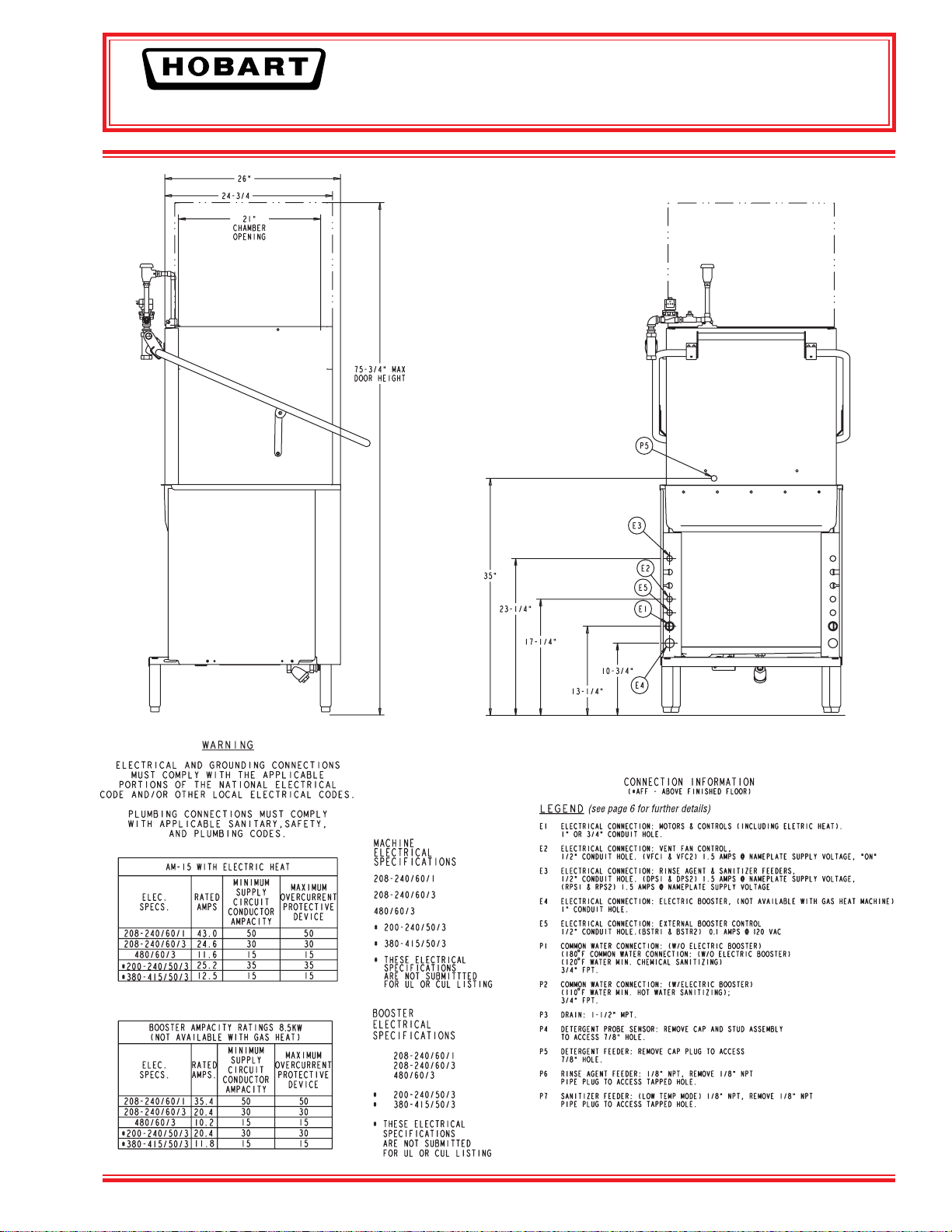

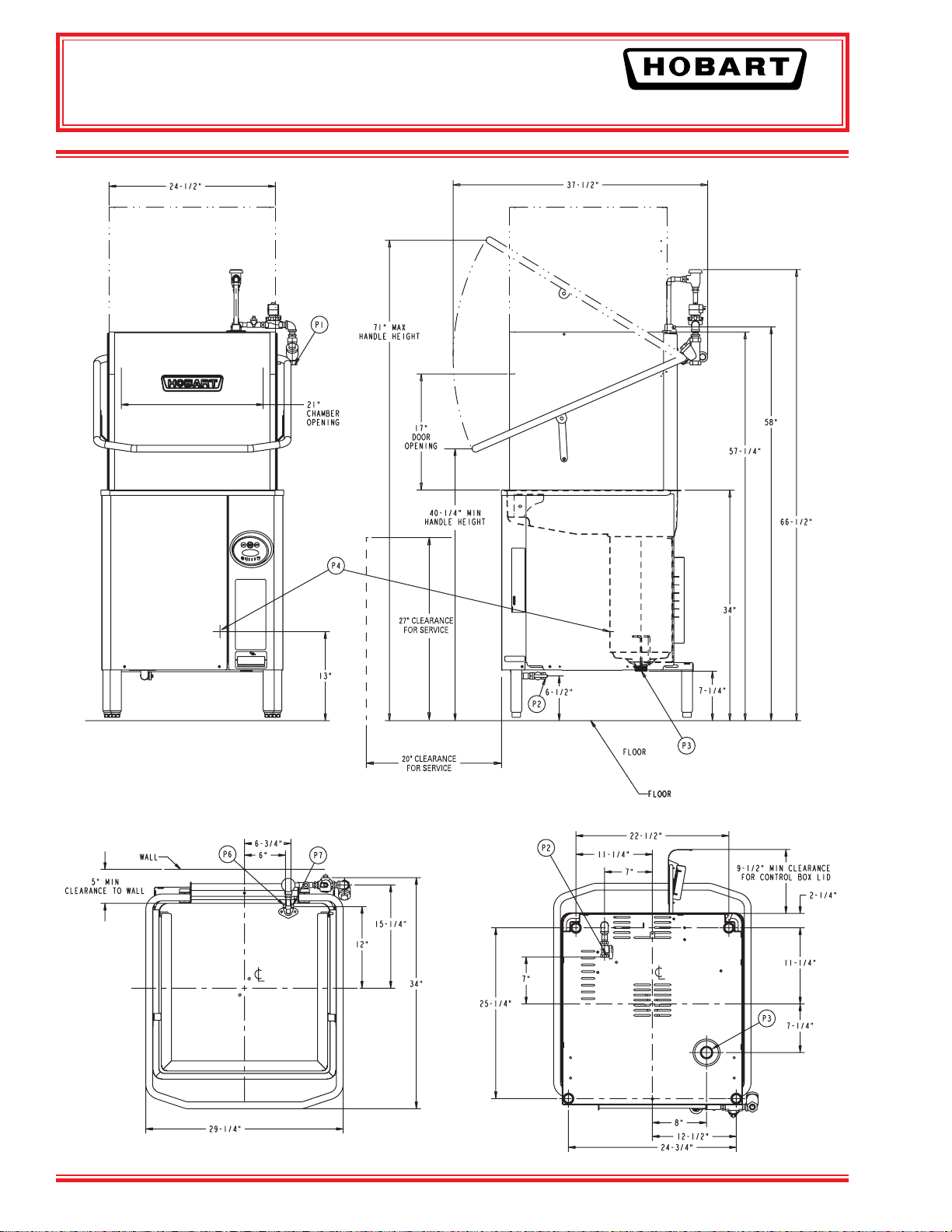

DISHWASHER – ELECTRIC

701 S Ridge Avenue, Troy, OH 45374

Page 2 of 8 F-40078 – AM Select Dishwasher

Page 5

AM SELECT

AM15 Dishwasher Technical Manual Page 5 of 83

701 S Ridge Avenue, Troy, OH 45374

DISHWASHER – ELECTRIC

F-40078 – AM Select Dishwasher Page 3 of 8

Page 6

AM SELECT

AM15 Dishwasher Technical Manual Page 6 of 83

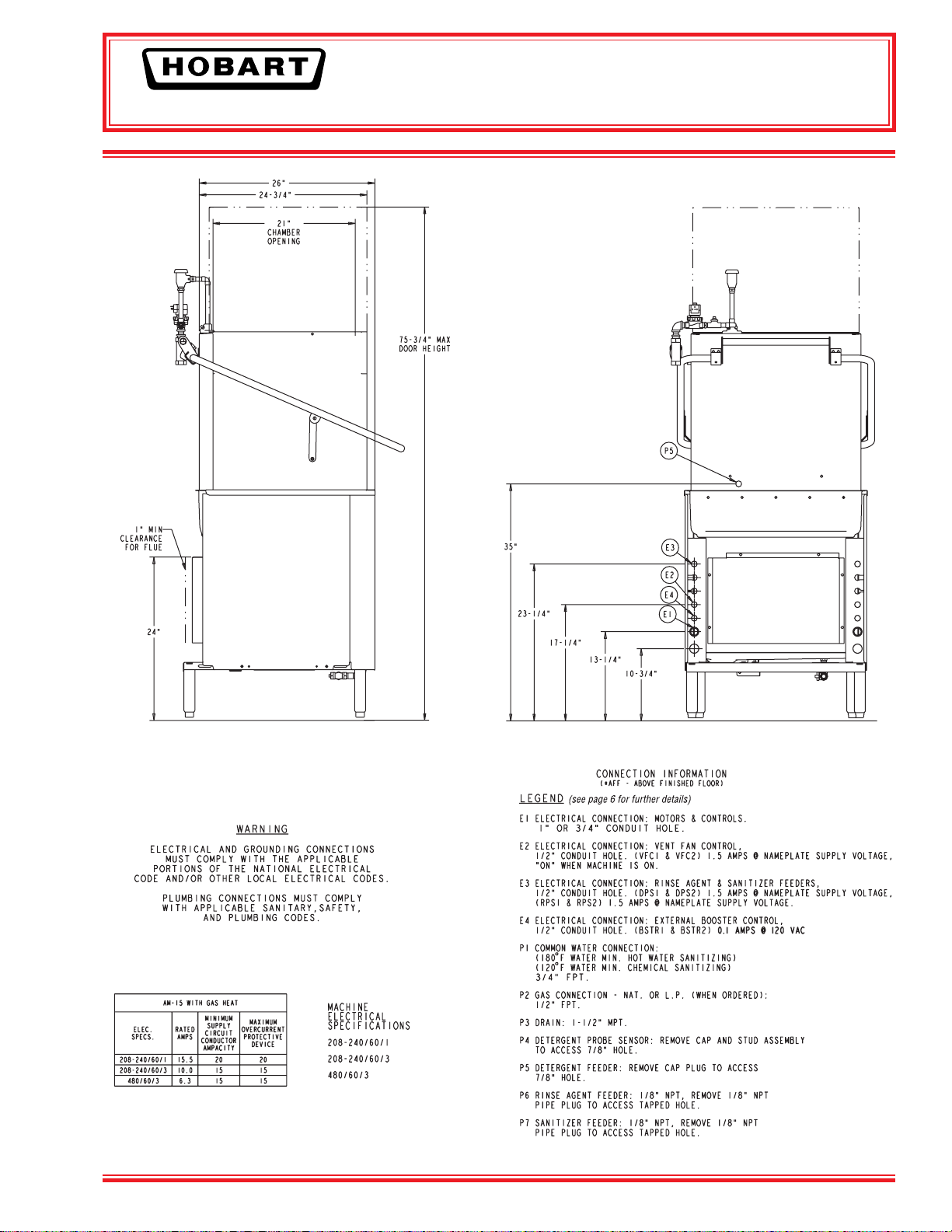

DISHWASHER – GAS

701 S Ridge Avenue, Troy, OH 45374

Page 4 of 8 F-40078 – AM Select Dishwasher

Page 7

AM SELECT

AM15 Dishwasher Technical Manual Page 7 of 83

701 S Ridge Avenue, Troy, OH 45374

DISHWASHER – GAS

F-40078 – AM Select Dishwasher Page 5 of 8

Page 8

AM SELECT

AM15 Dishwasher Technical Manual Page 8 of 83

DISHWASHER

ELECTRIC TANK HEAT

701 S Ridge Avenue, Troy, OH 45374

GAS TANK HEAT

Racks per Hour (Max.)

Dishes per Hour (Average 25 per rack) 1,450 1,625

Glasses per Hour (Average 45 per rack) 2,610 2,925

Inside Tank at Table Connection (Inches) 25

(H x W x D) (Inches) 66.5" x 27" x 28.5"

2 2

Gallons 14 14

Gallons per Minute - Weir Test 160 160

(For keeping power wash water hot)

Gas Burner (Regulated) Natural/LP Gas BTU/Hr.

Electric Heating Unit (Regulated) 5 kw 5 kw

Minutes operated during hour of capacity operation 9.66 10.83

Seconds of rinse per rack 10 10

Gallons per Minute - at 20 lbs. Flow Pressure 4.4 4.4

Gallons per Hour - at 20 lbs. Flow Pressure 42.9 48.1

Gallons per Rack - at 20 PSI Flow .74 - 180°F Min. .74 - 140°F Min.

if used based on 20 PSI steam - 20 PSI water owing

130°F entering water raised to 180°F min. (50°F rise) - Lbs. per Hour

Gallons per Minute (Initial rate with full tank) 38 38

450 450

Approx. lbs. - Unit only, with booster

58 65

1

⁄4" 251⁄4"

25,000 25,000

40 40

354 w/o Booster

384 w/Booster

354

Page 6 of 8 F-40078 – AM Select Dishwasher

Page 9

AM SELECT

AM15 Dishwasher Technical Manual Page 9 of 83

701 S Ridge Avenue, Troy, OH 45374

DISHWASHER

F-40078 – AM Select Dishwasher Page 7 of 8

Page 10

AM SELECT

AM15 Dishwasher Technical Manual Page 10 of 83

DISHWASHER

The microcomputer-based control system is built into the

AM Select dishwasher. It is available in standard electrical

specications of 208-240/60/1, 208-240/60/3, 480/60/3,

200-240/50/3, 380-415/50/3 and is equipped with a reduced

voltage pilot circuit transformer.

*CAUTION: CERTAIN MATERIALS, INCLUDING SILVER,

ALUMINUM AND PEWTER ARE ATTACKED BY SODIUM

HARDNESS MUST BE CONTROLLED TO 4-6 GRAINS FOR

CONSTRUCTION: Drawn tank, tank shelf and feet constructed

of 16 gauge stainless steel. Wash chamber and front trim panel

above motor compartment are polished, satin nish. Frame is

12 gauge stainless steel, chamber is 18 gauge, and removable

trim panels are 20 gauge.

CHAMBER LIFT: Chamber coupled by stainless steel handle,

spring counterbalanced. Chamber guided for ease of operation

and long life.

PUMP: With stainless steel pump and impeller, integral with

motor assures alignment and quiet operation. Pump shaft seal

with stainless steel parts and a carbon ceramic sealing interface.

Easily removable impeller housing permits ease of inspection.

Capacity 160 GPM. Pump is completely self-draining.

MOTOR: Built for Hobart, 2 H.P., with inherent thermal

protection, grease-packed ball bearings, splash-proof design,

ventilated. Single-phase is capacitor-start, induction-run type.

Three-phase is squirrel-cage, induction type.

MICROCOMPUTER CONTROL SYSTEM: Hobart

microcomputer controls, assembled within water-resistant

enclosure, provide built-in performance and reliability.

The microcomputer control, relays and contactors are housed

behind a stainless steel enclosure, hinged to provide easy

access for servicing. The line voltage electrical components are

completely wired with 105°C, 600V thermoplastic insulated wire

with stranded conductors and routed through listed electrical

conduit. Electrical components are wired with type ST cord.

Line disconnect switch NOT furnished.

CYCLE OPERATION: The microcomputer-timing program is

started by closing the doors, which actuates the door cycle

switch. The microcomputer energizes the wash pump motor

contactor during the wash portion of the program. After the

wash, a dwell permits the upper wash manifold to drain. At the

end of the dwell, the nal rinse solenoid valve is energized. After

the nal rinse valve closes, Sani-Dwell (Hot Water Mode only)

permits sanitization to continue. The Rinse display remains on

during this period, completing the program. If the microcomputer is interrupted during a cycle by the door-cycle switch,

the microcomputer is reset to the beginning of the program.

38

Second Wash, 2 Second Dwell, 10 Second Rinse, 7 Second

Sani-Dwell.

38 Second Wash, 2 Second Dwell, 10 Second Rinse.

Other programs can be pre-selected by your Hobart service

technician.

Manual wash cycle selector also provides selection of 2-, 4- or

6-minute wash cycles for heavier washing applications.

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

701 S Ridge Avenue, Troy, OH 45374

WASH: Hobart revolving stainless steel wash arms with unrestricted openings above and below provide thorough distribution of water jets to all dishware surfaces. Arms are easily

removable for cleaning and are interchangeable. Stainless steel

tubing manifold connects upper and lower spray system.

RINSE: Rotating rinse arms, both upper and lower, feature 14

rinse nozzles. The stainless steel upper and lower rinse arms

are easily removable without tools for inspection and are

interchangeable. Diaphragm-type rinse control solenoid valve

mounted outside machine. Machine is equipped with special hot

water vacuum breaker on downstream side of rinse valve –

mounted 6" above uppermost rinse opening. Easy open brass

line strainer furnished.

FILL: Microcomputer controlled ll valve installed on upstream

side of rinse vacuum breaker. Ratio ll method is used giving

the correct ll at any owing water pressure. (20 PSIG minimum

necessary for proper rinsing.)

DRAIN AND OVERFLOW: Large bell type automatic overow

and drain valve controlled from inside of machine. Drain

automatically closed by lowering chamber. Drain seal is large

diameter, high temperature “O” ring. Cover for overow is

integral part of the standpipe.

STRAINER SYSTEM: Equipped with large, exclusive self-ushing, easily removable perforated stainless steel, one-piece

strainer and large capacity scrap basket. Submerged scrap

basket minimizes frequent removal and cleaning.

Standard tank heat is 5KW electric

_immersion heating element. Regulated power infrared gas

immersion tube system is optional at extra cost. A solid-state

igniter board controls the gas valve and provides ame ignition.

A transformer steps the control circuit voltage down to 24 volts

to power the igniter board and gas valves.

Gas Heated Dishwasher: For natural gas, gas pressure

(customer connection) not to exceed 7" W.C. For liqueed

petroleum, gas pressure to burner (customer connection) not to

exceed 11" W.C. If gas pressure is higher than 7" W.C. natural

or 11" W.C. LP, a pressure regulating valve must be supplied

(by others) in the gas line to the dishwasher. Water temperature

regulation is controlled by thermistor sensor in combination with

microcomputer controls. The tank heat and positive low water

protection microcomputer circuits are automatically activated

when the main power switch is turned “on”. If tank is accidentally drained, low water protection device automatically turns heat

off. Gas immersion tube is additionally protected by a high limit

device mounted on the surface of the tube. These features are

standard with the Hobart Microcomputer Control System.

BOOSTER HEATER: Electric booster with Sense-A-TempTM

technology adequately sized to raise 110°F inlet water to 180°F

(not available on gas heat machines).

3

ACCESSORIES: 19

Splash shield for corner installations. End of cycle audible alarm

(eld activated). Delime notication (eld activated). Desirable

functional accessories can be furnished at added cost. See

listed options and accessories on this specication sheet. Write

to the factory for special requirements not listed above.

⁄4" x 193⁄4" peg and combination dish racks.

Page 8 of 8 F-40078 – AM Select Dishwasher

F-40078 (REV. 07/09) LITHO IN U.S.A. (H-01)

Page 11

AM SELECT DISHWASHERS

AM15 Dishwasher Technical Manual Page 11 of 83

MODELS

AM15 ML-130038

AM15F ML-130045

AM15T ML-130039

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 35320 Rev. C (Oct. 2009)

Page 12

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

AM15 Dishwasher Technical Manual Page 12 of 83

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT

DOWN UNIT(S) AT MAIN SHUTOFF VALVE AND

CONTACT THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VA PORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

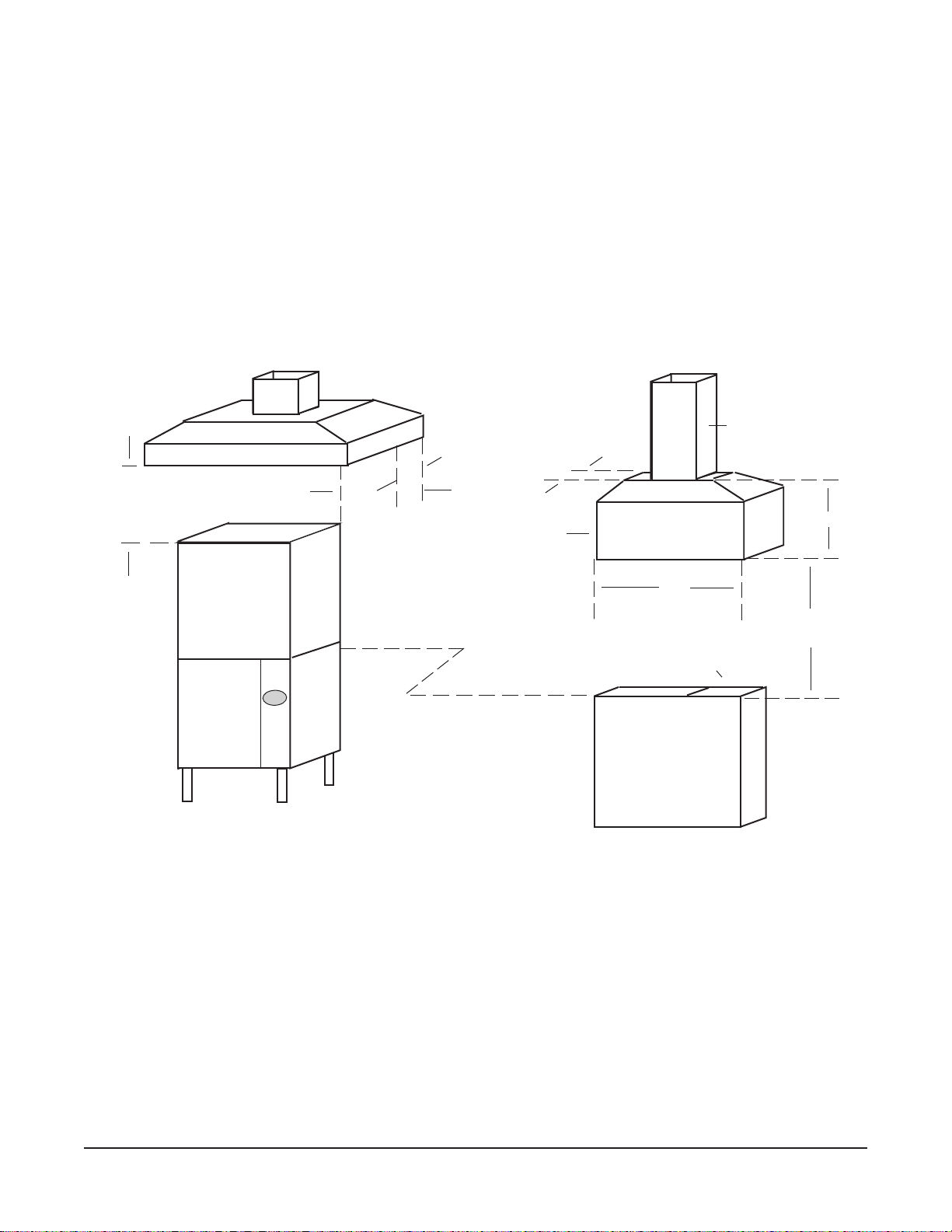

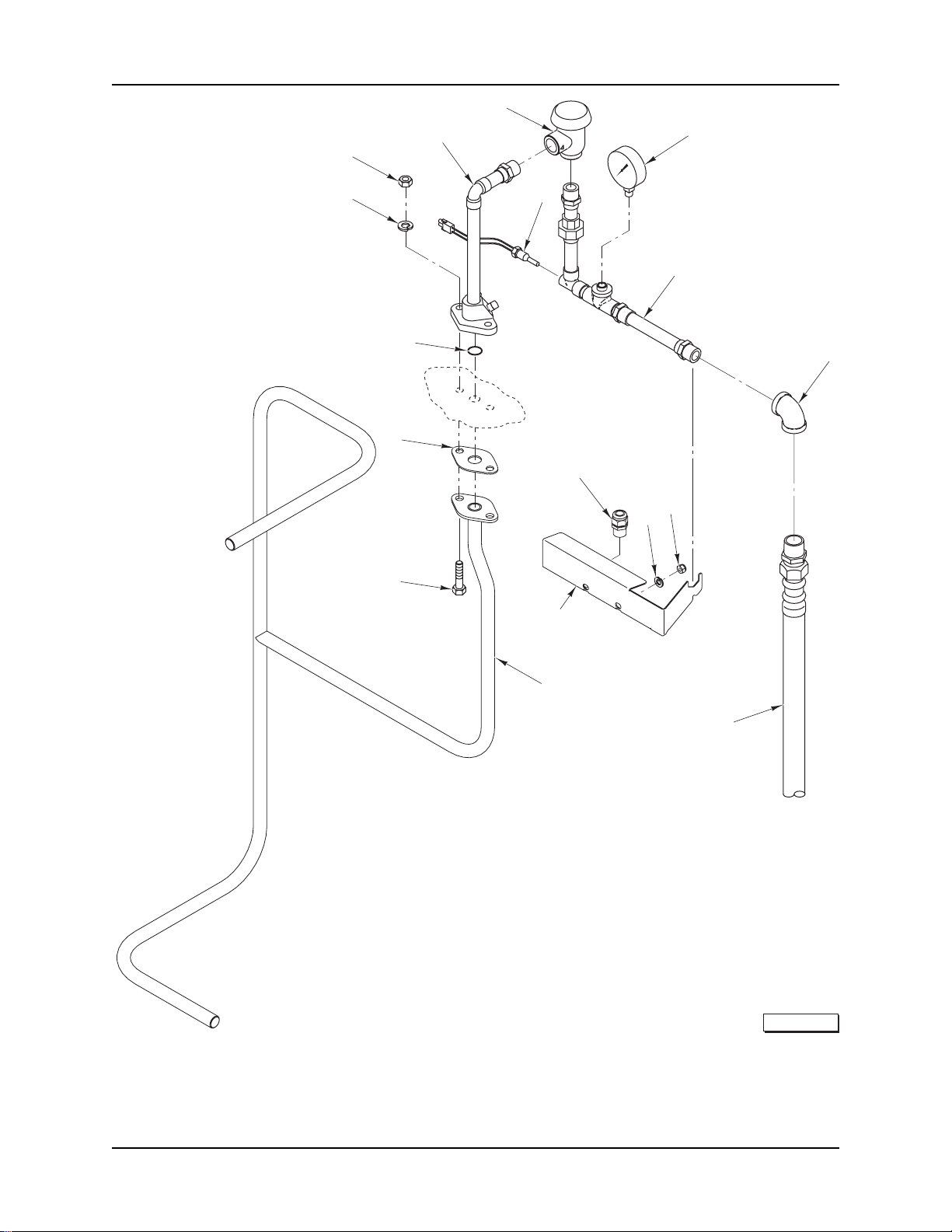

Model AM15 Model AM15F Model AM15T

PRESSURE

GAUGE

© HOBART CORPORATION, 2009

Fig. 1

– 2 –

Page 13

TABLE OF CONTENTS

AM15 Dishwasher Technical Manual Page 13 of 83

GENERAL ..................................................................4

INSTALLATION ..............................................................5

UNPACKING ..............................................................5

INSTALLATION CODES .....................................................5

LOCATION ...............................................................5

CORNER INSTALLATION ................................................6

WATER REQUIREMENTS ....................................................7

PLUMBING CONNECTIONS .................................................8

DRAIN CONNECTION ................................................... 8

WATER CONNECTION ..................................................8

Without Electric Booster Water Heater ...................................8

With Electric Booster Water Heater ......................................8

GAS TANK HEAT (When Specied) ............................................9

VENTING REQUIREMENTS — WITH GAS TANK HEAT ........................ 10

Rate of Exhaust Flow Calculations ..................................... 11

ELECTRICAL CONNECTIONS ...............................................12

Dishwasher Without Electric Booster ................................... 12

Check Rotation (Three Phase Machines Only) ............................12

Dishwasher With Electric Booster (Separately Connected) ................... 13

Dishwasher With Electric Booster (Single Point Electrical Connection) ..........13

EQUIPMENT CONNECTIONS ............................................... 13

Vent Fan Control ................................................... 13

Remote Booster Control ............................................. 13

DETERGENT, RINSE AID, SANITIZER DISPENSERS – TUBING INSTALLATION ......... 14

Detergent Dispenser ................................................ 14

Rinse Aid Dispenser .................................................14

Chemical Sanitizer Dispenser ......................................... 14

EQUIPMENT CONNECTIONS – Detergent, Rinse Aid, Sanitizer Dispensers ............ 15

Detergent Dispenser ................................................ 15

Rinse Aid / Sanitizer Dispenser(s) ......................................15

SETUP (All Models) ........................................................ 16

Sanitizing Mode ....................................................16

End of Cycle Buzzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

OPERATION ............................................................... 17

PREPARATION ....................................................... 17

DISHWASHING .......................................................18

CLEANING ........................................................... 19

DELIME INSTRUCTIONS ................................................20

DOs AND DON’Ts FOR YOUR NEW HOBART WAREWASHER .................. 20

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Wash Arms ........................................................21

Motor(s) ..........................................................21

Flue (Machines Equipped With Gas Tank Heat Only) ........................21

TROUBLESHOOTING ........................................................22

Manual Reset Button on Pump Motor ...................................22

SERVICE .................................................................. 24

– 3 –

Page 14

Installation, Operation, and Care of

AM15 Dishwasher Technical Manual Page 14 of 83

AM SELECT DISHWASHERS

SAVE THESE INSTRUCTIONS

GENERAL

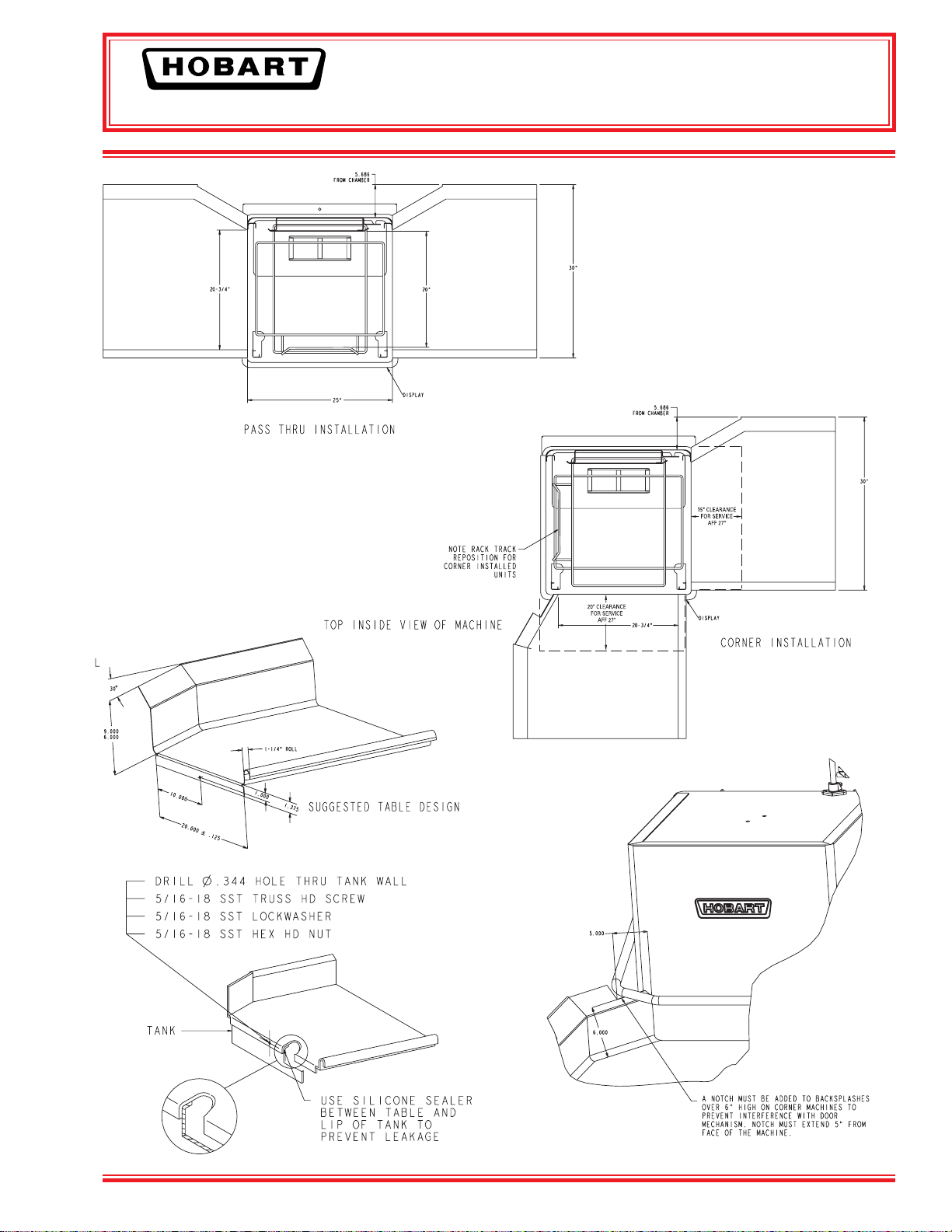

Models AM15 and AM15T dishwashers can be congured for straight through or corner operation.

Model AM15F is congured for front loading. AM15 and AM15T dishwashers are shipped from the

factory in straight-through conguration. Straight-through machines can easily be converted to corner

operation. Model AM15F includes a front-loader shelf and left- and right-side shields as standard

equipment. The front-loader shelf on AM15F can be positioned up (inside the machine during

operation) or down (outside the machine during operation).

AM15, AM15F and AM15T dishwashers are designed to operate in one of two modes: Hot water

sanitizing mode (designated by the letters “AH” or “AP” on the display when the machine is turned on),

or a chemical sanitizing mode (designated by the letters “AC” on the display when the machine is turned

on).

The serial number can be found on the machine data plate located on the bottom of the front panel.

DO NOT attempt to operate this dishwasher in the chemical sanitizing mode without a properly

installed, NSF-certied, chemical sanitizer feeder (not supplied with machine). Contact an authorized

detergent representative for information about a chemical sanitizer feeder.

The pump motor is rated 2 H.P. and has thermal overload protection.

The ll line incorporates an atmospheric vacuum breaker to prevent any reverse ow of water from the

dishwasher into the potable water supply.

The unit, once turned on, will ll the wash tank to the appropriate level and automatically stop lling

once the level is reached.

A oat, located in the wash tank, will shut off the heat supply if the water level becomes too low. When

the water returns to a proper level, the heating circuit is again operational.

A frame-mounted 8.5 KW electric booster water heater is available as an option on machines equipped

with electric tank heat. The booster water heater is designed to maintain a minimum nal rinse

temperature of 180°F provided the incoming water to the booster heater is at least 110°F.

High-temperature or gas heat dishwashers will probably require a hood or vent over the dishwasher in

order to meet local codes. Low-temperature chemical sanitizing machines or low usage electric heat

dishwashers may not require individual venting of the machine if the room is amply exhausted. Refer

to pages 10 and 11 for venting and hood requirements. Verify with local codes for nal authority.

– 4 –

Page 15

INSTALLATION

AM15 Dishwasher Technical Manual Page 15 of 83

UNPACKING

Immediately after unpacking the dishwasher, check for possible shipping damage. If this machine is

found to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to make sure it agrees with the specications on the

machine data plate; this includes the optional electric booster, if equipped. The dishwasher data plate

is located at the bottom of the front panel.

INSTALLATION CODES

Installation must be in accordance with state and local codes, or in the absence of local codes, with

the National Fuel Gas Code, ANSI Z223.1 (latest edition) if applicable, and the National Electrical Code

ANSI/NFPA 70 (latest edition). In Canada, the installation standards are: CAN/CGA B149.1,

CAN/CGA B149.2, and CSA C22.2 No.1 (latest editions).

LO CATION

Before nalizing the location, make sure that consideration has been given for the electrical conduit,

water supply, drain connection, gas supply and venting (if applicable), tabling (if needed), chemical

feeder replenishment (if applicable) and adequate clearance for opening the door.

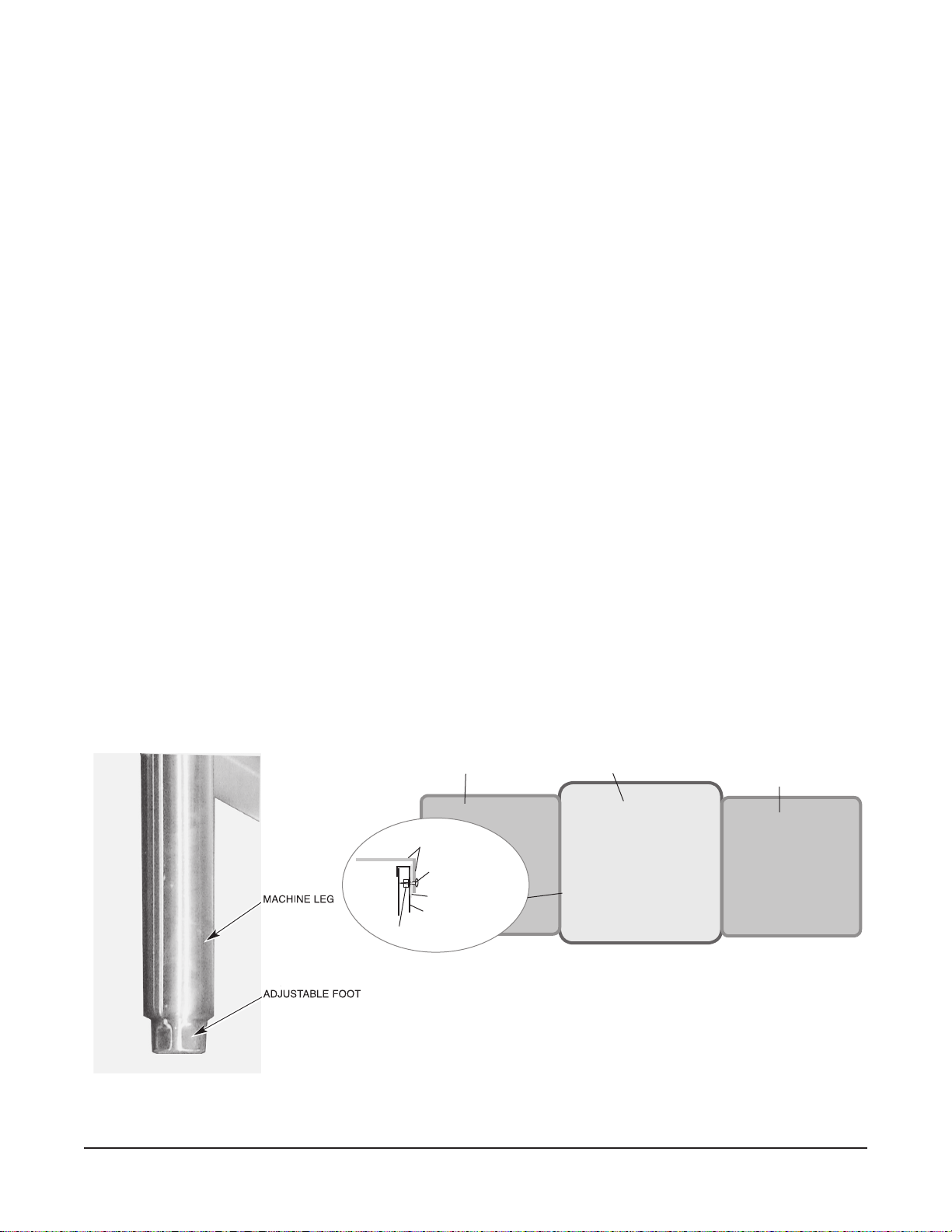

The dishwasher must be level before any connections are made. Turn the threaded feet (Fig. 2) as

required to level the machine and adjust to the desired height.

The edge of dish table that overhangs the AM15 wash tank should be turned down and tted over the

top of the dishwasher tank (Fig. 3). Apply an NSF approved sealant between the overhang of the dish

table and the inner wall of the wash tank to prevent leakage (Fig. 3). Fasten the dish tables to the inner

wall of the wash tank with non-rusting truss head screws or rivets (Fig. 3).

For straight-through installations, clearance at the front and 15 inches out from the dishwasher at the

right side by 27 inches above the nished oor must be provided for servicing.

WASH TANK

DISH TABLE

Fig. 3

DISH TABLE

MACHINE SC REW

OR RIVE T

SEALANT

INNER WA LL OF

WASH TANK

NUT

DISH TABLE

STRAIGHT-THROUGH OPERATION SHOWN

Fig. 2

– 5 –

Page 16

CORNER INSTALLATION

AM15 Dishwasher Technical Manual Page 16 of 83

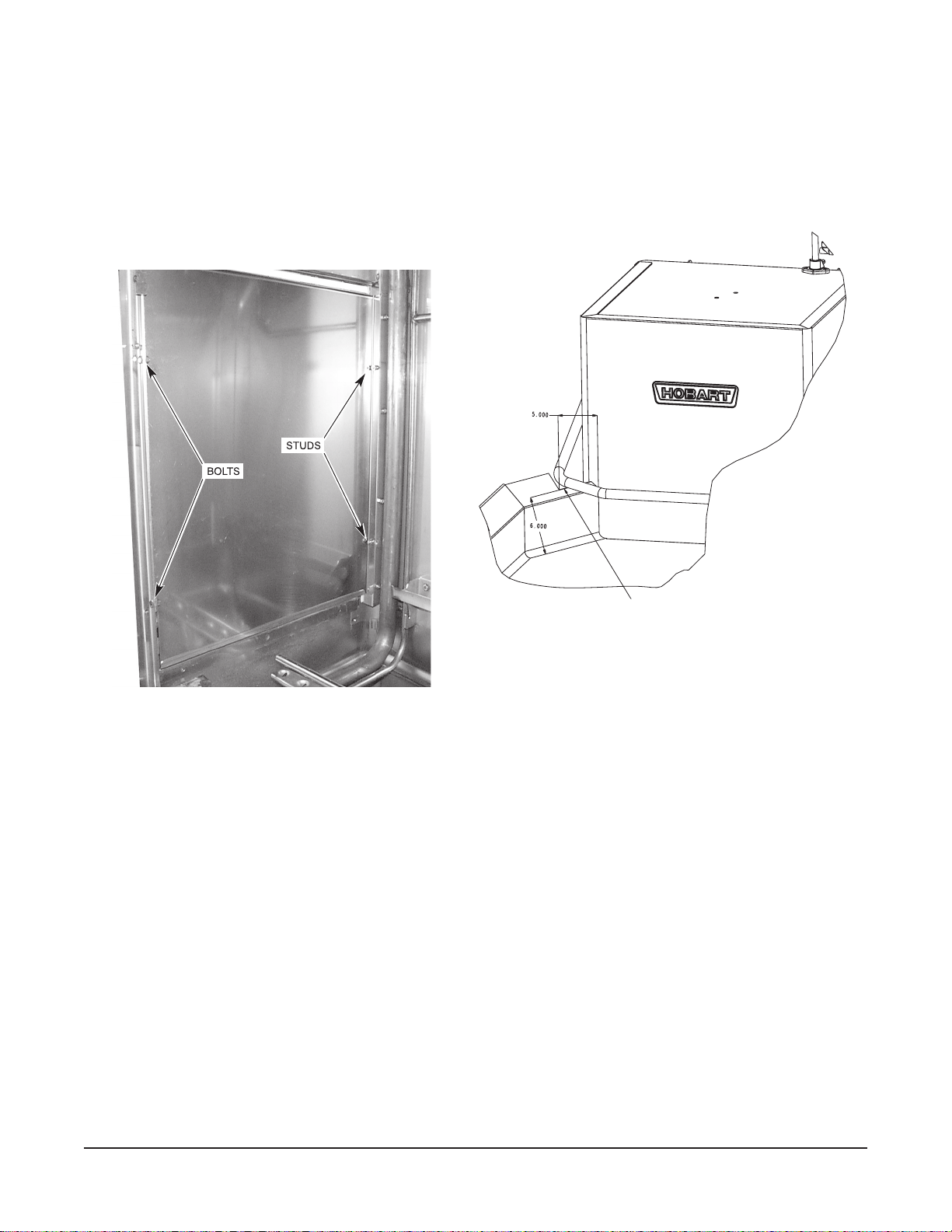

Before placing the dishwasher in its operating location, check machine conguration. If the machine

is being installed in a corner (Figs. 4, 5), clearances of 20 inches out from the dishwasher under the

left-hand tabling by 27 inches above the nished oor and 15 inches out from the dishwasher at the

right side by 27 inches above the nished oor must be provided for servicing. For proper installation

of a corner machine, the control and display should be positioned at the front corner for operator access

(Fig. 5).

For corner installation, rotate the rack track so the guide rail is positioned on the left side (Fig. 6). For

corner machines, remove the front door deector (unscrew three bolts / nuts, Fig. 7).

WASH TANK

CORNER OPERATION SHOWN

DISH TABLE

DISH TABLE

MACHINE SC REW

OR RIVE T

SEALANT

INNER WA LL OF

WASH TANK

NUT

CONTROLS MUST BE ACCESSIBLE AT

FRONT CORNER.

DISH TABLE

Fig. 4 Fig. 5

Fig. 6 Fig. 7

– 6 –

Page 17

A splash shield is available (at extra cost) for corner installations to cover the left side opening to the

AM15 Dishwasher Technical Manual Page 17 of 83

1

wall. Install the splash shield on the left side using the two

lockwasher and nut for each (Fig. 8) and using the two

⁄4-20 studs on the left rear corner with a

1

⁄4-20 bolts, lockwashers and nuts on the left

front corner (fasteners are provided in the kit).

For corner installations, tabling with backsplashes over 6" high require that a notch be provided to

prevent interference with the door mechanism (Fig. 9).

A NOTCH MUST BE ADDED TO BACKSPLASHES

OVER 6" HIGH ON CORNER MACHINES TO

PREVENT INTERFERENCE WITH DOOR

MECHANISM. NOTCH MUST EXTEND 5" FROM

FACE OF THE MACHINE.

Fig. 8 Fig. 9

WATER REQUIREMENTS

Proper water quality can improve warewashing performance by reducing spotting, lowering chemical

supply costs, improving productivity and extending equipment life. Local water conditions vary from

one location to another. The recommended proper water treatment for effective and efcient use of

this equipment will also vary depending on the local water conditions. Ask your municipal water

supplier for details about local water specics prior to installation.

Recommended water hardness is 3 grains of hardness per gallon or less. Chlorides must not exceed

50 parts per million. Water hardness above 3 grains per gallon should be treated by a water conditioner

(water softener or in-line treatment). Water treatment has been shown to reduce costs associated with

machine cleaning, reduce the need for deliming the dishwasher and reduce detergent usage.

Sediment, silica, chlorides or other dissolved solids may lead to a recommendation for particulate

ltration or reverse osmosis treatment.

If an inspection of the dishwasher or booster heater reveals lime build-up after the equipment has been

in service, in-line water treatment should be considered, and, if recommended, should be installed and

used as directed. Contact your Hobart Service ofce for specic recommendations.

– 7 –

Page 18

PLUMBING CONNECTIONS

AM15 Dishwasher Technical Manual Page 18 of 83

WARNING:

PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY AND

PLUMBING CODES.

DRAIN CONNECTION

The drain connection is a 1

1

⁄2 " externally threaded pipe connected

straight down from the bottom of the wash tank (Fig. 10). The

connection can be made in any direction by using the proper tting

(not supplied) and routing to the appropriate drain line.

If a grease trap is required by code, it should have a minimum ow

capacity of 38 gallons per minute.

Fig. 10

WATER CONNECTION

A suitable water hammer arrestor should be installed in the water line just ahead of the dishwasher.

Without Electric Booster Water Heater

3

The water supply line is connected to the line strainer (top rear, Fig. 1) with

⁄4" pipe. A manual shutoff

valve and pipe union are required (not supplied).

REQUIRED INCOMING WATER TEMPERATURE

Model Sanitizing Mode

Without Built-in Booster Hot Water Sanitizing 180°F

Without Built-in Booster Chemical Sanitizing 120°F (49°C) 140°F (60°C)

With Built-in Booster Hot Water Sanitizing 110°F (43°C) 140°F (60°C)

Minimum Temperature Recommended Temperature

(82°C) 180°F (82°C)

Water Supply

Proper dishwasher operation requires a owing pressure of 20 ± 5 psig at the dishwasher. If the owing

pressure exceeds 25 psig, a pressure reducing valve (not supplied) must be installed in the water

supply line. CAUTION: The water pressure regulator must have a relief by-pass. Failure to use

the proper type of pressure regulator may result in damage to the unit.

A pressure gauge (Fig. 1) is provided (not installed) for verication of proper water pressure. The water

pressure is monitored when the solenoid valve is open and water is owing.

With Electric Booster Water Heater

The water supply line is connected below the booster with the line strainer (supplied) and

3

⁄4" pipe. A

manual shut off valve and pipe union are required (not supplied).

The water supply should have a minimum temperature of 110°F, and a owing pressure of 20 ± 5 psig

at the pressure gauge on top of the machine. If the owing pressure exceeds 25 psig, a pressure

reducing valve (not supplied) must be installed in the water supply line. CAUTION: The water

pressure regulator must have a relief by-pass. Failure to use the proper type of pressure

regulator may result in damage to the unit.

Incoming water temperature below 110°F may require longer wash cycle time than the 57 second cycle;

refer to OPERATION, pages 17 – 18.

When the ll / nal rinse valve is on, water from the booster tank enters the dishwasher through the nal

rinse arms. During the rinse cycle, this water is 180°F. A small amount of water will likely dribble out

of the lower rinse arm into the tank between cycles due to the natural expansion of water as it is being

heated.

– 8 –

Page 19

GAS TANK HEAT (When Specified)

AM15 Dishwasher Technical Manual Page 19 of 83

Check the gas data plate attached to the dishwasher or the tag attached to the incoming gas piping

for the type of gas to be used.

GAS PRESSURE SPECIFICATION

The burner is not adjustable. The maximum

owing inlet gas pressure must not exceed

the Maximum value in the table. If line

pressure exceeds the Maximum value in

the table, an additional pressure regulator

(not supplied) must be installed in the

[FLOWING GAS PRESSURE — NOT STATIC]

Type

of

Gas

Natural 25,000 3.5 7. 0 3.2

Propane 25,000 9.0 11.0 8.2

BTU/HR

Inches W.C. (Water Column) FLOWING

Incoming Line Pressure

Minimum Maximum

Manifold

Pressure

supply line.

Static inlet line pressure should not exceed 14" W.C. The minimum value is for input adjustment.

The gas valve is provided with a pressure tap to measure the gas

pressure downstream, which is also the manifold pressure. Gas

supply piping must have a sediment trap (supplied by others)

installed ahead of the dishwasher’s gas control. Connect the gas

1

supply to the

⁄2" NPT gas inlet underneath the machine (Fig. 11).

NOTE: DO NOT use Teon tape on gas line pipe threads. For

gas line pipe connections, use L

o c t i t e 565, Hobart part 546292,

or a exible sealant suitable for use with Natural and Propane

Gases.

Fig. 11

The appliance and its gas connections must be leak tested before placing the appliance in operation.

Use soapy water for leak test. DO N OT use open ame. The installation must conform with local codes,

or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition). Copies

may be obtained from American Gas Association, Inc., 1515 Wilson Boulevard, Arlington, VA 22209.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

1

during any pressure testing of that system at test pressures in excess of

⁄2 psig (3.45kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or

1

less than

⁄2 psig (3.45kPa).

Dissipate test pressure from the gas supply line before re-connecting the appliance and its manual

shutoff valve to the gas supply line. Caution: Failure to follow this procedure may damage the gas

valve.

The dishwasher must be installed so that the ow of combustion and ventilation air will not be

obstructed. Do not store material underneath the machine; air openings into the combustion chamber

must not be blocked. Make sure there is an adequate supply of make-up air in the room to allow for

combustion of the gas at the burner.

Keep the appliance area free and clear from all combustible substances. Do not obstruct the ow of

combustion and ventilation air. The dishwasher must have a minimum clearance from combustible

construction of 1 inch from the ue at the rear. Clearances of 20 inches out from the dishwasher at

the front (or left side in a corner installation) by 27 inches above the nished oor and 15 inches out

from the dishwasher at the right side by 27 inches above the nished oor must be provided for

servicing.

The burner is ignited automatically by solid state electronic circuitry; there is no pilot light. Gas ow

is regulated by the temperature control circuit.

– 9 –

Page 20

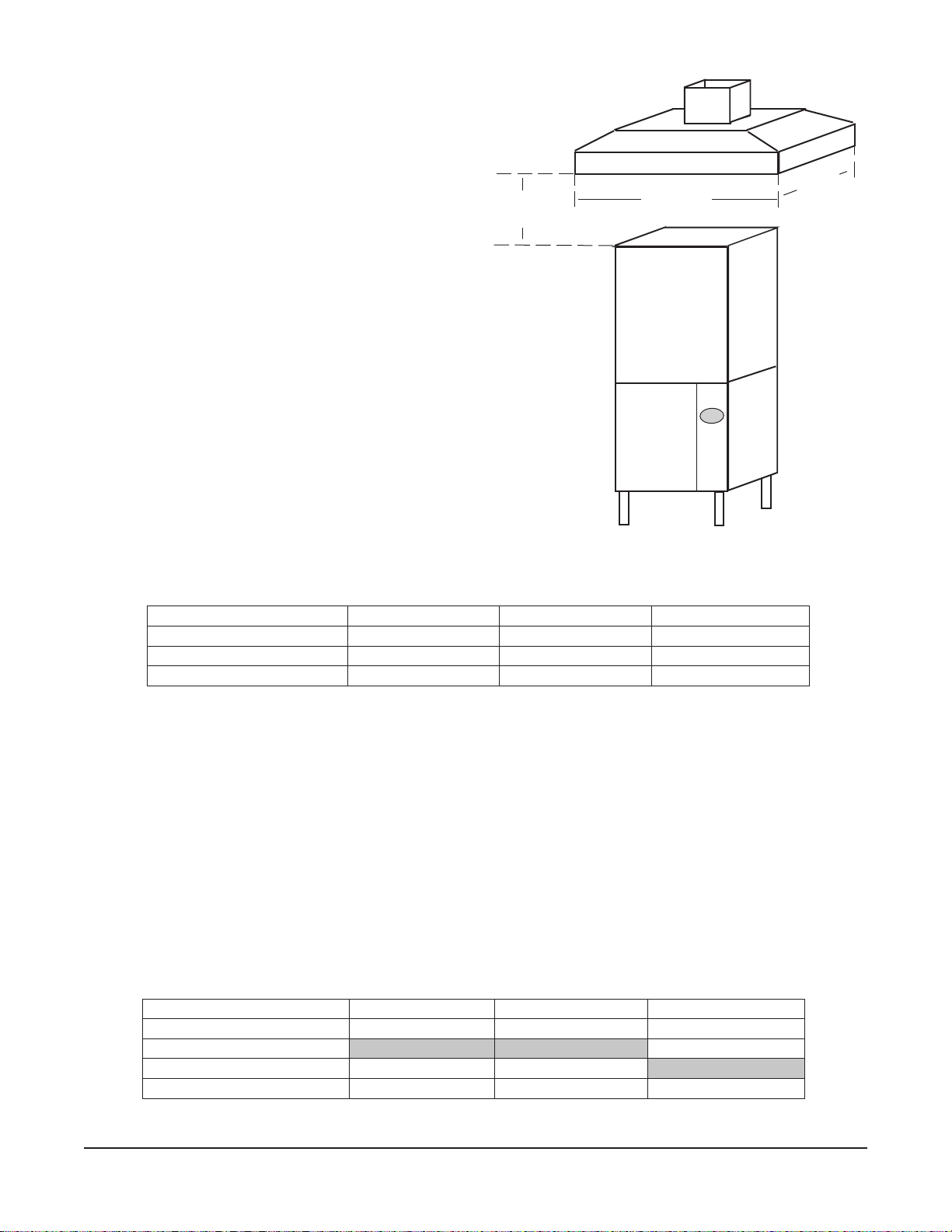

VENTING REQUIREMENTS — WITH GAS TANK HEAT

AM15 Dishwasher Technical Manual Page 20 of 83

Hobart model AM15, AM15F or AM15T dishwashers equipped for gas tank heat are not provided with

a ue collar and are not intended to have the ue directly connected to a ventilation system. However,

the products of combustion must be vented to the outside air. The most common method of venting

is a vent hood over the entire dishwasher (Fig. 12). Refer to Rate of Exhaust Flow Calculations on the

next page for calculations of the proper vent rate for your hood. Another method is a small vent hood

(Fig. 13) positioned about ve inches above the ue exit at the rear of the dishwasher and connected

to existing ductwork. In either case, an electrical interlock must be installed to allow the ow of gas

to the dishwasher burner ONLY when the exhaust system is energized. For additional information,

refer to the National Fuel Gas Code, ANSI Z223.1, NFPA 54.

•IMPORTANT: Make sure the installation meets the local code for your area.

3" x 3" DUCT INTO

➤

CURRENT SYSTEM

➤

1' TO 4'

CLEARANCE

➤

➤

6"

MINIMUM

OVERHANG

ON ALL SIDES

➤

➤

➤

MINI VENT HOOD

18" OVERHANG

RECOMMENDED

OVER LOADING OR

UNLOADING DOORS

31⁄2"

➤

➤

➤

➤

6"

➤

MINIMUM

➤

4"

➤

➤

5" GAP

DISHWASHER FLUE EXIT

Fig. 12 Fig. 13

➤

➤

– 10 –

Page 21

NOTE: Any listed and labeled factory-built

AM15 Dishwasher Technical Manual Page 21 of 83

commercial exhaust hood tested in accordance

with UL Standard 710 by a nationally recognized

testing laboratory, should be installed according

to the terms of its listing and the manufacturer’s

installation instructions.

RATE OF EXHAUST FLOW CALCULATIONS

Based on the 1996 International Mechanical Code.

The Rate of air ow required for a vent hood is

calculated using the following denitions (Fig. 14):

Q = Rate of Air Flow in Cubic Feet Per Minute

or [ CFM ] Required for the Hood.

2

A = Area of Hood Opening in Feet

= (L x W)

D = Clearance Height = Distance in Feet from

lower lip of hood to top of dishwasher

chamber.

P = Perimeter of Hood that is Open. This

depends on the hood design, as follows:

➤

CLEARANCE

HEIGHT

➤

➤

WIDTH

➤

➤

LENGTH

Fig. 14

➤

Perimeter Calculation Formula

Hood Design

Number of Open Sides

P =

Dimensions

Corner Wall Island

2 Sides Open 3 Sides Open 4 Sides Open

L + W L + W + W L + L + W + W

Feet Feet Feet

If there are four open sides (Island Design), the calculation of the Rate is as follows:

Q = 75 x A

If there are three or fewer open sides, the calculation of the Rate is as follows:

Q = 50 x A

As an alternate method, the Rate can be calculated as follows:

Q = 50 x P x D

Example:

L = 3 W = 3 D = 2

Rate Calculations

Hood Design

Number of Open Sides

Q = 75 x A

Q = 50 x A

Q = 50 x P x D

Corner Wall Island

2 Sides Open 3 Sides Open 4 Sides Open

675 CFM

450 CFM 450 CFM

600 CFM 900 CFM 1200 CFM

– 11 –

Page 22

ELECTRICAL CONNECTIONS

AM15 Dishwasher Technical Manual Page 22 of 83

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE (BOTH DISHWASHER AND

BOOSTER IF APPLICABLE) AND FOLLOW LOCKOUT / TAGOUT PROCEDURES.

Refer to the wiring diagram attached inside the front trim panel and to the machine data plate for service

size requirements when connecting the dishwasher. Also, refer to Electrical Data, page 12.

To access the controls area, remove the right side panel, remove the front panel and open the control

3

panel door. The dishwasher electrical service connection can be made through the 1

3

⁄4 inch trade size conduit located on the right side at the rear of the machine. By removing a

for

knockout, this hole can be enlarged to 1

3

⁄8" diameter for 1 inch trade size conduit, if required.

⁄32" diameter hole

ELECTRICAL DATA

Minimum Circuit Ampacity

Maximum Protective Device

AMPS

Models Volts / Hz / Ph Tank Heat

Dishwasher

ONLY

208 - 240 / 60 / 1

AM15

AM15F

AM15T

Compiled in accordance with the national electrical code, NFPA 70 (latest edition).

208 - 240 / 60 / 3

480 / 60 / 3

200 - 240 / 50 / 3 Electric 30 30 60

380 - 415 / 50 / 3 Electric 15 15 30

Electric 50 50

Gas 20

Electric 30 30 60

Gas 15

Electric 15 15 30

Gas 15

Optional 8.5 KW Electric Booster

8.5 KW

Booster

ONLY

Optional Single Point

Electrical Connection

3 Phase Only

Dishwasher and Booster

A fused disconnect switch or circuit breaker (not supplied) must be installed in the electrical service

line(s) supplying this dishwasher and should meet the requirements of your local electrical code.

Dishwasher Without Electric Booster

For single-phase machines, power supply connections are made to terminal blocks. For three-phase

machines connections are made to contactor lugs. The machine must be grounded according to

electrical code(s); a grounding lug is provided in the controls area. Electrical connections for machines

with gas tank heat are made to contactor 1CON in the controls area.

Check Rotation (Three-Phase Machines Only)

Three-phase motors must rotate in the direction of the arrow on

the pump housing. In order to check rotation, remove the bearing

cap to observe the motor shaft (Fig. 15). Close the machine doors

and press the power switch to ON. When the machine is completely

lled, open and close machine doors to verify that the motor shaft

rotates in the clockwise direction.

If the rotation is incorrect, DISCONNECT ELECTRICAL POWER

SUPPLY and interchange any two of the incoming power supply

leads. Reconnect the power supply and verify correct rotation.

Replace the motor bearing cap.

– 12 –

Fig. 15

Page 23

Dishwasher With Electric Booster (Separately Connected)

AM15 Dishwasher Technical Manual Page 23 of 83

Single phase machines with an electric booster require two separate connections, one for the booster

and the other for the dishwasher (including motor, controls and tank heat). For single-phase machines,

all power supply connections are made to terminal blocks (Fig. 16). The single phase dishwasher is

connected to terminal block 1TB in the controls area. The single phase booster is connected to

terminal block 2TB in the controls area.

If the machine is three phase, the electrical connection for the dishwasher is made to the contactor

2CON in the controls area. The electrical connection for the three phase booster is made to the

contactor 3CON in the controls area (Fig. 17).

Dishwasher With Electric Booster (Single Point Electrical Connection)

Three phase machines congured with the optional single point electrical connection are connected

to terminal block 1TB in the controls area (Fig. 18). The machine must be grounded according to

electrical code(s); a grounding lug is provided.

Fig. 16 Fig. 17 Fig. 18

EQUIPMENT CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE (BOTH DISHWASHER AND

BOOSTER IF APPLICABLE) AND FOLLOW LOCKOUT / TAGOUT PROCEDURES.

Vent Fan Control

The vent fan control feature is standard on all machines. The vent fan control relay provides switch

contacts only and does not provide power to the vent fan motor. The rating for a vent fan control relay

connected to terminals VFC1 and VFC2 is 1.5 Amps at 240 Volts maximum. When the dishwasher is

connected to the vent fan, the vent fan is switched on when the dishwasher is on, and off when the

dishwasher is off.

Remote Booster Control

The booster control feature is standard on all machines. The load rating for remote booster control

connections to BSTR1 and BSTR2 is 0.1 Amp. at 120 Volts maximum. The booster control provides

a control signal only and does not provide power to the remote booster. When a remote booster

is connected to the dishwasher, the booster is on when the dishwasher is on and off when the

dishwasher is off.

– 13 –

Page 24

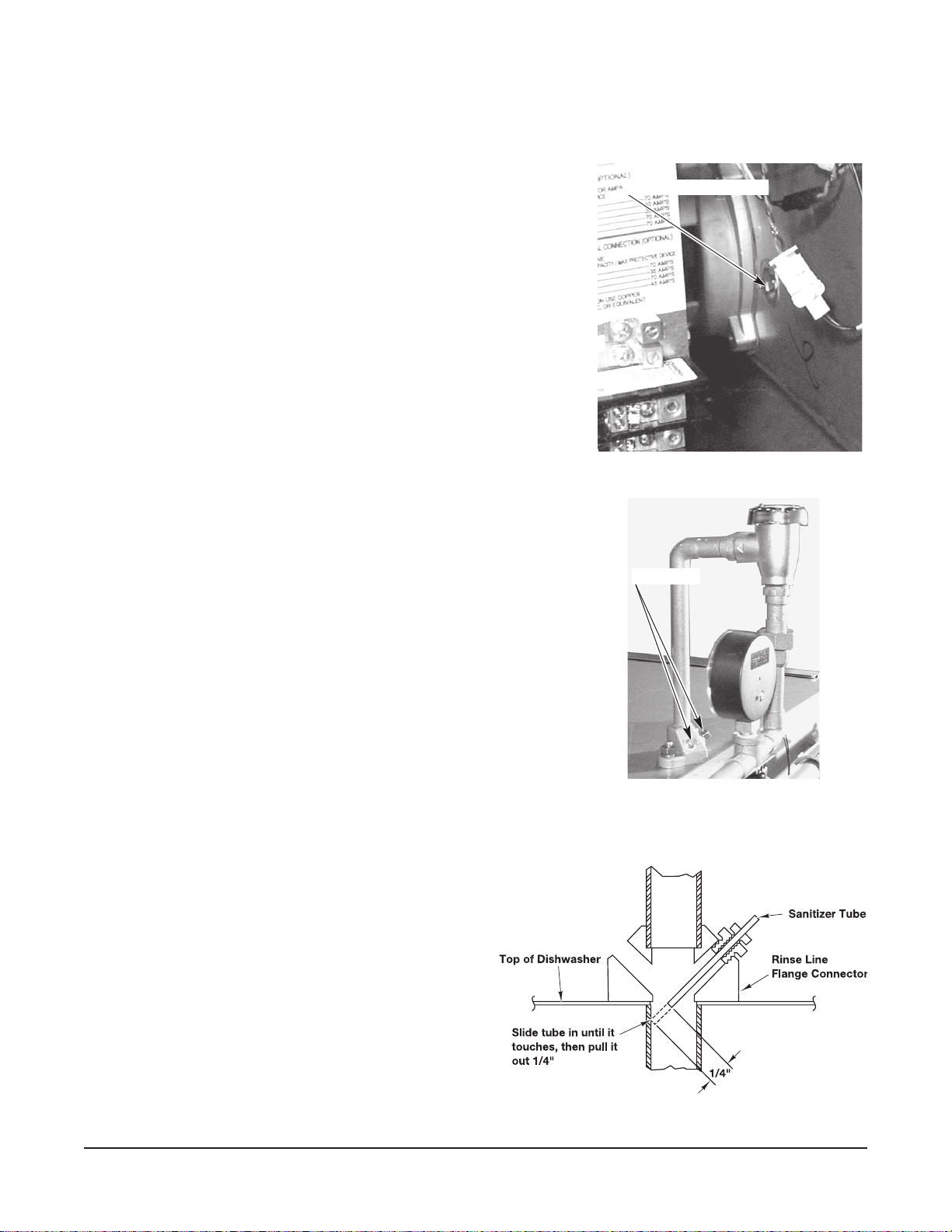

DETERGENT, RINSE AID, SANITIZER DISPENSERS — TUBING INSTALLATION

DETERGENT SENSOR PORT

PIPE PLUGS

AM15 Dishwasher Technical Manual Page 24 of 83

Detergent, rinse aid and / or sanitizer dispensers (not provided by Hobart) must have all connections

sealed against leakage.

The dishwasher uses 0.74 gallons of rinse water per rack at a

ow rate of 4.4 gallons per minute at 20 psig owing pressure

(equivalent to a maximum head pressure of 46 feet of water).

This information is used when setting the detergent, rinse aid

or sanitizer pumps.

Detergent Dispenser

7

The dishwasher has two

⁄8" diameter plugged holes, one on

the rear of the chamber and one on the lower part of the tank

near the pump (Fig. 19). With the tank empty, remove both

plugs to install the detergent dispenser.

• Thechamberholeisforinstallationofthedetergentfeeder

tube.

• Thelowertankholeisusedforinstallationofthedetergent

Fig. 19

sensor.

Rinse Aid Dispenser

The rinse line ange connector on top of the dishwasher has two

1

⁄8" NPT pipe plugs (Fig. 20).

• Remove the plug(s) (Fig. 20) for installation of the rinse aid

dispenser tube and / or chemical sanitizer tube, as needed.

Chemical Sanitizer Dispenser

When the dishwasher is to be operated in the chemical sanitizing

mode, the machine must be converted to low-temperature

sanitization (refer to Setup, page 16). A chemical sanitizer

dispenser that has been tested and certied by NSF International

must be installed.

• Remove the pipe plug (Fig. 20) for installation

of the chemical sanitizer tube. To assure an

unobstructed flow of sanitizer, locate the

sanitizer tube in the center of water ow by

drilling the sanitizer tube tting so that its inside

diameter is equal to the outside diameter of the

tube. Slide the tube into the ange until it

touches the opposite side and then pull it back

1

⁄4 inch (Fig. 21).

out

Fig. 20

• Rate for 6% Sodium hypochlorite (bleach) —

3 ml. within 10 seconds (maximum).

• Ratefor8.4%Sodiumhypochlorite(bleach)—

2 ml. within 10 seconds (maximum).

Fig. 21

– 14 –

Page 25

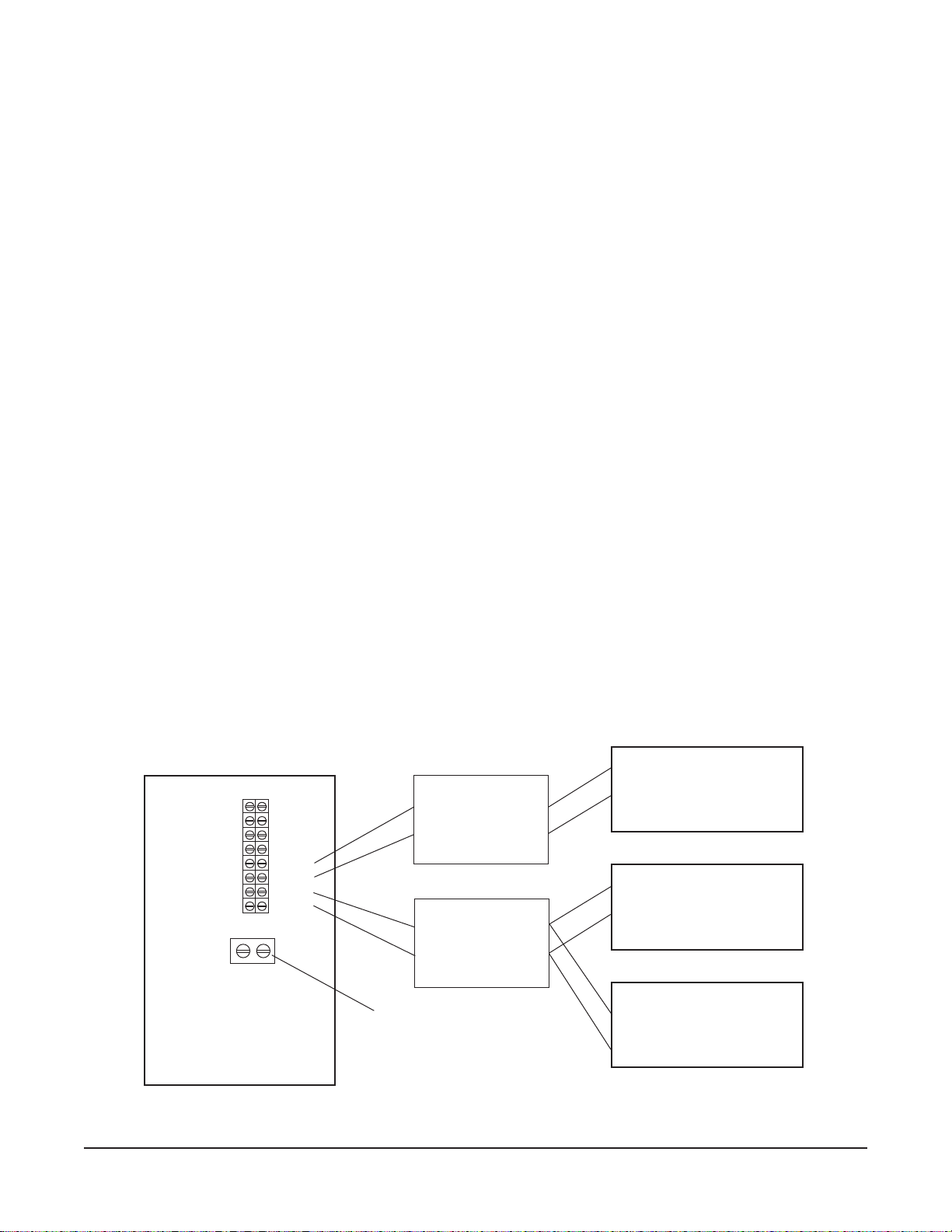

EQUIPMENT CONNECTIONS — Detergent, Rinse Aid, Sanitizer Dispensers

AM15 Dishwasher Technical Manual Page 25 of 83

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE APPLICABLE

PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE (BOTH DISHWASHER AND

BOOSTER IF APPLICABLE) AND FOLLOW LOCKOUT / TAGOUT PROCEDURES.

This machine must be operated with an automatic detergent feeder and, if applicable, an automatic

chemical sanitizer feeder, including a visual means to verify that detergents and sanitizers are

delivered or a visual or audible alarm to signal if detergents and sanitizers are not available for delivery

to the respective washing and sanitizing systems. Refer to the installation section of this manual and

to the chemical feeder equipment manual(s).

Detergent Dispenser (Fig. 22)

Terminals DPS1 and DPS2 are supplied with controlled machine line voltage. They are ON during the

wash cycle and OFF between cycles or when the machine power supply is OFF. Maximum rating for

detergent dispenser connected to DPS1 and DPS2 is 1.5 Amps at line voltage. Check the machine

supply voltage and use corresponding feeder transformer voltage. Use UL listed 600 volt minimum

insulated wire for the connections. Do not use bell wire, lamp cord or similar type wire. Splice

connections, if required, must be made in the feeder transformer junction box — not in the main

7

controls enclosure. Remove

⁄8" diameter cap plug(s) for 1⁄2" trade size conduit ttings from the rear

of the enclosure. Remove the side panel. Strain relief ttings must be provided for all wiring.

Rinse Aid / Sanitizer Dispenser(s) (Fig. 22)

Terminals RPS1 and RPS2 are supplied with controlled machine line voltage and are ON during the

rinse cycle only. Maximum rating for rinse aid dispenser connected to RPS1 and RPS2 is 1.5 Amps

at line voltage. Check the machine supply voltage and use corresponding feeder transformer voltage.

Use UL listed 600 volt minimum insulated wire for the connections. Do not use bell wire, lamp cord

or similar type wire. Splice connections, if required, must be made in the feeder transformer junction

7

box (supplied by others) — not in the main controls enslosure. Remove

1

⁄2" trade size conduit ttings from the rear of the enclosure. Strain relief ttings must be provided for

⁄8" diameter cap plug(s) for

all wiring.

DETERGENT

DISPENSER

RINSE AGENT

DISPENSER

CHEMICAL

SANITIZER

DISPENSER

— VFC1

— VFC2

— BSTR1

— BSTR2

— DPS1

— DPS2

— RPS1

— RPS2

RIGHT SIDE OF

CONTROL AREA

TRANSFORMER

PRIMARY

TRANSFORMER

PRIMARY

GROUND LUG

SECONDARY

SECONDARY

Fig. 22

– 15 –

Page 26

SETUP (All Models)

AM15 Dishwasher Technical Manual Page 26 of 83

Sanitizing Mode

• WiththemachineOFF,presstheONkey.

• ImmediatelypressandholdtheOFFkey.

The display initializes until 88 displays.

Next, SET X

°F

displays. X can be H, C or P:

°C

H = Hot Water Sanitizing, Internal Booster.

C = Chemical Sanitizing, No Booster.

P = Hot Water Sanitizing, External Booster.

• PressCYCLEtoselectP,H,orCasthesanitizingmode.

After 5 seconds, the selection is saved and the machine turns off.

End of Cycle Buzzer

• WiththemachineOFF,presstheONkey.

• ImmediatelypressandholdtheOFFkey.

The display initializes until 88 displays.

°F

Next, SET X

displays. X can be P, H or C. (See above).

°C

SET H

SET C

SET P

SHORTCUT IF

PROGR AMMING BOTH FEATURES

AT THE SAME TIME.

°F

°C

°F

°C

°F

°C

• PressandholdtheOFFkey.

Next, SET WASH XX displays. XX can be On or OF:

SET WASH On = End of Cycle Buzzer is ON.

SET WASH OF = End of Cycle Buzzer is OFF.

• PressCYCLEtoselectOnorOFfortheEndofCycleBuzzer.

After 5 seconds, the selection is saved and the machine turns off.

SET WASH On

SET WASH OF

– 16 –

Page 27

OPERATION

AM15 Dishwasher Technical Manual Page 27 of 83

PREPARATION

The overow tube must be in its proper location below the strainer pan (Fig. 23). Place the strainer

pan and the strainer bucket in their proper positions (Fig. 24).

Fig. 24

Fig. 23

An automatic detergent dispenser is recommended. Closely

follow supplier’s instructions.

Close the door; this will automatically close the drain.

Open the manual gas valve (if applicable). Press the ON

button to turn the power on (Fig. 25). If the machine’s door is

closed and no water is in the tank, the ll cycle will begin

automatically. During the ll cycle, the word FILL is displayed.

When the ll cycle has completed, the readout will display the

wash temperature. During the rinse cycle, the rinse icon and

temperature will be displayed. Select the wash cycle: 1 for

normal serving ware, 2, 4 or 6 for pots and pans. Each wash

cycle is followed by an automatic rinse. When the rinse cycle

is complete, the door can be opened.

Fig. 25

– 17 –

Page 28

DISHWASHING

AM15 Dishwasher Technical Manual Page 28 of 83

Scrape the dishes to remove large particles of food and debris. Never use steel wool on ware to be

loaded into the dishmachine.

Fig. 26

Arrange the dishes in a rack. Do not stack dishes one on top of another, as water must have free access

to all sides of every dish. Stand plates and dishes up edgewise in a peg-type rack (Fig. 26). Cups,

glasses, and bowls should be inverted in an open-type or compartment type rack (Fig. 26). Silverware

and other small pieces may be scattered loosely over the bottom of a at bottom rack.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants.

After lling a rack, open the door, slide the rack into the dishwasher and close the door.

Throughout the wash cycle, the tank water temperature will be displayed on the front panel display,

along with the word WASH and an icon. During the rinse cycle, the rinse water temperature will be

displayed, along with the word RINSE and an icon. When the rinse cycle is completed, the readout will

display the tank water temperature.

When the cycle is nished and the rinse icon disappears, open the door, remove the clean dishes, slide

in another rack and close the door.

To add a dish after the wash cycle has started, open the door slightly. Wait 10 seconds to allow the

wash arm to coast down and to avoid water splashing before opening the door fully.

Operating temperatures for all models are as follows:

Sanitizing Mode

Hot Water

Chemical

Minimum Wash Recommended Wash Minimum Rinse Recommended Rinse

150°F (66°C) 150°F (66°C) 180°F (82°C) 180°F (82°C)

120°F (49°C) 14 0° F (60°C) 120°F (49°C) 140 °F (60°C)

Wash Temperature Rinse Temperature

Model AM15F has a front loader door and loading tray. The machine can operate with the loader tray

positioned vertical inside the chamber (up position) or positioned horizontal outside the chamber (down

position).

– 18 –

Page 29

CLEANING

AM15 Dishwasher Technical Manual Page 29 of 83

The machine must be thoroughly cleaned at the end of each working shift or at least daily. Never use steel

wool to clean warewasher surfaces. Use only products formulated to be safe on stainless steel.

1. Push the OFF button.

2. Open the machine door.

3. Clean off the dish tables into the dishwasher.

4. Drain the machine by lifting up the drain lever (Fig. 27).

5. Thoroughly cleanse and flush the dishwasher interior.

Remove remaining soil with a soft cloth or brush and mild

cleanser. Rinse again. Do not allow food soil to accumulate

on the tank bottom.

6. Remove and empty the strainer pan and the strainer bucket.

Wash and rinse them thoroughly.

Fig. 27

7. Clean the pump cover with a soft cloth or brush. Do not allow food soil to accumulate on the tank

bottom or to enter the drain.

8. Remove the overow tube. Wash and rinse the overow tube inside and out.

9. Make sure that the wash and rinse arms rotate freely and are free of any obstructions. If not,

remove arms and clear out any obstructions.

10. Remove and check wash arms and rinse nozzles (Figs. 28, 29) to make sure they are free of any

lime and solids. Refer to Maintenance, page 21.

NOTE: Do not bang wash arms or rinse arms to clean.

11. Replace all removed parts. Leave the machine door open to allow the interior to air out and dry.

Fig. 28 Fig. 29

– 19 –

Page 30

DELIME INSTRUCTIONS

AM15 Dishwasher Technical Manual Page 30 of 83

if the optional delime notication is activated and the DELIME light is on, follow the instructions, below.

Delime is also necessary if deposits are visible inside or outside the machine.

DELIME INSTRUCTIONS

1. Remove rack, drain tank, press “OFF”.

2. Press and hold “CYCLE” & “ON” for 3 seconds;

close door, unit fills then indicates “ADD DELIME”.

3. Open door & add delime agent per supplier

instructions for 14 gallon tank.

4. Close door, pump starts & display flashes “DELIME”.

After 12 minutes display scrolls “DRAIN”.

5. Check interior, close door to run additional cycles

if necessary.

6. Drain tank, turn unit off.

DOs AND DON’Ts FOR YOUR NEW HOBART WAREWASHER

DO assure proper water hardness (3 grains or less per gallon is recommended).

DO pre-scrap dishes thoroughly.

DO use only detergents recommended by your chemical professional.

DO at the end of the day, thoroughly cleanse the machine, rinse and dry (leave door open).

DO closely follow your chemical professional’s prescribed deliming schedule.

DO use only products formulated to be safe on stainless steel.

DO NOT use detergents formulated for residential dishwashers.

DO NOT allow food soil to accumulate on the tank bottom.

DO NOT exceed chemical manufacturer’s recommended concentrations for detergent, sanitizer, rinse

aid or lime scale remover.

DO NOT use steel wool to clean ware or warewasher surfaces.

DO NOT allow foreign objects to enter the unit, especially metallic contaminants such as paper clips,

retainers, etc.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warewasher

warranty.

– 20 –

Page 31

MAINTENANCE

AM15 Dishwasher Technical Manual Page 31 of 83

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE (BOTH DISHWASHER AND

BOOSTER IF APPLICABLE) AND FOLLOW LOCKOUT / TAGOUT PROCEDURES.

Wash Arms

Upper and lower wash and rinse arms (Figs. 28, 29) should turn freely and continue turning for a few

seconds after being whirled by hand. To check, DISCONNECT ELECTRICAL POWER SUPPLY

(BOTH DISHWASHER AND BOOSTER IF APPLICABLE), rotate arms and remove any obstructions

causing improper operation.

If either the strainer pan or the strainer bucket is not properly in place, obstructions (such as food

particles or bones) may clog the wash arm nozzles. The wash arms are easily removed for cleaning.

To remove the lower wash arm, unscrew the hand knob and lift the rinse arm off (Fig. 28). The wash

arm can be lifted off once the rinse arm is removed.

The upper wash and rinse arms are removed by unscrewing the hand knob (Fig. 29) and lowering both

arms together. Be careful not to drop these arms.

Motor(s)

The wash pump motor and the blower motor used on gas heat machines are equipped with

permanently lubricated bearings and require no lubrication maintenance.

Flue (Machines Equipped With Gas Tank Heat Only.)

When cool, check the ue opening every three months for obstructions.

– 21 –

Page 32

TROUBLESHOOTING

AM15 Dishwasher Technical Manual Page 32 of 83

Manual Reset Button on Pump Motor

If the pump motor becomes overheated, the thermal overload protector will cause the motor to not

operate. If this occurs, contact Service.

To avoid a service call, check symptoms and related possible causes. If machine still does not operate

properly, contact Service.

SYMPTOM POSSIBLE CAUSE

No machine operation. 1. Machine off, turn machine on.

2. Blown fuse or tripped circuit breaker at power supply.

3. Check tank water level.

Dishes not clean. 1. Insufcient wash water due to drain obstruction preventing proper drain

closing.

2. Worn or torn drain O-ring allowing wash water to drain.

3. Loss of water pressure due to pump obstruction.

DISCONNECT ELECTRICAL POWER SUPPLY (BOTH DISHWASHER

AND BOOSTER IF APPLICABLE) and drain tank. Check for any obstruction

at the pump intake.

4. Incorrect water temperature. Contact Service for adjustment or repair.

5. Incorrect detergent dispensing. Contact your detergent representative.

6. Excessive mineral deposits throughout wash and rinse system. Deliming

may be necessary, refer to page 20.

7. Check wash and rinse arms to make sure they rotate properly.

8. Strainers clogged causing inadequate water supply to pump; clean machine

according to Cleaning, page 19.

9. Obstruction in wash arms or wash arms will not turn; clean machine according

to Cleaning, page 19.

10. Detergent dispenser may be clogged.

11. Excessive soil quantity; scrape dishes before cycle.

12. Improper rack loading; refer to Preparation and Dishwashing, pages 17, 18.

13. Incoming water supply turned off.

Spotting silverware, 1. Improperly loaded racks.

glasses and dishes. 2. Incorrect rinse water temperature or rinse pressure.

3. Loss of water pressure due to pump obstruction.

DISCONNECT ELECTRICAL POWER SUPPLY (BOTH DISHWASHER

AND BOOSTER IF APPLICABLE) and drain tank. Check for any obstruction

at the pump intake.

4. Excessively hard water.

5. Incorrect detergent for water type.

6. Incorrect rinse additive for water type.

7. Incorrect concentration of detergent, rinse additive and/or sanitizer.

8. Excessive soil quantity; scrape dishes before cycle.

– 22 –

Page 33

SYMPTOM POSSIBLE CAUSE

AM15 Dishwasher Technical Manual Page 33 of 83

Inadequate rinse or rinse 1. Dirty line strainer causing reduced water ow. Turn off water supply, remove

water temperature too low. strainer cap, withdraw and clean screen. Reassemble.

Possible EE display. 2. Low supply line pressure.

3. Excessive mineral deposits throughout wash and rinse system. Deliming may

be necessary, refer to page 20.

4. Incoming water temperature to booster (if applicable) below 110°F. Machine

will automatically extend wash time until booster heats up (this applies to

booster equipped machines only).

5. If EE displays: Booster did not reach temperature within 8 minutes after initial

ll. Press OFF, wait 5 seconds and press ON. May be booster heater failure.

Leaking valve. 1. Foreign material preventing proper valve operation. NOTE: A critical period

is soon after installation when pipe compound or metal shavings may lodge

at the valve seat. Shut off supply line. Unscrew and lift bonnet from valve

body. Clean valve and reassemble.

2. If a solenoid valve is malfunctioning (not opening or not closing), it is

recommended that you contact Hobart Service.

No wash tank heat. 1. The machine is equipped with a low water safety device which shuts off heat

if the water level drops. Check for proper water level. If the water level is

too low, the overow tube might be out of position. Or, something may be

inhibiting free movement of the low water oat; remove any foreign object from

around the low water oat or its magnet.

2. Gas line closed.

3. Blown fuse or tripped circuit breaker at power supply.

If a failure occurs due to the gas heat control board or gas pressure,

contact Hobart Service.

No or slow ll. 1. Debris may be obstructing standpipe movement allowing ll water to drain.

Possible E2 display. 2. Water supply may be off; make sure water supply valve is open.

3. Dirty line strainer causing reduced water ow. Turn off water supply, remove

strainer cap, withdraw and clean screen. Reassemble.

4. Worn or torn drain O-ring allowing wash water to drain.

5. If E2 displays: Water did not reach the oat during a ll within 2.5 minutes.

Press OFF, wait 5 seconds and press ON.

Possible Ed display. 1. Slow leak. Make sure the drain lever is closed, the standpipe is seated and

the O-ring is clear of all food soil or other debris.

Dribbling water from lower 1. If equipped with electric booster, normal dripping from the lower rinse arm

rinse arm. will occur during water heating due to expansion of the water. This will occur

once between machine cycles.

2. If water dribbles or leaks continuously from rinse arms on any machine, refer

to Leaking Valve, above.

Possible E6 display. 1. Contact your local Hobart Service Ofce.

Wrench lights up and P1, 1. Contact your local Hobart Service Ofce.

P2 or P3 displays.

– 23 –

Page 34

SERVICE

AM15 Dishwasher Technical Manual Page 34 of 83

Contact your local Hobart-authorized service ofce for any repairs or adjustments needed on this

equipment. If a gas orice tting is to be replaced, have it serviced by qualied Hobart-authorized

service personnel. Long-term service contracts are available on this and other Hobart products. Call

1-888-4HOBART for Hobart Service 24 hours a day.

FORM 35320 Rev. C (Oct. 2009) PRINTED IN U.S.A.

– 24 –

Page 35

SERVICE

AM15 Dishwasher Technical Manual Page 35 of 83

CONNECTION

SERVICE

CONNECTION

WARNING

ELECTRICAL AND

GROUNDING CONNECTIONS

MUST COMPLY WITH THE

APPLICABLE PORTIONS OF

THE NATIONAL ELECTRICAL

CODE AND/OR OTHER LOCAL

ELECTRICAL CODES

IT TRANSFORMER

PRIMARY CONNECTIONS

60 Hz

208V - LINE H1 & H2

240V - LINE H1 & H3

480V - LINE H1 & H4

50 Hz

380V - LINE H1 & H3

415V - LINE H1 & H4

MEMBRANE

BLK RED

WASH

BLK RED

RINSE

RED

BOOSTER

(OPT)

RED

TANK FLOAT

BLK

1LS

DISPLAY

SWITCH

1QTM

3QTM

DOOR

INTERLOCK

2QTM

BLK

IFS

RED

GRN/

YEL

GRN/YEL

BLK

BLK

X2

BLK/

RED

J1-2

CONTROL

CIRCUIT

J2-6

J2-1

J2-7

J2-2

J2-3

J2-8

J2-4

J2-10

J11-2

J11-1

H2 H3

H1

1T

120VAC

X2 X1

120VAC

2T

12VAC

J1-1

POWER

SUPPLY

CONTROL

BOARD

BLK

BLK

BLK

BLK

BLK

BLK

BLK

H4

BLK

BLK

X1

RED

GRAY

RED

RED

BLK/

RED

J1-1

J1-3

0.1

F1

AMP

J6-8

J6-10

J6-6

J14-2

J14-1

J3-3

J3-1

J3-5

J3-10

J6-1

J6-7

J12-2

J12-1

J6-5

J6-3

J6-9

J3-4

J3-6

J3-8

J3-2

ELECTRICAL DIAGRAM

AM-15 / 15T / 15F

ELECTRIC HEAT

ELECTRIC BOOSTER

3 PHASE

L1

L2

L3

L1

L2

L3

L1

L2

L3

J1-3

F2

3CON

2CON

1CON

4

8

RED

J11

1.0

AMP

1CR

J10-2

J10-1

J8-1

J8-2

J5-1

J5-2

J9-1

J9-2

2

6

T1

T2

T3

YEL

BRN

T1

T2

T3

T1

BLK

T2

BLK

T3

BLK

RELAY

BOARD

K6

K5

K8

K9

Q4

Q2

Q3

YEL

BLU

BLU

RED

RED

YEL

BLU

YEL

BRN

BLU

C

NO

C

NO

C

NO

J1-4

J1-7

J1-2

J1-8

BLK

BLK

BLK

BLK

ORG

PINK

RED

PUR

RED

TAN

PUR/

WHT

1TAS

IP/IS

-2

WHT/BLU

WHT/ORG

TANK

BLK

BSTR,HTR

HIGH LIMIT

2TAS

TAN/

BLK

PUMP

L1

MTR

L2

L3

PUMP

HIGH

LIMIT

ORG/

GRN

FILL/RINSE

1

BLK

RINSE

FEEDER

HIGH

LIMIT

3TAS

TAN/

BLK

BSTR

HTR

TANK

HTR

3TB

DPS1

DPS2

RPS1

RPS2

3TB

C1

TANK

HEAT

C1

1SOL

2

1P/2S

-3

1

BOOSTER

(OPT)

3CON

C1

MAX LOAD 1.5A @

SUPPLY VOLTAGE

MAX LOAD 1.5A @

SUPPLY VOLTAGE

VFC1

1.5A@ 240 VAC

SWITCHING CIRCUIT

VFC2

BSTR1

MAX LOAD 0.1A

@120 VAC

BSTR2

GRAY

C3

1CON

2CON

C3

1P/1S

-1

BLK

GRN/

YEL

1CR

0

C3

GRAY

GRAY

GRAY

GRAY

DERIVED FROM F-035377C

AI 2694

Page 36

DISPLAY

AM15 Dishwasher Technical Manual Page 36 of 83

J4

J3

POWER J1

J13

J11

CONTROL BOARD

3TB

2T

1T

J7

J2

J3

J10

J6

J15

RELAY BOARD

J1

F1

J11

F2

1CR

J9

1

CON

K8

C

NO

NC

C

K6

NO

C

K5

NO

2

CON

3

CON

OPT

C1

C3

C1

C3

C1

C3

1TB

(SPEC

OPTION)

CONTROL BOARD

LEGEND

TEST PINS =

TEST PAD =

SWITCH =

LED =

AI2695

Page 37

CACA

AM15 Dishwasher Technical Manual Page 37 of 83

CA

CACA

REPLACEMENTREPLACEMENT

REPLACEMENT

REPLACEMENTREPLACEMENT

PP

P

PP

TT

T

TT

ARAR

AR

ARAR

ALOG OFALOG OF

ALOG OF

ALOG OFALOG OF

TSTS

TS

TSTS

DISHWDISHW

DISHW

DISHWDISHW

AM15AM15

AM15

AM15AM15

AM15TAM15T

AM15T

AM15TAM15T

AM15FAM15F

AM15F

AM15FAM15F

ASHERASHER

ASHER

ASHERASHER

ML-130038ML-130038

ML-130038

ML-130038ML-130038

ML-130039ML-130039

ML-130039

ML-130039ML-130039

ML-130045ML-130045

ML-130045

ML-130045ML-130045

A product of HOBART 701 S. RIDGE AVENUE TROY, OHIO 45374-0001A product of HOBART 701 S. RIDGE AVENUE TROY, OHIO 45374-0001

A product of HOBART 701 S. RIDGE AVENUE TROY, OHIO 45374-0001

A product of HOBART 701 S. RIDGE AVENUE TROY, OHIO 45374-0001A product of HOBART 701 S. RIDGE AVENUE TROY, OHIO 45374-0001

FORM 43094 (October 2004)FORM 43094 (October 2004)

FORM 43094 (October 2004)

FORM 43094 (October 2004)FORM 43094 (October 2004)

Page 38

AM15 SERIES DISHWAM15 SERIES DISHW

AM15 Dishwasher Technical Manual Page 38 of 83

AM15 SERIES DISHW

AM15 SERIES DISHWAM15 SERIES DISHW

ASHER REPLACEMENTASHER REPLACEMENT

ASHER REPLACEMENT

ASHER REPLACEMENTASHER REPLACEMENT

P P

P

P P

ARAR

AR

ARAR

TSTS

TS

TSTS

F-43094 (October 2004)

- 2 -

© HOBART

Page 39

TT

AM15 Dishwasher Technical Manual Page 39 of 83

able of Contentsable of Contents

T

able of Contents

TT

able of Contentsable of Contents

AM15 SERIES DISHWAM15 SERIES DISHW

AM15 SERIES DISHW

AM15 SERIES DISHWAM15 SERIES DISHW

ASHER REPLACEMENTASHER REPLACEMENT

ASHER REPLACEMENT

ASHER REPLACEMENTASHER REPLACEMENT

5 CONTROLS

7 CONTROL BOX (ELECTRIC HEAT)

9 CONTROL BOX (GAS HEAT)

11 MOTOR AND PUMP

13 UPPER WASH ARM

15 LOWER WASH ARM

17 INSIDE PIPING AND OUTSIDE RINSE PIPING

(W/O BOOSTER)

19 INSIDE PIPING AND OUTSIDE RINSE PIPING

(W/BOOSTER)

21 ELECTRIC BOOSTER TANK

23 LOW WATER PROTECTION AND ELECTRIC HEAT

25 DRAIN UNIT

27 DOOR ASSEMBLY (AM15)

29 DOOR ASSEMBLY (AM15T & AM15F)

31 PANELS AND RACK SUPPORT

32 FRONT TRAY (AM15F)

33 GAS HEAT PIPING

35 GAS HEAT COMPONENTS

36 DISH RACKS

P P

P

P P

ARAR

AR

ARAR

TSTS

TS

TSTS

- 3 -

F-43094 (October 2004)

Page 40

AM15 SERIES DISHWAM15 SERIES DISHW

AM15 Dishwasher Technical Manual Page 40 of 83

AM15 SERIES DISHW

AM15 SERIES DISHWAM15 SERIES DISHW

1

28

ASHER REPLACEMENTASHER REPLACEMENT

ASHER REPLACEMENT

ASHER REPLACEMENTASHER REPLACEMENT

2

27

P P

ARAR

TSTS

P

AR

TS

P P

ARAR

TSTS

3

4

5

6

7

26

25

22

24

23

21

20

18

19

8

9

17

10

11

29

12

13

14

15

16

F-43094 (October 2004)

CONTROLSCONTROLS

CONTROLS

CONTROLSCONTROLS

- 4 -

PL-57404

Page 41

AM15 SERIES DISHWAM15 SERIES DISHW

AM15 Dishwasher Technical Manual Page 41 of 83

AM15 SERIES DISHW

AM15 SERIES DISHWAM15 SERIES DISHW

CONTROLSCONTROLS

CONTROLS

CONTROLSCONTROLS

ASHER REPLACEMENTASHER REPLACEMENT

ASHER REPLACEMENT

ASHER REPLACEMENTASHER REPLACEMENT

P P

P

P P

ARAR

AR

ARAR

TSTS

TS

TSTS

ILLUS.ILLUS.

ILLUS.

ILLUS.ILLUS.

PL-57404PL-57404

PL-57404

PL-57404PL-57404

1 00-893113 Switch – Membrane Keypad.................................................................................................... 1

2 - Bezel – Display Weldment.......................................................................................................1

3 00-526454 Tape – Foam ........................................................................................................................... AR

4 00-892458 Module – Display ...................................................................................................................... 1

5 00-294677-00003 Clamp – Wire ............................................................................................................................ 1

6 NS-047-94 Lock Nut 3/16 Washer Type ...................................................................................................... 1

7 00-294677-00003 Clamp – Wire ............................................................................................................................ 1

8 NS-011-18 Nut 10-24 Hex...........................................................................................................................1

9 NS-031-16 Stop Nut 10-24 Hex ................................................................................................................. 1

10 00-892720-00002 Standoff ...................................................................................................................................... 2

11 00-892932 Board – Control Assy. .............................................................................................................. 1

12 NS-031-50 Stop Nut 6-32 Hex ................................................................................................................... 2

13 00-892720-00002 Standoff ...................................................................................................................................... 2

14 00-892934-00001 Board – Relay Assy. ................................................................................................................ 1

15 NS-031-50 Stop Nut 6-32 Hex ................................................................................................................... 2

16 FE-022-29 Fuse (250 V., 1.0 Amp.) .......................................................................................................... 1

17 FE-026-30 Fuse (250 V., 0.1 Amp.) .......................................................................................................... 1

18 00-118349-00007 Standoff – Reed Board (Relay Board) ................................................................................... 2

19 00-118349-00007 Standoff – Reed Board (Control Board).................................................................................2

20 NS-047-94 Lock Nut 3/16 Washer Type ...................................................................................................... 4

21 00-294677-00003 Clamp – Wire ............................................................................................................................ 4

22 00-893642 Plate (Patent Numbers) ............................................................................................................ 1

23 0F-035324 Label – Warning (Fuse) (Electric Heat) ................................................................................. 1

24 0F-035373 Label – Warning (Fuse) (Gas Heat) ....................................................................................... 1

25 00-438131-00060 Label – Warning (W/Electric Booster) .................................................................................... 1

26 00-438131-00042 Label – Warning (W/Gas Heat, W/Electric Booster S.P.E.C., or W/O Electric Booster) . 1

27 0F-035331 Label (Error Code) .................................................................................................................... 1

28 00-438131-00175 Label – Instruction .................................................................................................................... 1

29 00-892793-00002 Ribbon Cable Assy. ..................................................................................................................1

PP

ARAR

TT

NO. NO.

P

AR

T

NO.

PP

ARAR

TT

NO. NO.

00-893447 Harness – Sensor Assy. ..........................................................................................................1

00-893448 Harness – Relay Board Assy. ................................................................................................. 1

00-893125 Cable – Rinse Thermistor ........................................................................................................ 1

00-893126-00001 Cable – Rinse Valve (Without Electric Booster) ...................................................................1

00-893126-00002 Cable – Rinse Valve (With Electric Booster) ........................................................................ 1

NAME OF PNAME OF P

NAME OF P

NAME OF PNAME OF P

ARAR

AR

ARAR

TT

T

TT

AMTAMT

AMT

AMTAMT

..

.

..

- 5 -

F-43094 (October 2004)

Page 42

AM15 SERIES DISHWAM15 SERIES DISHW

AM15 Dishwasher Technical Manual Page 42 of 83

AM15 SERIES DISHW

AM15 SERIES DISHWAM15 SERIES DISHW

3

ASHER REPLACEMENTASHER REPLACEMENT

ASHER REPLACEMENT

ASHER REPLACEMENTASHER REPLACEMENT

6

5

4

P P

P

P P

ARAR

AR

ARAR

TSTS

TS

TSTS

10

11

40-41

36

37

9

7

1

2

42

44

43

39

38

8

46

45

20

21

12

13

14

16

15

17

18

19

22

23

24

35

34

33

32

F-43094 (October 2004)

31

CONTROLCONTROL

CONTROL

CONTROLCONTROL

29

30

BOX (ELECTRIC HEA BOX (ELECTRIC HEA

BOX (ELECTRIC HEA

BOX (ELECTRIC HEA BOX (ELECTRIC HEA

- 6 -

ELECTRIC HEAT W/SPEC ONLY

SINGLE

PHASE ONLY

28

T)T)

T)

T)T)

25

26

27

PL-57403

Page 43

AM15 SERIES DISHWAM15 SERIES DISHW

AM15 Dishwasher Technical Manual Page 43 of 83

AM15 SERIES DISHW

AM15 SERIES DISHWAM15 SERIES DISHW

ASHER REPLACEMENTASHER REPLACEMENT

ASHER REPLACEMENT

ASHER REPLACEMENTASHER REPLACEMENT

P P

P

P P

ARAR

AR

ARAR

TSTS

TS

TSTS

CONTROLCONTROL

CONTROL

CONTROLCONTROL

ILLUS.ILLUS.

ILLUS.

ILLUS.ILLUS.

PL-57403PL-57403

PL-57403

PL-57403PL-57403

1 SD-008-25 Self-Tapping Screw 10-16 x 1/2 Phil. Pan Hd., Type B ....................................................... 3

2 00-294677-00004 Clamp – Wire ............................................................................................................................ 3

3 FE-026-29 Bushing – Snap (Electrical) ..................................................................................................... 3

4 SD-008-25 Self-Tapping Screw 10-16 x

5 WL-014-07 Lockwasher #10 External ......................................................................................................... 1

6 00-294500-00051 Transformer (30 VA, 50/60 Hz.) .............................................................................................. 1